Patents

Literature

339results about How to "Reduce the number of people" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

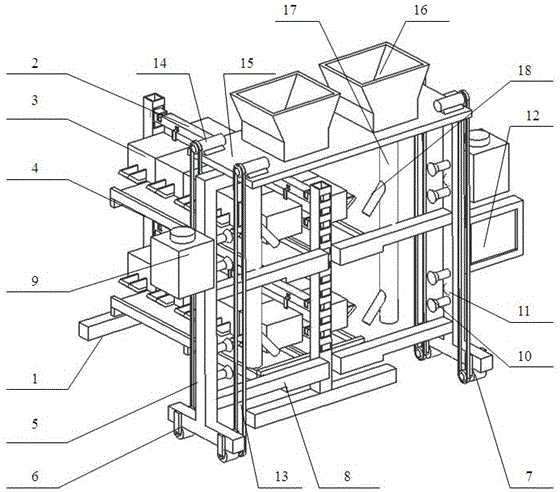

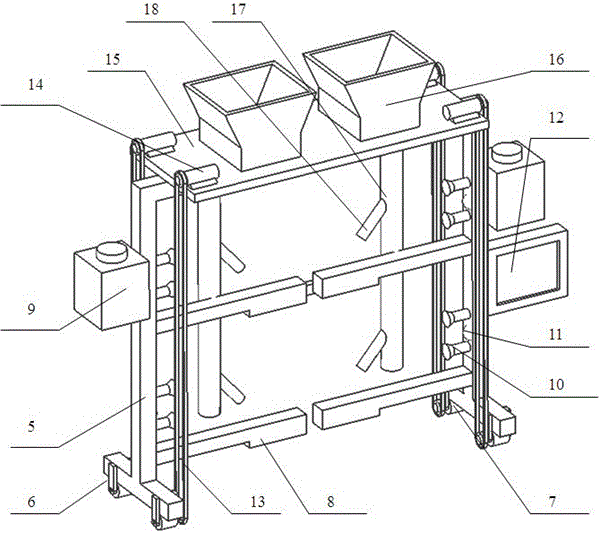

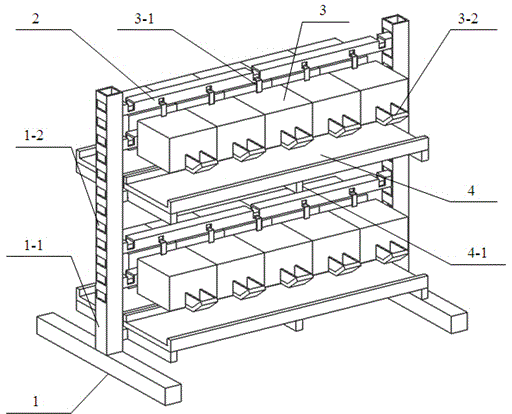

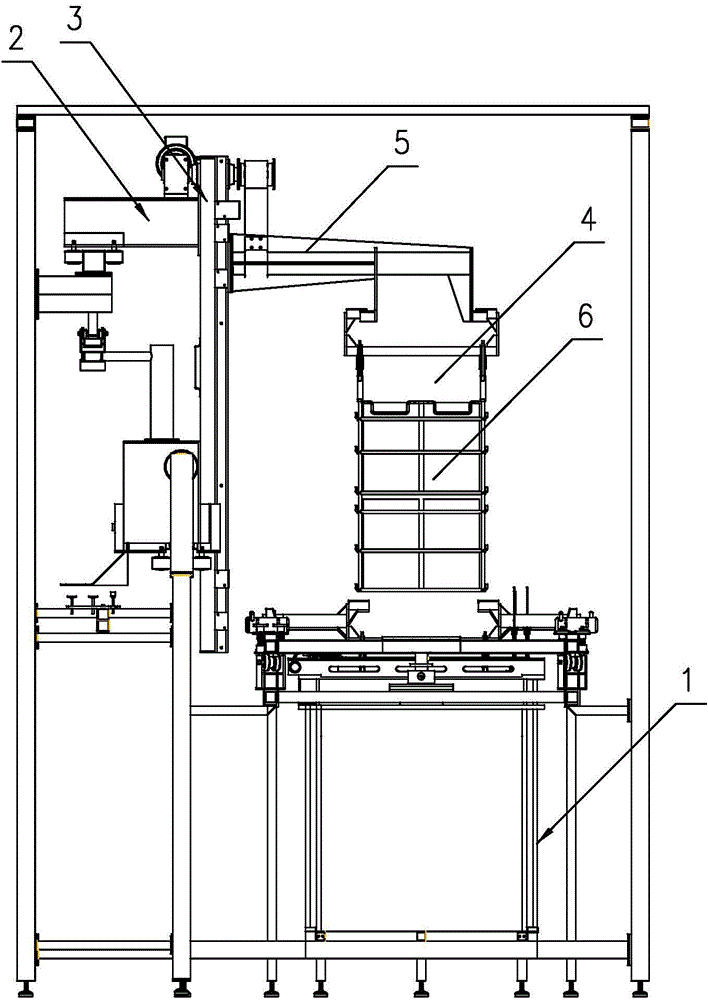

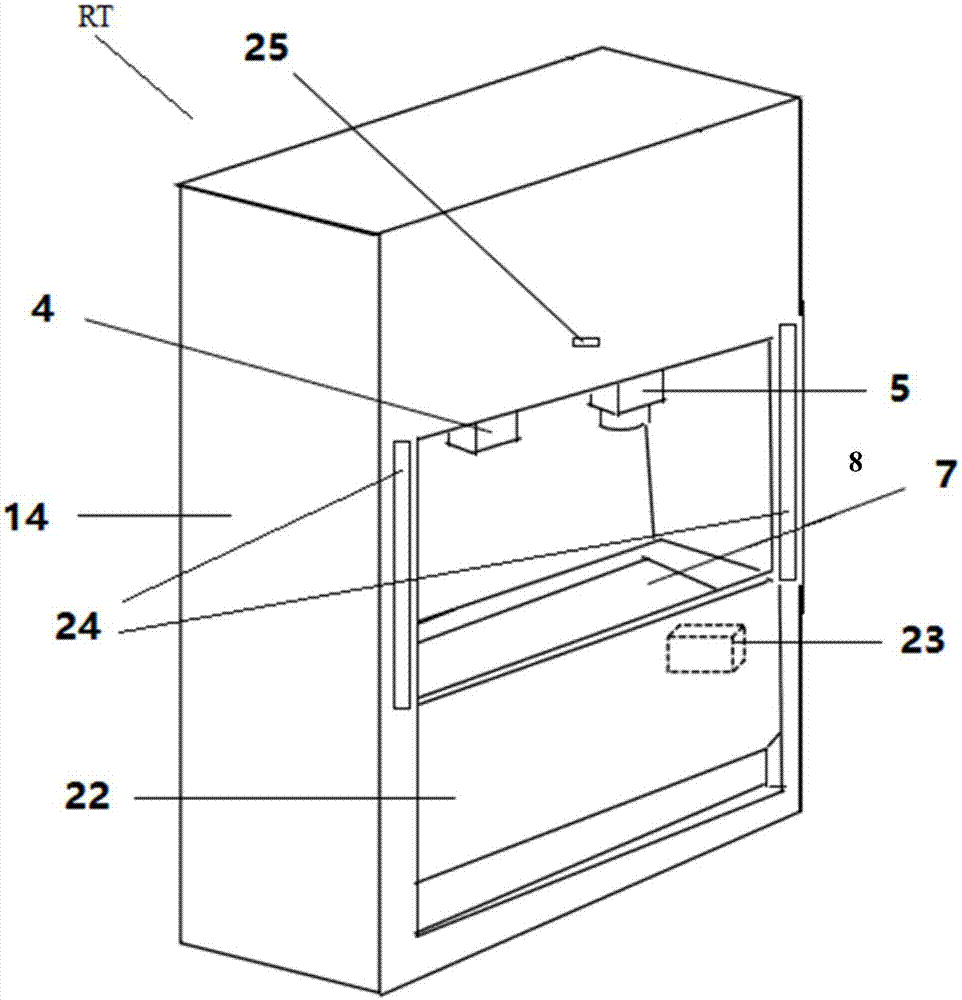

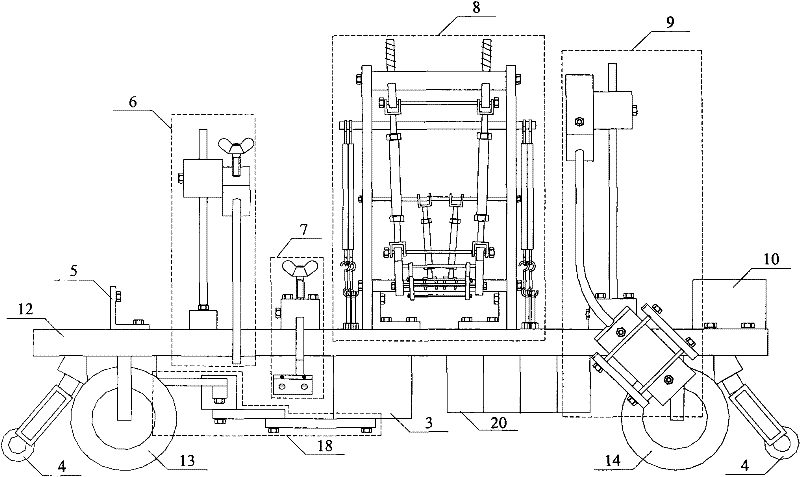

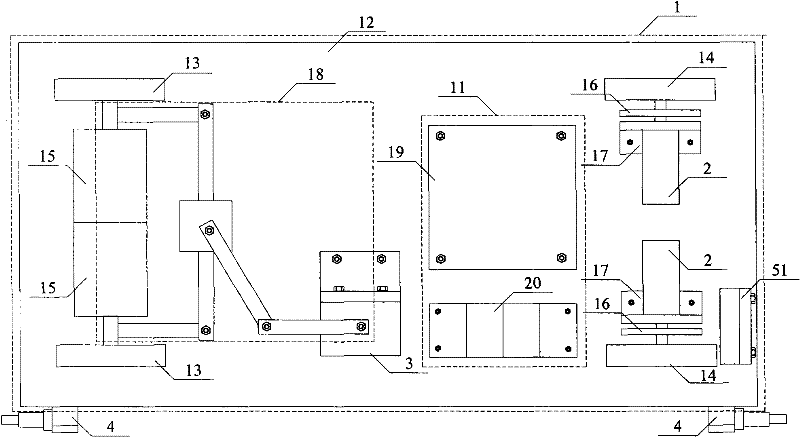

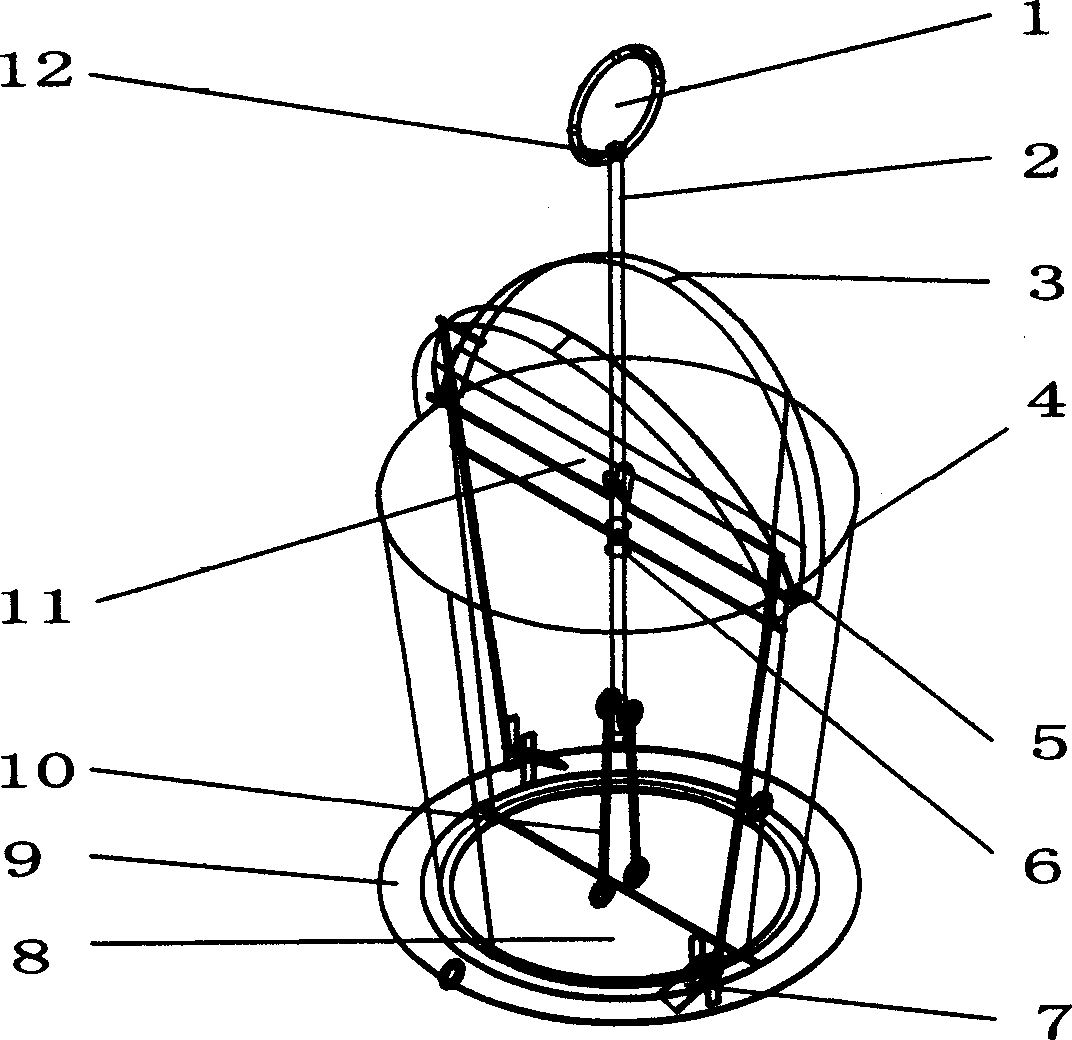

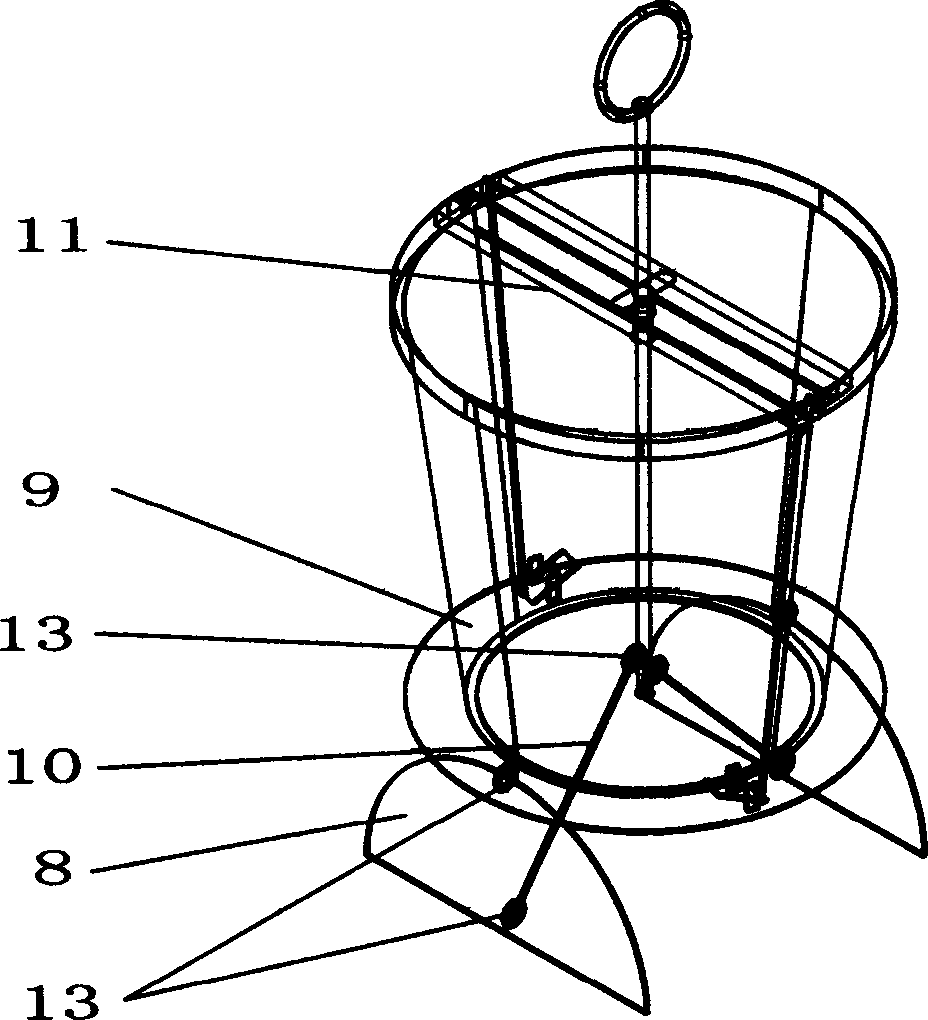

Intelligent pigeon massive-breeding device

ActiveCN104145844AReduce the number of peopleIncrease productivityBird housingsLiquid storage tankEngineering

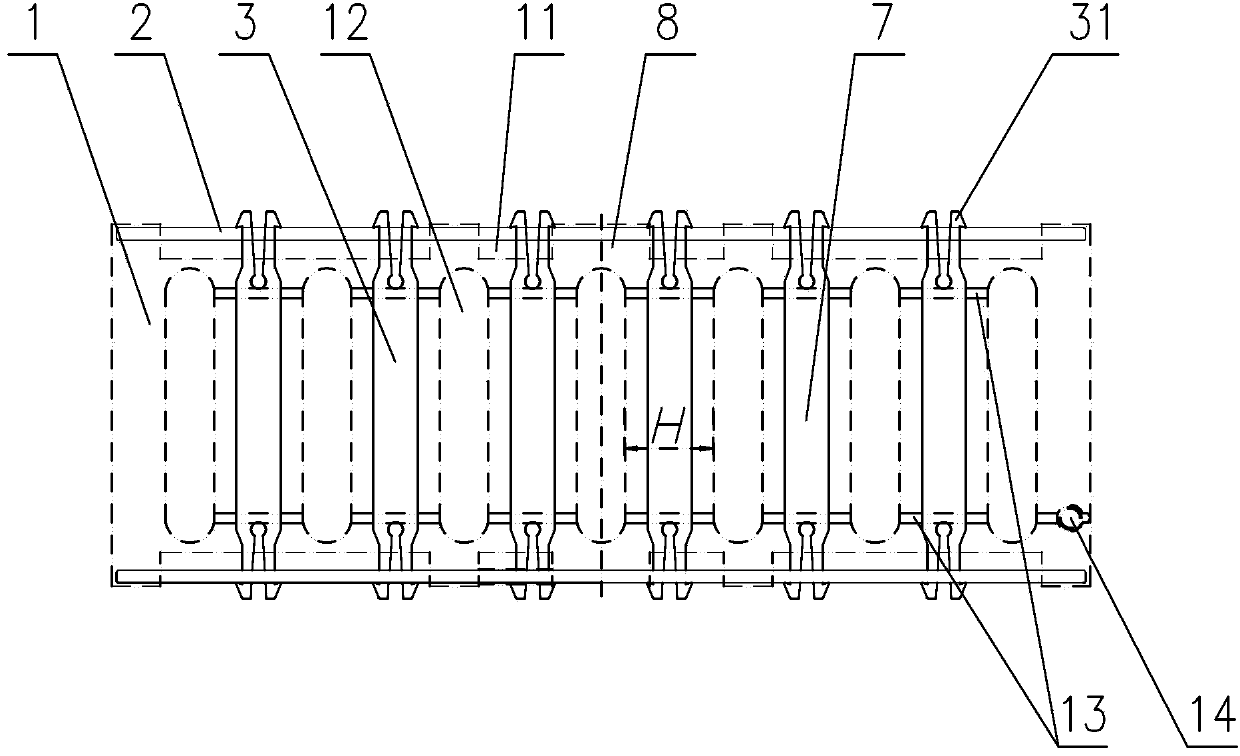

An intelligent pigeon massive-breeding device comprises a suspension type pigeon cage support and a feed structure. The suspension type pigeon cage support comprises pigeon cage stands, a support rod, pigeon cages and manure trays, wherein each pigeon cage stand is T-shaped. The feed structure comprises a door-shaped feed structure, roller supports, rollers, guide rails, brushes, liquid storage tanks, nozzles, infrared sensors, a control computer, a touch control screen, a temperature sensor, a humidity sensor, a carbon dioxide concentration sensor, conveying belts, motors, a support plate, fodder troughs, discharge pipes and branch pipes. The intelligent pigeon massive-breeding device comprises the suspension type pigeon cage support and the feed structure, the suspension type pigeon cage support is convenient to demount, easy to mount and low in cost, the feed structure is the moving door-shaped structure integrated with functions of automatic feeding, manure removing, environmental monitoring, body temperature monitoring, environment disinfection, vaccine spraying and remote monitoring, dependence on labor is greatly reduced, and massive, automatic and intelligent breeding is realized.

Owner:JINLING INST OF TECH

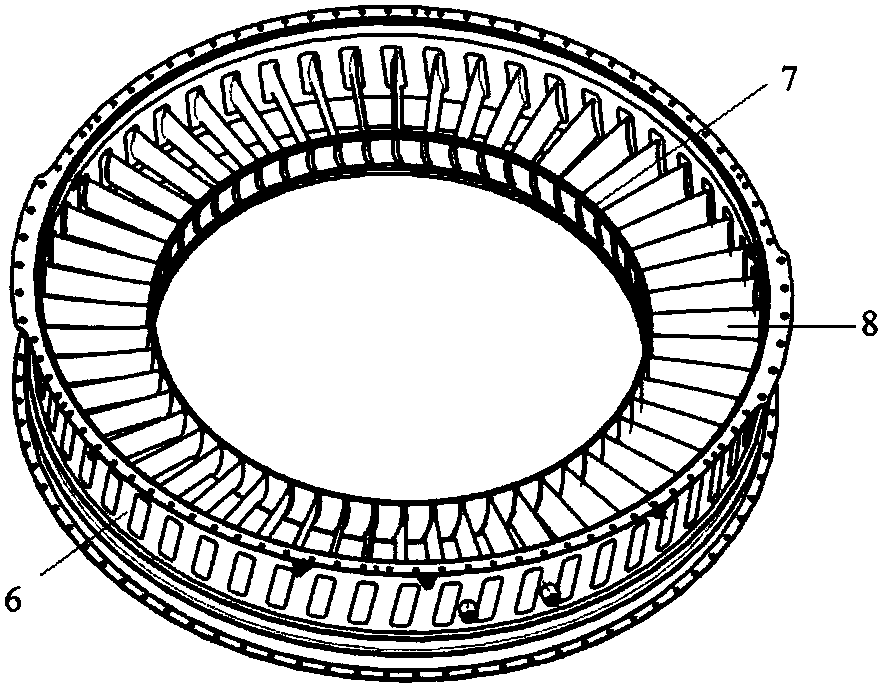

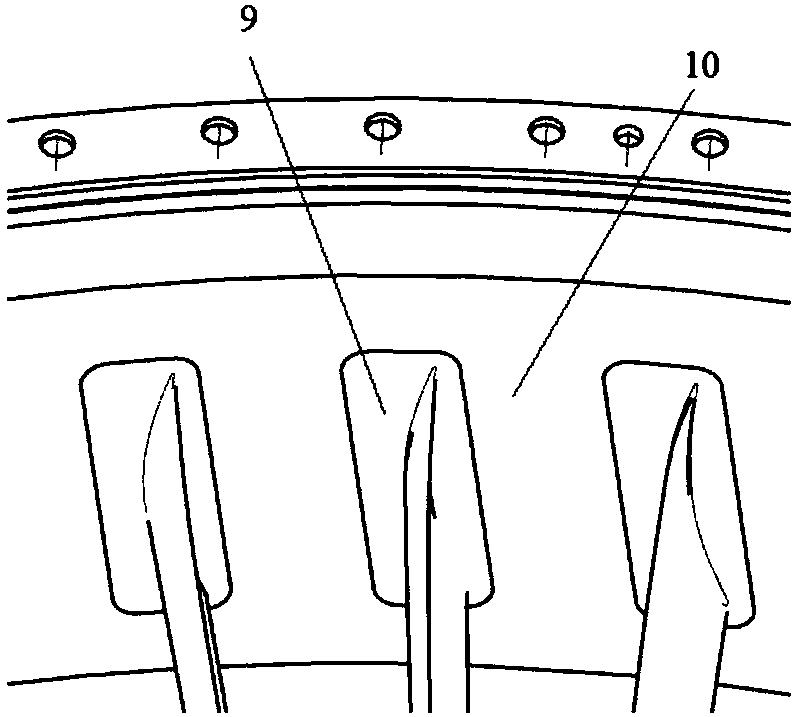

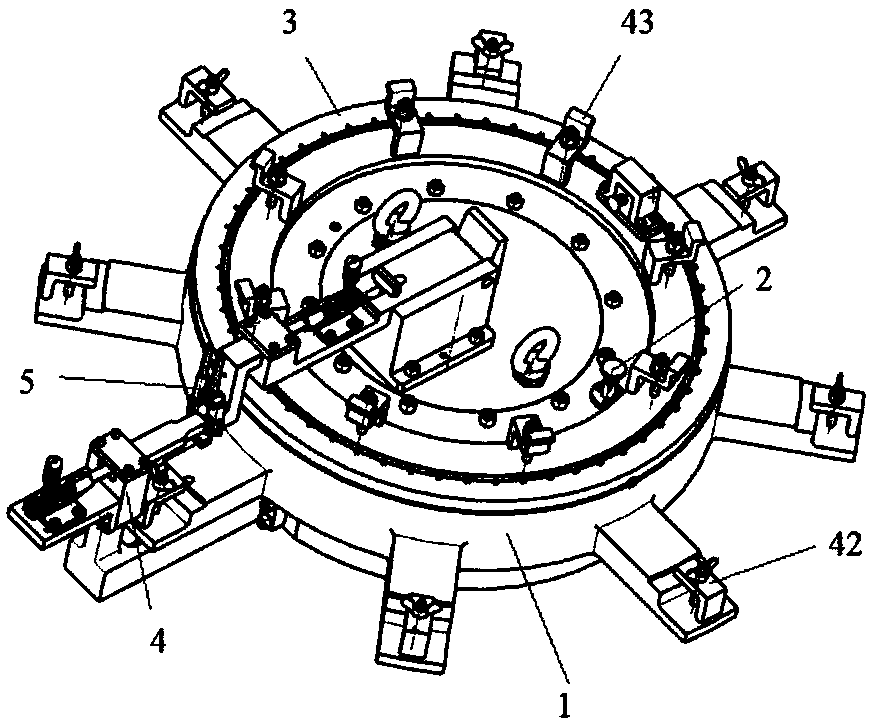

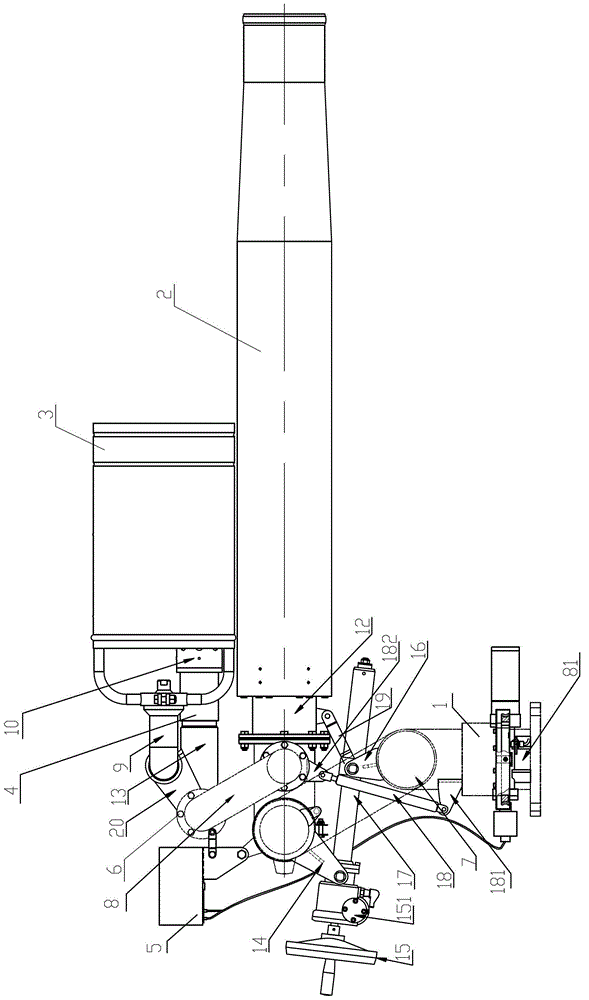

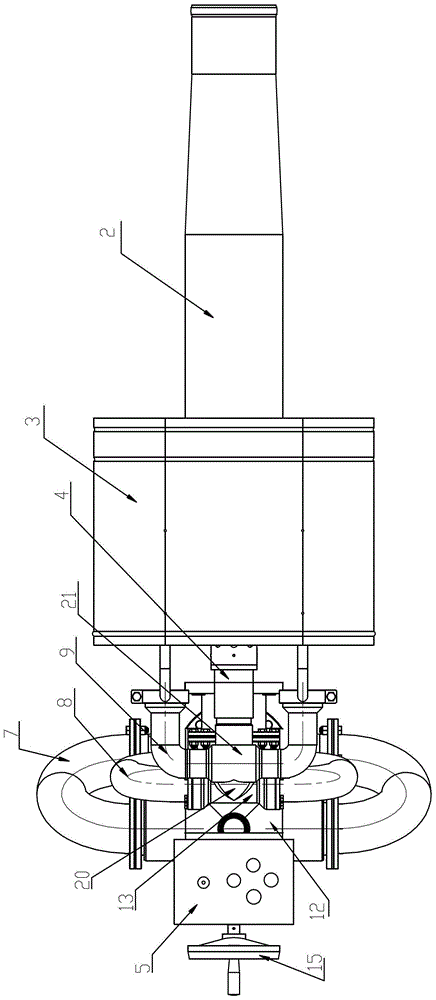

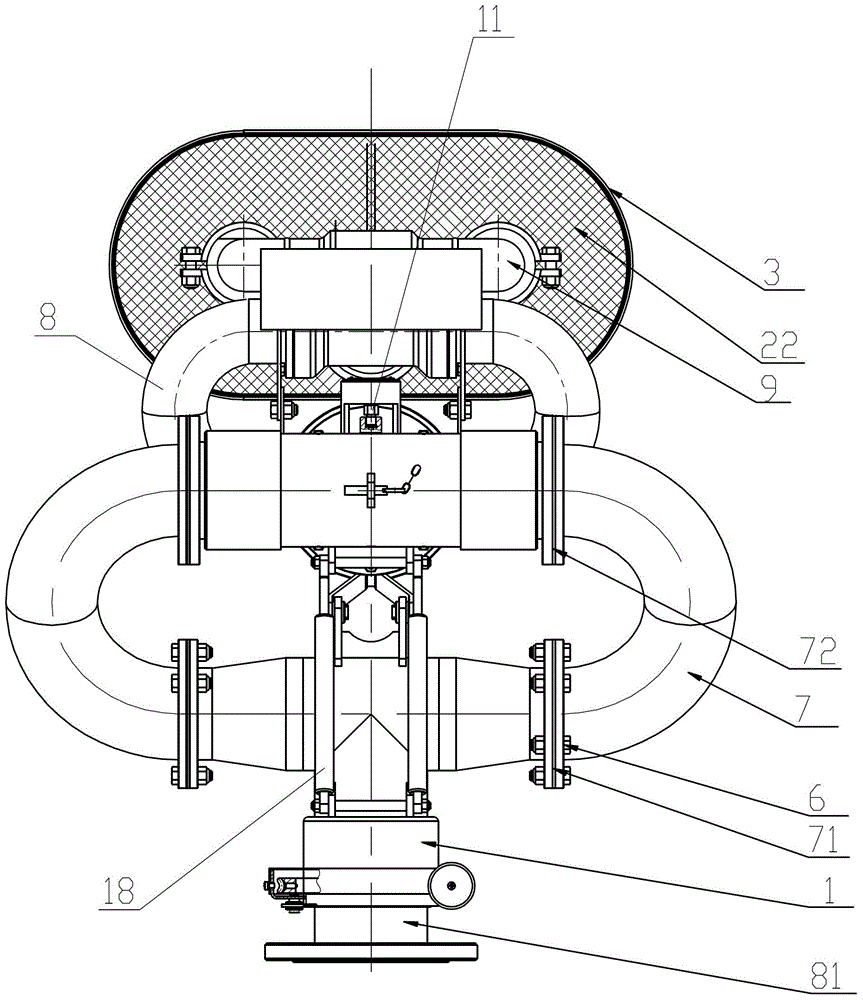

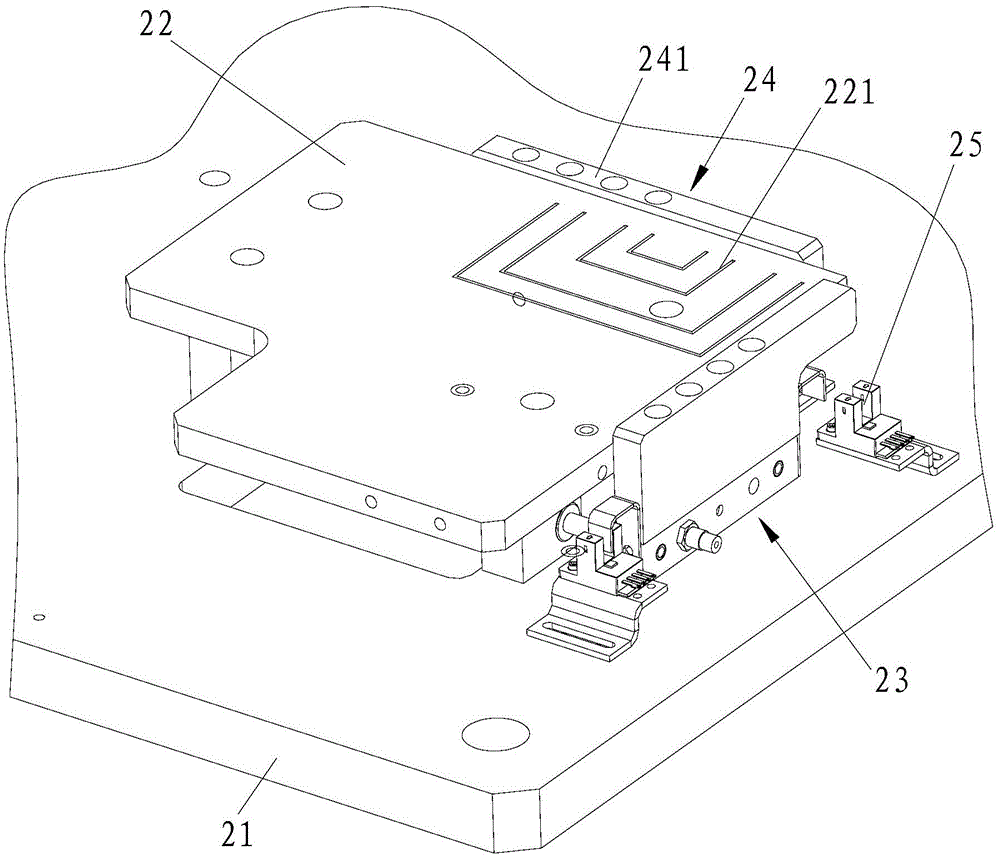

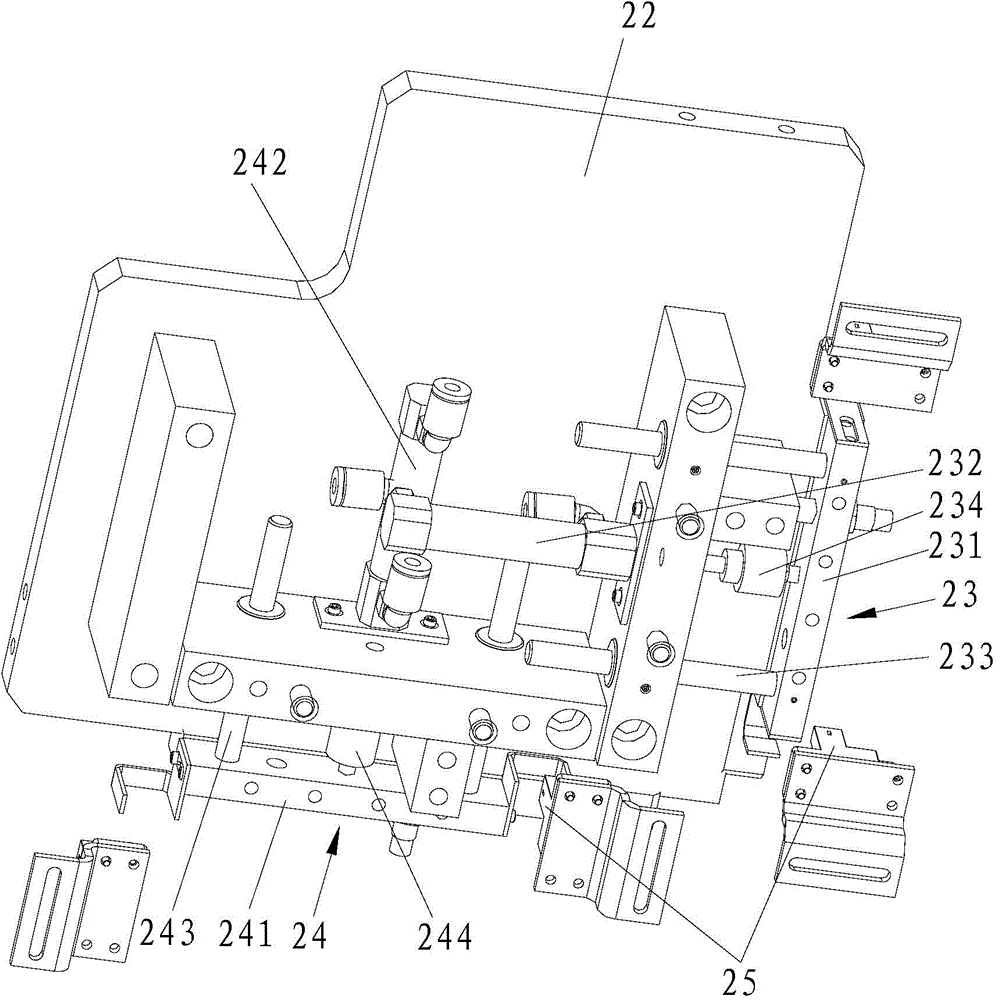

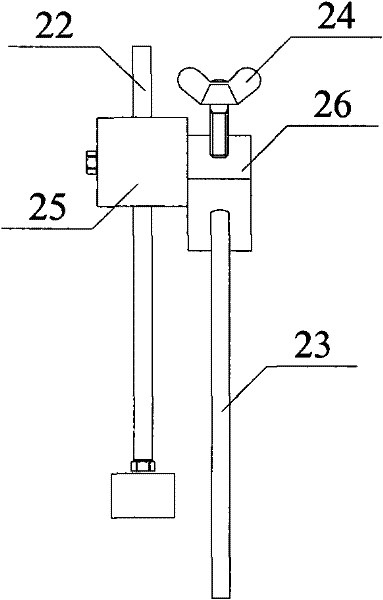

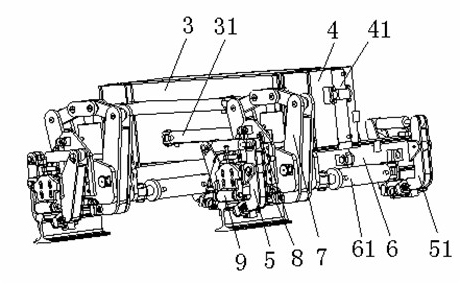

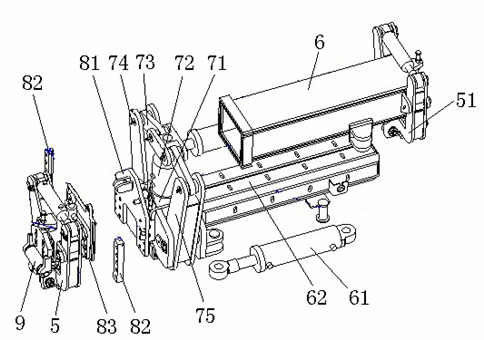

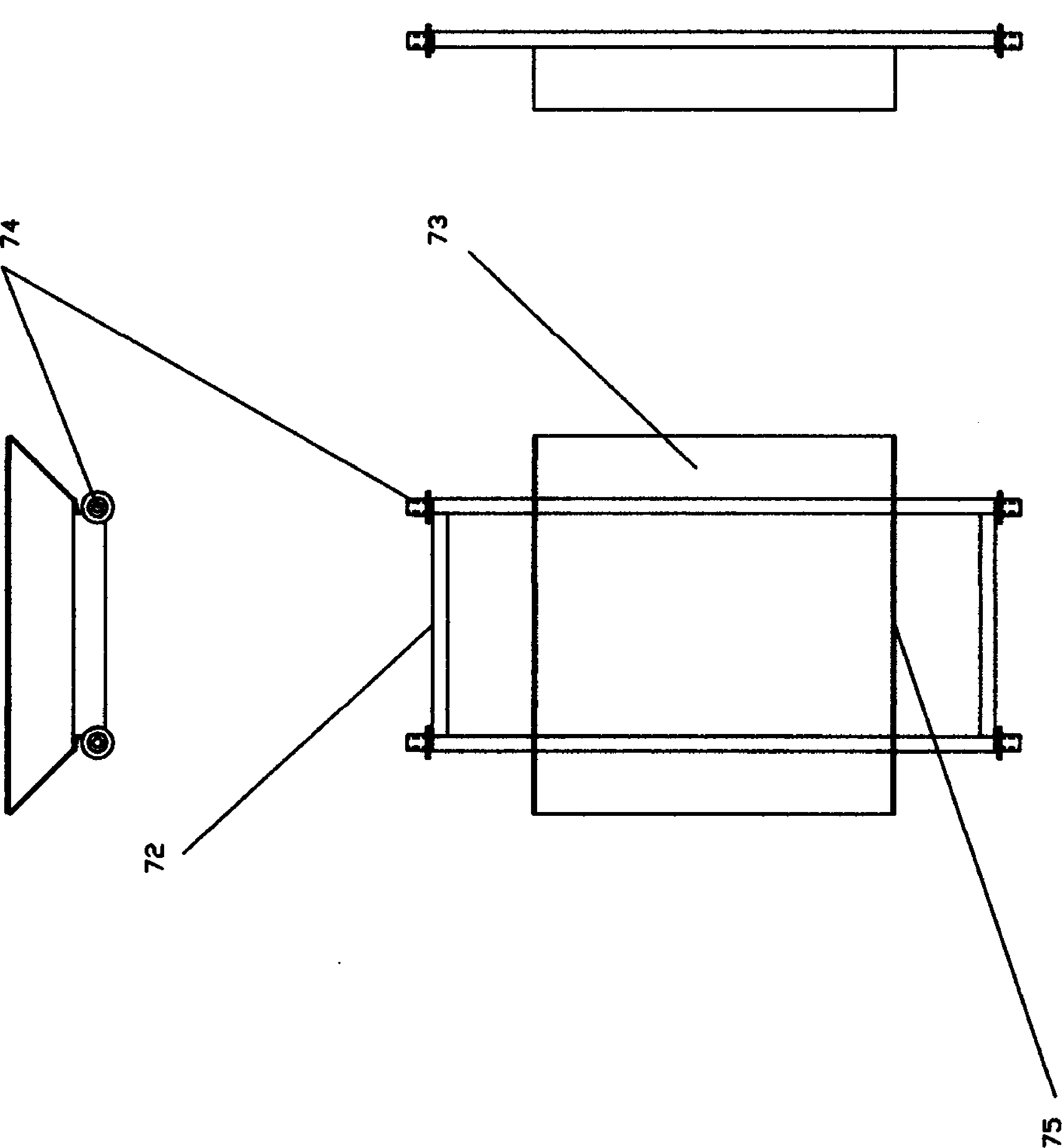

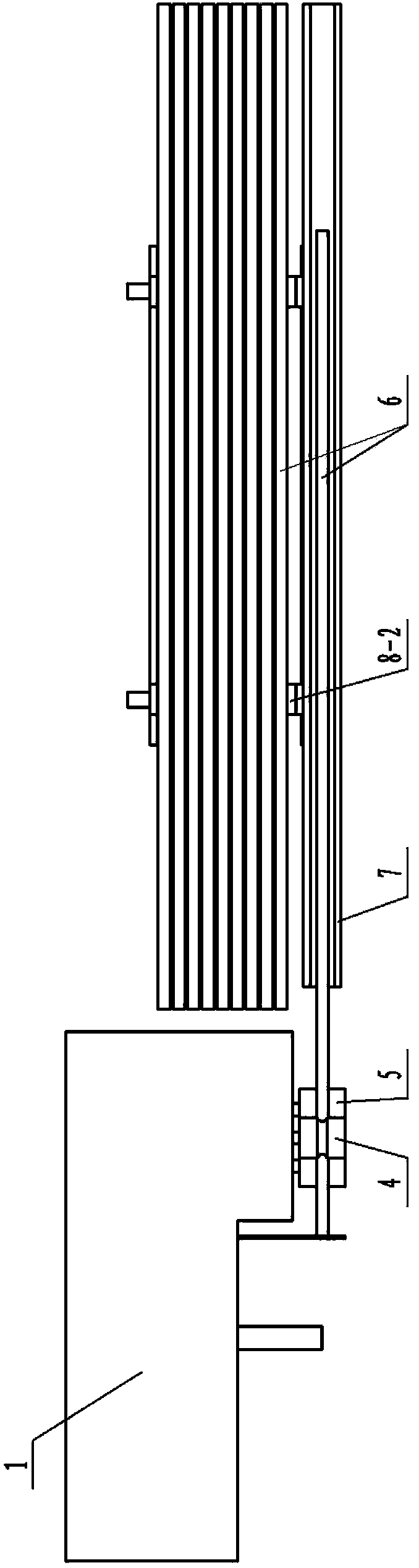

Device for assembling and welding fan casing combined piece

ActiveCN107803619AReduce the number of peopleReduce weightWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAngular direction

The invention discloses a device for assembling and welding a fan casing combined piece. The device comprises a body assembly, a gas protecting assembly and a positioning assembly; the body assembly comprises a hollow disk; a plurality of bosses used for supporting a casing are arranged on the periphery of the hollow disk; the positioning assembly comprises a casing positioning assembly used for positioning the axial direction, the angular direction and the circle center of the casing, an inner ring positioning assembly used for positioning the axial direction, the angular direction and the circle center of an inner ring, a blade boss positioning assembly used for positioning the angular direction of blades, and a blade axial direction positioning assembly; the blade axial direction positioning assembly is arranged on the inner side of the hollow disk, and comprises a hinge plate; one end of the hinge plate is hinged to an overturning base, and the other end of the hinge plate is connected with a positioning block in a sliding manner; a first pressing device is fixedly arranged on the hinge plate; and a pressing head of the first pressing device is fixedly connected with the positioning block. The device is convenient to operate, fast and capable of saving labor, reducing the number of operators, and making blade welding kept consistent.

Owner:AECC AVIATION POWER CO LTD

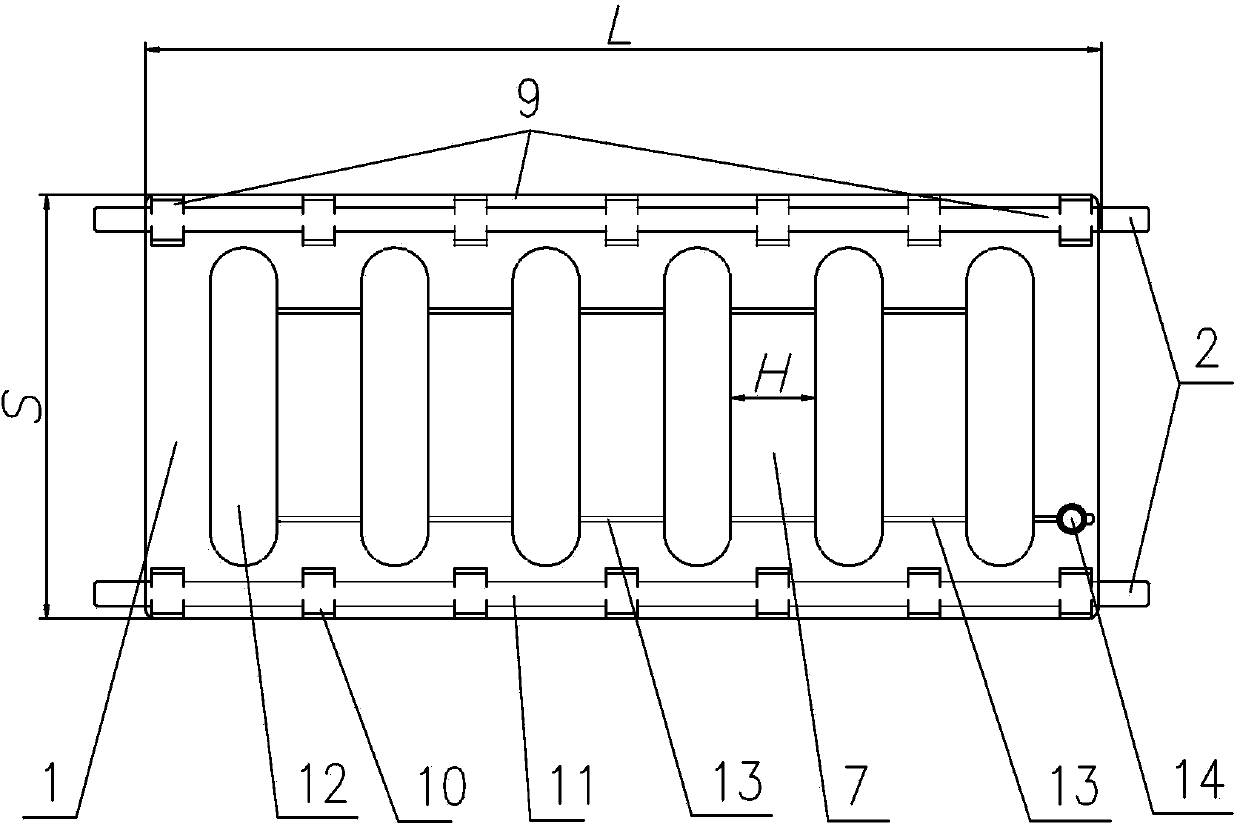

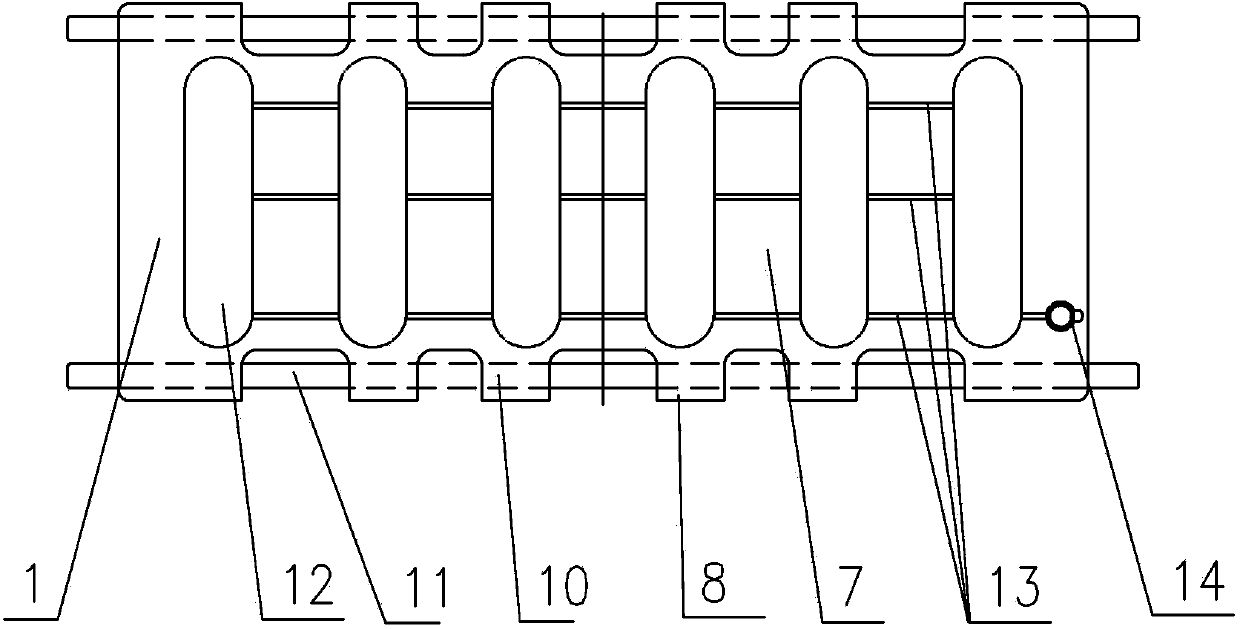

Multifunctional mattress

ActiveCN103800152AEasy to use and labor-savingThe mattress used is labor-saving and convenientTravelling sacksStretcherEngineering

The invention relates to a multifunctional mattress which is provided with N human body supporting pieces. A left stretcher rod penetrated connection area and a right stretcher rod penetrated connection area are respectively arranged in the L directions of the long edges, the stretcher rod penetrated connection areas are provided with stretcher holes for stretcher rods to penetrate, and the stretcher holes are extended in the direction parallel to the L directions of the long edges of a mattress body. The mattress body is provided with a plurality of air sac areas, and strip-shaped gaps are formed between the air sac areas and arranged in the direction perpendicular to the L directions of the long edges of the mattress body in parallel. The widths H of the strip-shaped gaps are larger than or equal to the widths h of the human body supporting pieces, and the thicknesses of the air sac areas after the air sac areas are inflated are larger than the thicknesses of the human body supporting pieces. The multifunctional mattress is rapid and convenient to operate, safe, portable and environmentally friendly, and saves force.

Owner:林黎明

Intelligent dish-frying machine and dish-frying method

InactiveCN110547667AReduce professional and technical requirements and the number of peopleImprove work efficiencyTime-controlled ignitorsCooking vessel constructionsEngineeringWater supply

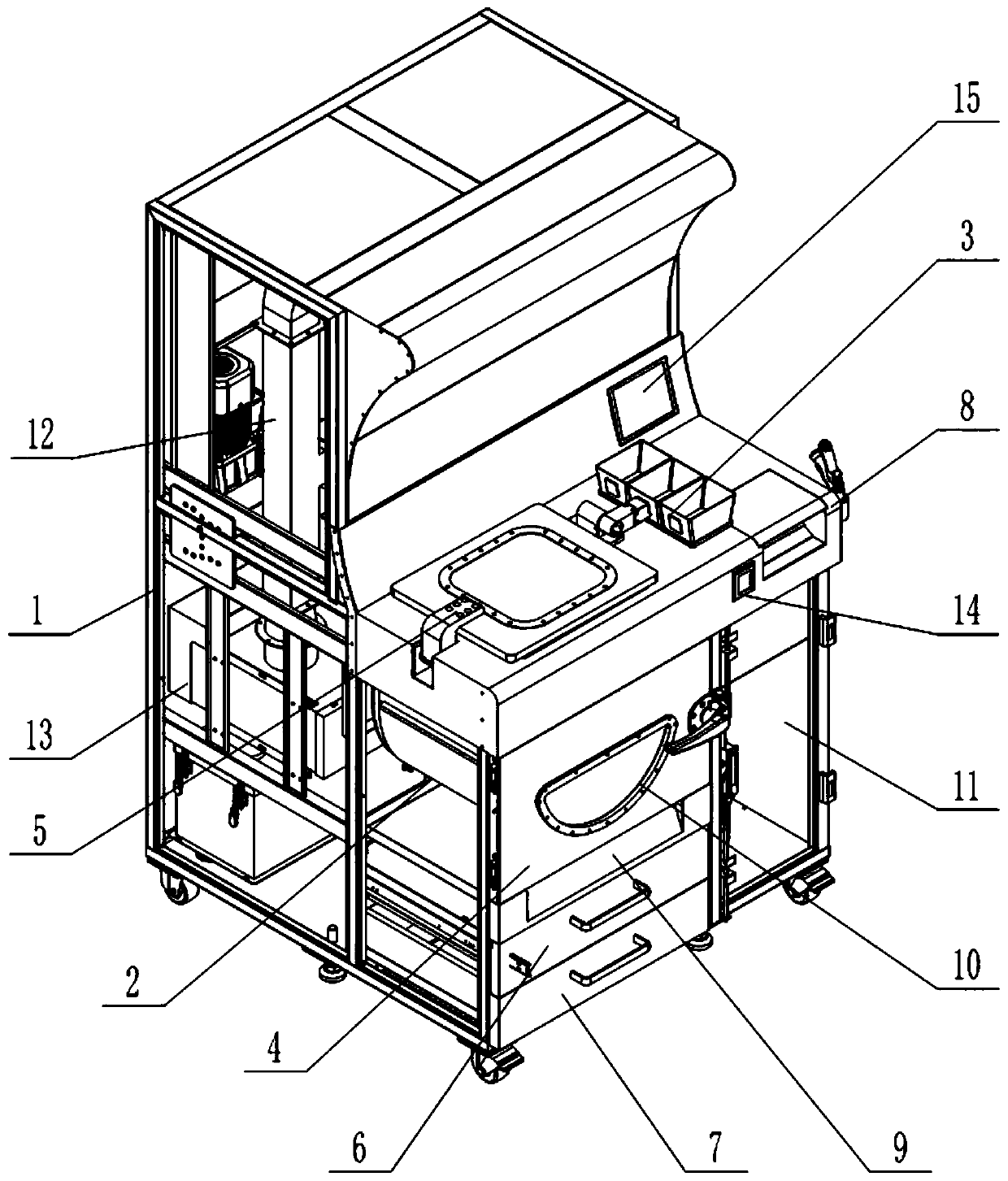

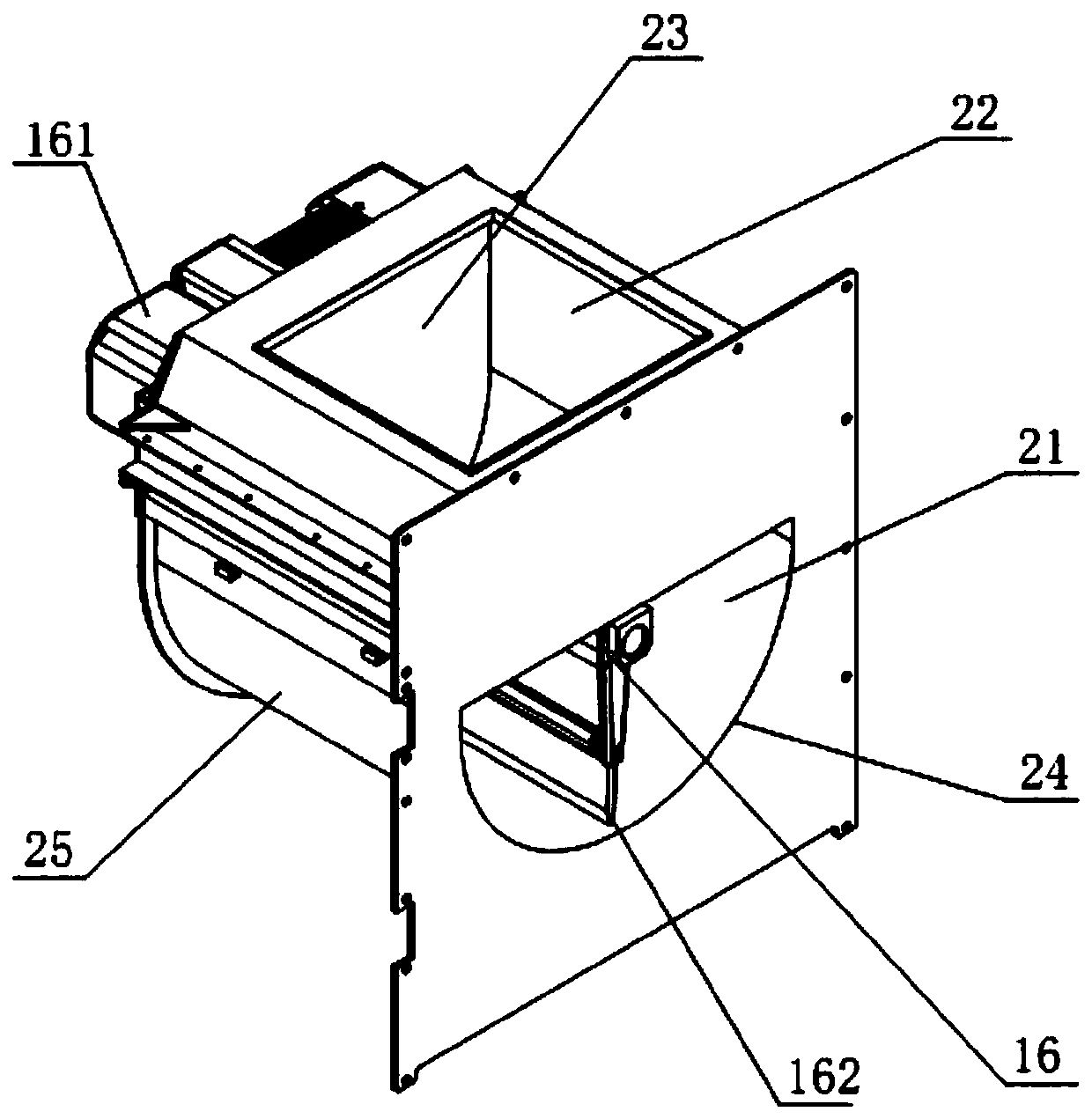

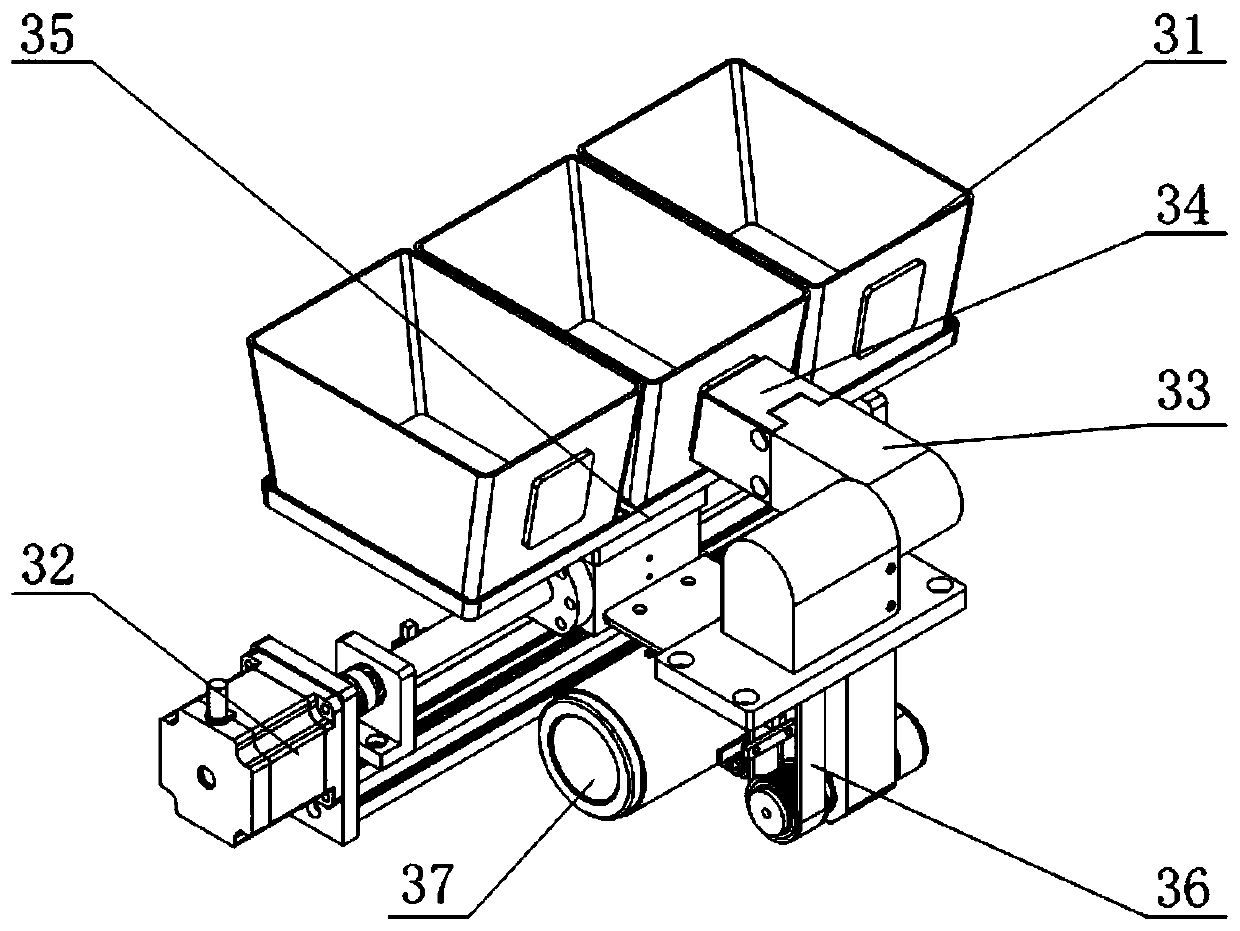

The invention discloses an automatic dish-frying machine. The automatic dish-frying machine comprises a rack, a heating pan, a pan spatula, an oil adding device, a water supply device, a seasoning placing device, a reading device, a control unit and a display unit. The invention further relates to an intelligent dish-frying method adopting the intelligent dish-frying machine. According to the technical scheme, delivered clean vegetables are adopted as the food materials, the intelligent dish-frying machine obtains the menu information by reading dish identifiers, the operation steps are automatically set according to the menu information, and the operation is carried out automatically. An operator places the to-be-processed food materials and places seasonings according to the requirementsof the menu, the device can carry out automatic heating, oil products, seasonings and water can be added quantitively and automatically according to the menu, and stir-frying is carried out automatically. The operator can carry out automatic dish frying only through material adding and dish outlet auxiliary work, thus the professional technical requirements for the operator and the number of theoperator are greatly reduced, the work efficiency is also greatly improved, and meanwhile, the consistency of the dishes is guaranteed. The technical scheme is particularly suitable for business places including dining halls, restaurants and the like.

Owner:无锡鼎丰膳供应链管理有限责任公司

Median-multiple fire-fighting foam monitor

InactiveCN103331007AImprove fire extinguishing efficiencyIncrease rangeFire rescueFire suppression systemMixed solution

Relating to the field of fire-fighting equipment, the invention provides a median-multiple fire-fighting foam monitor, which mainly solves the defects existing in single-multiple and median-multiple fire-fighting foam monitors. The median-multiple fire-fighting foam monitor includes a connecting pedestal, launch foam barrels and a pipeline barrel frame connecting the connecting pedestal and the launch foam barrels. The connecting pedestal, the pipeline barrel frame and the launch foam barrels are equipped with a mixed solution channel communicated with a mixed foam solution. The launch foam barrels include barrel bodies and nozzles disposed at front ports of the barrel bodies. The foam monitor is characterized in that there exist multiple launch foam barrels, which are fixed on the pipeline barrel frame in a vertical direction and have the same launch direction. Specifically, a low multiple launch foam barrel is positioned below, and launch foam barrels higher than the low multiple launch foam barrel are positioned above. The mixed solution pipeline in the pipeline barrel frame is communicated with the nozzles of all launch foam barrels, and each nozzle is respectively located in the front port of a corresponding barrel body. Compared with traditional low multiple foam extinguishing systems, the fire extinguishing efficiency is improved; compared with traditional high multiple foam extinguishing systems, the launch range is increased.

Owner:章丘市消防器材有限责任公司

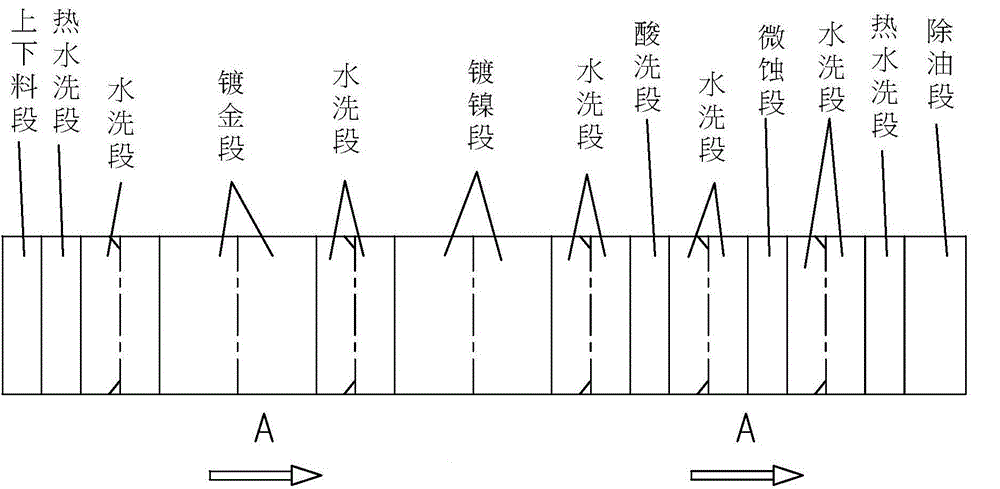

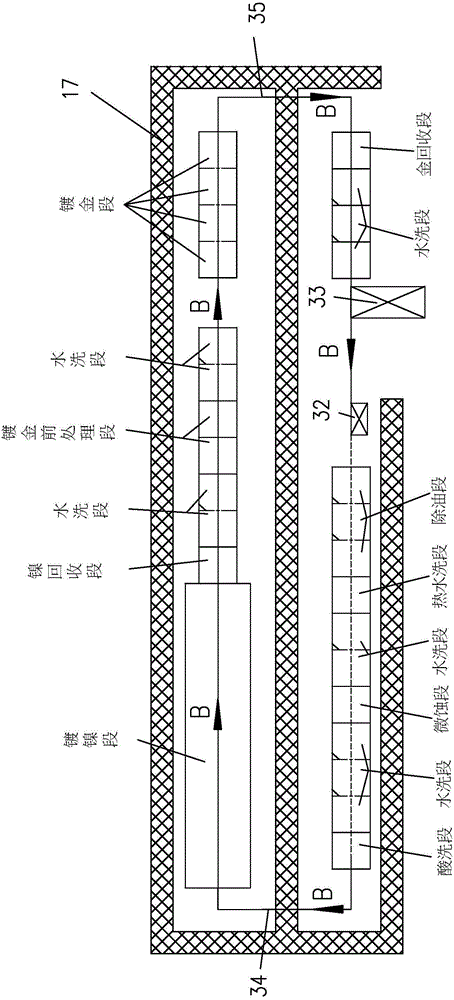

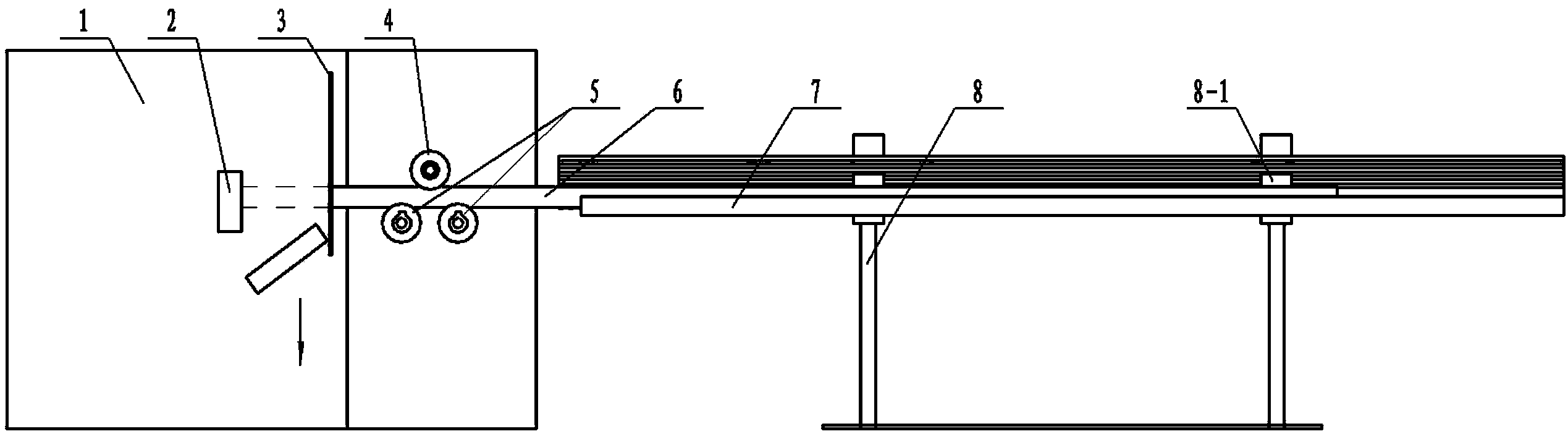

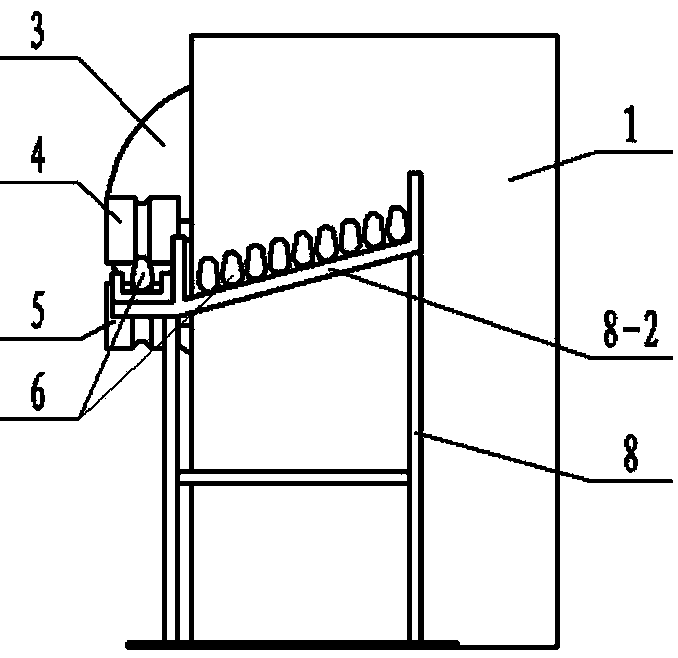

Vertical continuous PCB nickel or gold plating equipment

The invention discloses vertical continuous PCB nickel or gold plating equipment, comprising an electric control device, a nickel plating bath, a gold plating bath, a rack, a conveying mechanism, a nickel plating pretreatment tank, a nickel plating post-treatment tank, a gold plating pretreatment tank and a gold plating post-treatment tank, wherein the conveying mechanism is arranged on the rack, and is arranged above each tank body; the electric control device controls PCB plates to be conveyed to the corresponding treatment tank to gradually immerse or lift; the length direction of the nickel plating bath is consistent with the process flow direction; the conveying mechanism is used for gradually and continuously immersing the PCB plates into the nickel plating bath; each PCB plate is soaked into the nickel plating bath under the drive of the conveying mechanism, and moves along the length direction of the nickel plating bath; anodes are respectively arranged on two side walls of the nickel plating bath; the panels of the PCB plates are opposite to the anodes; two anodes are symmetrically distributed on two sides of each PCB plate; the consistency and the uniformity of the surface coatings of different PCB plates are ensured; the subsequent continuous gold plating consistency and uniformity are improved; waste of a liquid medicine is reduced; the wastewater treatment difficulty is lowered; the environmental pollution is reduced; and the cost is also reduced.

Owner:朱和平 +1

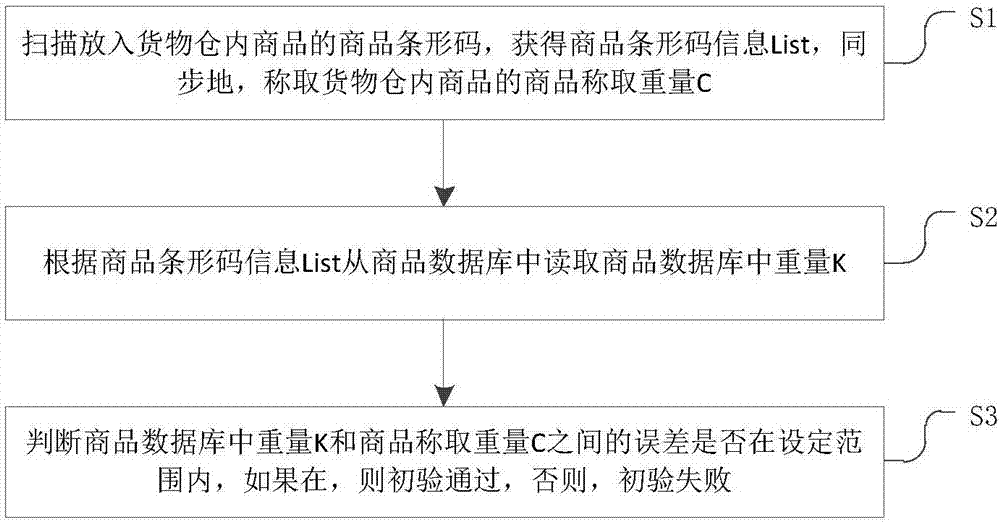

Method and system for supermarket shopping

ActiveCN107452164AReduce operating costsSave considerable salary expensesCash registersIndividual entry/exit registersSelf-serviceIndustrial engineering

The invention provides a method for supermarket shopping. The method comprises the steps that A1 an incoming customer is identified at a supermarket entrance gate, and the customer weight is weighed; A2 a self-service shopping system is provided for the customer to carry out self-service shopping and checking out; and A3 an export weighing system is arranged at a supermarket exit gate to compare the current customer weight and the weight of the customer entering a supermarket, and the customer is allowed to leave within a permissible range. The invention further provides a system for supermarket shopping. The system comprises the supermarket entrance gate which is arranged at the supermarket entrance to identify the incoming customer, an entrance weighing system which is used for weighing the incoming customer, the self-service shopping system which is used for customer self-service shopping and checkout, the supermarket exit gate which is arranged near the self-service shopping system, and the export weighing system which weighs the outgoing customer and compares the current customer weight and the weight of the customer entering the supermarket to release the customer within the permissible range. According to the invention, the operation cost and the risk of commodity loss can be reduced.

Owner:中驰智能机器人(杭州)有限公司

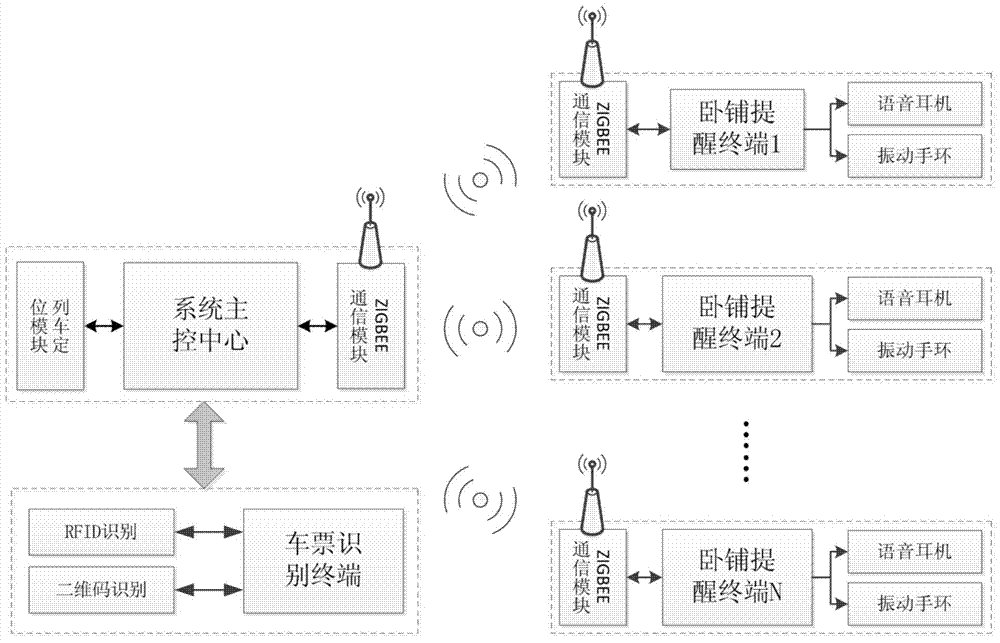

Train taking ticket-changing-free and automatic reminding device

InactiveCN104766199AReduce operating costsMaximize Carrying EfficiencyOffice automationSensing by electromagnetic radiationEngineeringComputer terminal

The invention relates to a train taking ticket-changing-free and automatic reminding device. By the adoption of the technical scheme, a single compartment is used as a control unit, and the total group is composed of a tick recognizer, a master control center and a sleeping berth reminding terminal; when a passenger purchases a ticket, the ticket with the corresponding time, train number, berth number and destination station information is sold at a train ticket office according to the requirement of the passenger, a two-dimensional code and a magnetic strip recognition code are printed on the ticket, and the magnetic strip recognition code is the ticket recognition code to form the RFID electronic ticket; a ticket recognition terminal is installed at the joint of the train berth compartments, and the ticket recognition terminal is composed of an RFID recognition module, a two-dimensional code recognition module, a processor module and an MAX 485 communication module. The train taking ticket-changing-free and automatic reminding device can replace manual ticket exchanging work, lower the working intensity of a trainman, improve the working efficiency, decrease train operation management and service workers, lower the operation cost, improve the service quality and maximize the train carrying efficiency.

Owner:HUNAN RAILWAY PROFESSIONAL TECH COLLEGE

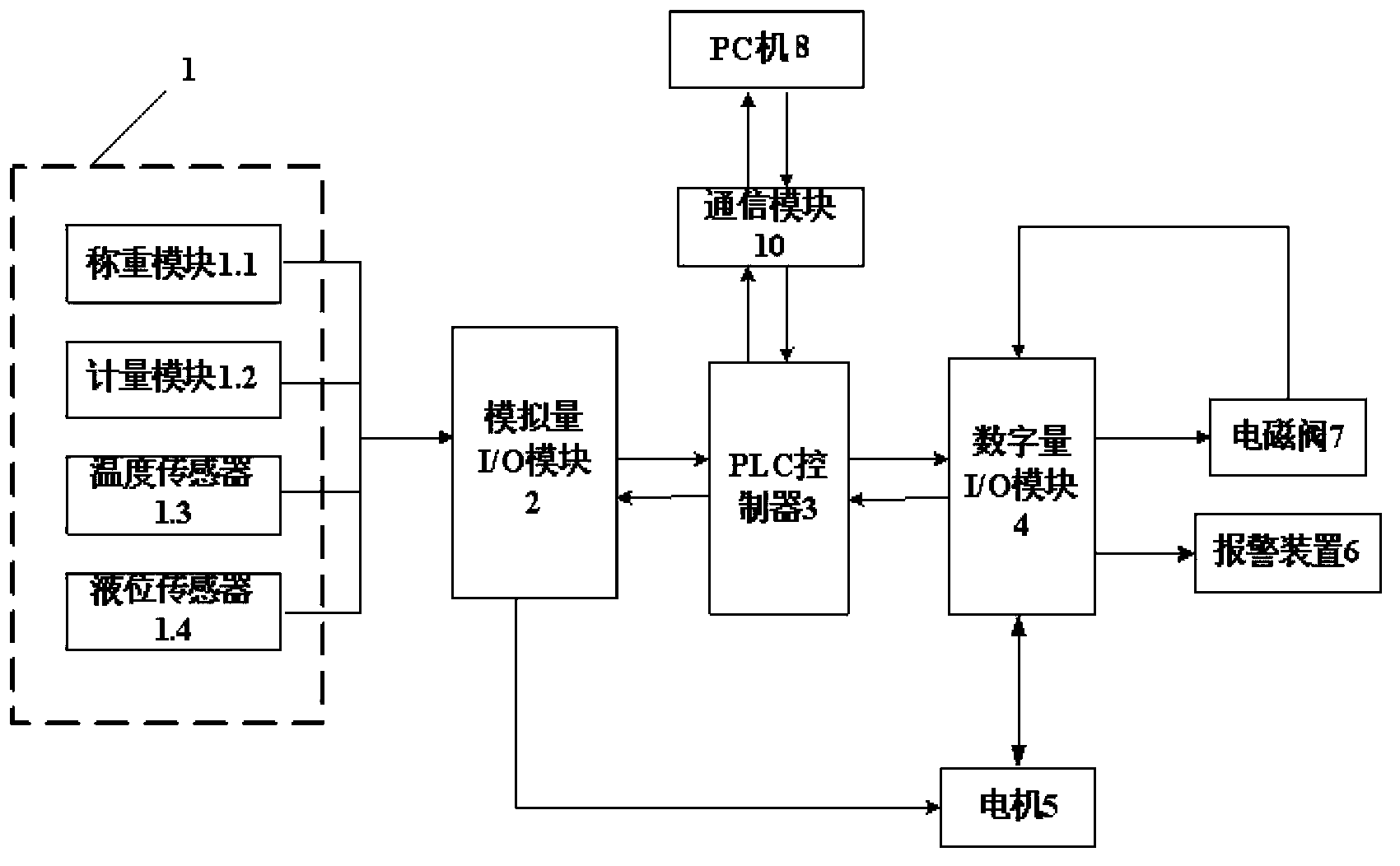

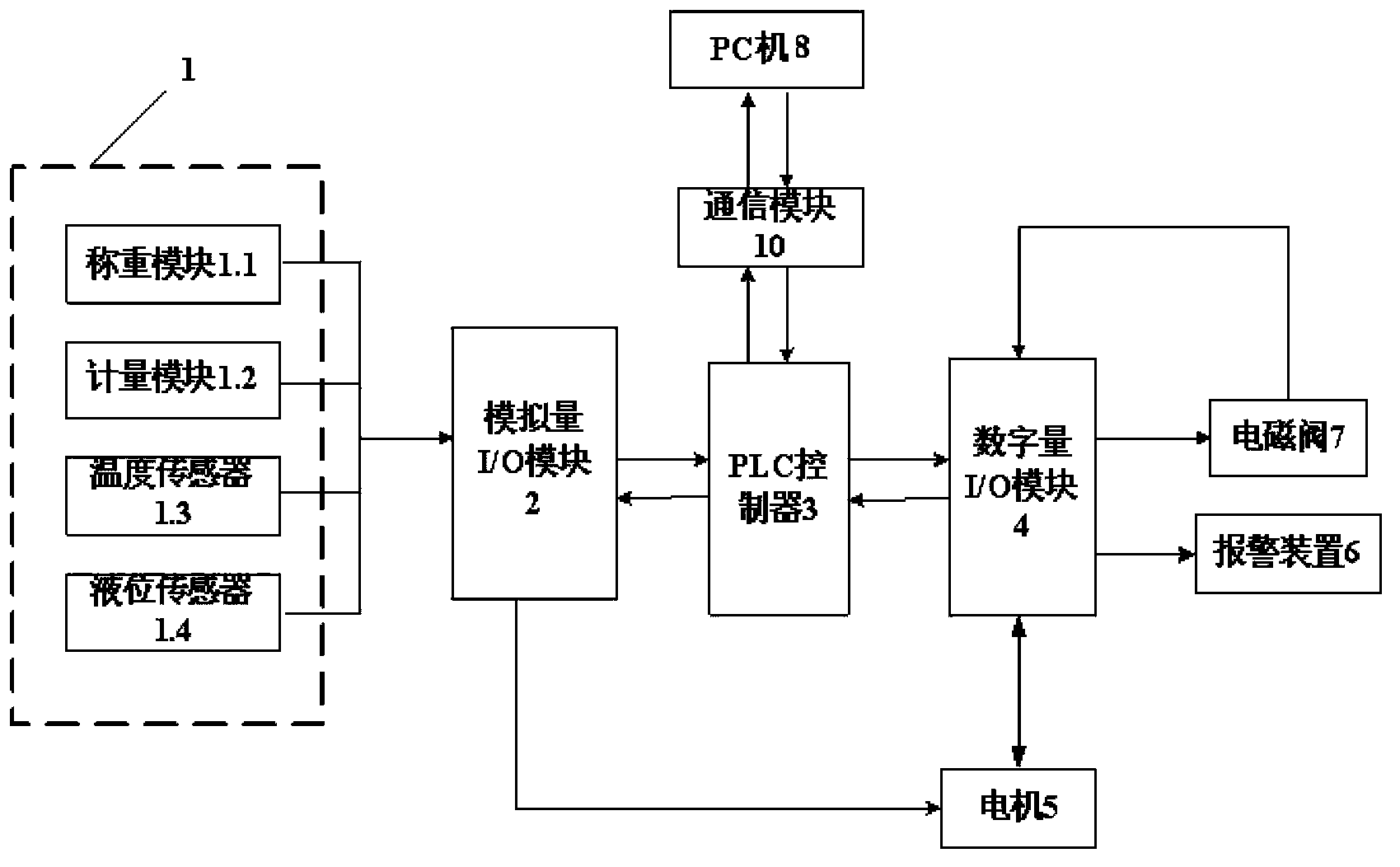

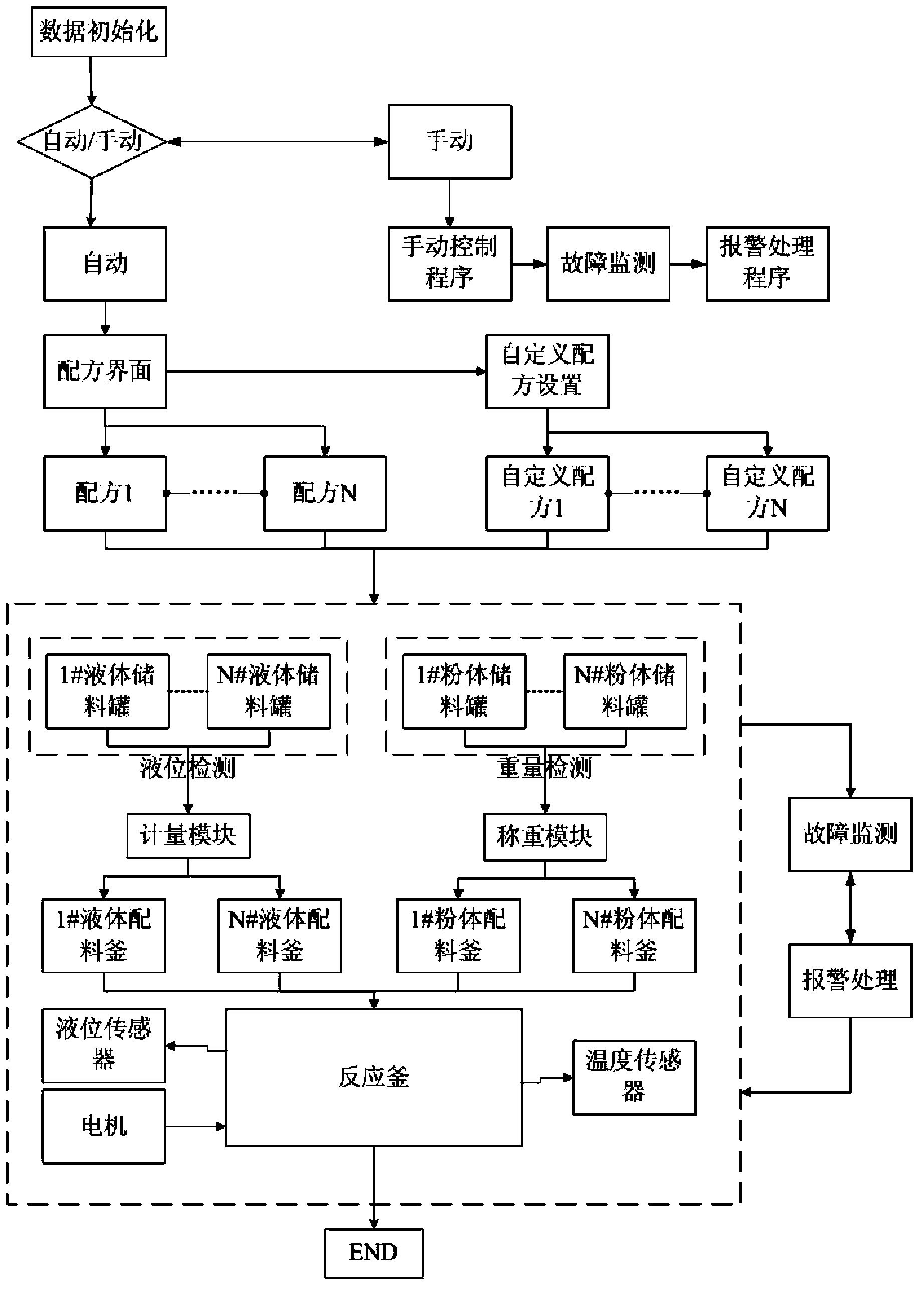

DCS control system for material processing

InactiveCN103823416AReduce operating intensity and number of peopleReduce manufacturing costTotal factory controlProgramme total factory controlAutomatic processingProgrammable logic controller

The invention provides a DCS control system for material processing. The system comprises a diaphragm pump arranged on a material storage tank and a motor used for starting material processing, an electromagnetic valve is arranged on the diaphragm pump, and a detection module is arranged inside the material storage tank. The detection module is in interactive connection with a PLC via an analog I / O module, the programmable logic controller is in interactive connection with a digital I / O module, the digital I / O module controls operation of the diaphragm pump through the electromagnetic valve, the output end of the electromagnetic valve is connected with the input end of the digital I / O module, and the output ends of the analog I / O module and the digital I / O module are both connected with the motor. According to the DCS control system for material processing provided by the invention, material weighing, material feeding, and the temperature, liquid level and the like inside the material storage tank in the process of material stirring, dispersing or grinding can be automatically and remotely controlled, a processing device can be automatically started or stopped, the purpose of automatic processing is achieved, the cost is saved, and the product quality is improved.

Owner:ANHUI LAND GRP

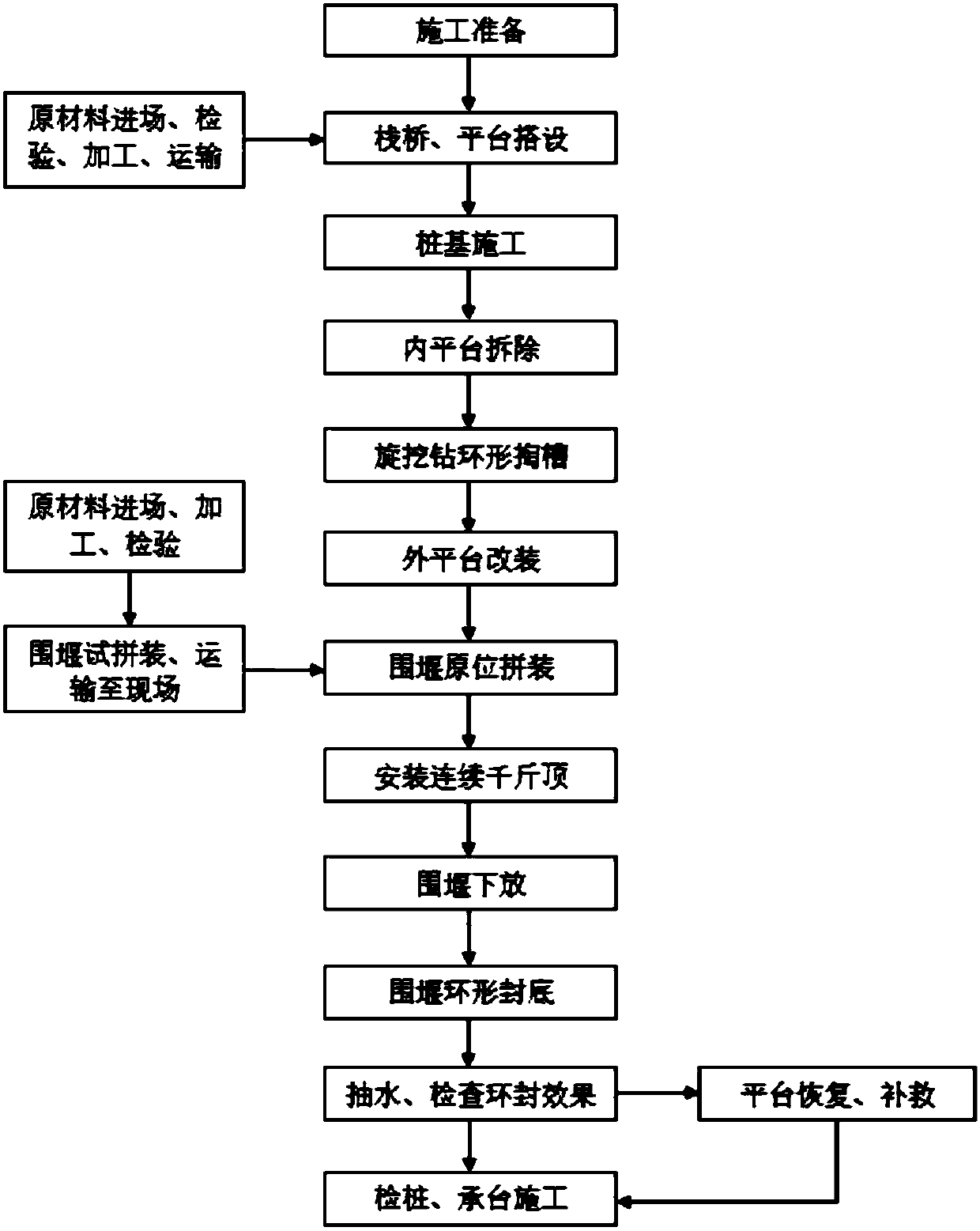

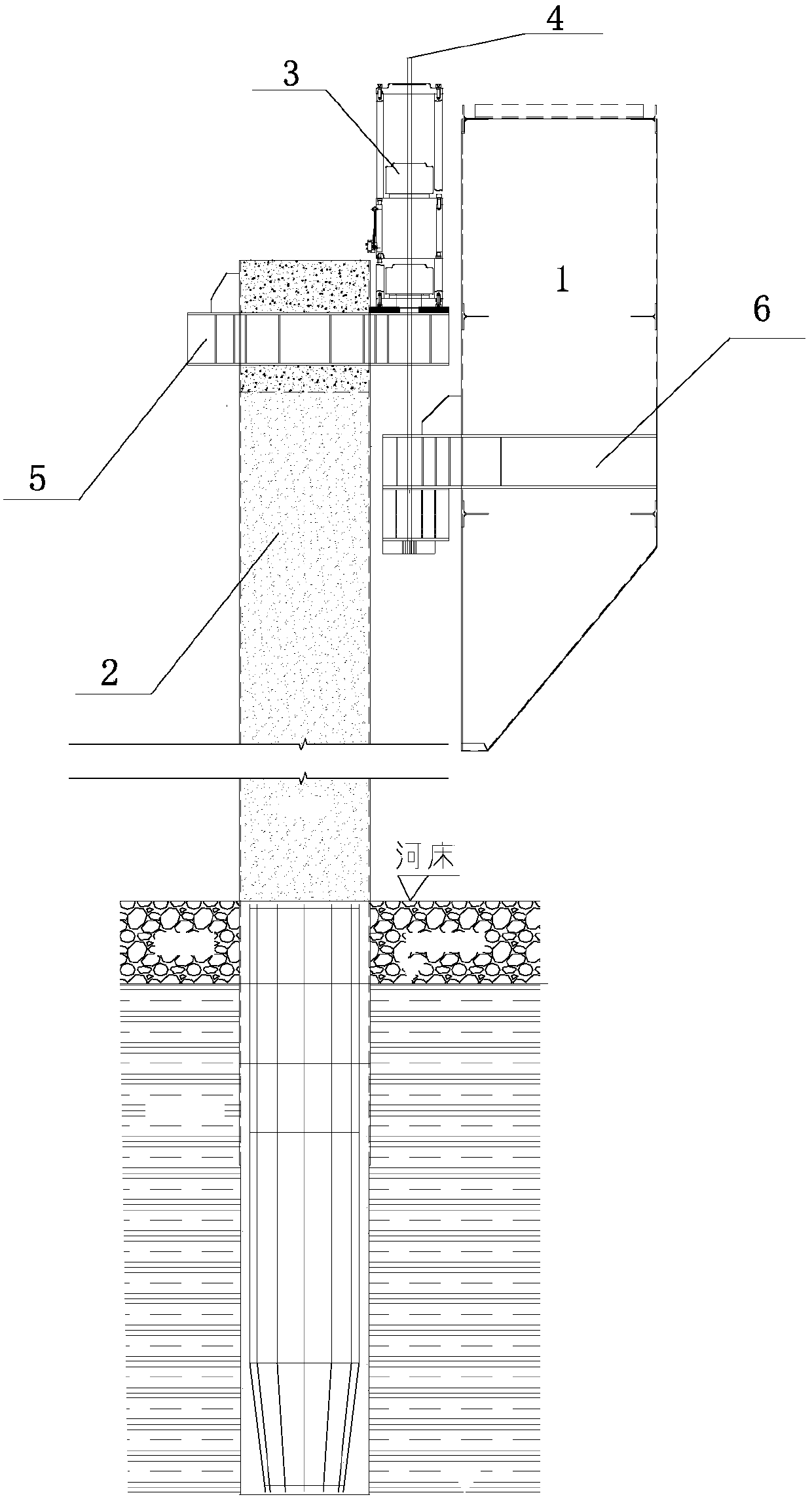

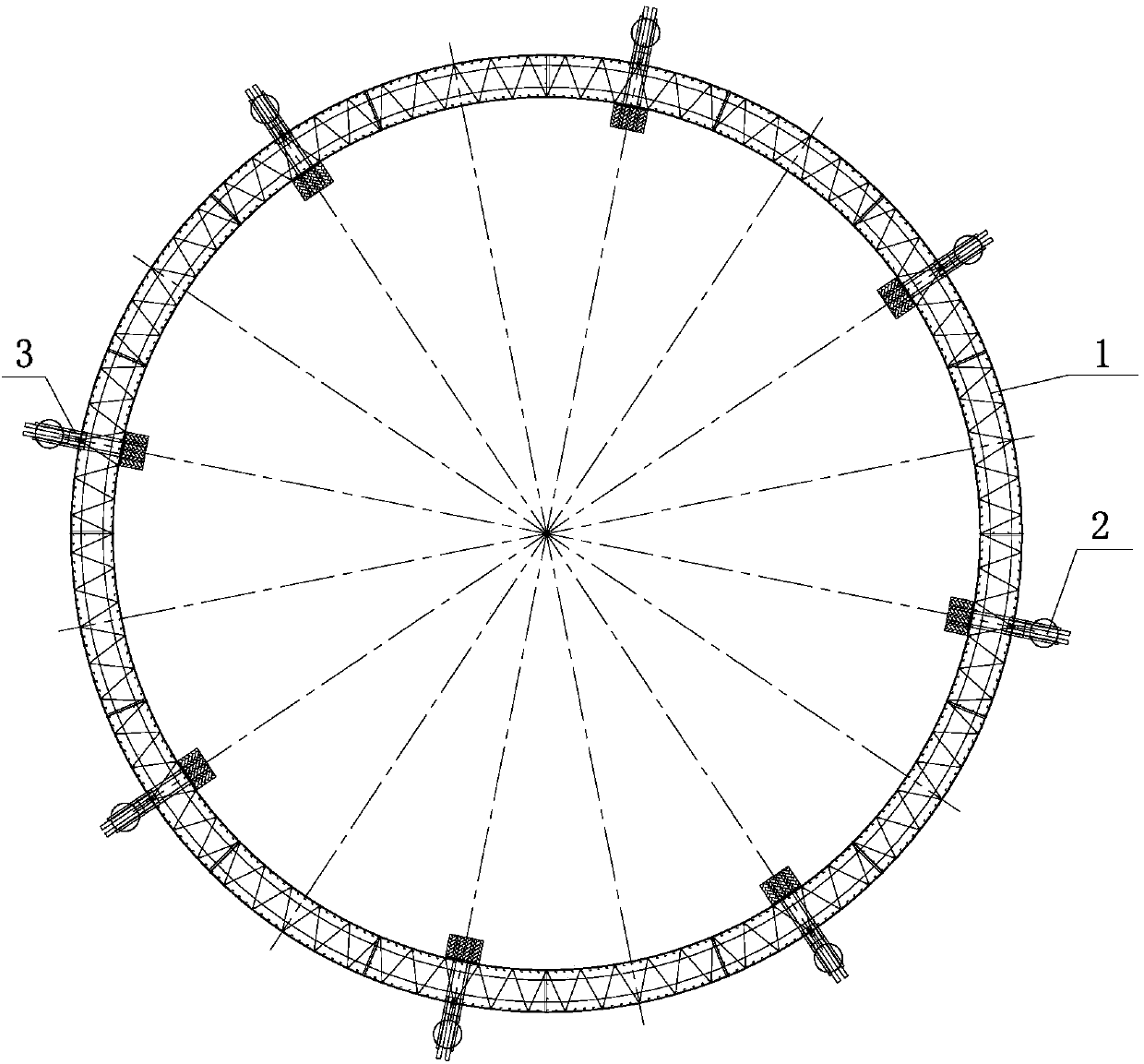

Comprehensive construction method for pre-cut groove loop-sealing double-wall steel cofferdam deep water foundation

ActiveCN107869144AHarm reductionReduce construction difficultyFoundation engineeringHydro energy generationArchitectural engineeringCofferdam

The invention discloses a comprehensive construction method for a pre-cut groove loop-sealing double-wall steel cofferdam deep water foundation. The method includes the following steps that (1) a trestle and a platform are set up; (2) pile foundation construction is performed; (3) a rotary excavating drill is used for precutting of grooves in a riverbed at the double-wall steel cofferdam blade foot position; (4) cofferdam splicing is conducted; (5) a cofferdam tripping system and a continuous jack are installed; (6) cofferdam tripping is carried out; and (7) the cofferdam bottom is sealed. According to the comprehensive construction method for the pre-cut groove loop-sealing double-wall steel cofferdam deep water foundation under complicated geological conditions, the construction technological level is perfected and improved, the purpose that the construction technology is advanced, reasonable, economical and safe is achieved, experience is provided for similar construction, and an important guiding function is provided for deep water foundation construction and cofferdam construction works.

Owner:中铁二十二局集团第四工程有限公司 +1

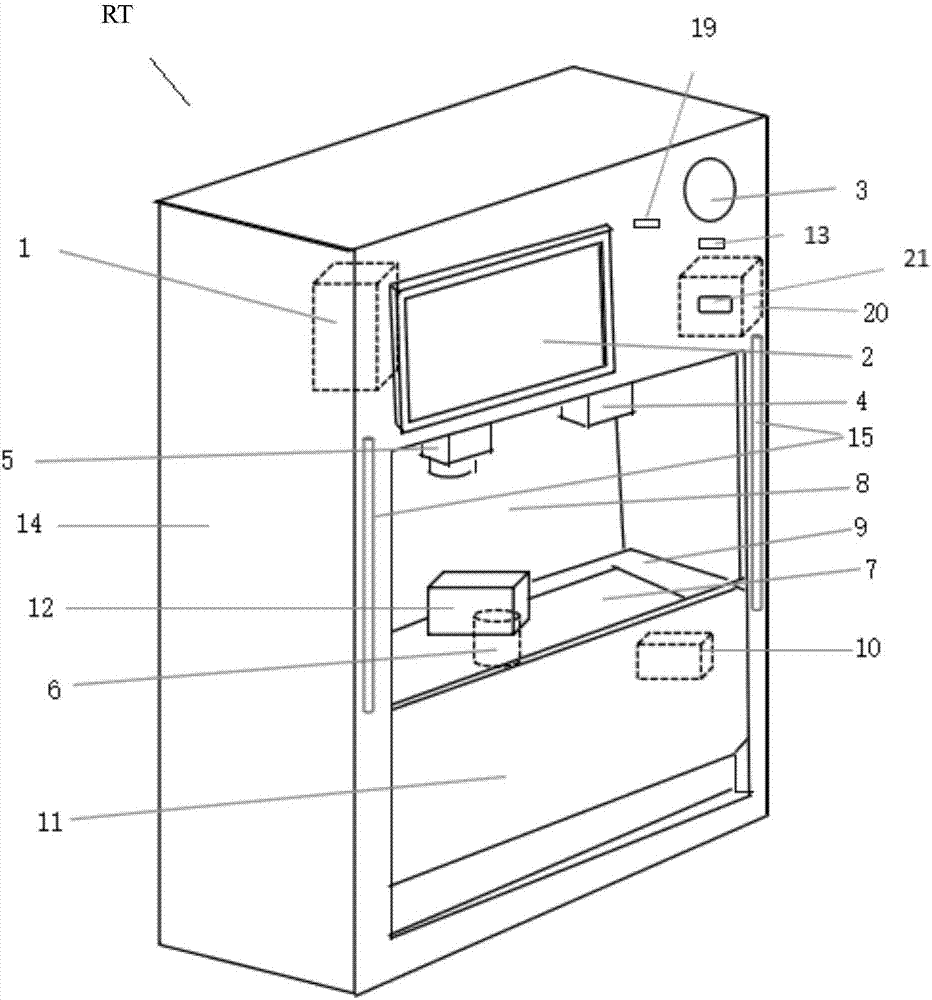

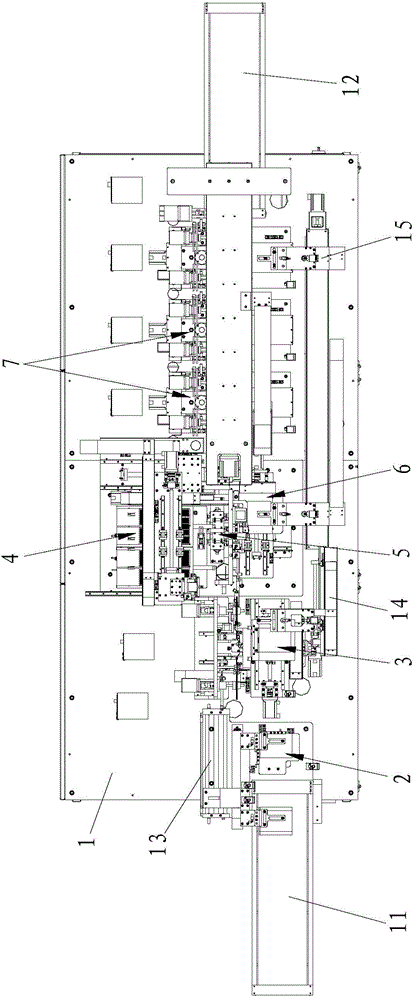

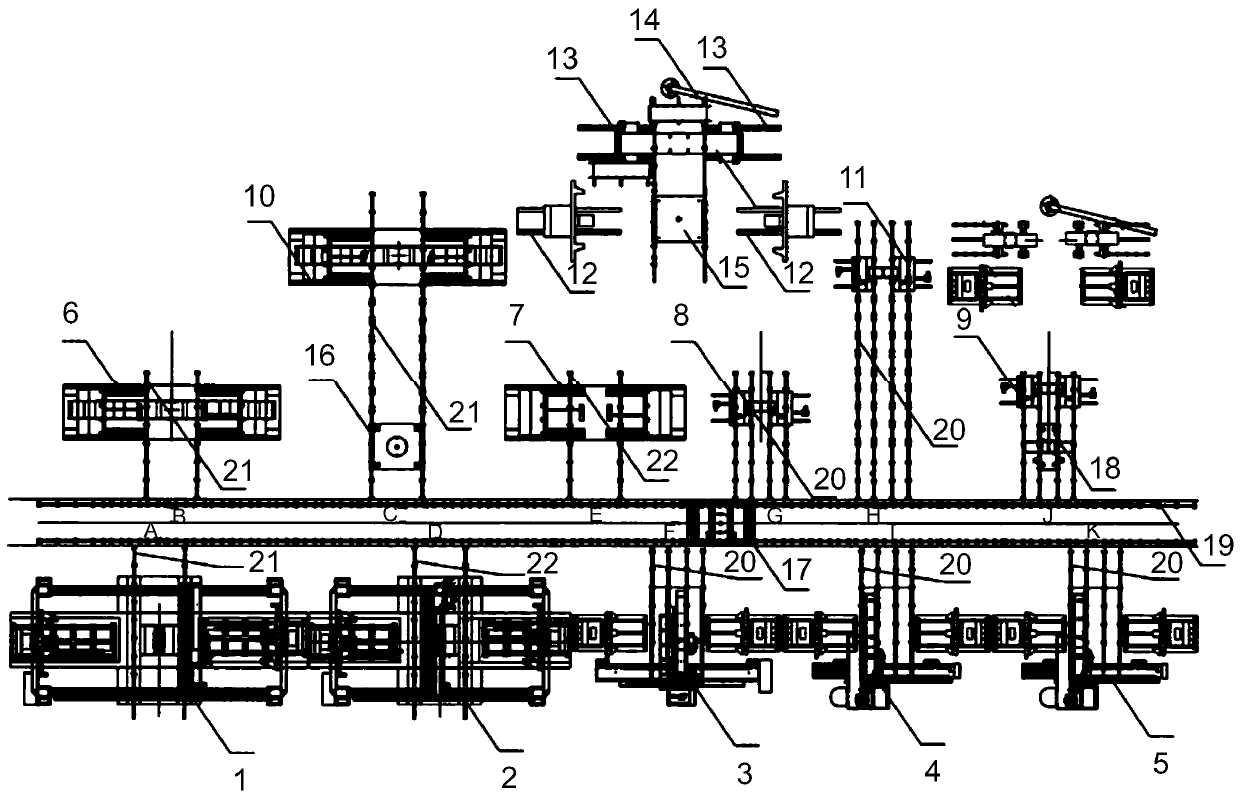

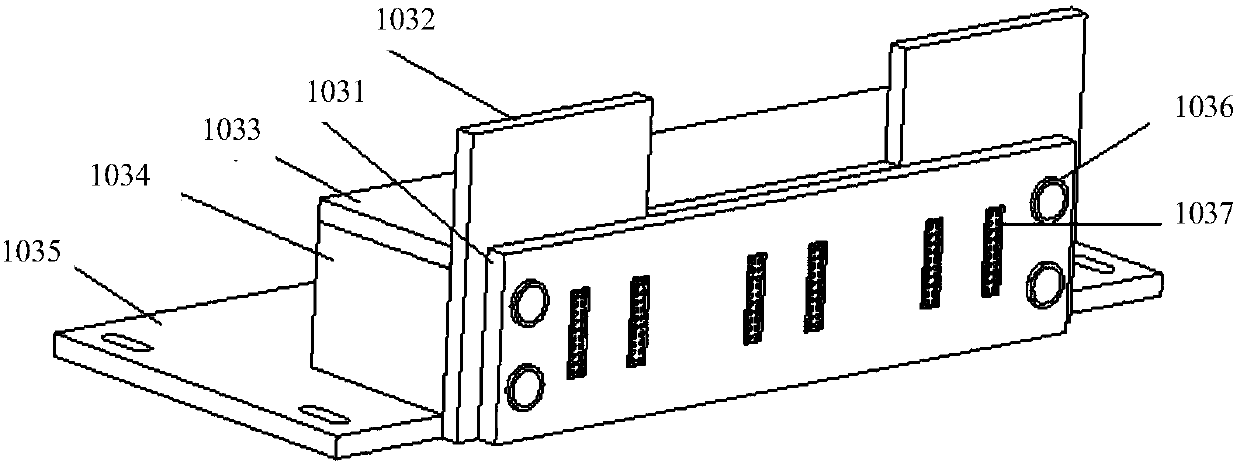

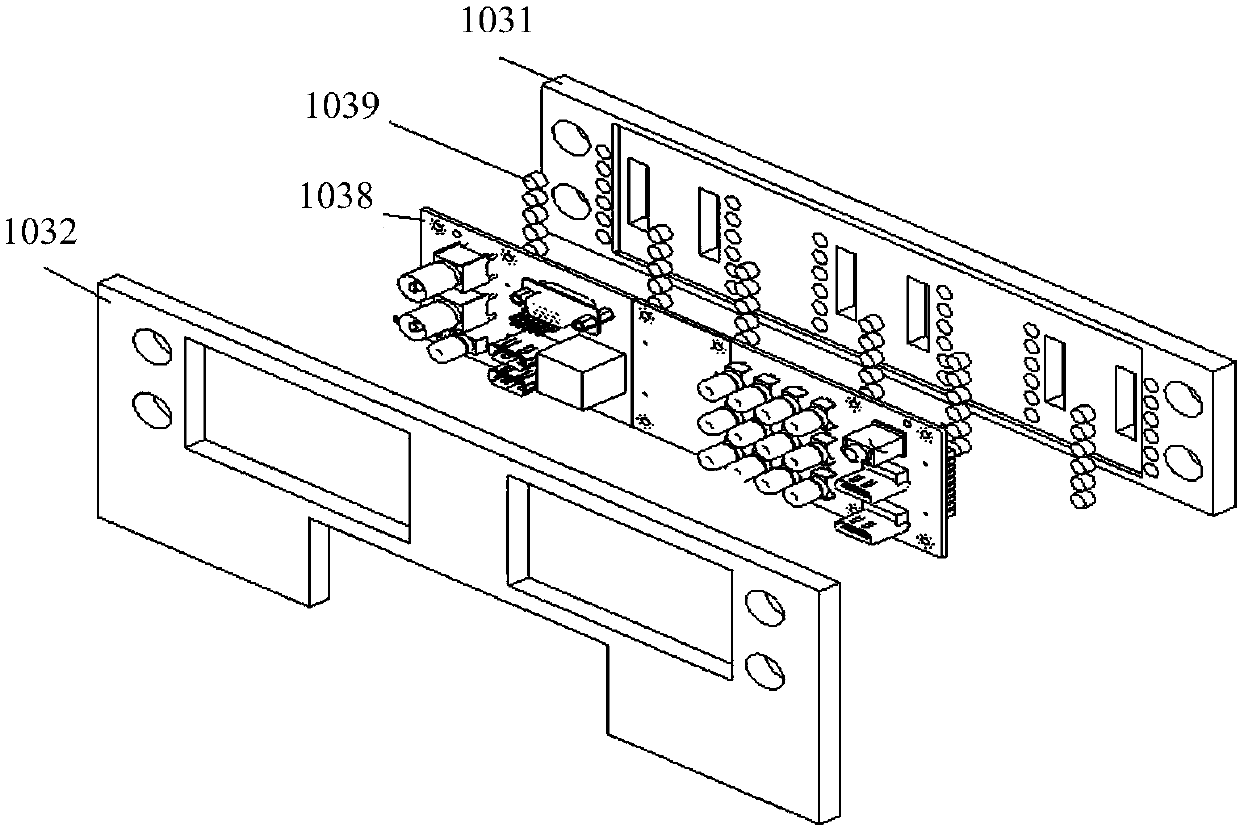

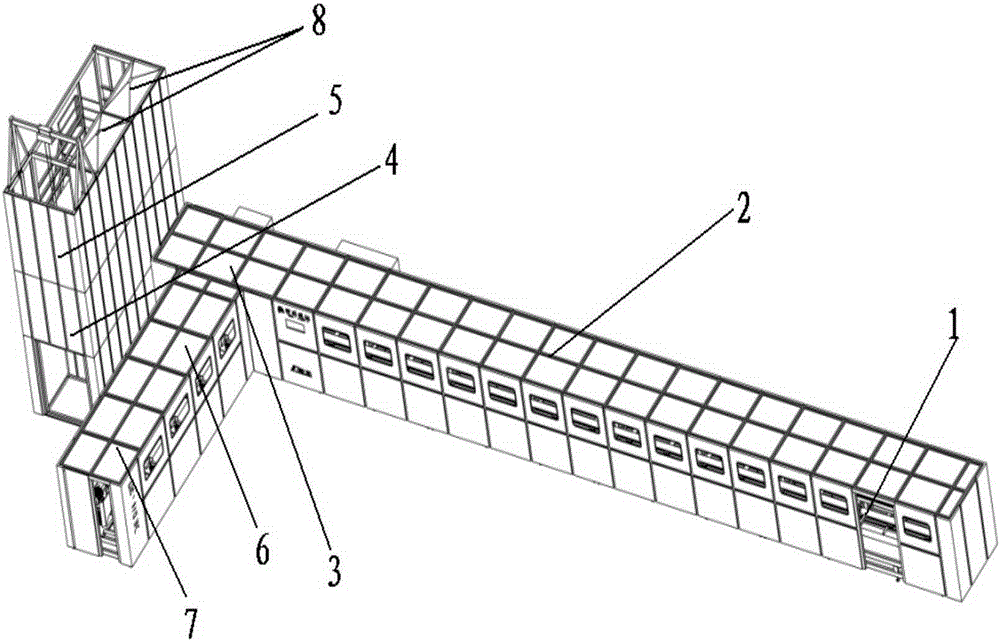

Intelligent LCM assembly machine

ActiveCN104090397AIntelligent assemblyImprove assembly accuracyNon-linear opticsManufacturing engineeringAssembly machine

The invention relates to the technical field of LCM assembly devices, in particular to an intelligent LCM assembly machine which comprises a rack. The rack is sequentially provided with an LCM feeding device, an automatic material conveying corrector, an ACF film pasting device, an IC pre-pressing assembling device, an LCM pressing device and an LCM discharge device according to the assembly process sequence. A material conveying system for conveying materials among all assembly processes is arranged on the rack. By means of the intelligent LCM assembly machine, the whole assembly process of the LCM can be completed automatically, intelligent assembly is achieved, the assembling accuracy is high, automatic feeding and discharge can be achieved among the processes, the working condition of operators is improved, every action of the machine work always keeps high consistency from start to finish, the production assembly efficiency is improved, meanwhile, the constantly climbing labor cost is reduced greatly due to the fact the number of the operators is reduced, and the high and stable product quality is guaranteed.

Owner:DONGGUAN LISHENG MACHINERY EQUIP

Automatic magnetic particle testing unit for toe cracks at inner wall of straight welded pipe

InactiveCN102346151ARapid Batch DetectionAutomatic detection speed adjustableOptically investigating flaws/contaminationMaterial magnetic variablesDrive wheelTransformer

The invention relates to a testing unit for a straight welded pipe, in particular to an automatic magnetic particle testing unit for toe cracks at inner wall of the straight welded pipe, comprising a car body consisting of a sweep template, a driving wheel, a stop block, a supporting plate, universal wheels and a guide bar which are connected with each other coaxially, and a rotary bearing, a driving motor, a control part, a steering engine, a position switch arranged on the two ends of one end of the car body, and a transformer bearing, a camera bearing, a sprayer bearing, a crossed yoke, an ultraviolet lamp bearing, and a water pump water tank bearing which are successively arranged on the top of the sweep template from left to right, wherein, the upper end of the stop block is fixedly connected with the two sides of the rear end of the sweep template bottom in parallel, the output end of the steering engine is fixedly connected with the universal wheels through the guide bar, the upper end of the rotary bearing is fixedly connected with the two sides of the rear end of the sweep template bottom in parallel, the lower end of the rotary bearing is fixedly connected with one end of the supporting plate, the other end of the supporting plate is fixed connected with the sweep template bottom, and output shaft of the driving motor is respectively connected with the two driving wheels fixedly. The invention can completely takes the place of manual work to carry out automatic magnetic particle testing, and has the advantages of compact structure and convenient operation.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

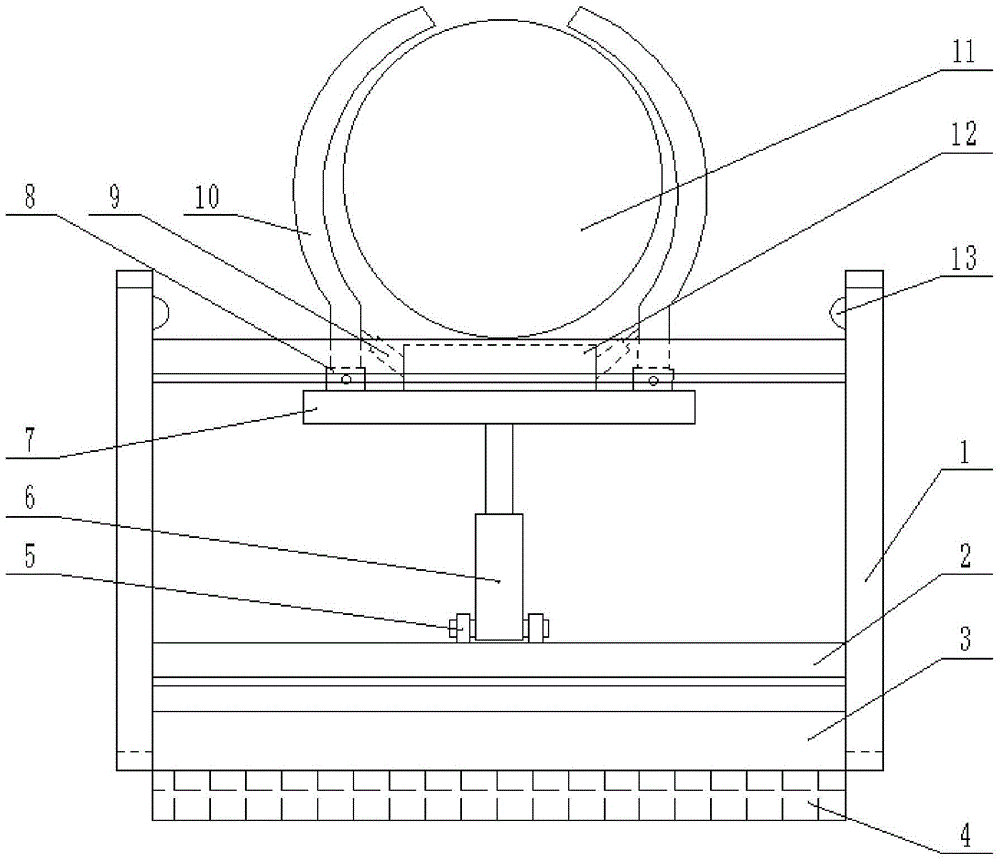

Solar-energy electric power overhauling ladder

InactiveCN105604476APrevent sideslipPrevent slippingBatteries circuit arrangementsLighting elementsSolar cellLED lamp

The invention discloses a solar-energy electric power overhauling ladder and belongs to the field of electric power overhauling equipment. The solar-energy electric power overhauling ladder comprises grab rods (1), foot rests (2), a control cabinet (3), a solar cell panel (4), a hinge joint seat I (5), an electric telescopic rod I (6), a connecting plate (7), hinge joint seats II (8), two electric telescopic rods II (9), two embracing hoops (10), a top plate (12) and LED lamps (13). The solar cell panel (4) is arranged on the control cabinet (3), and storage batteries are arranged in the control cabinet (3). Two ends of the electric telescopic rod I (6) are connected with the connecting plate (7) and the foot rests (2), the top plate (12) and the hinge joint seats II (8) are arranged on the connecting plate (7), the two embracing hoops (10) are hinged to the hinge joint seats II (8), and two ends of the two electric telescopic rods II (9) are hinged to the side faces of the top plate (12) and the embracing hoops (10). The solar-energy electric power overhauling ladder can be prevented from sideslipping and sliding down when leaning against a telegraph pole, and is capable of lighting, simple and convenient to operate and capable of ensuring safety.

Owner:XUZHOU BEIER ELECTRIC CO LTD

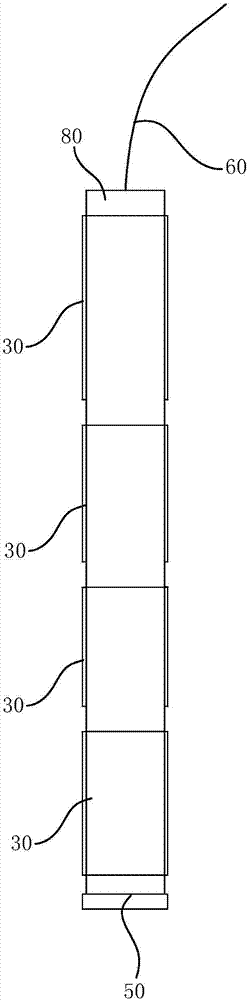

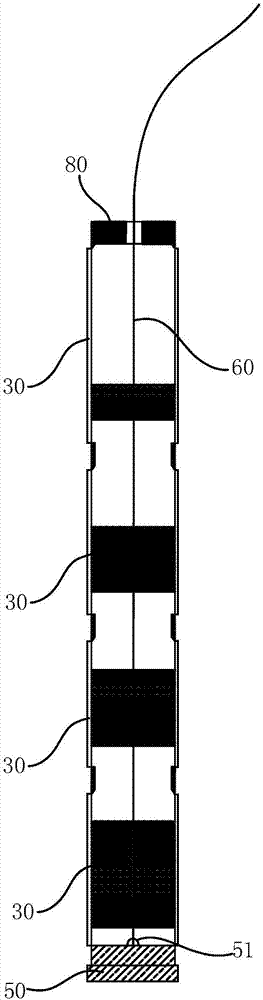

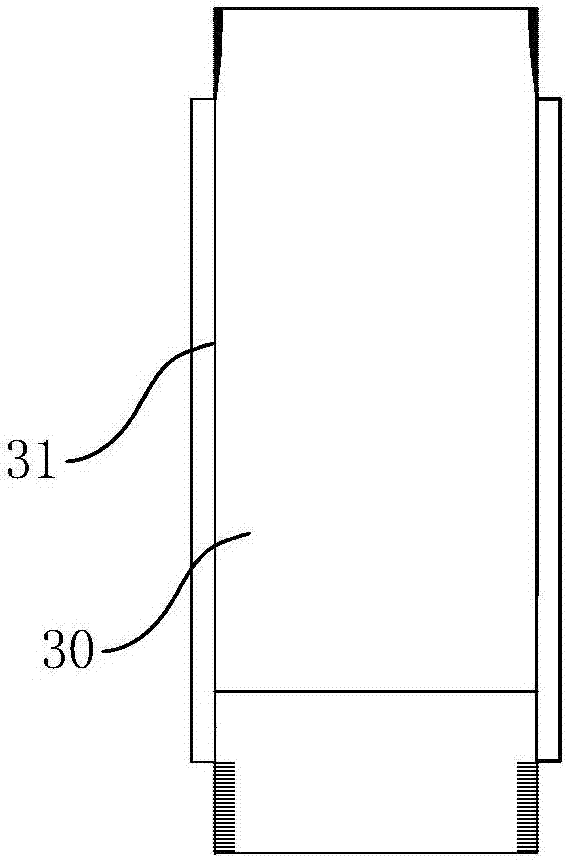

Deep-hole smooth tunnel blasting system and construction method for tunnel

ActiveCN107355229AImprove stabilityReduce harmUnderground chambersBlastingEngineeringExplosive material

The invention relates to a deep-hole smooth tunnel blasting system. The deep-hole smooth tunnel blasting system comprises a multi-shaft drilling mechanism and a deep-hole smooth blasting mechanism; the drilling mechanism comprises a drill rod arranged on an adjusting bracket, the drill rod is driven by a horizontal driving mechanism to move horizontally and implement hole digging operation, and a spatial position, located on the adjusting bracket, of the drill rod can be adjusted; the deep-hole smooth blasting mechanism comprises a plurality of explosive material charging tube standard joints arranged in a blasting hole; tube openings of the explosive material charging tube standard joints are sequentially connected to form a blasting tube, and trays are arranged on the connecting parts of adjacent explosive material charging tube standard joints for supporting explosive materials; a base is arranged at one end of the blasting tube, and a top cover is arranged at the other end of the blasting tube; and a through hole is formed in the tray surface of the tray for penetrating of a detonating cord, the detonating cord sequentially and upwardly penetrates through the through hole in the tray from the base and leads out from a through hole formed in the top cove of the blasting tube, and cracks are further arranged on the tray. The deep-hole smooth tunnel blasting system can improve the drilling efficiency, and weaken the influence of complex geological environment of a coal mine on explosive material charging at the same time, and premature overflowing of explosion gas is prevented.

Owner:ANHUI UNIV OF SCI & TECH

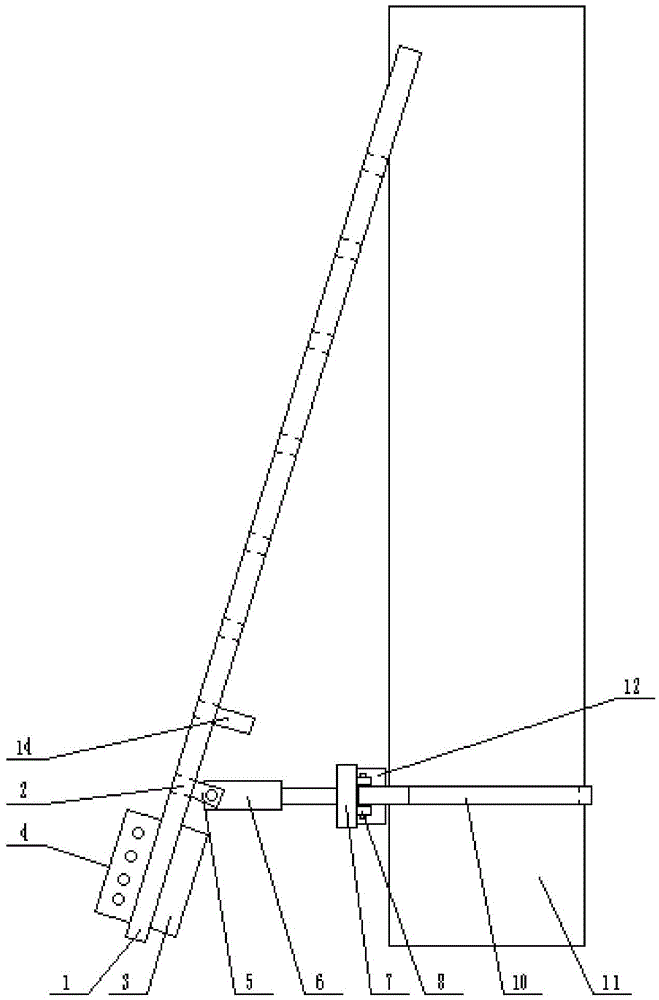

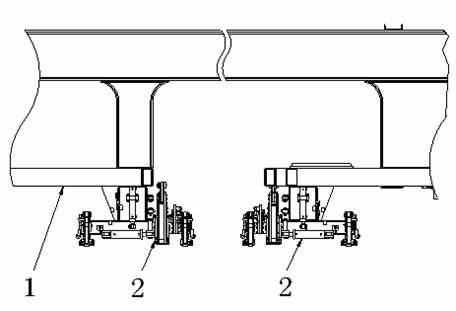

Rail pulling and aligning device

ActiveCN102493295AReduce preparation timeReduce the number of peopleRailway track constructionVehicle frameEngineering

The invention provides a rail pulling and aligning device, which comprises a transverse slippage mechanism fixed on a vehicle frame, vertical slippage mechanisms connected on two sides of the transverse slippage mechanism and longitudinal slippage mechanisms connected at the lower ends of the vertical slippage mechanisms. The rail pulling and aligning device is characterized in that rail clamping mechanisms are arranged in the middles of the longitudinal slippage mechanisms, and a front rail lifting mechanism and a rear rail lifting mechanism are correspondingly arranged on the front side and the rear side of each longitudinal slippage mechanism. An operator can operate the rail pulling and aligning device without matching of other operators so as to pull two steel rails to be welded to appropriate positions and align the two steel rails to the appropriate positions, thereby providing preparation for welding work of a welding machine, shortening welding operation preparing time and simultaneously decreasing the number of operating workers. The rail pulling and aligning device has the advantages of being high in work efficiency, flexible and convenient to operate, reliable in performance and the like, and the problems of the rail pulling and aligning in steel rail welding process can be solved.

Owner:CRCC HIGH TECH EQUIP CORP LTD +1

Broad-sense garbage collection and transportation method and device

InactiveCN103832756ASolve collection and transportation proceduresReduce collection and transportation proceduresRefuse receptaclesRefuse vehiclesBulky wasteEngineering

The invention provides a broad-sense garbage collection and transportation method and device, and belongs to the technical field of urban environmental sanitation equipment. Broad-sense garbage is a general item of household garbage, construction waste and bulky waste. At present, urban environmental sanitation equipment can only realize collection and transportation of the household garbage and can not realize collection and transportation of the construction waste and the bulky waste. To solve the technical problem, the technical schemes of a tipping bucket with a bi-directional open / close cover, an uncovered tipping bucket, a crane trolley, a dump truck provided with a lifting device and a compacting device, a dump truck provided with a lifting device and an open cover and other devices are provided, and therefore not only the household garbage by also the construction waste and the bulky waste can be collected and transported by the urban environmental sanitation department.

Owner:浙江长大建设技术有限公司

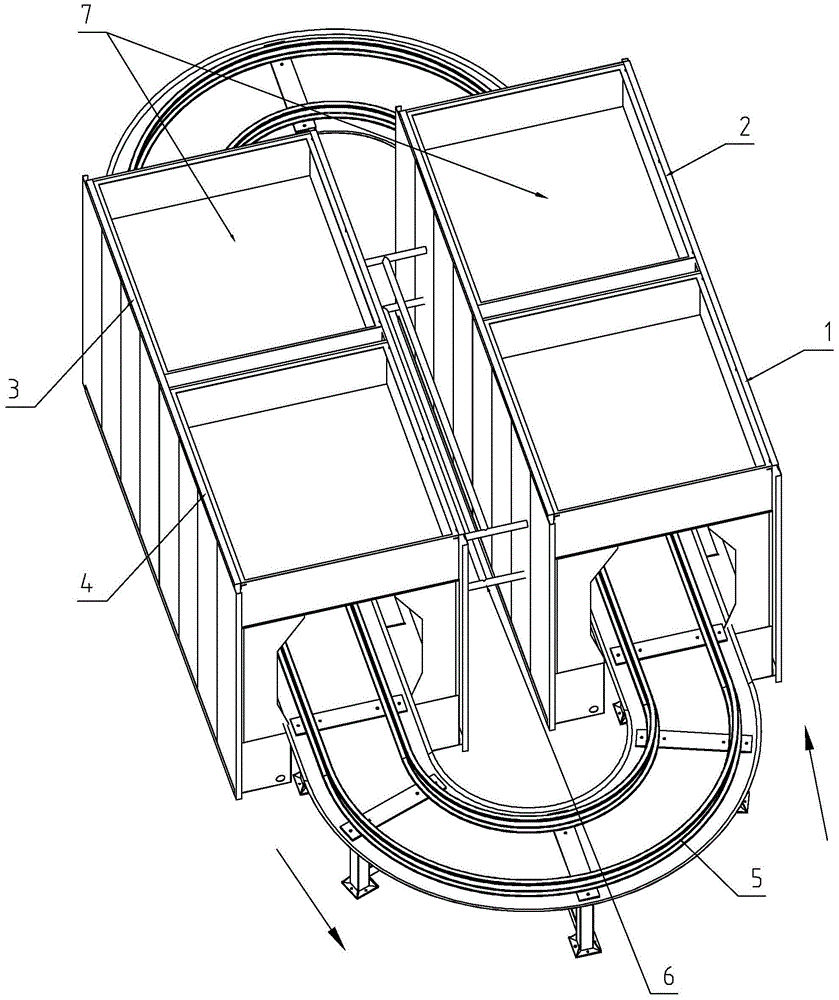

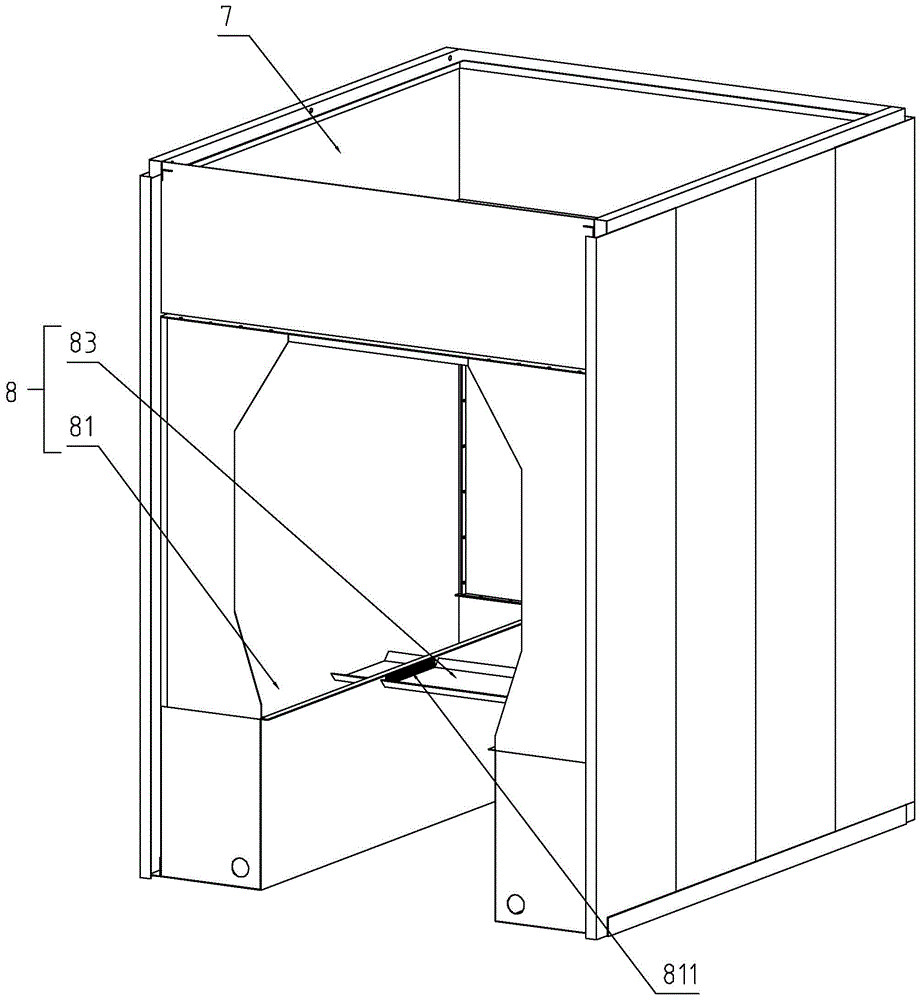

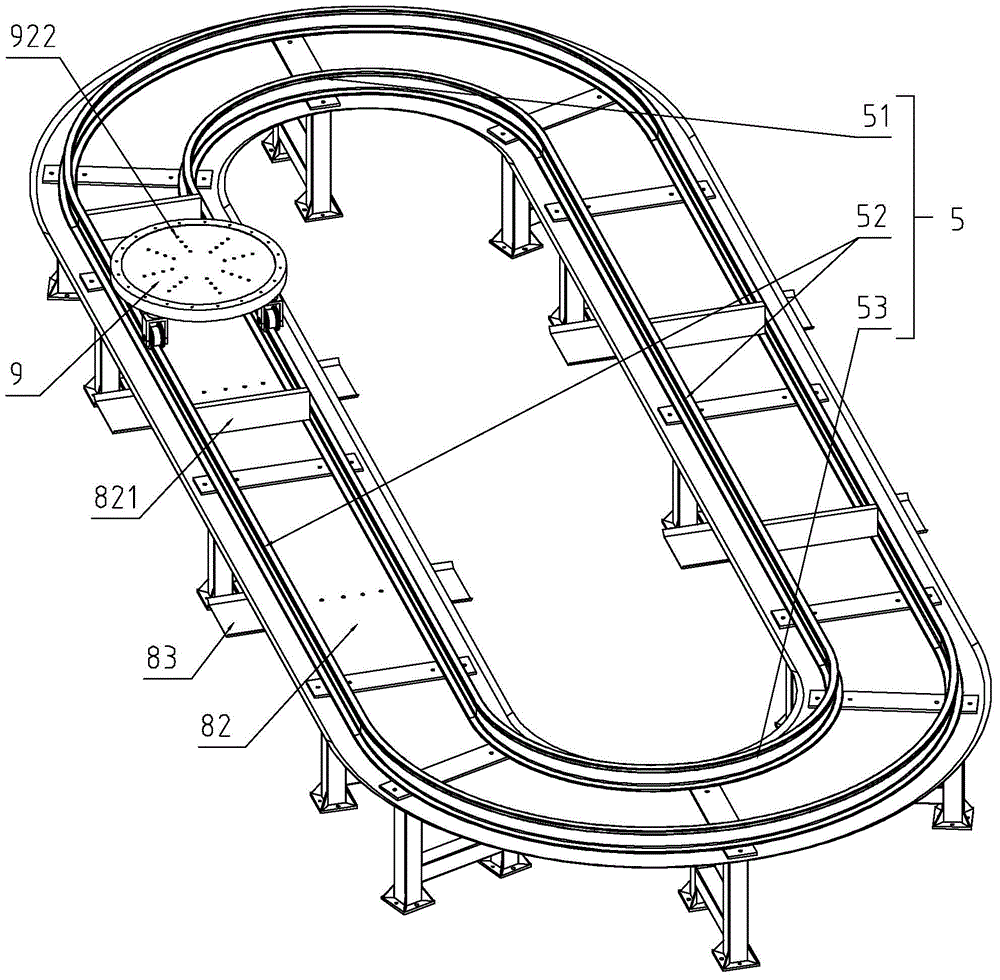

Cleaner

ActiveCN106552799AShorten footprintReduce the number of peopleHollow article cleaningCleaning using liquidsEngineeringAssembly line

The invention discloses a cleaner. The key point of the technical scheme is that the cleaner comprises a degreasing device, a rough cleaning device, a finish cleaning device and a drying device as well as a conveying track for conveying a to-be-cleaned product. The conveying track successively penetrates through the degreasing device, the rough cleaning device, the finish cleaning device and the drying device. The conveying track comprises a turning rail between the head and the tail of the conveying track and the head and the tail of the conveying track of are arranged adjacently. According to the cleaner disclosed by the invention, the whole conveying track can be adjacent at the head and tail through the turning rail, so that the land-occupying length of the whole cleaning assembly line can be greatly reduced; the to-be-cleaned product enters from the head end of the conveying track and goes out from the adjacent tail end, so that loading and taking operations can be performed by only one operator, and therefore, the number of operators can be effectively reduced, and the production cost is favorably reduced.

Owner:SUZHOU ENVIL MACHINERY

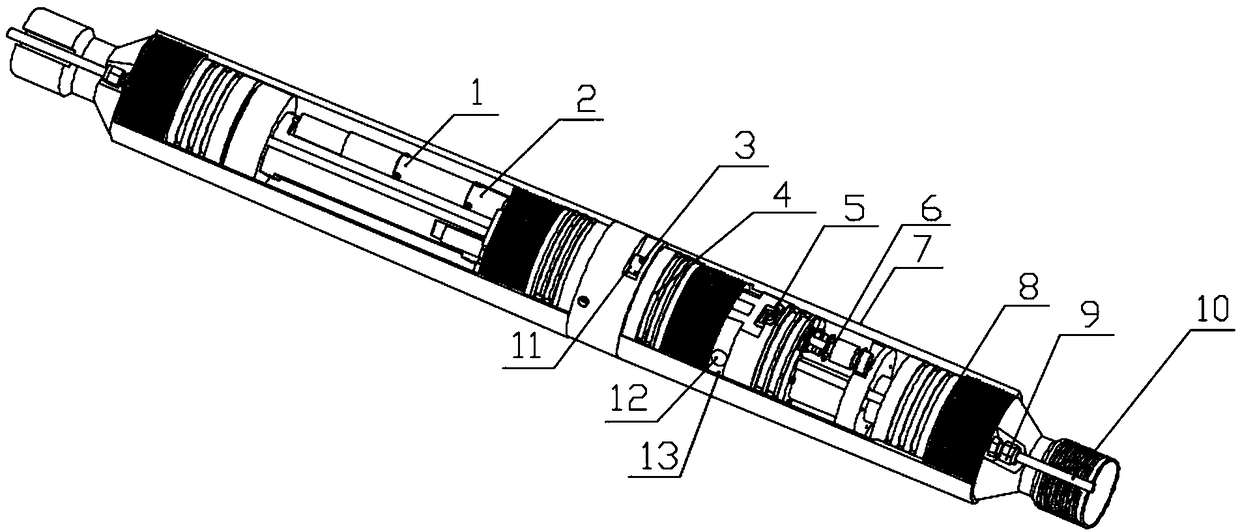

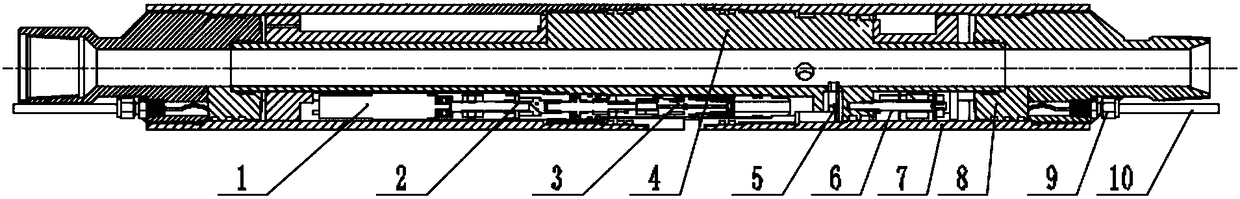

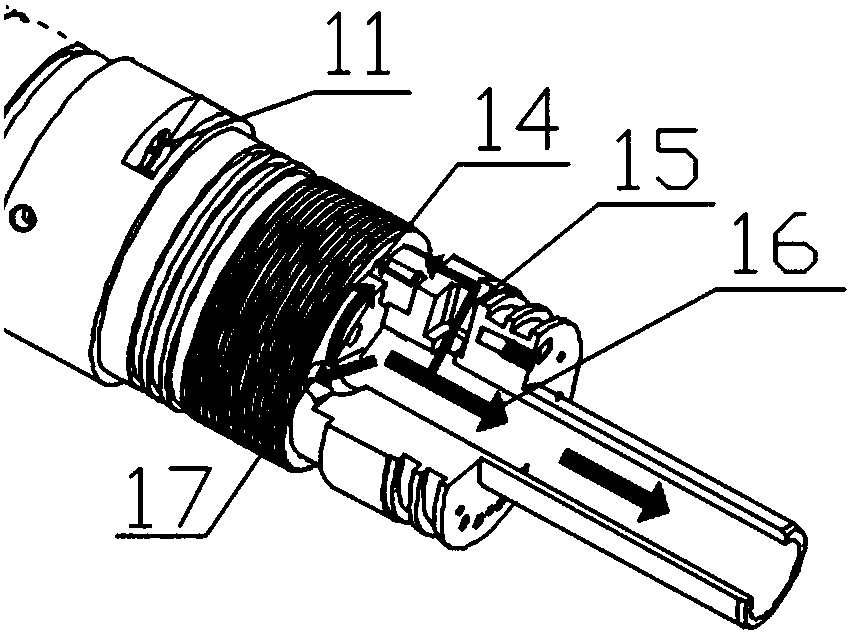

Shunting type intelligent water distributor for large flow water injection of oil fields

ActiveCN108166958AGuaranteed test accuracyImprove water injection efficiencyFluid removalShunt typesOil field

The invention discloses a shunting type intelligent water distributor for large flow water injection of oil fields. The shunting type intelligent water distributor includes a main body, a motor, a limiting device, an adjustable water nozzle and an electromagnetic flow meter body; the motor, the limiting device and the water nozzle are mounted on mounting holes of the main body, and a water flow ring groove channel with dividing water inlet holes are formed in the main body; a water inlet of the water nozzle communicates with the water flow ring groove channel with the dividing water inlet holes, and an electromagnetic flow meter is installed on a main water inlet hole previously formed in the main body; and injected liquid flow enters the water nozzle through a main water inlet and a plurality of dividing water inlet holes, and enters stratum from an water outlet hole on the main body to achieve the large flow water injection and the flow regulation.

Owner:四川省科学城久利电子有限责任公司

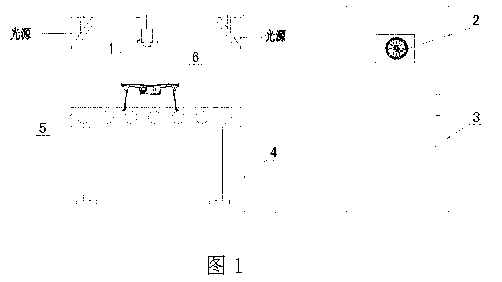

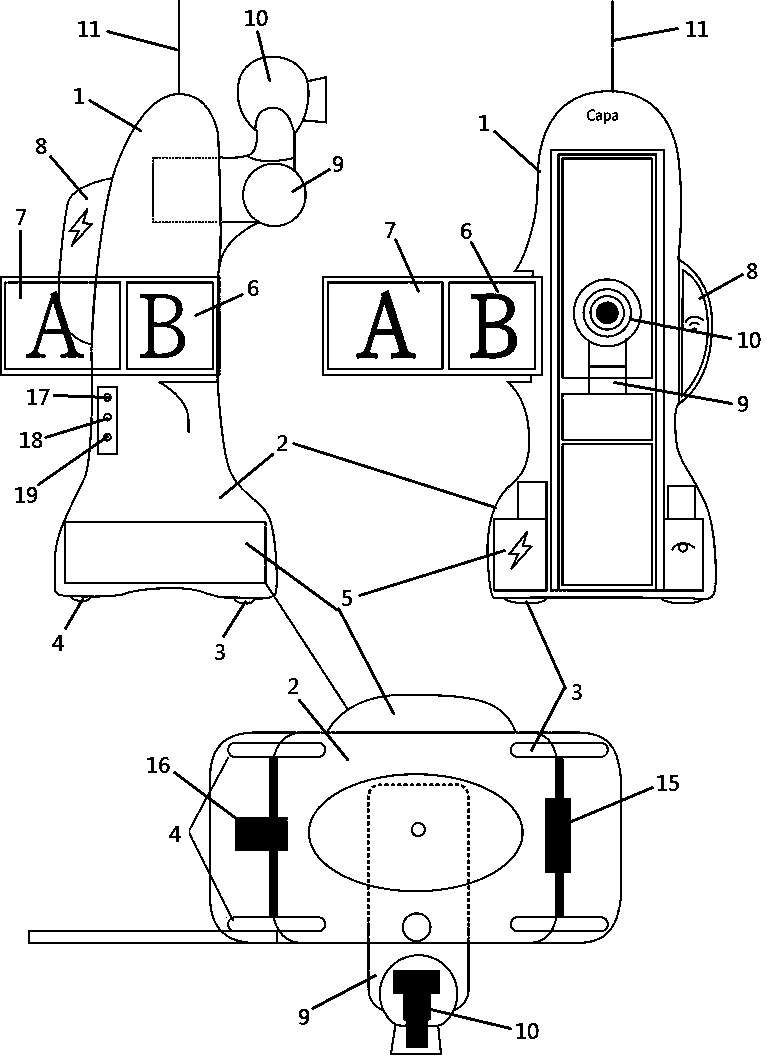

Aluminum alloy hub visual identification system

InactiveCN103268486AReduce the number of peopleReduce scrapCharacter and pattern recognitionControl engineeringVisual recognition

The invention relates to an aluminum alloy hub visual identification system which comprises a camera (1), an integration control box (3) and an integral frame (5), wherein the upper part of the integral frame (5) is provided with the camera (1), a working platform surface positioned on the intermediate part of the integral frame (5) is provided with a hub (6); and the integration control box (3) comprises a monitor (2), a controller and a manipulator. The aluminum alloy hub visual identification system is characterized in that the integration control box (3) is connected with and integral frame (5) through a communication control wire (4); and the camera (1) takes a photo to extract the characteristic data of the hub (6) and feeds back to the controller, and the controller automatically regulates processing parameters. The structure disclosed by the invention can reduce the operator number of each equipment and the scrap rate during processing, not only enhances the qualification rate of products, but also increases the working efficiency.

Owner:江苏天宏智能装备有限公司

Balance beam intelligent welding method based on robot welding production line

ActiveCN109885007AImprove welding efficiencyReduce types of workTotal factory controlWelding apparatusProduction lineScheduling instructions

The invention discloses a balance beam intelligent welding method based on a robot welding production line. An MES issues a production line production scheduling instruction; a balance beam is manually hung and conveyed to a feeding and blanking station; manual code scanning confirmation is performed; an RGV automatically conveys the balance beam to an MES specified welding station; a welding robot performs welding seam welding in the balance beam according to offline program; after the welding is completed, the balance beam is conveyed to the feeding and blanking station by the RGV; the balance beam is manually hung and conveyed to a repair welding station for repair welding; a support pipe and an upper wing plate are installed; the balance beam is manually hung and conveyed to the feeding and blanking station again; the manual code scanning confirmation is performed again; the RGV automatically conveys the balance beam to the MES specified welding station; the robot performs weldingseam welding outside the balance beam according to the offline program; after the welding is completed, the RGV conveys the balance beam to the feeding and blanking station; the balance beam is manually hung and conveyed to the repair welding station; sealing plates at two sides of the box body, an electric pipe and an anti-shearing block are installed; the balance beam is conveyed off the line; and the manual inspection is completed. The method has the advantages that the work intensity of workers is reduced; the welding quality of the balance beam and the management level in the production process are improved; and the construction environment is improved.

Owner:SHANGHAI ZHENHUA PORT MACHINARY HEAVY IND CO LTD

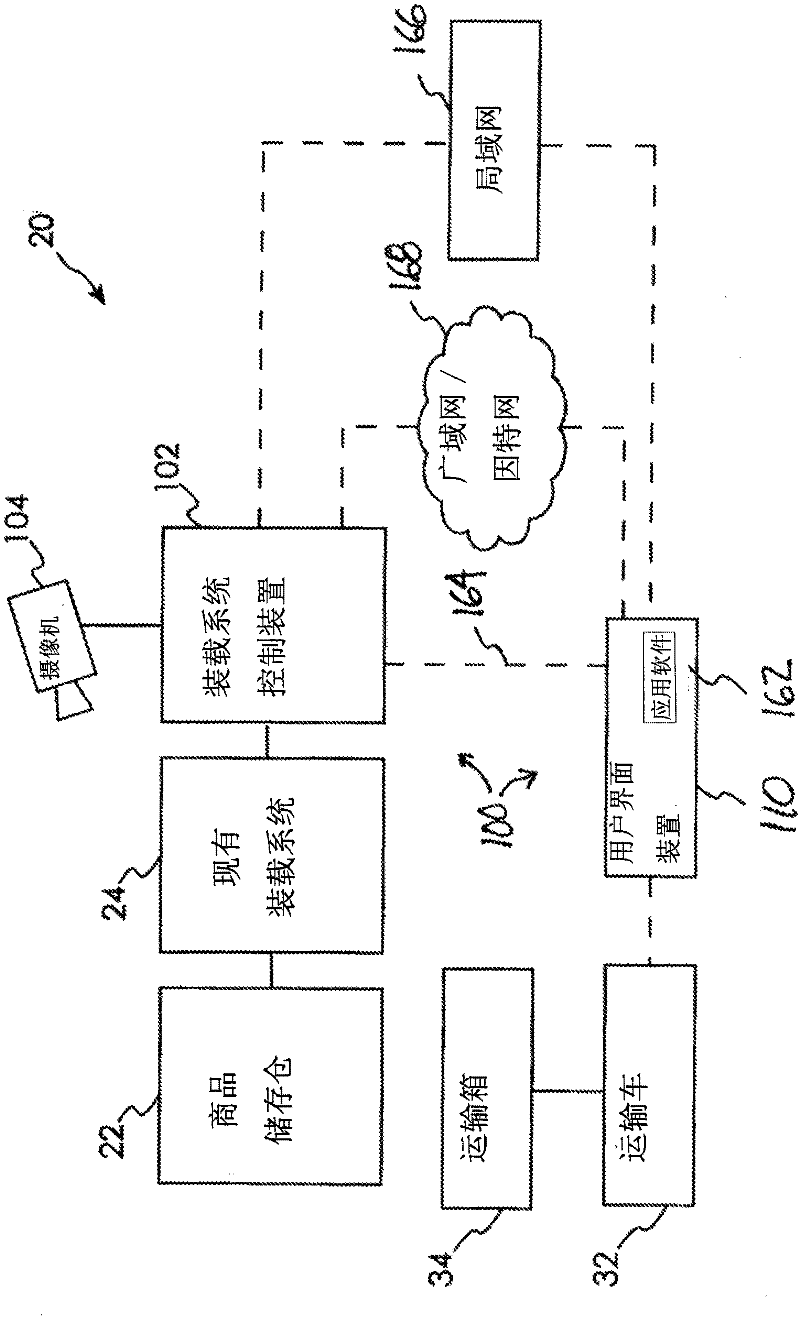

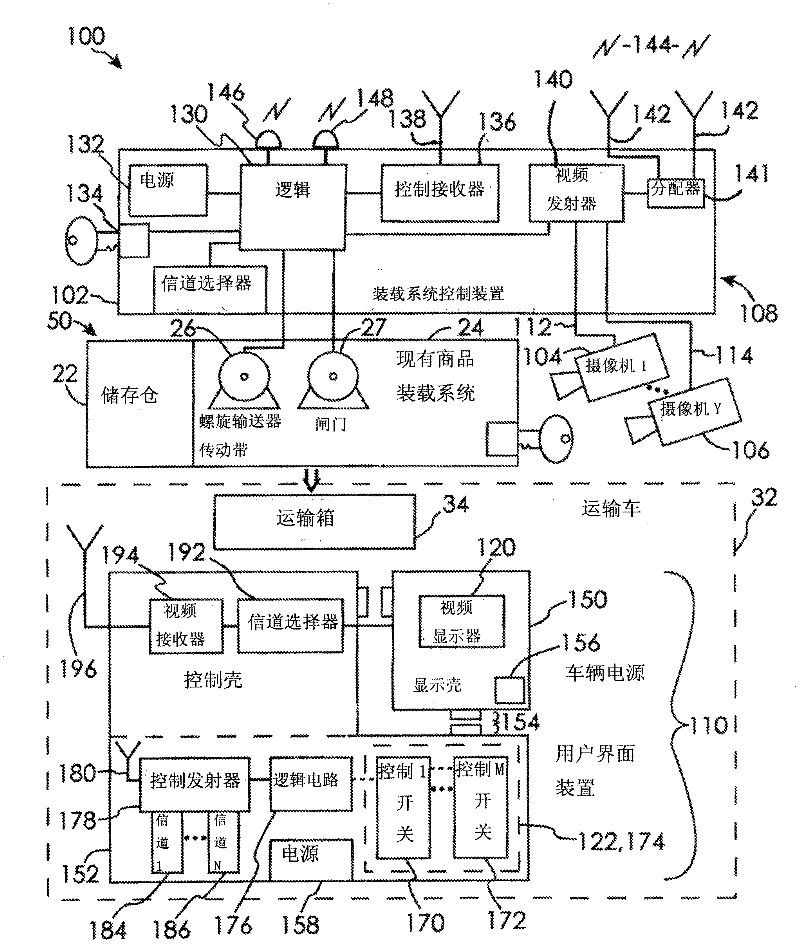

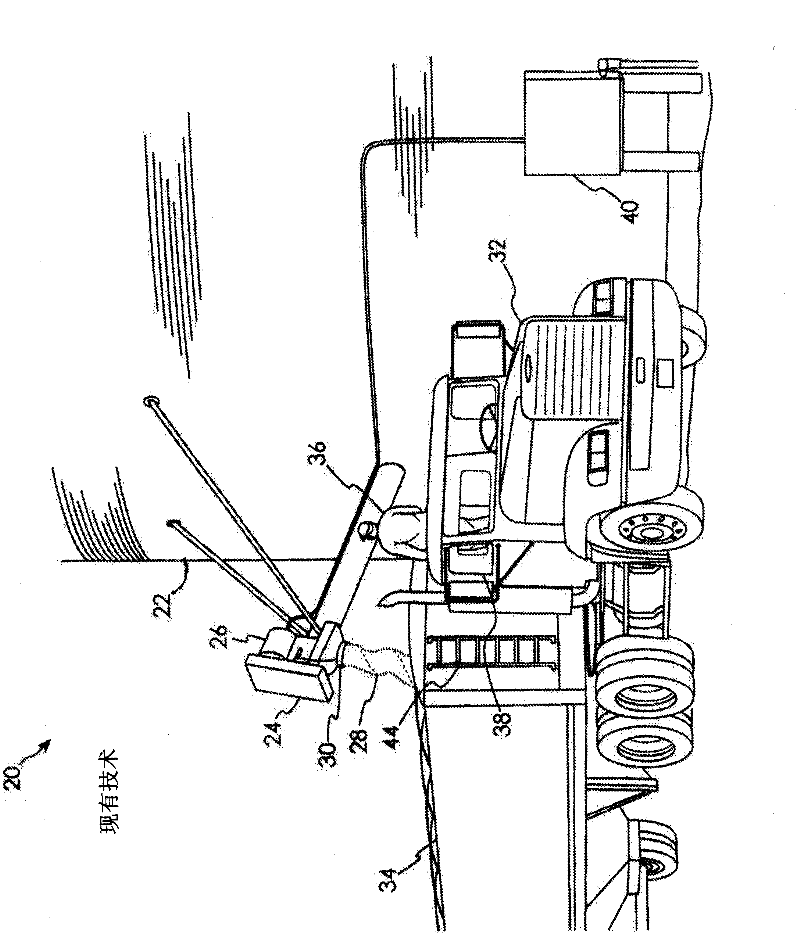

Monitoring and control system for commodity loading

InactiveCN102186755AReduce the number of peopleImprove securityTelevision system detailsControl devices for conveyorsIn vehicleDisplay device

A system (100) for in-vehicle (38) monitoring and control of commodity loading, such a grain or loose or fluid materials, from a storage bin (22) to a transport bin (34) using a loading system (24), includes a loading system control device (102) and a user interface device (110) capable of mutual wireless communication. The system (100) improves safety by eliminating the need for operators (36) to crawl up the side of vehicle in order to check levels of commodity (28) in the transport bin (34), while also trying to move the transport bin as required. The loading system control device (102) includes a logic switching unit (130) for selectively operating the loading system (24) that transfers the commodity (28) from the storage bin (22); one or more cameras (104, 106) providing visual feeds (112, 114) of the loading of commodity into the transport bin; and a security or safety feature (134). The user interface device (110) includes a display (120) for displaying the visual feeds (112, 114) and control switches (122) for operating the loading system (24).

Owner:尼尔 T 麦莱特

Method for preparing pet dog chew from cattle hide leather fragments

InactiveCN104472902AIncrease productivityGood strength and hardnessAnimal feeding stuffTaming and training devicesChemistrySizing

The invention relates to a method for preparing pet dog chew from cattle hide leather fragments. The method comprises the following steps: soaking cattle hide leather leftovers into 30DEG C water bath; then mincing through a meat mincer; pulping through a food processor; drying the pulp; injecting into a mold; drying and sizing; and sterilizing. For recycling, the cattle hide leather fragments are subjected to a series of processing into various shapes of dog chew products pets like very much, the pet dog chew is natural, rich in nutrition and capable of cleaning teeth and protecting health. The pet dog chew can meet demand of pet dogs of different types and ages, the processing is simple, and the effect is desirable.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

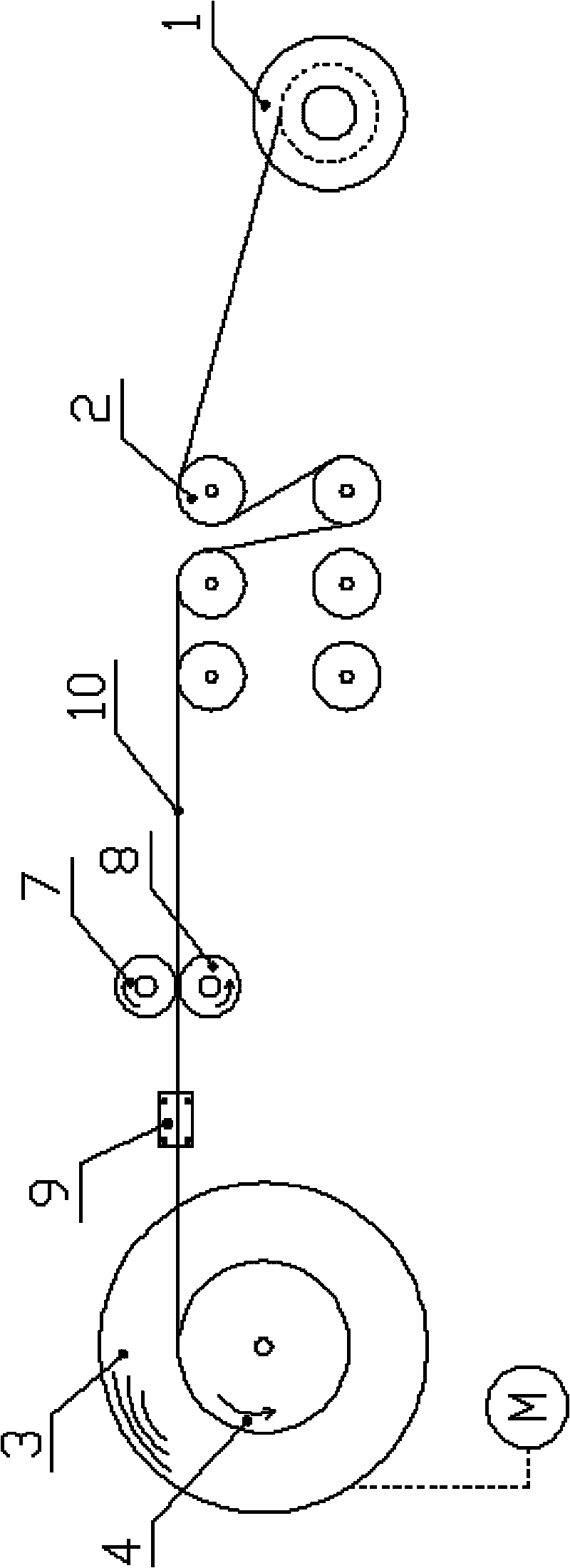

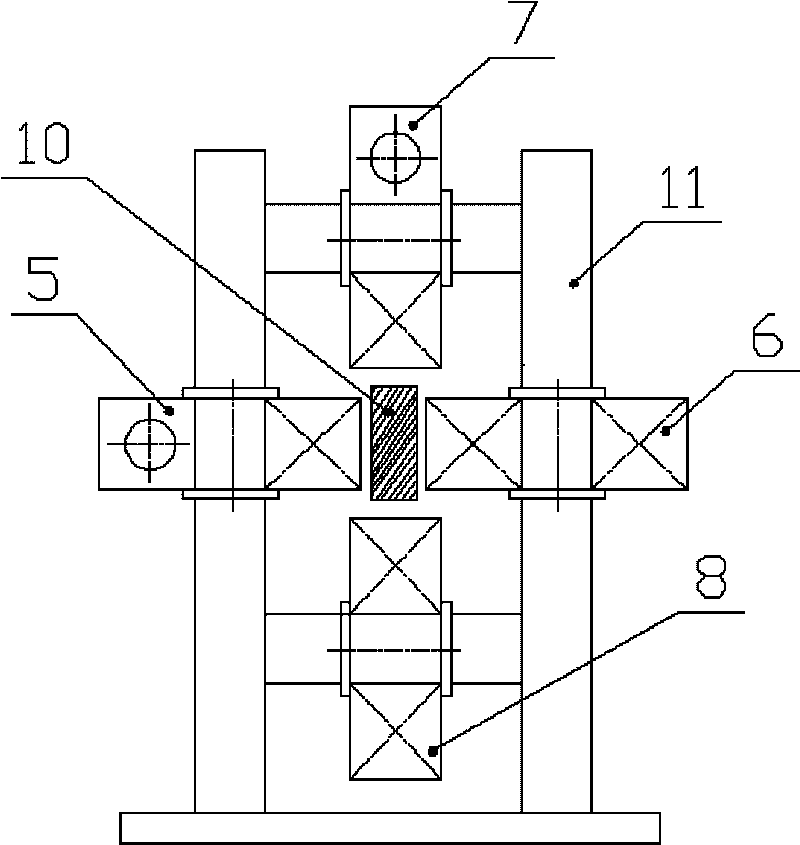

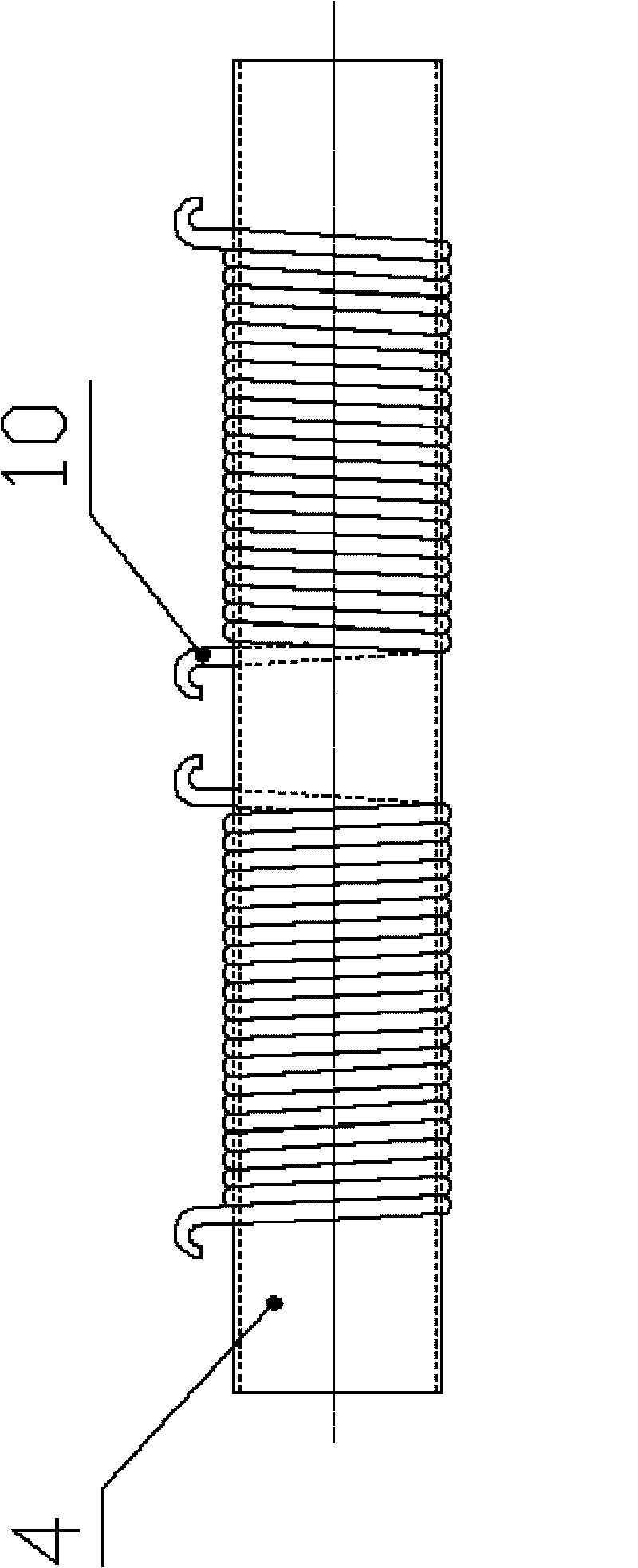

Device for winding coil by rectangular conducting wire

InactiveCN101702373AAxially arranged tightly and neatlyReduce labor intensityCoils manufactureWinding machineEngineering

The invention discloses a device for winding a coil by a rectangular conducting wire, which can enhance the winding quality of the rectangular conducting wire. The device for winding the coil by the rectangular conducting wire comprises a wire coil disk, a wire pressing device and a horizontal type wire winding machine which are sequentially arranged, wherein a coil framework is arranged on the horizontal type wire winding machine, and a positioning device which can penetrate and sleeve the rectangular conducting wire and enable the narrow side of the section of the rectangular conducting wire to be in a horizontal state is arranged between the wire pressing device and the horizontal type wire winding machine. The device has simple structure, very low cost and very convenient turning, lightens the labor strength of operators, reduces the number of the operators, lowers the winding difficulty, also shortens the winding time, ensures the tight and tidy axial arrangement and the tight radial winding of the coil after the winding is completed, ensures the winding quality and is especially suitable for popularization and use on a winding device which needs to wind the narrow side of the section of a conducting wire onto a coil framework; in addition, the rectangular conducting wire only needs to penetrate through the positioning device.

Owner:攀枝花钢城集团瑞泰电器有限公司

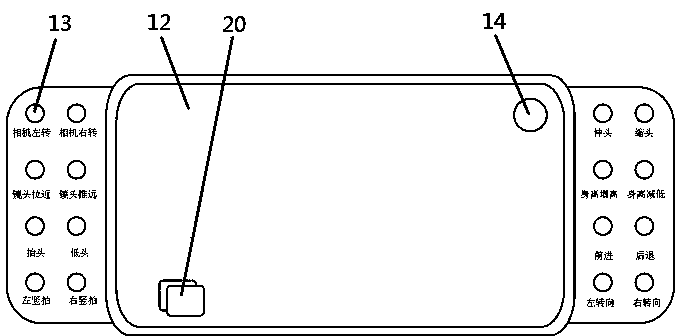

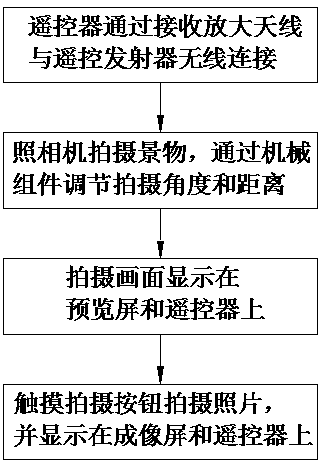

Photographing robot and application method thereof

InactiveCN104410796AReduce personal injuryEmission reductionTelevision system detailsColor television detailsMechanical componentsDrive wheel

The invention discloses a photographing robot. The photographing robot comprises a robot body, a base, a pair of front wheels, a pair of rear drive wheels, a power device, a preview screen, an imaging screen, a remote control transmitter, a mechanical component, a camera, a receiving amplifying antenna and a remote controller, wherein the base is arranged at the bottom of the robot body; the front wheels and the rear drive wheels are respectively arranged at the bottom end of the base by virtue of wheel shafts; one end of the preview screen is arranged on one side of the middle part of the robot body by virtue of a rotating shaft; the imaging screen is connected to the other end of the preview screen; the preview screen and the imaging screen rotate synchronously by virtue of the rotating shaft; the remote control transmitter is arranged behind the upper part of the robot body; the camera is arranged at the front end of the upper part of the robot body by virtue of the mechanical component and rotates by virtue of the mechanical component; the receiving amplifying antenna is arranged at the top end of the robot body; a touch photograph button and a plurality of control buttons are respectively arranged on the two sides of the remote controller; the remote controller is wirelessly connected with the remote control transmitter by the receiving amplifying antenna. The photographing robot disclosed by the invention reduces the occurrence of occupational diseases in the photographing industry and occupational diseases of security personnel and can be used for replacing a person for shopping in supermarkets.

Owner:张家恺

Profile feeding device for feeding machine

ActiveCN104128656AUniform processing forcePrevent slippingMetal sawing devicesUltimate tensile strengthMachining

The invention discloses a profile feeding device for a feeding machine and relates to the technical field of mechanical machining. The device comprises a limiting block and conveying rollers mounted on the feeding machine, one side of the feeding machine is provided with a feeding guide rail facing to the feeding rollers, the feeding rollers include a pressing roller and two holding rollers arranged below the pressing roller, the pressing roller and the two holding rollers are arranged in a staggered manner, and the surfaces of the pressing roller and two holding rollers are provided with positioning grooves matching with the profile respectively; a material rack is arranged besides the feeding guide rail and comprises a loading plate inclined downwardly facing to the feeding guide rail. Compared with the prior art, the profile bears the force evenly, skidding occurs rarely, the machining accuracy is high, and labor force of workers is lower.

Owner:柳州万众汽车部件有限公司

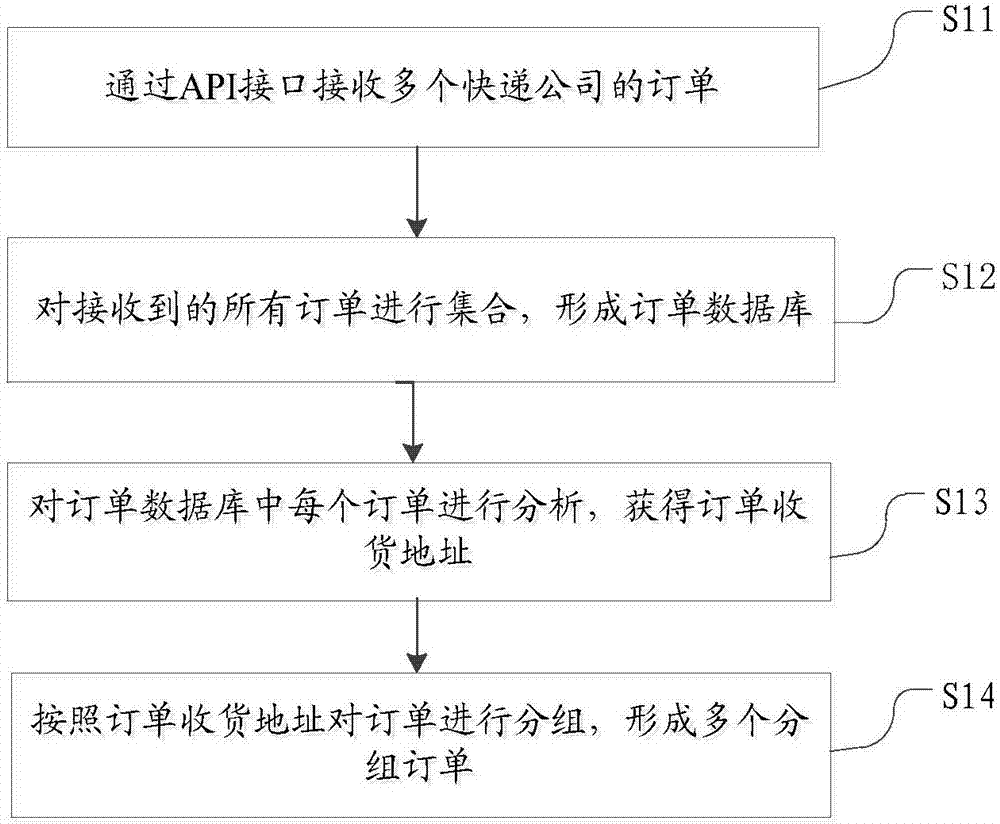

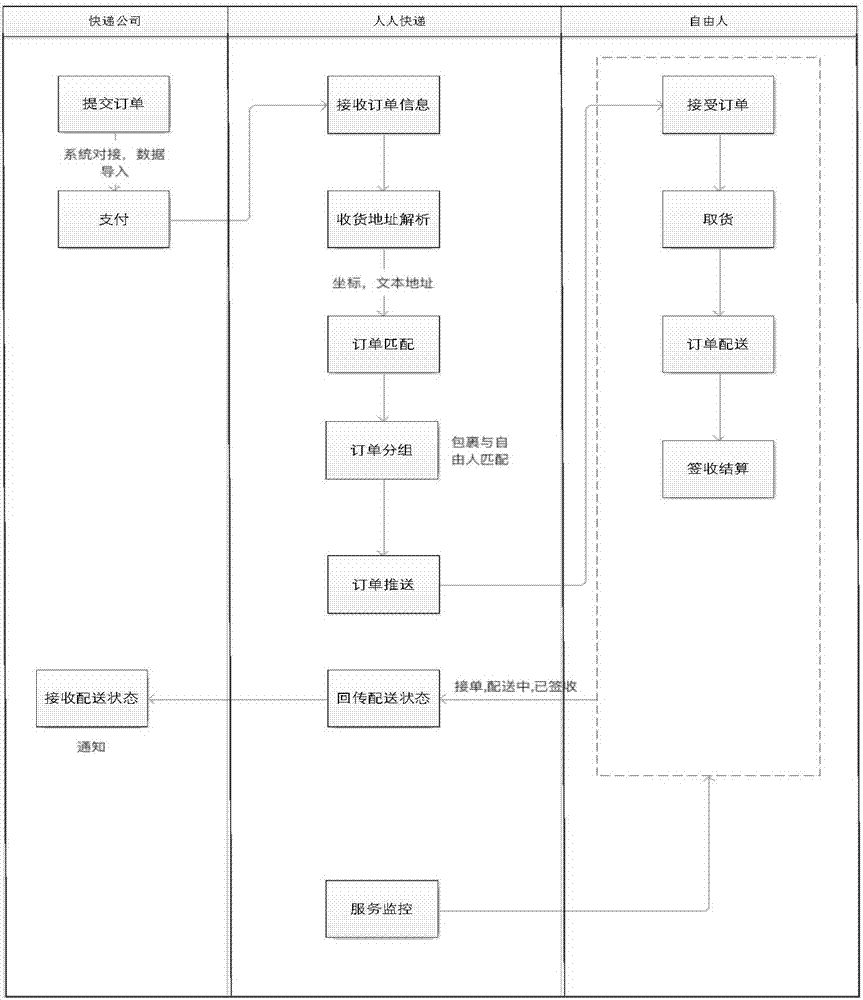

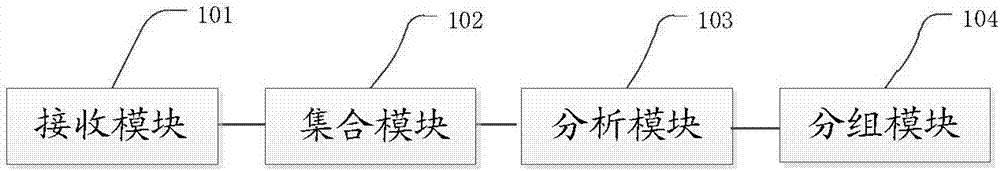

Order set grouping method and device

InactiveCN107016599AOverall headcount reductionReduce labor costsBuying/selling/leasing transactionsLogisticsGroup methodOrder set

The invention discloses an order set grouping method and device. The order set grouping method comprises the steps of receiving orders of a plurality of express companies through an API; collecting all of the received orders to form an order database; analyzing each order in the order database, and acquiring delivery addresses of the orders; and grouping the orders according to the delivery addresses of the orders so as to form multiple grouped orders. The order set grouping method reduces the labor cost.

Owner:四川创物科技有限公司

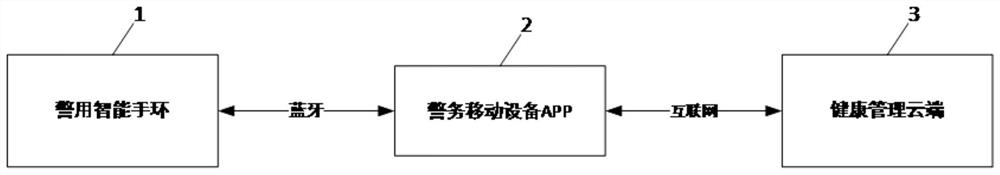

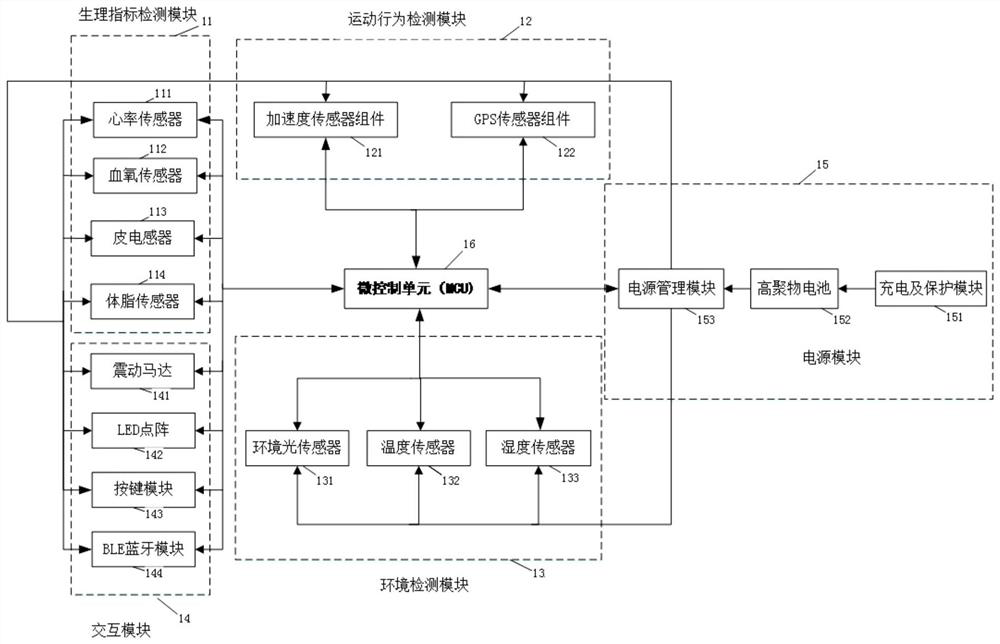

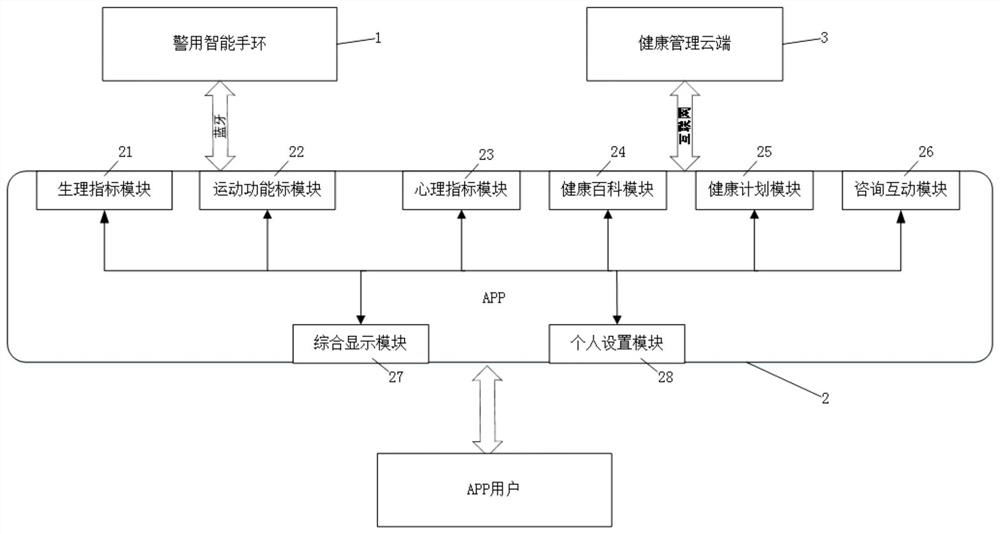

Police health management system and method

PendingCN111798982AImprove Mental Health QualityDetect health risks in timePhysical therapies and activitiesHealth-index calculationNursingReliability engineering

The invention discloses a police health management system and method. The system comprises a police smart wristband, an APP loaded on police mobile equipment and a health management cloud, the policesmart wristband is in communication connection with the APP; the APP is in communication connection with the health management cloud; real-time physiological index data and psychological scale data ofpolice officers are collected through the police smart wristband; a health classification model is established after deep learning is carried out on the health management cloud; and the real-time physiological and psychological health data are analyzed by using the established health model to obtain the current physical health condition of the police officers, and life work and rest prompt, fitness plan arrangement and health problem correction guidance are performed according to the health condition of the police officers, so that the purpose of improving the physical and psychological health quality of the police officers is achieved. According to real-time acquired data, the health risk of the police officers can be found in time, especially for sudden diseases, emergency quick response is achieved, and the number of people sacrificed by the police officers due to health crisis can be reduced.

Owner:重庆警察学院

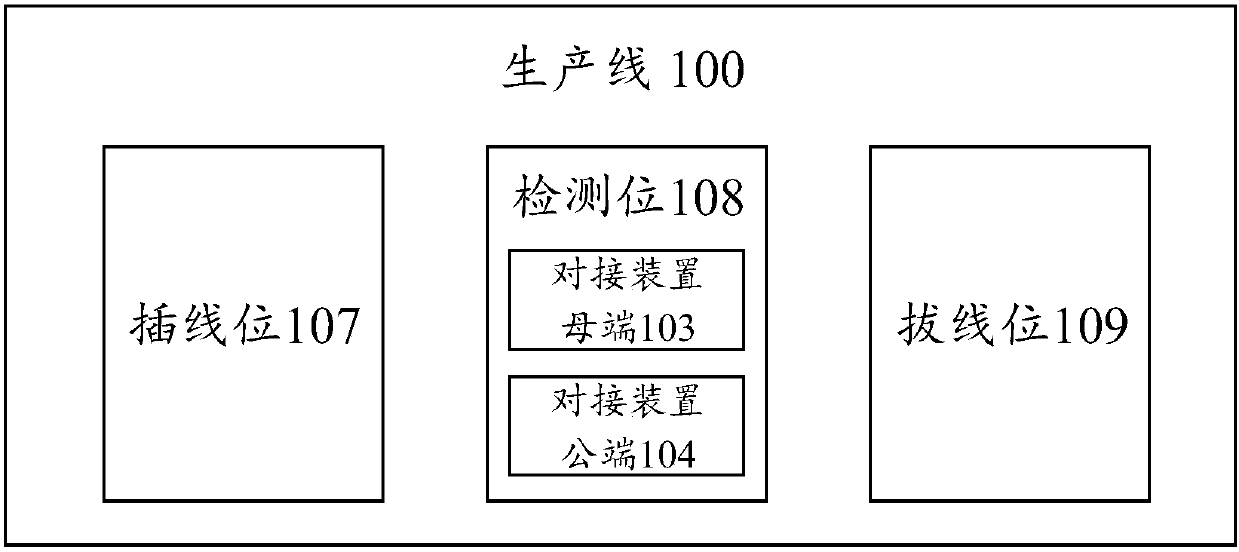

Signal automated alignment device

PendingCN107742803AReduce labor costsIncrease production capacityEngagement/disengagement of coupling partsTwo-part coupling devicesWire rodSignal source

The invention provides a signal automated alignment device. The signal automated alignment device comprises an alignment device male end and an alignment device female end, the alignment device male end is connected to a signal generation source and is internally provided with a connector male end, a first attraction part and a first guiding part; the alignment device female end is connected to ato-be-tested product, and is internally provided a connector female end, a second attraction part and a second guiding part; when the alignment device male end approaches the alignment device female end, the first attraction part and the second attraction part are automatically and mutually attracted to approach each other, so that the first guiding part and the second guiding part are mutually coupled, and the connector male end is connected with the connector female end. By means of the signal automated alignment device, the equipment damage caused by plug-unplug of wires and the labor costof automatic detection can be greatly reduced in an automatic alignment mode.

Owner:深圳市研祥智慧科技股份有限公司

Automatic assembly line for spraying adhesives in tires and production method

InactiveCN105327823AReduce voidsReduce the number of peopleLiquid surface applicatorsCoatingsAdhesiveEngineering

The invention discloses an automatic assembly line for spraying adhesives in tires. The automatic assembly line comprises two tire inner wall cleaning units, two heating units, three adhesive melting boxes, an adhesive collecting box, an adhesive spraying unit, a cooling unit and a packaging assembly line. The heating units, the adhesive spraying unit, the cooling unit and the packaging assembly line are sequentially arranged at the discharge ports of the tire inner wall cleaning units in the conveying direction of the automatic assembly line. The adhesive spraying feed port of the adhesive spraying unit is connected with the adhesive collecting box, the adhesive collecting box is provided with the adhesive melting boxes communicated with the adhesive collecting box, and mechanical arms are arranged between the tire inner wall cleaning units and the heating units and between the cooling unit and the packaging assembly line respectively. The automatic assembly line has the advantages that the mechanical arms are adopted for completing transferring so that mutual cooperation can be closer, the gap between the tires can be narrowed, the production quantity of the tires can be increased, one tire can be produced per minute, the cost can be effectively lowered, the number of employees can be greatly lowered, the safety can be high, and the auxiliary time can be shortened.

Owner:卢文哲

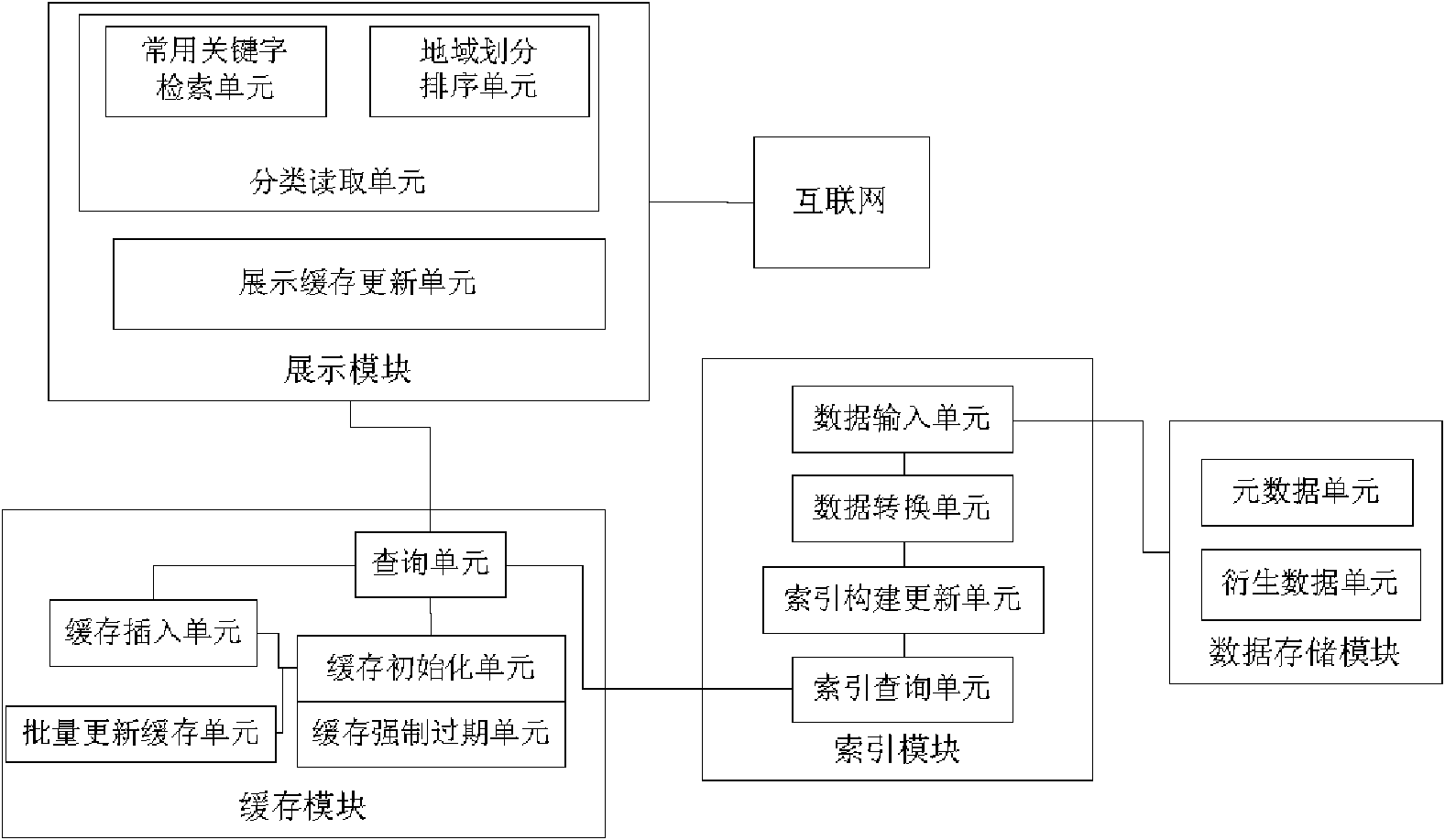

Search display system

InactiveCN101673308AReduce the number of peopleHigh degree of automationSpecial data processing applicationsSystem integrationAnalysis data

The invention relates to a search display system, belonging to the technical field of an Internet and comprising a displaying module, a buffer module, an index base module and a data storage module, wherein the output end of the database storage module is connected with the input end of the index base module so as to transmit basic data and intermediate analysis data; the output end of the index base module is connected with the buffer module so as to transmit a query index base; the output end of the buffer module is connected with the input end of the display module so as to transmit dynamicindex data; and the output end of the display module is connected with the Internet so as to transmit a real-time dynamic search query result. The search display system can integrate a plurality of types of remove interactive systems simultaneously, can carry out management and analysis to integrated system data, and effectively improve the utilization ratio of network bandwidth.

Owner:SHANGHAI TIANJUAN INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com