Patents

Literature

45results about How to "Improve wetting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

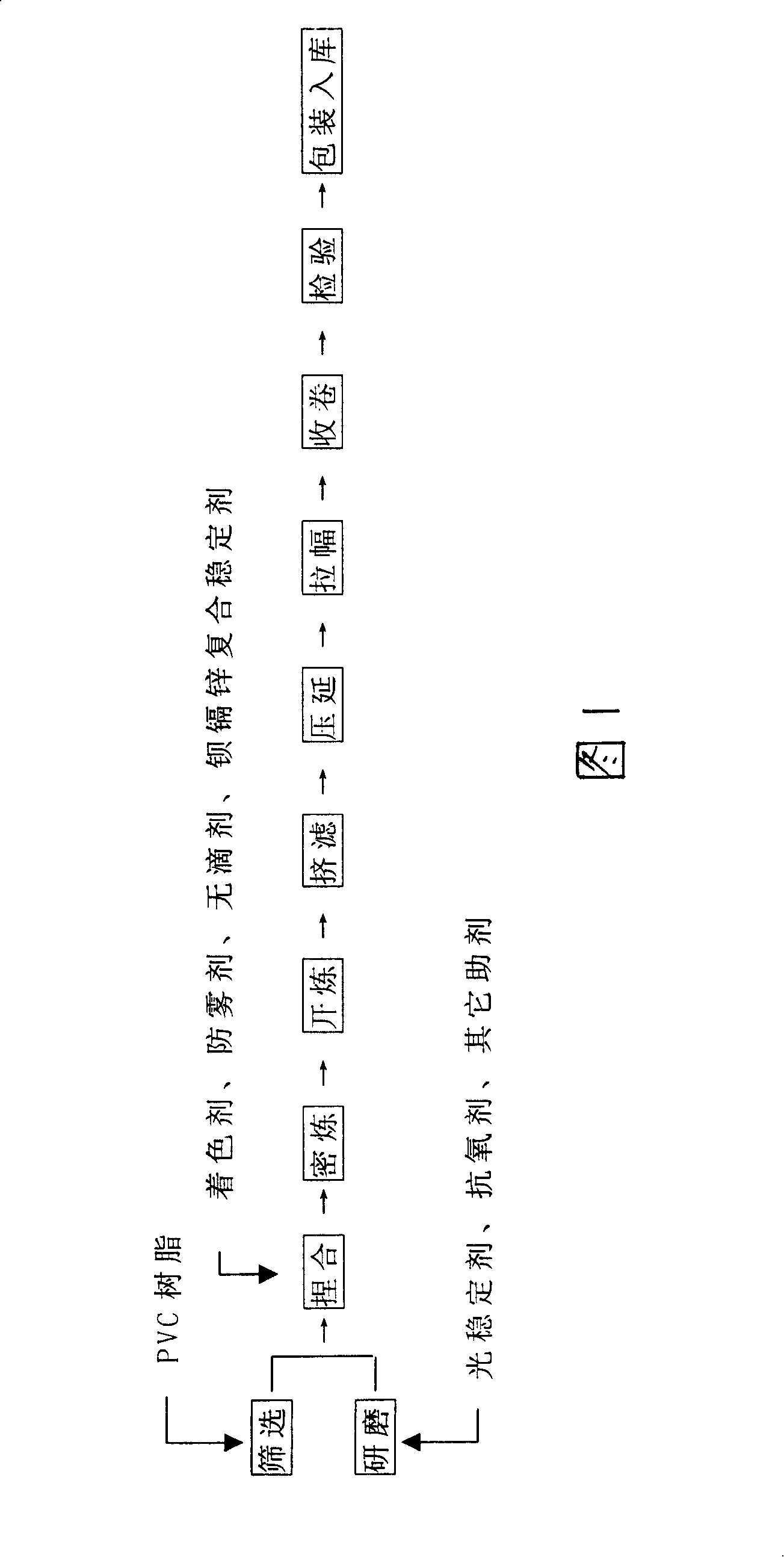

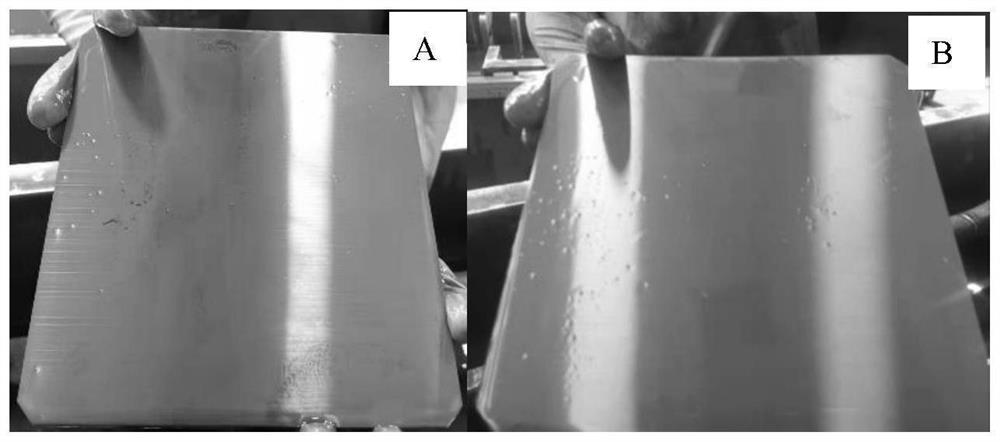

Polychloroethylene antifog non-drop greenhouse film

The invention relates to a transparent covering material for solar greenhouse in winter and for plastic greenhouse in early spring, in particular to a polyvinyl chloride antifogging dripless greenhouse film which can prevent from fogging in the greenhouse and enables the water drops in the condensed in the internal surface of the greenhouse film to wet and spread quickly. The polyvinyl chloride antifogging dripless greenhouse film adopts polyvinyl chloride resin as the base, adding plasticizer, heat stabilizer, ultraviolet absorbent, compound dripless agent and organosilicon antifogging agent into the polyvinyl chloride resin, and being prepared through calendering, stentering and other production process steps. The transparent covering material for solar greenhouse in winter and for plastic greenhouse in early spring has the advantages of good dripless antifogging effect, improvement of light transmittance for greenhouse film, incensement of light intensity, beneficial photosynthesis for crops, beneficial improvement of greenhouse temperature, acceleration of crops growth, and reduction of disease occurrence.

Owner:白山市喜丰塑业有限公司

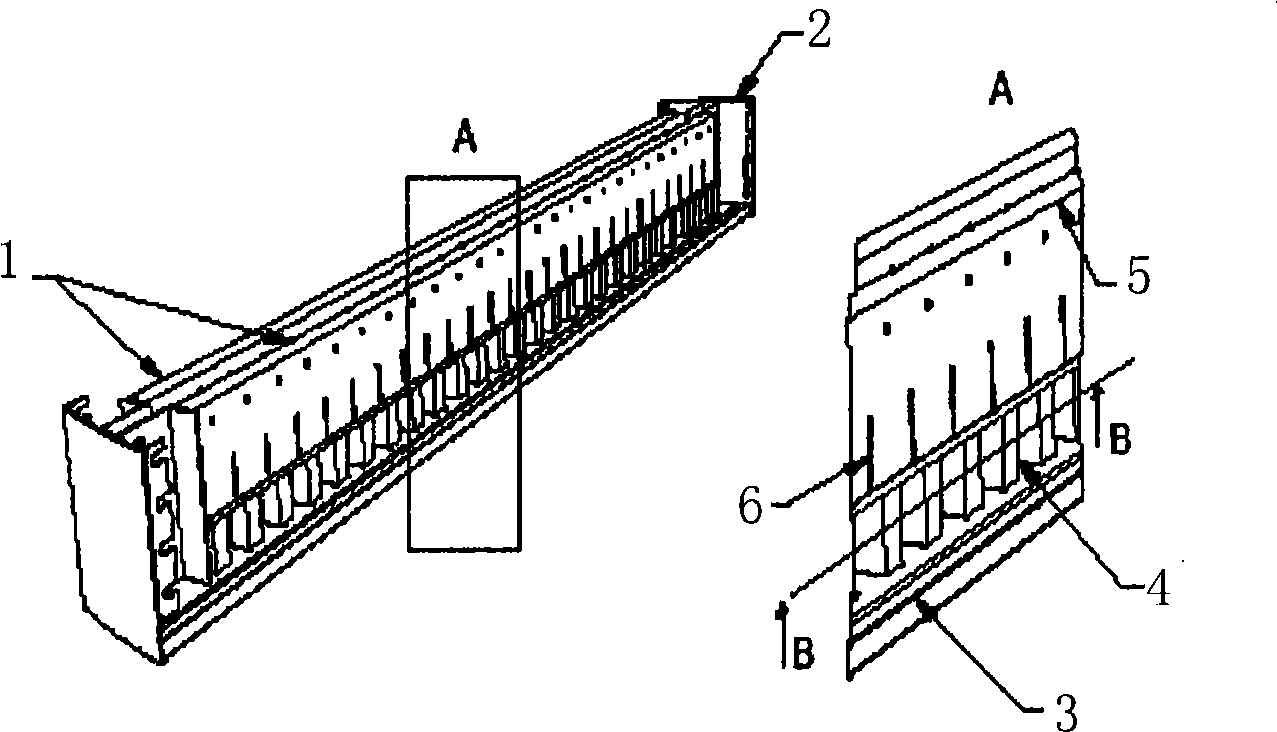

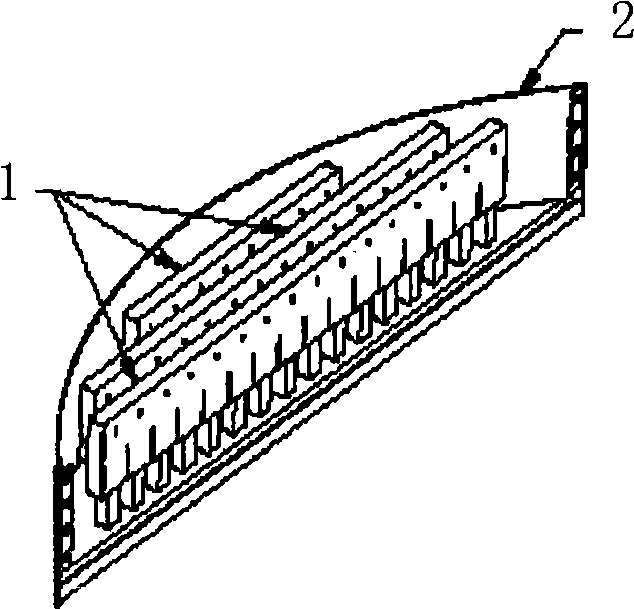

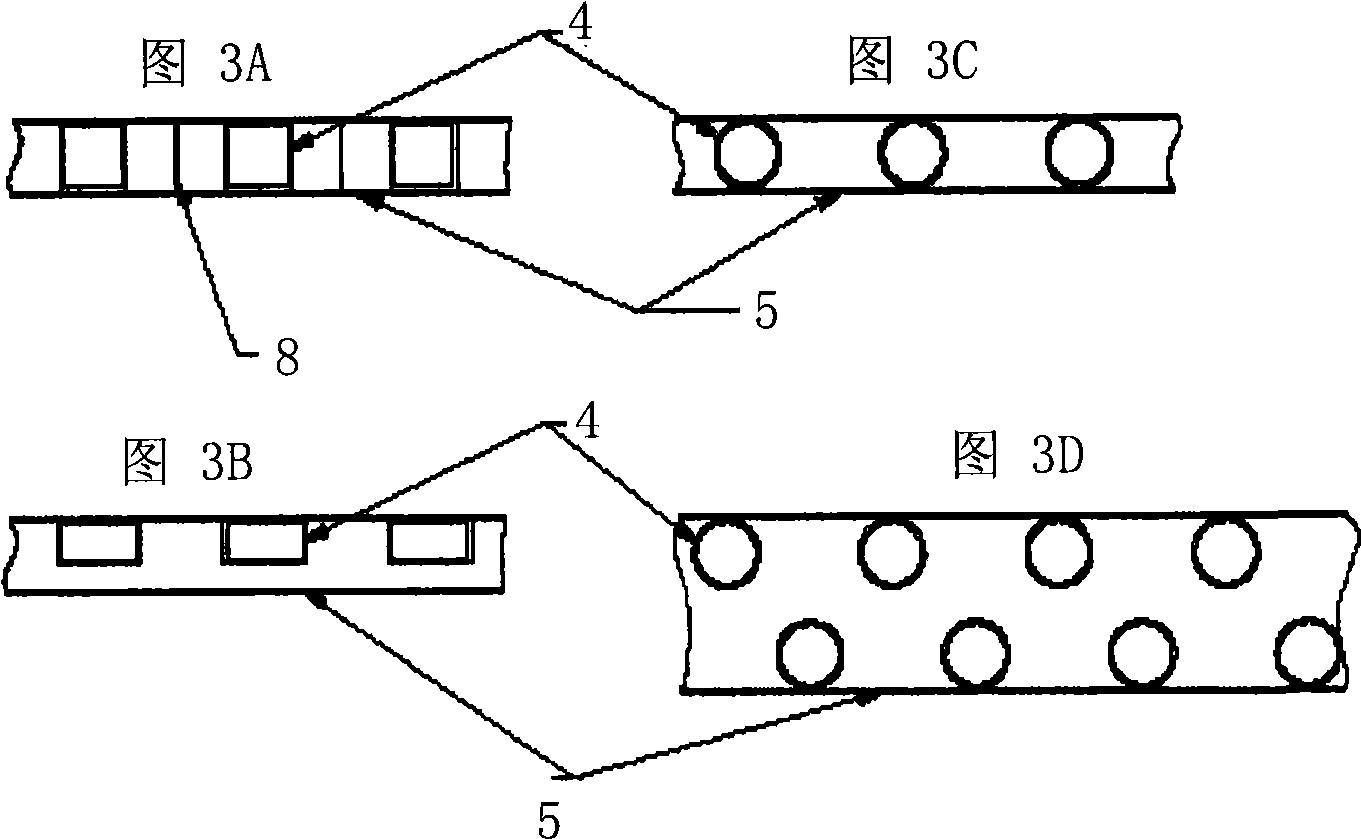

Vapour-liquid distribution device

ActiveCN101480535AOptimize allocationImprove wetting efficiencyTransportation and packagingMixing methodsEngineering

A liquid-vapour distribution device for use in two-phase stream concurrent down-flow vessels comprising: a plurality of BOXVLTs fabricated in form of self-supporting structures (beams) and tray panels when installed forms a tray which will be essentially leak free at the junctions and between the tray and the vessel wall; said horizontal self-supporting structure consisting of a bottom plate being perforated with at least one row of apertures of equal size, wherein each aperture is fitted with an elongated down-flow channel (downcommer) being in form of a tube or any other geometric shape with the same geometrical cross sectional shape as the apertures in said beam and the down-flow channel is provided with an inlet for the concurrent two-phase stream, and wherein at least two of said down-flow channels are fitted with a common riser cap being attached to and along at least one wall portion of each down-flow channel and mounted over and spaced apart the inlet of the down-flow channel.

Owner:HALDOR TOPSOE AS

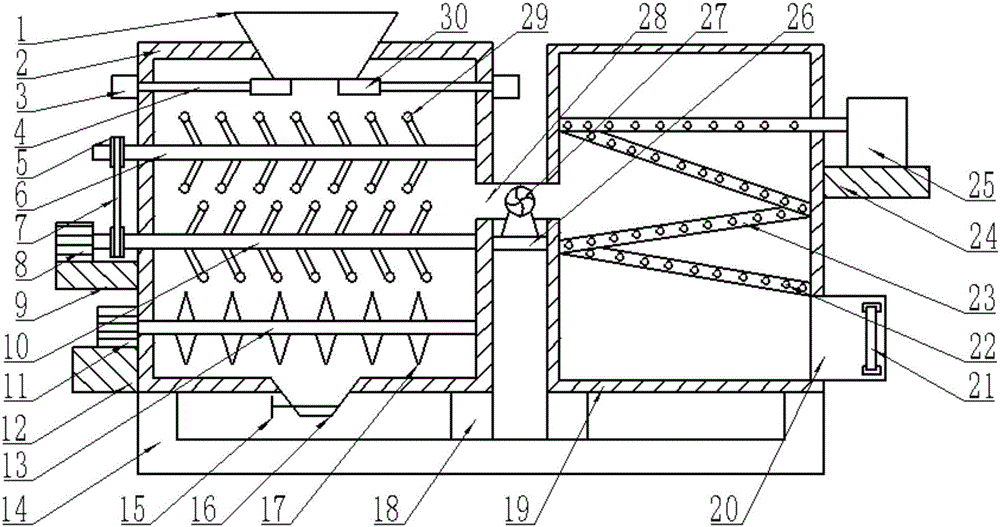

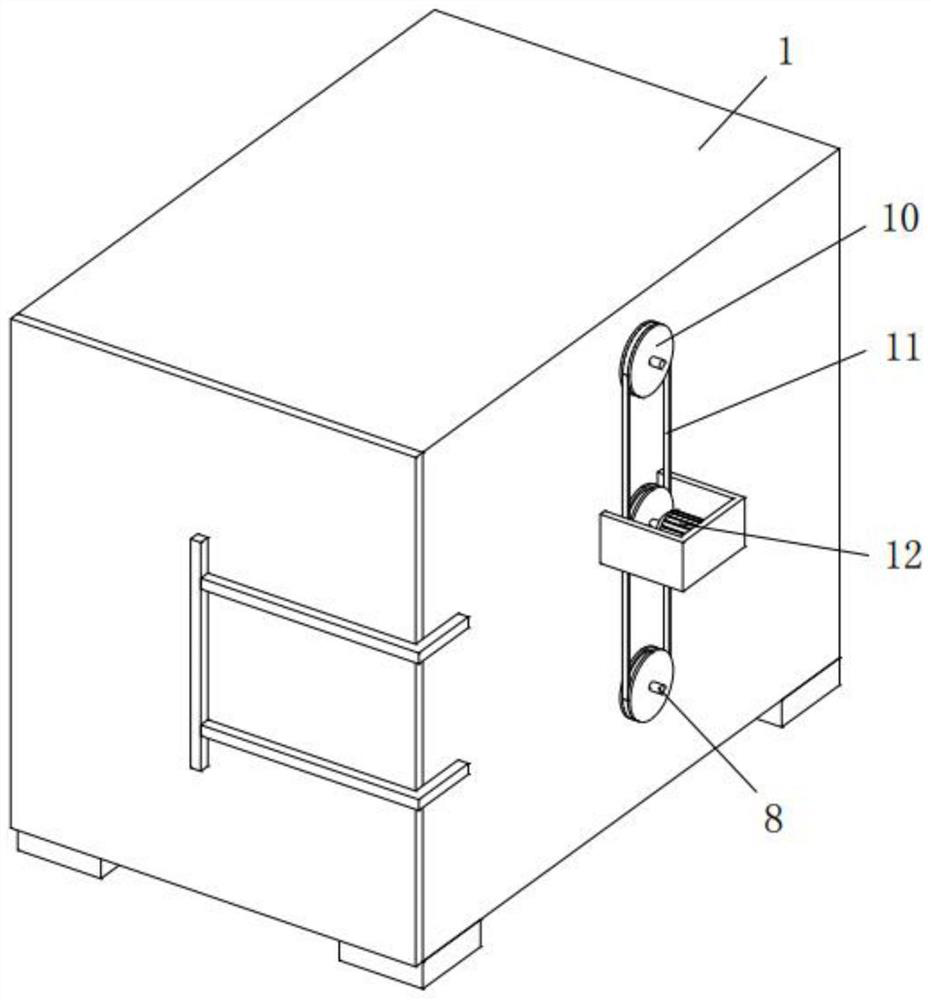

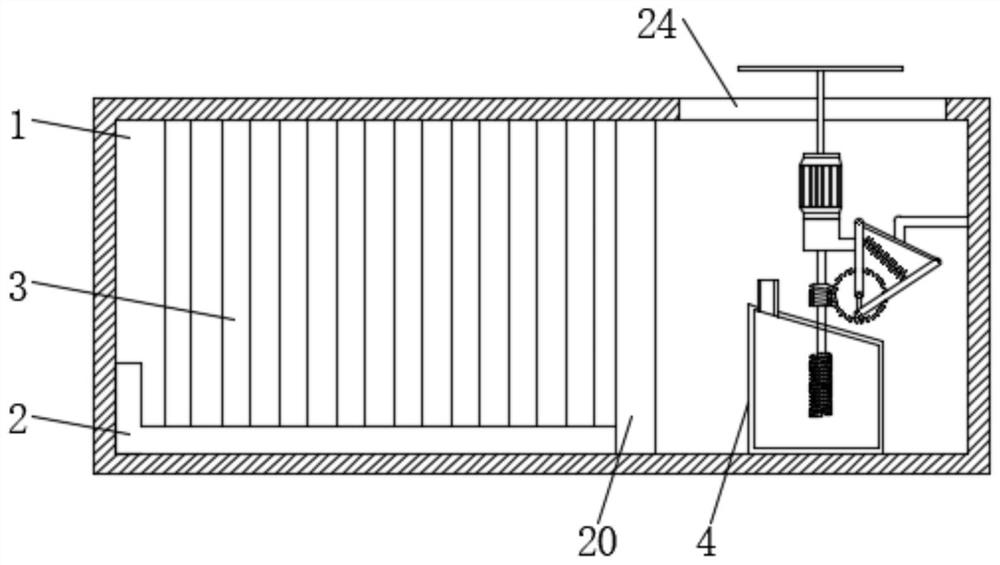

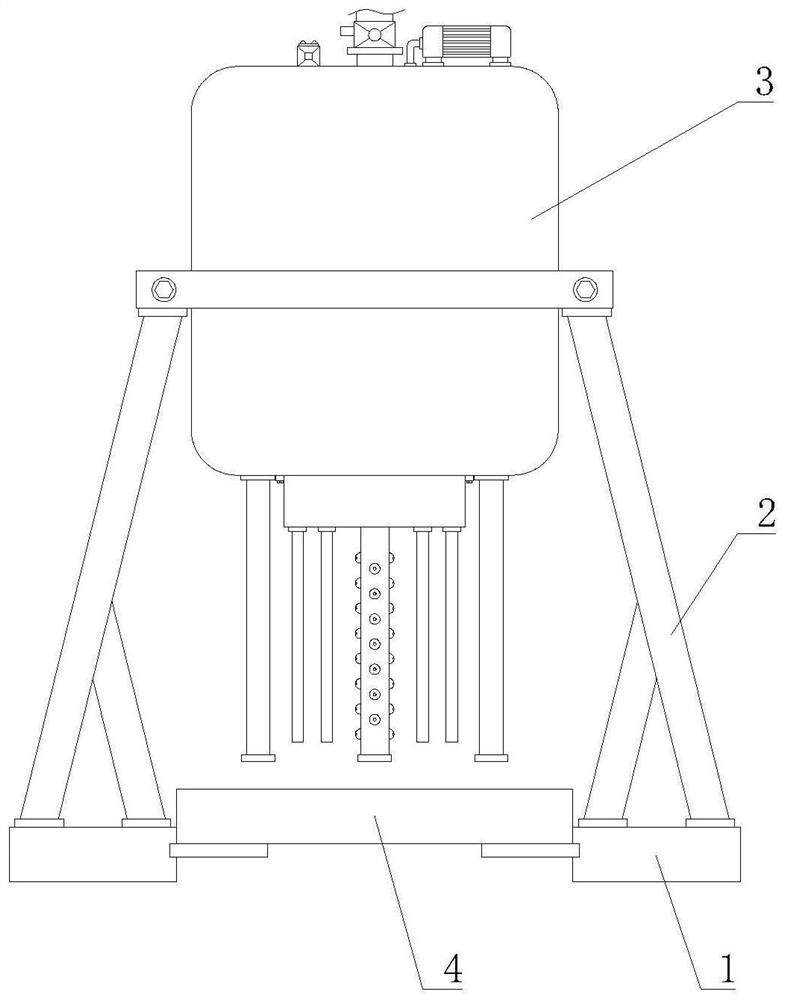

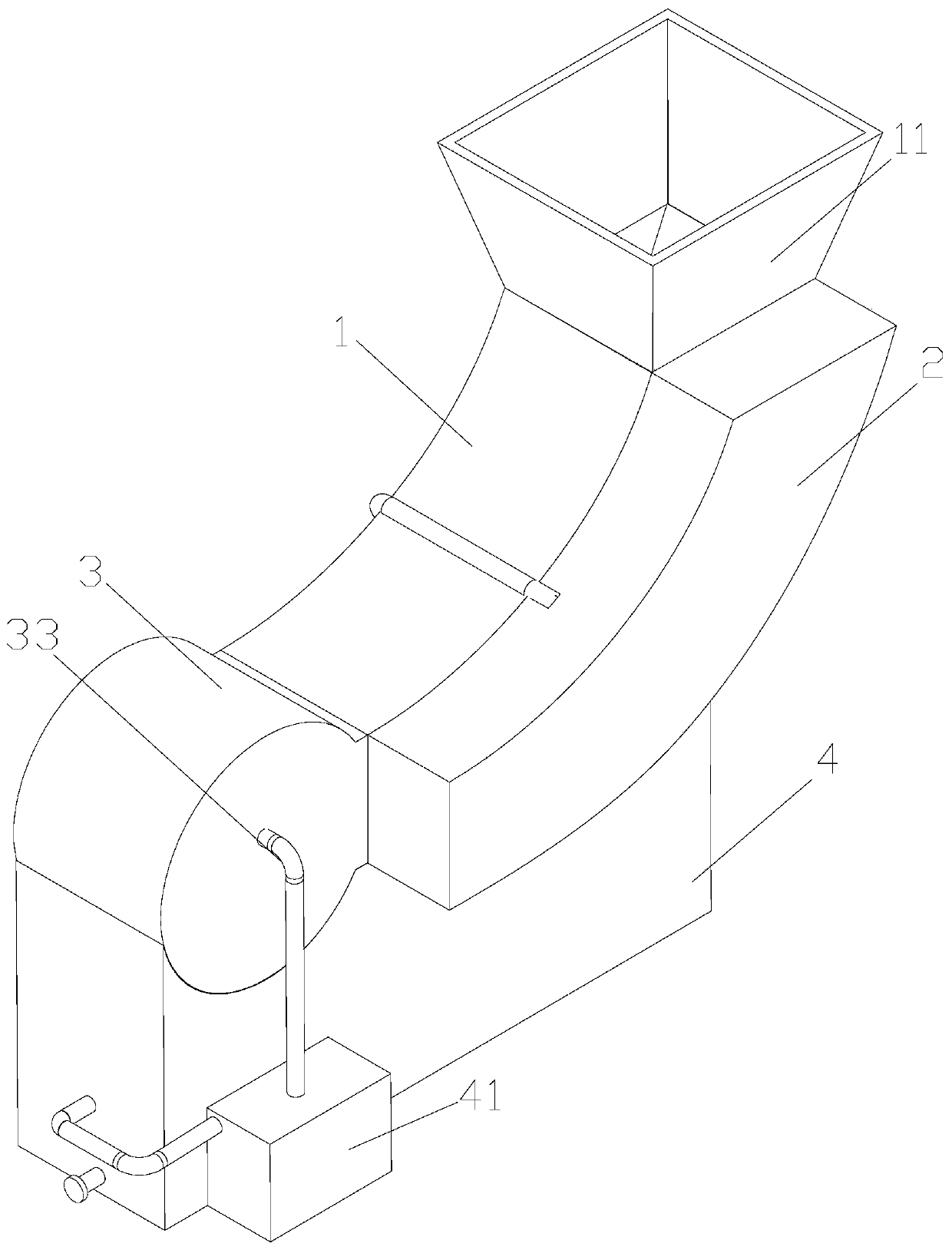

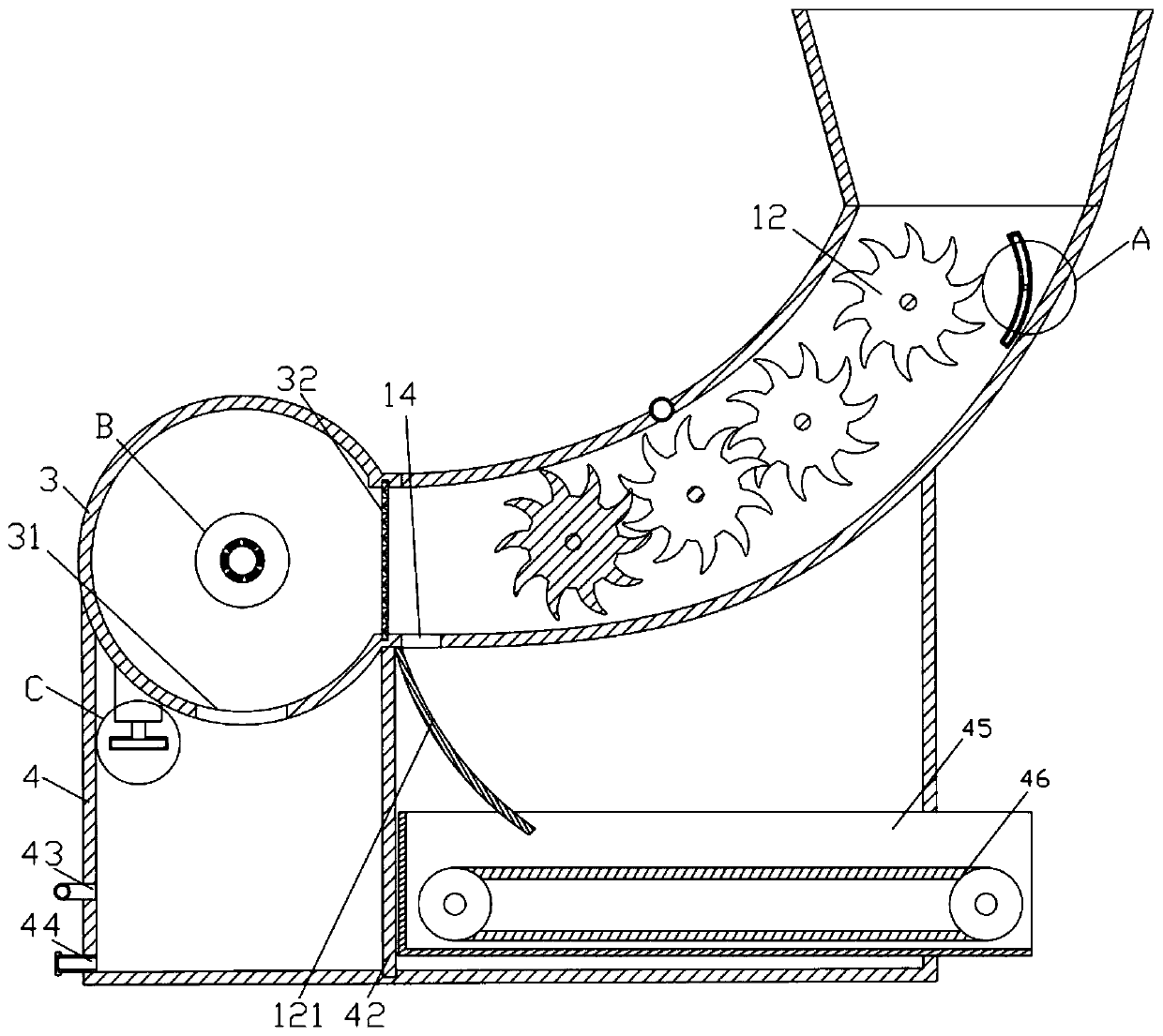

Coal gangue crushing and dust collection device

InactiveCN106733041AAvoid damageIncrease contact areaUsing liquid separation agentGrain treatmentsInlet channelPulley

The invention provides a coal gangue crushing and dust collection device. The coal gangue crushing and dust collection device comprises a crushing tank, a base and a dust collection tank. The crushing tank is provided with a feed hopper, air cylinders, a first driving motor, a first carrying plate, a second driving motor, a second carrying plate and a discharge port. The first driving motor is fixed to the first carrying plate. A lower rotary shaft and a belt pulley are arranged on the first driving motor. The second driving motor is placed on the second carrying plate. The right end of the second driving motor is provided with a crushing shaft. The base is arranged on the ground. Supporting legs are arranged on the base. The dust collection tank is provided with a tank door and a third carrying plate. A dust inlet channel is formed between the dust collection tank and the crushing tank. The third carrying plate is fixed to the right end of the dust collection tank and the upper end of the tank door in a welded mode. A water tank is arranged on the third carrying plate. The dust inlet channel is connected with the crushing tank and the dust collection tank. A draught fan is arranged in the dust inlet channel. The coal gangue crushing and dust collection device has the advantages that crushing is thorough, particles are uniform, the crushing speed is high, the efficiency is high, and dust collection is convenient.

Owner:郑州吉音动漫科技有限公司

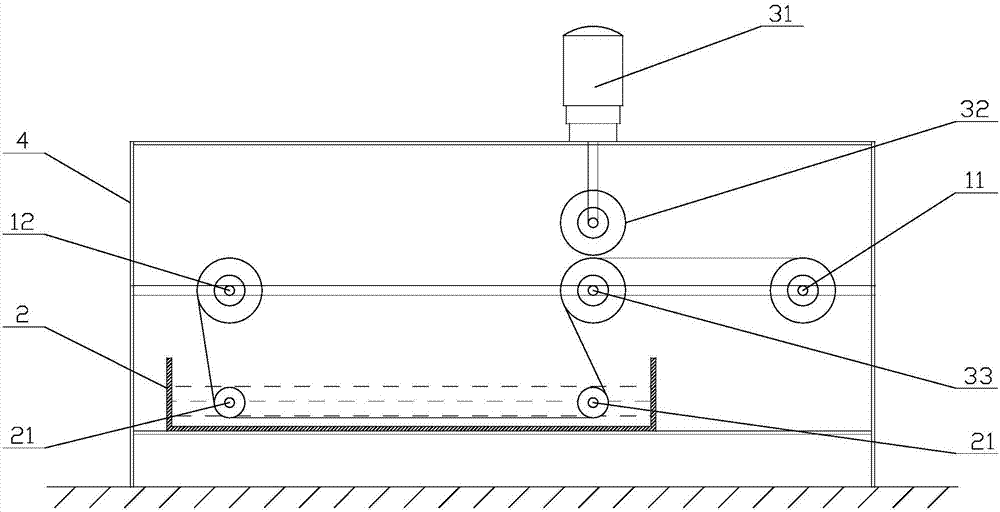

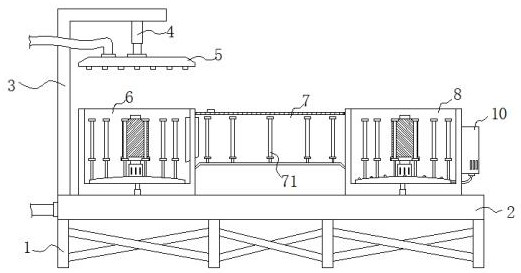

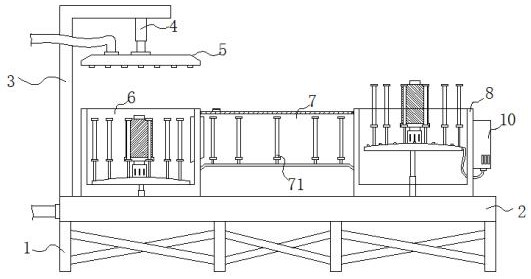

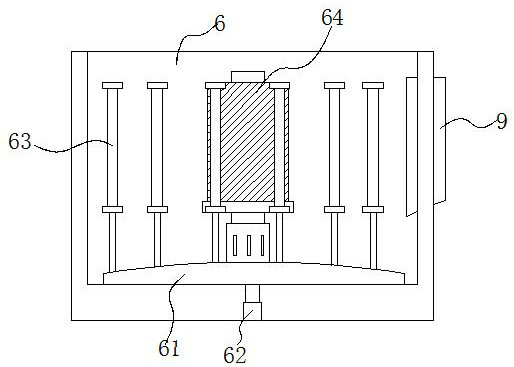

Printing and dyeing pre-wetting device

InactiveCN107964745AAvoid spillingEvenly pre-wetLiquid/gas/vapor removal by squeezing rollersTextile treatment carriersPulp and paper industryEngineering

Provided is a printing and dyeing pre-wetting device. The device relates to the field of printing and dyeing equipment, and particularly relates to a printing and dyeing pre-wetting device. Provided is a printing and dyeing pre-wetting device, of which the time of pre-wetting process is short and the pre-wetting is uniform. A pair of twitch rollers are divided into a driving twitch roller and a driven twitch roller, the driving twitch roller and the driven twitch roller are respectively fixed at two ends of a support, a motor drives the driving twitch roller, a squeezing device and a pre-wetting groove are respectively fixed on the support, the bottom of the pre-wetting groove is provided with an ultrasonic vibrator and a heater, and a pair of squeezing rollers are formed above the pre-wetting groove. The squeezing device comprises a first squeezing roller and a second squeezing roller, the first squeezing roller is driven by a hydraulic pressure device fixed on the support, the secondsqueezing roller is fixed on the support, and the first squeezing roller moves up and down relative to the second squeezing roller. The printing and dyeing pre-wetting device has the advantages thatthe time of pre-wetting process is short, pre-wetting is uniform, the processing steps are reduced, and the processing efficiency is improved.

Owner:扬州永圣机械装备科技有限公司

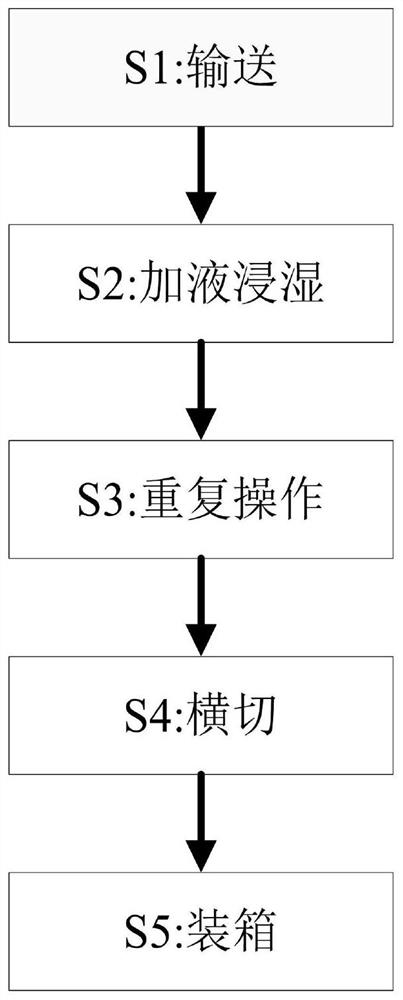

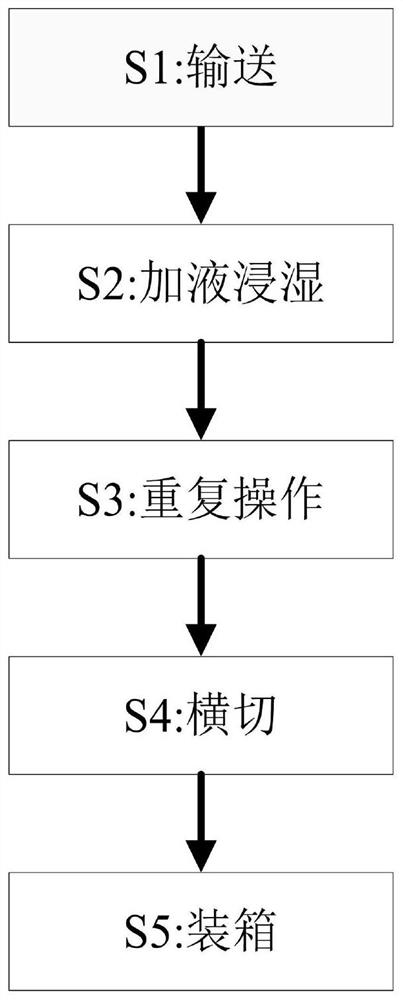

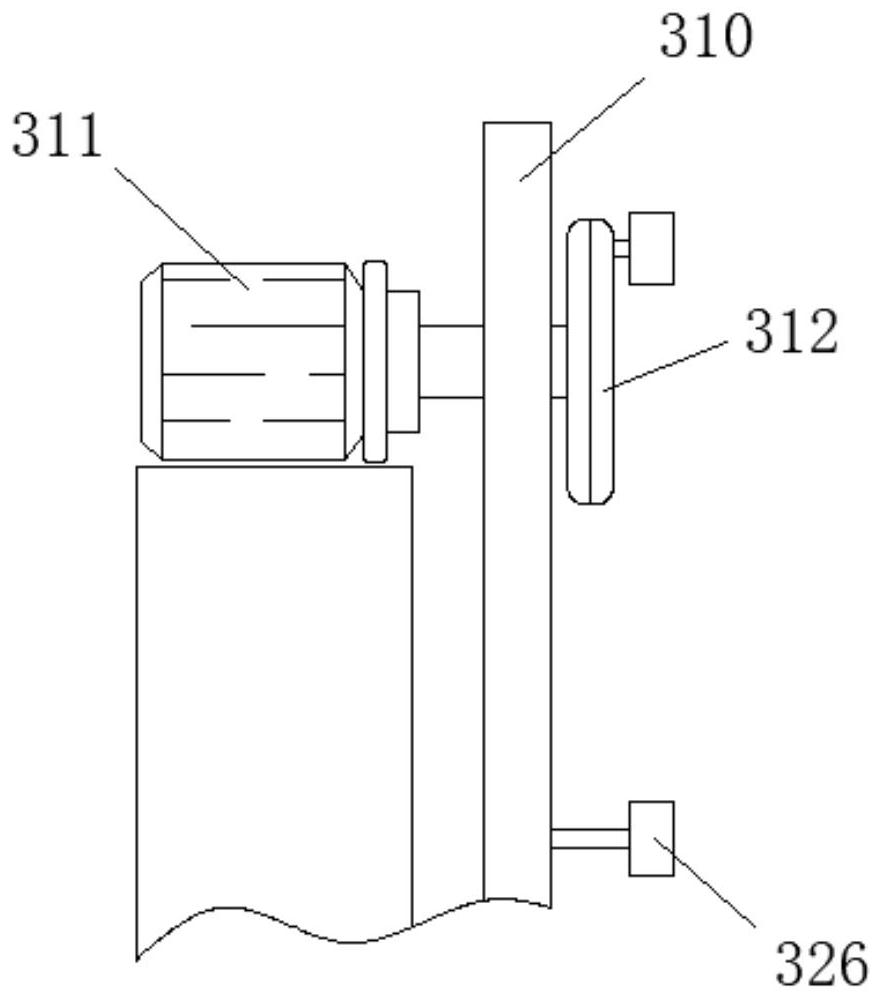

Manufacturing method of medical disinfecting and nursing wet tissue

ActiveCN112941754AReduce outputNo wasteTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentNursing careNonwoven fabric

The invention provides a manufacturing method of medical disinfecting and nursing wet tissue. A collection frame, a resistance increasing roller, a turning roller, an electric roller, a smooth plate, an extrusion device, a liquid storage frame, a liquid adding device and a heavy pressing cover are matched to complete operation. The medical disinfecting and nursing wet tissue can solve the problems that in a conventional liquid adding process, the wetting speed of the lower surface of a non-woven fabric is lower than that of the upper surface of the non-woven fabric in a top-down single-spraying mode, the lower surface of the non-woven fabric can be slowly wetted only under the permeation of chemical liquid after a large amount of the chemical liquid is sprayed into the non-woven fabric, the single-spraying mode needs continuous spraying of a large amount of the chemical liquid, the waste of the chemical liquid is easily caused, and due to continuous liquid spraying, the chemical liquid is still sprayed into the non-woven fabric when the non-woven fabric is soaked, and the chemical liquid is wasted.

Owner:TONGLING JIEYA BIOLOGIC TECH

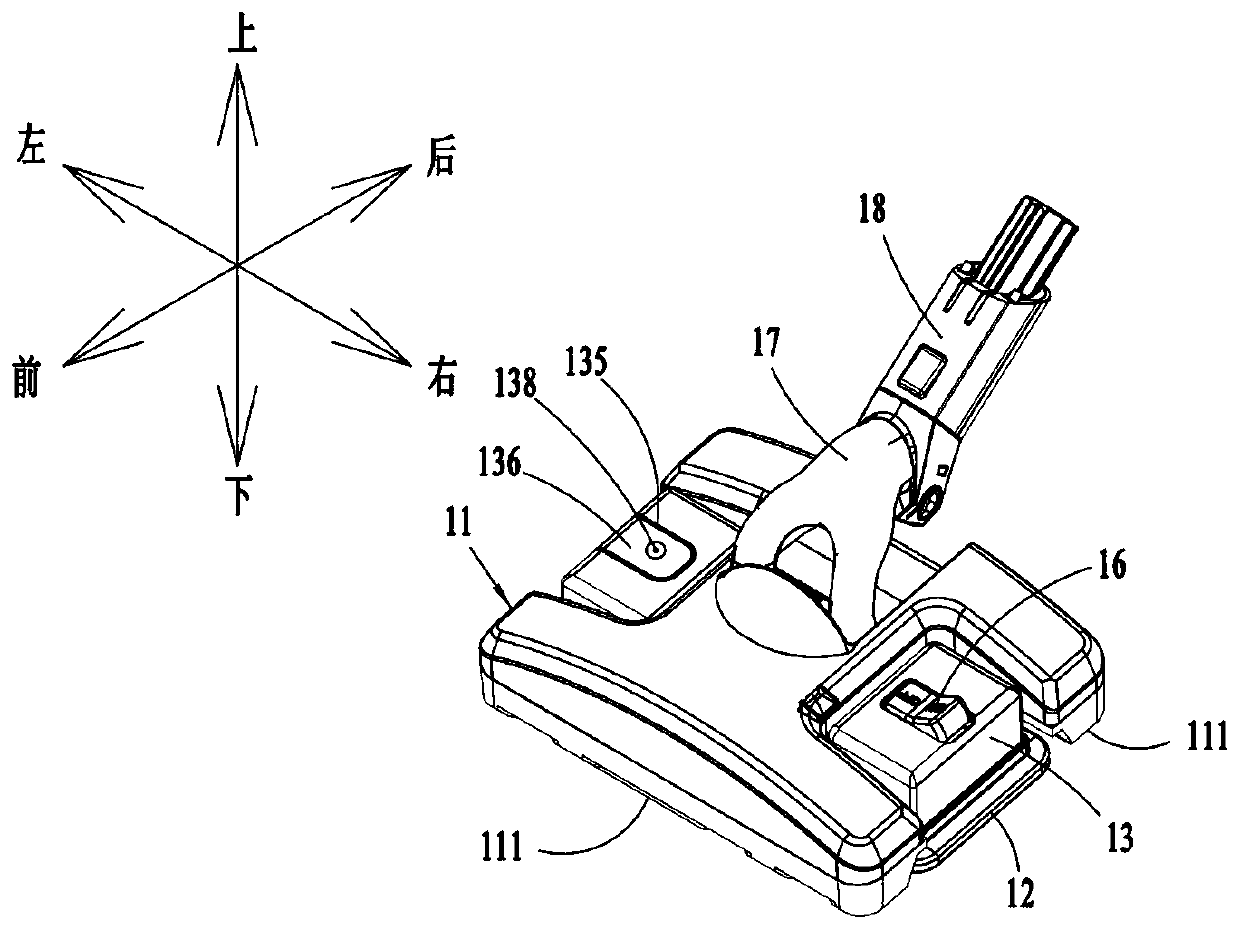

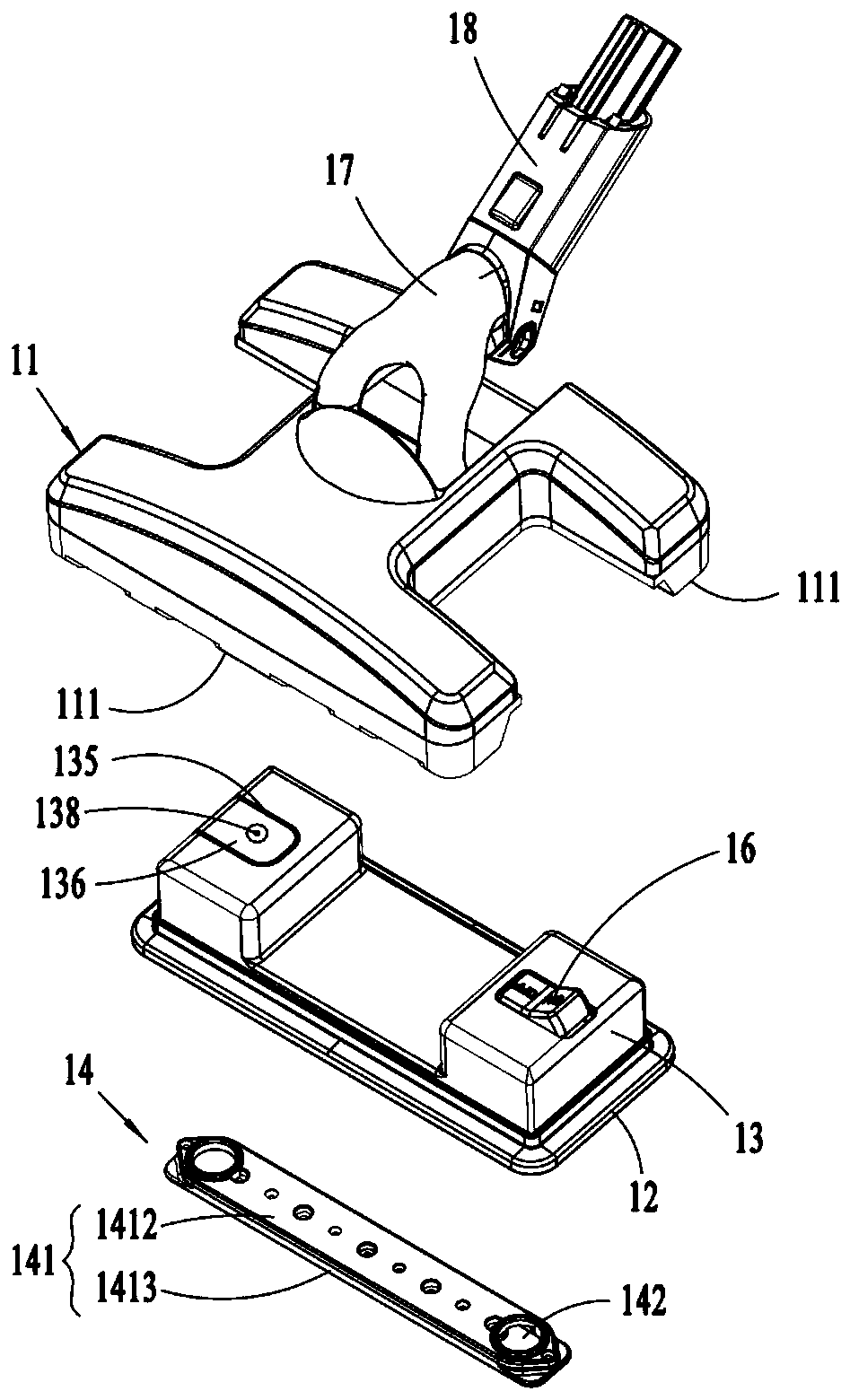

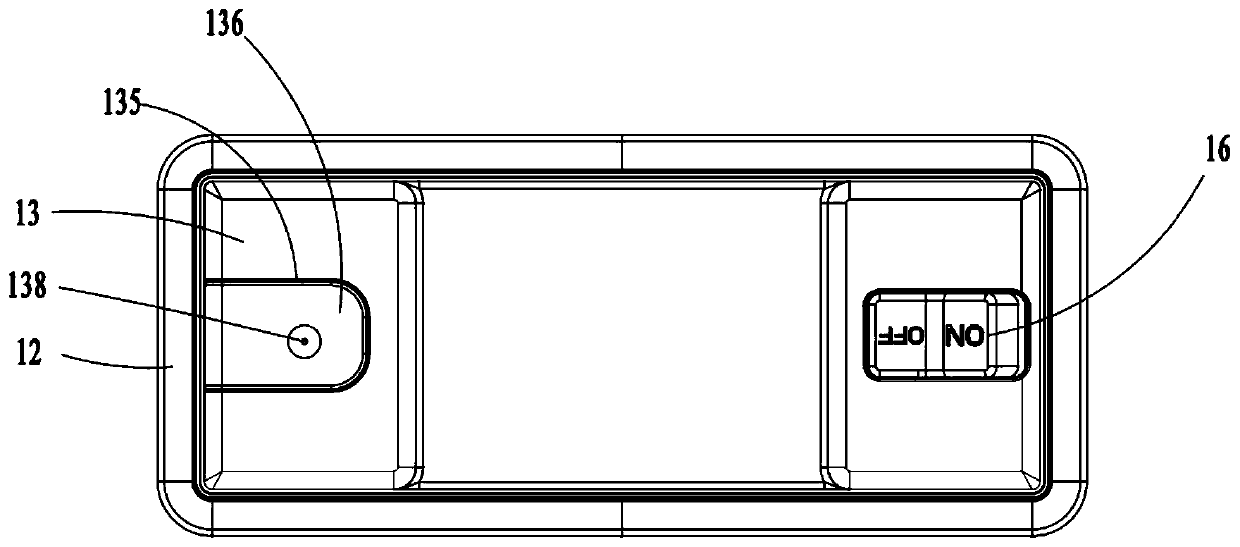

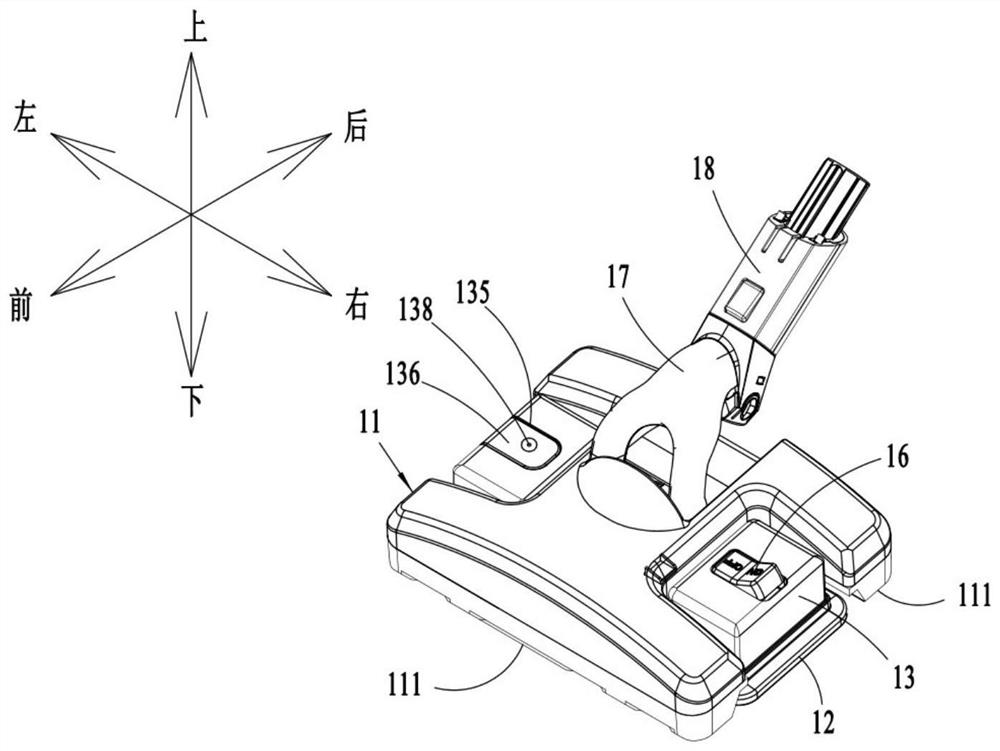

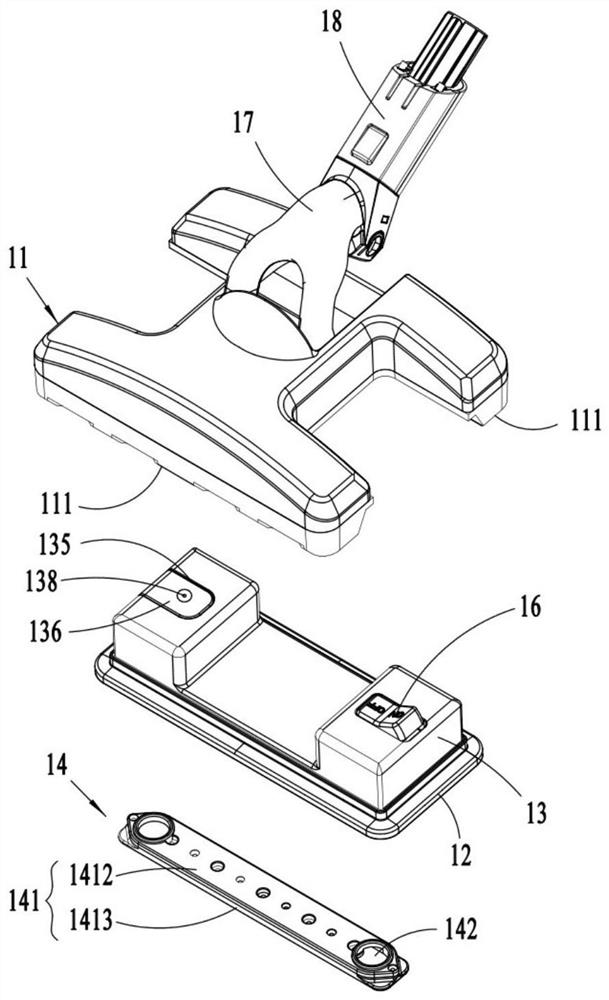

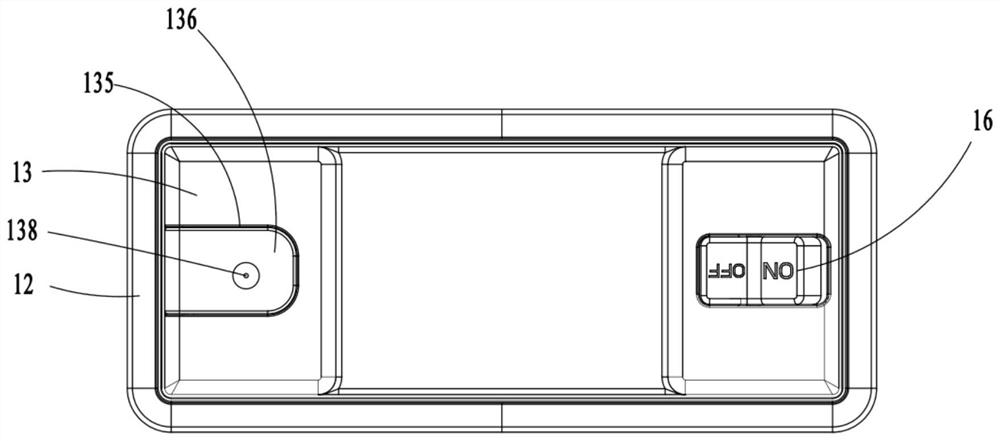

Cleaning head for ground cleaning equipment

The invention discloses a cleaning head for ground cleaning equipment. The cleaning head comprises a cleaning head body, a bottom plate, a water supply box, a water distributor and a communication pipe, wherein the cleaning head body is provided with at least one suction opening; the water supply box is arranged on the cleaning head body and is located at the upper side of the bottom plate; the water distributor is arranged on the bottom plate; a ventilation hole communicated with the outside is formed in the water supply box; a first cavity is formed inside the water supply box; a water outlet is formed in the lower part of the water supply box; the water distributor comprises a casing, a water inlet, a second cavity and a water outlet; the water inlet is formed in the top of the casing;the second cavity is formed inside the casing; the water outlet is formed in the lower part of the casing; the volume of the second cavity is smaller than the volume of the first cavity; the first cavity, the water outlet, the water inlet and the second cavity are sequentially communicated; the communication pipe is communicated with the first cavity and the second cavity; the communication pipe is provided with a lower end pipe opening and an upper end pipe opening; the lower end pipe opening of the communication pipe is communicated with the second cavity; the upper end pipe opening extendsinto the first cavity and is located at the upper part of the first cavity; the communication pipe has the water level with the height equal to the first cavity.

Owner:SUZHOU EUP ELECTRIC CO LTD

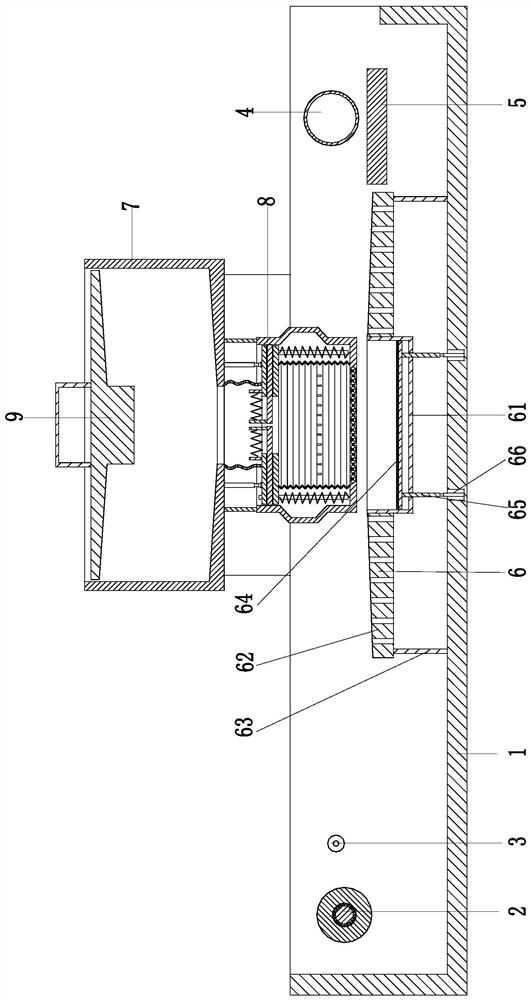

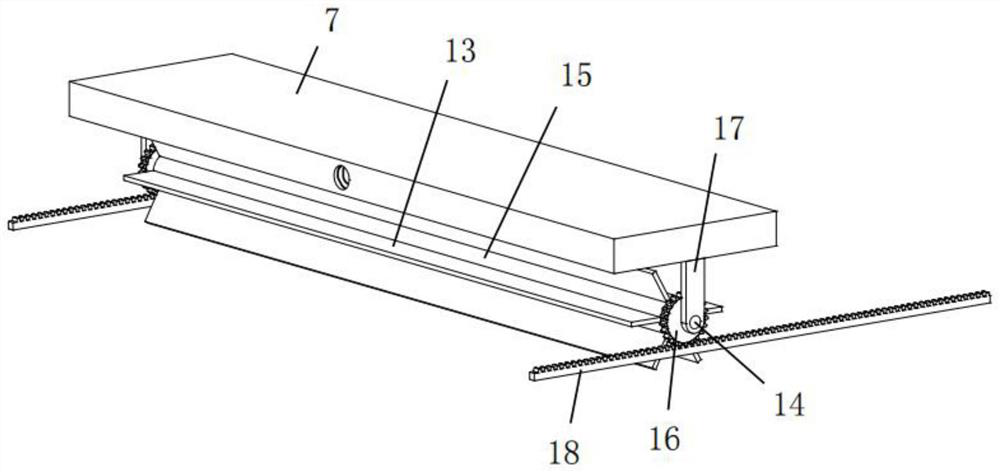

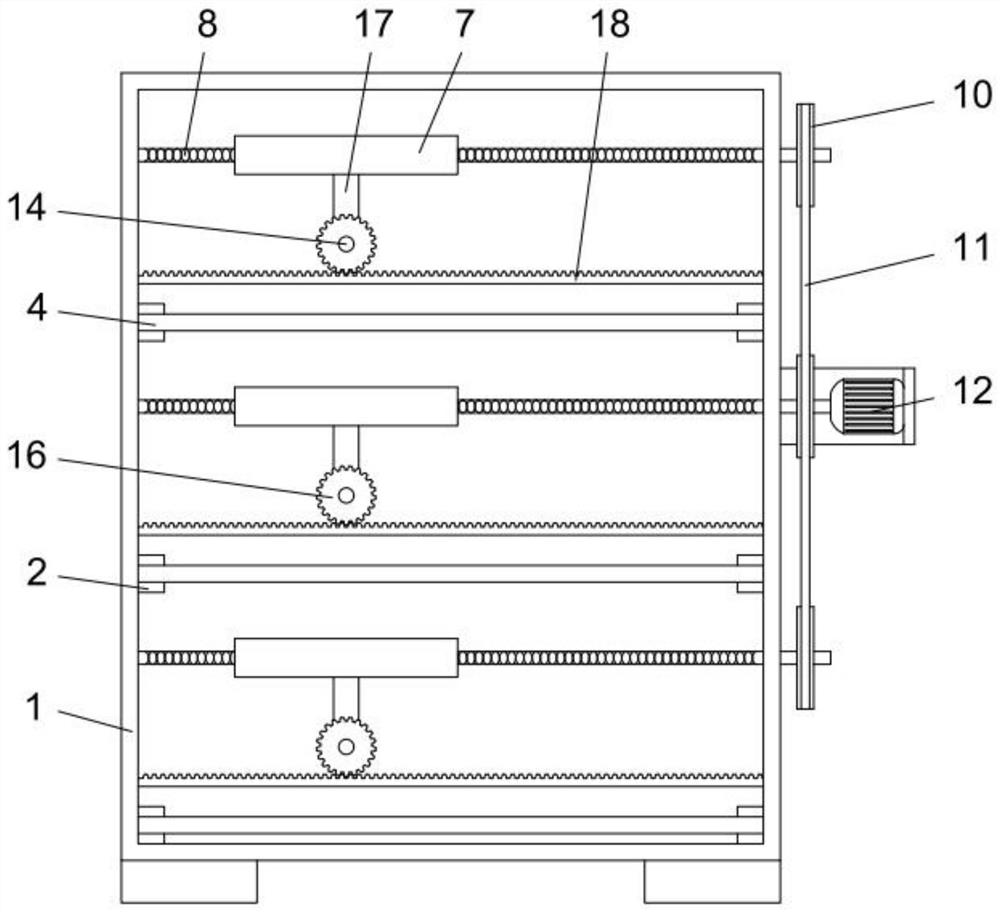

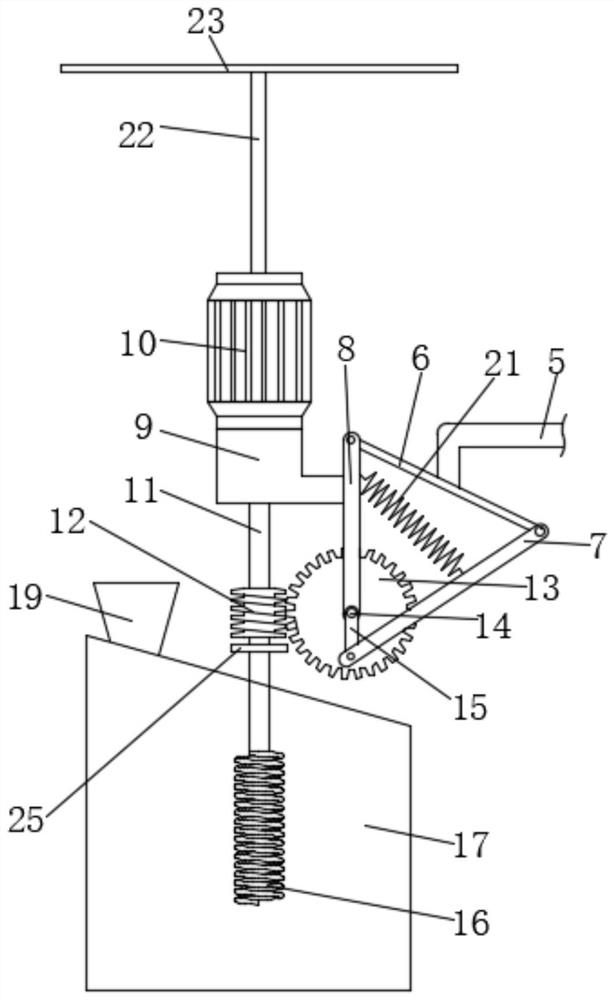

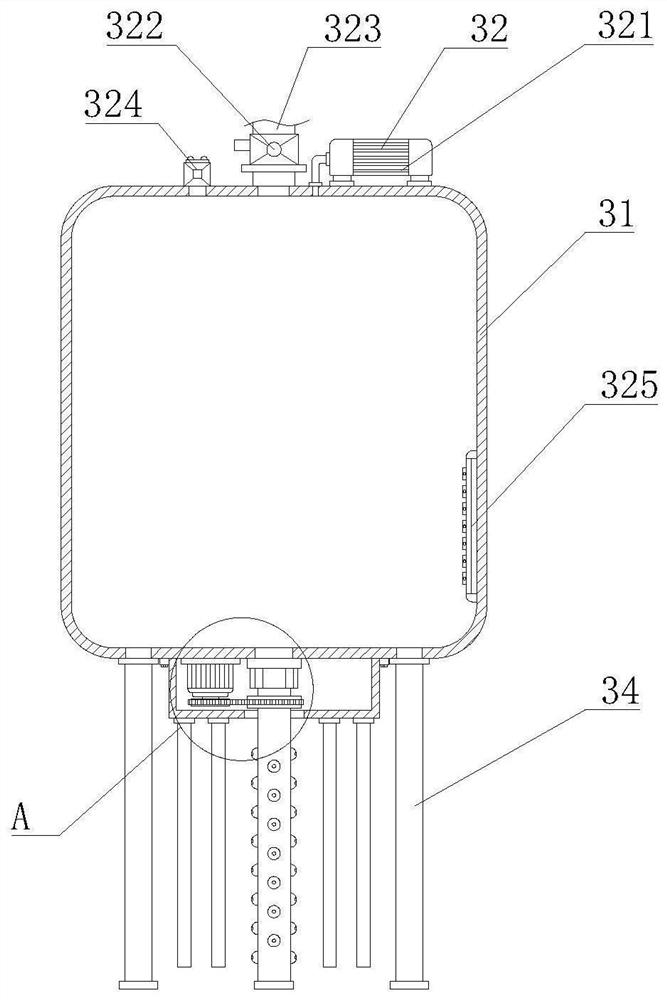

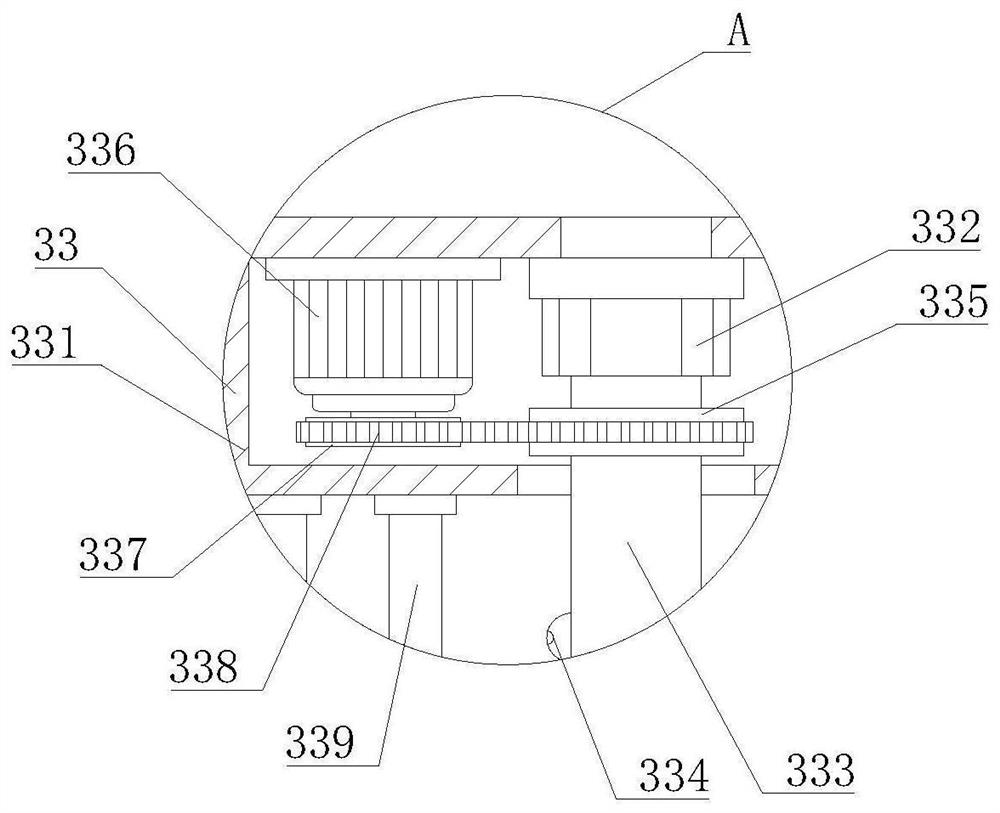

Medicine-separated navel moxibustion traditional Chinese medicine composition for nourishing YIN and clearing heat and vacuum medicine infiltrating machine

PendingCN113679784AEasy to wetImprove wetting efficiencyPowder deliveryPharmaceutical product form changeNavelDendrobium

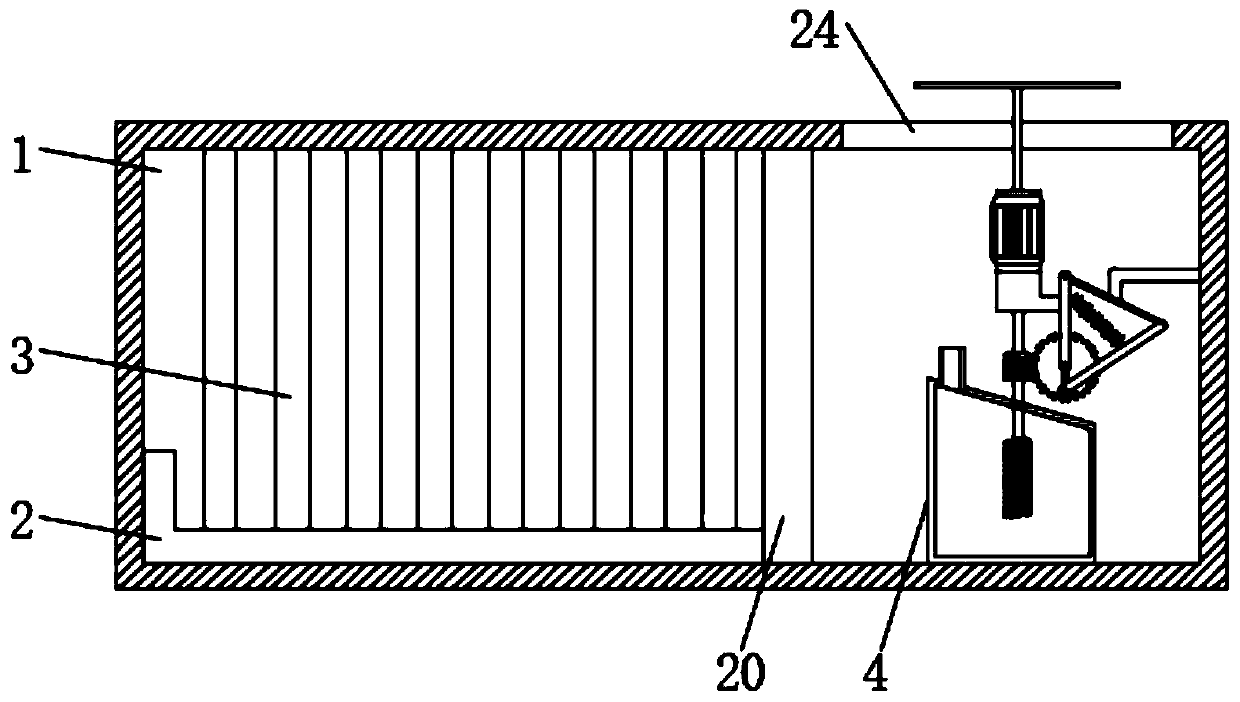

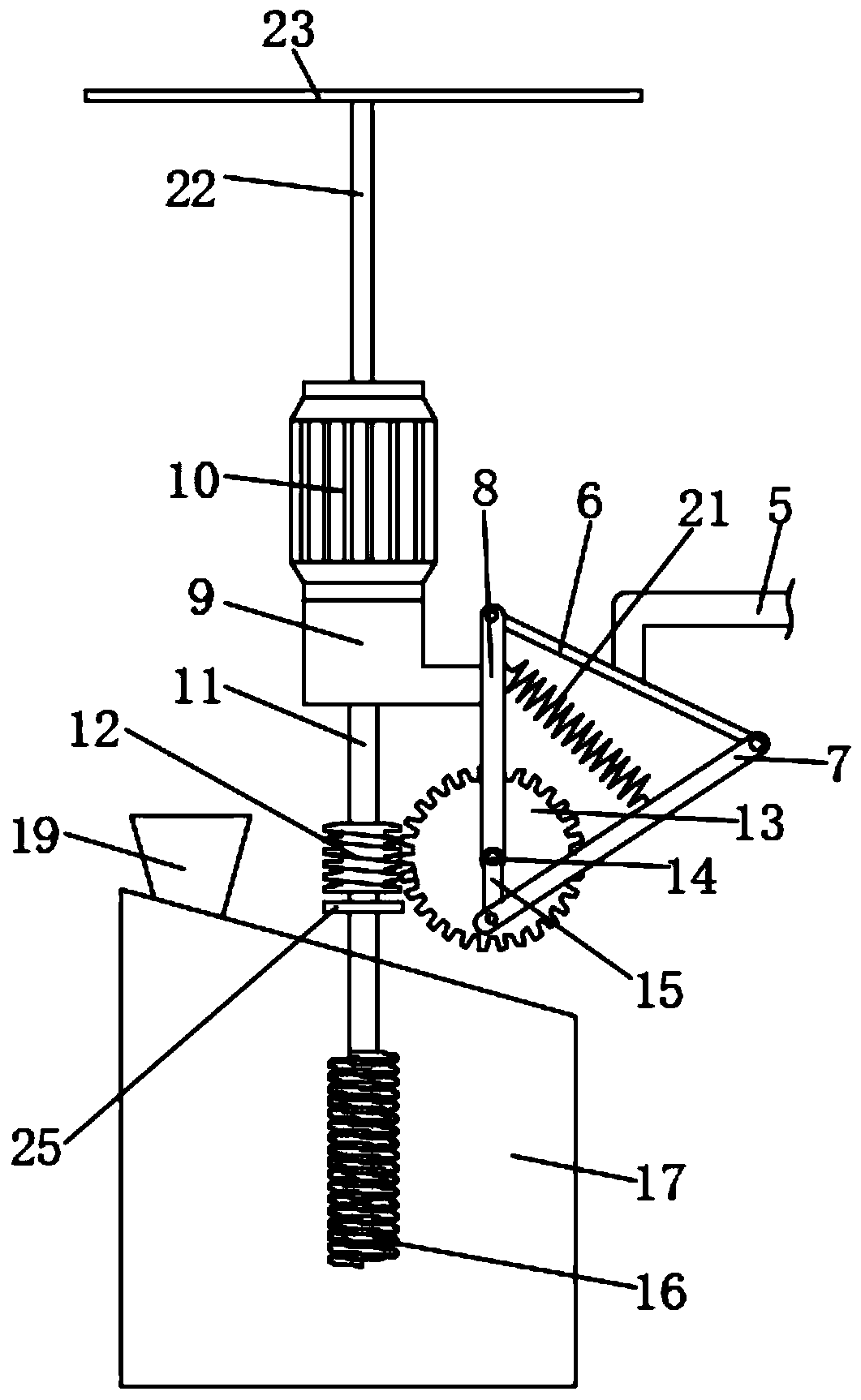

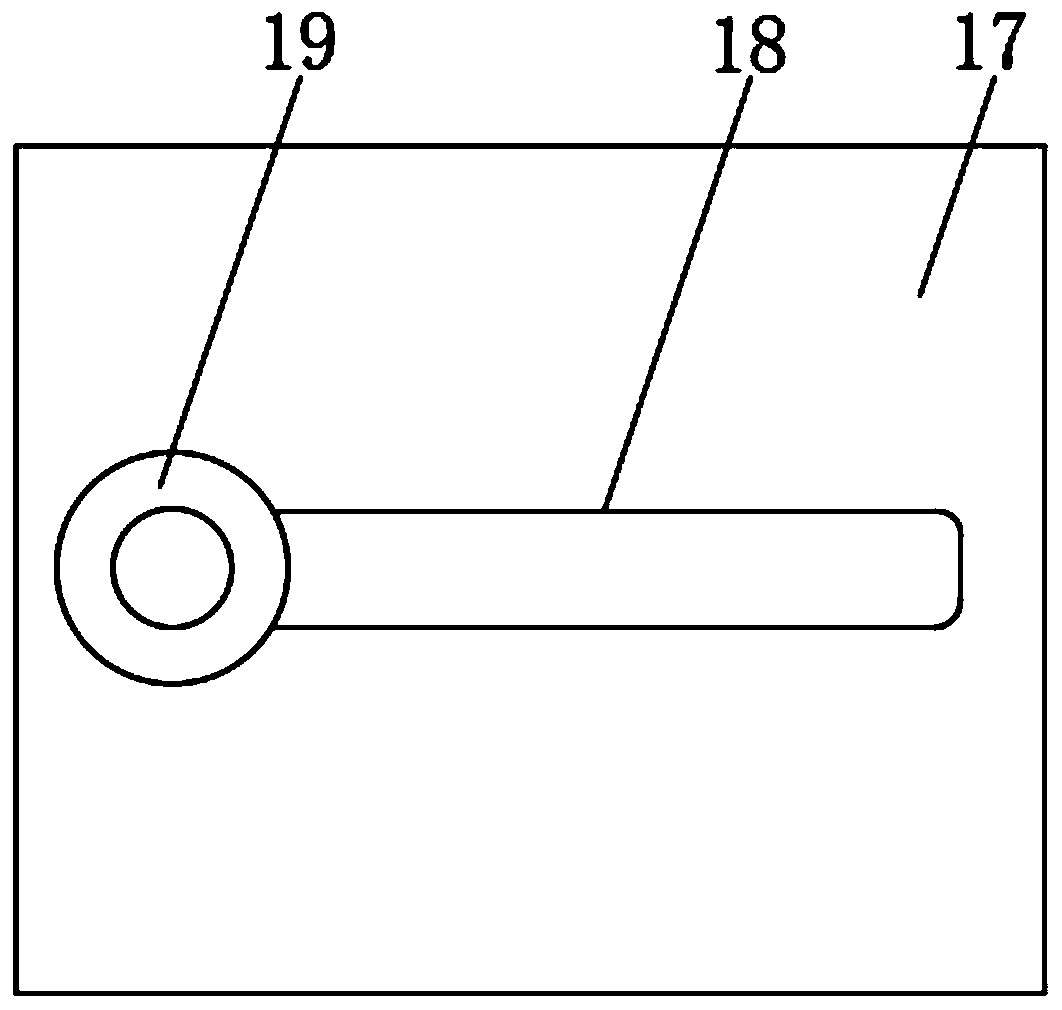

The invention discloses a medicine-separated navel moxibustion traditional Chinese medicine composition for nourishing YIN and clearing heat and a vacuum medicine infiltrating machine. The medicine-separated navel moxibustion traditional Chinese medicine composition comprises a box body, a turning mechanism, a driving mechanism and a spraying mechanism, wherein a plurality of clamping grooves are fixedly connected to the inner wall of the box body, and a bearing plate is slidably connected to the inner walls of the clamping grooves. According to the traditional Chinese medicine composition, dendrobium has the effects of nourishing YIN, clearing heat, tonifying the stomach and promoting fluid; houttuynia cordata has the effects of clearing away heat and toxic materials; radix scrophulariae has the effects of clearing heat, cooling blood, removing toxic materials and eliminating stagnation; radix ophiopogonis has the effects of nourishing YIN and promoting fluid; cortex moutan has the effects of clearing heat and cooling blood; fructus forsythiae has the effects of clearing away heat and toxic materials, eliminating stagnation and relieving swelling; and radix paeoniae alba has the effects of astringing YIN, arresting sweating, nourishing the liver and relieving pain. According to the traditional Chinese medicine composition, a turning plate is used for turning raw materials of the traditional Chinese medicine composition at the upper end of the bearing plate, so that the raw materials of the traditional Chinese medicine composition are conveniently wetted; and the turning plate is used for shifting a shifting plate, so that the shifting plate is used for opening and closing a through hole, and wetting liquid is sprayed to the raw materials of the traditional Chinese medicine composition after the raw materials of the traditional Chinese medicine composition are turned by the turning plate.

Owner:湖南善孝堂健康管理有限责任公司

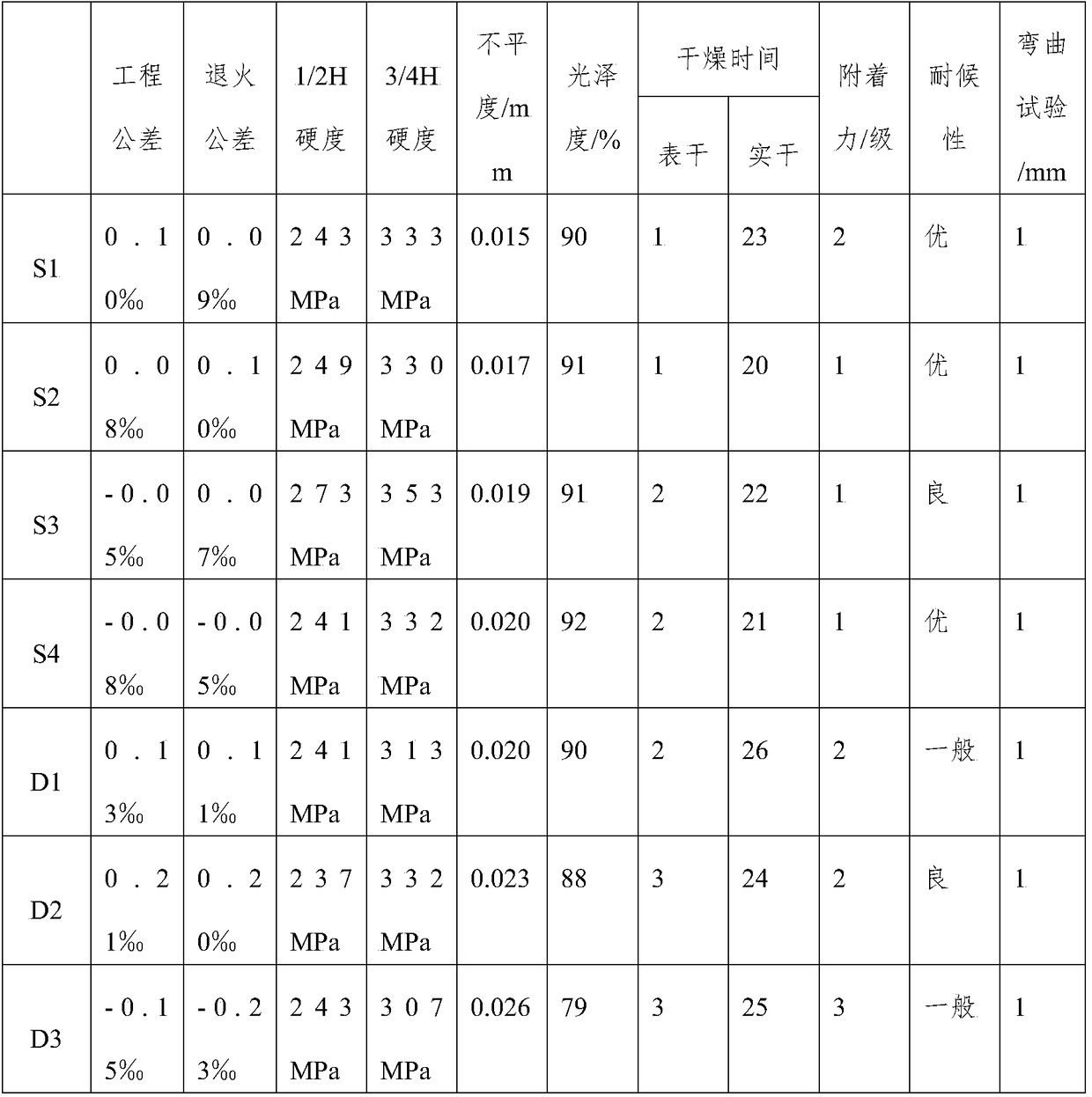

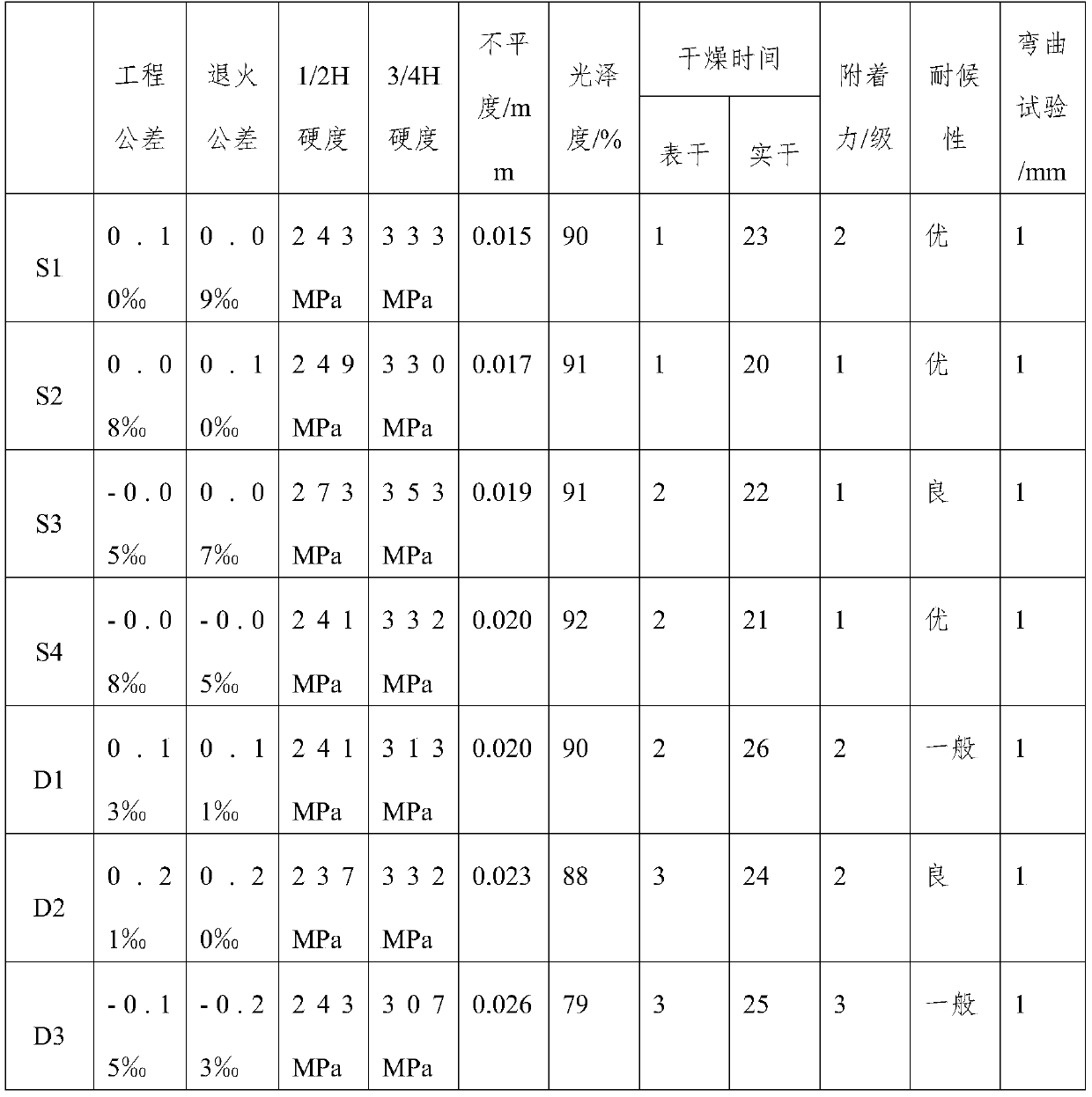

Production technology of SIM mobile phone card slot and coating preparing mobile phone card slot

The invention discloses a production technology of an SIM mobile phone card slot. The production technology includes the following successive technological steps that a production drawing is drawn according to the shape and size of a mobile phone card slot; stainless steel base metal with the matched size and material is selected according to the size of the mobile phone card slot, and the production technological steps are determined and include N steps, wherein N is larger than 0; the product production technological size is formulated and a product deformation pattern is drawn according tothe shape and size of the mobile phone card slot; M production dies are formed, wherein M is smaller than or equal to N; the first production die is loaded into a continuous rolling machine, after thebase metal enters the continuous rolling machine to be rolled, the rolled base metal is subjected to size detection, and then annealing is conducted; and continuous rolling and annealing are conducted five times. By means of the production technology, the product deformation pattern is designed, the deformation machining amount of each time is designed into the deformation pattern, and the product hardness is controlled; and the continuous rolling technology is adopted, a final sample can be formed by conducting rolling five times continuously, coherent productivity is achieved on clients with the large quantity demand, and the production speed is increased; and accurate grinding is conducted on a material surface, and the material surface is bright and free of burrs.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

Coarse cereal flour and preparation method thereof

The invention belongs to the technical field of food processing and particularly relates to coarse cereal flour and a preparation method thereof. The preparation method includes: (1) removing impurities; (2) weighing materials, adding into a mixer, spraying wetting liquid, stirring, mixing, discharging a mixture, spreading, centrifugally dripping, spraying salt water, and spreading to complete wetting; (3) milling the mixture, and separating out cortex, residues, cores and powder to obtain the coarse cereal flour. By mixing of coarse cereals before milling, problems of high energy consumption,low mixing efficiency and incompleteness in mixing after traditional coarse cereal milling are avoided. By adoption of the wetting liquid for wetting, bonding force of a cortex layer, an aleurone layer and endosperm is reduced through water adsorption of endosperm and the cortex layer before milling, and milling energy consumption differences of different materials are reduced; by mixing and mutual extrusion and friction of the different materials, milling efficiency is improved.

Owner:ANHUI FOZILING FLOUR IND

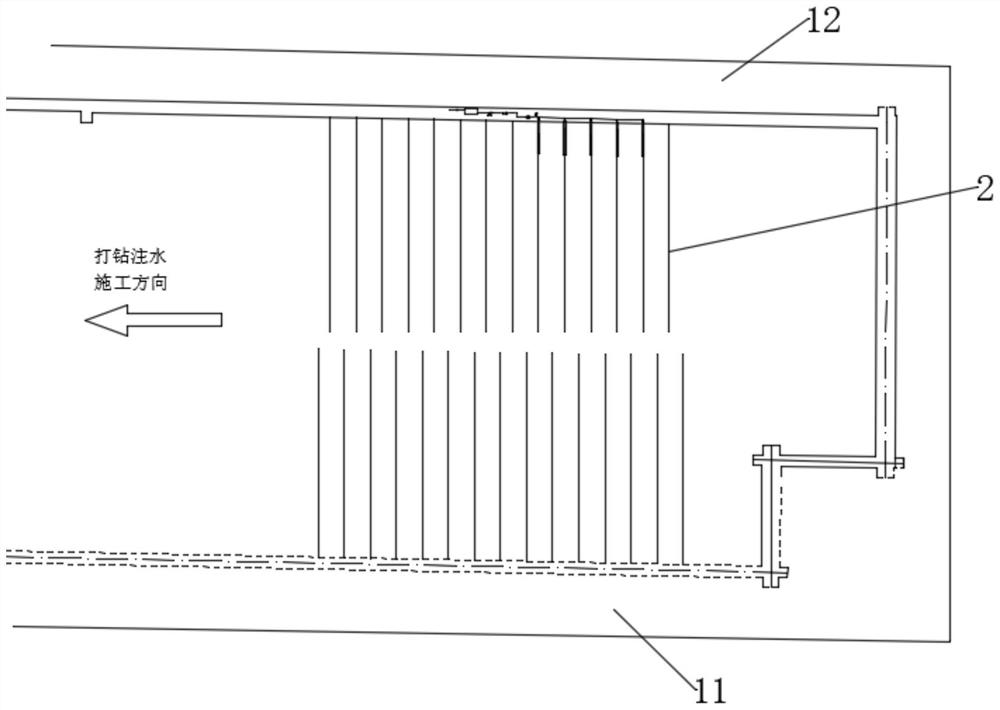

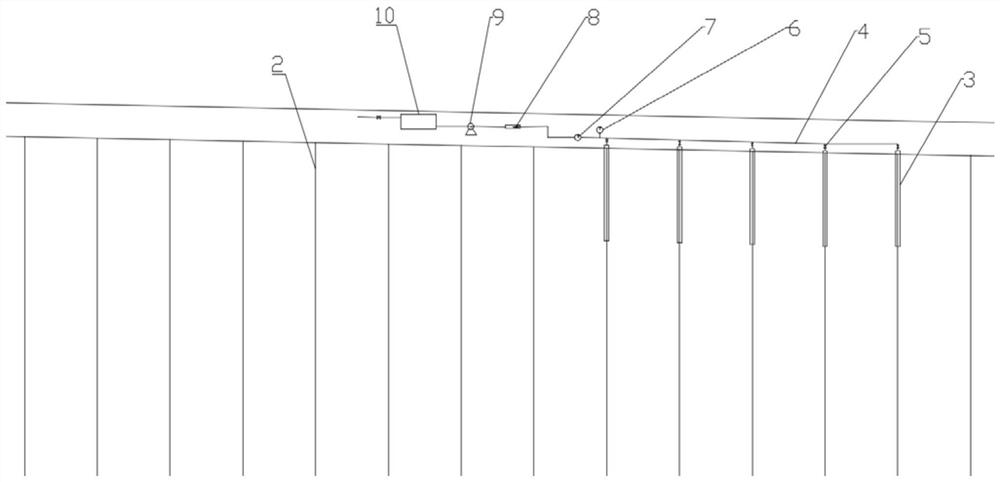

Roadway-mining face collaborative water injection structure for dust fall of coal mine and use method thereof

PendingCN113446049AReduce the amount of dust produced on the mining faceImprove wetting efficiencyDust removalFire preventionMining engineeringCoal

The invention discloses a roadway-mining face collaborative water injection structure for dust fall of coal mine. Water injection drill holes are formed in the sides, close to a coal seam, of an air inlet roadway and an air return roadway, the drill holes are single-row holes, the hole opening positions are located in the center line of a coal wall, the hole opening direction is along the dip angle of the coal seam, the horizontal angle is 0 degree, water injection pipes are installed in the drill holes, and hole sealing water injectors are fixed to the water injection pipes. The water injection method comprises the following steps that 1, roadway and mining face drilling construction and timely water injection are carried out, and the hole depth and the dip angle are adjusted according to the field condition; 2, a water injection hole is subjected to hole sealing treatment; and 3, a water injection main pipeline flowmeter is installed on site, and water is injected into the water injection holes through the water injector according to a water injection scheme. The method can effectively wet the coal body, reduce the dust yield of the mining face, improve the water injection efficiency of the coal seam, and inhibit the generation of dust from the dust production source.

Owner:平顶山天安煤业股份有限公司十二矿 +1

Production technology of sim mobile phone card slot and prepared coating for mobile phone card slot

The invention discloses a production technology of an SIM mobile phone card slot. The production technology includes the following successive technological steps that a production drawing is drawn according to the shape and size of a mobile phone card slot; stainless steel base metal with the matched size and material is selected according to the size of the mobile phone card slot, and the production technological steps are determined and include N steps, wherein N is larger than 0; the product production technological size is formulated and a product deformation pattern is drawn according tothe shape and size of the mobile phone card slot; M production dies are formed, wherein M is smaller than or equal to N; the first production die is loaded into a continuous rolling machine, after thebase metal enters the continuous rolling machine to be rolled, the rolled base metal is subjected to size detection, and then annealing is conducted; and continuous rolling and annealing are conducted five times. By means of the production technology, the product deformation pattern is designed, the deformation machining amount of each time is designed into the deformation pattern, and the product hardness is controlled; and the continuous rolling technology is adopted, a final sample can be formed by conducting rolling five times continuously, coherent productivity is achieved on clients with the large quantity demand, and the production speed is increased; and accurate grinding is conducted on a material surface, and the material surface is bright and free of burrs.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

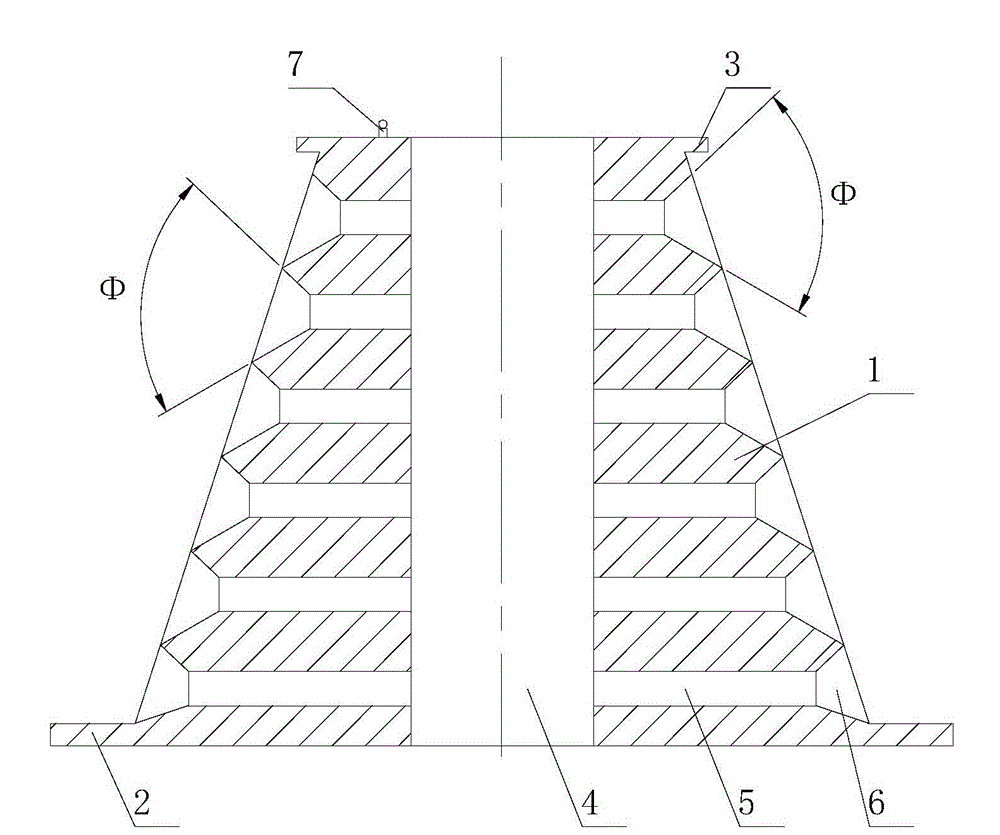

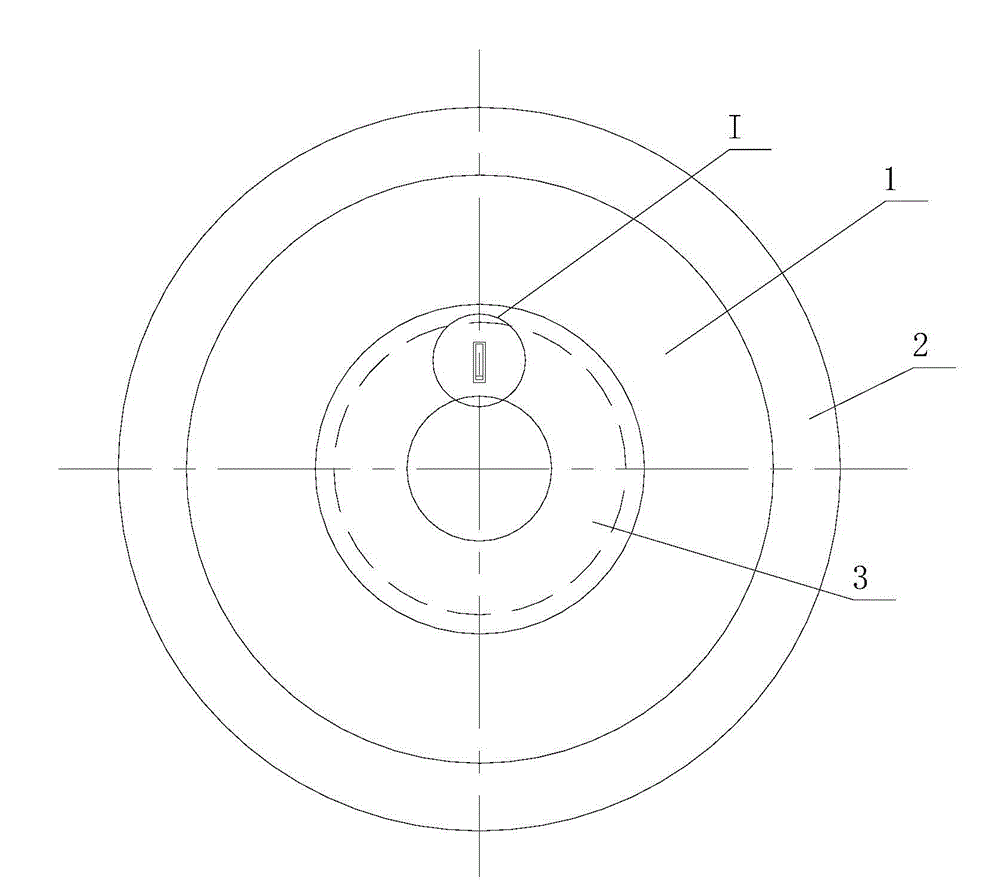

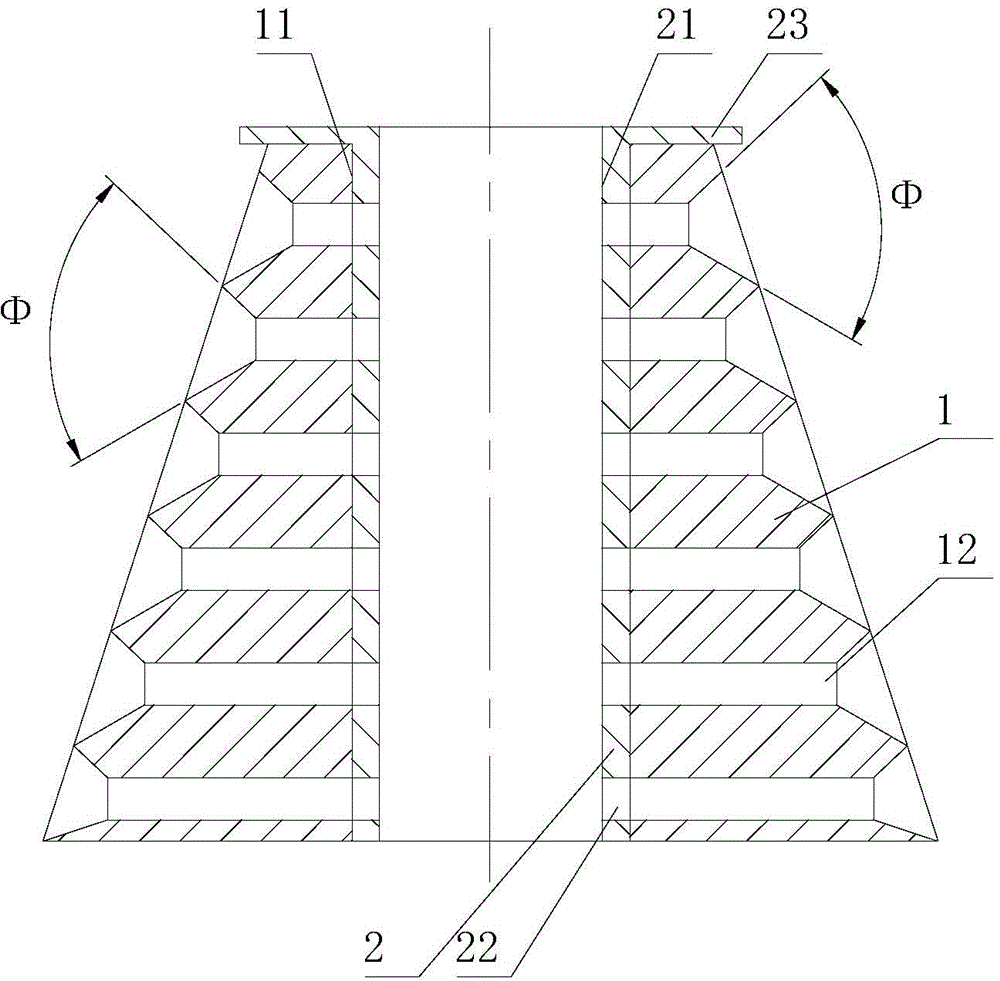

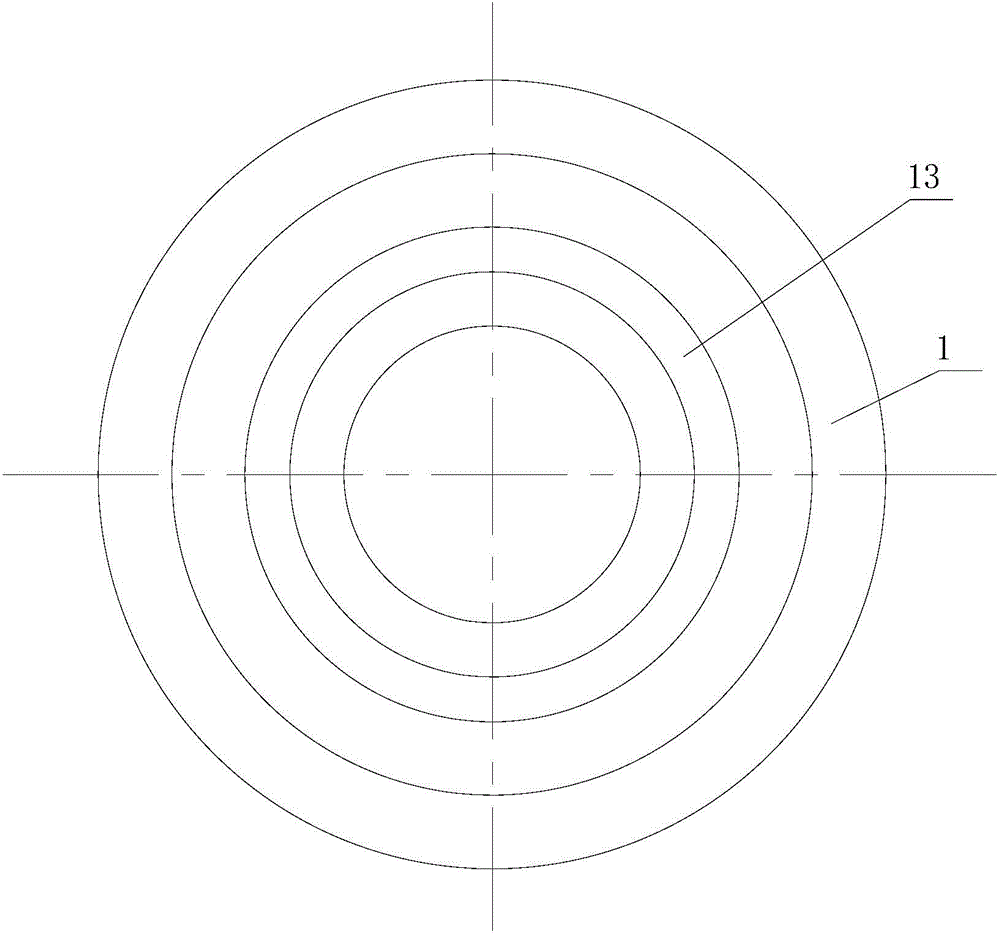

Weaving textile bobbin convenient for storage

The invention discloses a weaving textile bobbin convenient for storage. The textile bobbin comprises a conical tube body whose cone angle value is 30 to 60 degrees; a tube body installing hole which is arranged in the middle and along an axial direction of the conical tube body. The tube body installing hole is matched with a spindle of a weaving machine during usage; cross sections of the conical tube body are provided, in the radial direction, with multiple water spray holes which are annularly and uniformly distributed; each water spray hole comprises a straight through hole which is close to the tube body installing hole and a trumpet-shaped hole which is close to the outside of the conical tube body and opens outwards; the straight through hole communicates with the trumpet-shaped hole; the opening angle value phi of the trumpet-shaped hole is 100 to 160 degrees and outer edges of two trumpet-shaped holes at adjacent cross sections in the same direction are tangent to each other; the bottom end of the conical tube body is provided with a first baffle plate, the top end of the conical tube body is provided with a second baffle plate, and the top of the second baffle plate is provided with a hideable storage mechanism. The weaving textile bobbin is convenient for storage and guarantees uniform moistening of yarn.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

Compound surfactant for modifying low-permeability coal reservoir and modifying method of low-permeability coal reservoir

InactiveCN108361059AIncrease reaction rateShort reaction timeDust removalFire preventionPorosityFatty alcohol

The invention discloses a compound surfactant for modifying a low-permeability coal reservoir and a modifying method of the low-permeability coal reservoir, and belongs to the technical field of coalmining. The compound surfactant for modifying the low-permeability coal reservoir comprises the components of, by mass, 0.1-0.3% of fatty alcohol sodium sulfate, 0.1-0.3% of compound components, and the balance water. The compound components comprise a nonionic surfactant, a positive ion surfactant or a long chain polar organic matter. The modifying method of the low-permeability coal reservoir comprises the steps that a standard coal sample is manufactured and screened; the compound surfactant for modifying the low-permeability coal reservoir is prepared; the standard coal sample is soaked, after the standard coal sample is saturated, the initial porosity is calculated, soaking is conducted for 6-18 h at the temperature of 25-40 DEG C, and the mass loss rate and the porosity are calculated, and a static water wetting angle experiment is conducted. The compound surfactant for modifying the low-permeability coal reservoir is adopted to modify the low-permeability coal reservoir, and thedefects that a single surfactant is long in reaction time and incomplete in reaction are solved.

Owner:LIAONING TECHNICAL UNIVERSITY

Textile fabric wetting device for textile production

InactiveCN112127066APlay a role in cleaning upSmall footprintMechanical cleaningPressure cleaningTextile technologyActivated carbon

The invention discloses a textile fabric wetting device for textile production, and relates to the technical field of textiles. A first extrusion plate is fixedly connected to the telescopic end of ahydraulic rod, a second extrusion plate is hinged to one side of the first extrusion plate through a hinge, a plurality of sets of brushes are fixedly installed at the positions, not making contact with a water passing hole, of the bottom of the second extrusion plate, and the interior of a waste water collecting box is divided into a first cavity and a second cavity through a filter plate; and aplurality of sets of supporting rods are clamped in the waste water collecting box and located above the filter plate, reset springs are fixedly installed at the two ends of the interior of each supporting rod, the exterior of each supporting rod is sleeved with an activated carbon filter element, and an abutting column is fixedly installed at one end of each reset spring. In the using process, excess water on a textile fabric can be squeezed out, so that next processing operation is facilitated; and the structure is simple, manual operation is not needed, more time and labor are saved, the working efficiency is improved, used water can be recycled again, and water resources are saved.

Owner:郭建召

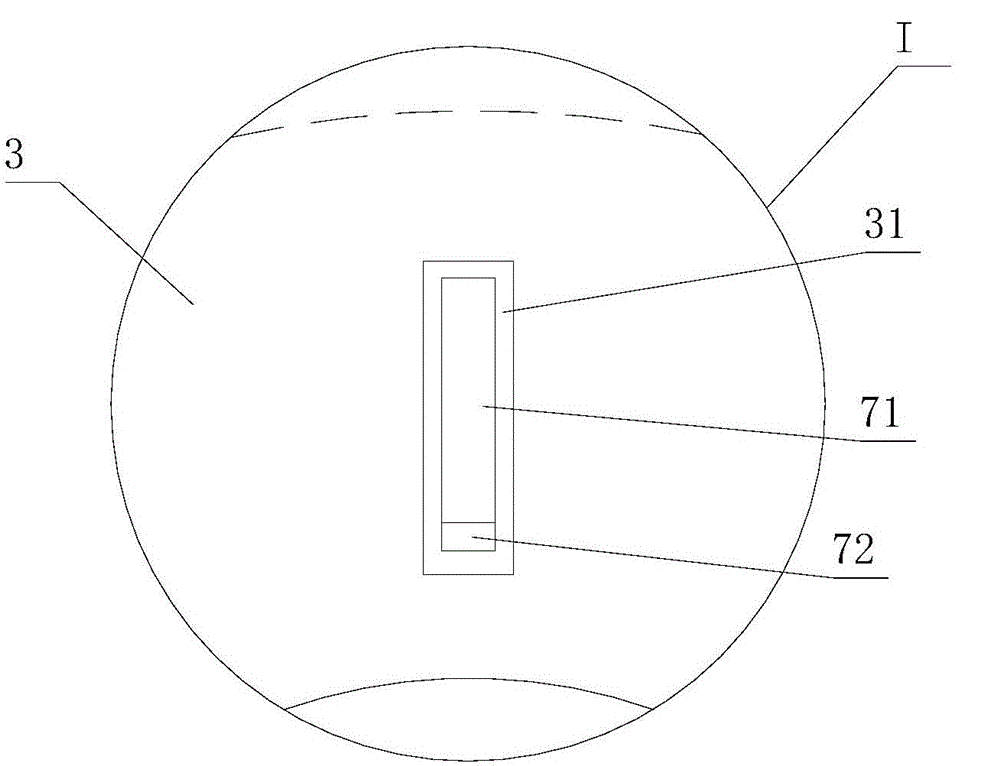

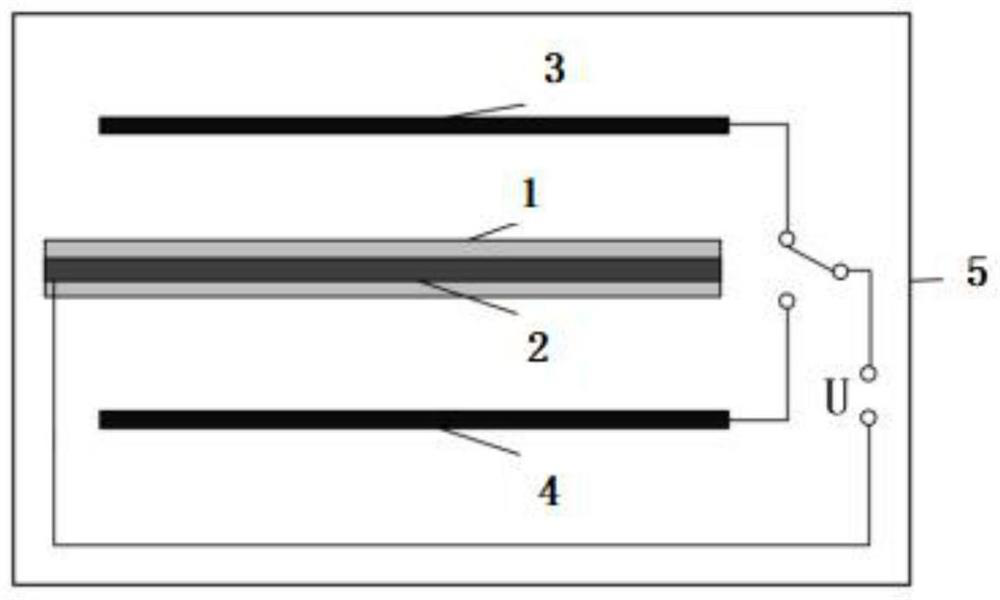

A graphene heater

ActiveCN111156576BImprove evaporation efficiencyImprove wetting efficiencyLighting and heating apparatusElectric heating systemWater storageWater storage tank

The invention discloses a graphene heater, which comprises a heater shell, the inner wall of the heater shell is fixedly connected with a heating tube, the upper surface of the heating tube is fixedly connected with a graphene heat dissipation tube, and the heater An evaporative and humidifying device is fixedly connected to the inner wall near the right side of the shell, and the evaporative and humidifying device includes a connecting arm, the right end of the connecting arm is fixedly connected to the inner wall of the heater shell, and the bottom of the connecting arm is fixedly connected to a fixed frame, and the bottom of the fixed frame is rotatably connected with a rotating arm one through a pin shaft. In the present invention, through the cooperative use of the above-mentioned structures, in the actual use process, due to the low evaporation efficiency in the water storage tank, less water vapor is formed, which is difficult to meet the actual use requirements, and the water vapor formed at the same time It is also difficult for the steam to be directed and emitted from multiple angles, making it difficult for the indoor air to be effectively humidified, which brings inconvenience to use.

Owner:河南煜和石墨烯应用技术研究院有限公司

Cleaning head for ground cleaning equipment

ActiveCN112075894AEasy dischargeDischarge in timeCarpet cleanersFloor cleanersMechanical engineeringWater resource management

The invention discloses a cleaning head for ground cleaning equipment. The cleaning head comprises a cleaning head body, a bottom plate, a water supply tank, a water distributor and a communicating pipe, wherein at least one suction port is formed in the bottom of the cleaning head body; the water supply tank is arranged on the cleaning head body and is positioned on the upper side of the bottom plate; the water distributor is arranged on the bottom plate; a vent hole communicating with the outside is formed in the water supply tank; a first chamber is formed inside the water supply tank; a water outlet is formed in the lower part of the water supply tank; the water distributor comprises a shell, a water inlet formed in the top of the shell, a second chamber formed inside the shell and a water outlet hole formed in the lower part of the shell; the volume of the second chamber is smaller than that of the first chamber; the first chamber, the water outlet, the water inlet and the secondchamber sequentially communicate; the communicating pipe communicates with the first chamber and the second chamber; the communicating pipe is provided with a lower end pipe orifice and an upper end pipe orifice; the lower end pipe orifice of the communicating pipe communicates with the second chamber; and the upper end pipe orifice extends into the first chamber and is positioned on the upper part of the first chamber.

Owner:SEB SA

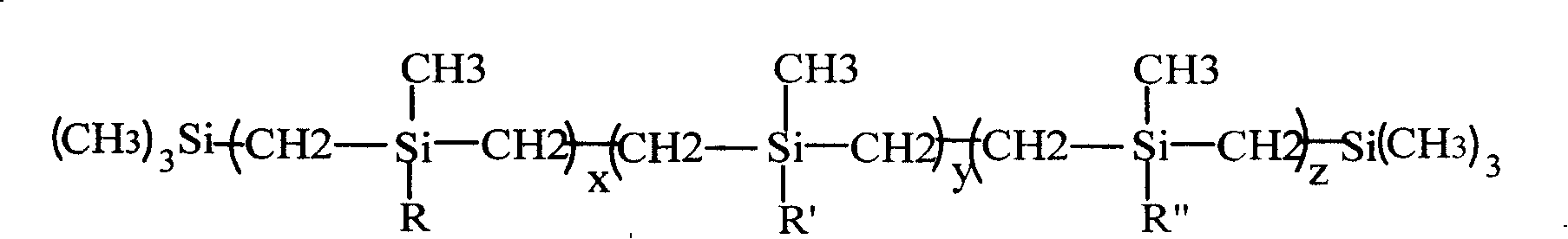

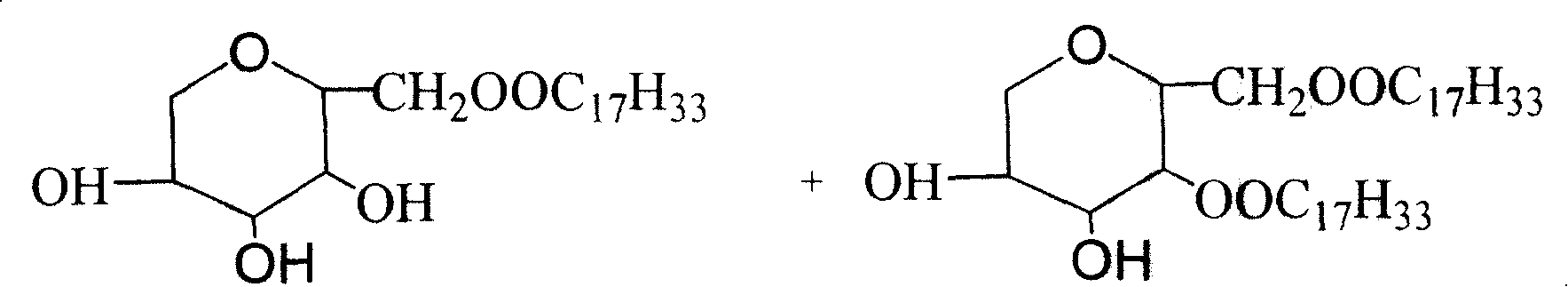

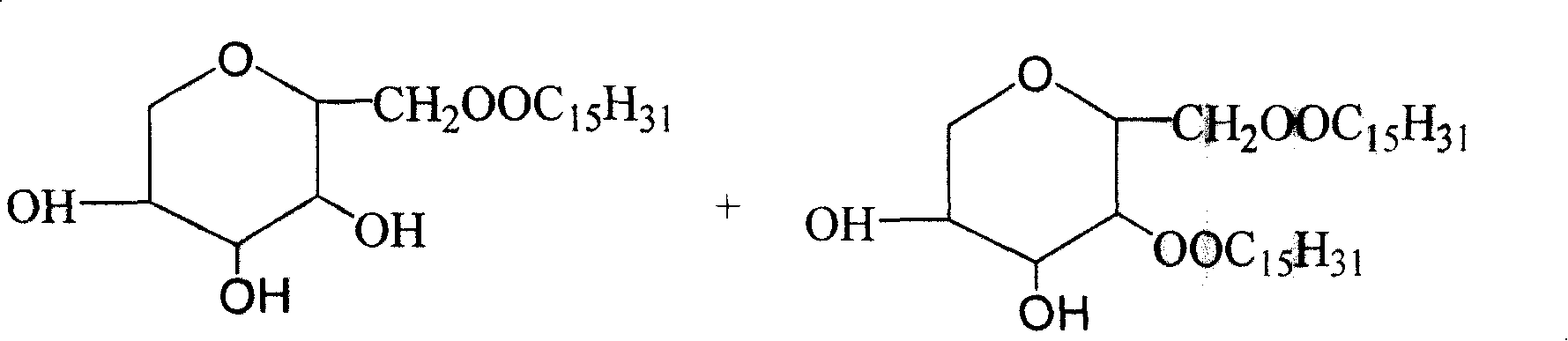

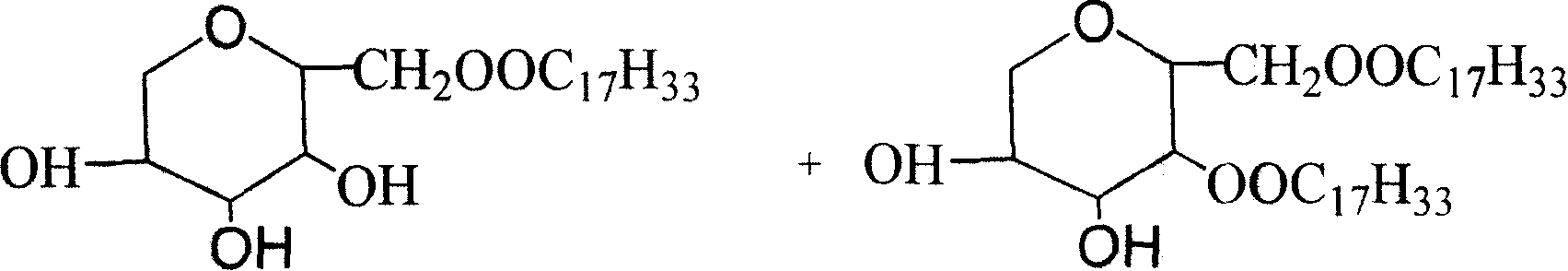

Agricultural polychloroethylene shed film composite dripless agent

The invention relates to a functional additive for an agricultural PVC shed film, in particular to a composite dripless agent for an agricultural PVC shed film. The composite dripless agent of the invention is prepared by compounding the nonionic surfactants and the anionic surfactants of the fatty acid polyol ester kind with different chain lengths proportionally. Due to the addition of the anionic surfactants, the invention enhances the wetting efficiency of the surfactants in combination and effectively enhances the initial effect of the dripless effects of the shed film, and drives the small water drops condensated on the PVC shed film surface to be changed into water films by spreading at a high speed with flowing down along the internal surface of the shed so as to enhance the transmittance of the shed film, increase the light intensity, deliver favorability for photosynthesis and the enhancement of the temperature in the shed, thus promoting the growth of the crops and reducing the occurrence of the diseases. The composite dripless agent of the invention has good thermal stability, can be conveniently processed and can adapt to the requirement for processing technique of the PVC shed film.

Owner:白山市喜丰塑业有限公司

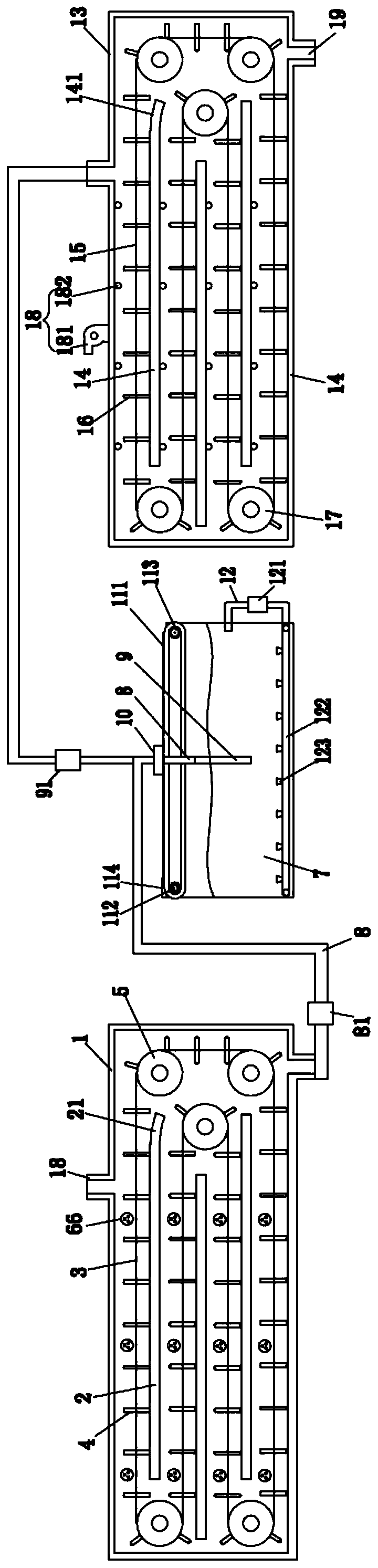

A washing machine for fabric finishing

ActiveCN113529320BAvoid adsorptionAvoid depositionSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersProcess engineeringWaste management

The invention relates to the technical field of cloth washing, in particular to a washing machine for cloth finishing, comprising a wetting chamber, a cleaning chamber and a draining chamber, the cleaning chamber is arranged between the wetting chamber and the draining chamber, and the cleaning chamber and the draining chamber The chamber is installed on the support platform, the bottom of the support platform is installed with a support frame, the wetting chamber is equipped with a first lifting platform, and on the first lifting platform, there are several first conveying rollers spirally distributed outwards with the first winding roller as the center. There are several second conveying rollers arranged alternately in the cleaning chamber, and washing nozzles are evenly installed on the two side walls of the cleaning chamber. A second lifting platform is installed in the draining chamber, and the second winding roller is used as the There are several extruding rollers and the third conveying roller respectively outside the center spiral. In the present invention, when the cloth is cleaned, the cloth is vertically arranged in the wetting chamber, the cleaning chamber and the draining chamber, so as to prevent the dirt diffused into the washing liquid from being adsorbed or deposited on the cloth again, causing re-accumulation. Contaminate or cause water staining.

Owner:佛山市南海德耀翔胜纺织有限公司

A kind of manufacturing method of medical disinfection care wet wipe

ActiveCN112941754BReduce outputNo wasteTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentMedicineEnvironmental engineering

The invention provides a method for making medical disinfection and nursing wet wipes, which is completed by the cooperation of a collection frame, a resistance increasing roller, a direction changing roller, an electric roller, a smooth plate, an extrusion device, a liquid storage frame, a liquid adding device and a heavy pressure cover Operation, the present invention can solve the problem of single spraying from top to bottom in the traditional liquid adding process, so that the wetting speed of the lower surface of the non-woven fabric is slower than that of the upper surface, only after a large amount of liquid medicine is sprayed into the non-woven fabric, Under the penetration of the liquid medicine, the lower surface of the non-woven fabric can be soaked slowly. This single spray method requires a large amount of continuous spraying of the liquid medicine, which is likely to cause waste of the liquid medicine, and the continuous spraying of the liquid makes no The woven fabric is still sprayed with liquid medicine in the state of being soaked, which causes problems such as waste of this part of liquid medicine.

Owner:TONGLING JIEYA BIOLOGIC TECH

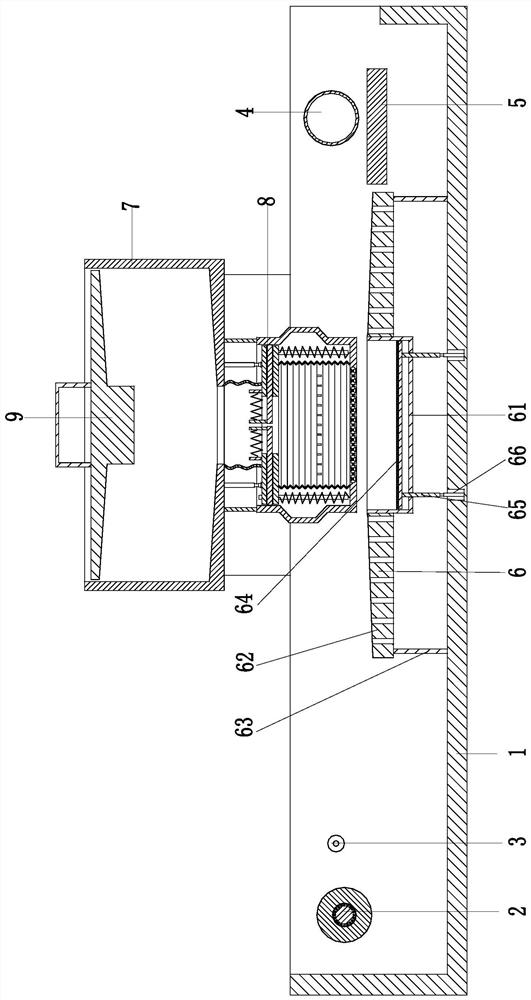

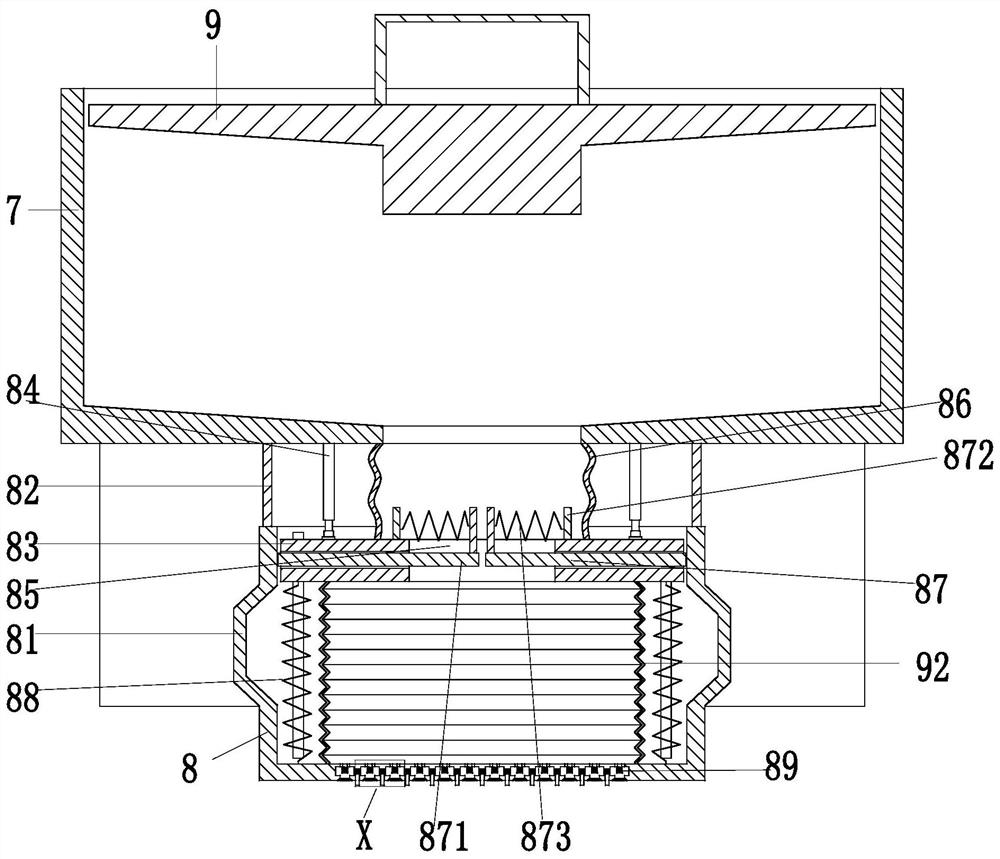

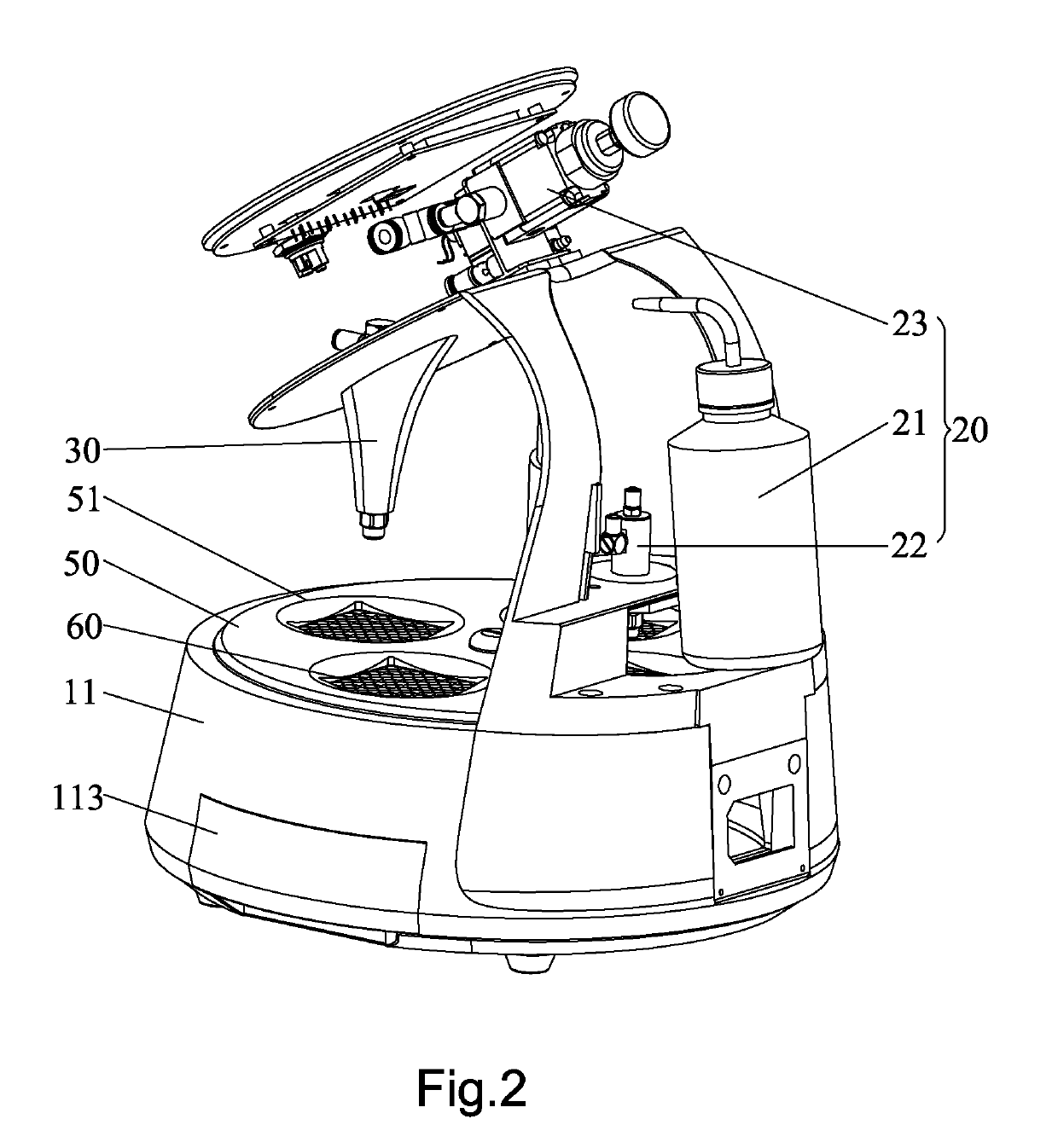

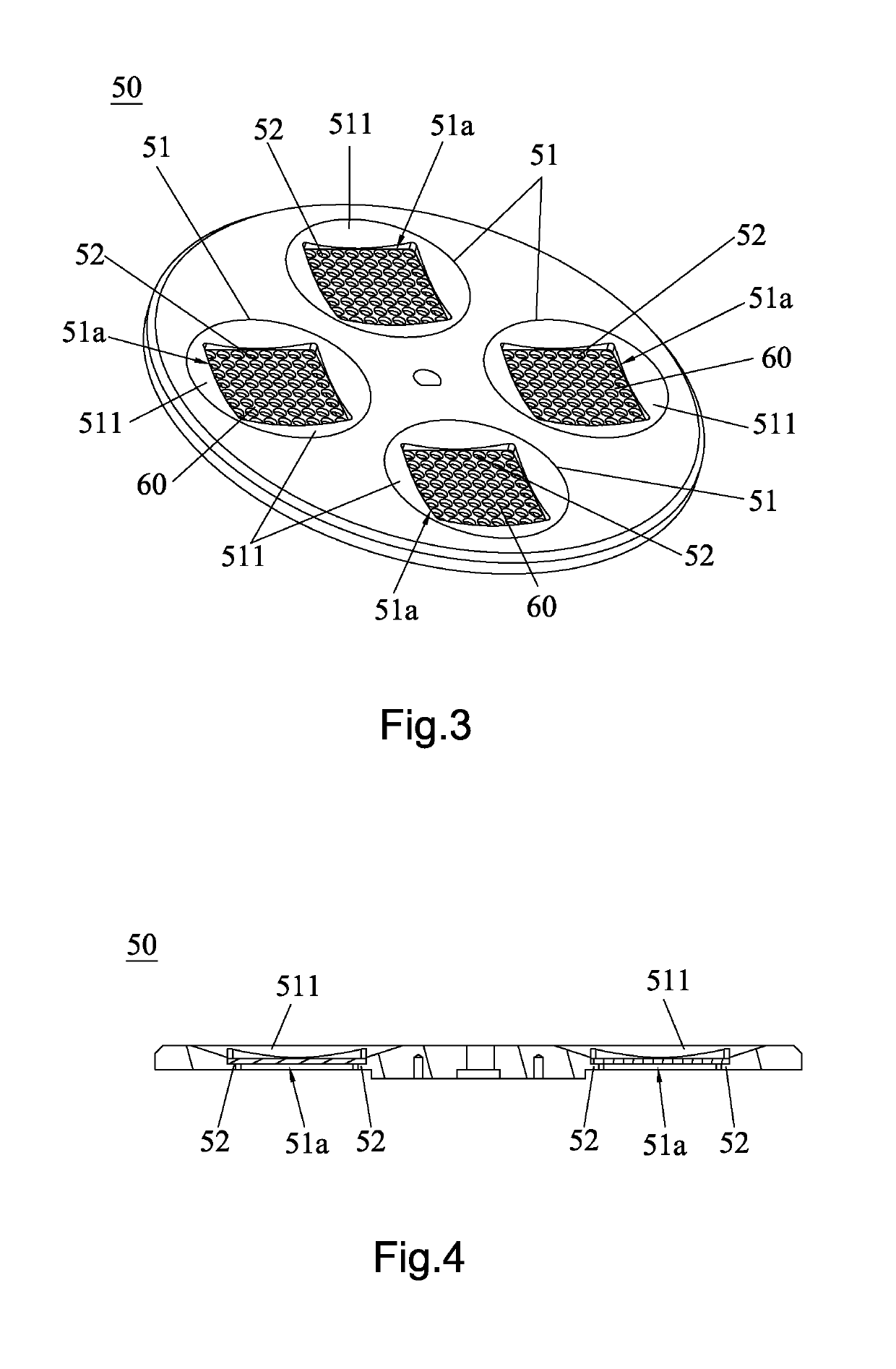

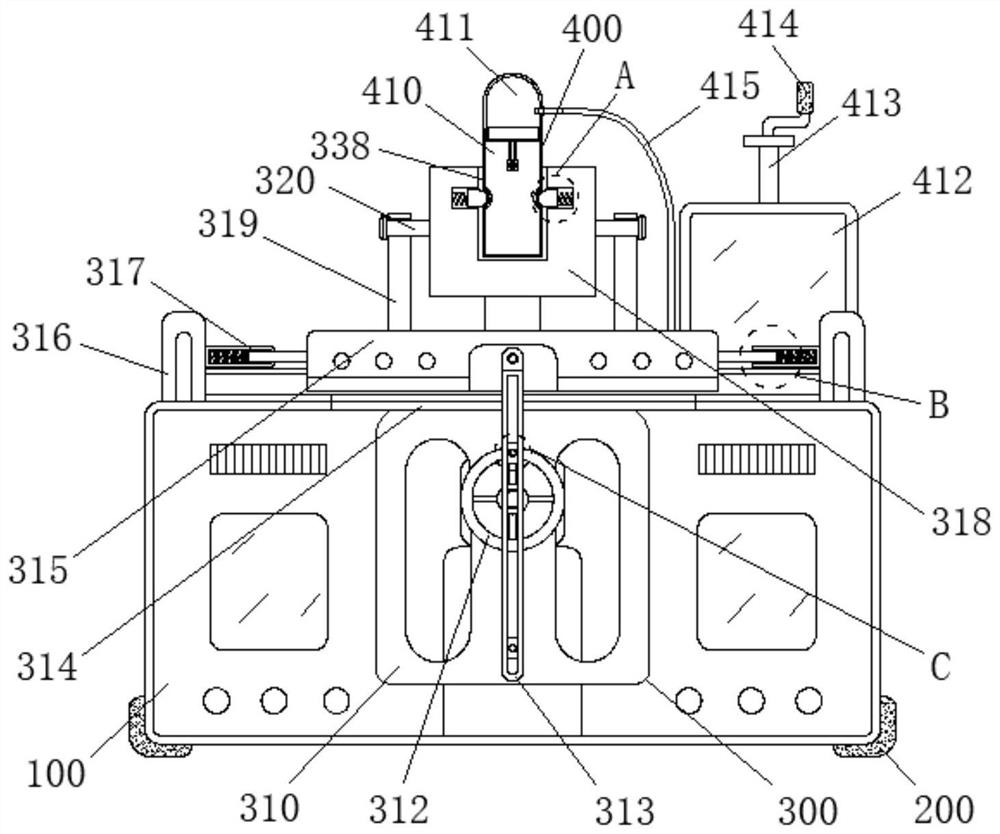

Automatic wetting apparatus

ActiveUS20190277732A1Affects timingImprove accuracyPreparing sample for investigationLiquid spraying apparatusElectrical and Electronics engineeringWetting

An automatic wetting apparatus includes a frame, and a wetting device, an air blowing device, a driving device and a station turntable. The frame is provided with a loading station, an wetting station, a unloading station and an air blowing station, the driving device includes an output end connected with the station turntable, the wetting device is cooperated with the wetting station, the air blowing device is cooperated with the air blowing station, the station turntable is provided with a support unit, the support unit is provided with a through hole, and the support unit is selectively rotatable to align with the loading station, the wetting station, the unloading station or the air blowing station, under an action of the driving device. The processes for loading, wetting and unloading are coherent, and the wetting accuracy and the wetting efficiency are high.

Owner:FINEETEX DONGGUAN CO LTD

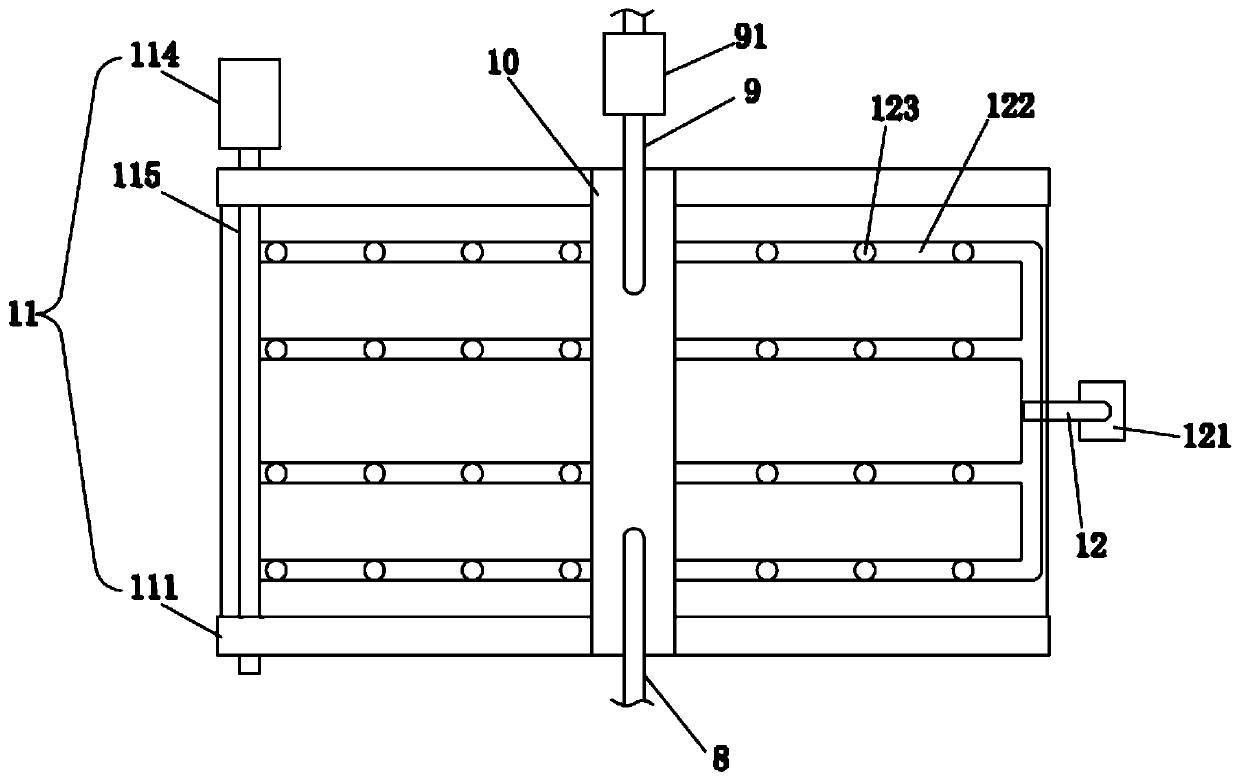

Desiccant regeneration device

PendingCN110292917AExtended delivery pathReduce the overall heightCombustible gas purificationSilicon compoundsDesiccantEngineering

The invention discloses a desiccant regeneration device, the desiccant regeneration device comprises a wetting box, a soaking box and a drying box which are sequentially communicated with each other,wherein the wetting box is divided into at least two first partition layers arranged up and down through a first seat plate, a feed inlet is arranged on the top-most first partition layer, each firstpartition layer is provided with a steam nozzle, the first partition layers are connected end to end in turn to form a cyclotron circulation channel, a first circulation conveying device is arranged in the circulation channel, a plurality of first scraping plates which are arranged at intervals along a conveying path are arranged on the first circulation conveying device, and the upper edges and the lower edges of the first scraping plates respectively correspond to the upper surfaces of the first seat plates of the upper and lower two adjacent first partition layers. According to the desiccant regeneration device, the desiccant can be wetted, soaked and dried in sequence, and the space of the box body can be fully utilized to wet a desiccant, so that the wetting is uniform, and the efficiency is high.

Owner:国智科学技术研究院(广州)有限公司

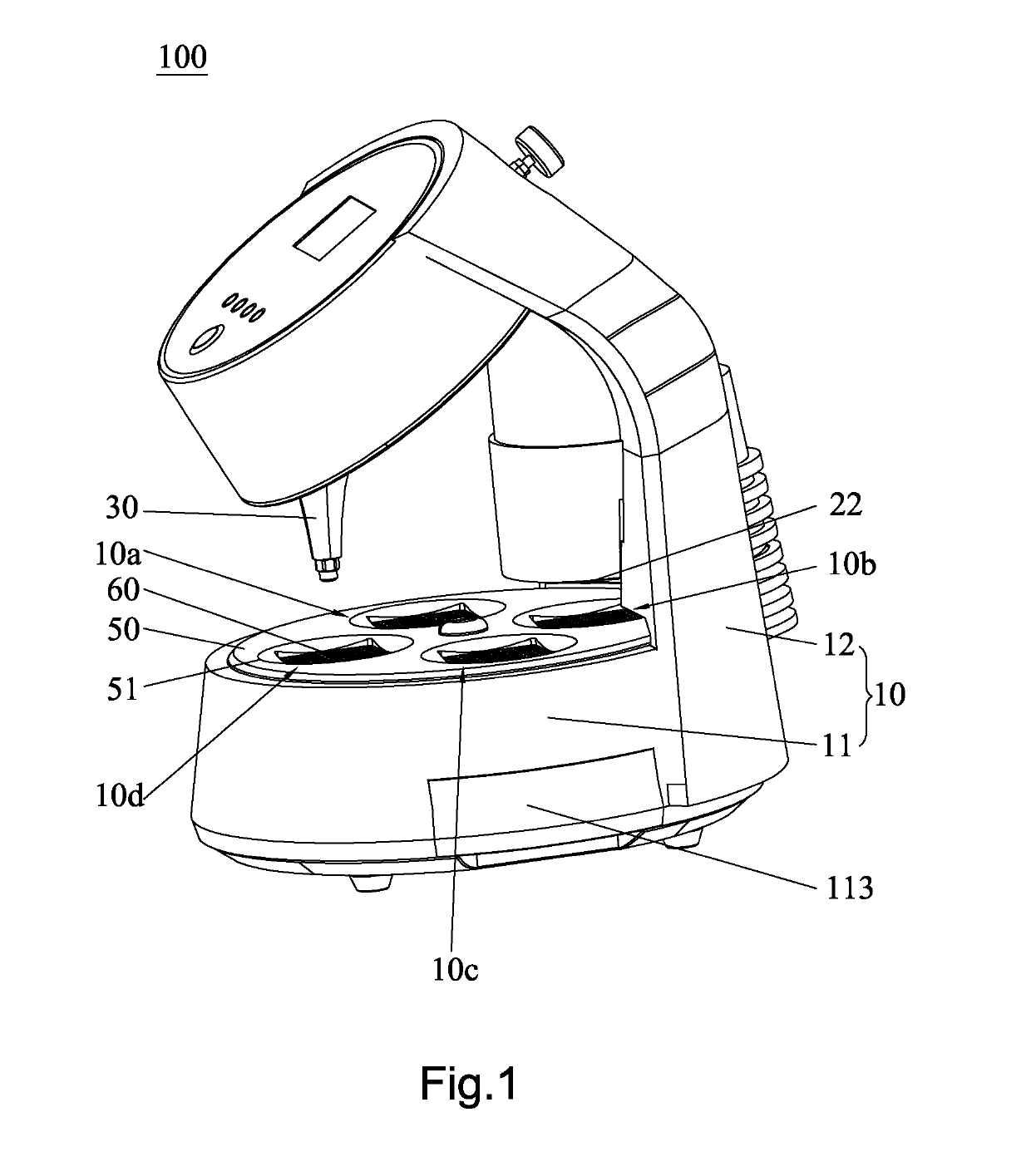

Convenient skin moisturizing device

InactiveCN111921080AMoist evenlyImprove user experienceMedical devicesMedical applicatorsMedicineEngineering

The invention relates to the technical field of moisturizing, in particular to a convenient skin moisturizing device comprising a base and a first groove. A servo motor is fixedly installed at the upper end of a base at the bottom end of the base, a rotating disc is fixedly installed at the end, extending to one side of a first fixing plate, of the servo motor, a transmission rod is fixedly installed on the inner wall of the first groove through a rotating shaft, and a sliding rod is placed and installed at the top end of the base. According to the invention, the servo motor, the rotating disc, the transmission rod and the sliding rod are arranged; the servo motor rotates to drive the rotating disc to rotate; therefore, the sliding rod moves left and right through a transmission structureof the transmission rod; a moisturizing instrument can automatically move left and right, people can conveniently and uniformly wet the face when using the moisturizing instrument at home; the user does not need to hold the moisturizing instrument with hands to wet the face, the user can free the hands to do other things; meanwhile, the face can be wetted, the practicability of the device is improved, and the use experience of the user is improved.

Owner:钟勇

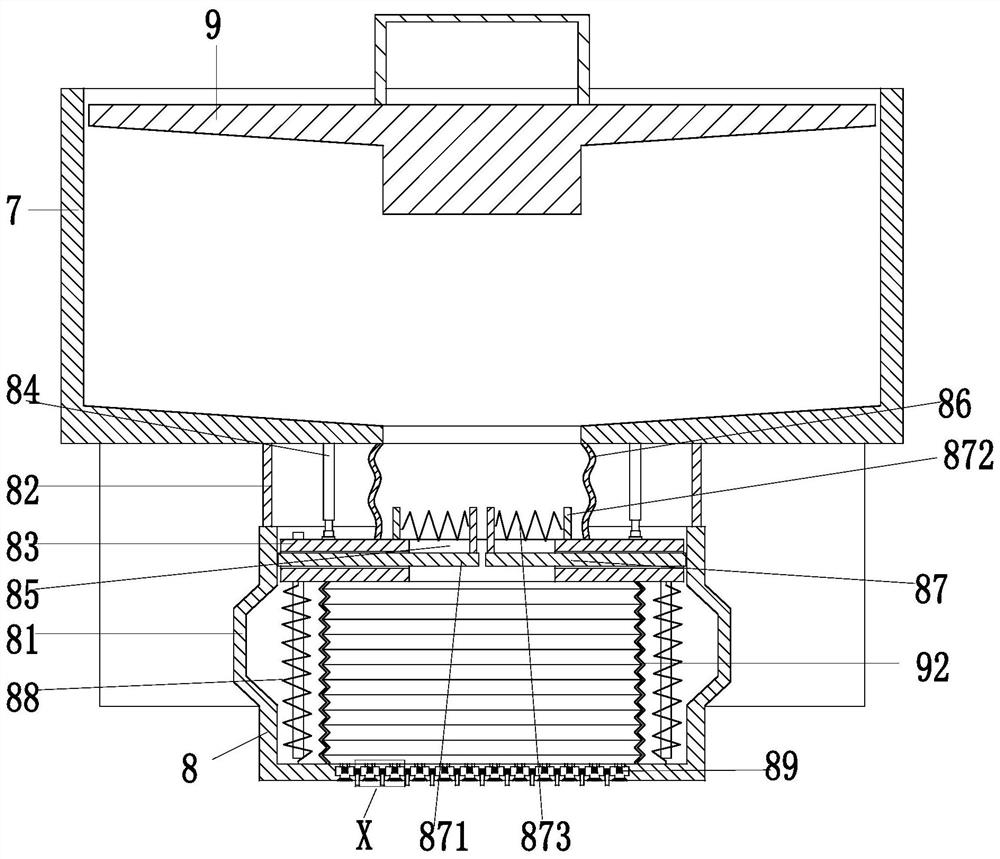

Graphene warmer

ActiveCN111156576AImprove evaporation efficiencyImprove wetting efficiencyLighting and heating apparatusElectric heating systemWater storageWater storage tank

The invention discloses a graphene warmer. The warmer comprises a warmer shell, wherein the inner wall of the warmer shell is fixedly connected with a heating pipe, the upper surface of the heating pipe is fixedly connected with a graphene heat dissipation pipe, the inner wall close to the right side of the warmer shell is fixedly connected with an evaporation wetting device, the evaporation wetting device comprises a connecting arm, the right end of the connecting arm is fixedly connected with the inner wall of the warmer shell, the bottom of the connecting arm is fixedly connected with a fixing frame, and the bottom of the fixing frame is rotatably connected with a rotating arm I through a hinge pin. According to the warmer, through the cooperative use among the structures, the problemsthat in an actual use process, due to the fact that the evaporation efficiency in a water storage tank is low, formed water vapor is little, actual use requirements are difficult to meet, meanwhile, the formed water vapor is difficult to guide and disperse at multiple angles, so that indoor air is difficult to effectively wet, and inconvenience is brought to use are solved.

Owner:河南煜和石墨烯应用技术研究院有限公司

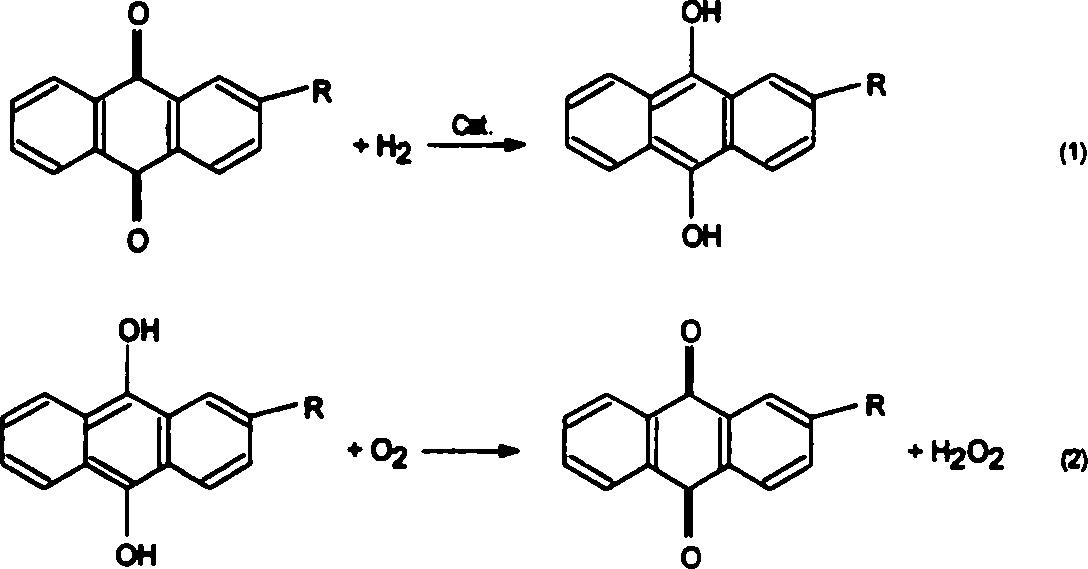

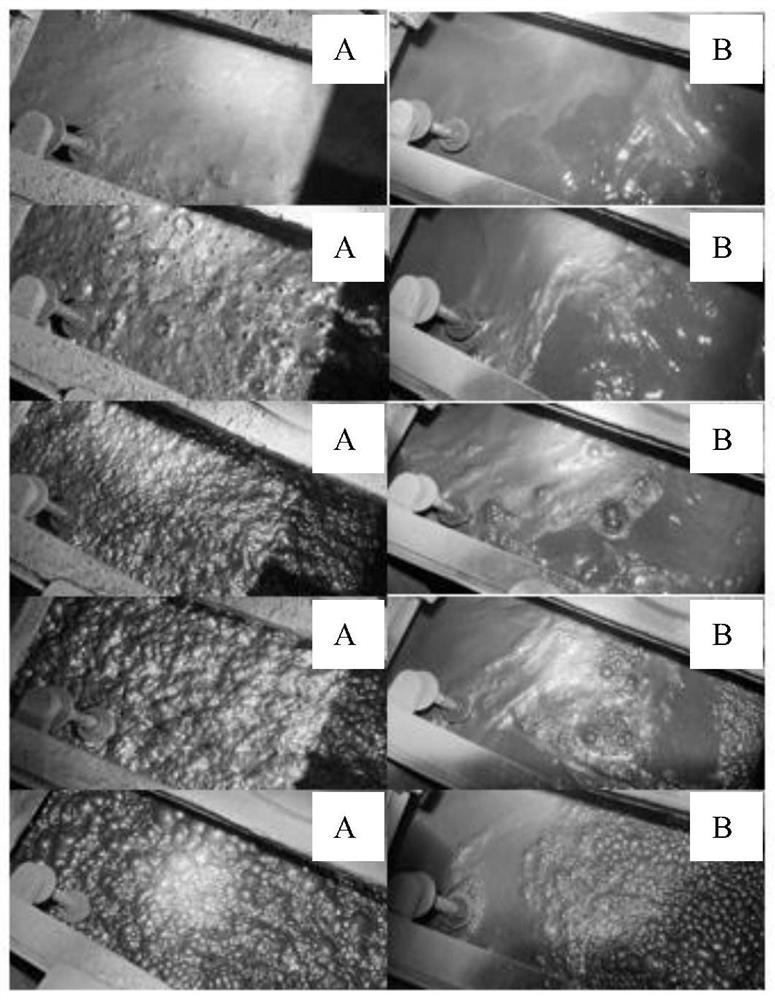

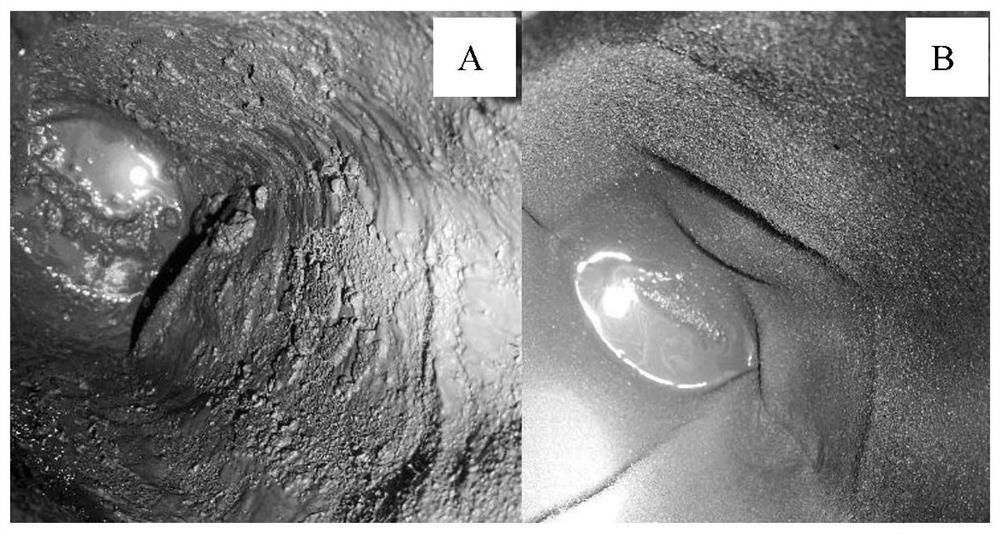

Operation process for hydrogenation reaction of anthraquinone work liquid during hydrogen perioxide production

InactiveCN1295143CImprove wetting efficiencyIncrease profitPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemistryAnthraquinone process

The present invention is operation process for hydrogenation reaction of anthraquinone work liquid during hydrogen peroxide production, and belongs to the field of hydrogen peroxide producing anthraquinone process technology. In a fixed bed reactor loaded with Pd / Al2O3 catalyst, anthraquinone work liquid and hydrogen are added from the top of the reactor. The method features the continuous addition of hydrogen, the periodical addition of anthraquinone work liquid in the period of 10-400 s, circulating fissionability of 0.1-0.9, reactor temperature of 40-70 deg.c and pressure of 101.3-400.0 KPa. The present invention has the advantages of easy control of the operation condition, raised reactor efficiency, obviously raised reaction conversion rate and selectivity.

Owner:TIANJIN UNIV

Uniform wetting device for non-woven fabric processing

PendingCN113215744AImprove uniformityImprove reliabilityTextile treatment machine arrangementsTextile treatment by spraying/projectingGear wheelAir pump

The invention discloses a uniform wetting device for non-woven fabric processing, and relates to the technical field of non-woven fabric processing. The uniform wetting device comprises a base; a support is fixedly installed at the top of the base; a uniform wetting mechanism is arranged at the top of the support; a waste water collecting mechanism is arranged on the inner side of the base; the uniform wetting mechanism comprises a sealing tank; the sealing tank is fixedly installed at the top of the support; and a power mechanism is arranged at the top of the sealing tank. According to the invention, an air pump works, an inner cavity of the sealing tank is inflated through an air pipe, water in the inner cavity of the sealing tank is sprayed out from circular nozzles and a water outlet pipe under the action of air pressure, a driving motor drives a driving gear to rotate, a centrifugal water spraying pipe is driven to rotate through the cooperation of a transmission chain and a driven gear, and the water sprayed by the circular nozzles is irregularly sprayed under the action of centrifugal force, so that the wetting uniformity of the device is improved, and the problem that an existing device is not uniform enough in wetting is solved.

Owner:魏永清

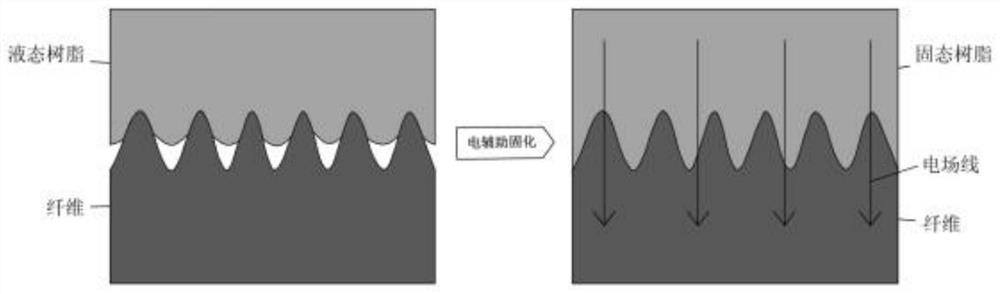

Preparation method of high-interface-strength fiber composite material

ActiveCN113638228AImprove wetting efficiencyImprove interface strengthCarbon fibresUltrasonic/sonic fibre treatmentPolymer chemistryFibrous composites

The invention discloses a preparation method of a high-interface-strength fiber composite material. The preparation method comprises the steps of material soaking, electric field auxiliary infiltration and high-temperature curing, wherein in the material soaking step, liquid resin is firstly put into a resin tank; the fibers enter the resin tank to infiltrate liquid resin, and the fibers and the liquid resin are fully infiltrated through liquid resin shower; electric field auxiliary infiltration and high-temperature curing are that the fibers subjected to liquid resin shower infiltration pass through a high-temperature electric field box with an electric field, and the electric field drives the liquid resin to flow, so that the liquid resin and the fibers are further wetted; and high-temperature curing is carried out while electric field auxiliary infiltration is performed, so that the liquid resin is cured in micro-grooves in the fiber surface to form mechanical meshing, thereby preparing the high-interfacial-strength fiber composite material. The wetting efficiency of the fibers and the liquid resin is effectively improved under the conditions that the fibers are not modified and procedures are increased excessively, the interface strength of the composite material is remarkably improved, and the comprehensive performance of the composite material is improved.

Owner:XI AN JIAOTONG UNIV

Bobbin for spinning

The invention discloses a bobbin for spinning. The bobbin for spinning comprises a tapered bobbin body; a bobbin body mounting hole is formed in the middle of the tapered bobbin body in the axial direction; a detachable bobbin sleeve is disposed in the bobbin body mounting hole in a sleeved mode; a bobbin sleeve mounting hole is formed in the axial direction of the bobbin sleeve; the bobbin sleeve mounting hole is used by being matched with a spindle of a textile machine; multiple annularly and uniformly distributed moisture spraying holes are formed in the radial direction of the cross section of the tapered bobbin body; each moisture spraying hole comprises a straight through hole close to the bobbin body mounting hole and a trumpet-shaped hole which is close to the outer side of the tapered bobbin body and opens outwards; the straight through holes are communicated with the trumpet-shaped holes; the opening angle phi of each trumpet-shaped hole is 100-160 degrees; the outer edges of every two trumpet-shaped holes in the two adjacent cross sections and in the same direction are tangent; multiple annularly and uniformly distributed through holes are formed in the radial direction of the cross section of the bobbin sleeve, and after the bobbin is mounted, the through holes are in one-to-one correspondence with the moisture spraying holes. The bobbin for spinning can effectively save resources and guarantee that yarns are uniformly wetted.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

Automobile crushing device for recovering waste automobiles

ActiveCN109876910AEffective wet treatmentRealize wet treatmentCombination devicesGrain treatmentsWaste management

The invention discloses an automobile crushing device for recovering waste automobiles. The automobile crushing device comprises a crushing cavity, a driving cavity, a dust collecting cavity and a material collecting cavity, wherein the driving cavity is arranged on the side wall of the crushing cavity; the dust collecting cavity and the crushing cavity are arranged above the material collecting cavity; a feeding hopper is arranged at the top of the crushing cavity; a first discharging opening is formed in the bottom of the crushing cavity; and a discharging opening is formed in the bottom ofthe dust collecting cavity. According to the automobile crushing device disclosed by the invention, the above structures are arranged, so that in the crushing process of the waste automobiles, dust removing can be effectively performed in the crushing cavity, the direct discharging of dust can be reduced, the situation that the environment is damaged caused by direct discharging of the dust is avoided, the influence of the dust to the health of human bodies is reduced, and the environmental protection performance of the automobile crushing device is improved.

Owner:广东省车汇莱再生物资回收有限公司

Cutting fluid for thin-sheet and large-size solar-grade silicon wafer

ActiveCN114480009AGood dispersionImprove dispersion efficiencyLubricant compositionPhotovoltaic industryAlcohol

The invention discloses a cutting fluid for a thin-sheet and large-size solar-grade silicon wafer, and belongs to the technical field of linear cutting processing in the photovoltaic industry. The cutting fluid consists of the following components in parts by weight: 25-40 parts of a dispersing agent, 8-15 parts of a wetting agent, 8-12 parts of a stabilizing agent and the balance of pure water, the total parts of the components are 100 parts. Wherein the dispersing agent is a polyether dispersing agent with a multi-branched structure, can provide more active adsorption sites, has higher dispersion efficiency on silicon powder, and has excellent wettability; the wetting agent is dialkynyl alcohol polyether with a symmetrical structure, and the wetting performance is higher than that of common isomeric alcohol ether, and the wetting efficiency is better. Through scientific cooperation of the dispersing agent and the wetting agent, the cutting fluid has excellent dispersion, dynamic wetting, static wetting, defoaming and other properties, the yield of silicon wafers can be effectively improved, and the stability of the cutting process is kept.

Owner:GUANGDONG GOKIN SOLAR ENERGY TECH CO LTD +1

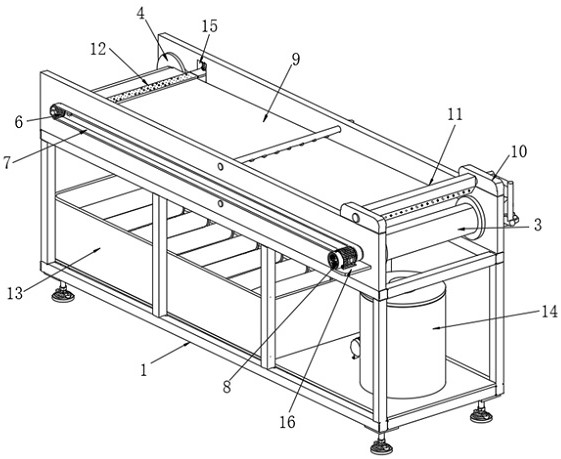

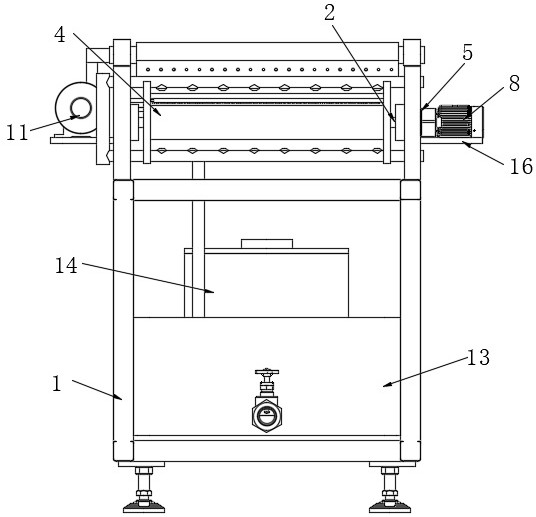

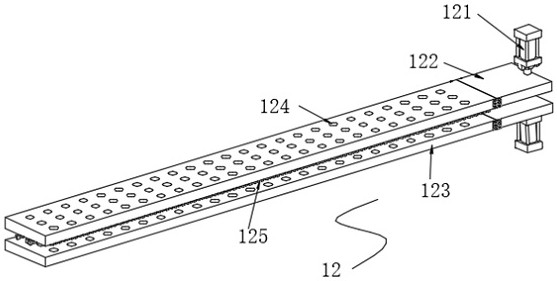

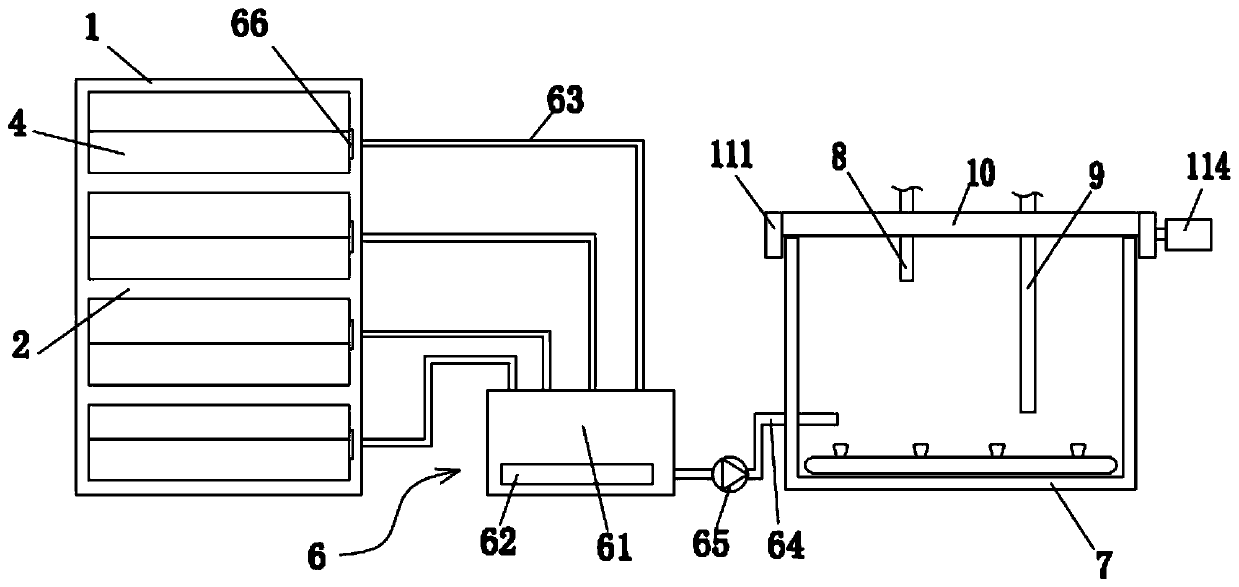

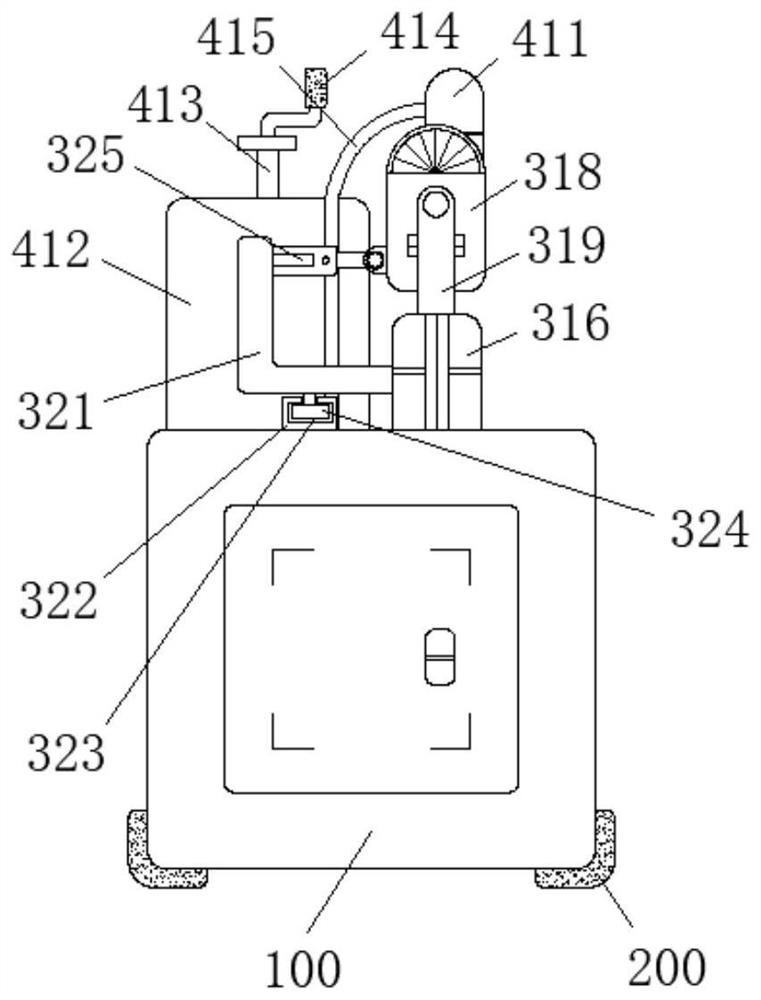

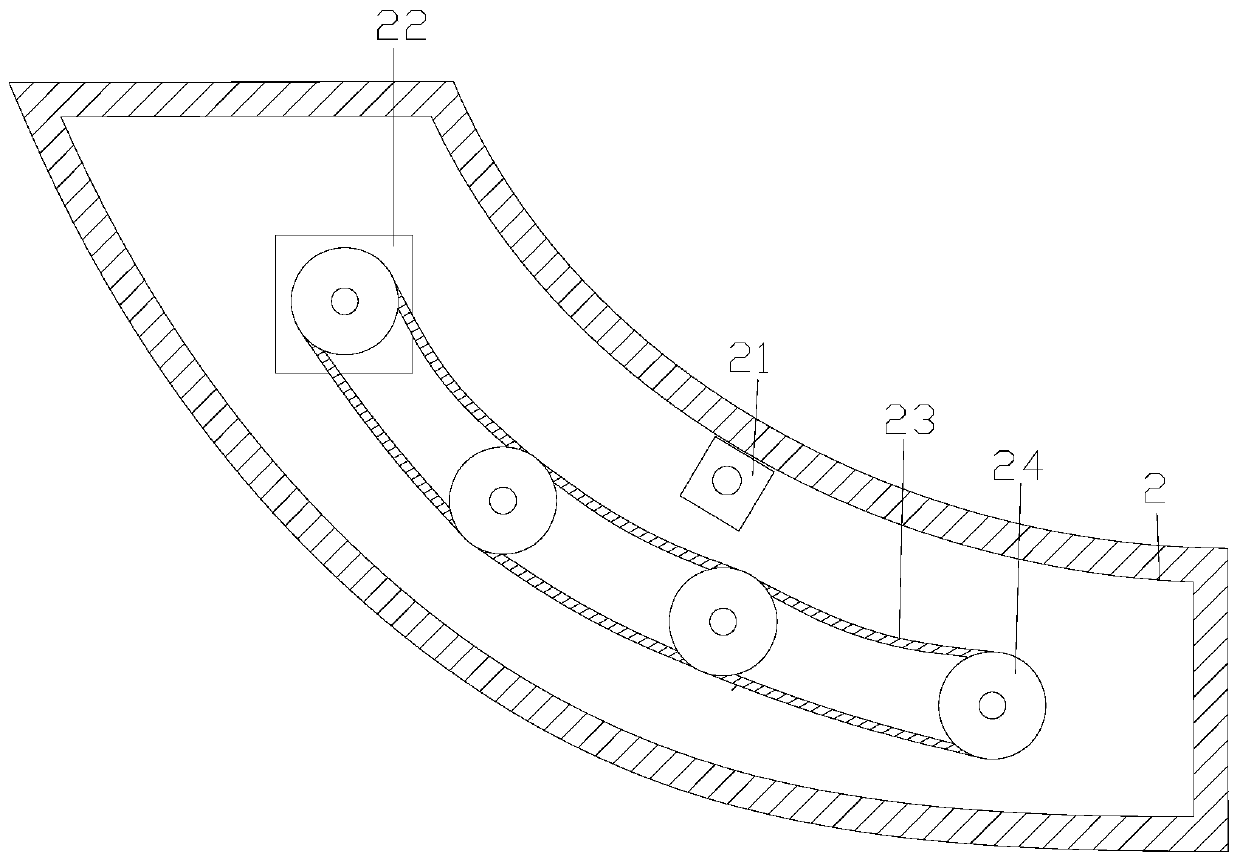

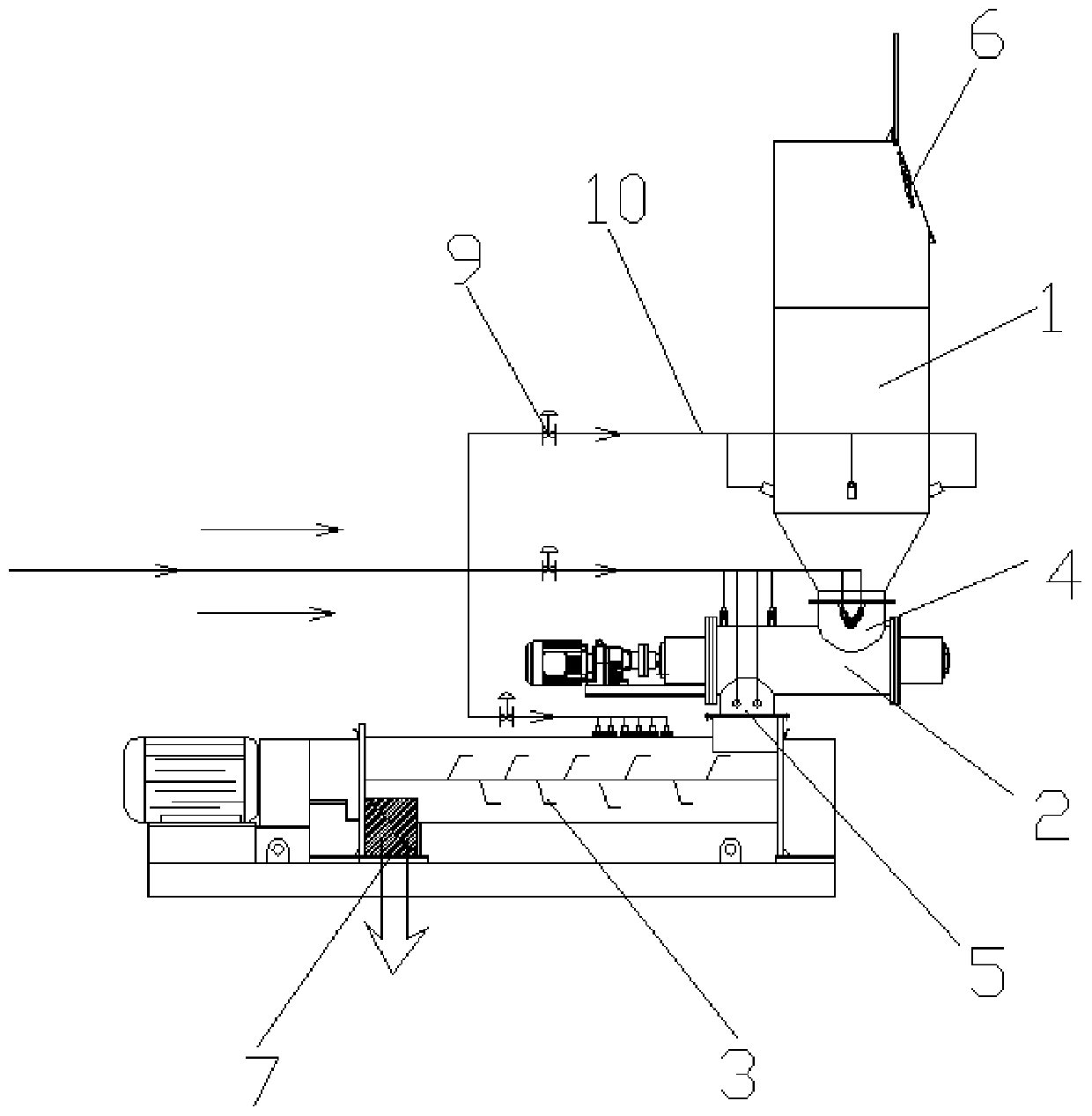

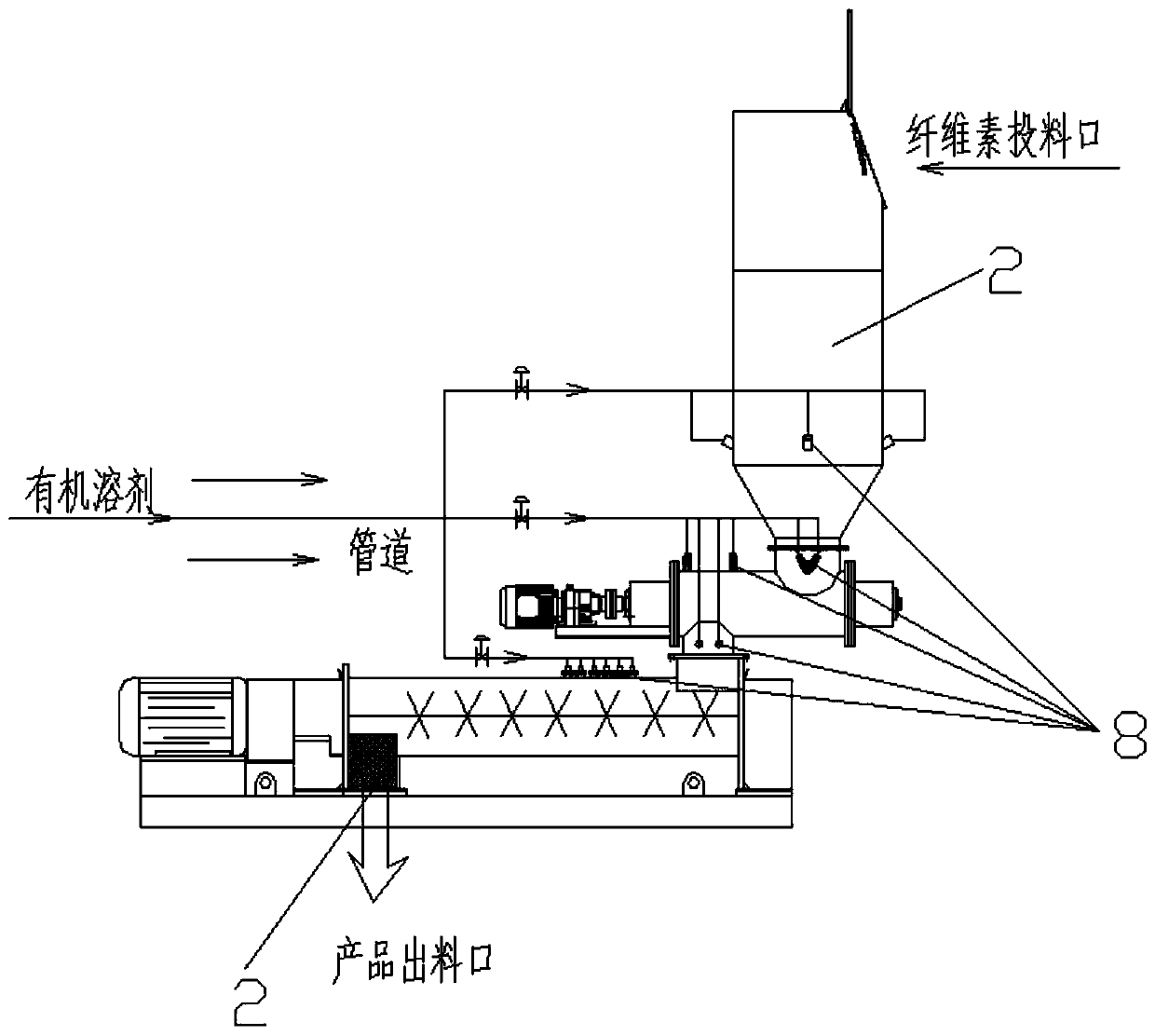

Rapid cellulose wetting equipment and rapid cellulose wetting process

PendingCN110404433AImprove wetting efficiencyImprove wetting qualityTransportation and packagingRotary stirring mixersCelluloseOrganic solvent

The invention discloses rapid cellulose wetting equipment and a rapid cellulose wetting process. The equipment comprises a material bin, a pre-mixer, a high-speed continuous mixer, cellulose, an organic solvent, a pipeline and a control system, wherein the material bin is arranged on the upper end of the pre-mixer, the material bin, the pre-mixer and the high-speed continuous mixer form one connection, the material bin, the pre-mixer and the high-speed continuous mixer are respectively provided with a plurality of solvent inlets, the solvent inlet is provided with a spraying nozzle, and one end of the spraying nozzle is connected to the pipeline. According to the present invention, the organic solvent is gradually sprayed onto cellulose through the spraying nozzles, such that the cellulosecan be fully infiltrated, the wetting quality is improved, the continuity of cellulose wetting is achieved, the production efficiency is greatly improved, the precise control of the solvent consumption is achieved, and the use cost is reduced.

Owner:HANGZHOU LIANGSHENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com