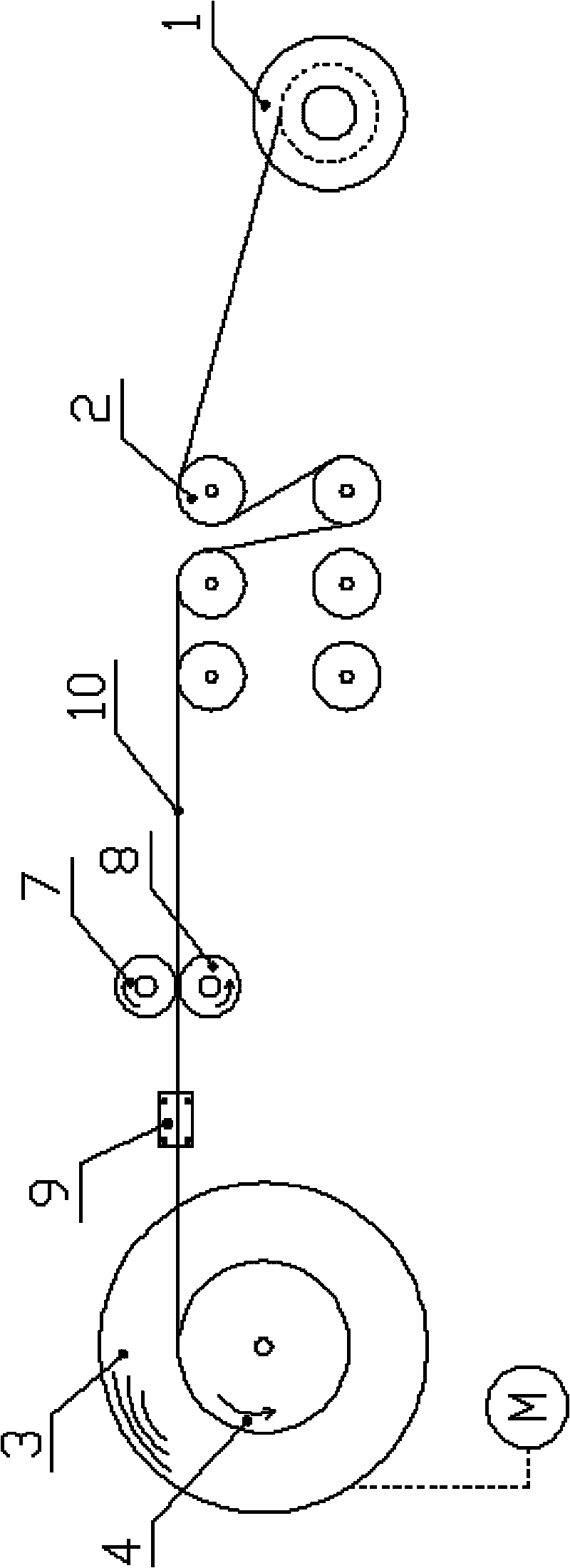

Device for winding coil by rectangular conducting wire

A rectangular wire and coil-winding technology, which is applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problem of inability to ensure radial winding tightness of winding, difficulty in guaranteeing winding quality, and uncertain winding time and other problems, to achieve the effect of reducing the number of operators, simple structure, and meeting the needs of production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

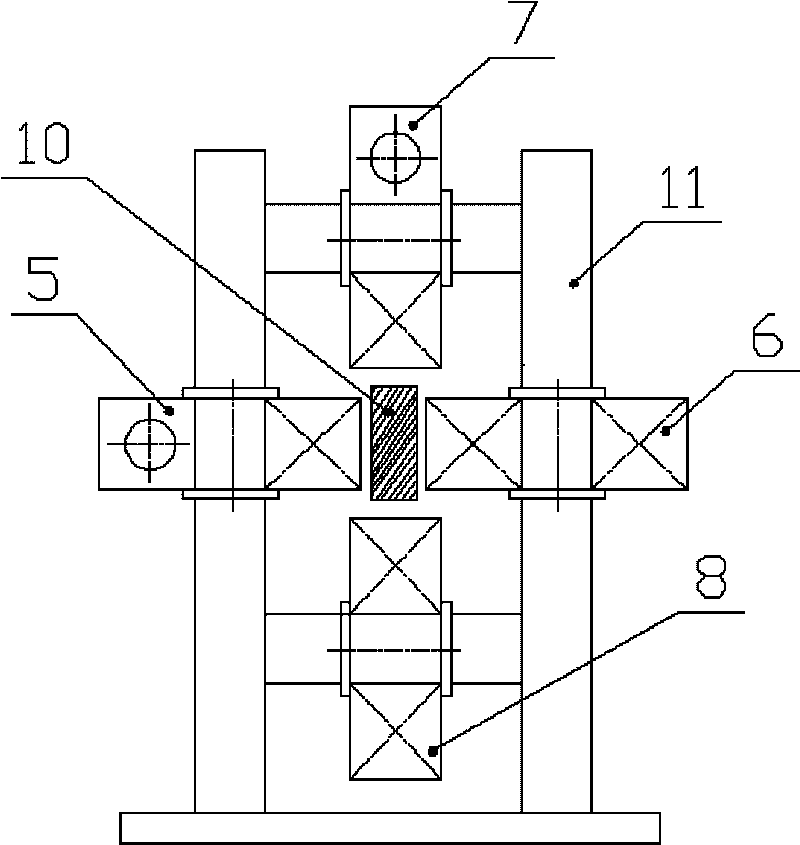

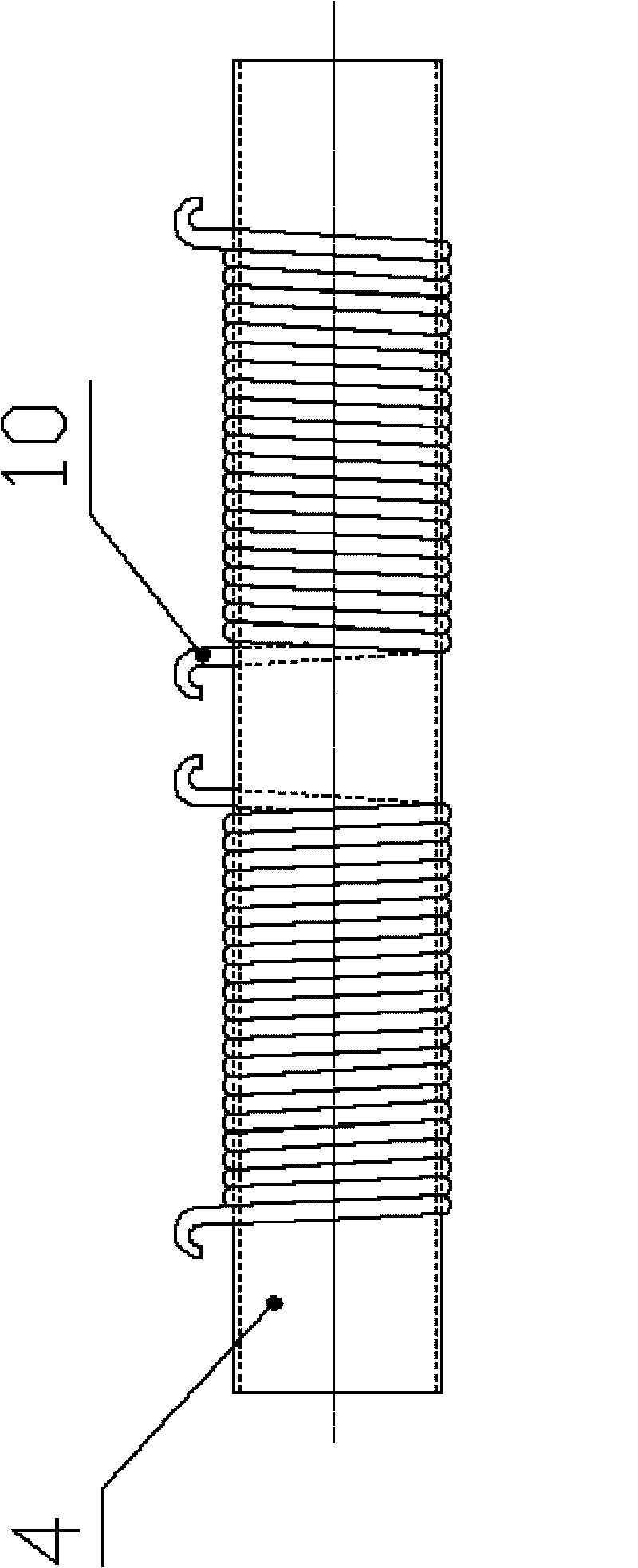

[0022] The ore that has been magnetically separated in the concentrator has a large coercive force and remanence, resulting in strong magnetic agglomeration of the ore, affecting the classification and screening accuracy, and deteriorating the technical and economic indicators of the ore dressing. Therefore, the ore must be processed before classification and screening. The demagnetizer performs demagnetization to eliminate the adverse effects of magnetic agglomeration. The demagnetizer is an electrical circuit composed of demagnetization coils. When the pulp passes through the demagnetization coil pipeline, it is effectively demagnetized due to the effect of the attenuated oscillating magnetic field. The technical data of the demagnetization coil are as follows:

[0023] Degaussing coil material: dip-dyed flat copper wire (rectangular wire) wrapped in double yarn fiberglass wire, its size: narrow side φ5.0mm×wide side φ10.0mm;

[0024] Demagnetization coil skeleton material:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com