Arrangement structure and arrangement method of roller ways of hot mill in aluminum plate strip hot rolling shop

A rolling mill roller table and layout structure technology, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of unable to meet the length of hot rolling mill roller table, restricting construction implementation, site length constraints, etc. , to achieve the effect of simple structure, saving floor space and reducing floor length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

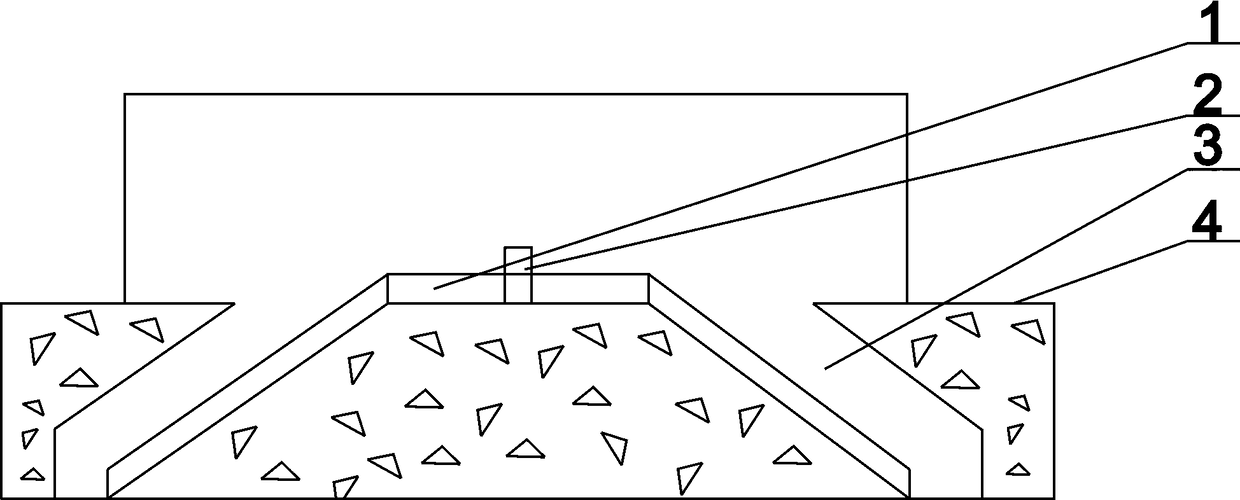

[0015] combined with figure 1 The layout structure of the rolling mill roller table in the hot-rolling workshop of aluminum strips includes a hot-rolling workshop, a hot-rolling stand and a hot-rolling mill 2. A hot-rolling stand is arranged in the hot-rolling workshop, and the hot-rolling mill 2 is arranged on a hot-rolling mill. In the rolling span, the inlet and outlet ends of the hot rolling mill 2 are equipped with a roller table composed of multiple rollers. Each roller is driven in two directions independently or in groups, and the ingot or hot-rolled slab is reciprocally transported to the hot rolling mill. 2. The middle section of the hot rolling mill roller table 1 is set on the ground 4, each roller is parallel to the ground 4, and the elevatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com