Patents

Literature

108results about How to "Improve water injection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

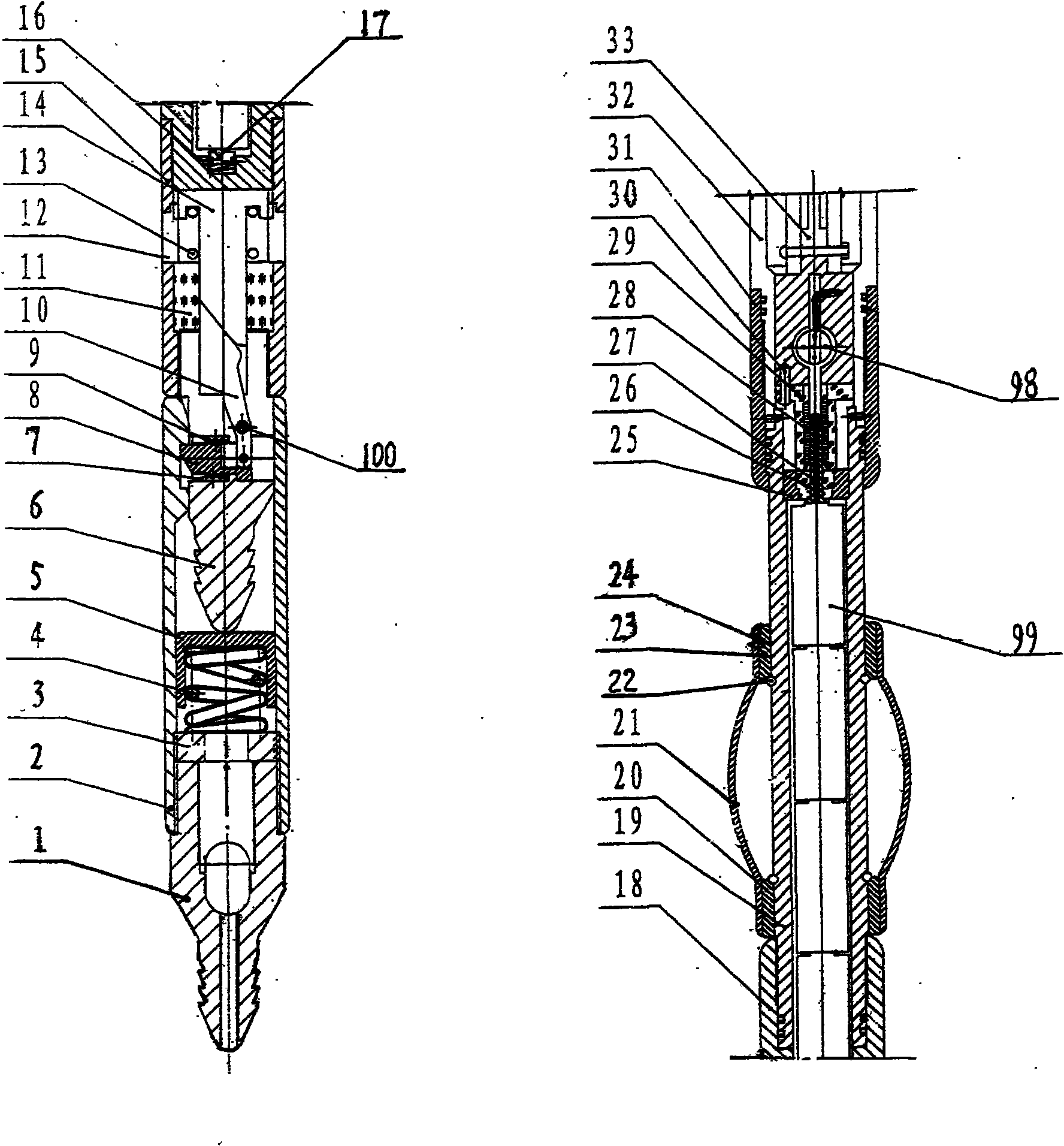

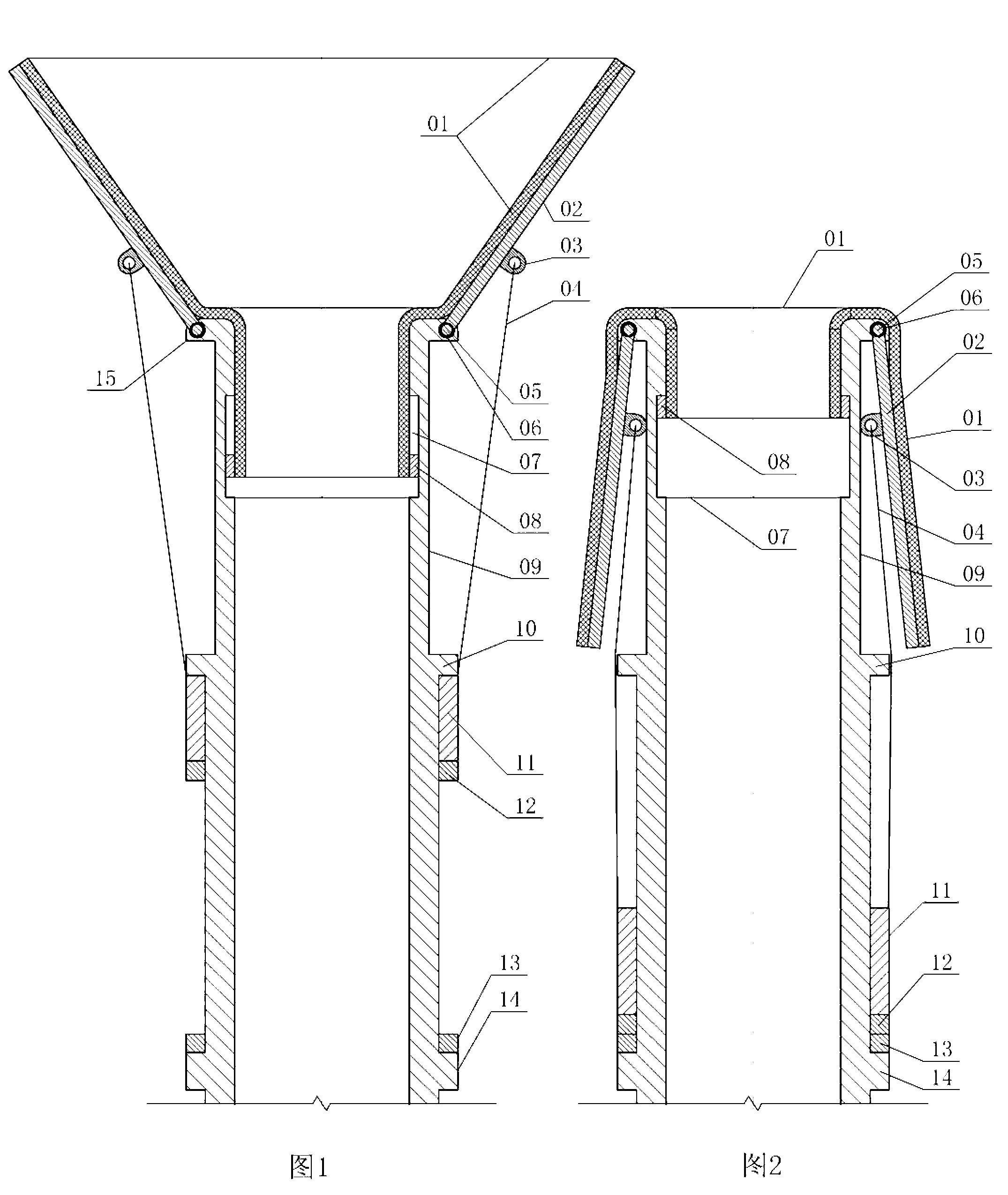

Intelligent synchronous testing and adjusting method capable of simultaneously infusing, testing and regulating

InactiveCN101672179AExtension of Advanced Standing PeriodImprove water injection efficiencySurveyFluid removalWater infusionBridge type

The invention relates to an intelligent synchronous testing and adjusting method capable of simultaneously infusing, testing and regulating, belonging to the field of oil extraction technologies in oil fields. A method of adopted equipment comprises the following steps: (1) a synchronous intelligent testing and adjusting device release part; (2) an intelligent testing and adjusting part; (3) a guiding part; and (4) an eccentric water distribution part. The adopted equipment is characterized in that the intelligent synchronous testing and adjusting method of the whole equipment comprises the following steps: descending into a well: using a steel wire to be suspended to descend into the well; placing the synchronous intelligent testing and adjusting device into a connected technological pipecolumn provided with an eccentric water distributor and a packer; and leading the adjustable blanking plug into an eccentric hole of the eccentric water distributor and releasing the adjustable blanking plug so that the adjustable blanking plug stays in the eccentric water distributor. The invention can realize the unchanged bridge type eccentric whole well working system, directly obtain the single-layer flow, achieve the simultaneous water infusion, testing and adjustment at multiple layers and enhance the work efficiency.

Owner:FUXIN CITY GASOLINEEUM TOOL FACTORY

Oil and water well sealing and plugging agent and preparation method thereof

ActiveCN102504781ASatisfy the requirements of sealing blow-byEasy to prepareDrilling compositionCuring (chemistry)Oil field

The invention relates to the technical field of oilfield chemistry, in particular to an oil and water well sealing and plugging agent and a preparation method of the oil and water well sealing and plugging agent. The oil and water well sealing and plugging agent is suitable for sealing and plugging an oil and water well. The oil and water well sealing and plugging agent consists of the following raw materials: XP lost circulation additive, G-class oil-well cement, blast furnace KZ micro powder, borax and water. The oil and water well sealing and plugging agent has the beneficial effects that the oil and water well sealing and plugging agent is simple to prepare, is convenient to construct, is safe and reliable and has high plugging strength; the oil and water well sealing and plugging agent has the characteristics of excellent suspension stability, low initial viscosity, easiness for pumping, high temperature resistance, high curing strength and the like and is mainly applied to non-corresponding production layers caused by poor cementing quality or damage to a sleeve above and below a perforated section of the oil and water well; the requirements on sealing and plugging of the oil and water well can be met; and currently, the oil and water well sealing and plugging agent is accumulatively implemented for over 90 well times, good sealing and plugging effects are obtained and the water injection efficiency is also improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Penetrant for coal-bed flooding

ActiveCN102337103AImprove water injection efficiencyHigh speedOther chemical processesDust removalCoal dustProcess engineering

The invention relates to a penetrant for coal-bed flooding. The penetrant comprises the following components by weigh percent: 0.01%-0.10% of sodium dodecyl sulfate, 0.01%-0.10% of sodium diisooctylester sulfosuccinate, 0.01%-0.10% of dodecylbetaine, 0.01%-0.10% of sodium oleoyl methyl ethanesulfonate, 0.1%-1.0% of calcium chloride and the balance of water. By using the penetrant for coal-bed flooding in the invention, the problems that a coal bed is not easily wetted and penetrated by water can be effectively solved, the efficiency of coal-bed flooding is improved, the flooding amount, wetting radius and flooding speed of the coal bed are greatly improved, the production amount of working face coal dust is effectively reduced, accident potential is eliminated, and coal mining efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

Efficient water injection method and device of hydraulic fracture permeability increase auxiliary coal seam

InactiveCN105422164AGood water permeabilityHigh densityDust removalFire preventionHydraulic fracturingHigh pressure water

The invention discloses an efficient water injection method and device of a hydraulic fracture permeability increase auxiliary coal seam. Before coal seam static pressure water injection, high pressure water generated by an emulsion pump is injected into a drilled static pressure water injection drilled hole through a high pressure pipeline, high pressure water is injected into a coal body fracture by means of the cutting and fracturing effect of a water wedge generated by the high pressure water on the coal seam on the periphery of the drilled hole to overcome the minimum principal stress and the anti-fracture pressure of the coal body, so that fractures are broadened, extended and communicated; in the fracturing process, quartz sand is added into the high pressure water, the quartz sand enters the fractures along with the high pressure water, the effect of a supporting agent is achieved, and the water injection drilled hole is connected to a static pressure pipeline to perform static pressure water injection on the coal seam after hydraulic fracturing is finished. Before static pressure water injection is performed, the breathability of a water pre-injection coal seam is increased, so that the coal seam water injection speed is increased, and the water injection efficiency and effect are improved. According to the method, no special emulsion pump is needed, the running time of the emulsion pump is short, the drilling construction work amount can be decreased, and the water injection working efficiency is improved.

Owner:HENAN POLYTECHNIC UNIV

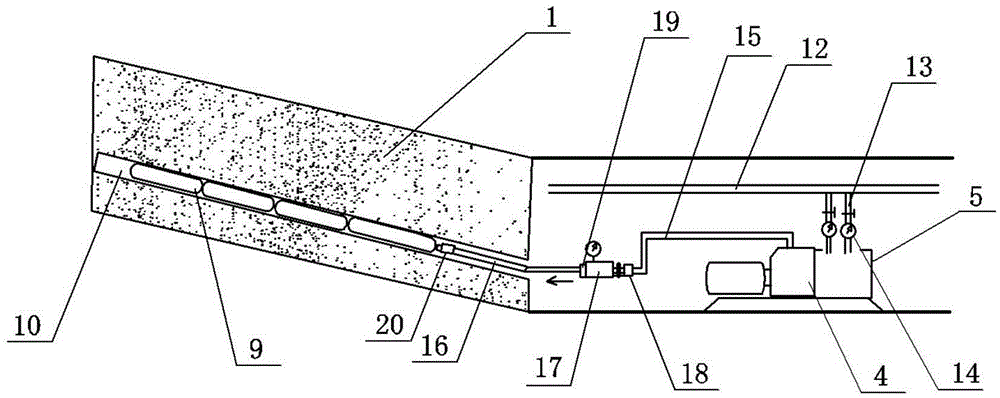

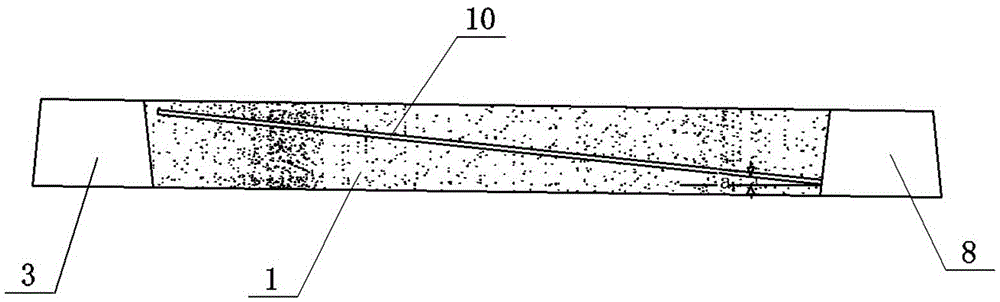

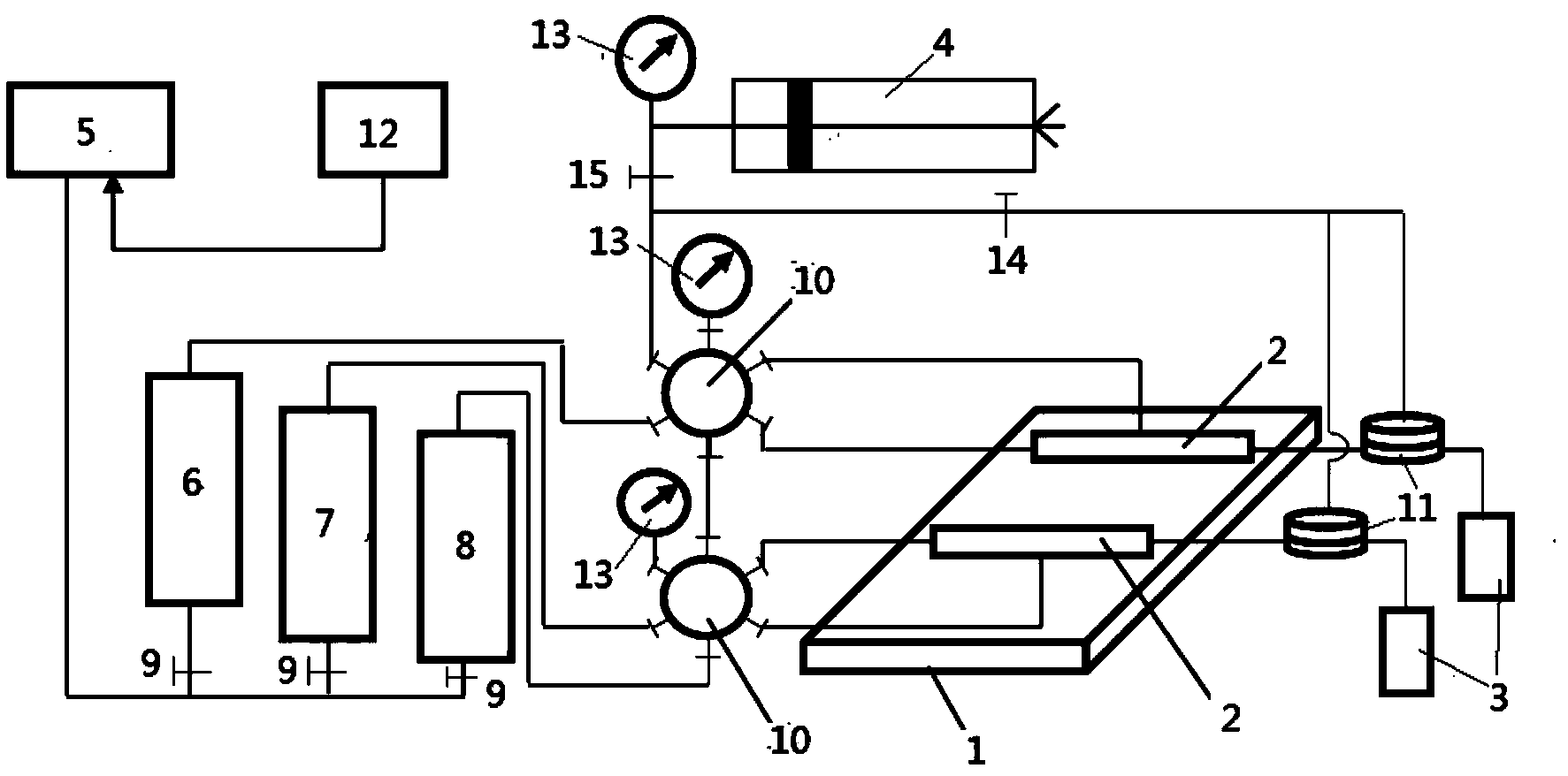

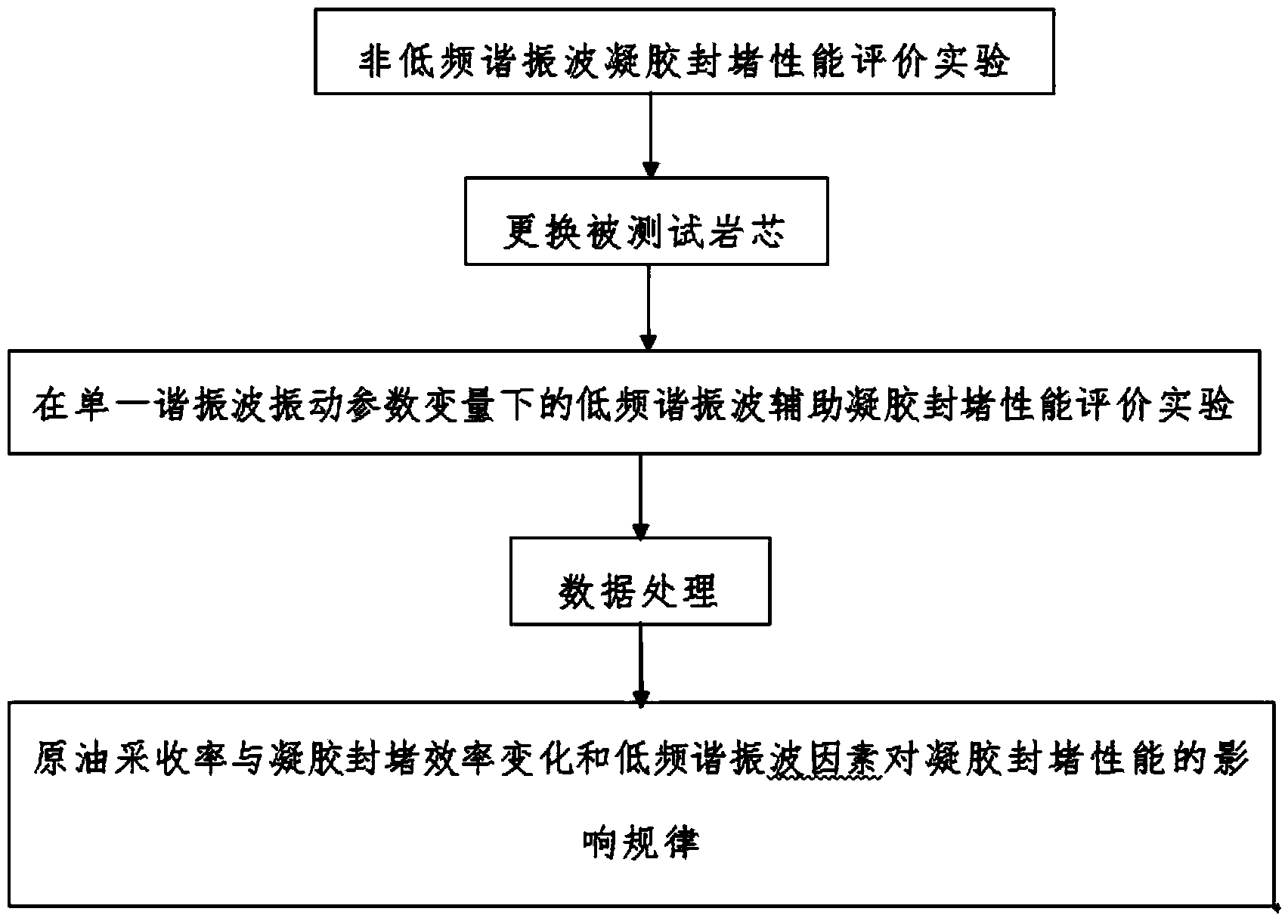

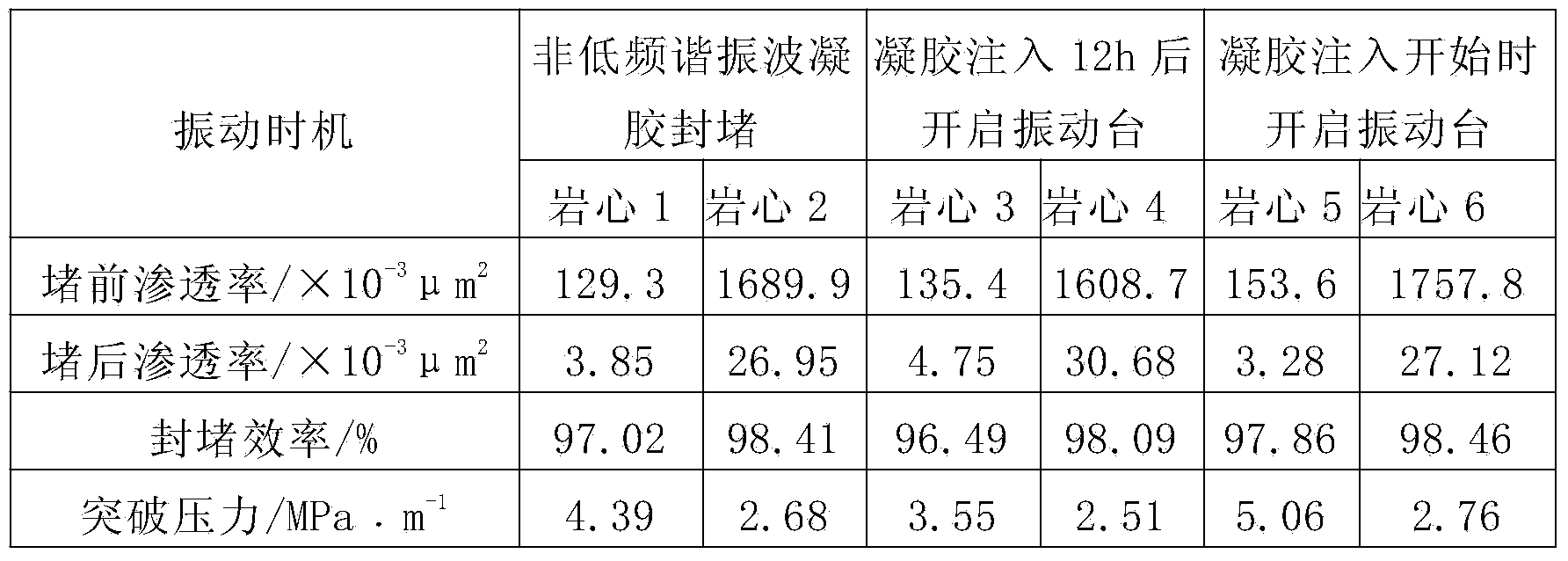

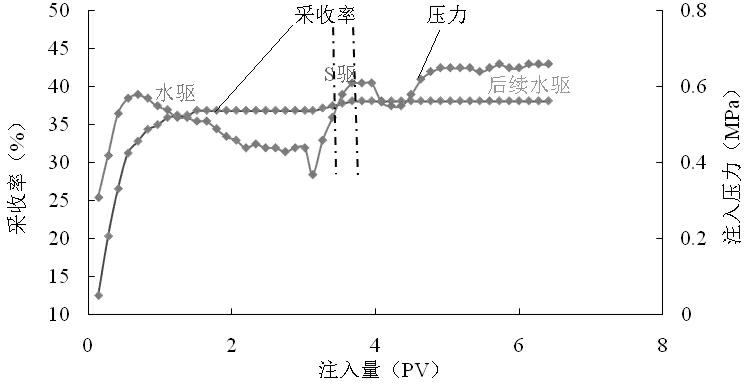

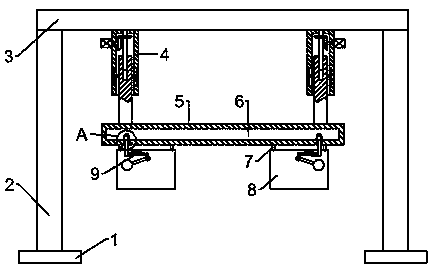

Low-frequency resonance wave assisted gel plugging performance evaluation testing device and method

ActiveCN104076124AImprove production conditionsImprove water injection efficiencyMaterial analysisTechnology developmentResonance

The invention relates to a low-frequency resonance wave assisted gel plugging performance evaluation testing device and method. The low-frequency resonance wave assisted gel plugging performance evaluation testing device comprises a low-frequency resonance wave test bed for producing low-frequency resonance, a core barrel which is arranged on the low-frequency resonance wave test bed and comprises an inlet, an outlet and a ring pressure opening, a liquid container connected with the outlet, and a ring pressure supply part connected with the ring pressure opening; the device also comprises a displacement pump, a middle water delivery container, a middle oil delivery container and a middle gel delivery container, the middle water delivery container, the middle oil delivery container and the middle gel delivery container are connected with one another in parallel, and the outlet of the displacement pump is connected with the inlet of the core barrel by the middle water delivery container, the middle oil delivery container and the middle gel delivery container. The low-frequency resonance wave assisted gel plugging performance evaluation testing device has high research and application values, gives good research guidance for low-frequency resonance wave combined profile control and displacement and profile control technology development and application, and contributes to improving the later production condition in oil field development and improving the oil field flooding efficiency.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

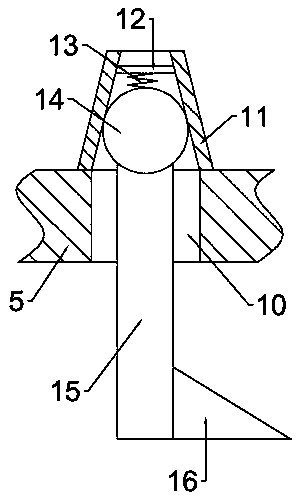

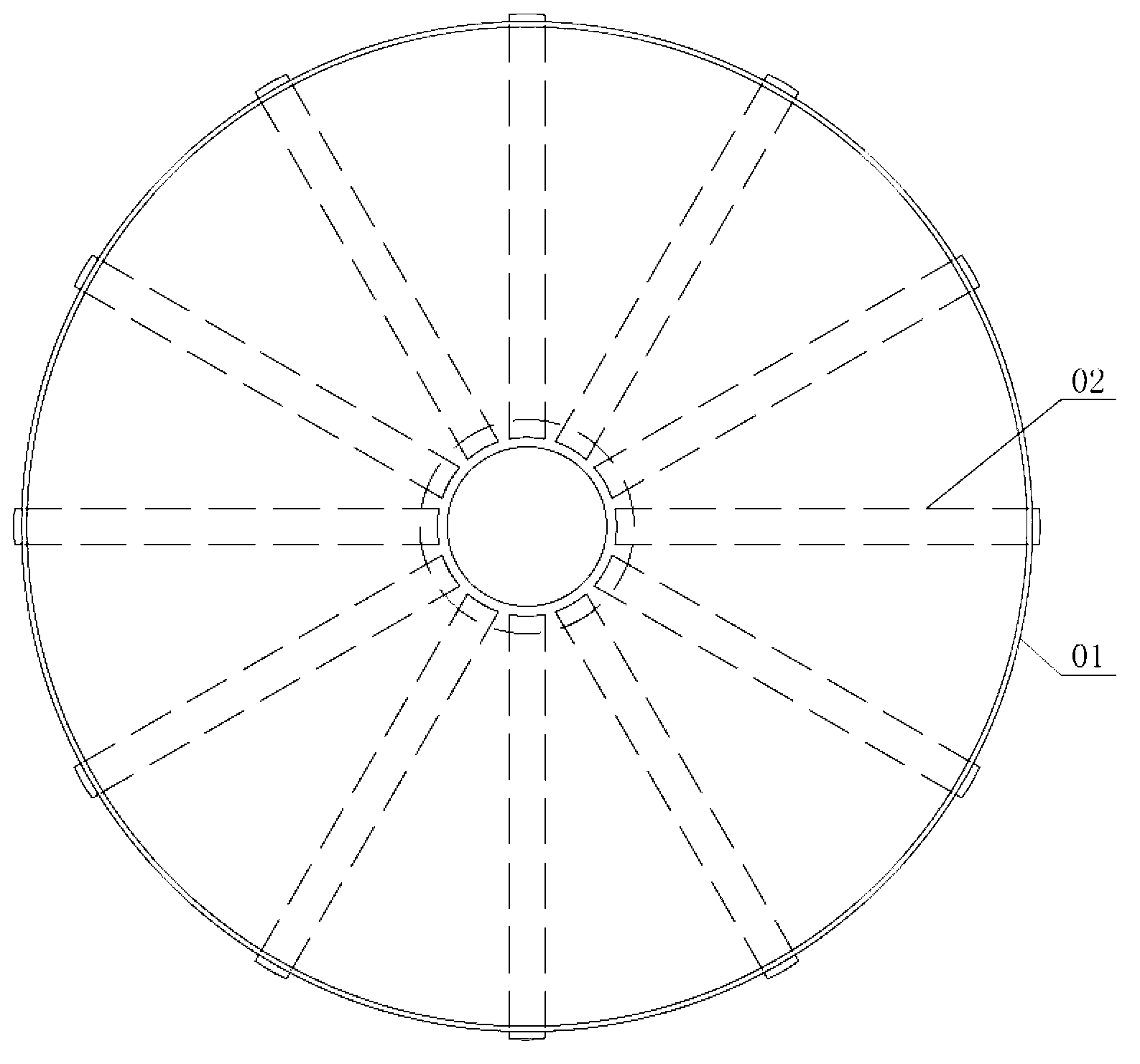

Shunting type intelligent water distributor for large flow water injection of oil fields

ActiveCN108166958AGuaranteed test accuracyImprove water injection efficiencyFluid removalShunt typesOil field

The invention discloses a shunting type intelligent water distributor for large flow water injection of oil fields. The shunting type intelligent water distributor includes a main body, a motor, a limiting device, an adjustable water nozzle and an electromagnetic flow meter body; the motor, the limiting device and the water nozzle are mounted on mounting holes of the main body, and a water flow ring groove channel with dividing water inlet holes are formed in the main body; a water inlet of the water nozzle communicates with the water flow ring groove channel with the dividing water inlet holes, and an electromagnetic flow meter is installed on a main water inlet hole previously formed in the main body; and injected liquid flow enters the water nozzle through a main water inlet and a plurality of dividing water inlet holes, and enters stratum from an water outlet hole on the main body to achieve the large flow water injection and the flow regulation.

Owner:四川省科学城久利电子有限责任公司

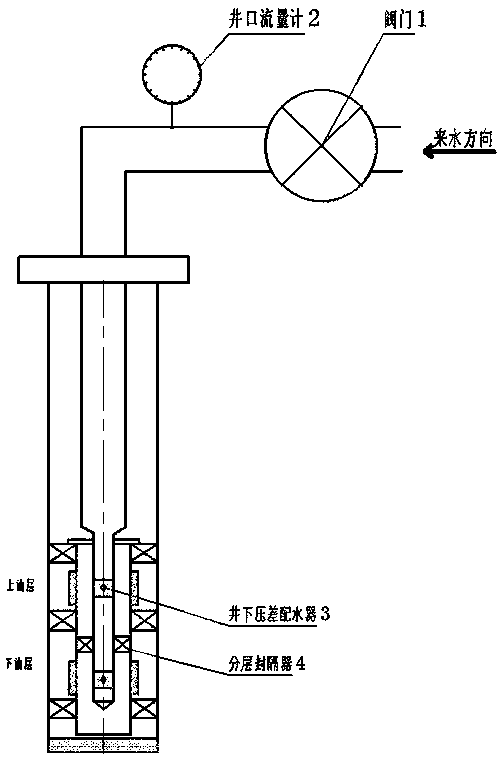

Intelligent water injection device and method

ActiveCN108222902AReliable dataAutomatically adjusts to flow changesFluid removalDifferential pressureElectric machinery

The invention provides an intelligent water injection device and method. The intelligent water injection device comprises a valve, a wellhead flowmeter and downhole differential pressure water distributors. The valve is located on a Christmas tree; by adjusting the valve, required pressure waves are formed, and pressure codes are sent to the downhole differential pressure water distributors; and the wellhead flowmeter meters the injection flow, the downhole differential pressure water distributors receive the pressure codes and decode the pressure codes, and an adjusting instruction is obtained, so that a motor of the device is controlled according to the adjusting instruction to rotate forward or reversely to a certain open degree, the change that the open areas S of water nozzles can beadjusted is generated, and flow adjusting is conducted. The situation that the injection distribution amount of downhole layers is sent to the ground is not needed, the flows of the layers are directly read through the ground downhole flowmeter, and thus data is more reliable; in the period of water injection, the flow change brought by pressure fluctuation can be adjusted automatically, and constant-flow water injection is guaranteed; and in the later period of water injection, only the allocation process of the earlier period needs to be repeated, the error of the open areas due to corrosionand scaling can be corrected, and the aging effect of water injection is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rock-like test piece crack water injection method for frost heave test

ActiveCN104764665AReduce workloadEasy to implementMaterial strength using tensile/compressive forcesTemperature controlEngineering

The invention discloses a rock-like test piece crack water injection method for frost heave test. The method comprises the steps of: 1. getting ready a non-isothermal control test device for water injection; 2. mounting a stress strain gauge at the crack opening of the rock-like test piece; 3. putting the rock-like test piece into a middle layer temperature control test box; 4. holing water in two measuring cups, and adding colored ink into the water of one of the cups and placing the two cups into a bottom temperature test box simultaneously; 5. dipping the frozen rock-like test piece in the water without adding the colored ink, then wrapping the surface crack leakage port surface with a preservative film, and placing the wrapped rock-like test piece into a top temperature control test box; 6. pouring the water added with colored ink into an infusion bottle and hanging it on an infusion rack, and regulating the flow to the minimum; 7. stabbing a vent hole and a water injection hole on the crack and injecting water; and 8. removing all the preservative film. The method provided by the invention is convenient to realize, improves the water injection efficiency, can effectively reduce water loss of the crack in the water injection process, prevents seepage, and is conducive to improving the precision of rock frost heave test.

Owner:XIAN UNIV OF SCI & TECH

High-low-pressure subarea fracturing anatonosis type coal seam water injection method

ActiveCN105649625AImprove permeabilityImprove water injection effectUnderground miningDust removalSlagMolecular materials

The invention discloses a high-low-pressure subarea fracturing anatonosis type coal seam water injection method. The method comprises the steps that drilling, hole sealing and water injecting are carried out on a coal face dynamic pressure area; drilling, hole sealing and water injecting are carried out on a coal face static pressure area; the coal face dynamic pressure area is a coal seam area distancing from the coal wall of a working face by 70-150 meters, and the coal face static pressure area is a coal seam area distancing from the coal wall of the working face by over 150 meters. The subarea coal seam drilling and water injecting mode is adopted, a twisted drill stem is selected as a drill stem adopted in the coal face dynamic pressure area, which is beneficial for discharging slag; moreover, a water powder swelling type hole sealing device and a high-molecular-material plugging structure are adopted for combined hole sealing, and then low-pressure water injecting is carried out; the coal face static pressure area is drilled multiple times by the adoption of a sectional type drilling implementation method, meanwhile, a three-ridge drill stem is selected, the contact area between the drill stem and the hole wall is reduced, and the phenomenon of tool sticking is prevented; high-pressure water injection is implemented to increase permeability of a coal seam, so that the coal seam water injection is optimal, and drilling and water injection efficiency are improved.

Owner:SHANDONG UNIV OF SCI & TECH

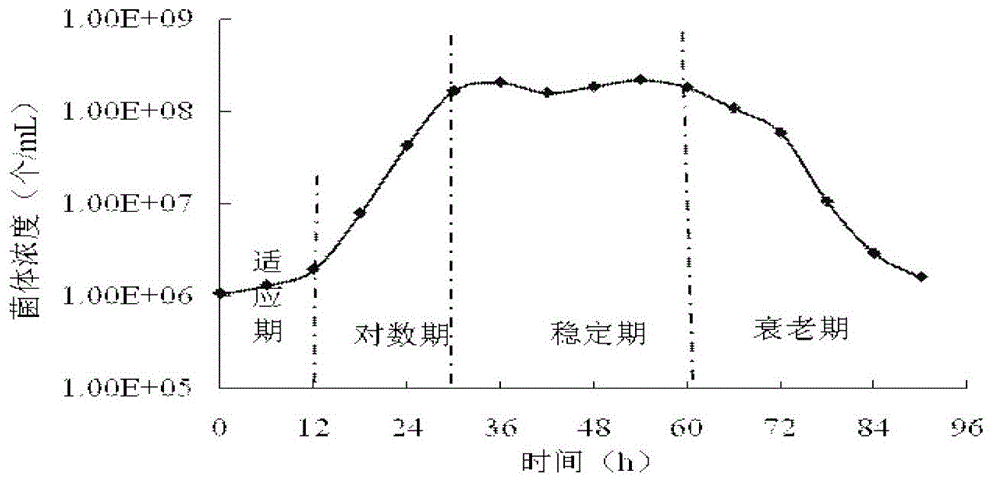

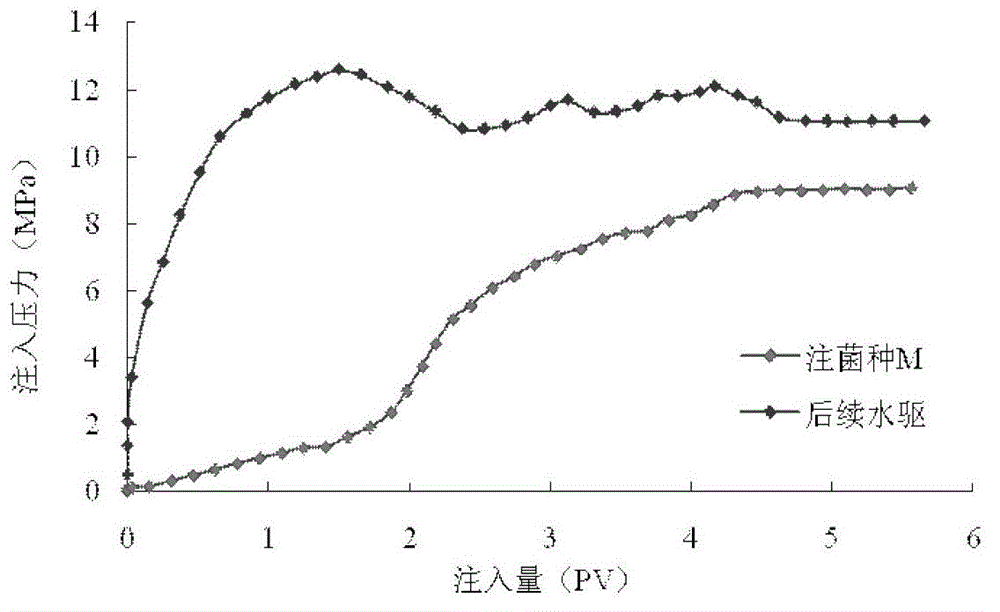

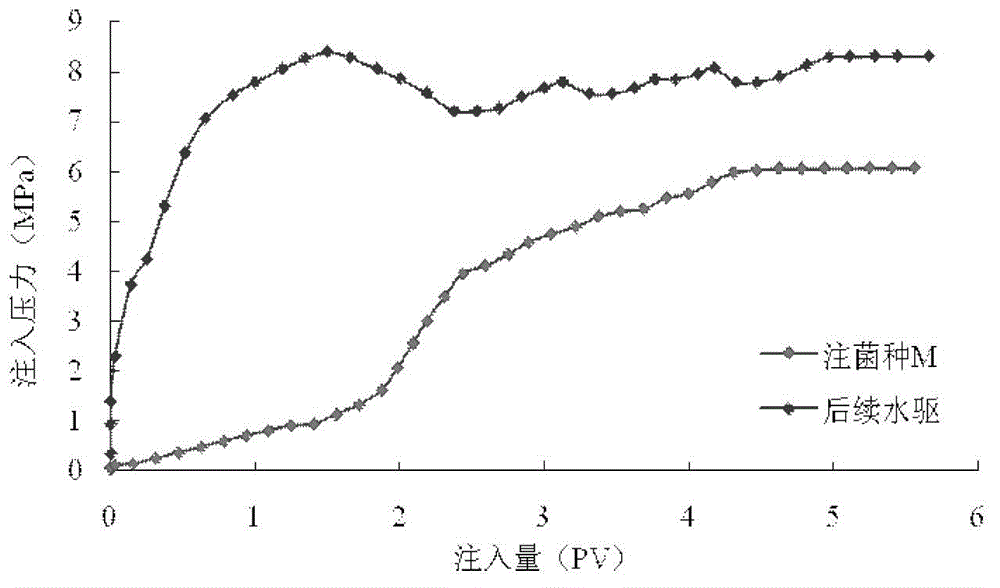

Pseudomonas aeruginosa, and culture method and application thereof

InactiveCN102533602AReduce interfacial tensionImprove rheologyBacteriaMicroorganism based processesPhosphateMonopotassium phosphate

The invention relates to pseudomonas aeruginosa YM4 CGMCC No.5243, and a culture method and application thereof. The culture method for the pseudomonas aeruginosa YM4 comprises the following steps: inoculating the pseudomonas aeruginosa YM4 into a fermentation culture medium; and cultivating in a shaking table at the temperature of 35 or 55 DEG C and at the rotating speed of 120 or 80 rpm, wherein the formula of the fermentation culture medium comprises glucose, peptone, corn paste, sodium nitrate, disodium hydrogen phosphate, potassium dihydrogen phosphate, magnesium sulfate and calcium chloride, and the pH value of the fermentation culture medium is 6.5 to 7.4. A biological surfactant generated by the pseudomonas aeruginosa YM4 can reduce oil water interface tension in the oil field; and after the action, the rheological property of the crude oil is obviously improved, viscosity is reduced, water injection pressure can be effectively reduced, water injection efficiency and recovery ratio of the crude oil can be improved; and large application prospect is achieved in the oil displacement process of the oil field.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

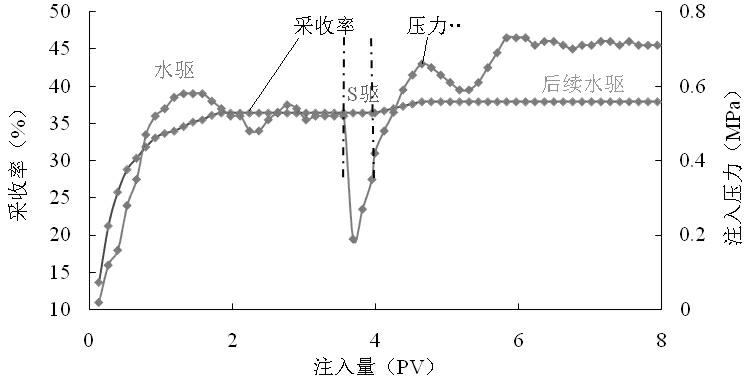

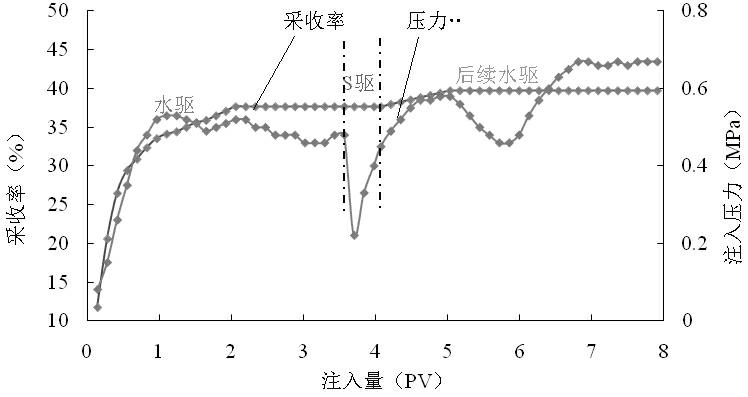

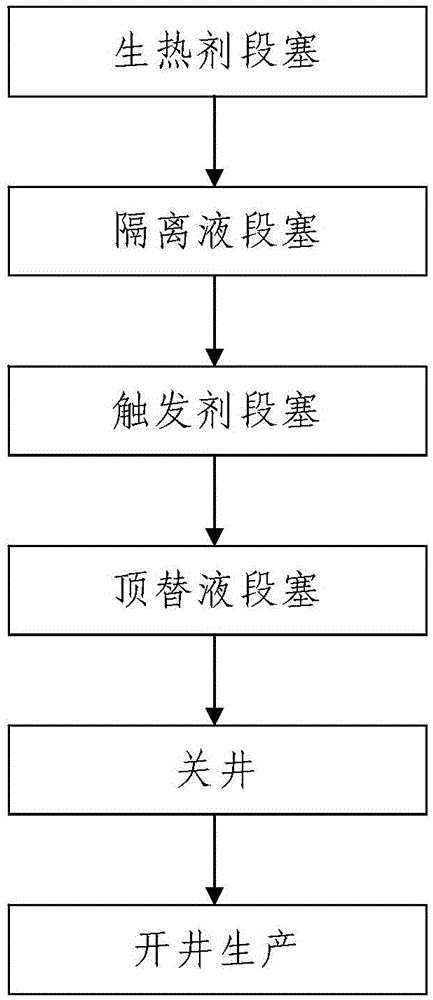

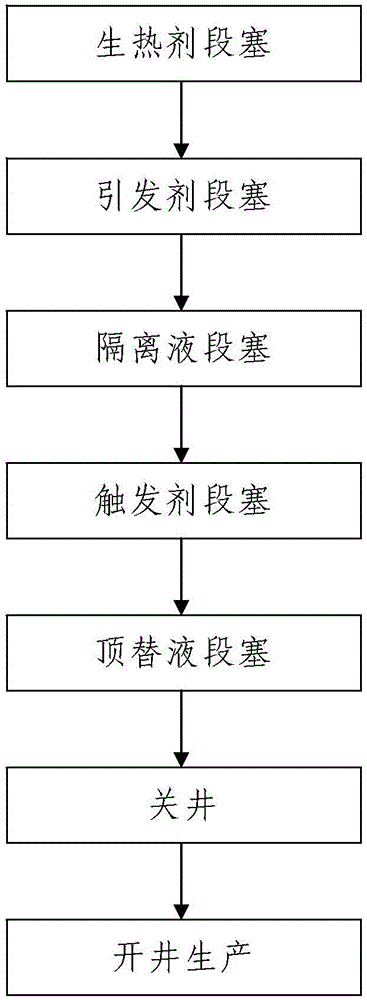

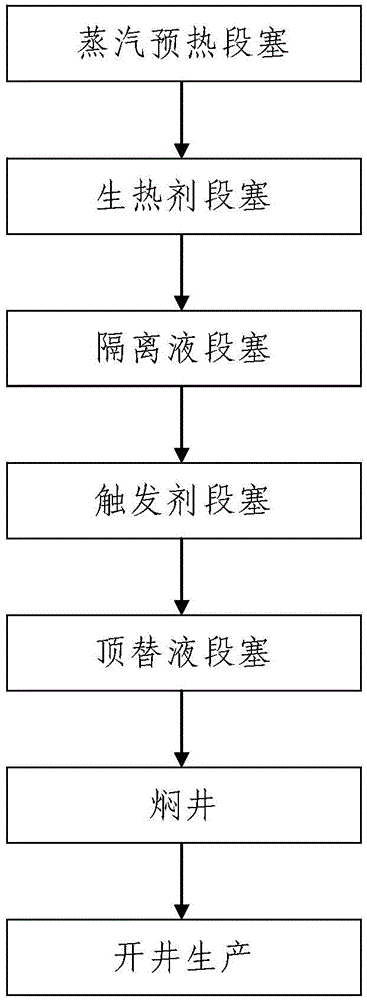

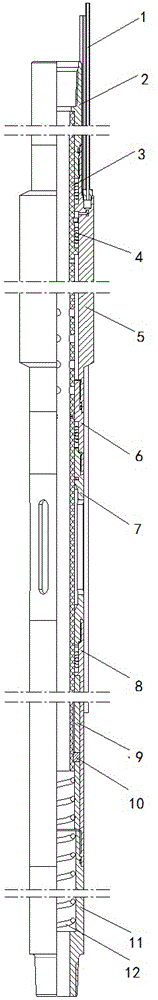

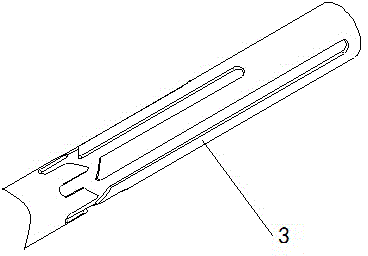

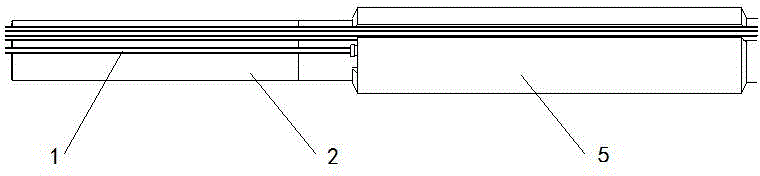

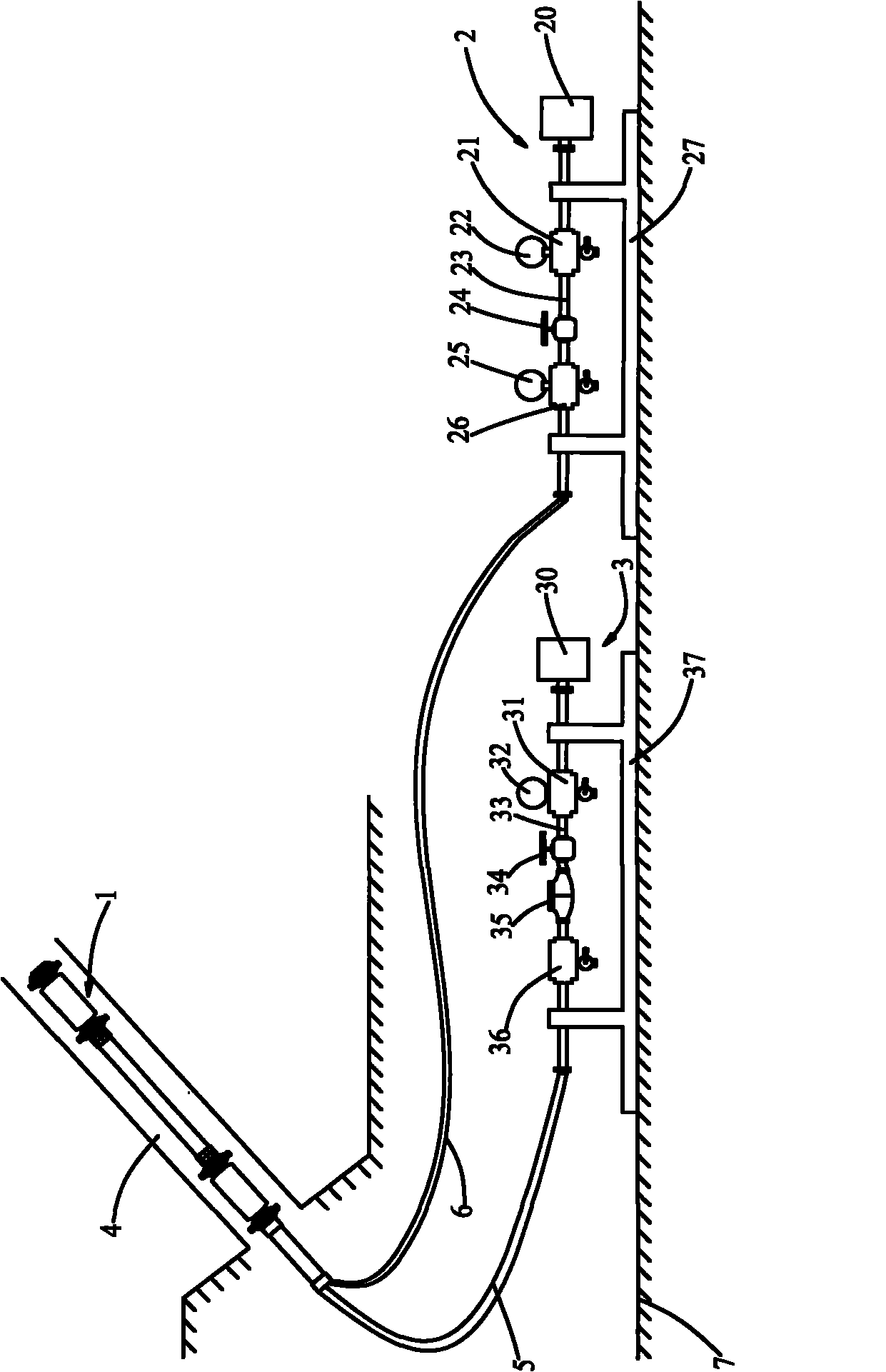

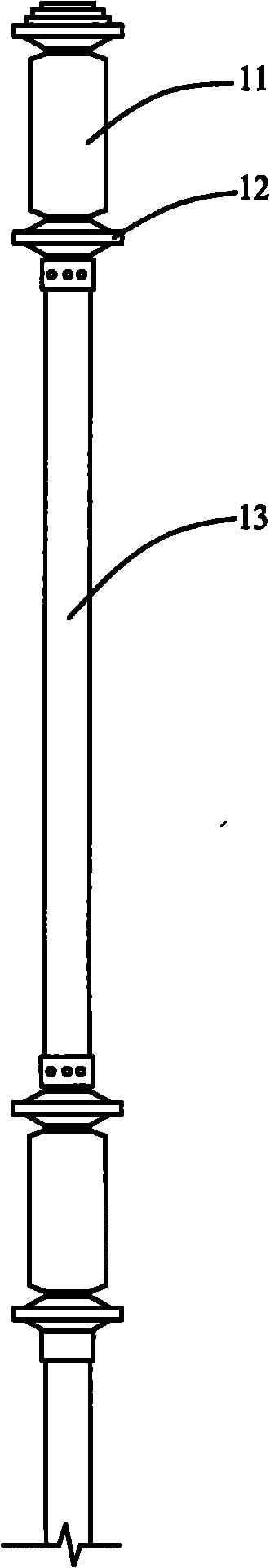

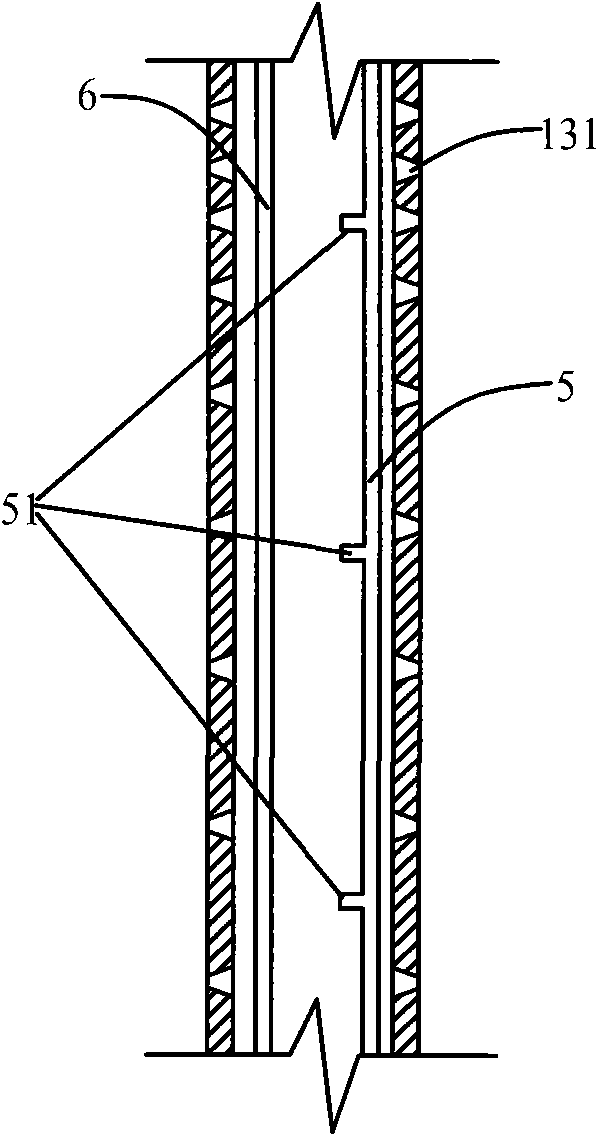

Injection process and injection equipment of chemical heat generating system in thick oil storage layer

ActiveCN105089592AThe injection process steps are simpleReasonable designFluid removalDrilling compositionInjection equipmentPlunger pump

The invention discloses an injection process of a chemical heat generating system in a thick oil storage layer; a cold production mode is used for injecting as follows: heat generating agent slug injection, separation liquid slug injection, trigger agent slug injection, replacement liquid slug injection, well closing and well opening production; a steam injection heat production mode is used for injecting as follows: steam preheating slug injection, heat generating agent slug injection, separation liquid slug injection, trigger agent slug injection, replacement liquid slug injection, well braising and well opening production; the process is simple in steps, reasonable in design, convenient to operate, safe and reliable in injection process and excellent in use effect, and can simply finish the injection process of the chemical heat generating system in the thick oil storage layer; moreover, the invention further discloses injection equipment of the chemical heat generating system in the thick oil storage layer; the equipment comprises four liquid mixing devices and one liquid injection pipe connected with a shaft of a target well; a plunger pump, a pressure detecting unit and a fifth one-way valve are mounted on the liquid injection pipe; and the equipment is simple in structure, reasonable in design, convenient for pipeline connection, simple in use and operation and excellent in use effect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

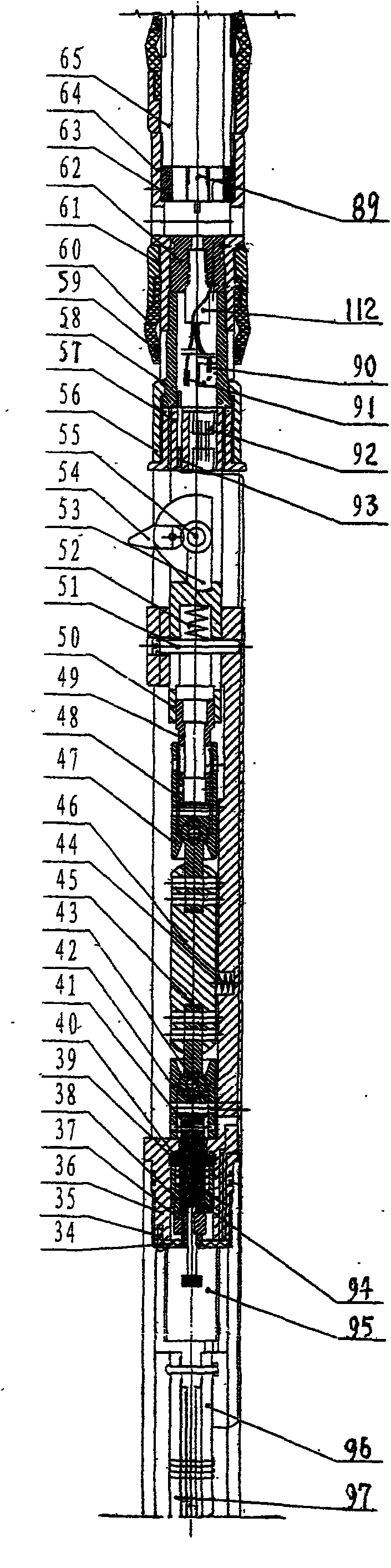

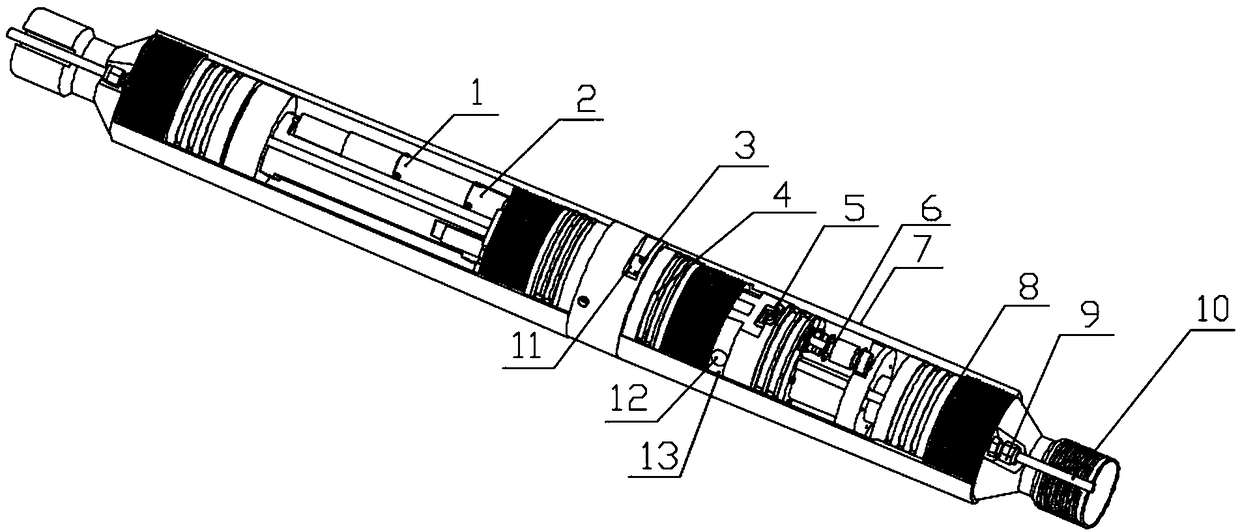

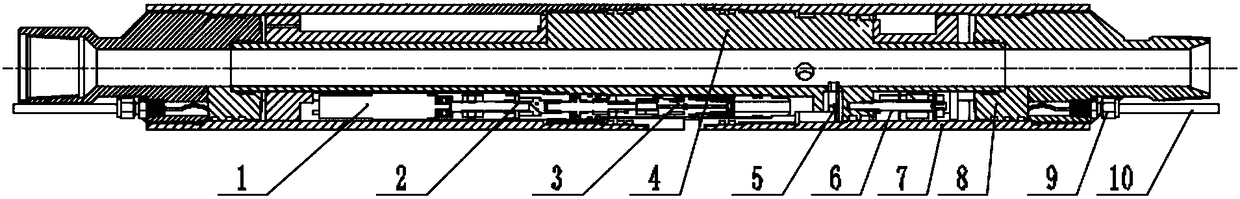

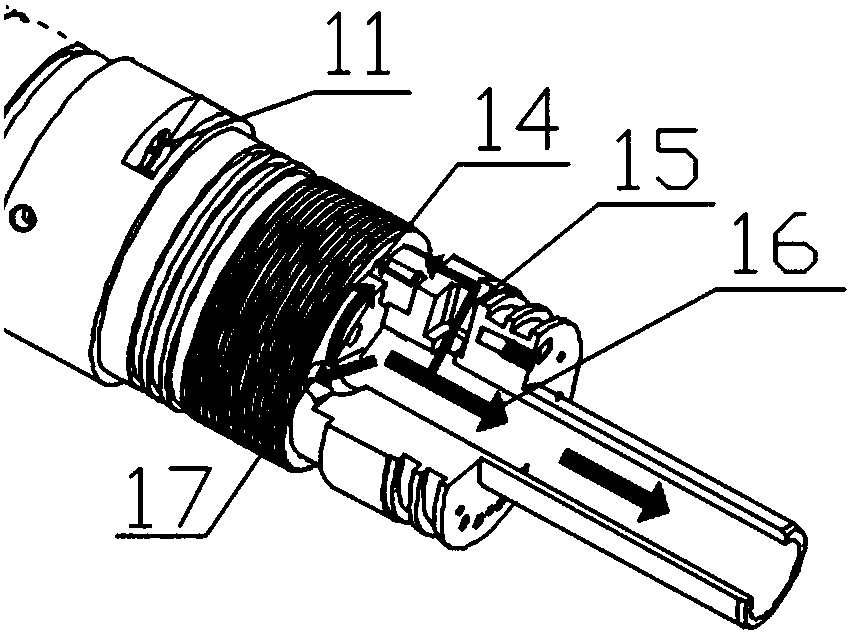

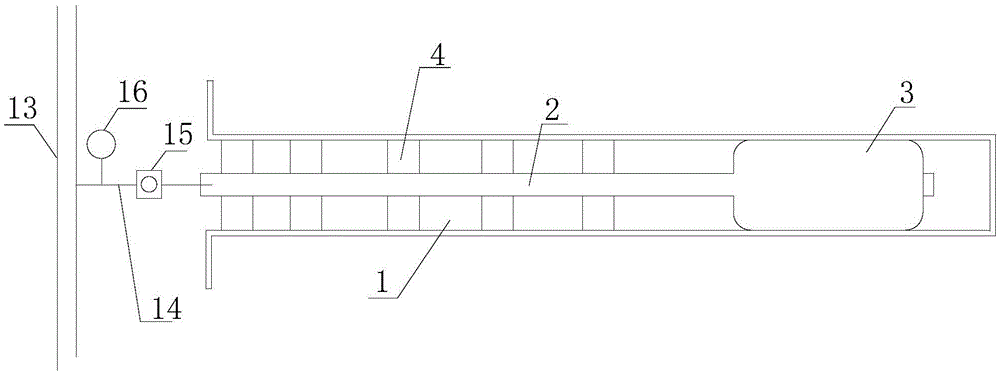

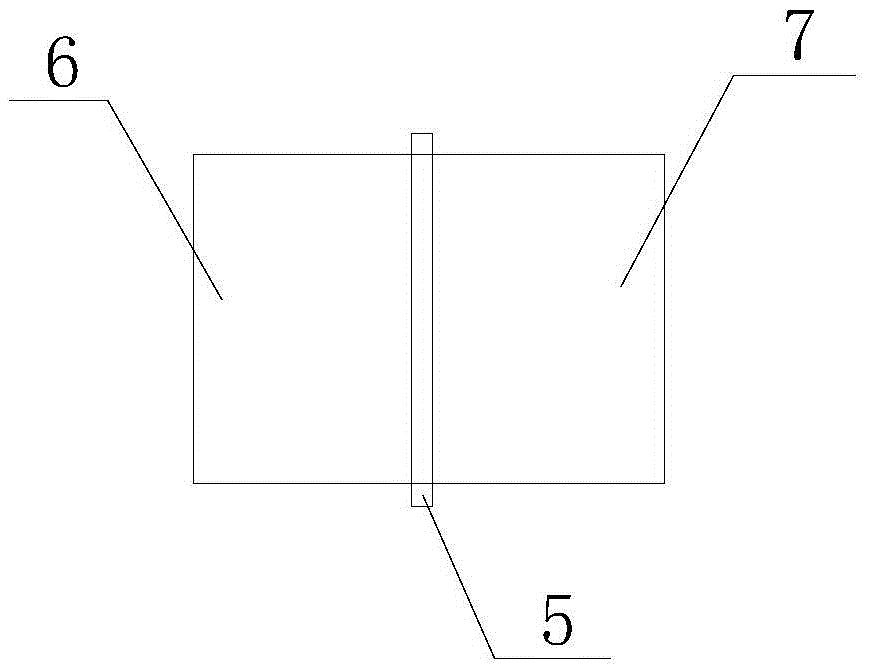

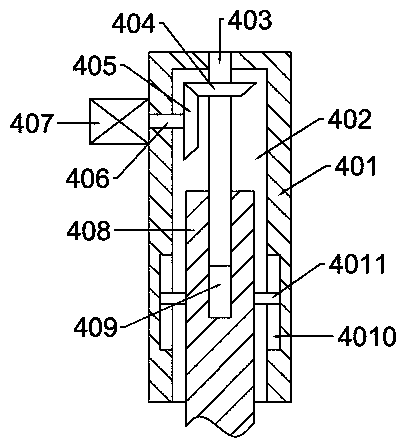

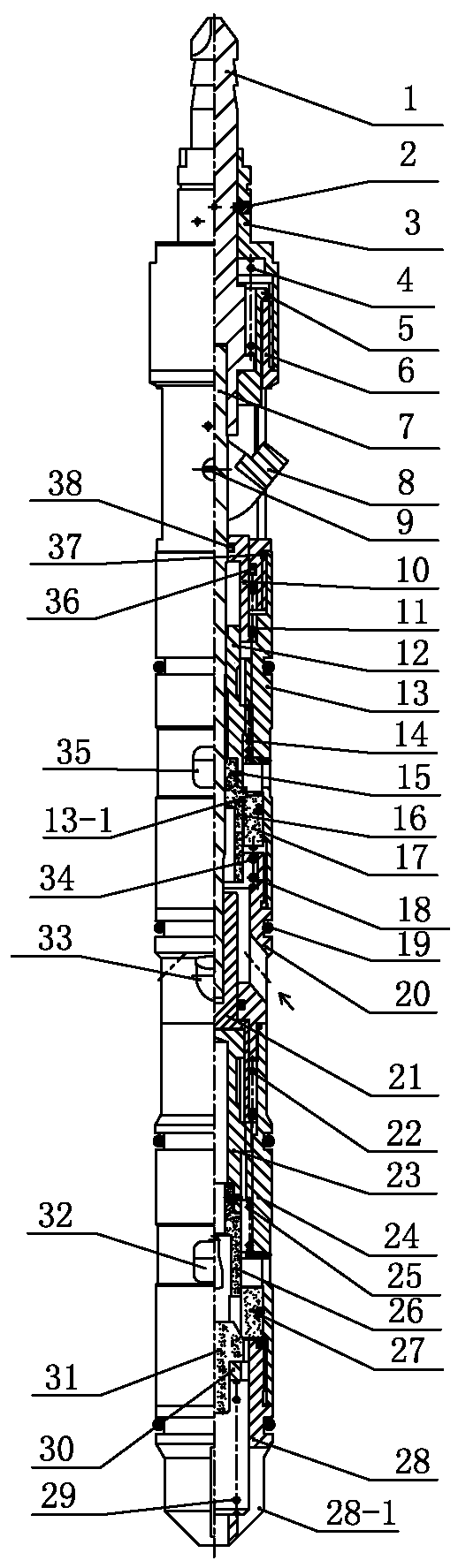

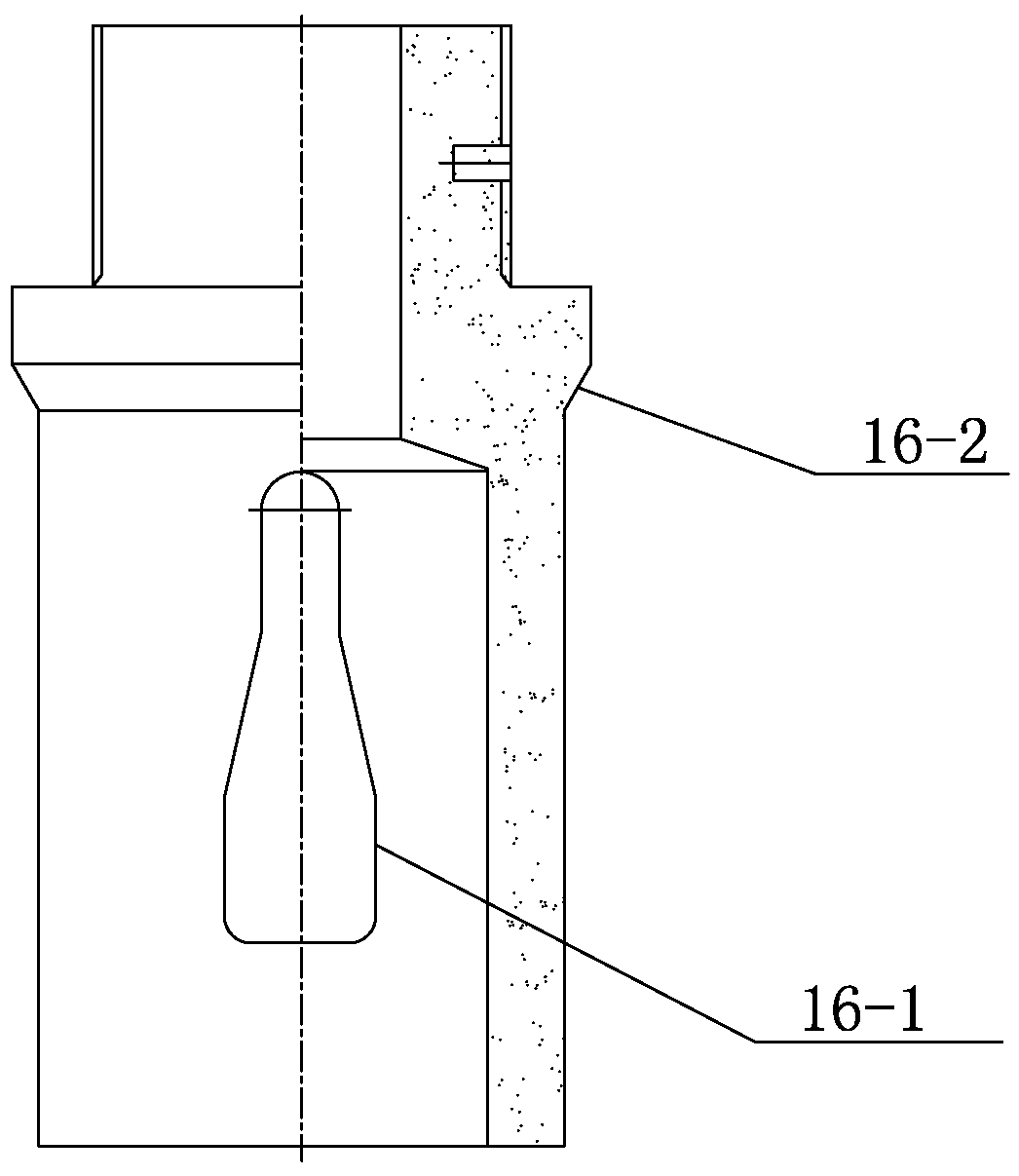

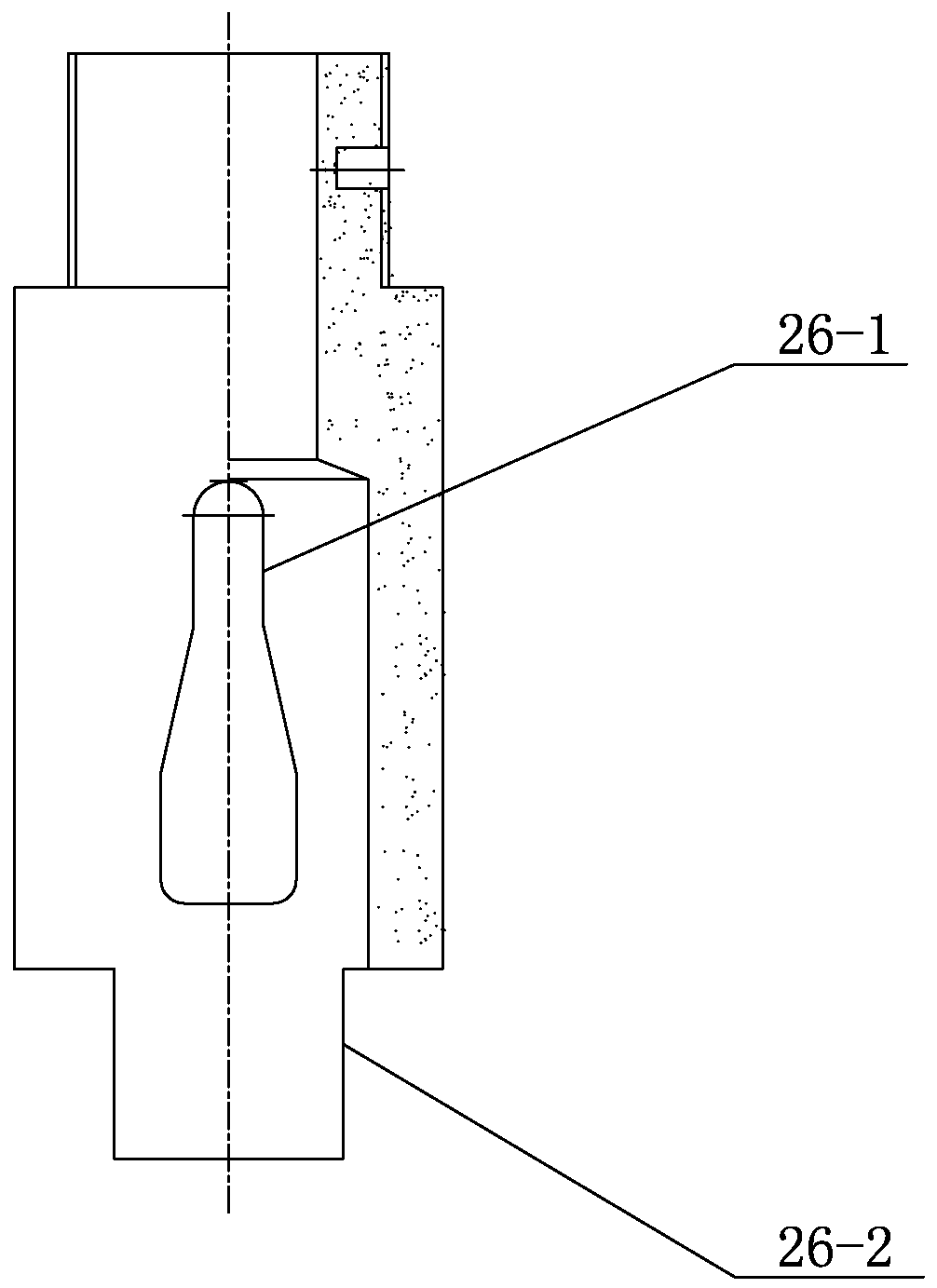

Intelligent water injection device

ActiveCN104453810AImprove water injection efficiencyLow costFluid removalHorizontal wellsReciprocating motion

The invention discloses an intelligent water injection device. The intelligent water injection device comprises a driving part, a sliding cavity, a piston part, a water injection part and a gearshift adjusting part. The driving part drives the piston part to reciprocate along the sliding cavity, the piston part comprises a central pipe provided with a plurality of water injection holes axially distributed, the water injection part is provided with water via holes, and the gearshift adjusting part shifts gears to change the number of the water injection holes communicated with the water via holes so as to control water injection flow of the water injection device. The water injection flow of the water injection device can be adjusted as the water injectivity index of the stratum without throwing and fishing, water injection efficiency is improved, and water injection cost is reduced. The intelligent water injection device is applicable to monolayer and multilayer water injection and to inclined and horizontal wells.

Owner:重庆峰丽能源技术有限公司

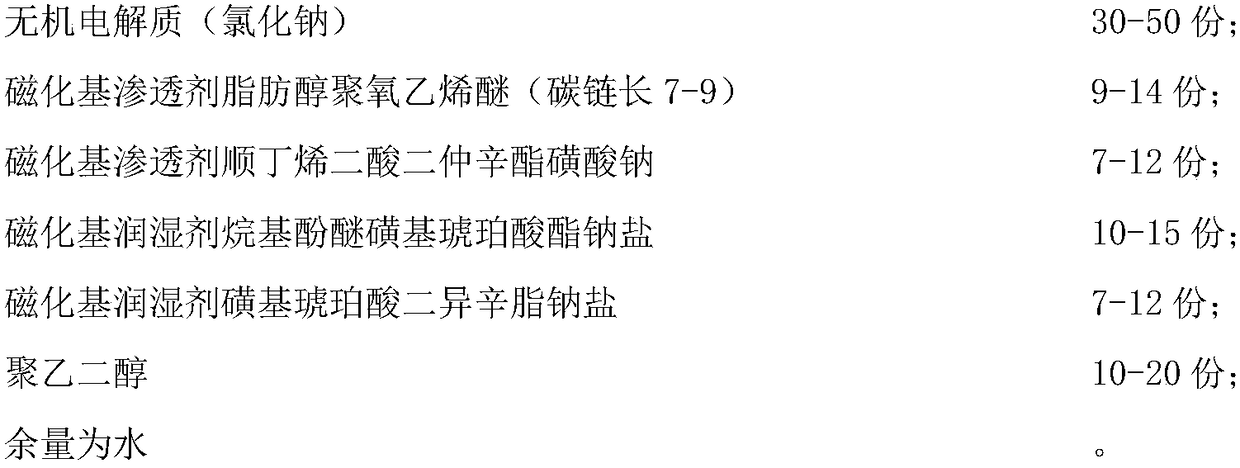

Magnetic anatonosis wetting agent capable of improving dust reduction effect of coal seam water injection

ActiveCN108084967AFast migrationReduce surface tensionOther chemical processesDust removalPolyethylene glycolAlkylphenol

The invention discloses a magnetic anatonosis wetting agent capable of improving a dust reduction effect of coal seam water injection. The magnetic anatonosis wetting agent is characterized by comprising the following components in parts by weight: 30-50 parts of inorganic electrolyte (sodium chloride), 9-14 parts of a magnetic penetrant fatty alcohol-polyoxyethylene ether (carbon chain length of7-9), 7-12 parts of a magnetic penetrant sodium diethylhexyl sulfosuccinate, 10-15 parts of a magnetic wetting agent alkylphenol ether sulfonylsuccinate sodium salt, 10-20 parts of polyethylene glycoland the balance of water. After the magnetic anatonosis wetting agent is injected into a coal seam, the water infiltration capability can be enhanced, the spreading range of water in the coal seam isexpanded, and the water injection effect is greatly improved. The magnetic anatonosis wetting agent is suitable for wide-range application to underground coal seam water injection due to the characteristics of simple and feasible preparation method, good dust reduction effect, convenient operation and low cost.

Owner:CHINA UNIV OF MINING & TECH

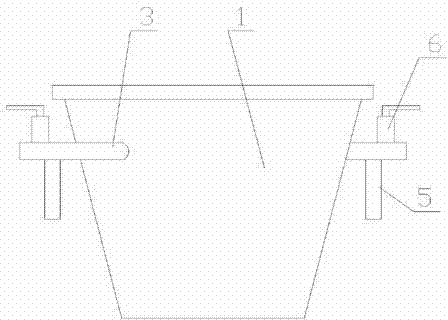

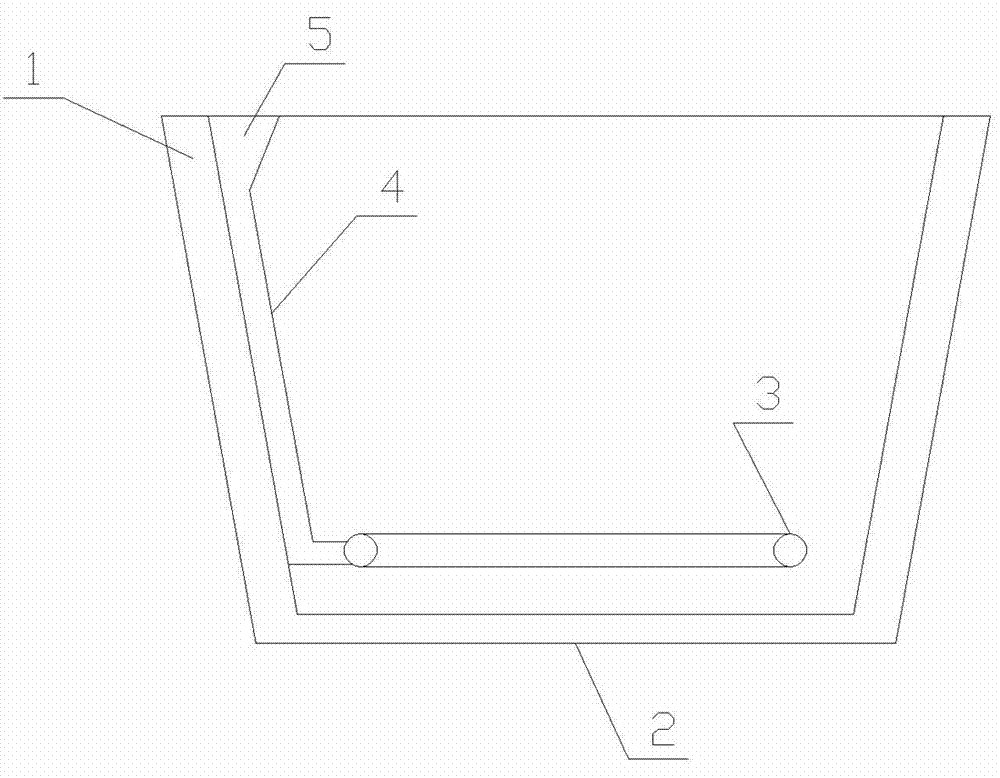

Flowerpot

InactiveCN102893823AEasy to loosen the soilImprove water injection efficiencyReceptacle cultivationEngineeringControl valves

The invention discloses a flowerpot which is provided with a side wall, a pot bottom and a horizontal bar, wherein the horizontal bar penetrates through the side wall of the flowerpot and is fixedly provided with more than one soil loosening columns, a handle is fixed at one end outside the side wall above the horizontal bar, the horizontal bar and the soil loosening columns are hollow and tubular, pipelines in the horizontal bar and the soil loosening columns are communicated with one another, a water control valve is arranged at the outer end of the horizontal bar, and a water outlet is arranged at the front section of each soil loosening column. As the flowerpot adopts a rocking-bar-type soil loosening mechanism, the soil loosening operation is time-saving and labor-saving, the water replenishing efficiency is improved, and the water injection effect is more thorough. The flowerpot is simple to operate and is not high in manufacturing cost.

Owner:王文生

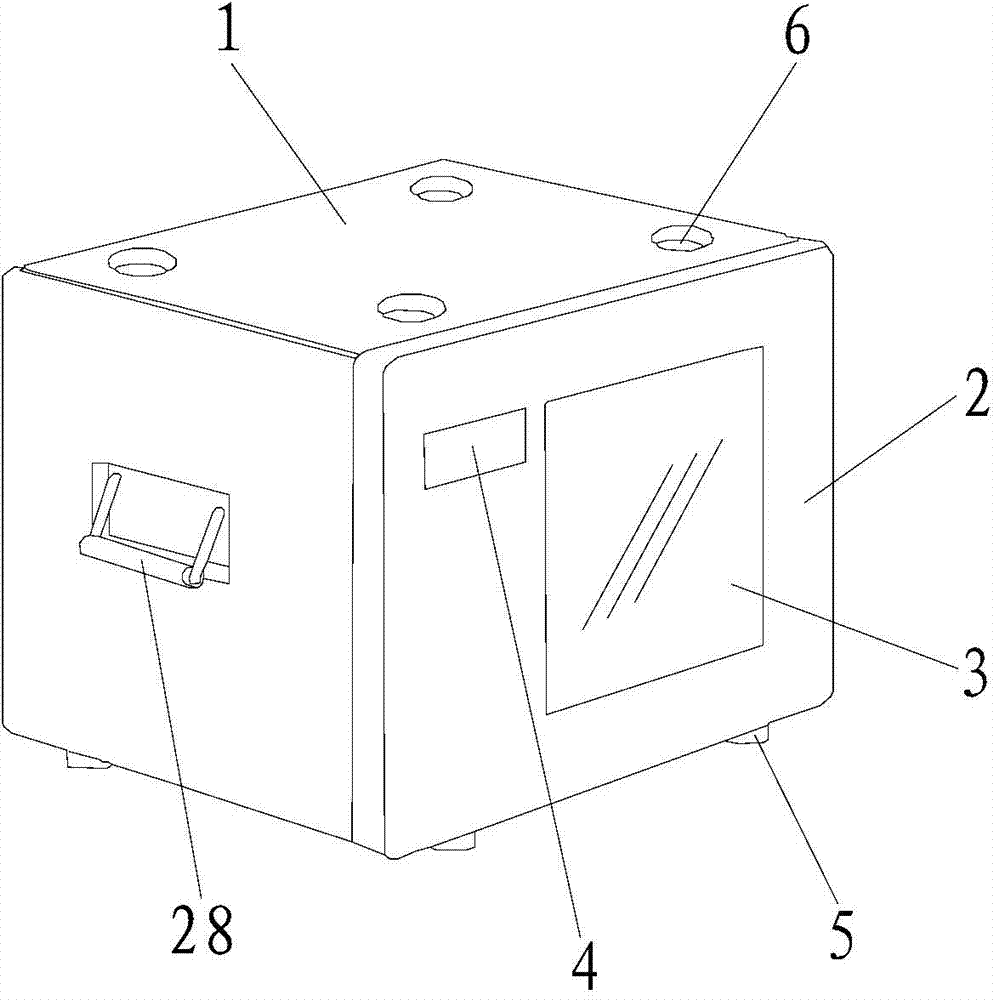

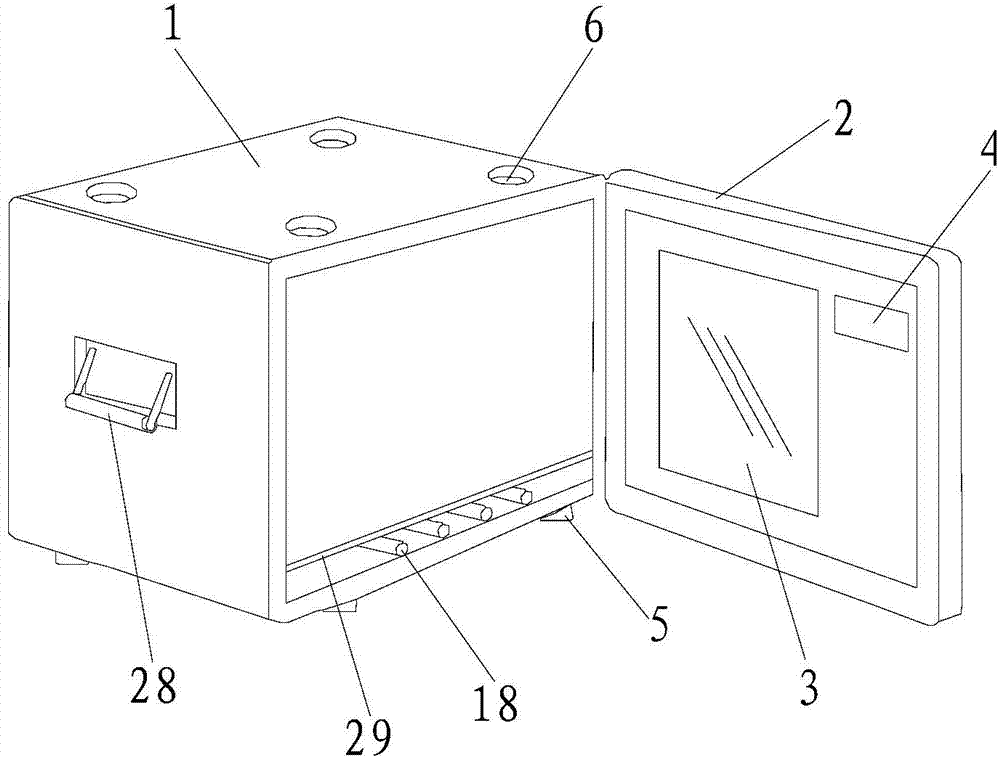

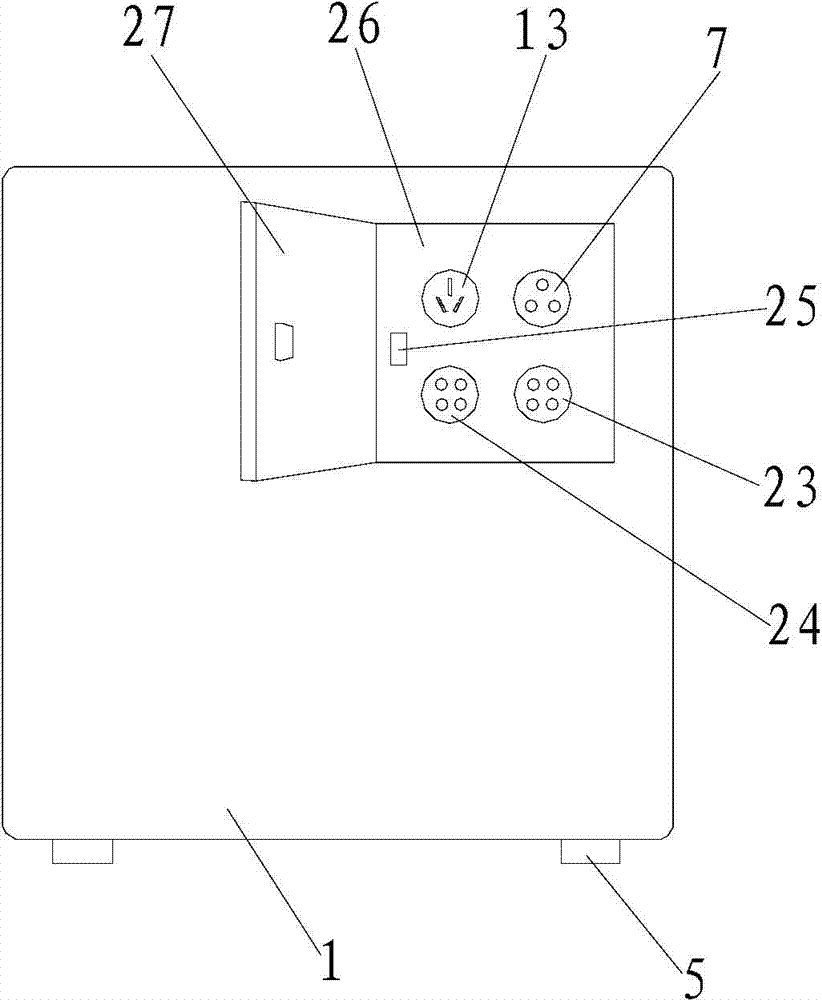

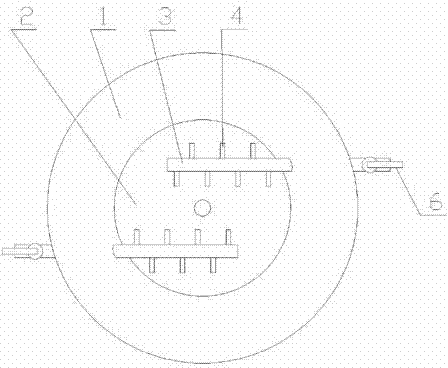

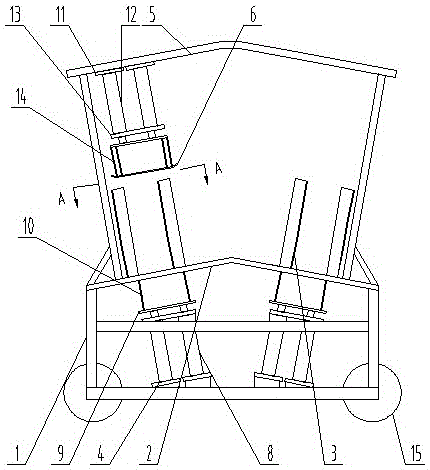

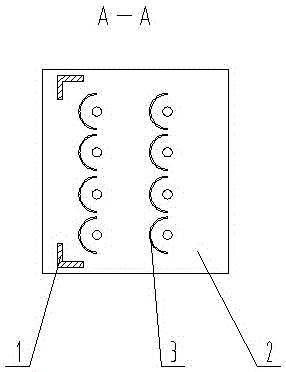

Automatic and efficient water injection machine for lentinus edodes

InactiveCN105165393AReasonable structural designEasy to operateCultivating equipmentsMushroom cultivationElectricityElectric power

The invention discloses an automatic and efficient water injection machine for lentinus edodes and relates to the technical field of injection devices for lentinus edodes. The automatic and efficient water injection machine comprises a rack (1), a pair of mushroom-stick bottom plates (2), two groups of mushroom-stick backing boards (3), a pair of bottom fixed water injection mechanisms, a top movable water injection mechanism, a water inlet module and a gas inlet module, wherein a group of water injection needle tube through holes is respectively formed in the pair of mushroom-stick bottom plates (2); the pair of mushroom-stick bottom plates (2) is fixed and mounted on the rack (1) respectively; and the pair of mushroom-stick bottom plates (2) is respectively symmetrically arranged in an inclined mode in the shapes of inverted Vs; the mushroom-stick backing boards (3) are in the shapes of semi-cylinders, and the bottoms of the mushroom-stick backing boards (3) are fixed and mounted on the mushroom-stick bottom plates (2); and semicircular centers of the mushroom-stick backing boards (3) are superposed with the water injection needle tube through holes. The automatic and efficient water injection machine for lentinus edodes is reasonable in structural design, convenient in operation, high in water injection efficiency and capable of completing water injection for 16 mushroom-sticks within a operation cycle, and an automatic water injection machine with no needs of electricity is developed particularly by virtue of an idea that power insufficiency in rural areas and safe use of electricity are combined.

Owner:荆门市五三新欣食用菌研发种植基地

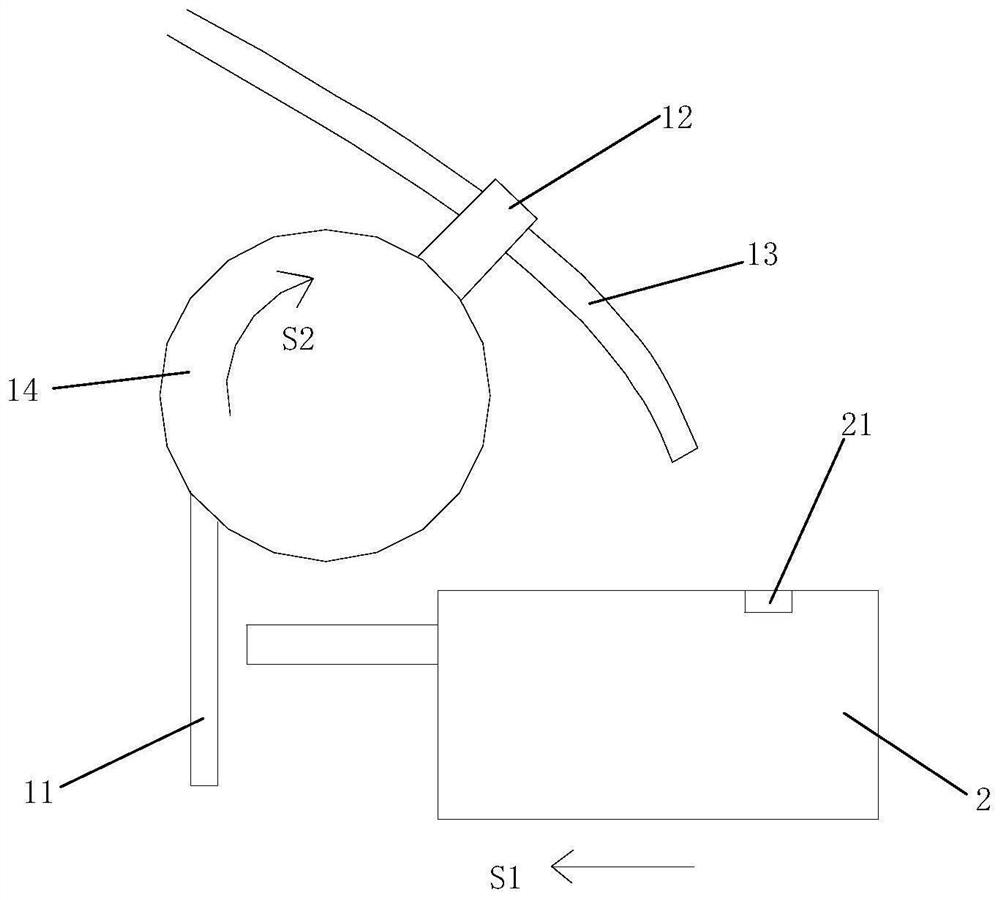

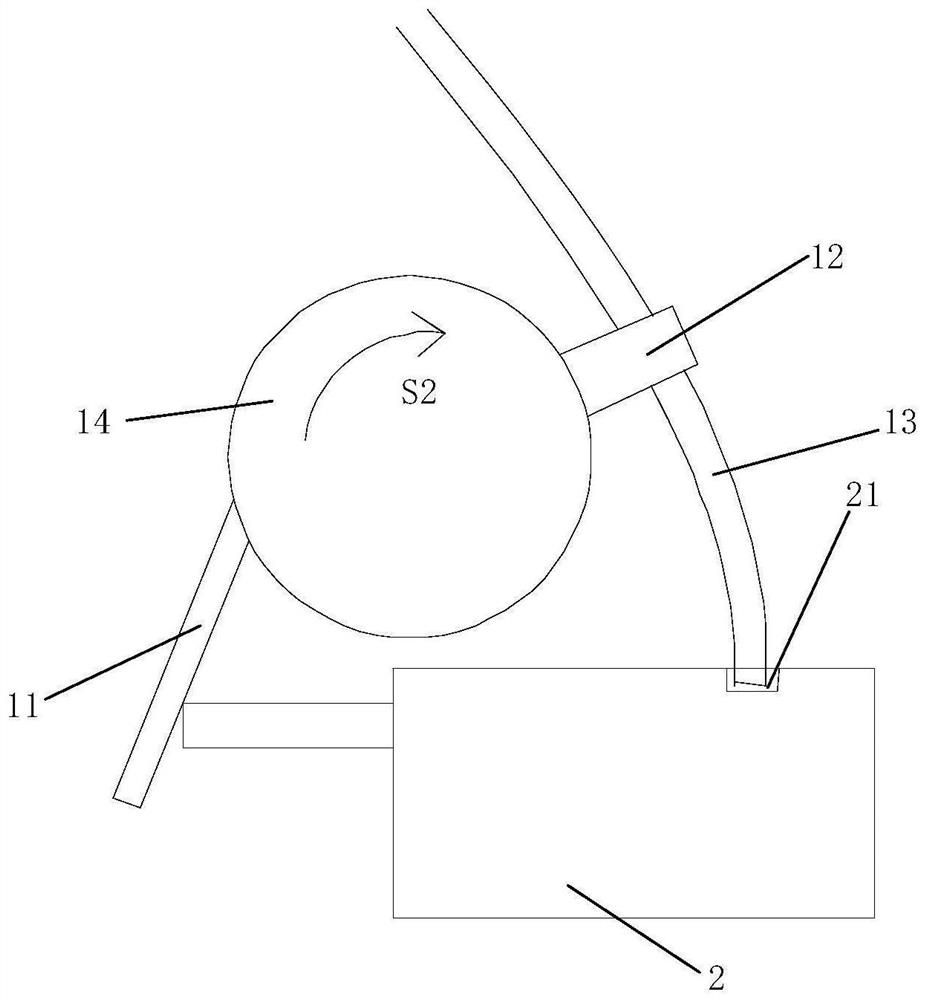

Water injection mechanism, base station and cleaning system

ActiveCN112842144ASimple structureSimple and fast operationCarpet cleanersFloor cleanersEnvironmental engineeringChange positions

The embodiment of the invention provides a water injection mechanism, a base station and a cleaning system. The water injection mechanism comprises a first component used for making contact with equipment to be injected with water and generating triggering action along with movement of the equipment to be injected with water; a second component connected with the first component; and a water injection pipe arranged on the second component; wherein the first component generates a triggering action to trigger the second component to change positions, so that the water injection pipe is changed from a first position where a distance exists between a pipe orifice and a water injection port of the equipment to be injected with water to a second position where the water injection pipe is inserted into the water injection port. According to the technical scheme, the first component and the second component are arranged in the water injection mechanism in the linkage mode, and after the device to be injected with water makes contact with the first component, the first component triggers and drives the second component to smoothly convey the water injection pipe located on the second component to the water injection opening of the equipment to be injected with water along with movement of the equipment to be injected with water. Therefore, the water injection mechanism provided by the embodiment of the invention is simple in structure and convenient to operate.

Owner:ECOVACS COMML ROBOTICS CO LTD

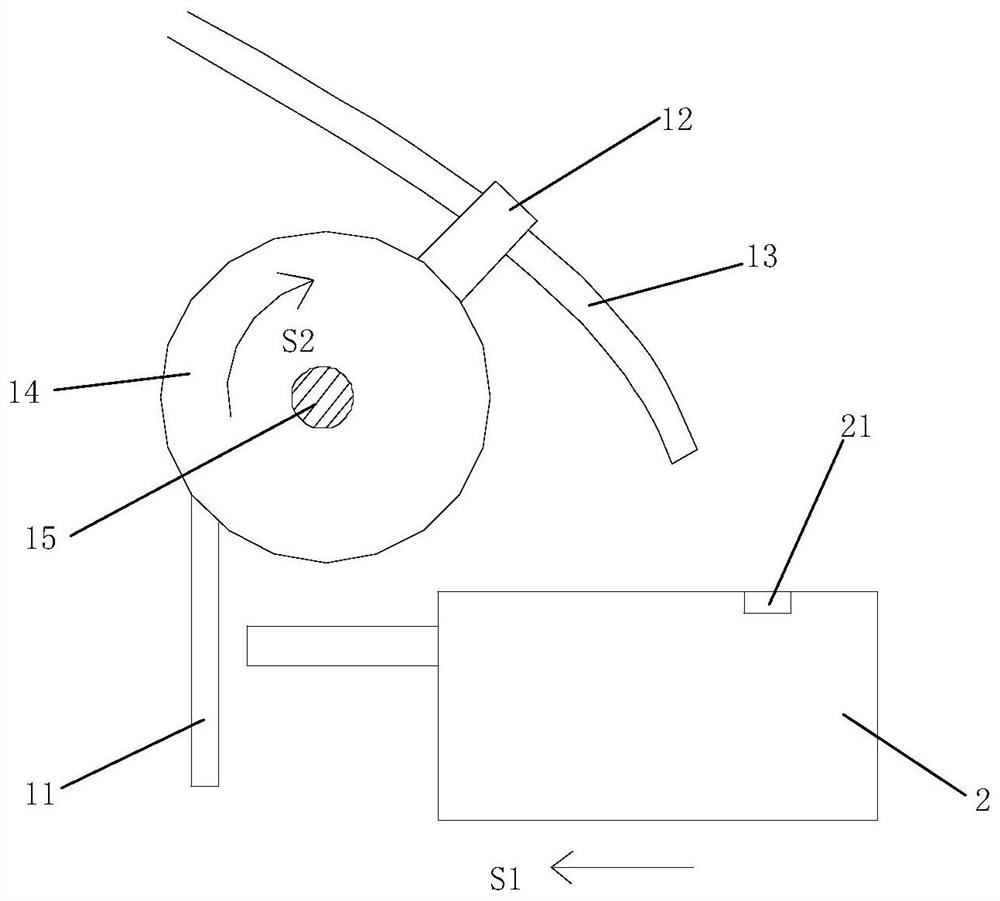

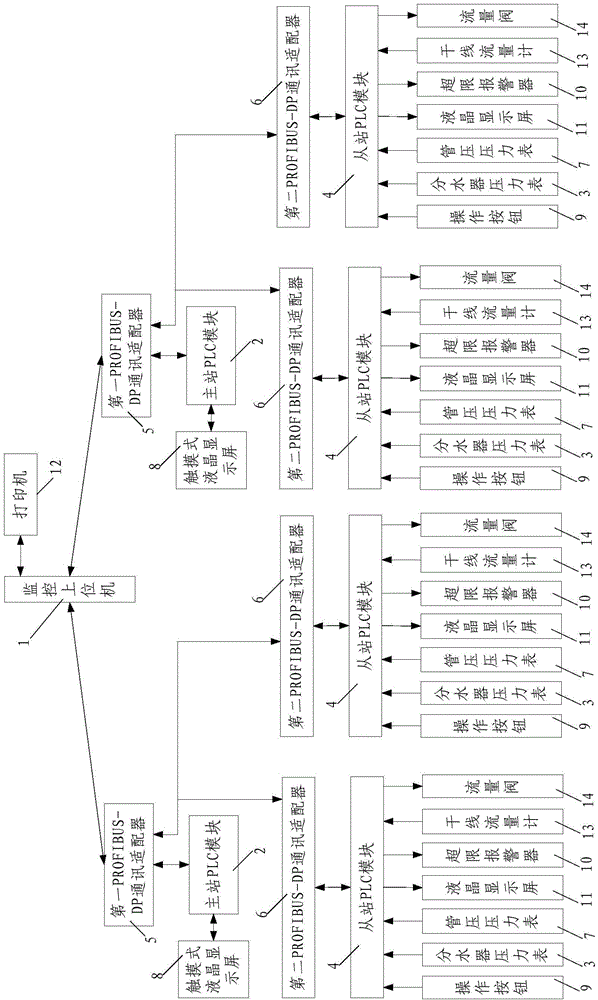

Oil field water flooding monitoring system based on PROFIBUS fieldbus

InactiveCN105589436ASimple structureReasonable designProgramme total factory controlLiquid-crystal displayWater flooding

The invention discloses an oil field water flooding monitoring system based on a PROFIBUS fieldbus, comprising a monitoring host computer, a plurality of master station PLC modules, and a plurality of slave station PLC modules; wherein the monitoring host computer is connected with a printer, each master station PLC module is connected with a first PROFIBUS-DP communication adapter and a touch type liquid crystal display screen, each slave station PLC module is connected with a second PROFIBUS-DP communication adapter; the input end of each slave station PLC module is connected with an operation button, a water knockout trap pressure meter, a pipe pressure meter and a main line flow meter; and the output end of each slave station PLC module is connected with a flow valve, a liquid crystal display screen ad an over-limit alarm. The oil field water flooding monitoring system of the present invention is simple in structure, reasonable in design, convenient in realization, high in system stability, quick in communication speed, high in reliability, good in real-time performance, helpful for improving water flooding efficiency, good in usage effect, and convenient in popularization and usage.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

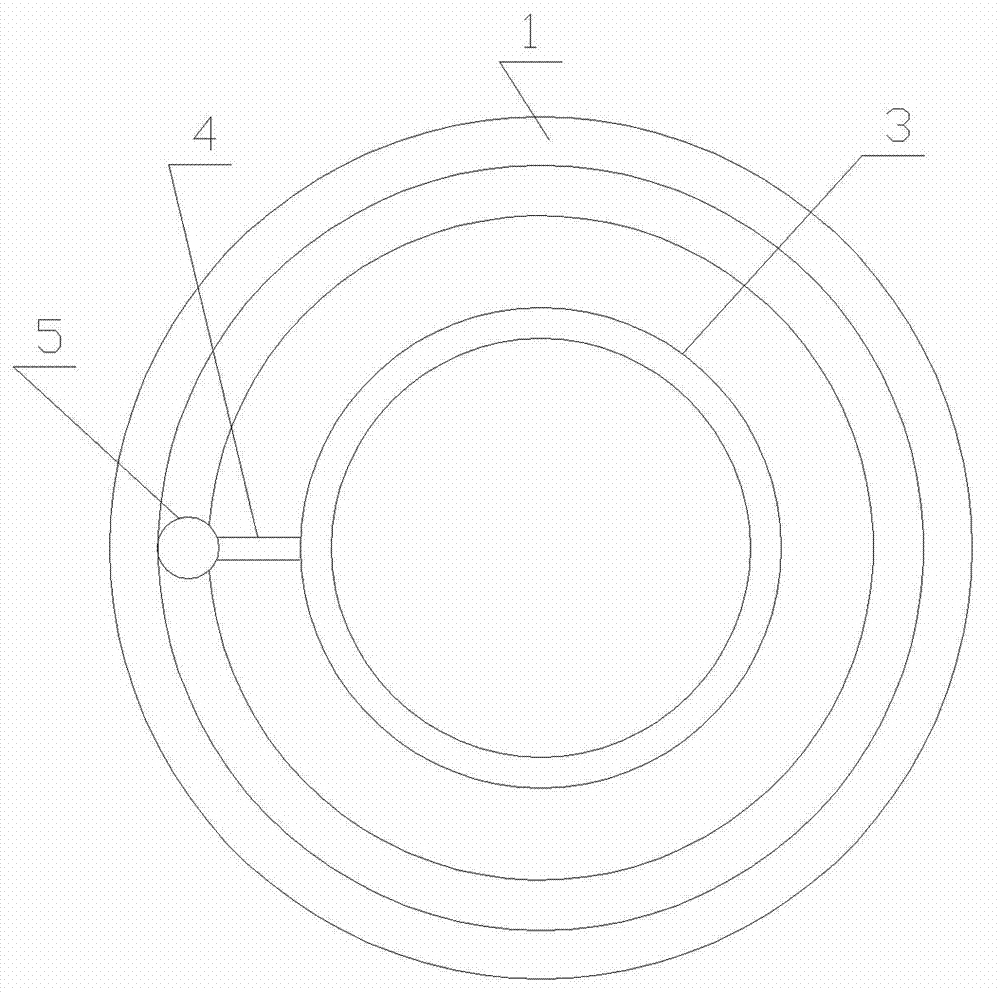

Water-delivery flowerpot

InactiveCN102893822AEasy to loosen the soilImprove water injection efficiencyRoot feedersReceptacle cultivationEngineeringFlowerpot

The invention discloses a water-delivery flowerpot which is provided with a side wall and a pot bottom. The water-delivery flowerpot is characterized in that a water guide pipe is arranged on the inner side of the side wall, a water inlet is arranged at the top of the water guide pipe, and the bottom of the water guide pipe is communicated with a ring of water delivery pipe which is provided with a plurality of water outlets. By virtue of the structure, water can be injected in a soil body, so that the efficiency of water injection is improved, a water injection effect is more thorough, and the phenomenon that the soil body is not drenched can be prevented well.

Owner:王文生

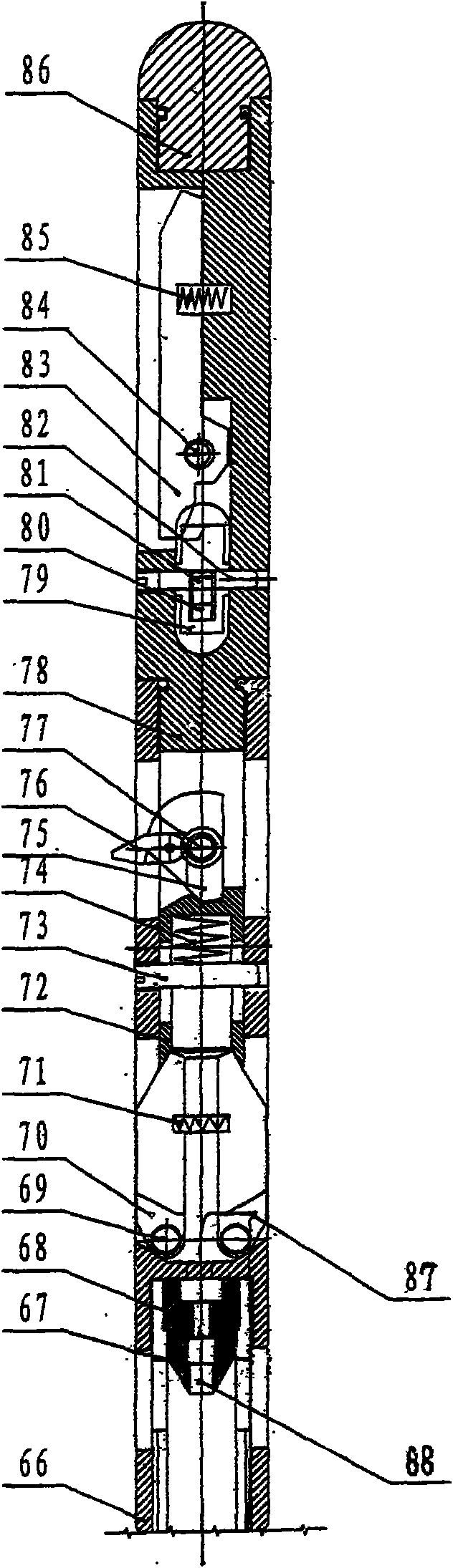

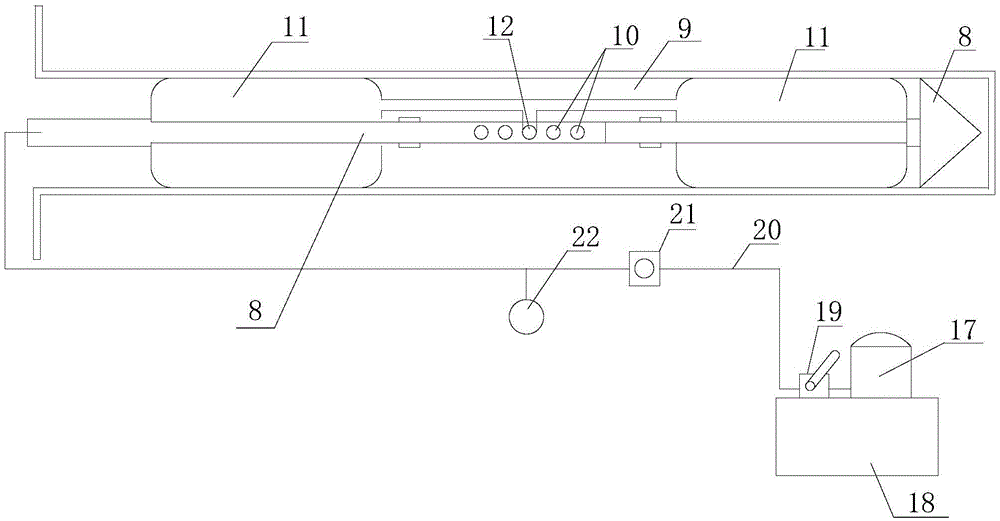

Exploring tube used for observing coal seam goaf fissure zone subsection water injection

InactiveCN101886543AImprove water injection efficiencyFinely evaluate the degree of crack developmentTesting machinesEnvironmental engineeringCoal

The invention discloses an exploring tube used for observing coal seam goaf fissure zone subsection water injection, comprising two aeration capsules and a water injection pipe which is arranged between the two aeration capsules through a connecting piece; the water injection pipe is provided with a plurality of water injection holes; the exploring tube is provided with a gas delivering pipeline and the water delivering pipeline; water inlet holes are arranged on the part of the water injection pipe on the water delivering pipeline; and aeration holes are formed on the part of the aeration capsule on the gas delivering pipeline. The exploring tube of the invention has high water injection efficiency, can inject water rapidly, has good practicality, simple structure, convenient use and low production cost, and is beneficial for promotion.

Owner:陕西省煤炭地质测量技术中心

A method for composite microbial oil recovery in low permeability oilfields

InactiveCN102852497BImprove mobility ratioLarge spreading areaFluid removalRecovery methodMicrobial oil

The invention discloses a compound microorganism oil extraction method for a low permeability oilfield. The compound microorganism oil extraction method comprises the following steps of (1) cultivating pseudomonas aeruginosa YM4 strains and pseudomonas stutzeri DP1 strains in an indoor shaking flask respectively, and obtaining fermentation broth of high-activity pseudomonas aeruginosa YM4 strains and fermentation broth of polymer produced strains through first-stage and second-stage seeding tank amplification and fermentation production of a production tank; (2) mixing surface active agent produced strains and the pseudomonas stutzeri DP1 strains fermented and produced in the step (1) according to volume ratio of 1:1; and (3) enabling compound microorganism bacterium liquid obtained in the step (2) to serve as an oil-displacing agent to inject in an oil layer directly through a water injection well, and obtaining crude oil from a producing well. The YM4 strains and the DP1 strains are both facultative anaerobic microorganisms and can both grow and breed in a ground layer, polymers produced by the DP1 strains can improve mobility ratio, increases water injection affecting area, and the product surface active agent of the YM4 strains can reduce oil-water interfacial tension and improve oil recovery.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

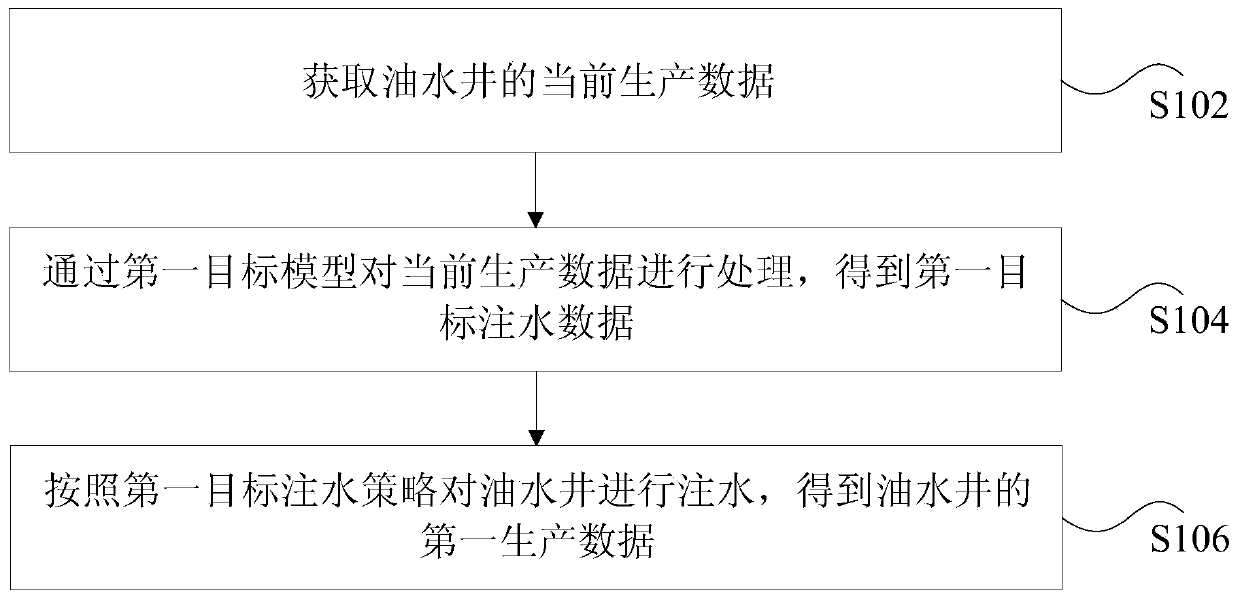

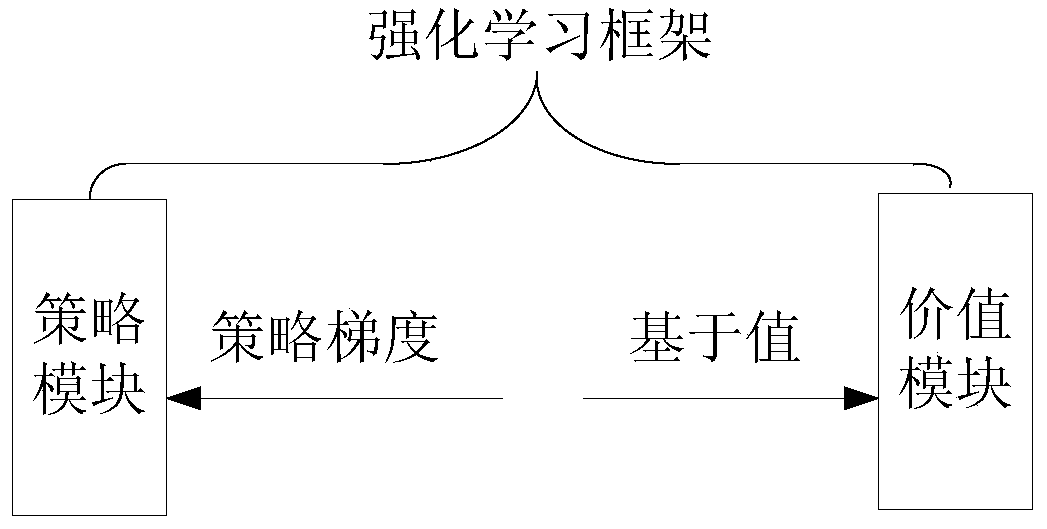

Oil field water injection data processing method and device, storage medium and processor

ActiveCN109948836AImprove water injection efficiencySolve the technical problem of low efficiency of water injectionForecastingNeural architecturesOil fieldData processing

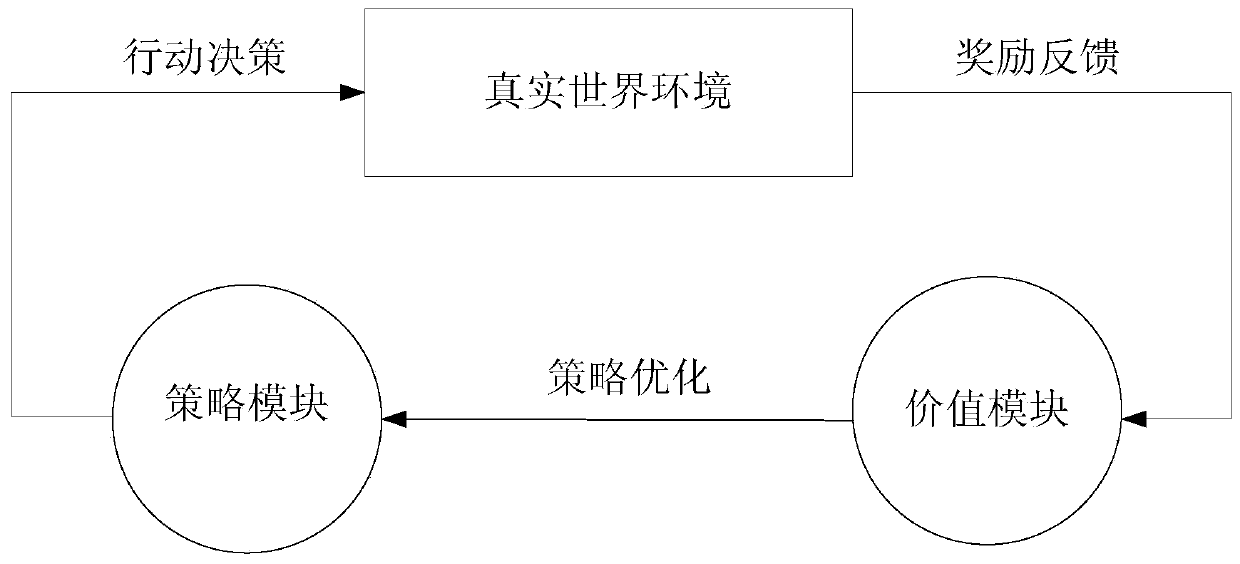

The invention discloses an oil field water injection data processing method and device,, a storage medium and a processor. The method comprises the steps of obtaining current production data of the oil-water well; Processing the current production data through a first target model to obtain first target water injection data, the first target model being obtained by performing reinforcement learning training based on first historical production data of the oil-water well, and the first target water injection data being used for indicating a first target water injection strategy performed on theoil-water well; And performing water injection on the oil-water well according to the first target water injection strategy to obtain first production data of the oil-water well. The technical problem that due to extensive management, the water injection efficiency of the oil-water well is low is solved.

Owner:BEIJING GRIDSUM TECH CO LTD

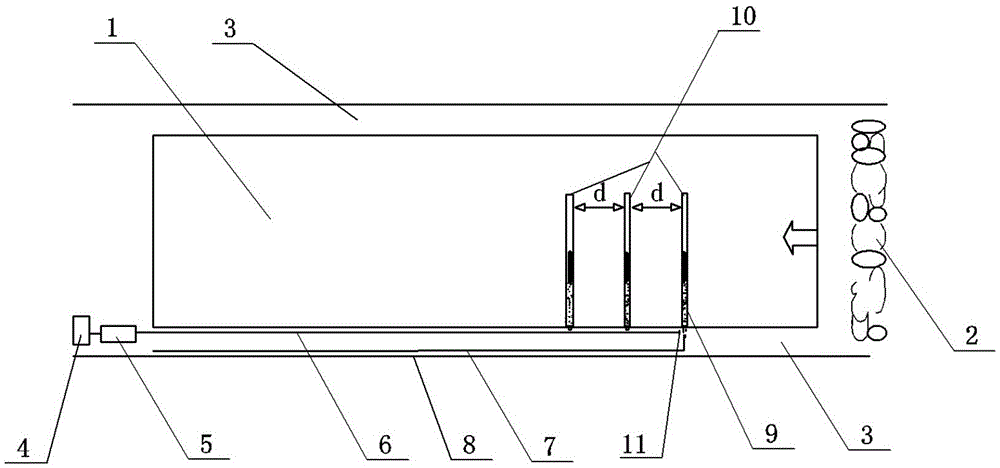

Method and device for determining liquid output rules of commingled producing well

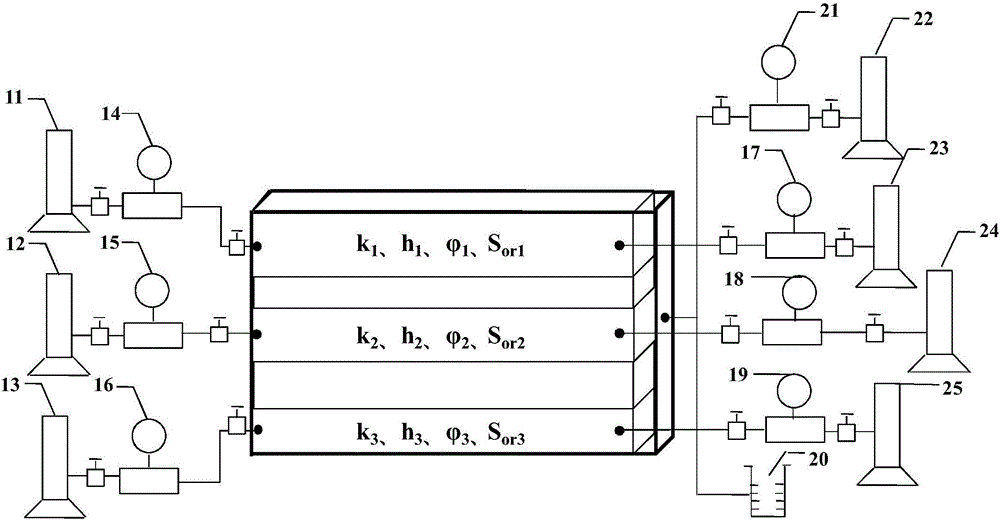

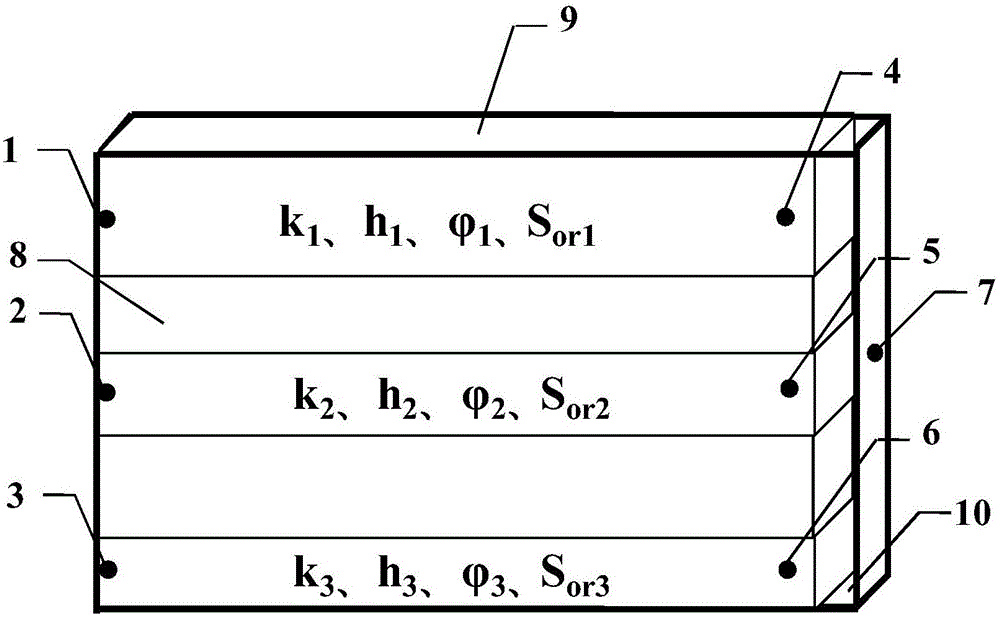

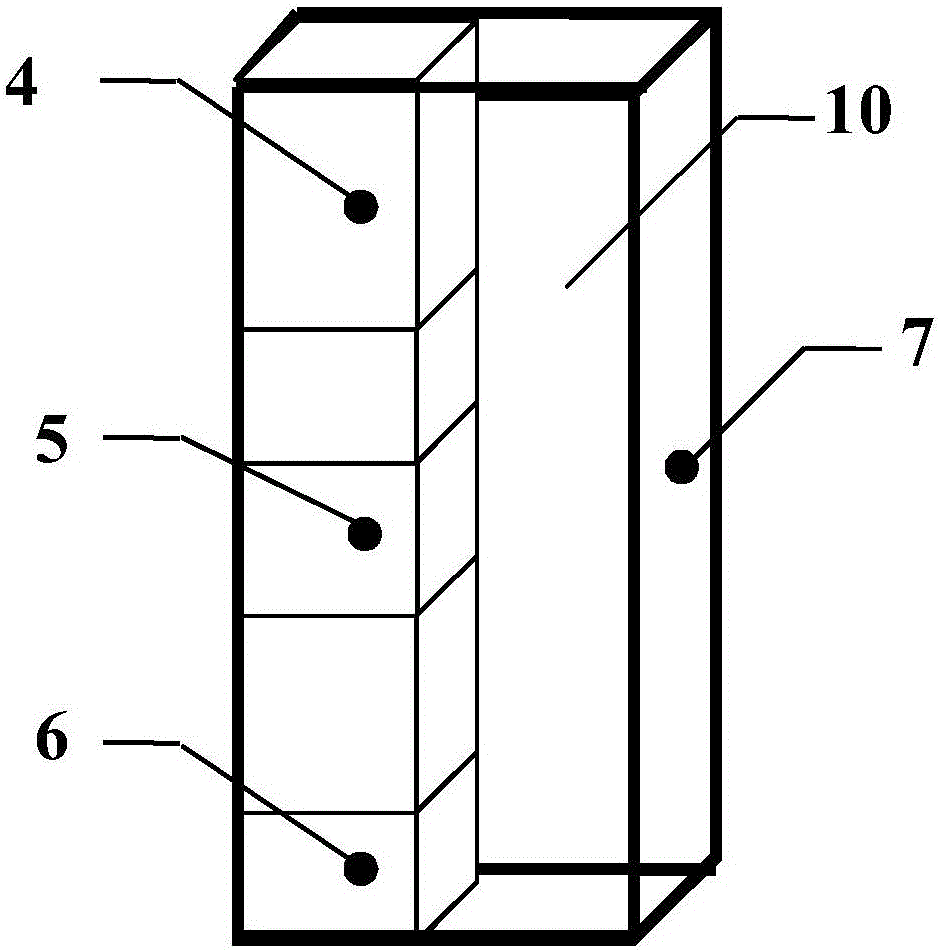

ActiveCN105840160AImprove water injection efficiencyHigh yieldSurveyFluid removalEngineeringPressure difference

The invention relates to a method and a device for determining liquid output rules of a commingled producing well and mainly aims at understanding layering liquid output rules of the commingled producing well and further improving the water injection efficiency. The device is characterized by comprising a multi-layer pore medium model, an injecting system and an output amount measuring system, wherein the injecting system and the output amount measuring system are connected with the left end and the right end of the multi-layer pore medium model respectively; the liquid output amount of each small layer can be calculated according to the pressure difference between an outlet end and an injecting end of each small layer in the model; a small hole is drilled in the connected center of a cavity at the right end of the model and an outer epoxy resin sleeve from right to left, and total outlet pressure and total liquid output amount of the multi-layer pore medium model are measured; by means of multiple experiments, relations between the ratio of the liquid output amount of each small layer in the multi-layer pore medium model to the total liquid output amount of the model and multiple influence factors including permeability, thickness, inlet and outlet pressure difference, kh / mu and the like can be obtained, a linear multivariate equation set is solved to determine coefficients of the multiple influence factors, and accordingly, the liquid output rule of each small layer in the commingled producing well is finally confirmed.

Owner:NORTHEAST GASOLINEEUM UNIV

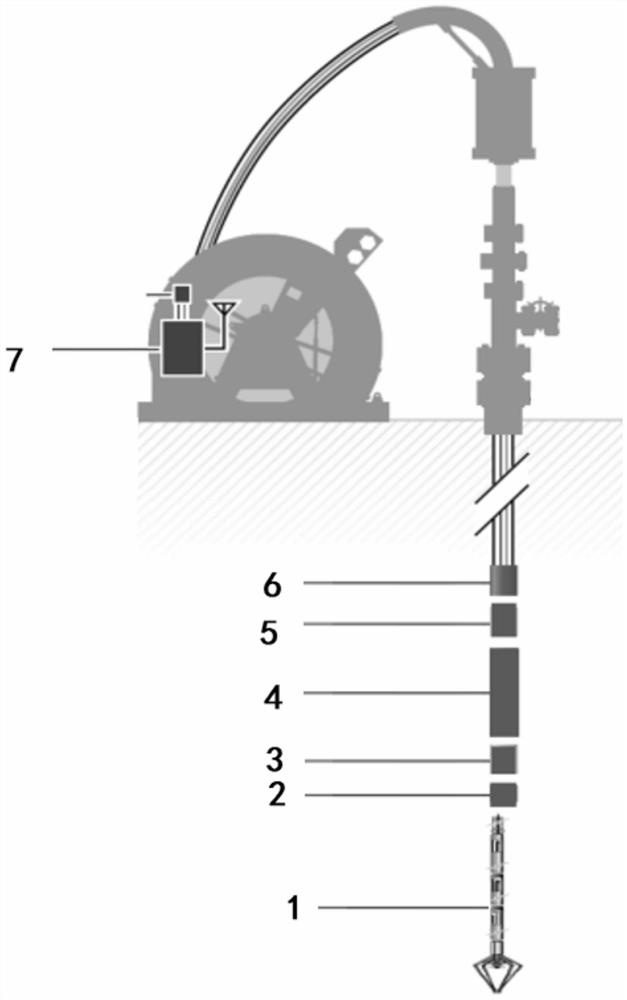

Multi-phase fluid measuring device for horizontal well

ActiveCN113431553AImprove water absorption indexImprove mining efficiencySurveyConstructionsHorizontal wellsTester device

The invention relates to a multi-phase fluid measuring device for a horizontal well. The multi-phase fluid measuring device comprises an underground visual imaging tester, a universal adapter, a releasing tool, an optical signal adapter, an electronic pressure gauge, a distributed optical fiber temperature sensor, an optical fiber connector, a coiled tubing connector and a central control unit; the underground visual imaging tester is used for measuring the output profile of underground fluid; the universal adapter is used for rotating the underground visual imaging tester; the releasing tool is connected with the universal adapter, and a weak point is arranged in the releasing tool; the optical signal adapter is used for converting a received electric signal into an optical signal and transmitting the optical signal through an optical fiber; the electronic pressure gauge is arranged below the optical signal adapter and is used for monitoring the flowing bottomhole pressure and transmitting monitored data to the optical signal adapter; the distributed optical fiber temperature sensor is used for measuring the temperature of a shaft and transmitting the measured temperature to the optical signal adapter; the optical fiber connector is connected with the optical signal adapter . The central control unit calculates injection-production parameters according to the flow velocity, the water holdup and the gas holdup to determine the water injection parameters of petroleum, the water injection efficiency is improved, and therefore the petroleum exploitation efficiency is improved.

Owner:大庆亿莱检验检测技术服务有限公司

Explosive-proof water bag with automatic water injection

The invention relates to the technical field of explosive-proof water bags, in particular to an explosive-proof water bag with automatic water injection. The explosive-proof water bag comprises bottomplates, supporting frames are fixedly connected to the upper sides of the bottom plates, a top plate is shared by and fixedly connected to the top ends of the two supporting frames, two height increase and decrease devices are symmetrically and fixedly connected to the lower sides of the bottom plates, a water injection plate is shared by and fixedly connected to the top ends of the two height increase and decrease devices, and multiple water bags are connected to the lower side of the water injection plate through hooks; a cavity is formed in the water injection plate, and a water outlet channel is formed in the lower side of the cavity. The explosive-proof water bag has the following advantages that the other ends of movable plates extrude triangular inclined blocks so that the triangular inclined block can move downwards, accordingly, vertical pillars drive plugging balls to overcome pull force of springs to move downwards, water in the cavity will flow downwards into the water bags through the water outlet channel, in this way, the function of water injection is realized without manual operation, the efficiency of water injection is effectively improved, and the explosive-proof water bag has application and popularization value.

Owner:盐城市吉平人造革有限公司

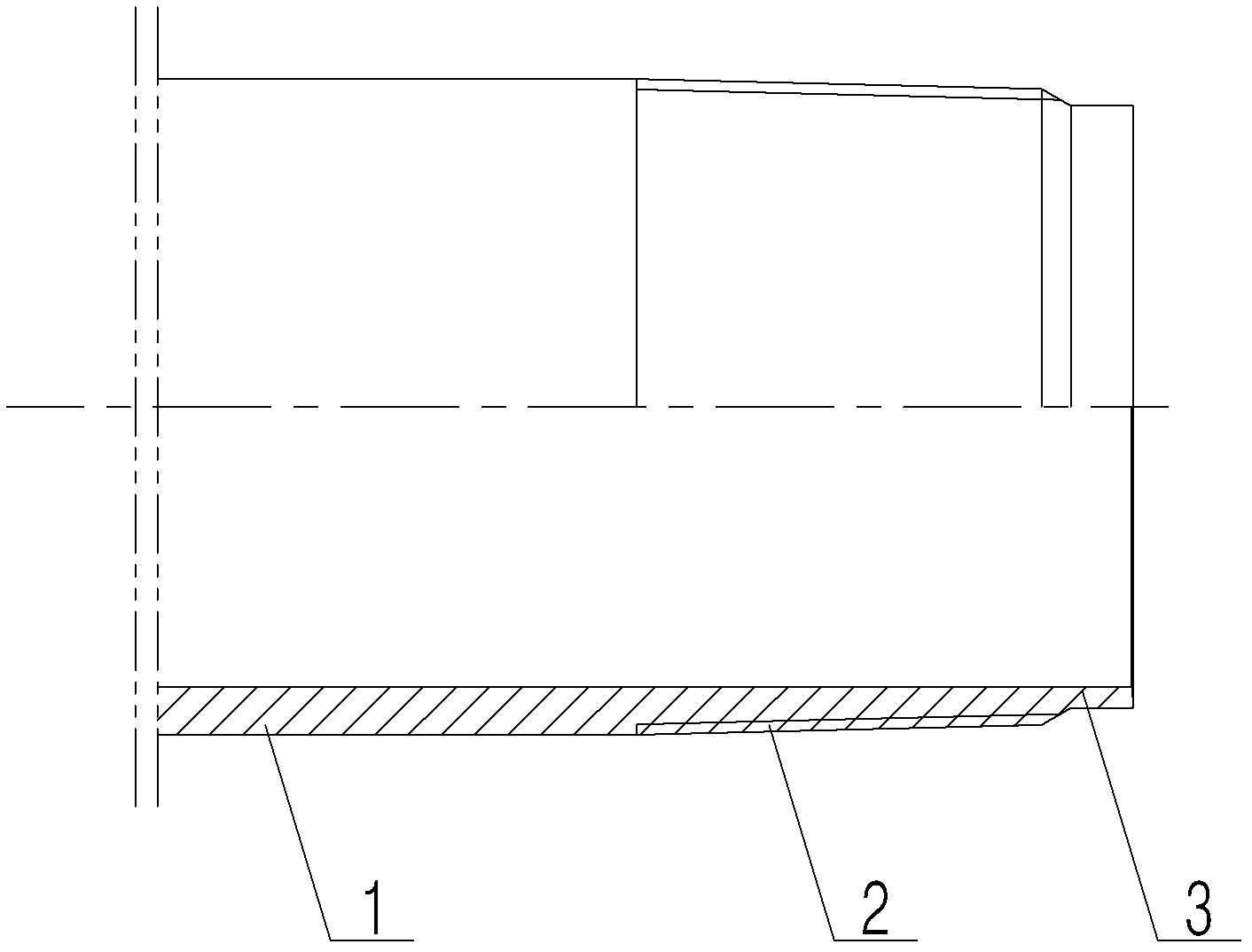

Double-closing and double-opening plugging device

ActiveCN110107266APrevent leakageEliminate backlashFluid removalWell/borehole valve arrangementsEngineeringScrew thread

The invention relates to a double-closing and double-opening plugging device in the field of oil field layered water injection tools. The double-closing and double-opening plugging device comprises anupper spout sleeve which is arranged in an upper screw shell in a floating sealed mode; the upper end of the upper spout sleeve is provided with a limiting step, and the lower end of the upper spoutsleeve abuts against a reset spring; an upper spout core is arranged in the upper spout sleeve, and the upper spout core and the upper spout sleeve are in sliding clearance fit in the circumferentialdirection; a radial water outlet is formed in the circumferential direction of the upper spout core, and the upper side, matched with the upper spout core, of the upper spout sleeve is provided with asealed conical surface in a matched mode in the circumferential direction; the upper part of the upper spout core is connected with an upper screw shaft, the upper screw shaft is inserted in the outer circumference of a main driving shaft in an axial sliding mode, and the outer circumference of the upper screw shaft is in threaded transmission connection with the upper screw shell; a lower spoutsleeve is fixedly arranged in a lower screw shell of the main driving shaft part, the inner circumference of the lower spout sleeve is provided with a lower spout core in a matched mode, a radial water outlet is formed in the circumferential direction of the lower spout core, and the upper part of the lower spout core is connected with a lower screw shaft in a rotation following mode; and the lower screw shaft is connected with the main driving shaft through a lower driving sleeve in a rotation following mode, the outer circumference of the lower screw shaft is in threaded transmission connection with the lower screw shell, the inner circumference of the lower part of the lower spout sleeve is provided with a matched conical surface, and the lower side of the lower spout sleeve is providedwith a cone valve assembly abutting against the matched conical surface in a matched mode.

Owner:CHINA PETROLEUM & CHEM CORP +2

Semi-automatic timely-guidance cleanser filling pipe for motor vehicles

InactiveCN103253237APrevent splashProtection securityVehicle cleaningLow-density polyethyleneCleansers skin

The invention relates to an automobile part, in particular to a semi-automatic timely-guidance cleanser filling pipe for motor vehicles. The semi-automatic timely-guidance cleanser filling pipe for motor vehicles comprises a guide membrane, a plurality of support ribs, a loop, a plurality of stainless steel wires, rotary shafts, a torsion spring, a slide, a slip ring, a pipe body, an upper limit ring, a sleeve, an upper ring magnet, a lower ring magnet, a lower positioning ring and a plurality of rotary shaft carriers. The rotary shaft carriers are disposed at the top end of the pipe body. Each rotary shaft carrier is fixed to one rotary shaft. The guide membrane made of low-density polyethylene is adhered to the inner surface of an umbrella frame composed of the support ribs. Stainless steel wires are evenly distributed on the outer periphery of the sleeve. When idle, the guide membrane is contracted on the outer wall of the pipe body; and the guide membrane can extend out to form a funnel shape timely and automatically. Therefore, the inner precious space of an engine hood is freed at normal times, and the guide membrane can be automatically positioned and formed as required by opening an orifice cover.

Owner:佘玲

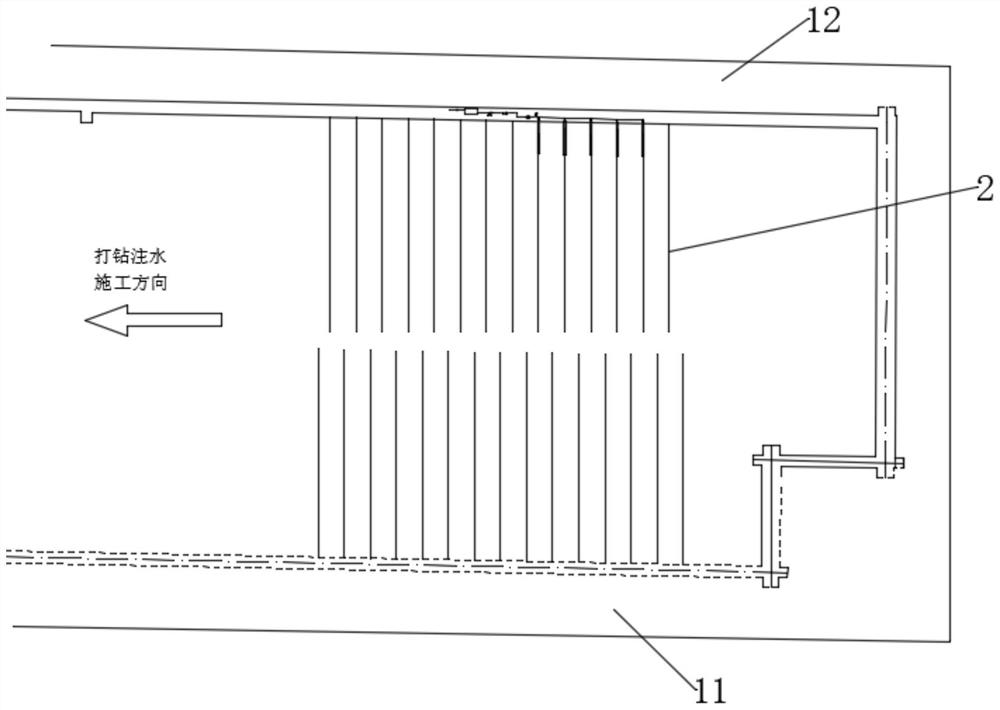

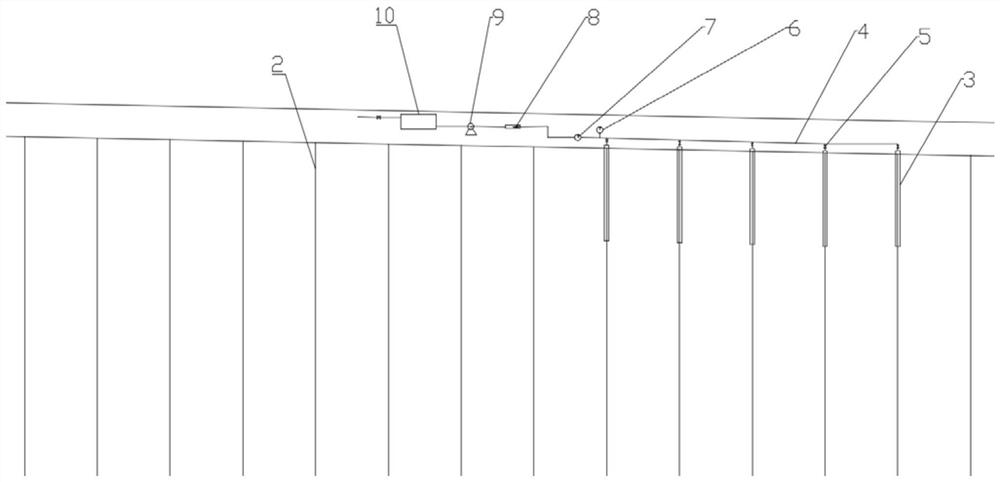

Roadway-mining face collaborative water injection structure for dust fall of coal mine and use method thereof

PendingCN113446049AReduce the amount of dust produced on the mining faceImprove wetting efficiencyDust removalFire preventionMining engineeringCoal

The invention discloses a roadway-mining face collaborative water injection structure for dust fall of coal mine. Water injection drill holes are formed in the sides, close to a coal seam, of an air inlet roadway and an air return roadway, the drill holes are single-row holes, the hole opening positions are located in the center line of a coal wall, the hole opening direction is along the dip angle of the coal seam, the horizontal angle is 0 degree, water injection pipes are installed in the drill holes, and hole sealing water injectors are fixed to the water injection pipes. The water injection method comprises the following steps that 1, roadway and mining face drilling construction and timely water injection are carried out, and the hole depth and the dip angle are adjusted according to the field condition; 2, a water injection hole is subjected to hole sealing treatment; and 3, a water injection main pipeline flowmeter is installed on site, and water is injected into the water injection holes through the water injector according to a water injection scheme. The method can effectively wet the coal body, reduce the dust yield of the mining face, improve the water injection efficiency of the coal seam, and inhibit the generation of dust from the dust production source.

Owner:平顶山天安煤业股份有限公司十二矿 +1

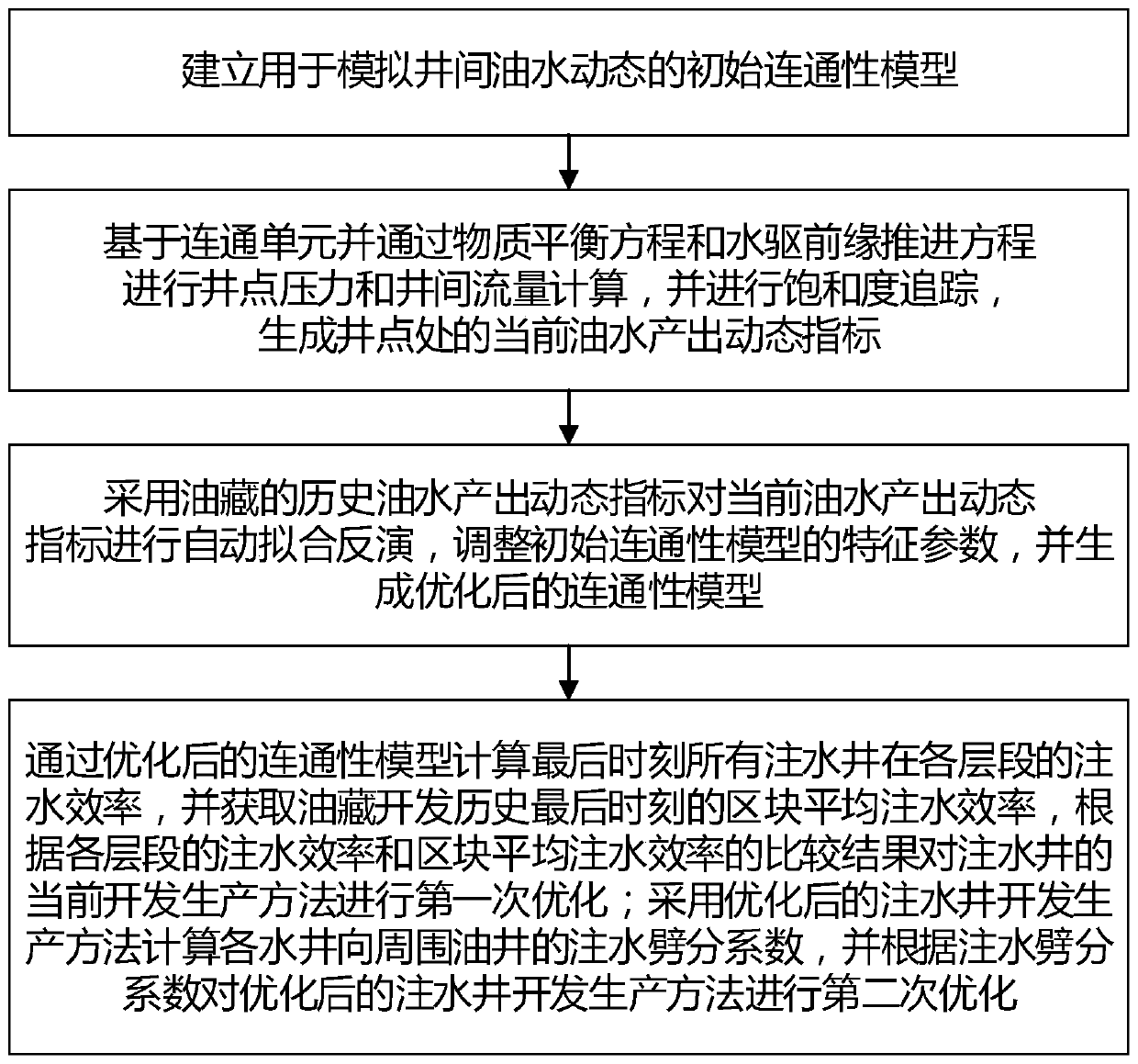

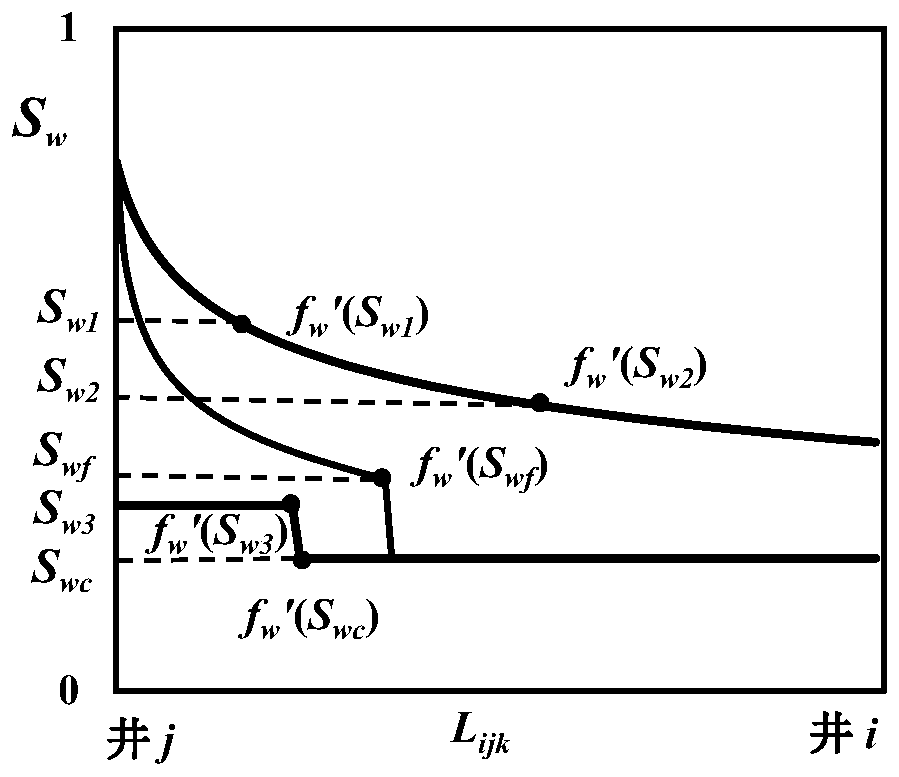

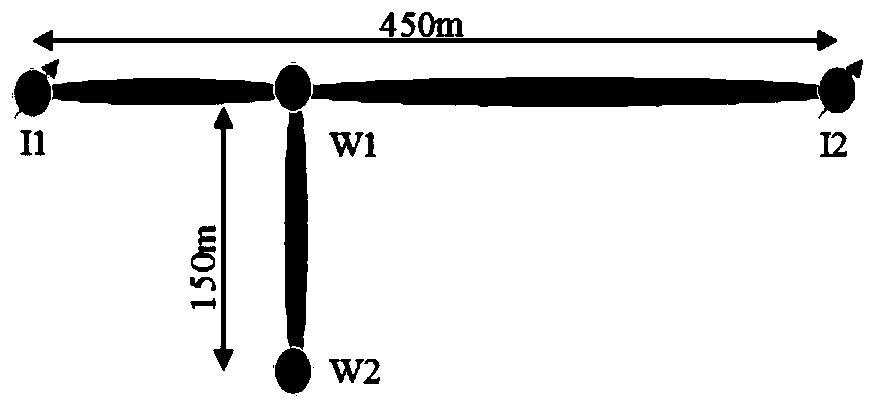

A Reservoir Development and Production Optimization Method and System Based on Connectivity Method

ActiveCN108868712BAccurate dynamic indicatorsImprove the development effectFluid removalDesign optimisation/simulationProduction optimizationCommunication unit

The invention relates to a production method of an oil deposit, in particular to an oil deposit development production optimization method and system based on a connectivity method. The method comprises the steps that saturation calculation is conducted by taking inter-shaft communication units as objects to establish a precise front edge tracking method to obtain oil-water dual-phase production dynamics of each layer at shafts; information of inter-shaft conductivity, flow splitting, water injection efficiency and the like is obtained by inverting connectivity model parameters though automatically fitting oil deposit historical dynamics, and the information is taken as the basis to perform layered dynamic production allocation and injection allocation automatic optimizing design on the oil deposit through iterative computation to reduce low-efficiency water drive direction flow and improve injection-exploitation conflict. Application examples show that the method can perform rapid computation, accurate saturation tracking and production dynamics computation, an obtained layered water injection scheme can well achieve a water reducing and oil increasing effect, 50,000 cubic metersof predicted oil increasing after actual optimization of the oil deposit is conducted is achieved, and a novel idea for performing real-time optimization on an oil field injection-exploitation schemeis provided.

Owner:YANGTZE UNIVERSITY

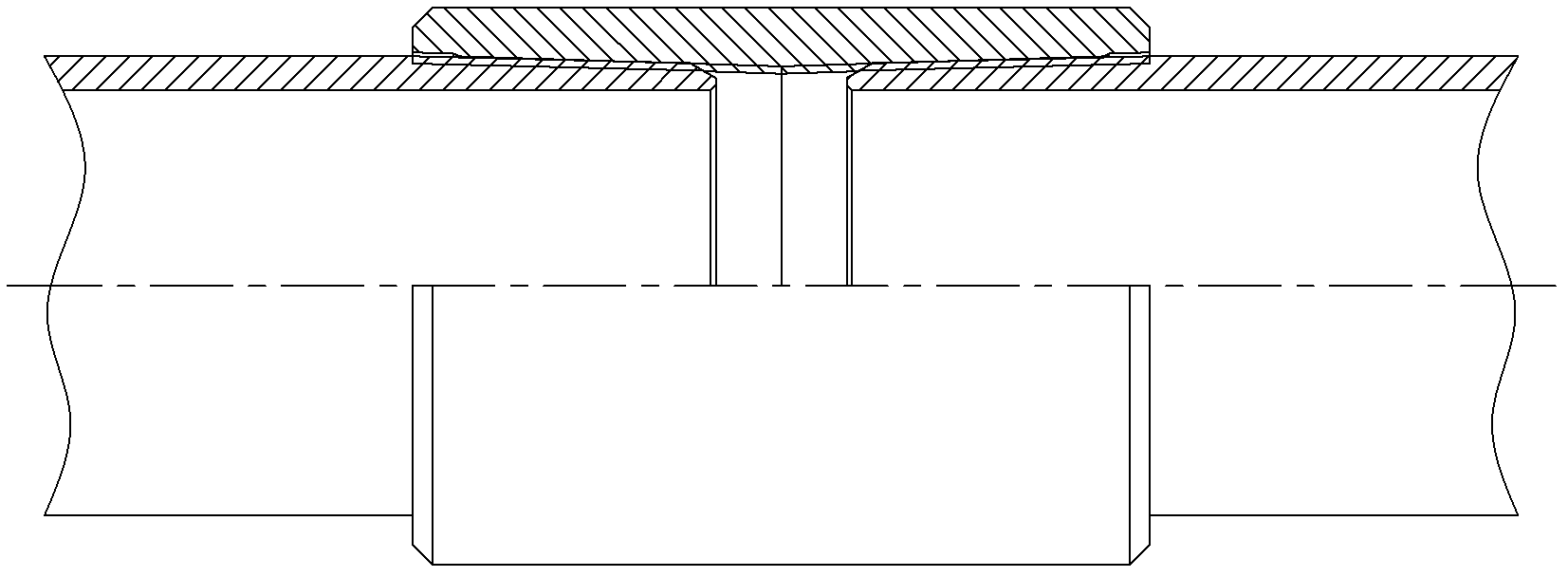

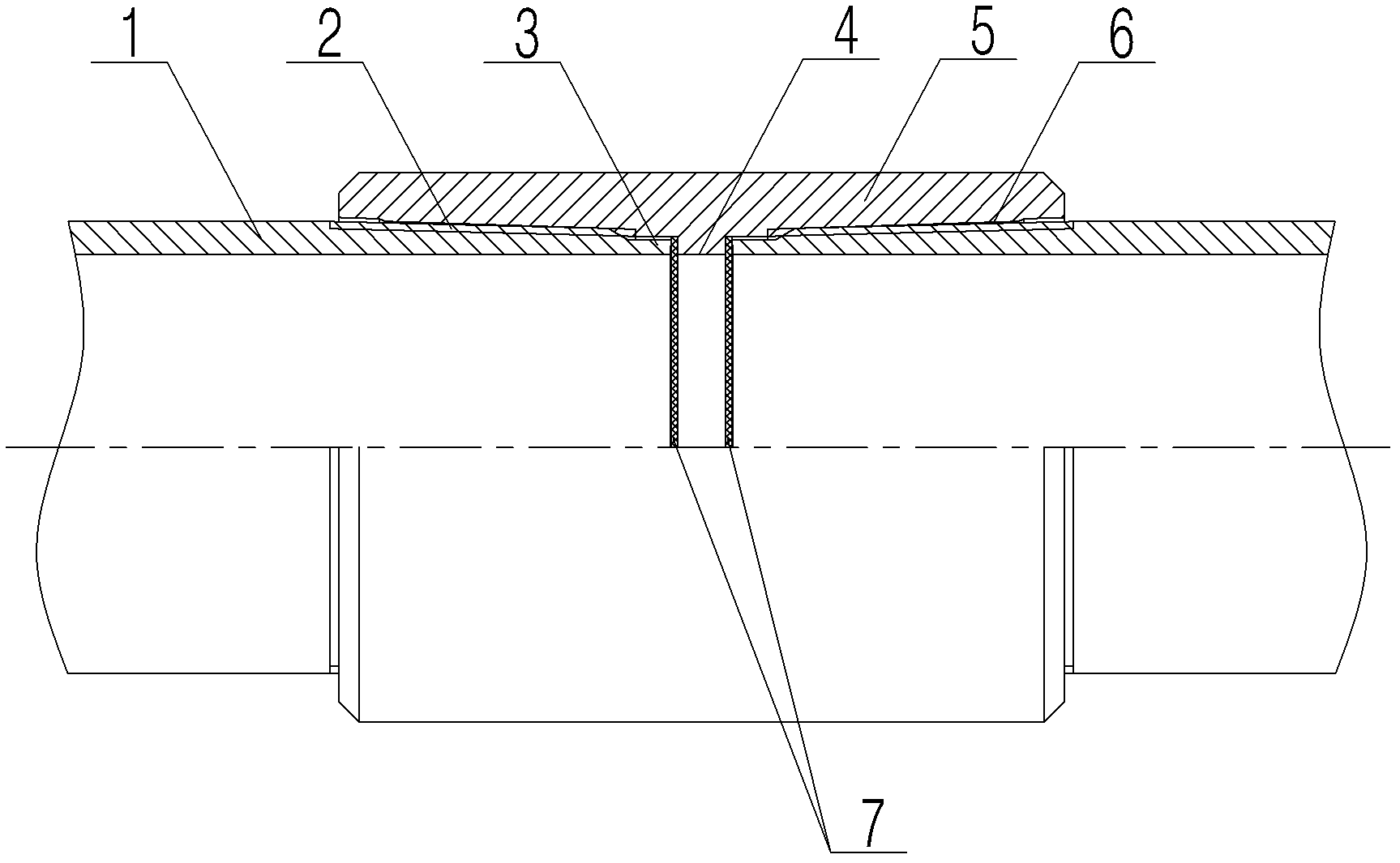

A water injection pipe for offshore water injection wells

InactiveCN102278073AExtend continuous working life Working lifeEliminate the effects ofDrilling rodsFluid removalCouplingWorking life

The invention discloses a water injection pipe for an offshore water injection well, which comprises a pipe body provided with external threads at both ends, the pipe bodies are connected by couplings provided with internal threads, and the ends of the external threads of the pipe are provided with The axially elongated nose of the body, the inner wall in the middle of the coupling is provided with a radial inner boss, the thickness of the nose is consistent with the height of the radial inner boss, so that the inner diameter of the water injection pipe is consistent; the radial inner boss of the collar is consistent with the height of the radial inner boss A polytetrafluoroethylene gasket is arranged between the nose ends of the pipe body; an epoxy resin protective layer is arranged on the inner wall of the pipe body and the radially inner boss surface of the collar. The present invention adopts a pipe body thread structure with a nose end and a coupling structure with a radially inner boss, so that the inner diameter of the water injection pipe is completely consistent, effectively eliminating the influence caused by the eddy current, and preventing severe erosion and large-scale scaling , Extend the continuous working life of the water injection pipe, improve the water injection efficiency, increase the water injection volume, increase the formation pressure, reduce the frequency of downtime and maintenance, and reduce the production cost.

Owner:CHINA NAT OFFSHORE OIL CORP +1

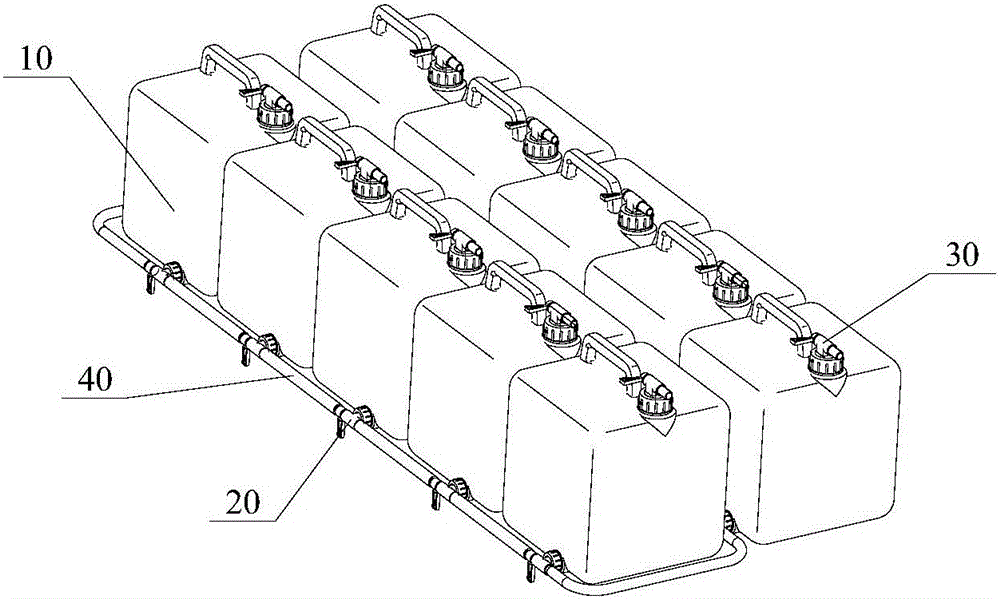

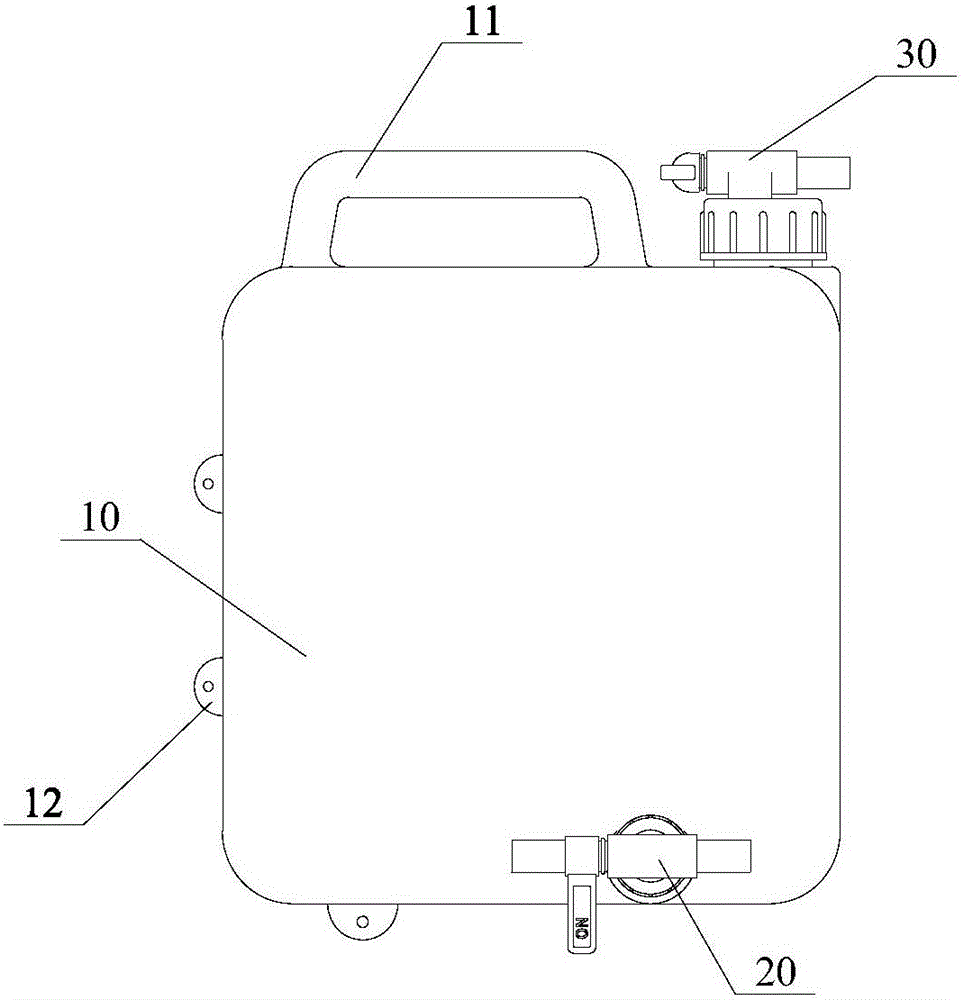

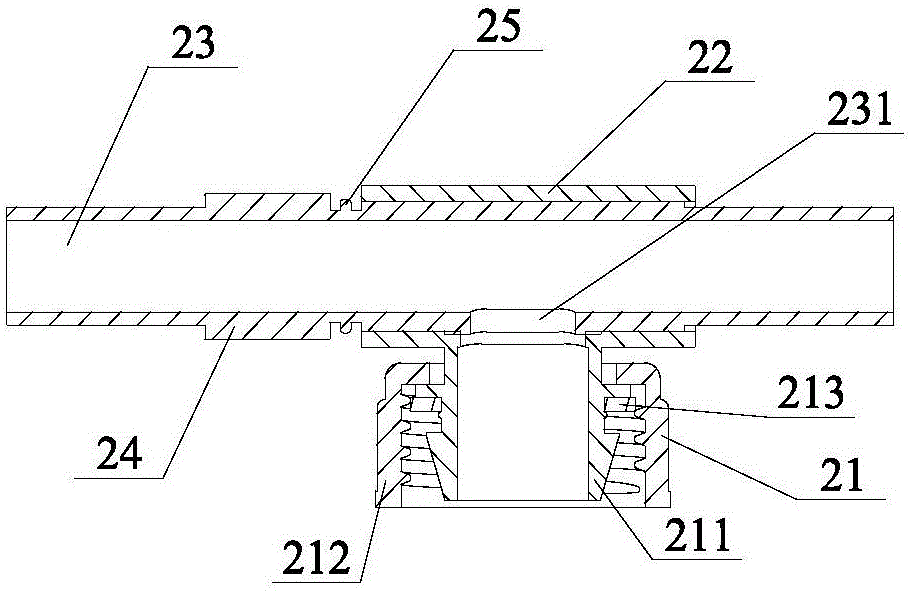

Assembling type foldable kettle assembly

ActiveCN105966730ASuitable for reserveSuitable for transportationRigid containersWater basedWater source

The invention discloses an assembling type foldable kettle assembly. The assembling type foldable kettle assembly comprises a plurality of foldable kettles. Water injection ports are formed in the top surfaces of the kettles, water outlets are formed in the bottoms of the kettles, detachable first valves are arranged on the water outlets, matched communicating pipes are arranged at the two ends of the first valves, and the kettles are connected through the communicating pipes. According to the assembling type foldable kettle assembly, the foldable kettles are adopted and can be conveniently transported to various destinations, the kettles are communicated through the communicating pipes, the foldable kettles can be assembled according to the needed capacity after being transported to the destinations, transportation is convenient, and flexibility is high; in the water injection process, it is only needed to inject water into one or more kettles, and the other kettles can be successively full of water based on the communicating vessel principle; besides, water injection can be carried out after the kettles are assembled on a transport cart or other equipment, the problems that water is injected into existing kettles one by one and carrying is carried out only after water injection is completed are solved, and thus water injection efficiency and carrying efficiency are greatly improved; the assembling type foldable kettle assembly is simple in structure, easy to operate, low in production cost and very suitable for storage and transport of large-capacity water sources.

Owner:杜朗

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com