Dual-optical-path optical current sensor

A current sensor, dual optical path technology, applied in the direction of only measuring current, measuring current/voltage, instruments, etc., can solve the problems of inability to accurately measure the DC component or aperiodic component of the current, declination deviation, etc., to improve the measurement stability and reliability. The effect of measuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

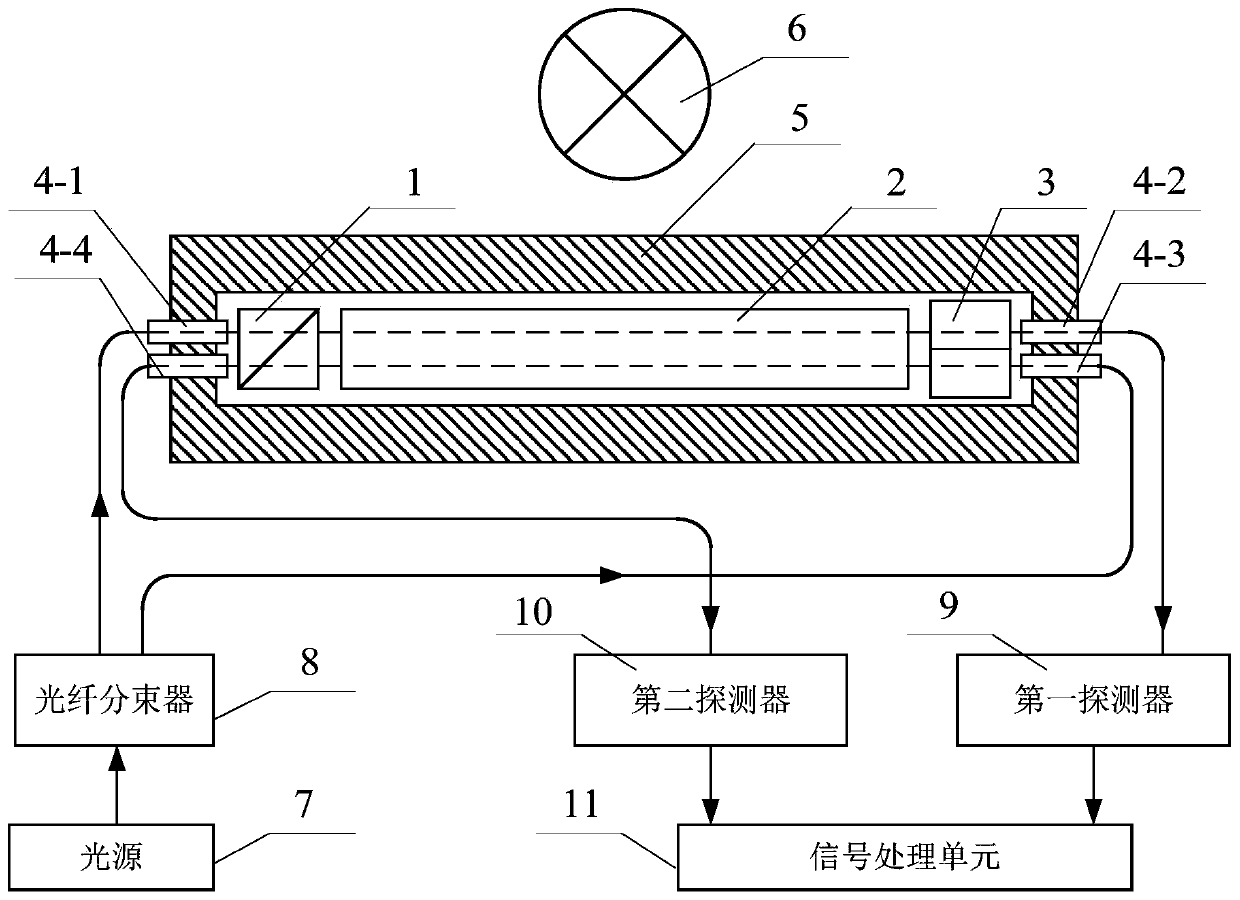

[0059] Specific implementation mode one: refer to figure 1 This embodiment is specifically described. The dual optical path optical current sensor described in this embodiment includes: a first polarizing beam splitting prism 1, a magneto-optic glass beam 2, a second polarizing beam splitting prism 3, a first fiber collimator 4-1, a second polarizing beam splitting prism Second fiber collimator 4-2, third fiber collimator 4-3, fourth fiber collimator 4-4, metal substrate 5, fiber beam splitter 8, first detector 9, second detector 10 And signal processing unit 11.

[0060] The first polarizing beam-splitting prism 1 and the second polarizing beam-splitting prism 3 are respectively located at the two ends of the magneto-optic glass beam 2, and the angle between the transmission axis of the first polarization beam-splitting prism 1 and the transmission axis of the second polarization beam-splitting prism 3 is 45° °, the first fiber collimator 4-1 and the fourth fiber collimator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com