Cleaner

A cleaning machine and cleaning liquid technology, applied in the field of cleaning machines, can solve the problems of increasing the cost of use, increasing the labor intensity of operators, and the length of cleaning equipment, etc., to achieve the effects of reducing the length of land occupation, reducing the number of people, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

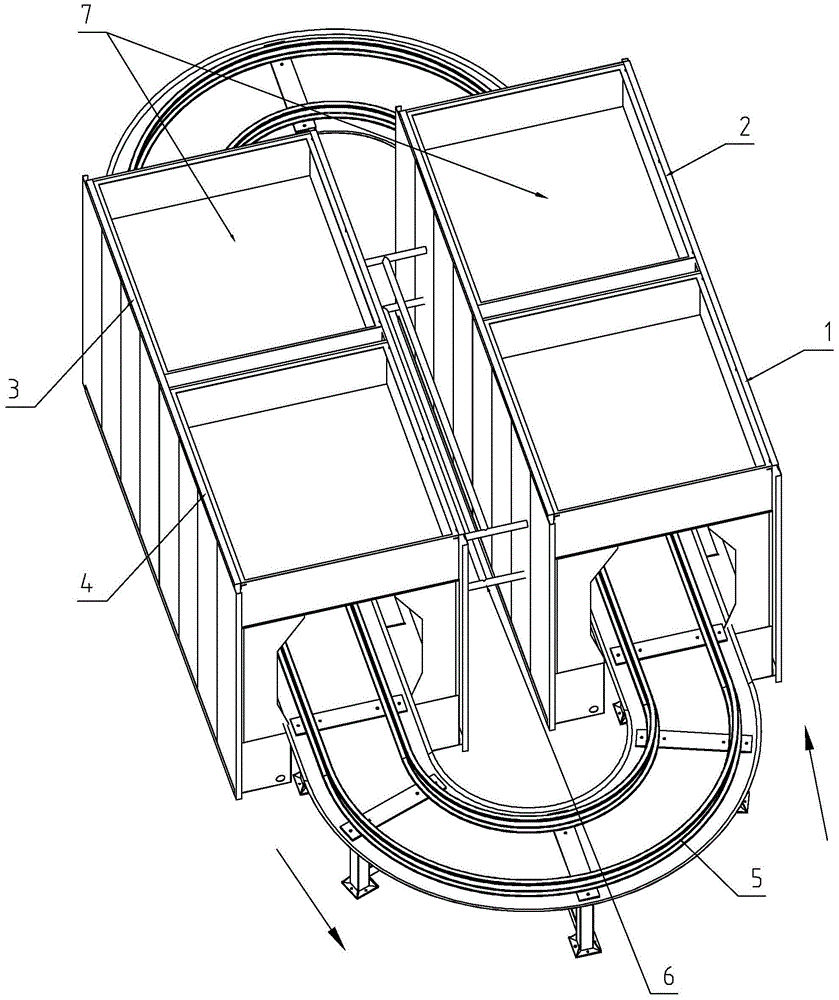

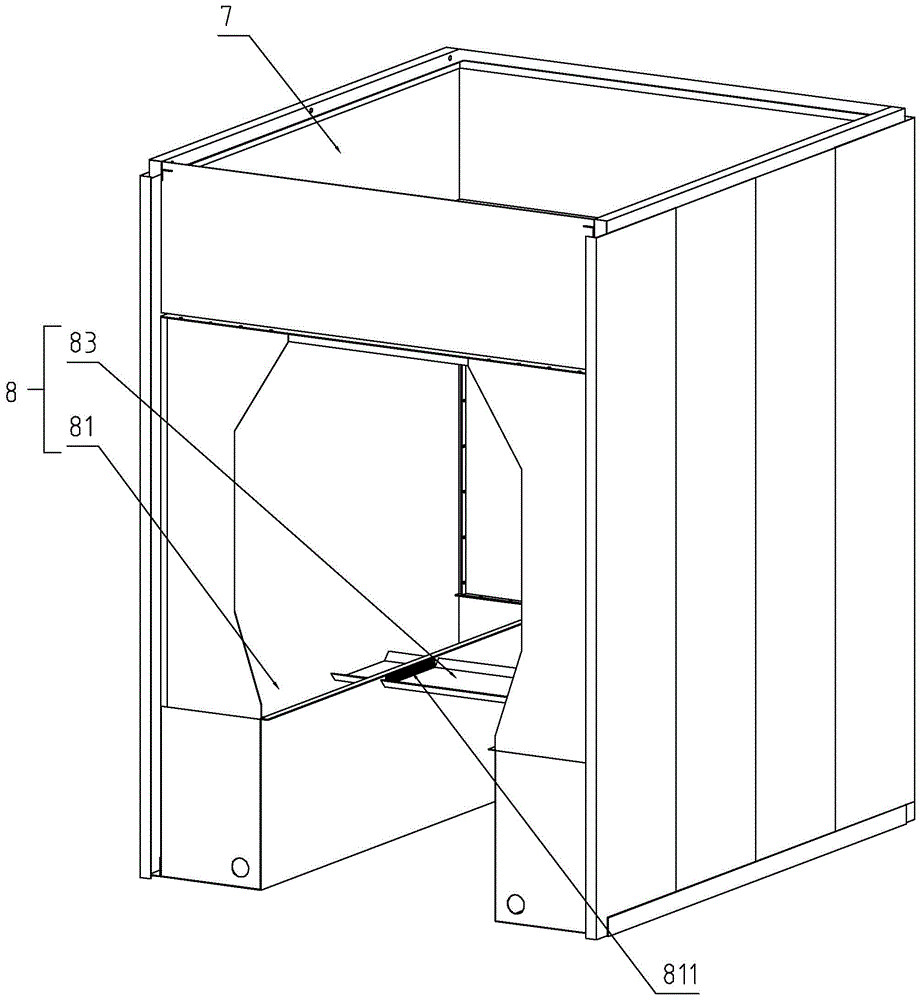

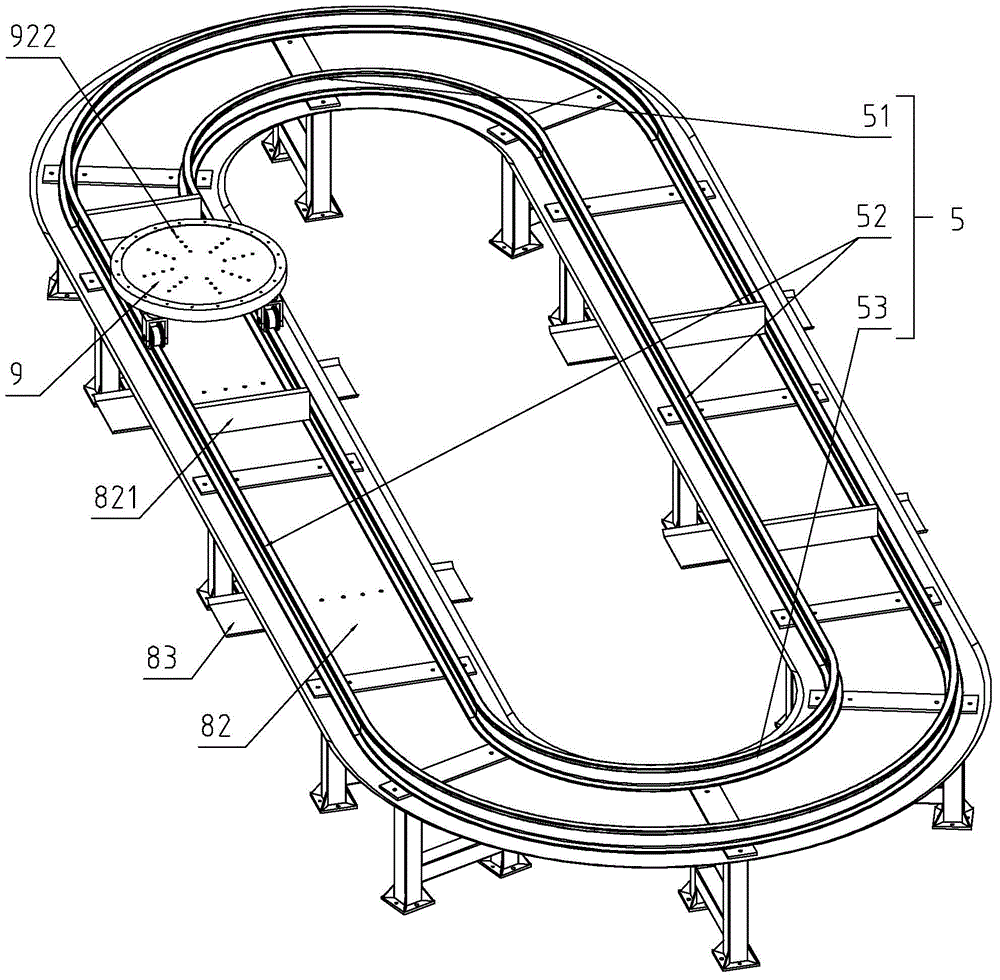

[0023] refer to Figure 1 to Figure 6 The embodiment of the cleaning machine will be further described.

[0024] A cleaning machine, comprising a degreasing device 1, a rough cleaning device 2, a fine cleaning device 3, a drying device 4, and a conveying track 5 for transporting products to be cleaned, and the conveying track 5 passes through the degreasing device 1 and the rough cleaning device 2 in sequence , fine cleaning device 3 and drying device 4, the above-mentioned devices all belong to the prior art, and its specific performance is: after the parts to be cleaned are placed on the conveying track 5, the conveying track 5 drives the parts to be cleaned to move, and when passing through the degreasing device 1 The nozzle inside sprays the degreasing agent onto the parts to be cleaned, and the degreasing agent saponifies, solubilizes, moistens, disperses, and emulsifies all kinds of oils, so that the oils are separated from the surface of the workpiece and become soluble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com