Patents

Literature

91results about How to "Play a role in cleaning up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

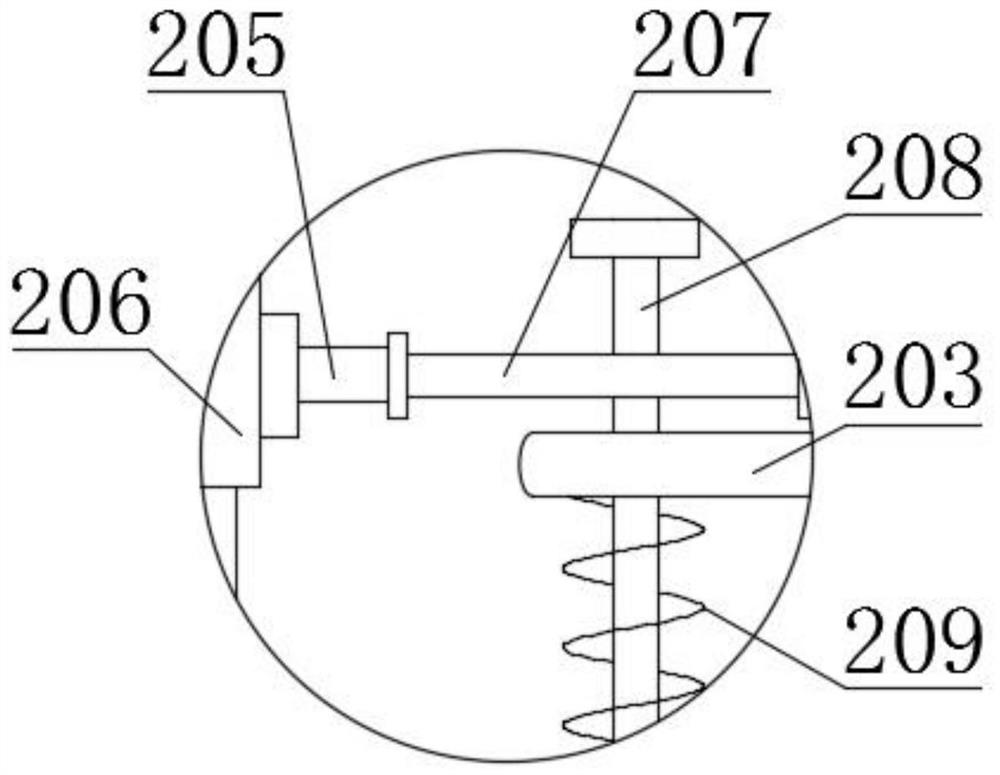

Waste cable recovery device

InactiveCN107979032AEasy to scrape awayEnable mobilityApparatus for removing/armouring cablesCopper wireEngineering

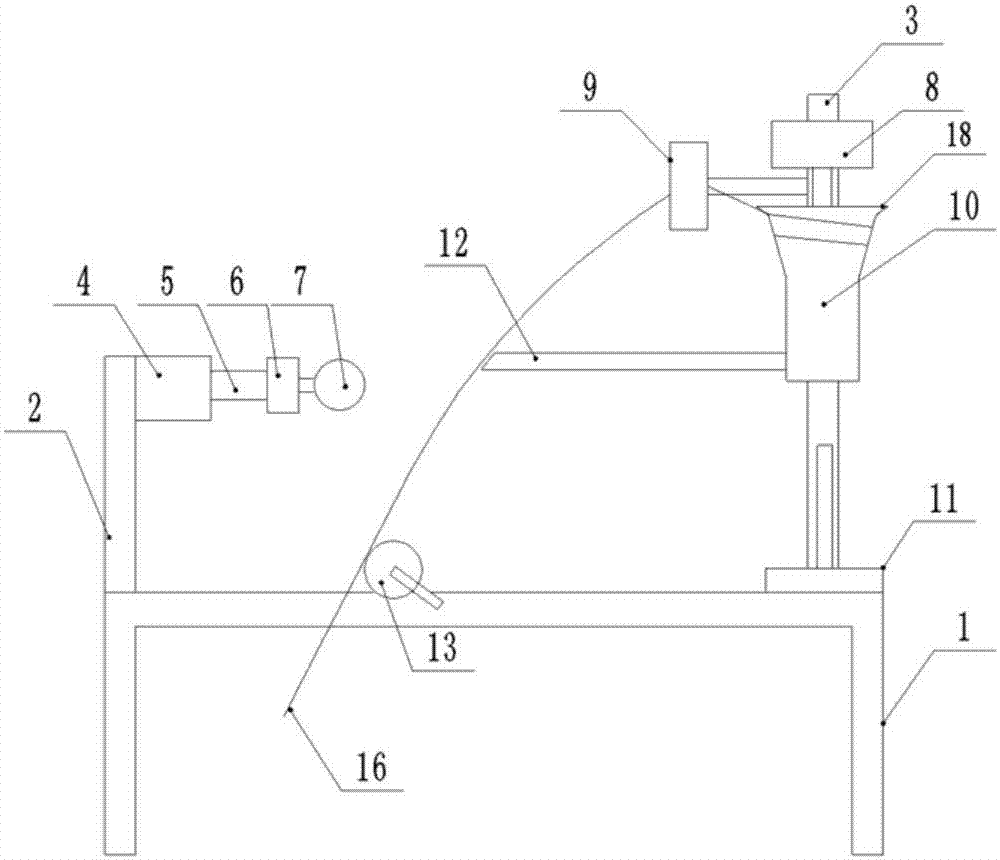

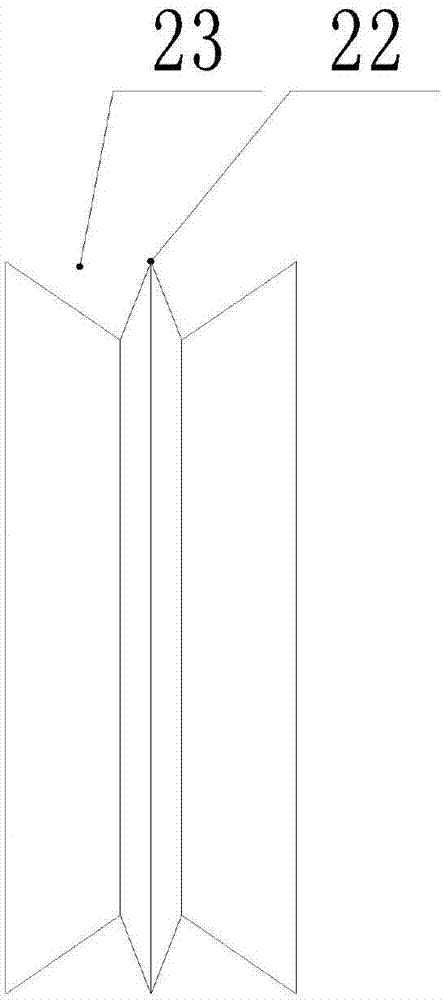

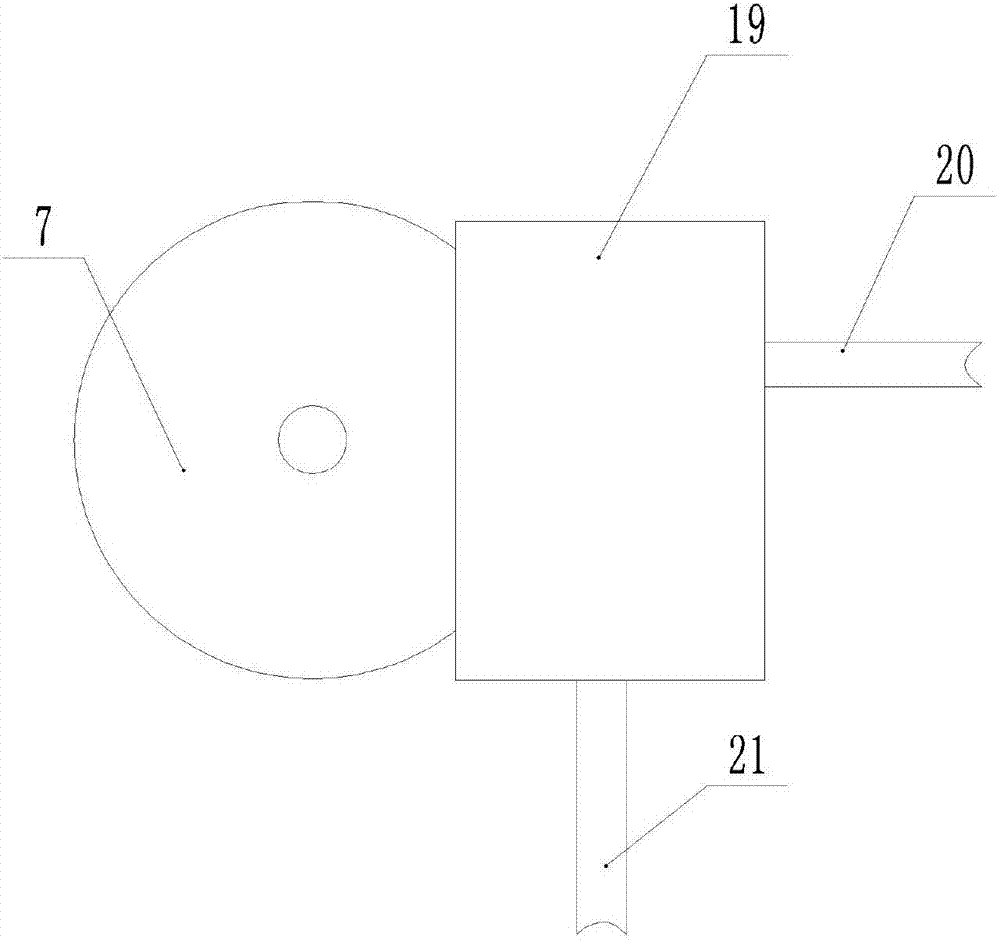

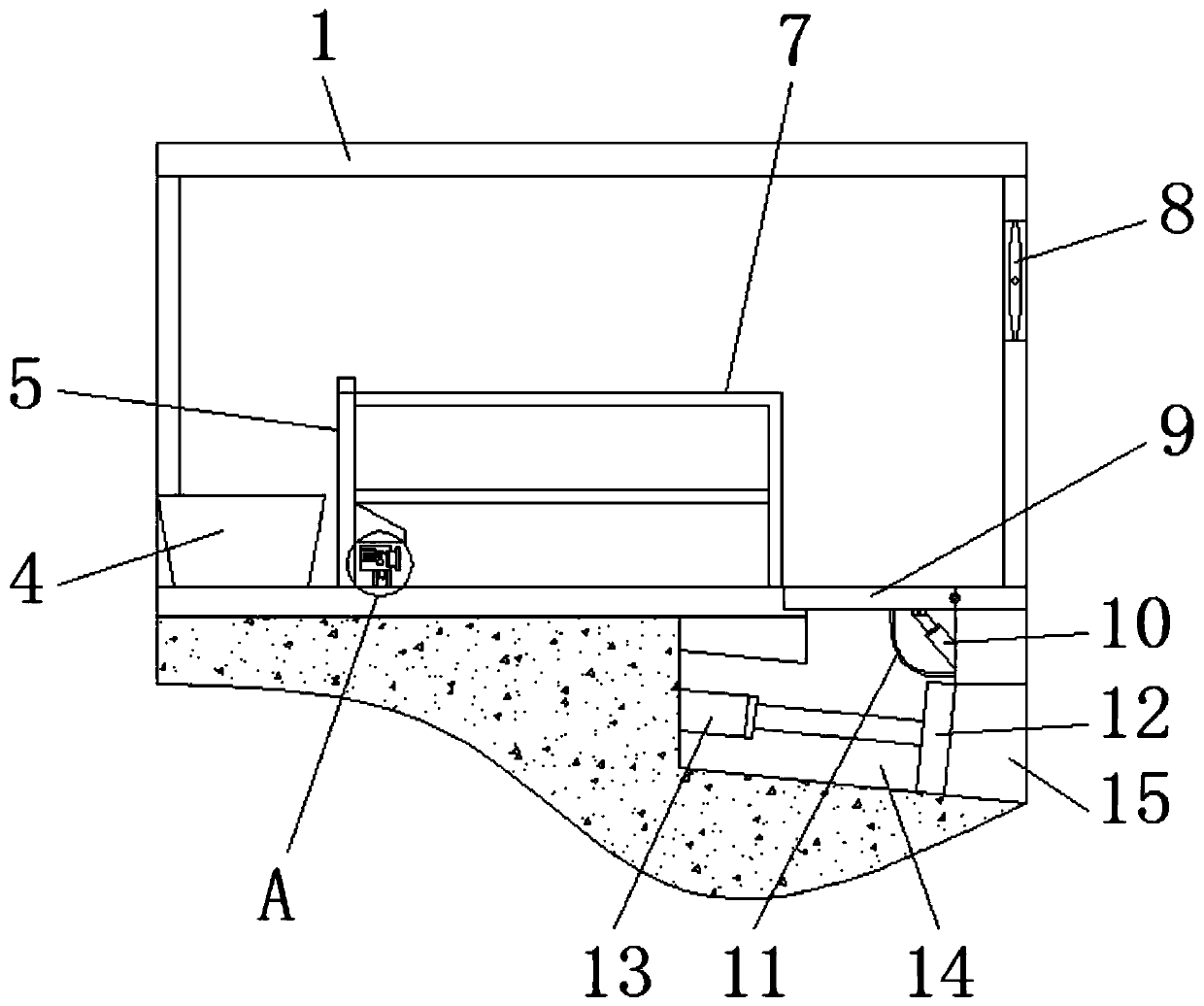

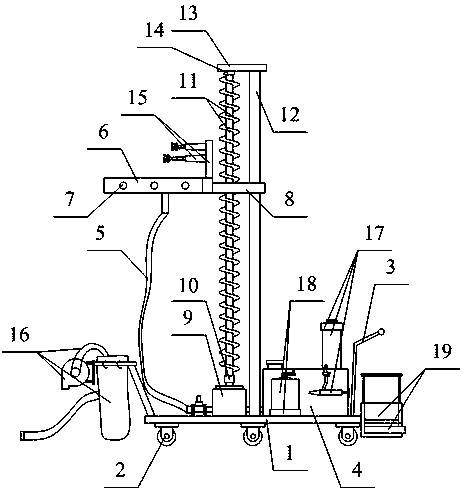

The invention belongs to the technical field of cable waste treatment equipment and particularly discloses a waste cable recovery device. The waste cable recovery device comprises a rack, wherein a support rod is arranged at one end of the rack and a bracket is arranged at the other end of the rack; an air cylinder is arranged at the upper end of the support rod; a first motor is arranged on a telescopic pole of the air cylinder; a cutter knife is arranged on an output shaft of the first motor; a second motor and a guide roller are arranged at the upper end of the bracket; a winding roller isarranged on the output shaft of the second motor; the upper end of the winding roller is in an inverted cone form; a horizontal guide hole is formed in the guide roller; a wire spool opposite to the winding roller is arranged on the rack; a horizontal scraper is arranged in the middle of the bracket; and a wire feeding roller in rotational connection is arranged in the middle of the rack. The waste cable recovery device is mainly used for recovering copper wires in waste cables and wires, so that the problem that the recovery efficiency is reduced due to the fact that the peeled copper wires cannot be automatically wound and collected in the recovery process is solved.

Owner:宁波得晴电器科技有限公司

Heavy oil multiphase thermal huff and puff oil recovery method

InactiveCN102367730AImprove the spread factorPlay a role in increasing oilFluid removalSealing/packingRecovery methodCombustion

The invention relates to a heavy oil multiphase thermal huff and puff oil recovery method. By adopting the heavy oil multiphase thermal huff and puff oil recovery method, the main problems that the existing steam huff and puff oil recovery method is performed in a place which is far away from a near wellbore zone, the recovery is difficult due to temperature drop and the recovery rate is low are solved. The heavy oil multiphase thermal huff and puff oil recovery method is characterized in that mixed gas of high-temperature and high-pressure water vapor, N2 and CO2 is generated by combustion of a rocket power oil recovery device, the mixed gas, a high-temperature foaming agent and the water vapor generated by a steam boiler are injected into a formation, and the injection time and the sequence of all components are determined according to the status of the formation, subject to the fact that the pressure can not exceed the bursting pressure of the formation. The heavy oil multiphase thermal huff and puff oil recovery method has the characteristics of high recovery rate and good oil driving effect in the place which is far away from the near wellbore zone.

Owner:大庆黑帝庙稠油试采技术开发有限公司

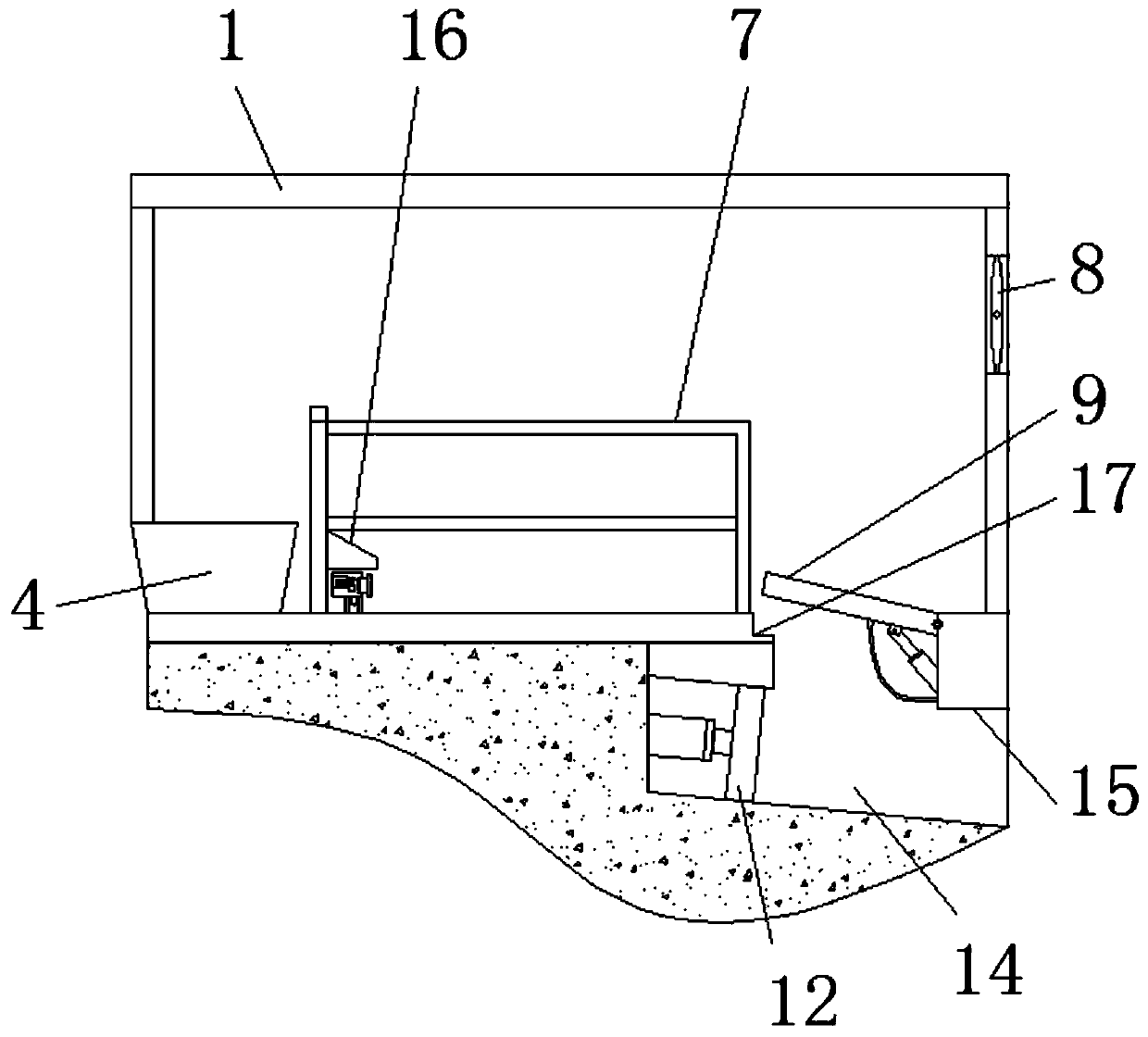

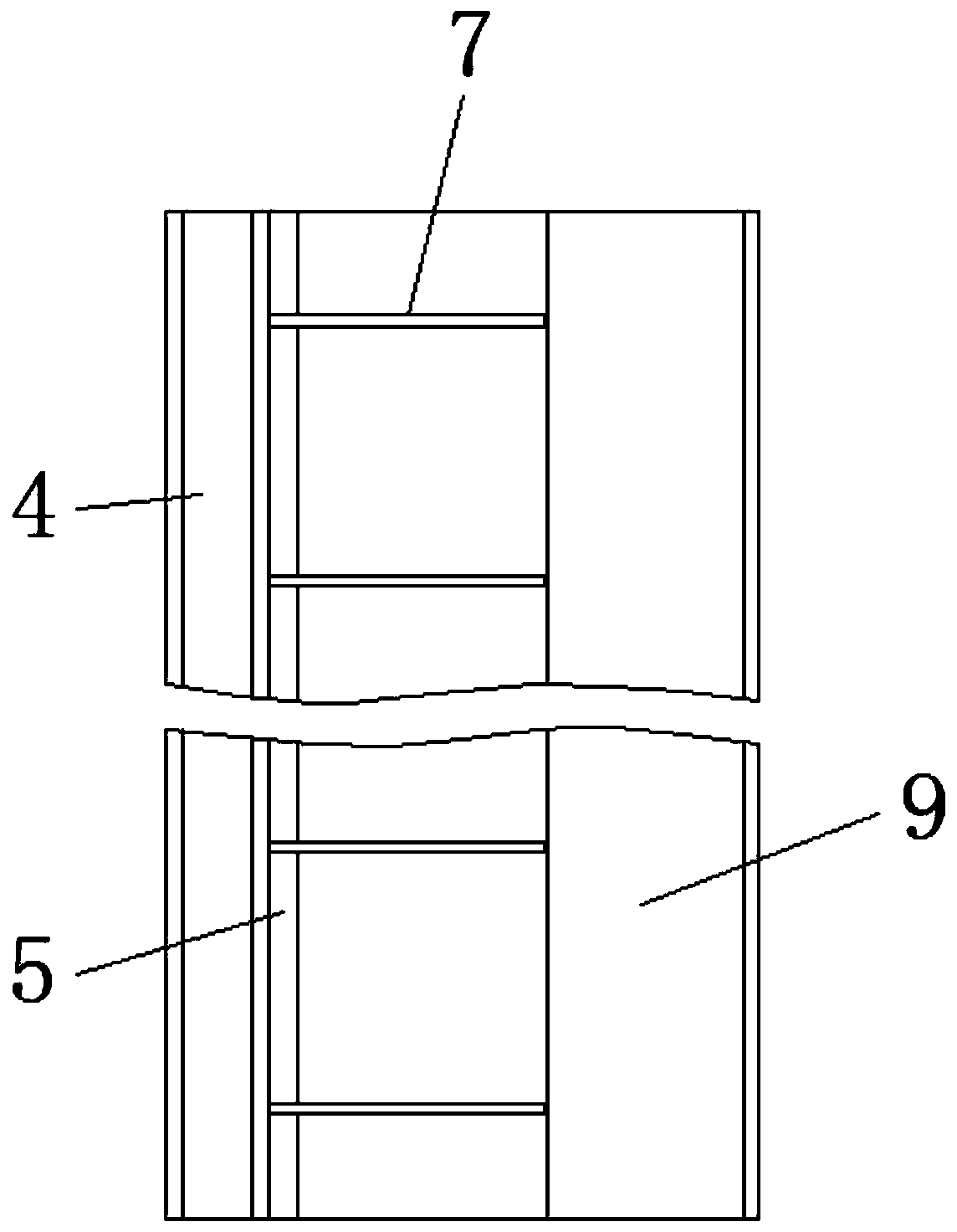

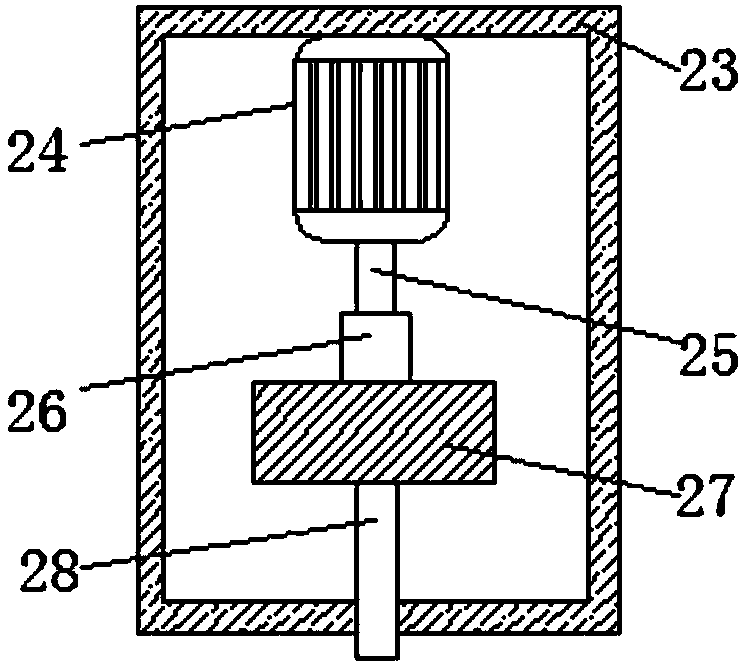

Breeding shed convenient for cleaning excreta for livestock breeding

The invention discloses a breeding shed convenient for cleaning excreta for livestock breeding. The breeding shed comprises a breeding shed roof, a moving wheel, balls, a feeding trough, a protectivefence, a partition fence, a ventilation fan, a first electric telescopic rod, a protective cloth, a second electric telescopic rod, a motor, a turbine, a worm, a connecting block, a water spraying pipe, a water spraying head and a breeding shed side plate, wherein the feeding trough is arranged at the lower part of the breeding shed roof; the protective fence is arranged at the right side of the feeding tough; the partition fence is arranged at the right side of the protective fence; and the ventilation fan is arranged at the right side of the breeding shed roof. According to the breeding shedconvenient for cleaning excreta for livestock breeding, a cleaning device is arranged on the lower side of the protective fence, so that the effect of cleaning the breeding ground is achieved; and cleaning brushes are arranged on both sides of the lower end of the cleaning device, and water spraying pipes are arranged inside the cleaning brushes, so that the cleaning of the breeding ground is facilitated.

Owner:嘉兴金旅燕科技有限公司

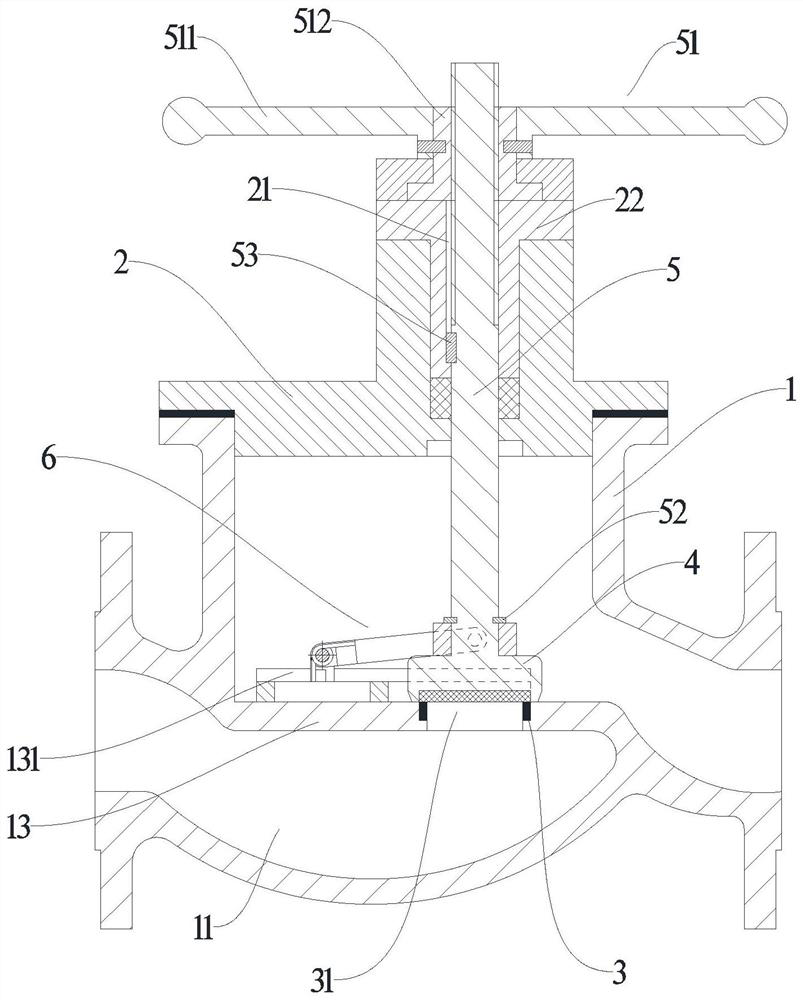

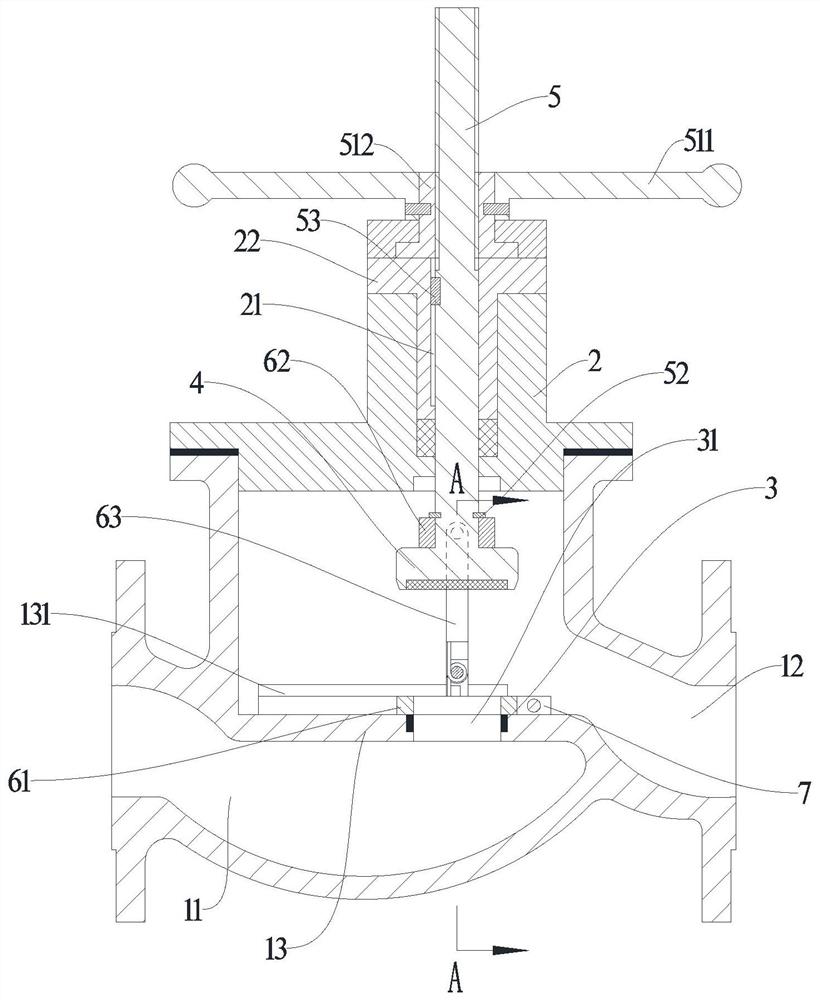

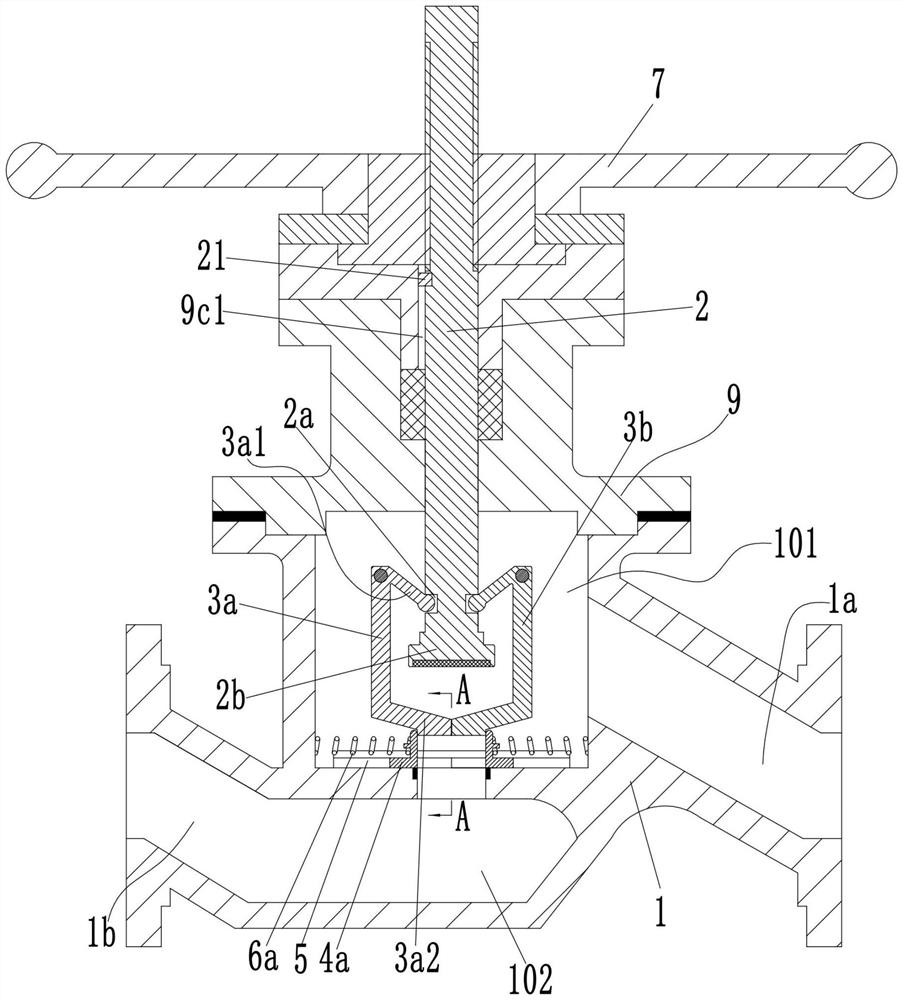

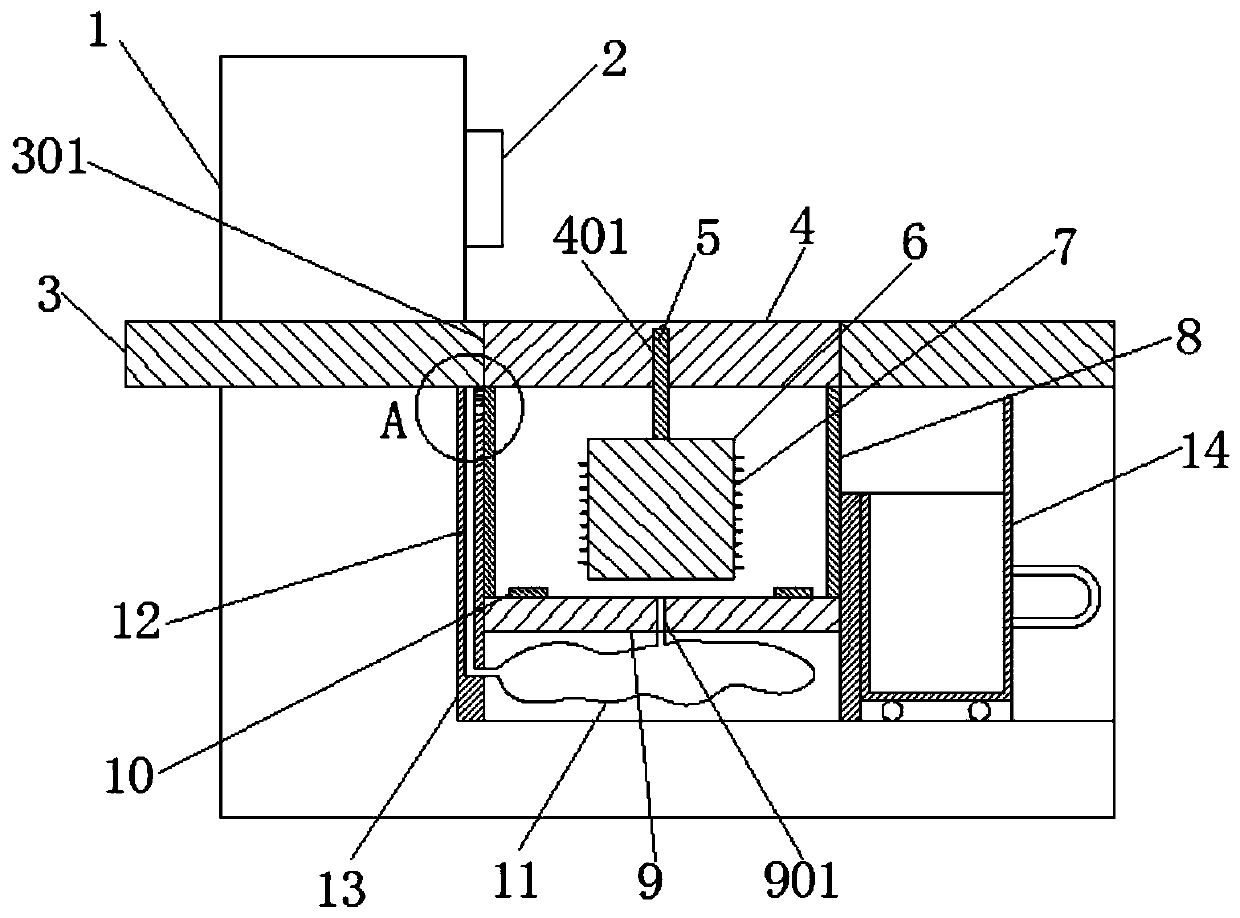

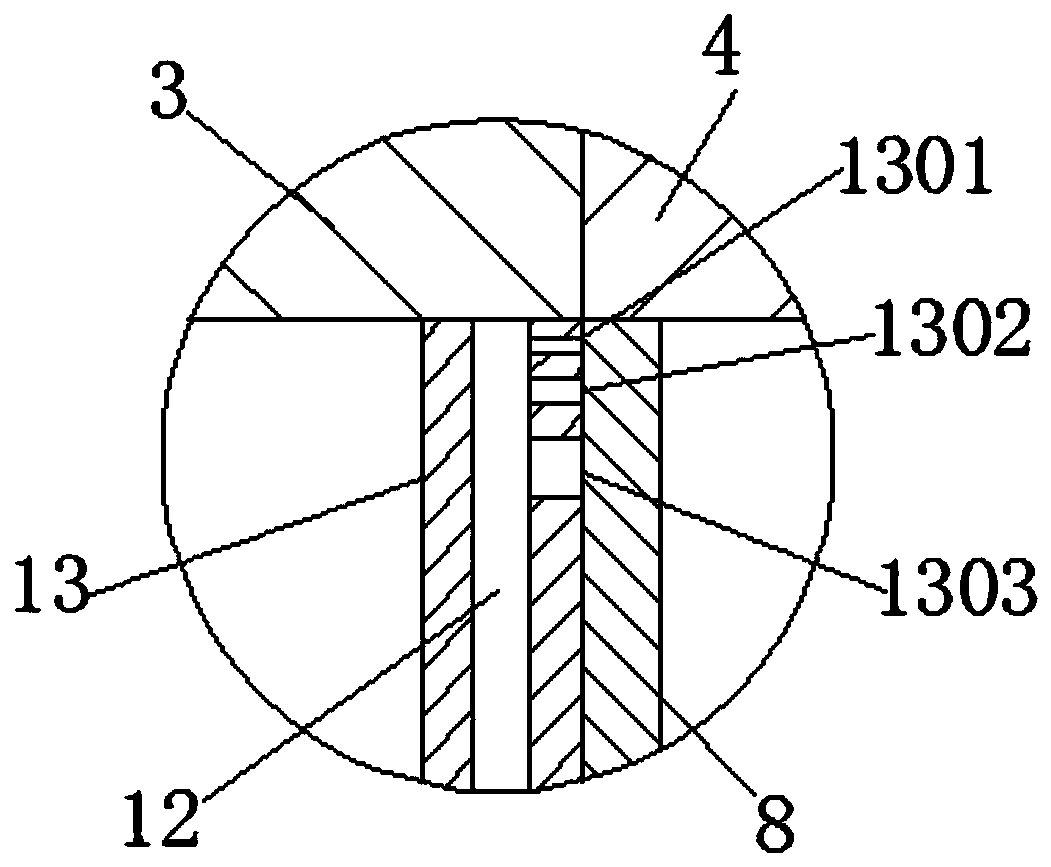

Stop valve

InactiveCN111720564APlay a role in cleaning upHas a barrier effectOperating means/releasing devices for valvesCleaning using toolsStructural engineeringMechanics

The invention relates to a stop valve which comprises a valve body and a valve cover. An inlet runner and an outlet runner are arranged in the valve body. A division plate is arranged between the inlet runner and the outlet runner. A valve seat is arranged on the side, located on the inlet runner, in the valve body. The stop valve further comprises a clearing mechanism and a protection plate cleaning part. The clearing mechanism is connected with the valve body, and media deposited on the surface of the valve seat can be cleaned away. The clearing mechanism comprises a protection plate, a connecting plate and a hinged part. Through ascending and descending of a valve clack, the protection plate can be controlled to clear the sealing face of the valve seat, and the protection plate cleaningpart can clean the protection plate. The stop valve has the advantages that through the arrangement of the clearing mechanism and the protection plate cleaning part, the clearing mechanism can be used for clearing the valve seat and can be cleared, and therefore the sealing effect of the valve clack and the valve seat is guaranteed, and maintenance cost is reduced.

Owner:张文波

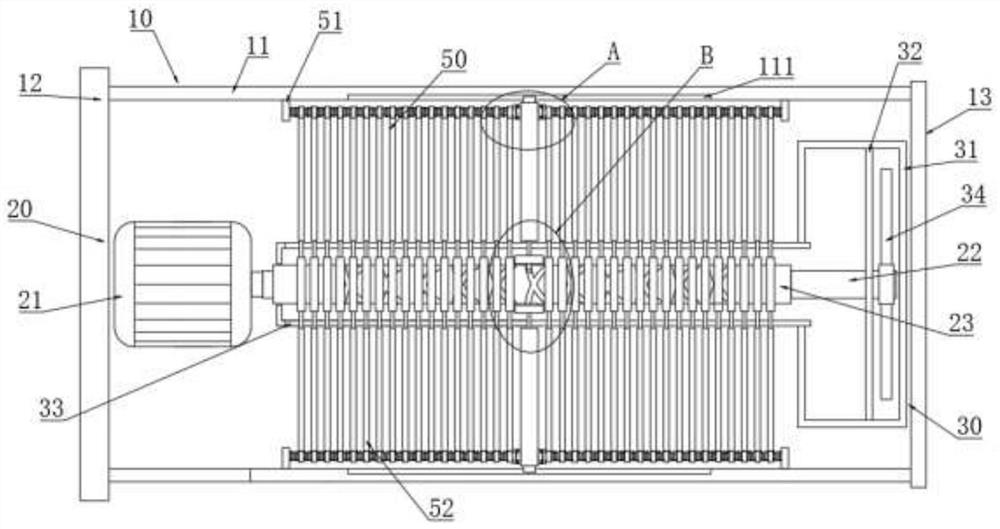

Coal mill for coal chemical gasification furnace slag decarburization

The invention discloses a coal mill for coal chemical gasification furnace slag decarburization. The coal mill comprises a feeding port, a cleaning plate, a handle, a motor and a supporting base, wherein the feeding port is formed in the left end of a coal milling roller, a first gear is arranged on the right side of the feeding port, and the cleaning plate is connected with the coal milling roller through a connecting block and a fixing bolt; the cleaning plate and the coal milling roller are both connected with the connecting block, the handle is arranged on the upper end face of the cleaning plate, and the motor is connected with the first gear in an engaged mode through a second gear; and the supporting base is arranged on the right side of the second gear, and the supporting base is connected with a groove through a supporting rolling wheel. The groove is formed in the outer side of the coal milling roller. The coal mill for coal chemical gasification furnace slag decarburization is provided with the cleaning plate above the coal milling roller to play a role of cleaning the inner part of the coal milling roller, so as to prevent coal slag or sundries from being blocked inside the coal milling roller, and thus protection to the coal mill for coal chemical gasification furnace slag decarburization is facilitated.

Owner:开阳浩洋环保科技开发有限公司

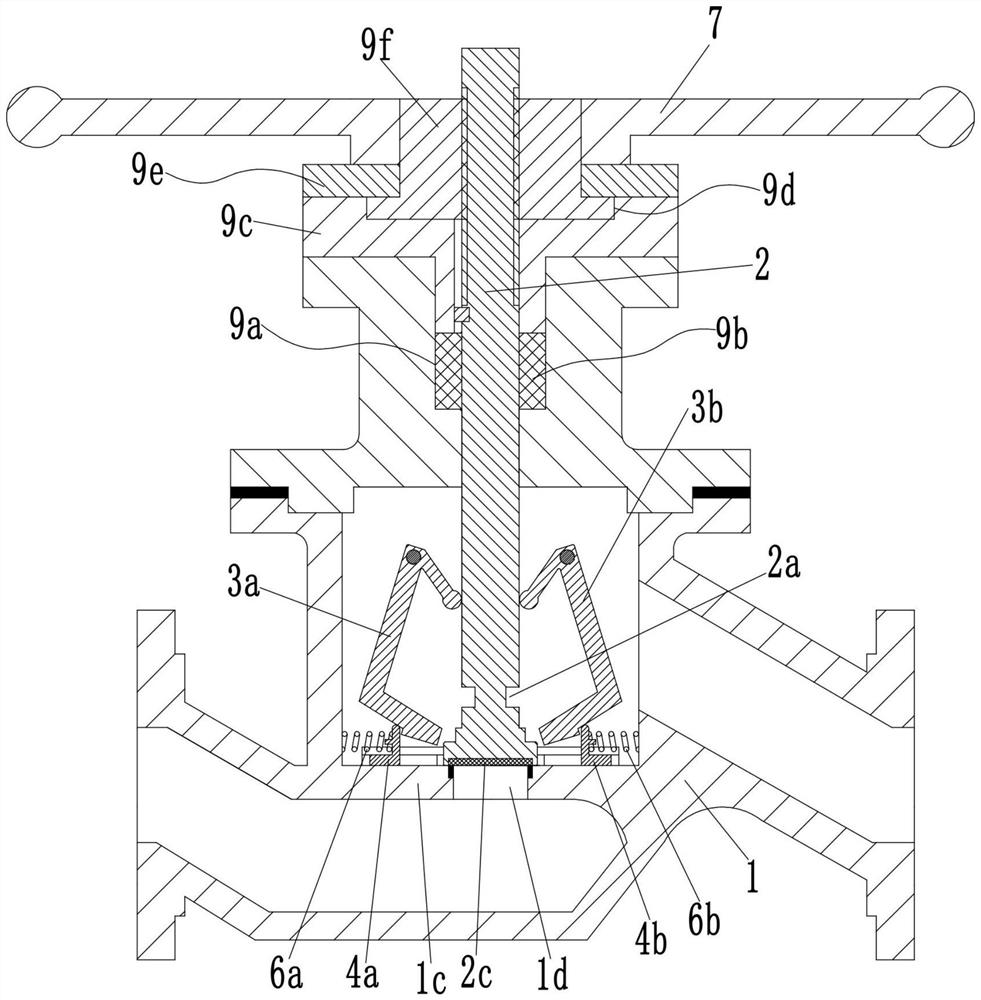

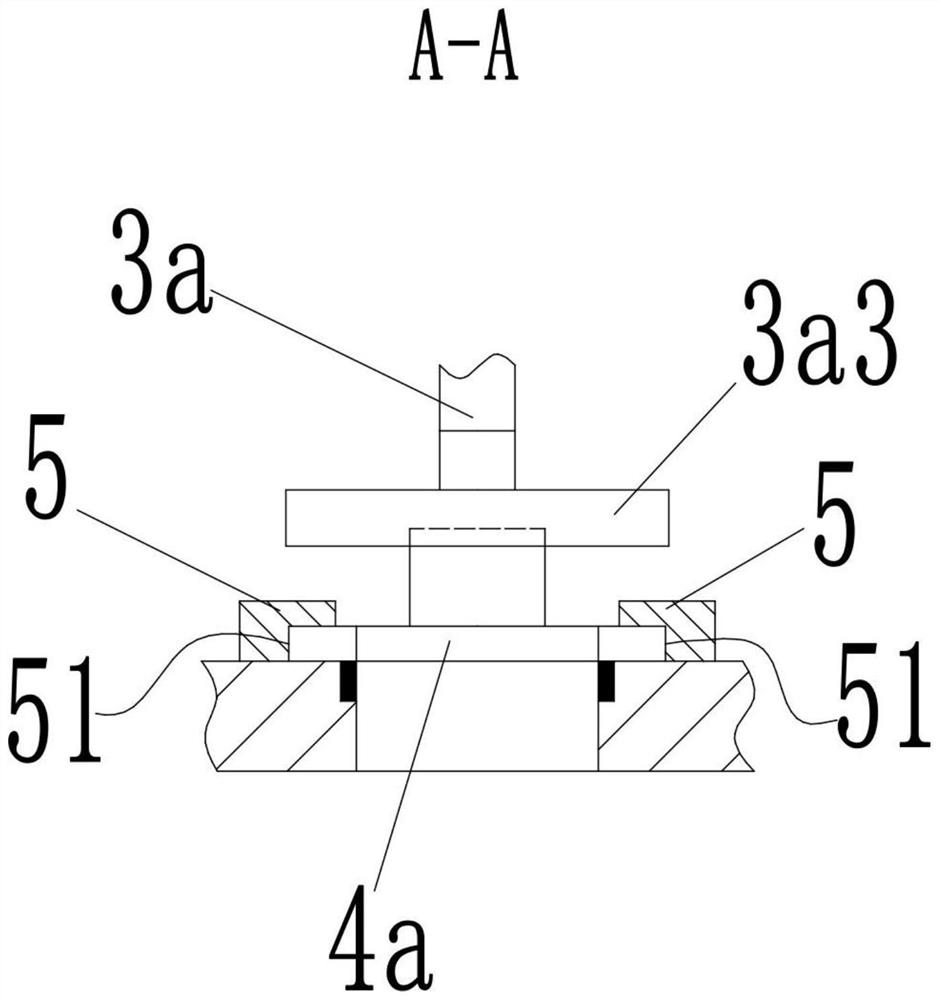

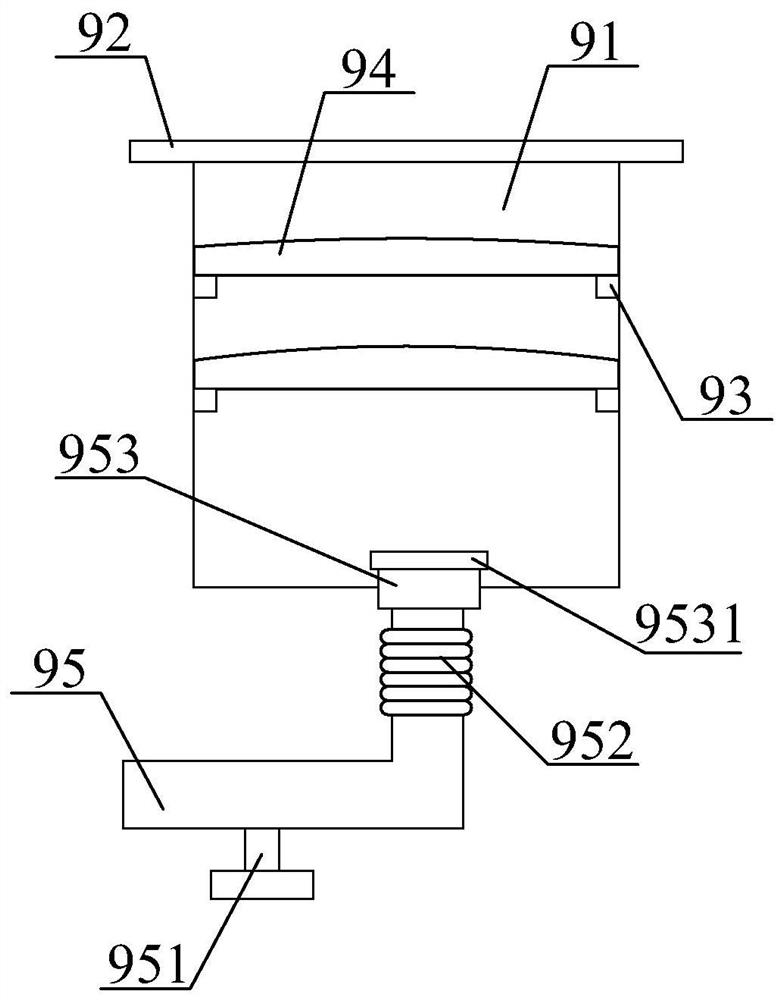

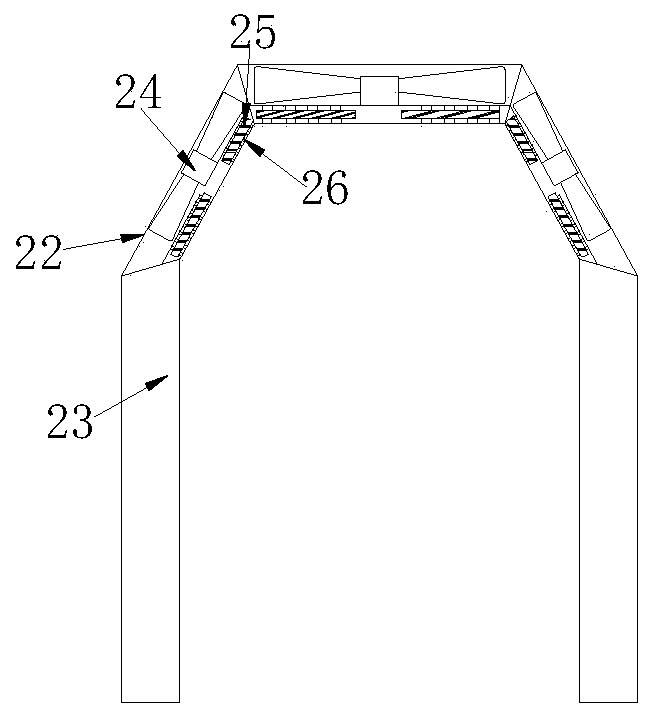

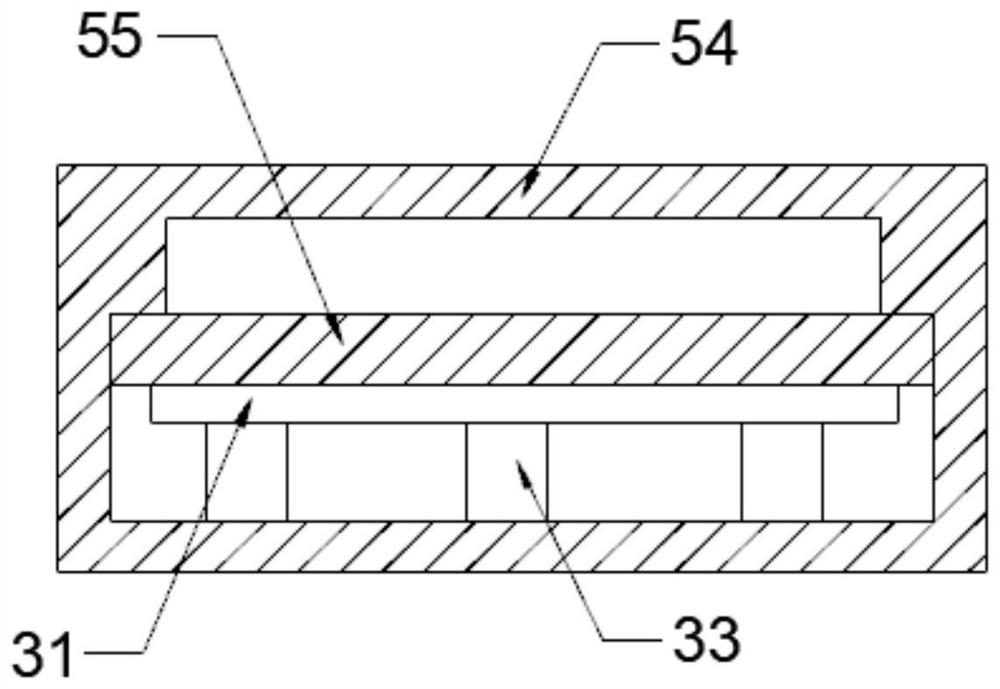

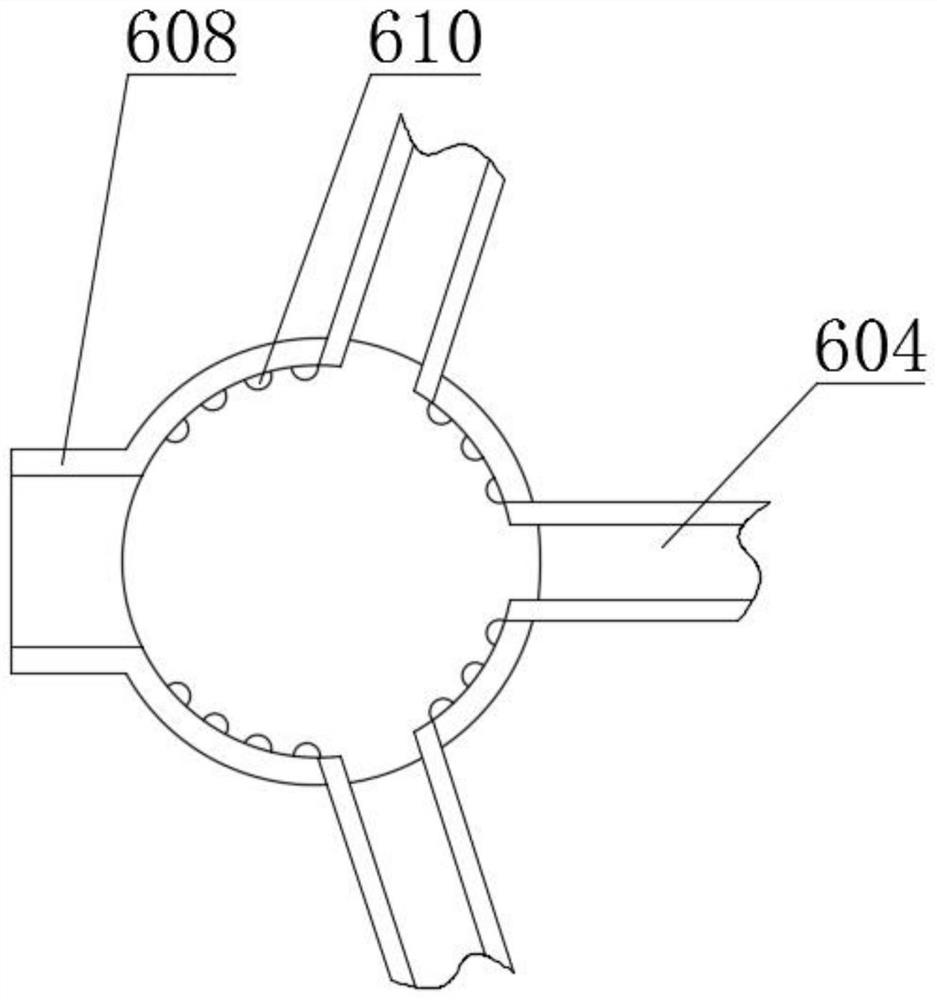

Self-cleaning stop valve

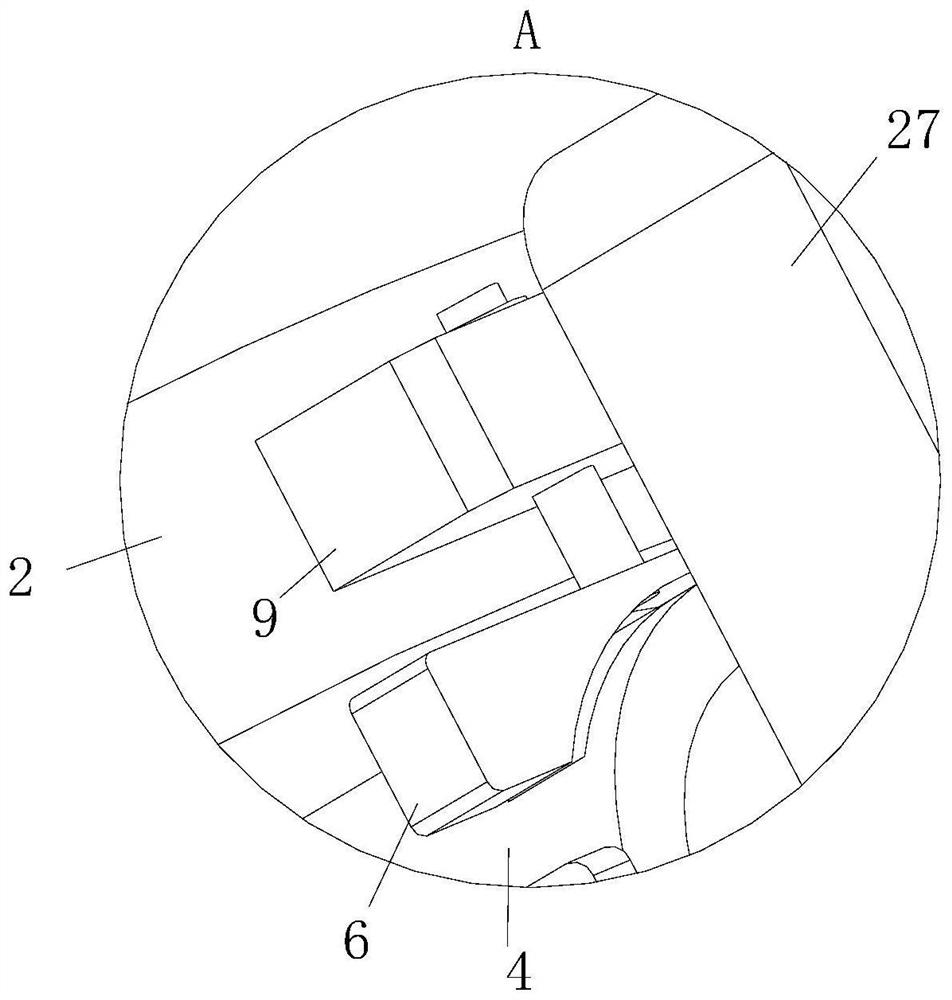

InactiveCN111706679APlay a role in cleaning upPlay a protective effectOperating means/releasing devices for valvesFouling preventionPhysicsGlobe valve

The invention discloses a self-cleaning stop valve. The self-cleaning stop valve comprises a valve body, wherein an upper valve cavity and a lower valve cavity are formed in the valve body; a valve plate is arranged in the valve body; a valve hole is formed in the valve plate; an outlet pipe which is in communication with the upper valve cavity and an inlet pipe which is in communication with thelower valve cavity are arranged on the side face of the valve body; a valve cover is fixedly arranged at an opening in the upper end of the upper valve cavity; a valve rod is arranged in the valve cover; a valve flap is arranged at the lower end of the valve rod; slide rails are arranged on the two sides of a sealing surface at the upper end of the valve hole in the valve plate; a left scraper assembly and a right scraper assembly are symmetrically arranged on the two sides of the valve hole between the two slide rails; a left driving lever and a right driving lever are symmetrically hinged tothe two sides of the valve rod in the upper valve cavity; the upper end of the left driving lever is connected with the valve rod, and the lower end is connected with the left scraper assembly; and the upper end of the right driving lever is connected with the valve rod, and the lower end is connected with the right scraper assembly. The self-cleaning stop valve is simple in structure, and can beused for cleaning the sealing surface at the upper end of the valve hole.

Owner:韩国昊

Easy-to-fix anti-slip wireless charger

ActiveCN109586377APrevent slippingImprove securityBatteries circuit arrangementsElectric powerEngineeringCard holder

The present invention discloses an easy-to-fix anti-slip wireless charger, comprising a base body, a rotating bracket and an electromagnetic coil, wherein a front side of the base body is provided with six sets of heat dissipation slots at equal intervals, and outer surface of lower end of the base body is fixedly installed with a sliding card holder, and four corners of outer surface of lower endof the sliding card holder is fixedly installed with a fixed suction cup, the base body is mounted on upper part of the rotating bracket, and the base body and the rotating bracket are movably connected through a rotating shaft, middle part of outer surface of front end of the rotating bracket is fixedly installed with an anti-slip mat, and outer surface of front end of the rotating bracket is fixedly installed with an anti-slip strip close to upper portion of the anti-slip mat; the easy-to-fix anti-slip wireless charger can strengthen a mobile phone during the charging process and avoid slipping phenomenon, and can clean mobile phone screen during process of pulling out the mobile phone, so that the wireless charger is placed more firmly to increase security and functionality.

Owner:深圳市美仕奇科技有限公司

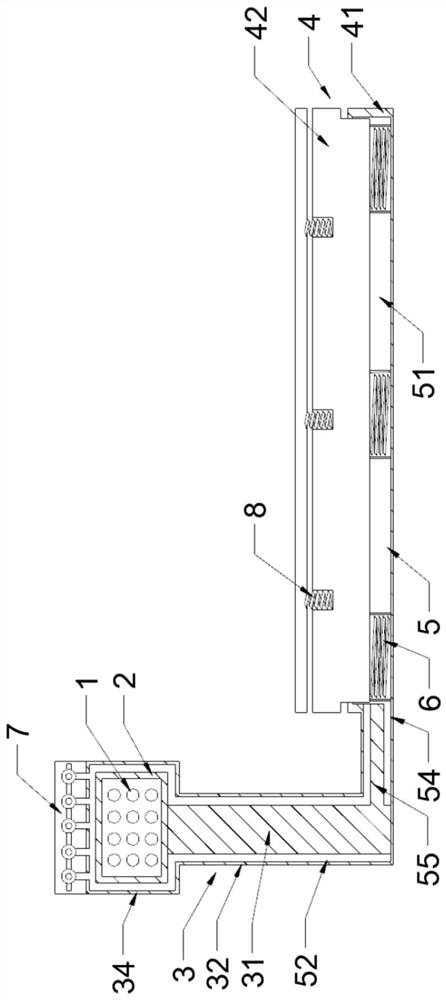

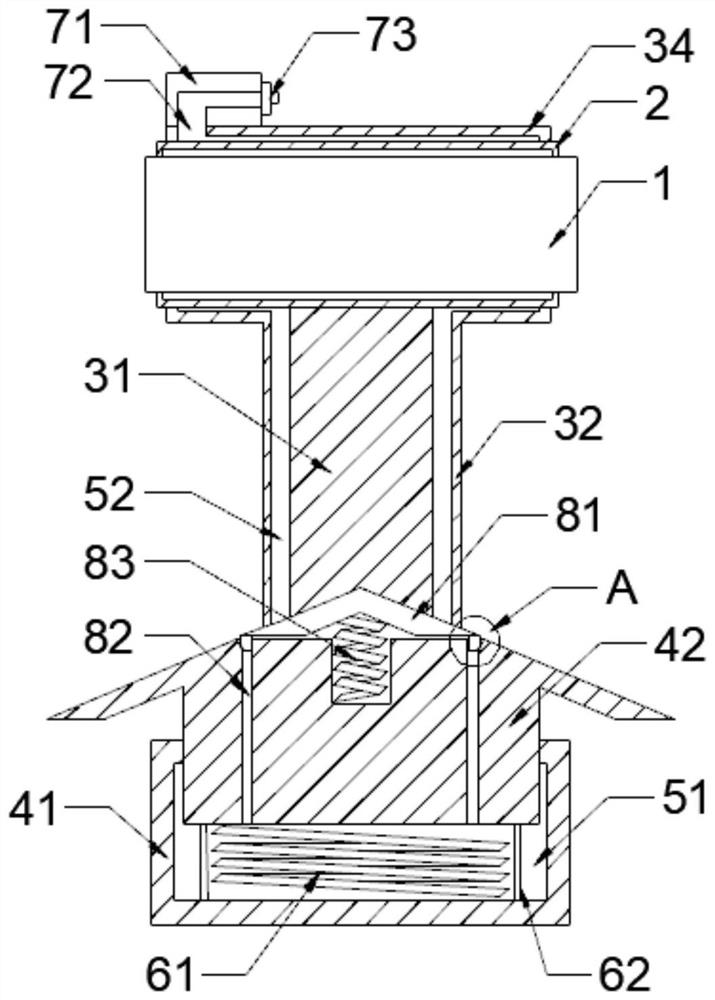

Yarn cleaning device

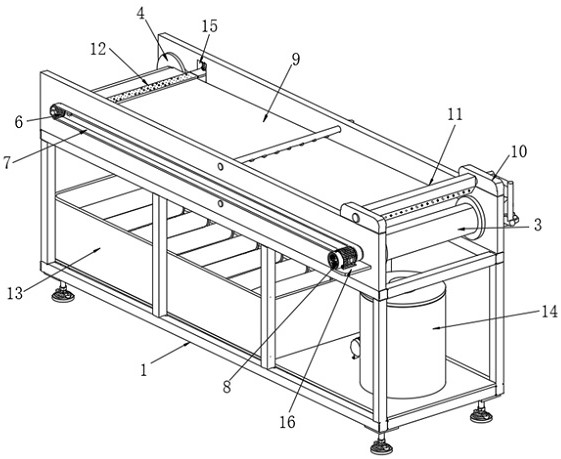

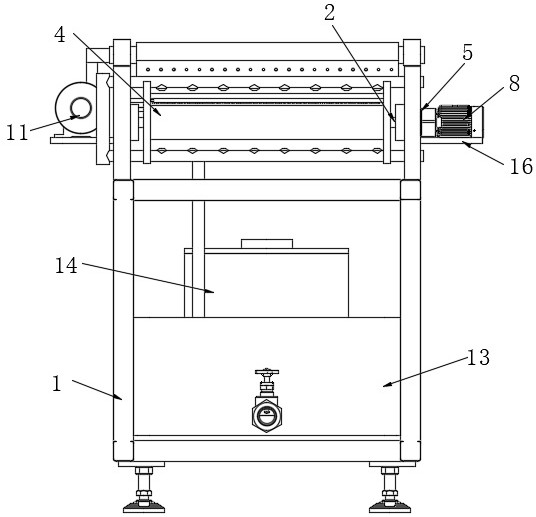

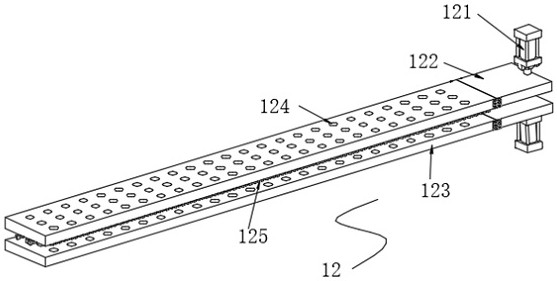

PendingCN112195584ACleaning operations need to be metImprove cleaning efficiencyFibre cleaning/openingLiquid/gas/vapor removal by suctionYarnWater storage tank

Owner:邵阳市昌兴实业有限公司

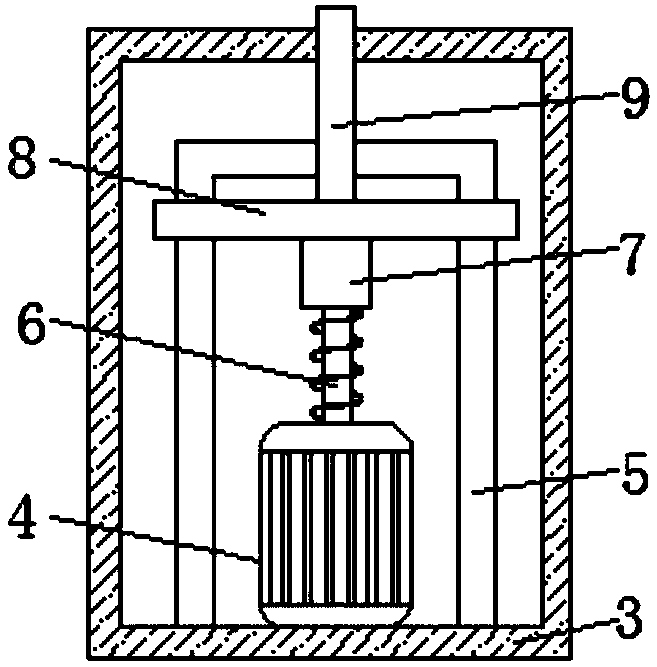

Safe training horizontal bar for fitness convenient to adjust

InactiveCN107661591APlay a role in anti-slipProtect your bodyHorizontal barsEngineeringHorizontal bar

The invention discloses a safe training horizontal bar for fitness convenient to adjust. The training horizontal bar comprises a base, two mounting bolts transversely symmetrical are fixedly connectedto the top of the base, a power box is fixedly connected to the inner wall of the bottom of the base, a stepper motor is fixedly connected to the inner wall of the bottom of the power box, and two limiting rods symmetrically located on both sides of the stepper motor are fixedly connected to the inner wall of the bottom of the power box. According to the training horizontal bar, through arrangement of a non-slip pad and non-slip finger grooves, the non-slip effect on hands of a fitness worker is achieved, occurrence of the condition that the fitness worker falls due to palm slipping is further prevented, and the effect of protecting the body safety of the fitness worker is achieved, so that the effect that the worker exercises safely and healthily is achieved; through arrangement of a rubber plate and buffer springs, the buffering effect when the fitness worker accidentally falls is achieved, and the effect of protecting the safety and health of the fitness worker is further achieved.

Owner:绍兴柯桥雷霄机械科技有限公司

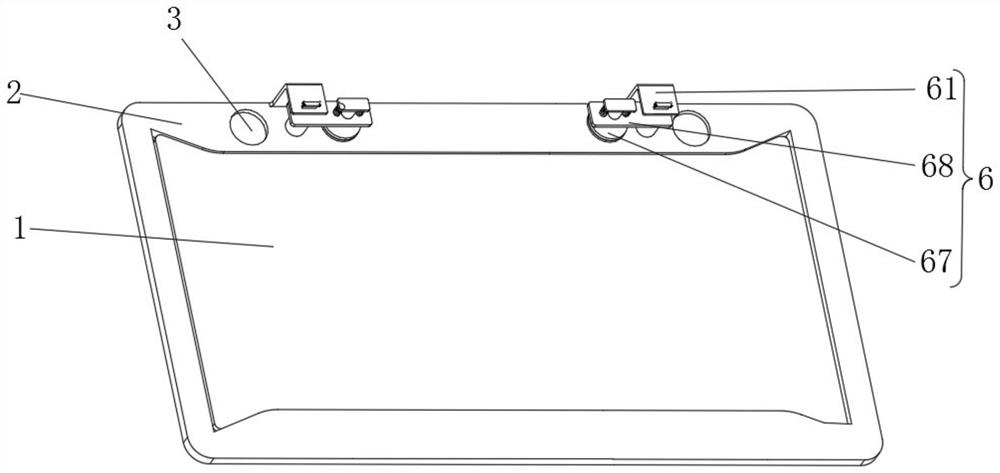

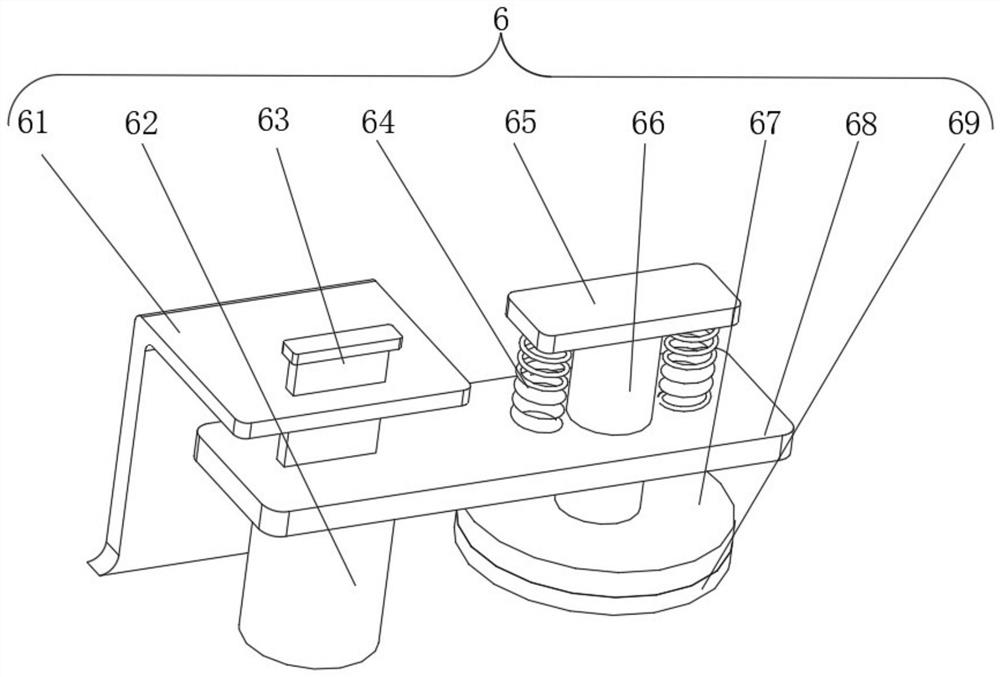

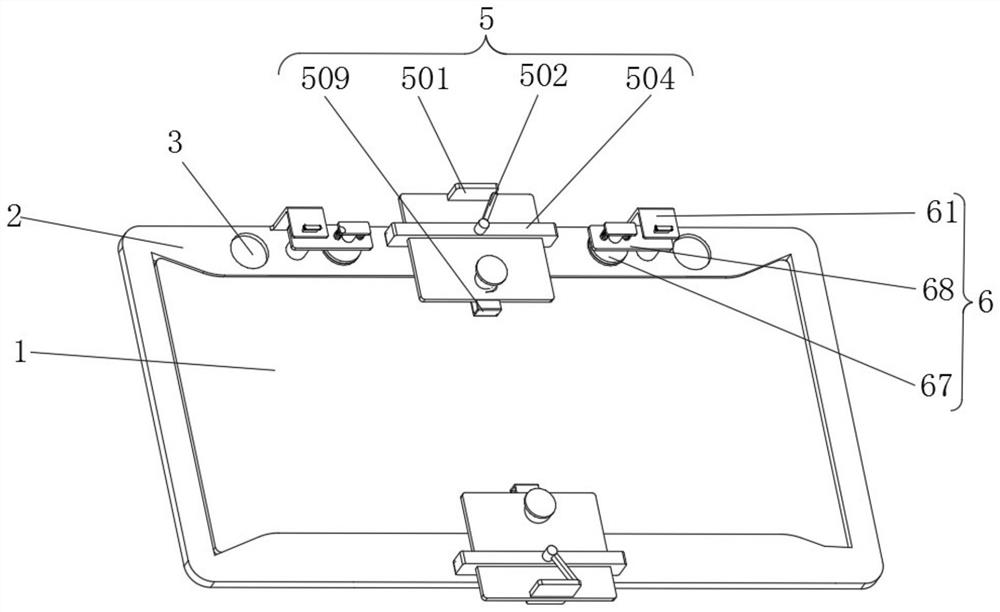

License plate frame rear-view camera device and application system thereof

ActiveCN112866530APlay a role in cleaning upAct as a fixationTelevision system detailsColor television detailsView cameraStructural engineering

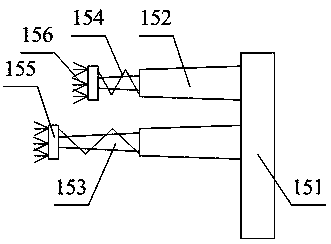

The invention provides a license plate frame rear-view camera device and an application system thereof, and relates to the technical field of cameras, the license plate frame rear-view camera device comprises a connecting frame and a protective device, a placing plate is clamped on the inner wall of the connecting frame, two probes are arranged on one side of the connecting frame, and a cleaning device is arranged on one side, close to the probes, of the connecting frame. The cleaning device comprises two connecting columns, one ends of the two connecting columns are rotationally connected with the connecting frame, rotating blocks are fixedly connected to the ends, away from the connecting frame, of the connecting columns, pushing columns are inserted into the rotating blocks in a penetrating mode, and connecting discs are fixedly connected to the ends, close to the connecting frame, of the pushing columns; and the end, away from the push column, of the connecting disc is fixedly connected with a sponge block, and the end, away from the connecting disc, of the push column is fixedly connected with a push block. According to the invention, the problem that in rainy days, rainwater may fall onto the camera, so that the camera is blurred by the rainwater, and the camera cannot be clearly close to the rear part of a vehicle on a mobile phone is solved.

Owner:深圳市威群视科技有限公司

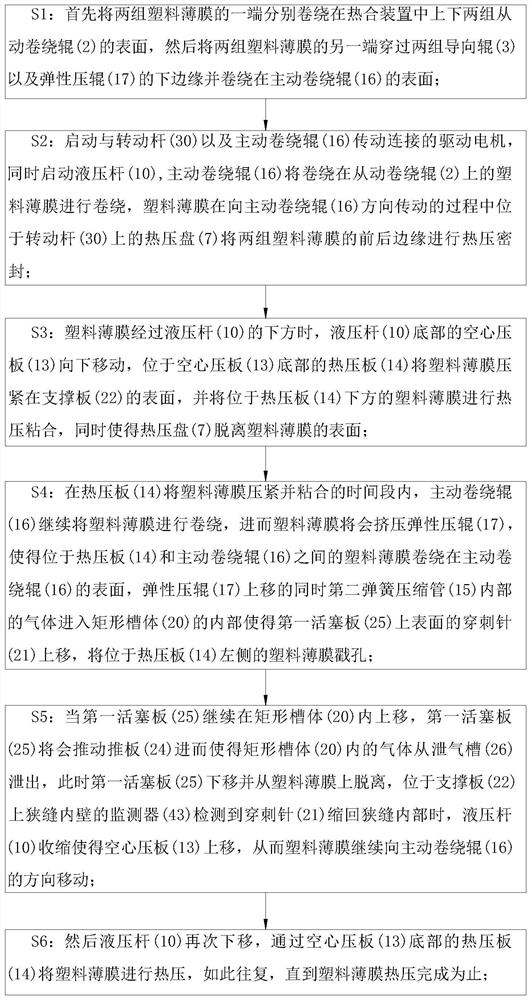

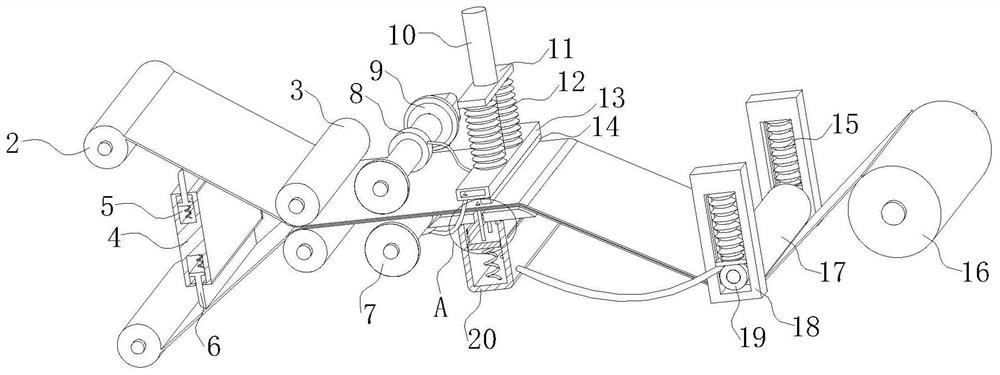

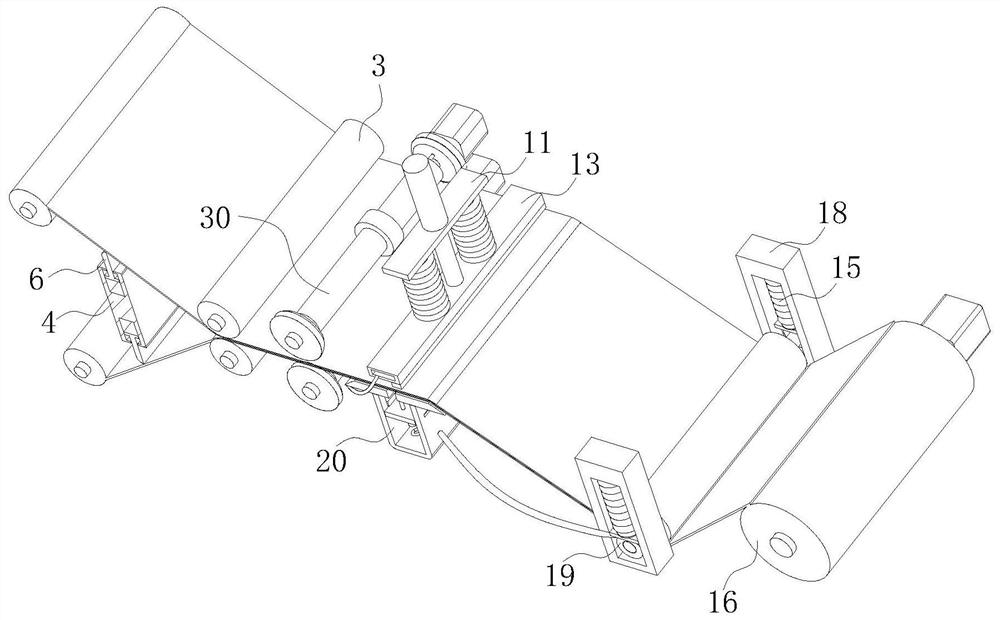

Improved plastic film heat-seal production process

InactiveCN112318880AExtension of timeAvoid accumulationCleaning using toolsElectric machineDrive motor

The invention belongs to the technical field of plastic film heat sealing processes, and particularly relates to an improved plastic film heat-seal production process. The process includes the steps of S1, firstly, respectively winding one ends of two groups of plastic films on the surfaces of an upper group of driven winding rollers and a lower group of the driven winding rollers in a heat sealing device; and then, the other ends of the two groups of the plastic films penetrate through the lower edges of the two groups of guide rollers and an elastic pressing roller and are wound on the surface of a driving winding roller. According to the improved plastic film heat-seal production process, the contact time of a hot pressing plate and the plastic films can be prolonged, and a driving motor in transmission connection with a rotating rod and a driving motor in transmission connection with the driving winding roller do not need to be stopped in the time period, so that the driving motoris prevented from being controlled to stop when a hollow pressing plate moves downwards each time, and therefore, control components and a system are saved; and the situation that the service life ofthe driving motor can be shortened by frequently switching on and off the driving motor, and the energy consumption can be increased is avoided.

Owner:王艳军

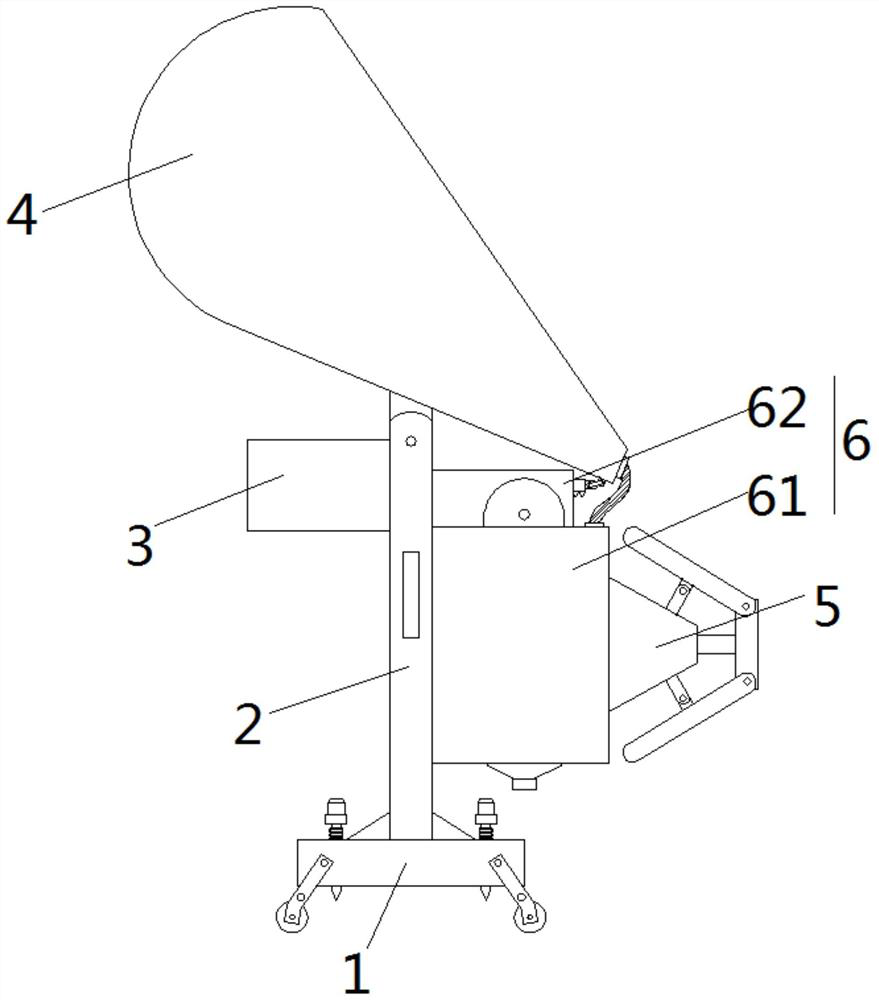

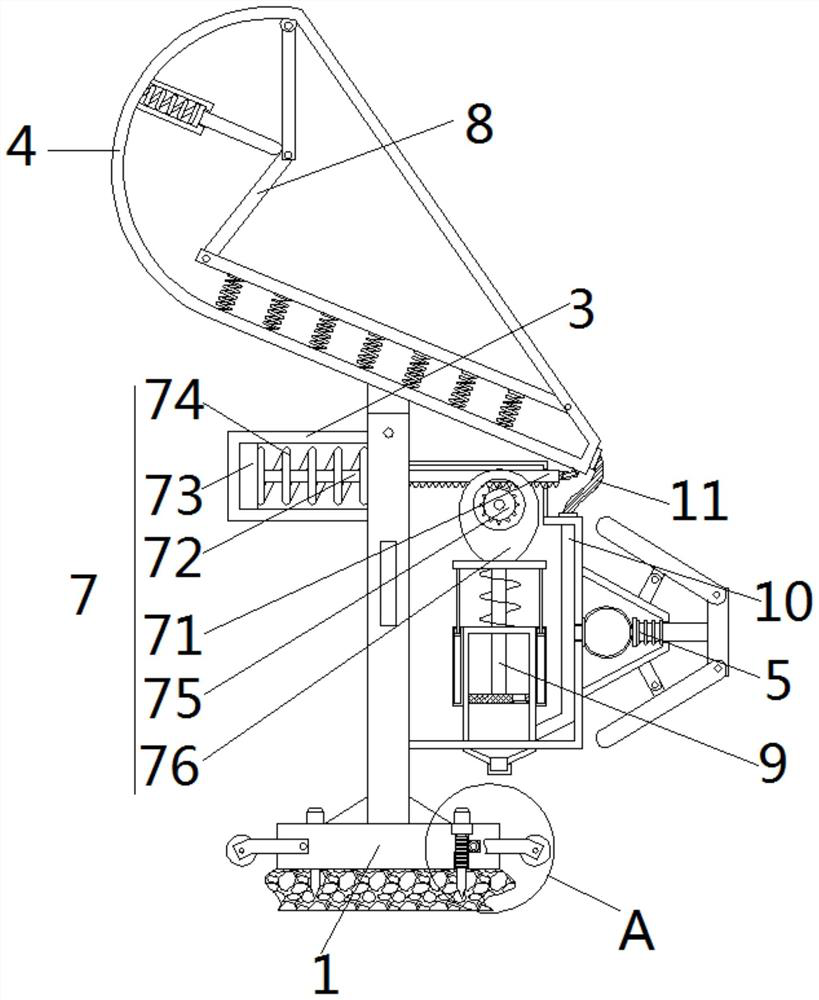

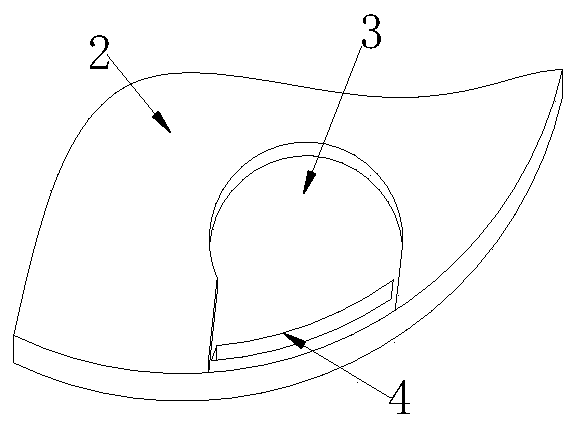

Anti-flying-rock protection assembly for mining

PendingCN111895876AAvoid breakingTo achieve the effect of cushioningDirt cleaningBlastingMining engineeringWorking environment

The invention provides an anti-flying-rock protection assembly for mining. The anti-flying-rock protection assembly for mining comprises a supporting movable part, a supporting plate, bearing boxes, aprotection part, drive devices, a damping device, dust suction devices, connecting pipes and telescopic pipes. The center position of the top of the supporting movable part is fixedly connected withthe supporting plate, the top of the supporting plate is movably connected with the protection part, the front and rear sides of the upper end of the left side of the supporting plate are fixedly connected with the bearing boxes, the upper end of the right side of the supporting plate is fixedly connected with a part box, the connecting pipes communicate with dust blowing shielding devices, the drive devices are mounted at the front and rear ends of the center positions in an upper part box, one ends of the drive devices stretch into the bearing boxes, the other ends of the drive devices stretch to the outer end of the right side of an upper connecting box and are movably connected with the right side of the bottom of the protection part, and the upper ends of the front and rear sides of the supporting plate are fixedly connected with handles. By means of the anti-flying-rock protection assembly for mining, the problems that an existing anti-flying-rock device has single functionality,cannot achieve a dust removal effect, affects working environments, and is inconvenient to move are solved.

Owner:周翔

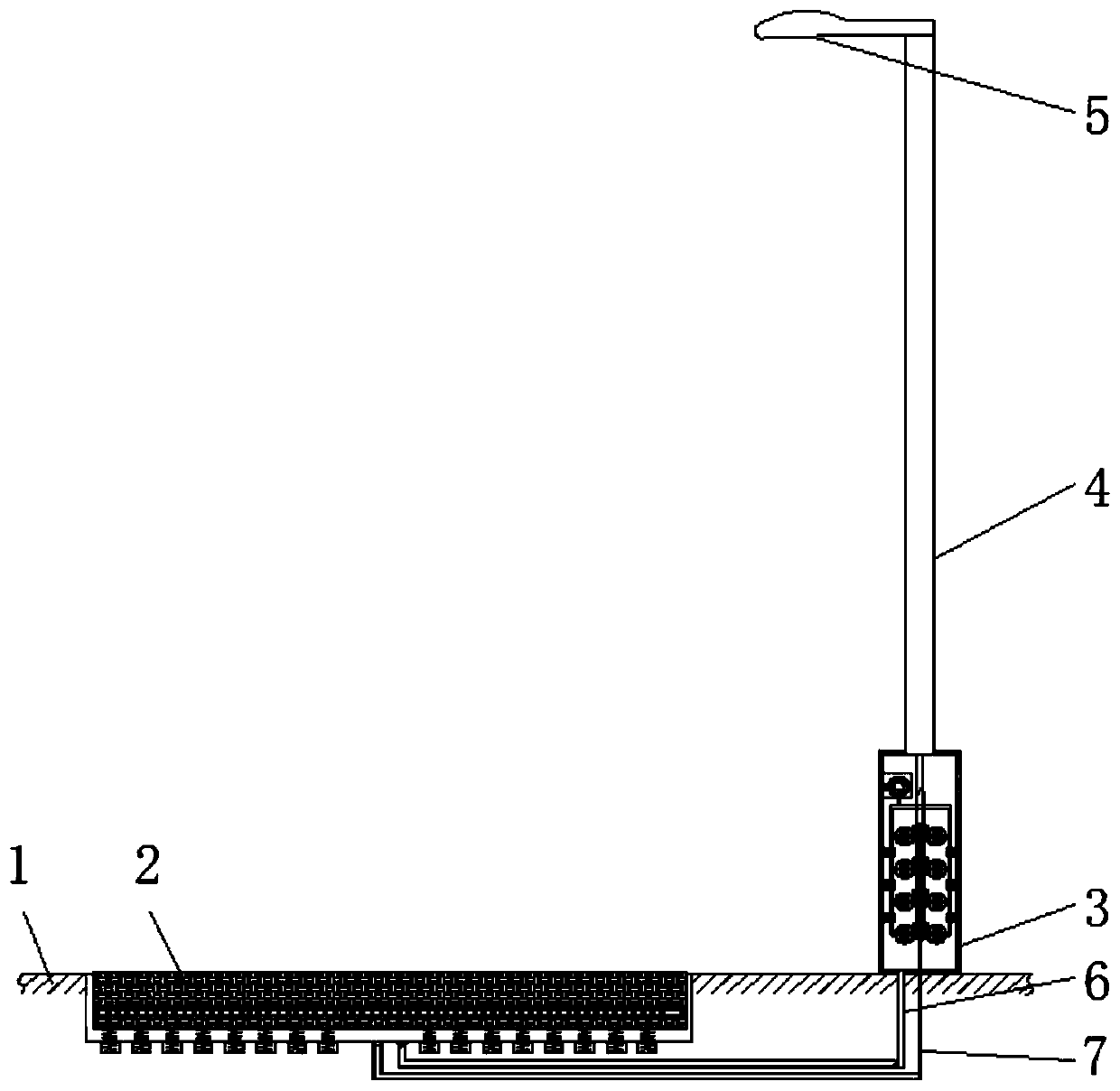

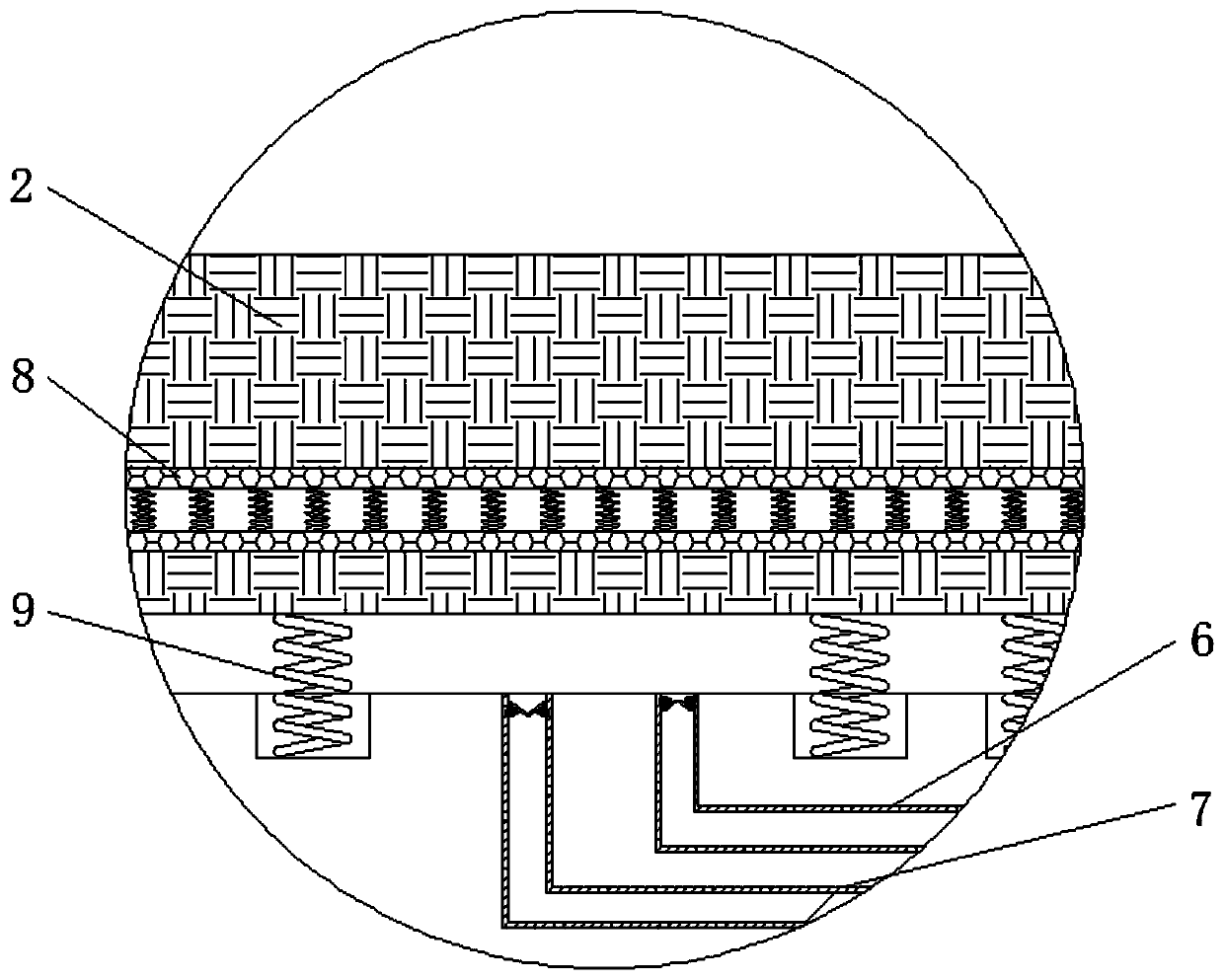

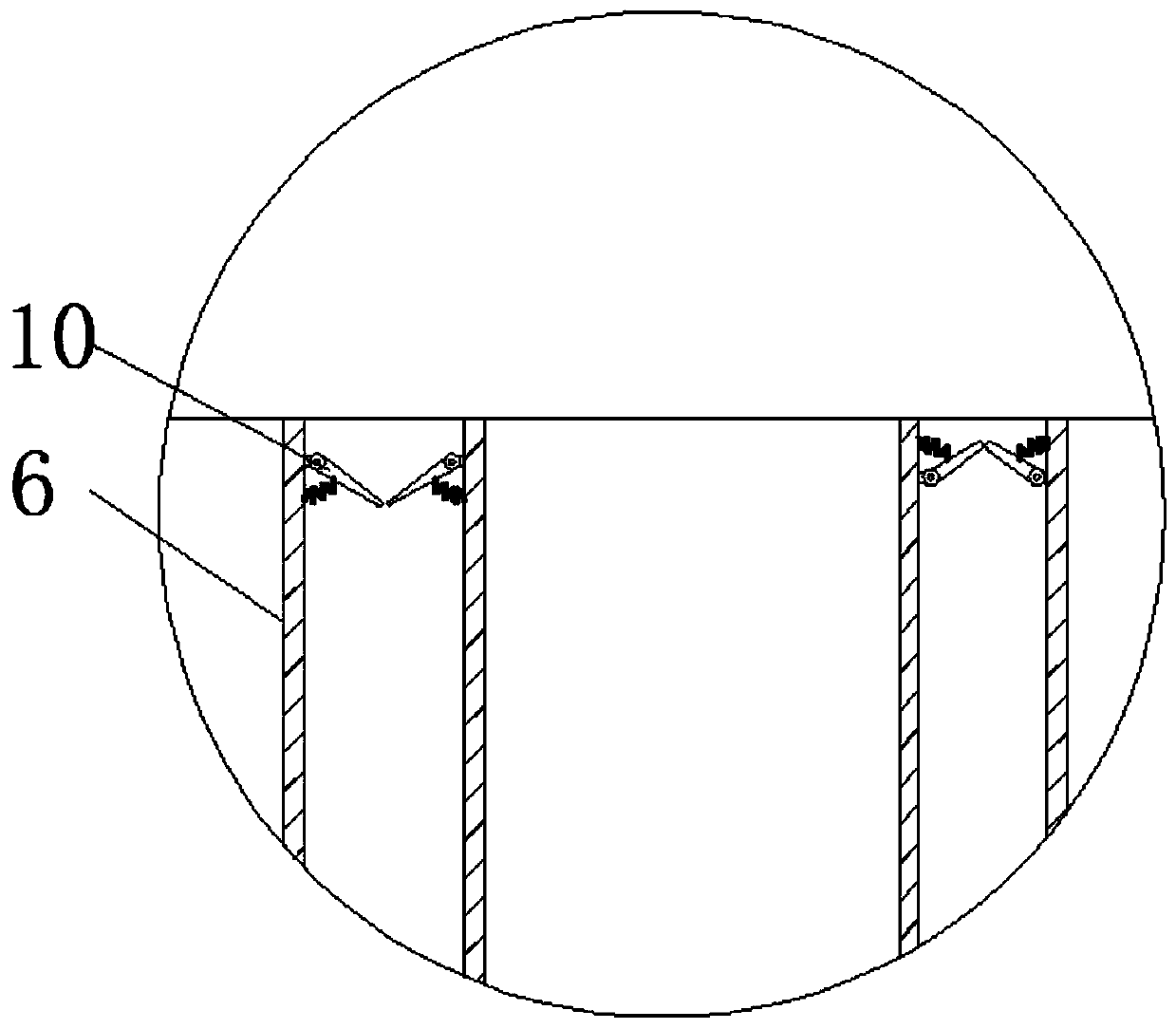

Energy-saving environment-friendly street lamp capable of generating electricity based on pressure

InactiveCN110836351AImprove stabilityImprove practicalityPositive displacement pump componentsElectric circuit arrangementsNew energyRoad surface

The invention relates to the energy-saving technical field of new energy, and discloses an energy-saving environment-friendly street lamp capable of generating electricity based on pressure. Accordingto the street lamp, a road surface is included, wherein a pressure block is installed in the road surface; a power supply box is fixedly connected to the top of the road surface; a supporting rod isfixedly connected to the top of the power supply box; a street lamp is fixedly connected to the top of the supporting rod; an air inlet pipe and an air conveying pipe are fixedly connected to the bottom of the power supply box; a damping bag is fixedly connected to the bottom of the pressure block; and an elastic spring is installed at the bottom of the damping bag. When a vehicle passes by, the air in the pressure block continuously flows to the air storage bag, the air pressure in the air storage bag is gradually increased, and the pressure in a flow stabilizing box is increased; meanwhile,the pressure of the air in the flow stabilizing box on an adjusting rod is increased, the adjusting rod moves downwards under the action of air pressure, a connecting rod and an ejector pin are drivento move downwards, the channel between the connecting pipe and the flow stabilizing box is reduced, and the air pressure in the flow stabilizing box is reduced, so that the air pressure in the flow stabilizing box can be kept stable.

Owner:李思佳

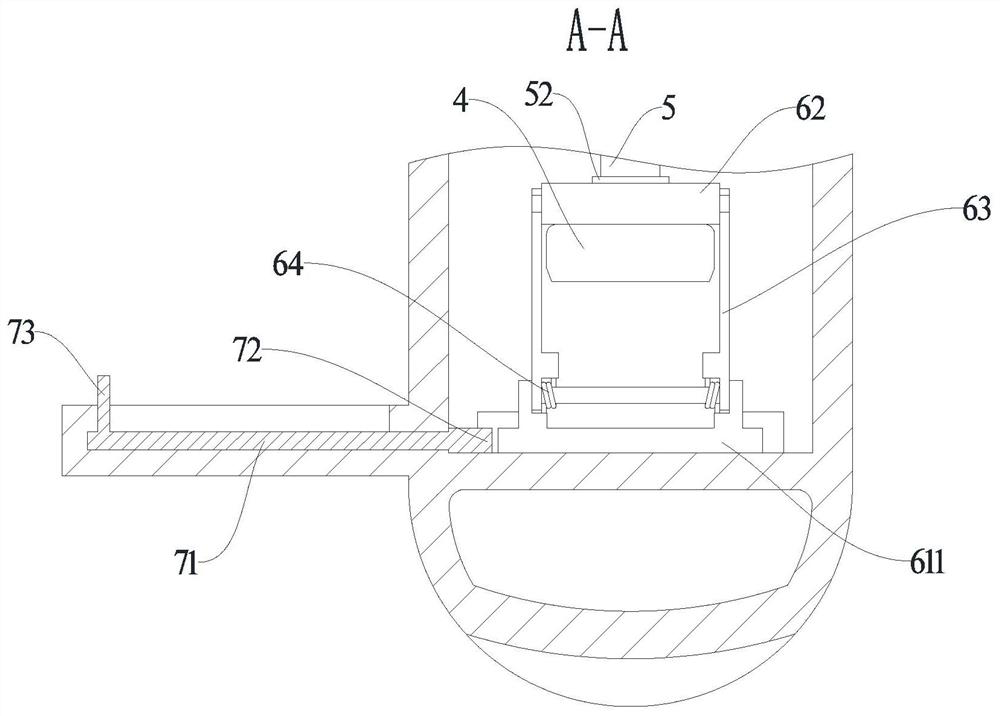

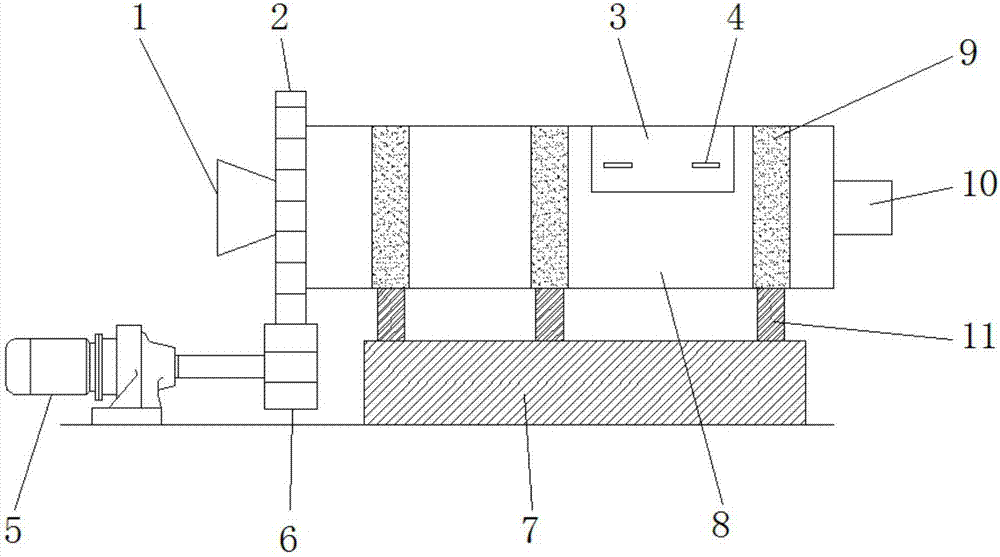

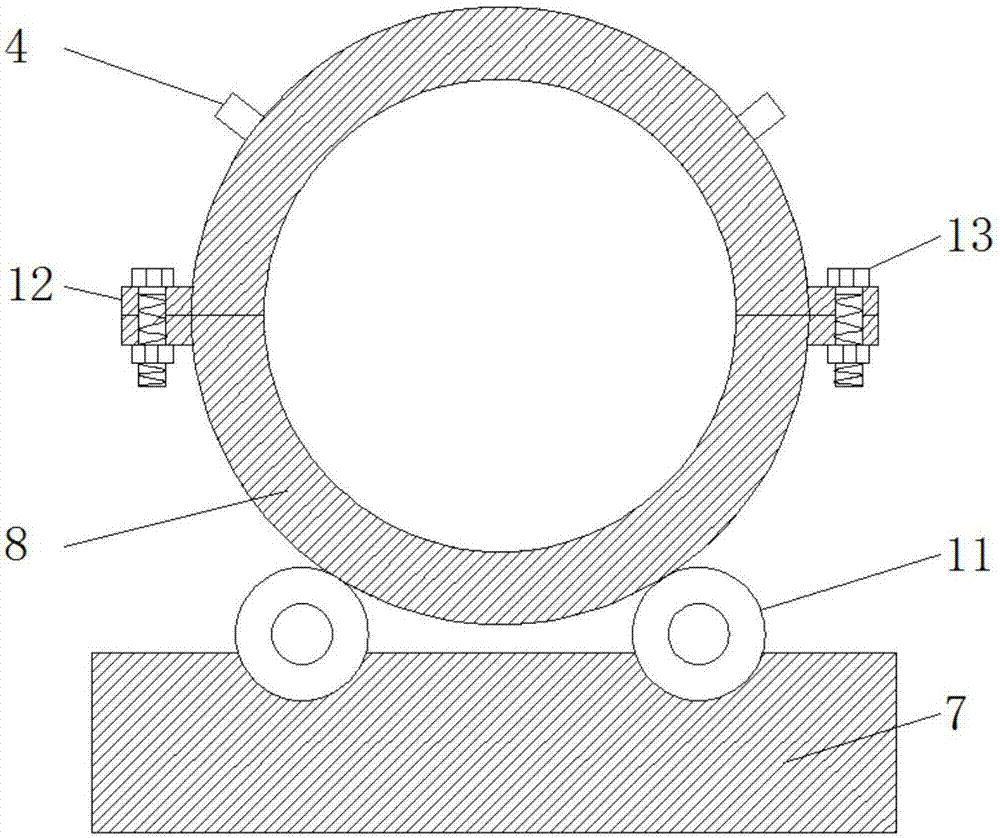

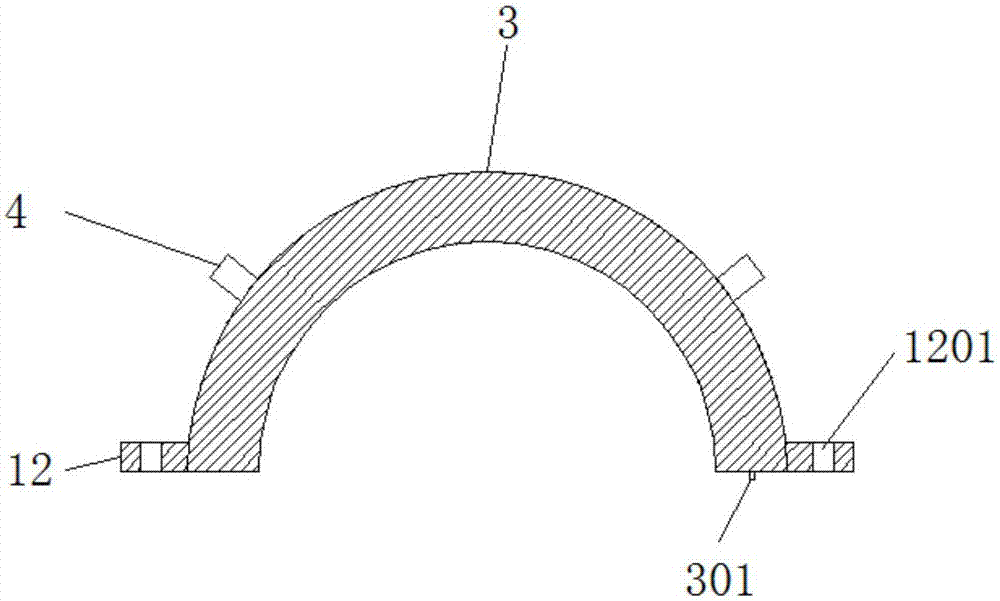

Electromagnetic mechanism for cleaning waste scraps by lathe

ActiveCN110434667AReduce extra energy consumptionPlay a role in cleaning upMaintainance and safety accessoriesEngineeringMachining

The invention relates to the technical field of lathe machining equipment, and discloses an electromagnetic mechanism for cleaning waste scraps by a lathe. The electromagnetic mechanism comprises a lathe frame; the middle part of an operation fixing platform is connected with an operation moving platform; the lower part of the operation moving platform is slidably connected with an iron rod; the lower end of the iron rod is connected with an iron core; the outer side of the iron core is connected with a wire; the lower part of the operation moving platform is connected with a cylindrical connecting plate; the lower end of the cylindrical connecting plate is connected with a permanent magnet; and the middle part of the lower end of the permanent magnet is connected with an air bag. The permanent magnet moves upward on the inner wall of a circular guide plate, and the iron rod magnetizes the operation moving platform through the iron core to absorb scrap iron. This structure absorbs andcleans the scrap iron uniformly through the electromagnetic effect, so that the scrap iron cleaning efficiency is high and the problems of energy waste and unsatisfactory cleaning by directly using the magnet are solved. At the same time, the iron core and the wire will generate a large amount of heat, and the permanent magnet presses down the air bag to clean up the scraps on the operation movingplatform.

Owner:嘉兴卓十生物科技有限公司

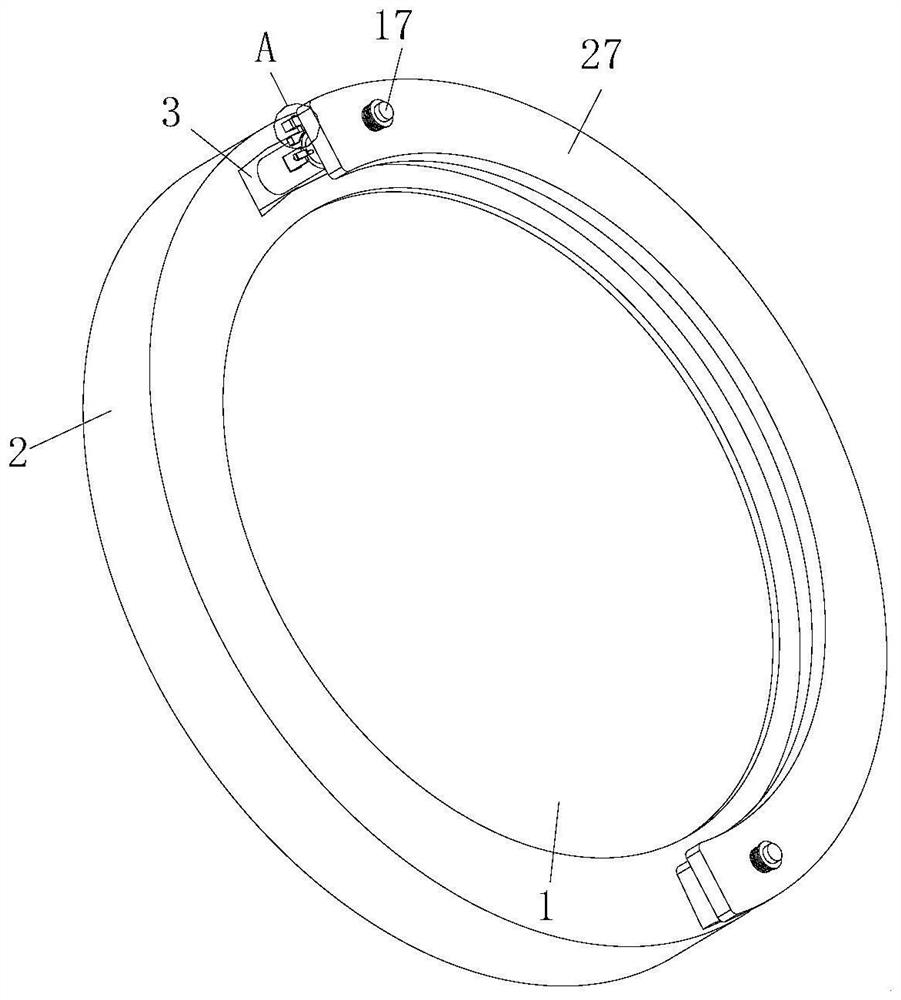

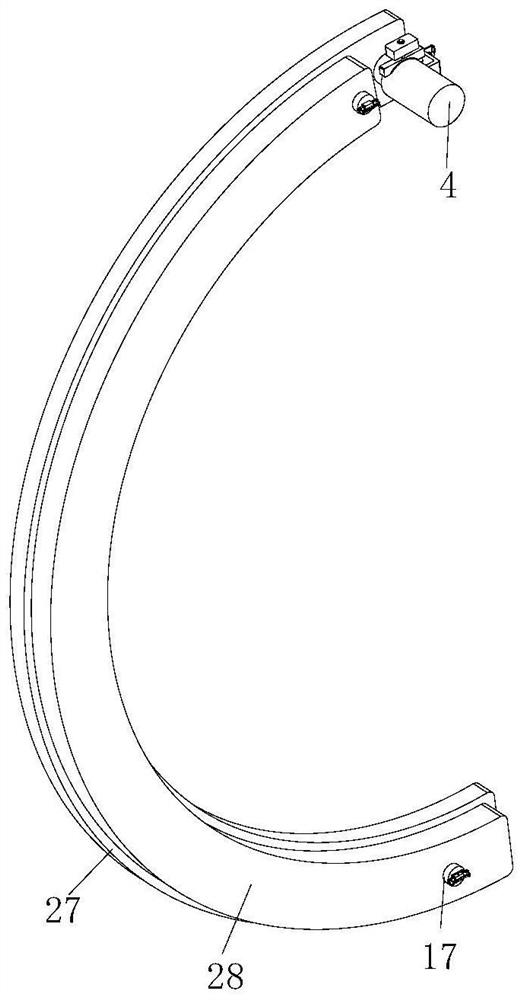

Optical glass cleaning device

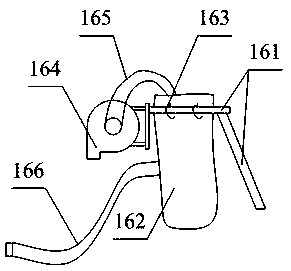

ActiveCN114345783APlay a role in cleaning upEasy to useFlexible article cleaningCleaning using toolsOptical glassMaterials science

The invention belongs to the field of optical glass, and particularly relates to an optical glass cleaning device which comprises an optical glass body. A fixing ring is fixedly connected to the side wall of the optical glass body, a rectangular groove is formed in one side of the fixing ring, a sliding column is slidably connected to the inner wall of the rectangular groove, a rotating column is rotatably connected into the sliding column, an arc-shaped plate is fixedly connected to the end, away from the sliding column, of the rotating column, and a sponge block is arranged on the side, close to the rotating column, of the arc-shaped plate; by rotating an arc-shaped plate, the arc-shaped plate drives a sponge block to rotate, at the moment, the sponge block does not make contact with a fixing ring any more, the sponge block can move to the optical glass body, at the moment, due to the flexibility of the sponge block, the sponge block deforms and makes contact with the optical glass body, and therefore the sponge block makes contact with the optical glass body; and a sponge block is arranged, so that dust on the optical glass body is cleaned by the sponge block, the optical glass body is cleaned, and the use effect of the optical glass body is improved.

Owner:JIANGSU ETERN OPTOELECTRONICS TECH CO LTD

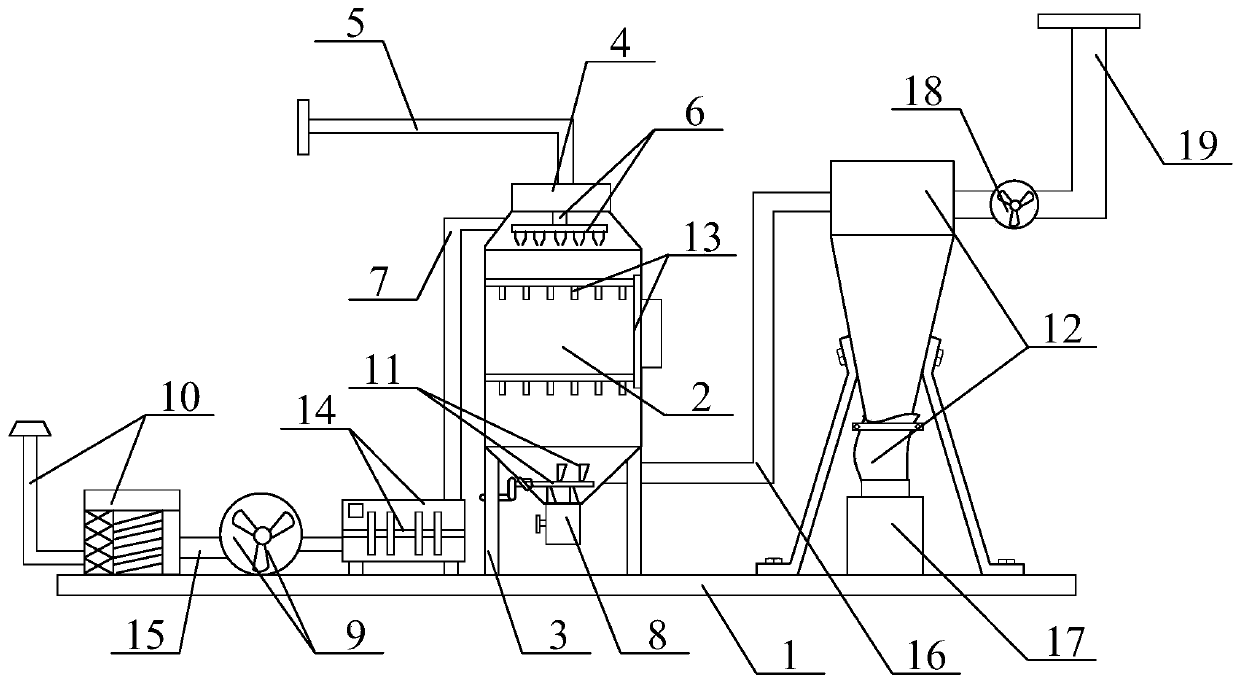

Spray drying machine used for solid dye production

InactiveCN110327642AQuality improvementPrevents debris from mixing with dyeCombination devicesEvaporator accessoriesExhaust gasSheet structure

The invention provides a spray drying machine used for solid dye production. The spray drying machine used for solid dye production comprises a supporting pedestal plate, a drying tank, supporting columns, an atomizer, a dye liquid inlet pipe, a nozzle, a hot air conduit, a discharge valve, a blower fan, a cold air purifying filtering tank structure, an anti-blocking hand-operated material overturning sheet structure, a discharging airborne-dust-prevention cyclone separator structure, an ultrasonic vibration particle shaking-off ring structure, an air heating tank structure, a gas guiding connecting pipe, a secondary separation conduit, a collecting tank, an induced draught fan, and an exhaust gas discharge connecting pipe. According to the spray drying machine, a purifying tank, a sealingtank bovver, an air inlet pipe, a stainless steel pipe filter screen, a nylon filter screen, and a HEPA filter layer are adopted, so that it is beneficial for filtering impurity removing of dried air, and filtering purifying of particles or harmful gas in the air is realized; a hand-operated rocking bar, a material overturning sheet, a ball bearing, a hand-operated wheel, and a handle are adopted, so that it is beneficial for dredging and blocking prevention in discharge process of dried solid dye particles.

Owner:浙江正裕化学工业有限公司

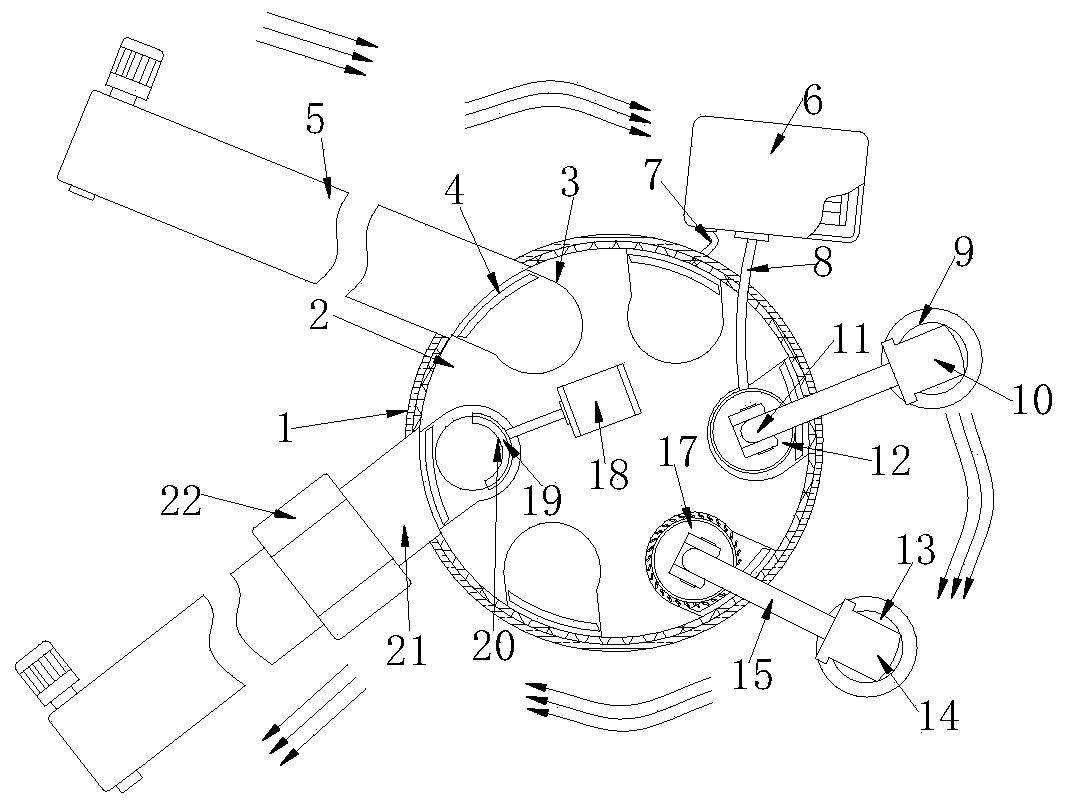

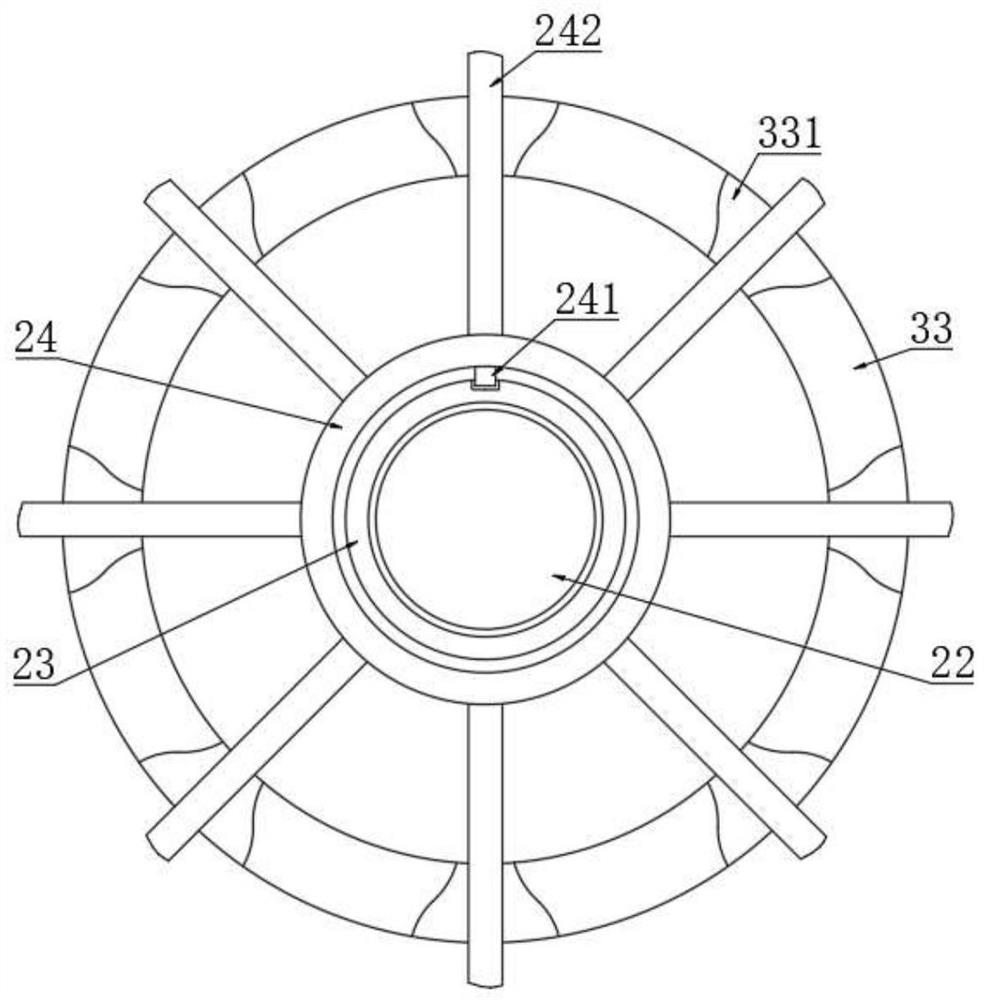

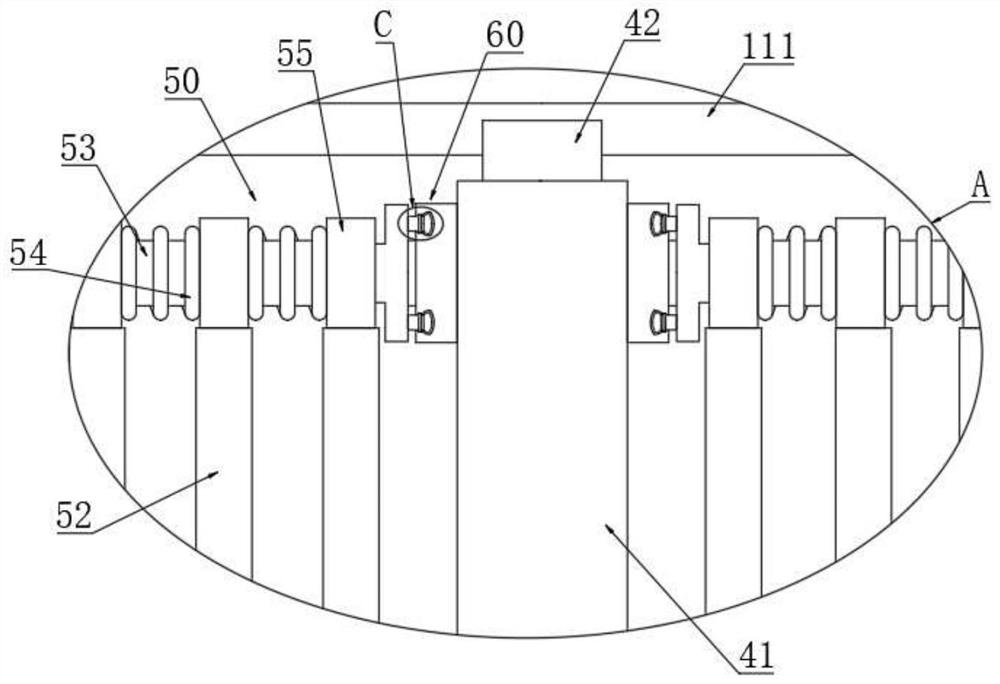

Intelligent loop waist transferring device of paper diaper production line

ActiveCN108451720AAdjustable sizeEasy to useDispersed particle filtrationAbsorbent padsProduction lineCoupling

The invention provides an intelligent loop waist transferring device of a paper diaper production line. The transferring device comprises a mounting plate, a bearing seat, a connecting bearing, an inserting shaft, a coupler, a motor, a connecting wheel, a communicated pipeline, a sealing cover, an air transmitting pipe, an air pump, an electromagnetic valve, an air outlet head frame structure, a protective tube structure, an adjusting frame structure, a cleaning frame structure and a collecting box structure, the bearing seat is installed in the transverse middle of the exact front surface ofthe mounting plate through bolts, and the connecting bearing is installed inside the bearing seat; the inserting shaft is inserted inside the connecting bearing, and the left end of the inserting shaft is connected with an output shaft of the motor through the coupler. The loop waist transferring device has the advantages that through the arrangement of the air outlet head frame structure, it is beneficial to adjust the size of the upper portion of the air outlet frame head structure when the device is in use, loop waists with different sizes can be conveniently caught, and it is further beneficial to conveniently use the loop waist transferring device.

Owner:DADDY BABY

Autonomous cooling polishing and grinding robot

InactiveCN111531558AFacilitate automatic processingImprove polishing efficiencyDrying gas arrangementsGrinding feedersPhysicsGrinding

The invention belongs to the technical field of workpiece machining, and particularly relates to an autonomous cooling polishing and grinding robot. The autonomous cooling polishing and grinding robotcomprises a rotary disc, a first base is installed on one side of the rotary disc, a first telescopic rod is installed on the upper surface of the first base, a first rotary plate is fixedly connected to the outer side wall of the first telescopic rod, a grinding part is rotationally connected to the bottom face of the end face of the first rotary plate, and a fixed barrel is installed on the bottom face of the rotary disc. A cleaning part which rotates rapidly sweeps away chippings on a workpiece, the cleaning effect is achieved, and finally, when the cleaning part rotates to a second conveying belt, a sensor detects the existence of the workpiece, an electric push rod descends to drive an air cylinder to descend, a telescopic shaft of the air cylinder drives a push plate to stretch out,the workpiece in a containing groove is pushed to the second conveying belt, and the second conveying belt completes the conveying process of the ground workpiece. In conclusion, automatic process operation is formed for polishing and grinding of the workpiece, automatic machining is facilitated, and the polishing and grinding efficiency is improved.

Owner:CHONGQING ACAD OF METROLOGY & QUALITY INST

Outdoor parking lot camera heat dissipation device

ActiveCN112584020AAchieve consumptionPlay a cooling effectTelevision system detailsColor television detailsWater collectionMechanical engineering

The invention discloses an outdoor parking lot camera heat dissipation device. The heat dissipation device comprises a camera mechanism which comprises a camera and a protection housing; a supportingmechanism which comprises a supporting column, a supporting pipe, a supporting block and a heat dissipation sleeve, wherein the supporting column is installed in the supporting pipe, the top end of the supporting column is fixedly connected with the bottom of the protective shell, and the heat dissipation sleeve is fixedly connected to the top end of the supporting pipe. a deceleration strip mechanism that comprises a mounting shell and a deceleration strip main body, wherein the deceleration strip main body is fixedly mounted in the mounting shell through an elastic mechanism; and a liquid guide mechanism which is used for changing the position of the heat dissipation liquid and comprises a mounting cavity, a liquid guide cavity, a liquid separation plate, a connecting pipe and a liquid separation plate. Potential energy generated when a vehicle passes by is utilized, liquid is changed to circulate, heat dissipation treatment is conducted on the camera, meanwhile, the heat dissipationsleeve can be cleaned, and rainwater is recycled through the rainwater collecting mechanism.

Owner:深圳市超越智能电子有限公司

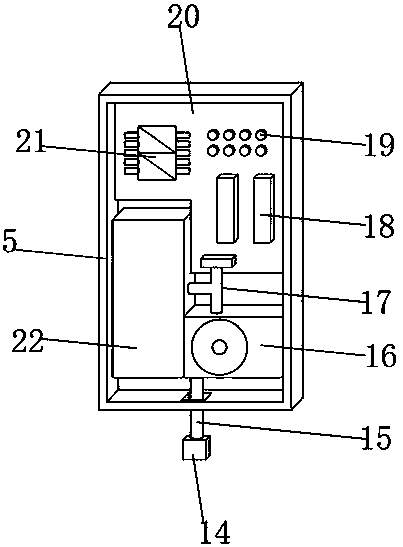

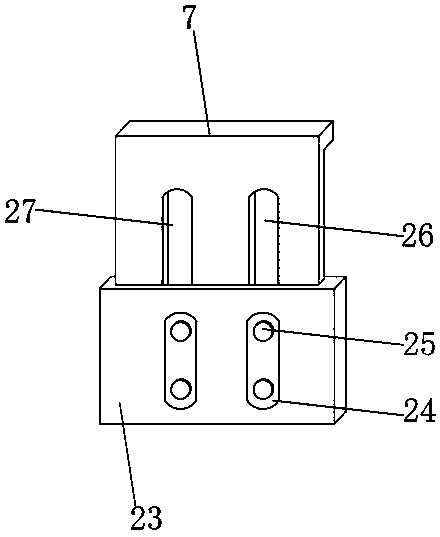

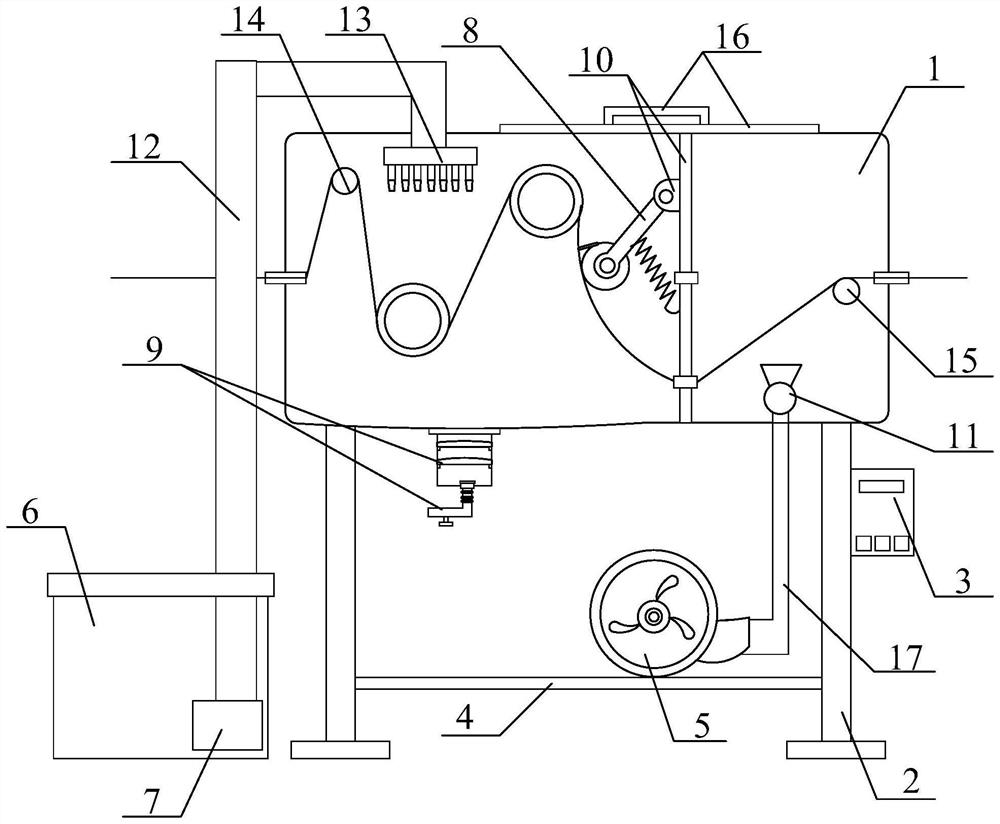

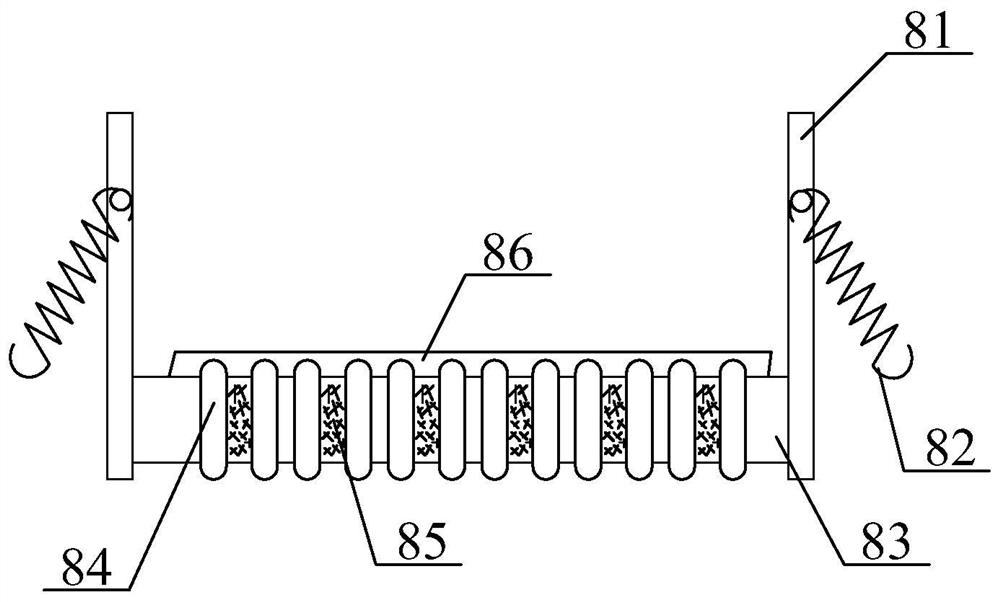

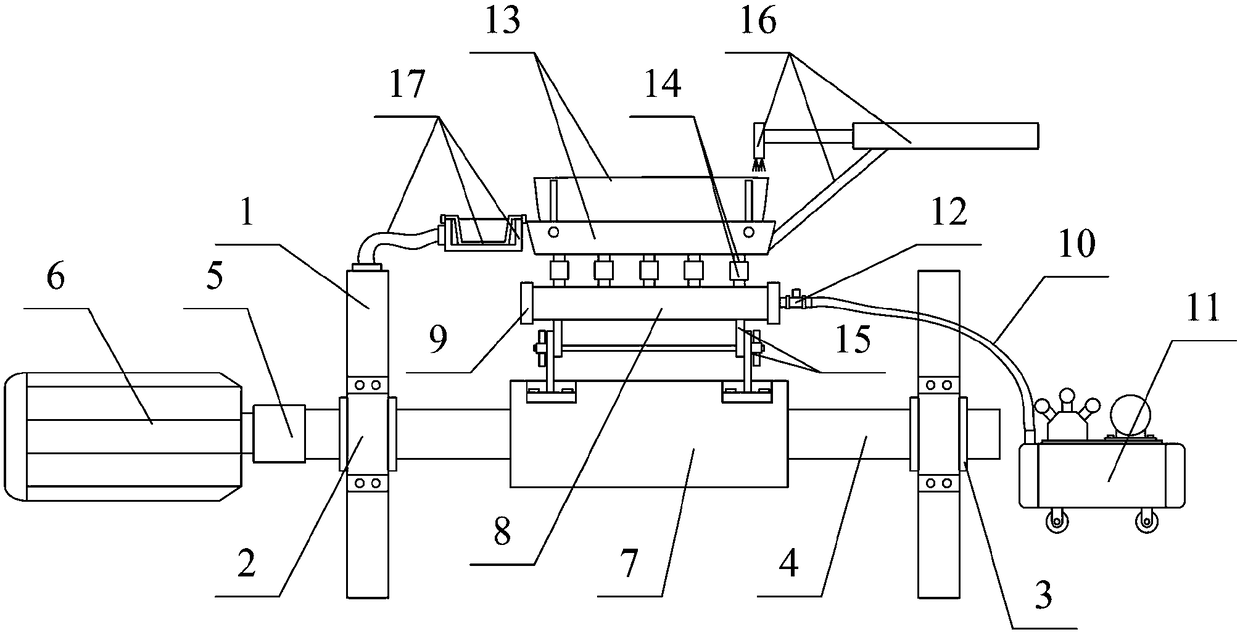

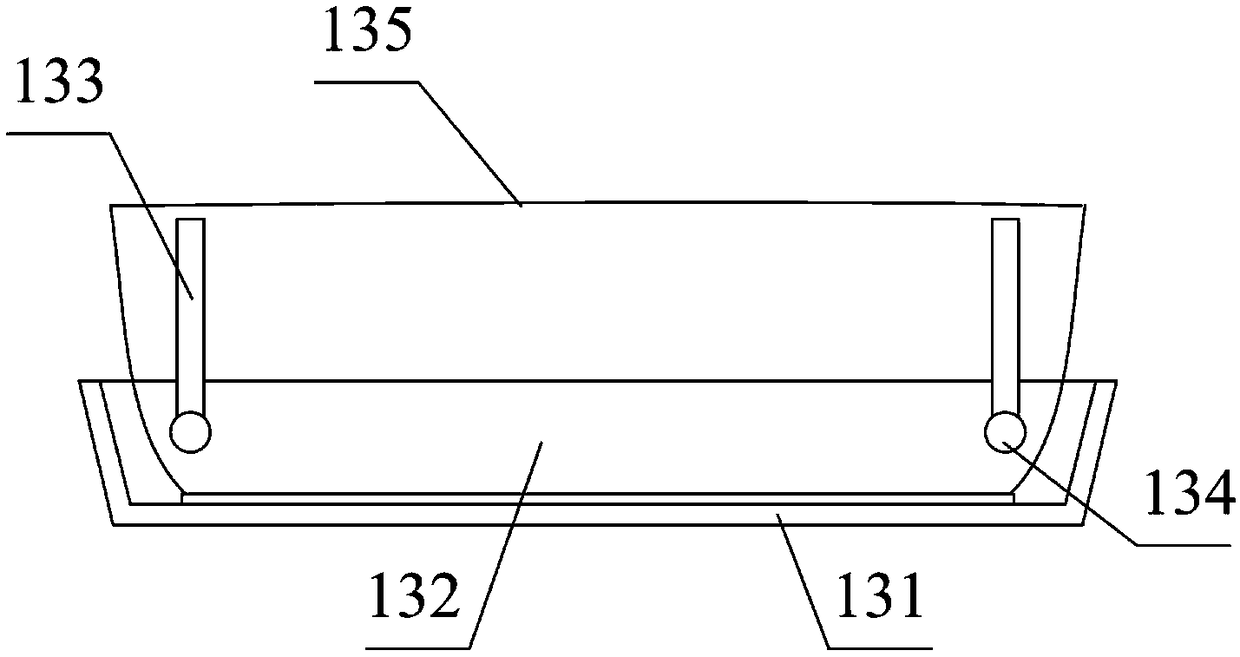

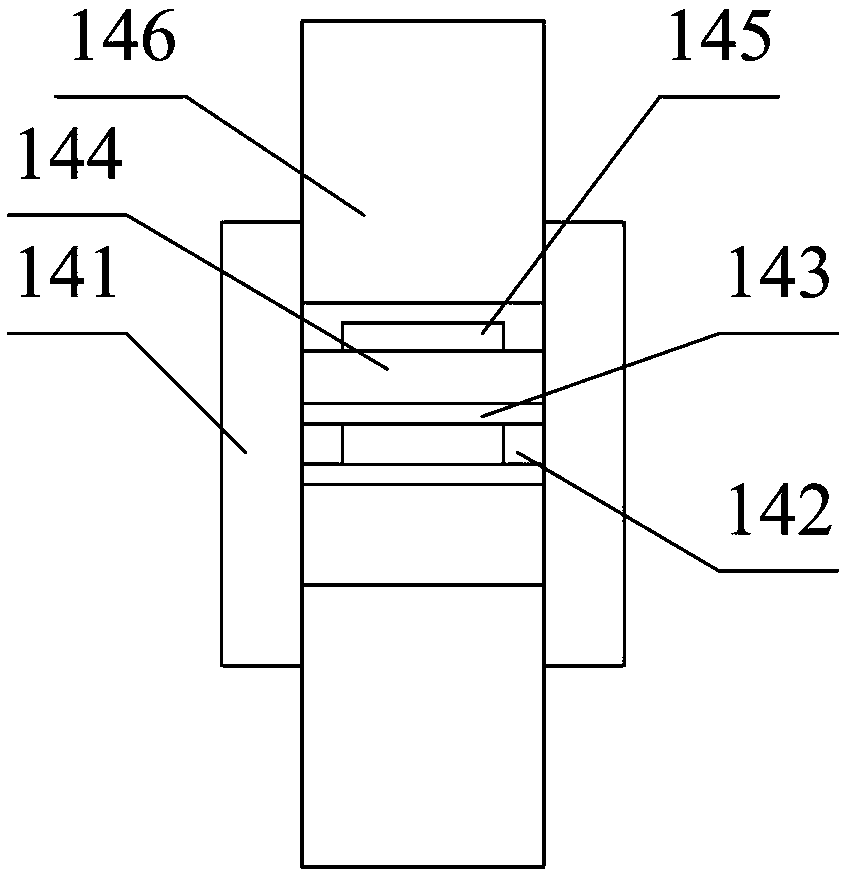

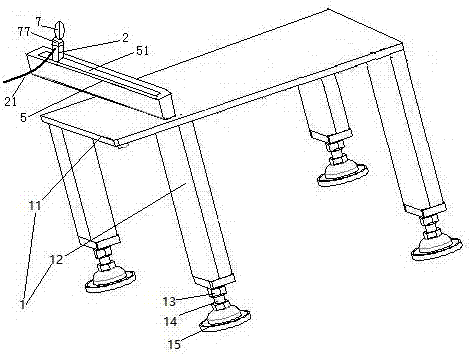

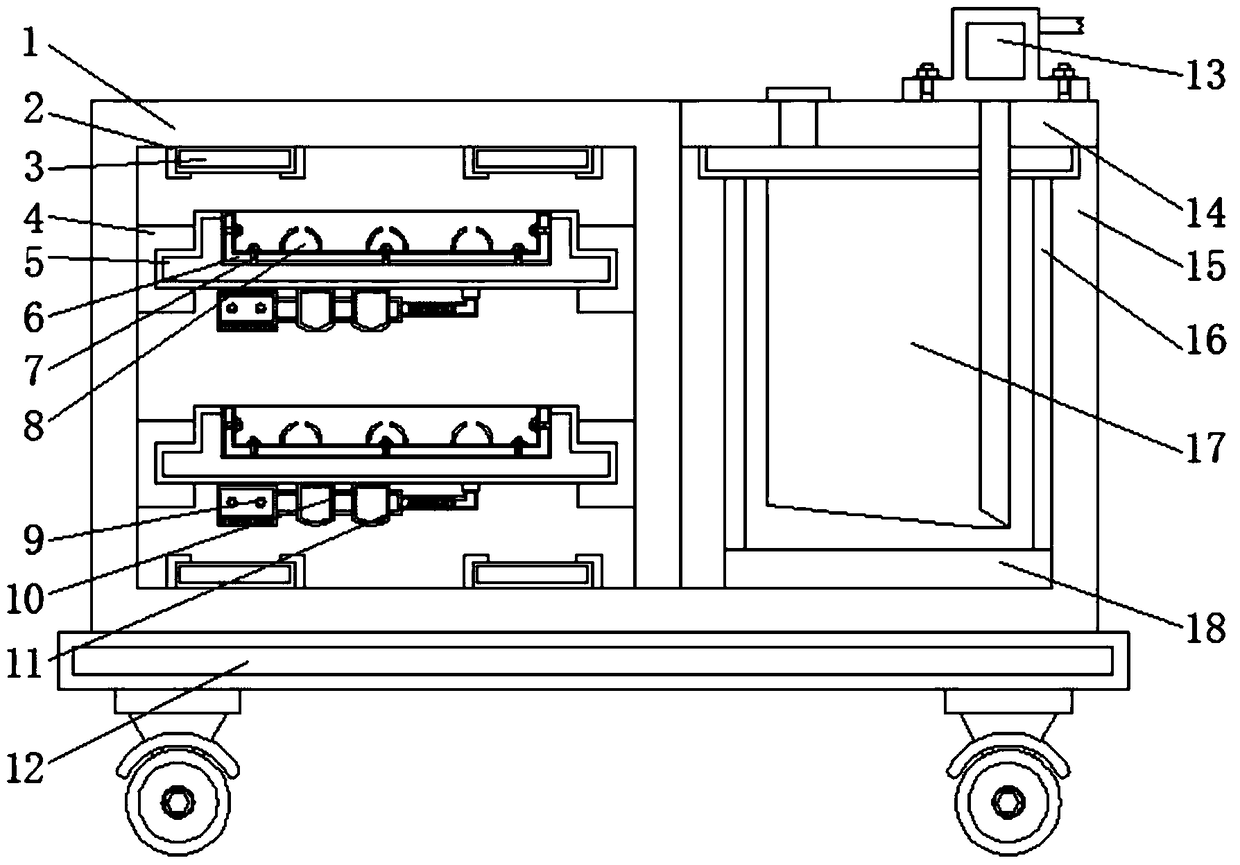

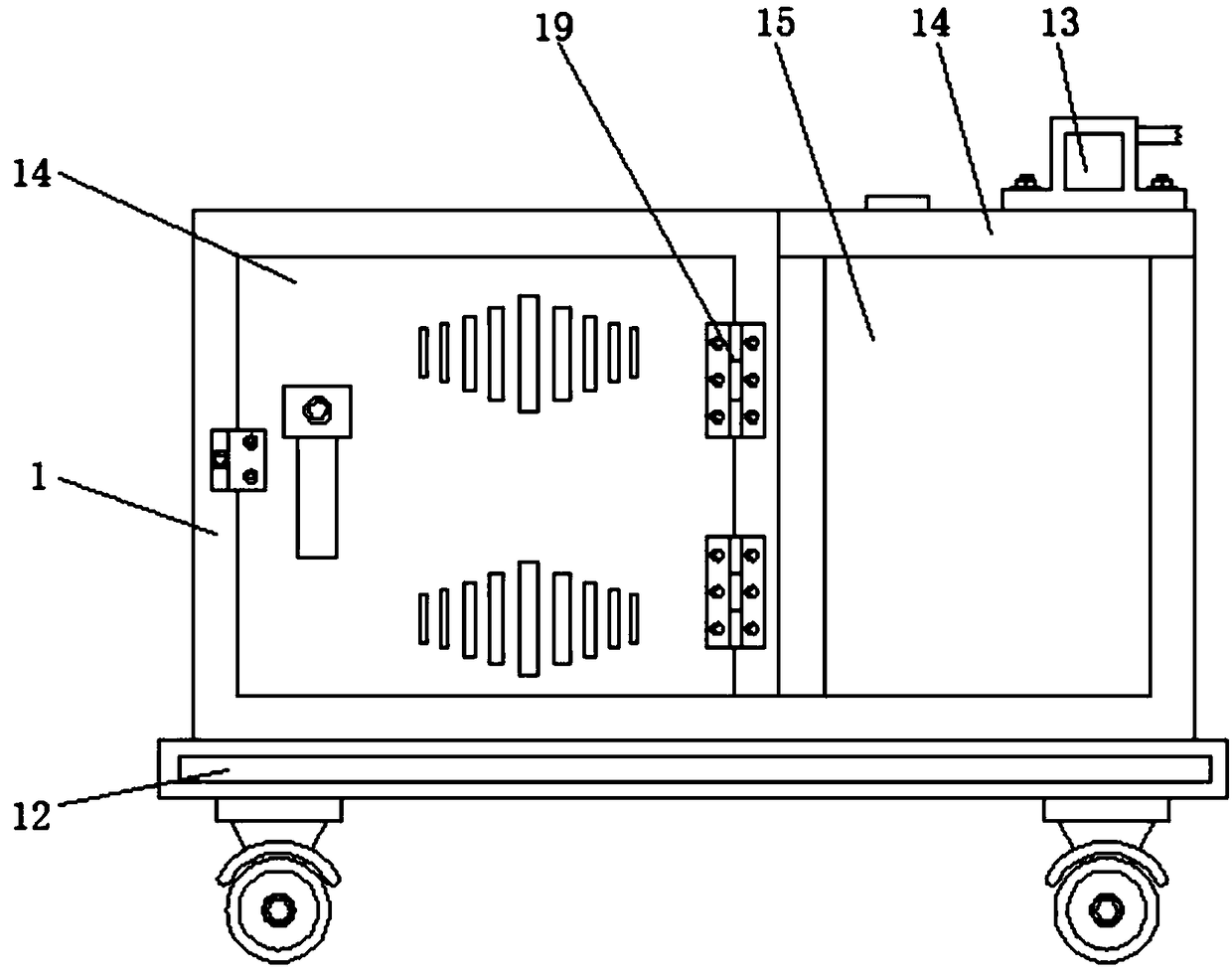

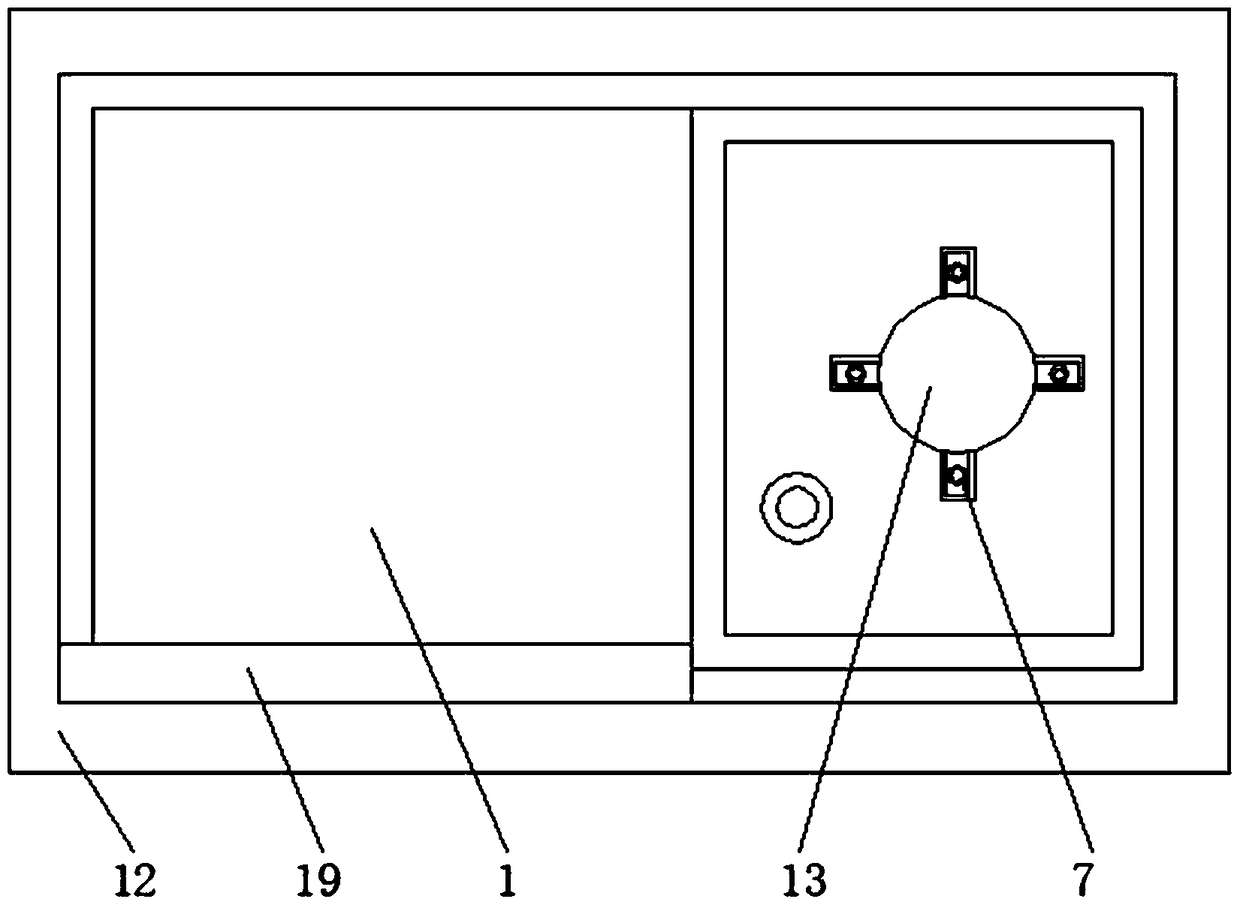

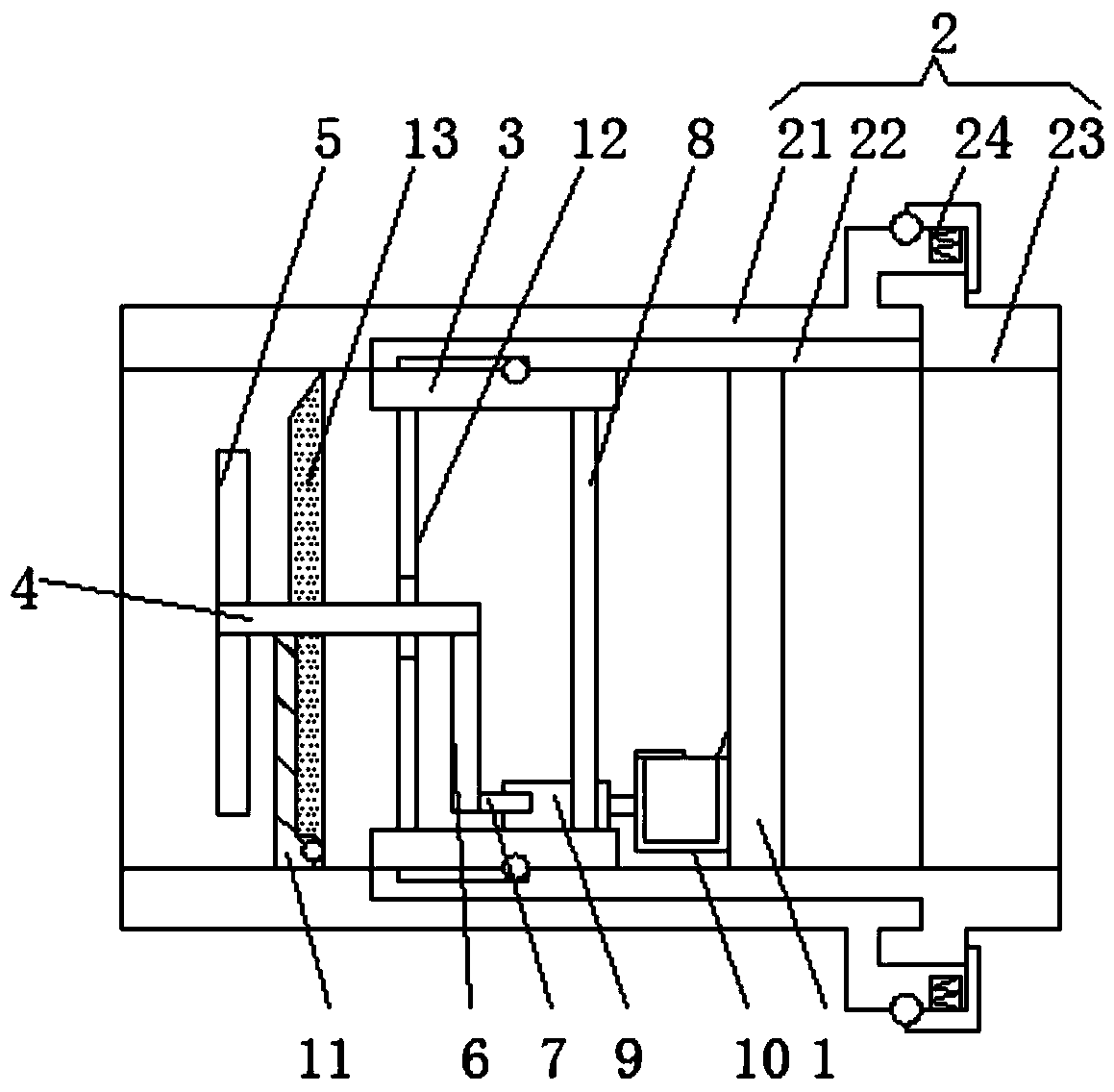

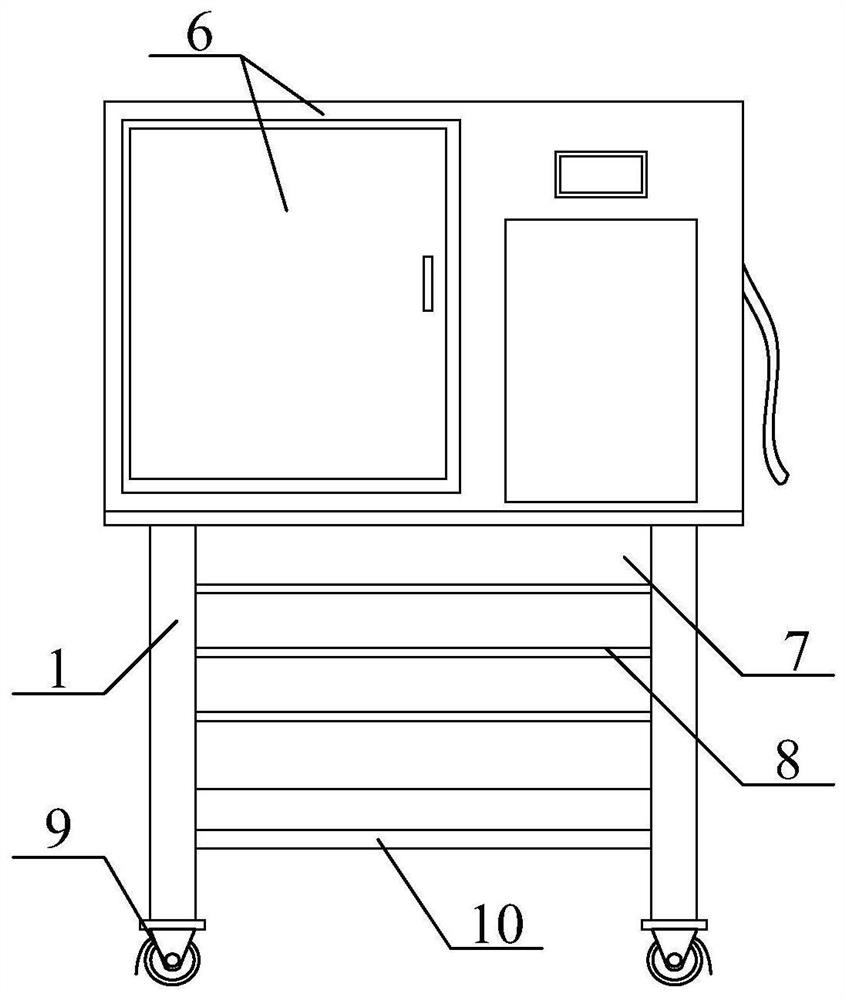

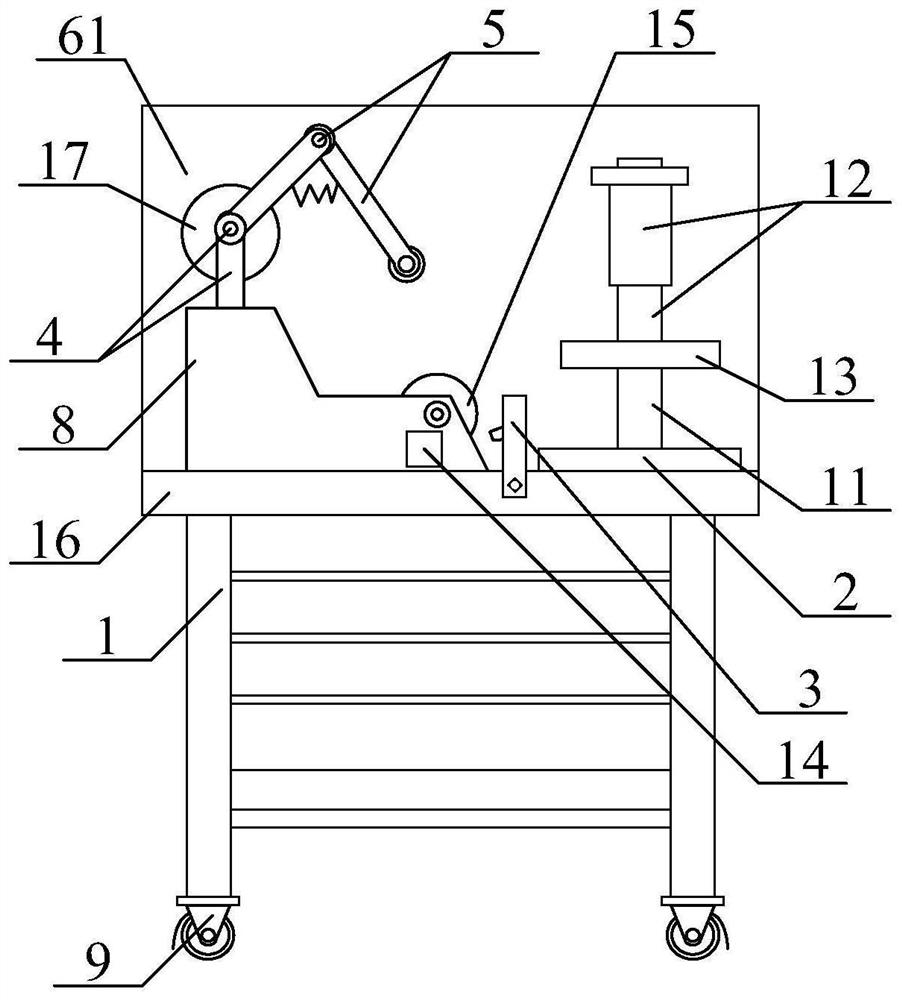

Rack of lead seal machine

The invention relates to a device for mounting a lead seal to an electricity meter, and in particular relates to a rack of a lead seal machine. The rack comprises a rack body, wherein the rack body comprises a panel and support legs, a slide rail is arranged on the rack body, a lamp holder is connected to the slide rail in a sliding manner, an illuminating lamp is connected to the lamp holder, nuts are arranged at the lower ends of the support legs, the nuts are in threaded connection with screw rods, and support foot soles are arranged at the lower ends of the screw rods. The invention provides the rack of the lead seal machine which has the advantages that the illuminating lamp can be moved and the height of the support legs can be adjusted, and therefore, the problems that for the existing racks, no illuminating lamps are arranged, and the height of the support legs can not be adjusted, are solved.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

Tool sorted storage box with oil injecting function for automobile parts

InactiveCN109176438AAct as a fixed supportStable supportWork tools storageOther workshop equipmentSurface mountingEngineering

The invention discloses a tool sorted storage box with an oil injecting function for automobile parts. The box comprises a tool box body, a layering plate and an inner barrel. Supporting racks are mounted on the inner surfaces of the upper and lower ends of the tool box body, drying blocks are connected to the inner surfaces of the supporting racks, the supporting racks are elastically connected to the drying blocks in a clamping manner, chutes are formed in the surfaces of the inner walls of the left and right ends of the tool box body, the tool box body is connected to the chutes through screws, a soft cushion is mounted on the surface of the inner wall of the layering plate, and the layering plate is located on the surface of the inner wall of the chute. According to the tool sorted storage box with the oil injecting function for automobile parts, compared with an existing tool sorting storage box for automobile parts, dryness of the inner part of the storage box can be maintained and a phenomenon that the tools are corroded as being affected with dampness; stains left on the surfaces of the tools can be eliminated, so that the tools are stored conveniently; and meanwhile, oil is injected to the parts, so that parts are used by the tools conveniently.

Owner:湖北鹏良工贸股份有限公司

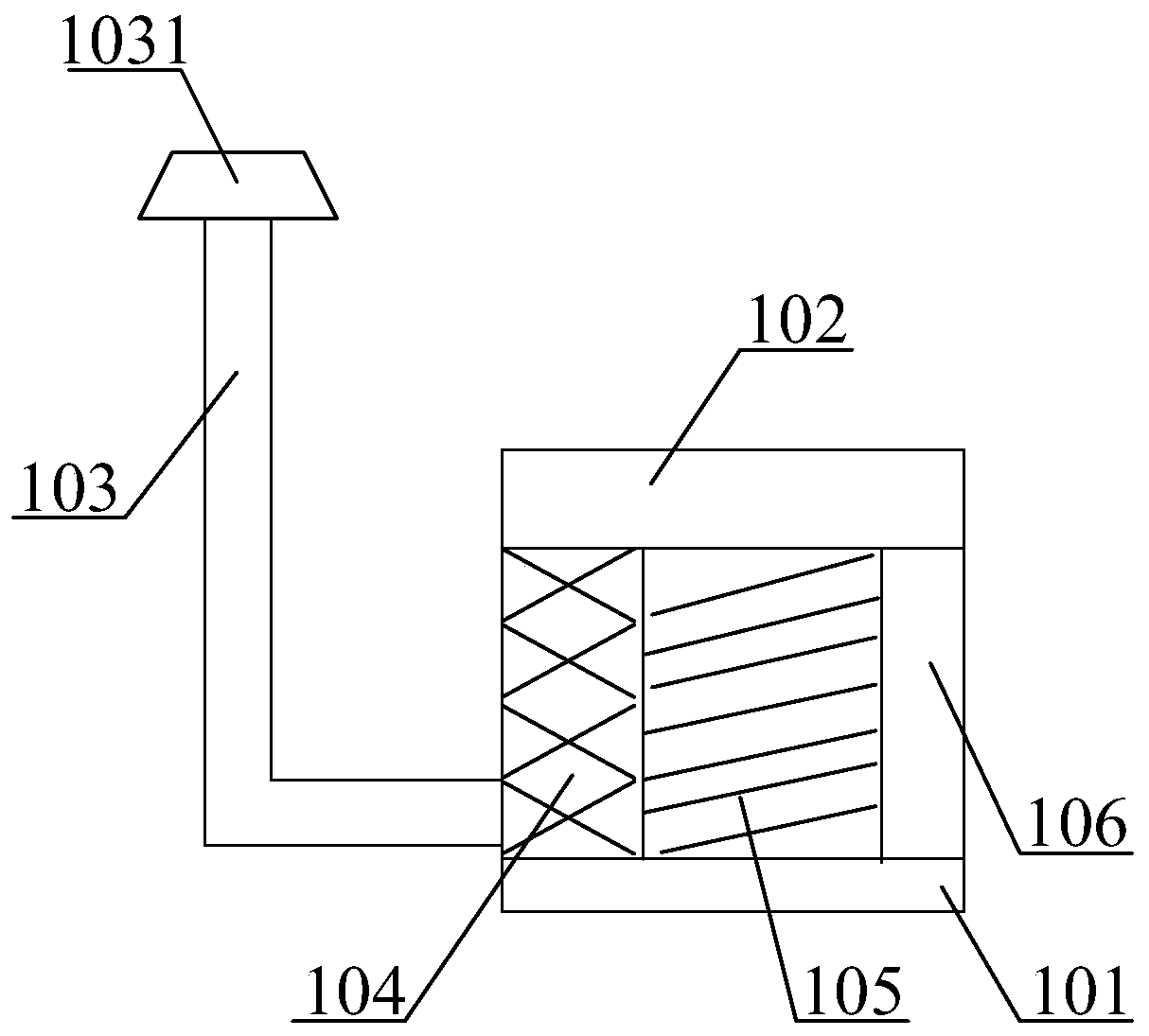

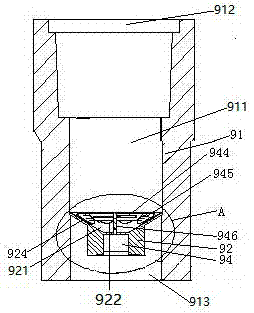

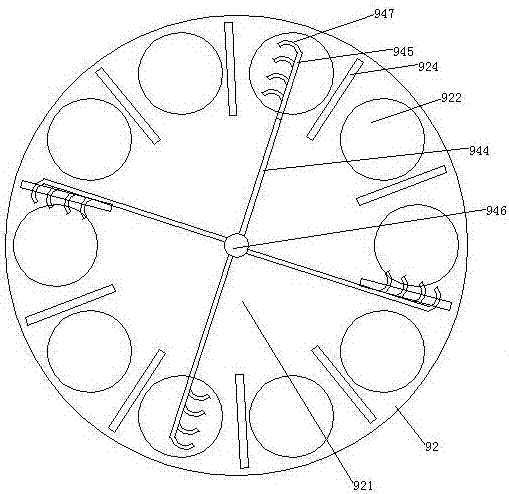

Water channel system of gas heating water heating furnace

InactiveCN109373570APlay a role in cleaning upAvoid cloggingWater heatersStationary filtering element filtersWater channelWater flow

The invention discloses a water channel system of a gas heating water heating furnace, and belongs to the technical field of gas heating water heating furnaces the water channel system. The water channel system comprises a pipe body, a filter screen is arranged on the right side of the inner cavity of the pipe body, a turbine is arranged at the left end of a rotating rod, a connecting rod is arranged on the right side of the bottom side wall of the rotating rod, a receiving frame is arranged on the right side wall of a sliding block, an inserting rod is movably inserted into the inner cavity of a sliding groove, and the left side wall of the inserting rod is fixedly connected with the bottom of the right side wall of the connecting rod. The water channel system is used for filtering impurities in water through the filter screen, the water flow drives the turbine to rotate so as to drive a cross rod and the connecting rod to rotate, so that the receiving frame moves upwards, impuritieson the left side of the filter screen are shoveled by a shovel plate on the right side of the top of the receiving frame, the cleaning function of the filter screen can be achieved, the filter screenis prevented from being blocked, the working efficiency of the filter screen is guaranteed, impurities are prevented from being attached to the inner cavity wall of the gas heating water heating furnace, so that the heating effect of the gas heating hot water furnace to the water flow is ensured.

Owner:江苏索西热能科技有限公司

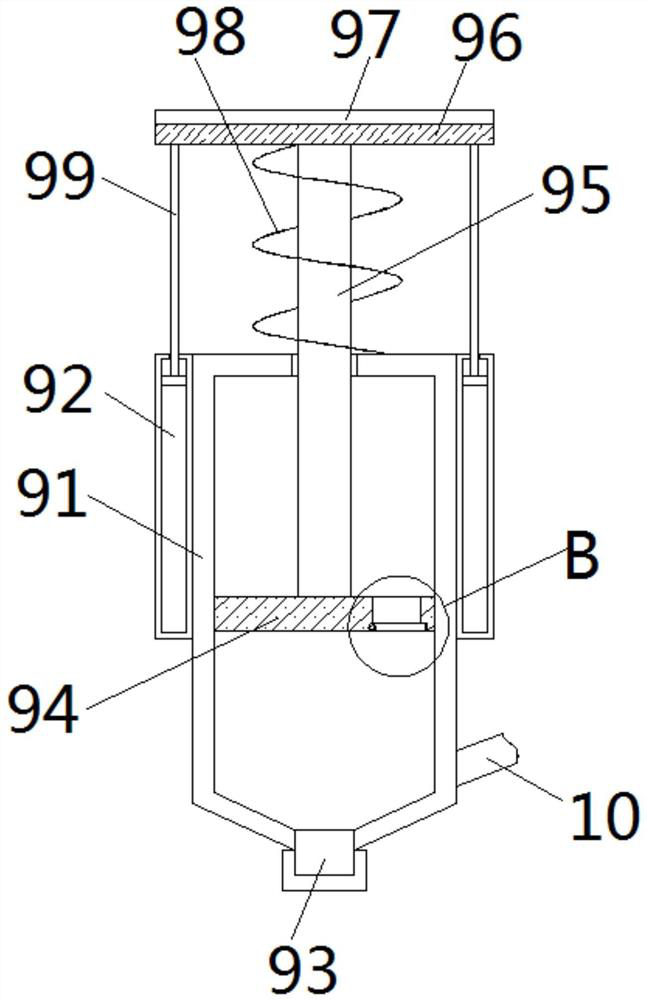

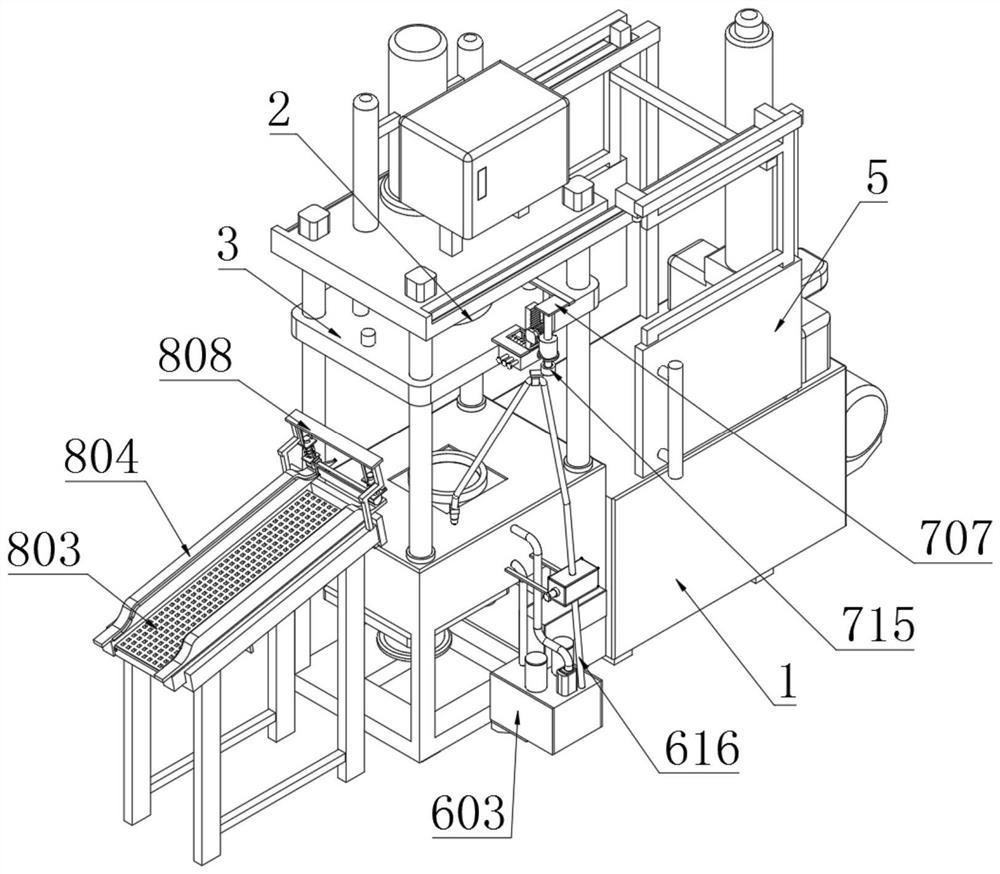

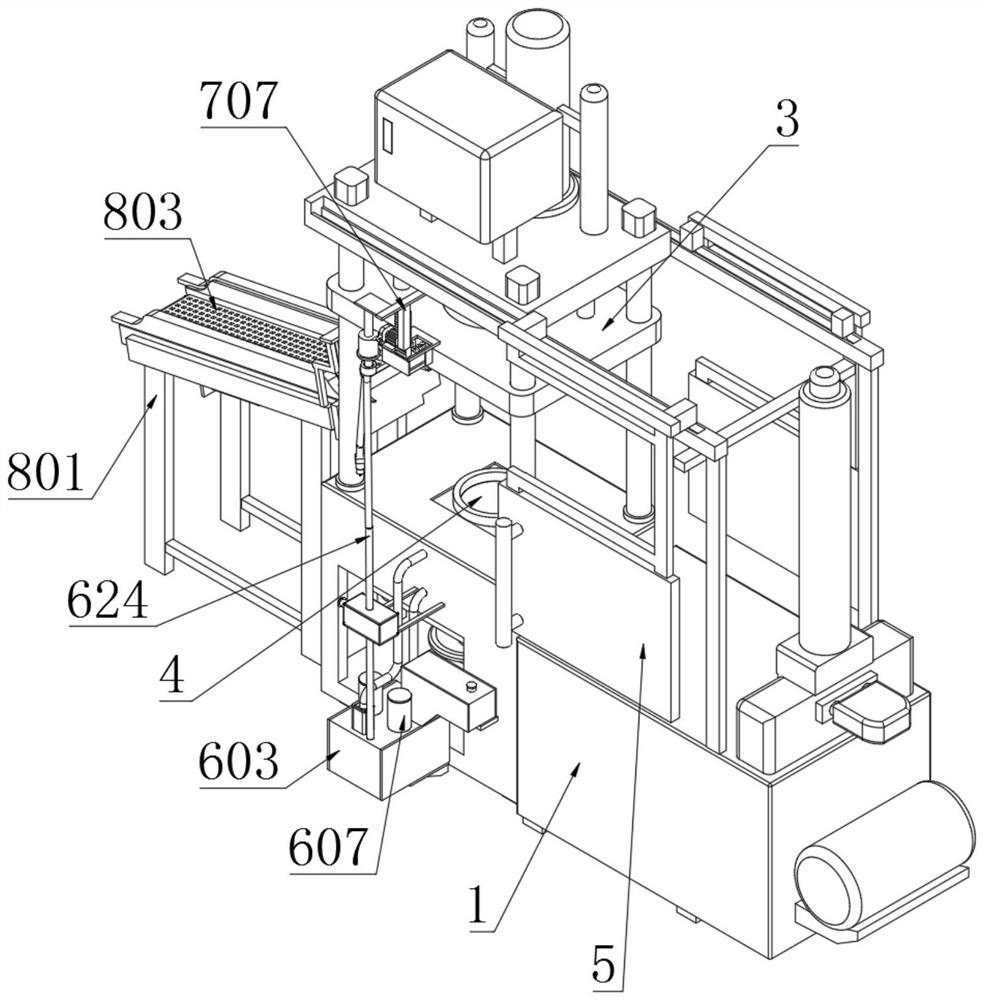

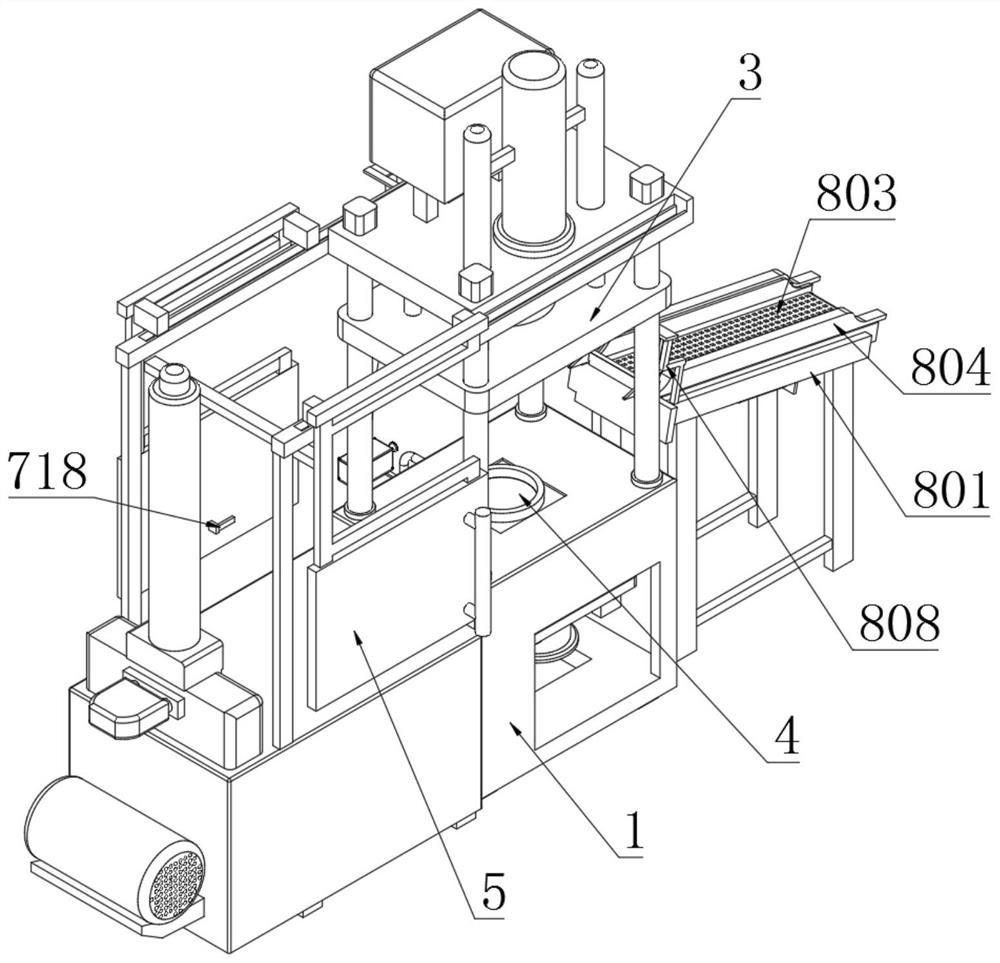

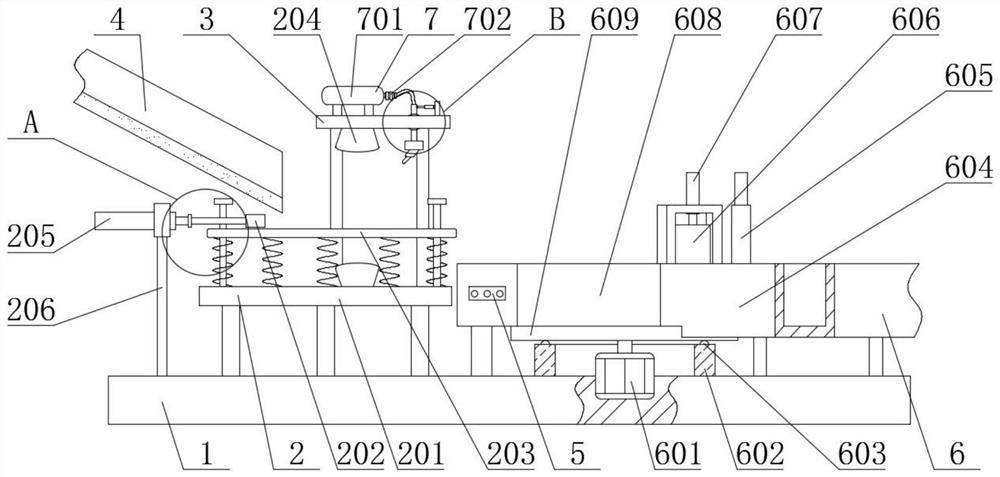

Vertical high-pressure casting machine

InactiveCN113059142AIncrease pressureImprove cleaning efficiencyCleaning using gasesPressure castingEngineering

The invention discloses a vertical high-pressure casting machine. A heat absorption cavity is formed in the position, located on one side of a pressure chamber, in a machine body, an oil outlet pipe is fixedly connected to the bottom end of the heat absorption cavity, an evaporation pressurization box body is fixedly installed at the bottom end of the oil outlet pipe, a spiral pipeline is fixedly installed in the evaporation pressurization box body, an oil inlet pipe is fixedly connected to the top of the evaporation pressurization box body, a micro oil pump is fixedly installed at the bottom of the oil inlet pipe, and pressure accumulation cylinders are symmetrically and fixedly installed in the middle of the top end of the evaporation pressurization box body. The heat conduction oil in the heat absorption cavity is used for absorbing heat generated in the casting process, the heat conduction oil circularly flows in the heat absorption chamber and a spiral pipeline to heat water in the evaporation pressurization box body, the interior of the evaporation pressurization box body is kept sealed, so that force generated by pressure generated in the evaporation pressurization box body is stored in a pressurization spring, airflow generated by the pressure is aligned to a pressure chamber through an exhaust pipe and a gas spray head, and an effect of cleaning the pressure chamber is achieved.

Owner:刘华

Automatic sorting equipment for express items

ActiveCN111921881ARealize sortingGet rid of tediousCleaning using gasesSortingElectric machineryIdentification device

The invention relates to the technical field of express item sorting, in particular to automatic sorting equipment for express items. The automatic sorting equipment for the express items comprises abase, a blanking slope and a controller, wherein the upper side of the left end of the base is provided with a fallen material identification device; and the top end of the base is fixedly connected with a supporting plate. In the automatic sorting equipment, through arranged components, including a motor, a rotary disk, a sorting disk, an outlet baffle plate and the like, in the sorting equipment, the express items can be sorted, complexity brought by manual sorting is avoided, and the sorting equipment has good practicality. When the sorting equipment begins to work, a first electric telescopic rod on the top end of a material discharging plate which needs to discharge materials can be retracted, the first electric telescopic rod drives the outlet baffle plate to be upwards opened, the inlet end of the material discharging plate can be opened, the motor drives the rotary disk to rotate so as to drive the express item to rotate, while the express item rotates, centrifugal force is generated, and the express item has force which moves to the outer side of the rotary disk.

Owner:溆浦县远宏速递有限责任公司

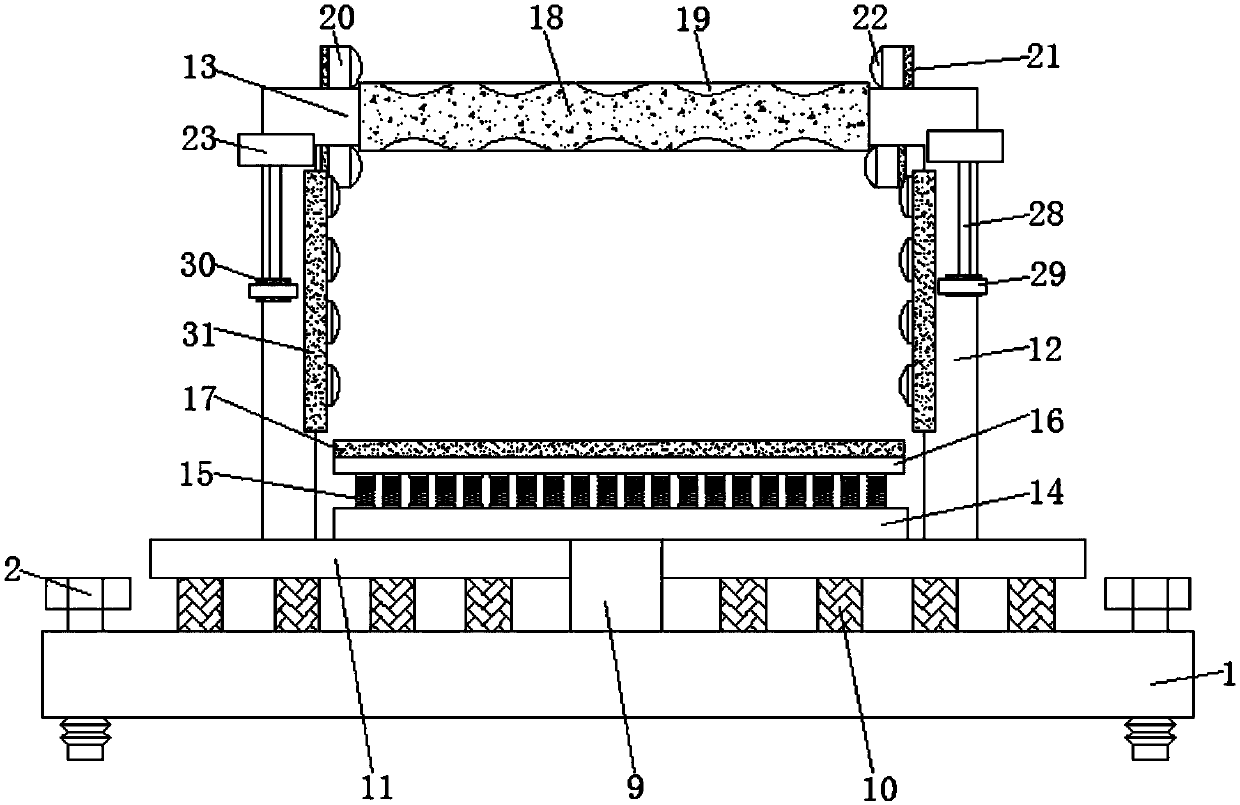

Touch screen film covering equipment

PendingCN113120299AImprove conveniencePlay a role in cleaning upWrapping material feeding apparatusPackaging protectionElectric machineryEngineering

The invention provides touch screen film covering equipment which comprises supporting legs, a touch screen clamping base assembly with a protection function, a cutting knife assembly capable of being connected with an air pipe, an adjustable rolling film support assembly, a rolling film pressing rod assembly, a protection box assembly facilitating material taking and placing, a lower object containing cabinet, a partition plate, moving wheels, a shaping strip, supporting columns, a film covering pressing machine, a touch screen film covering mold base, a steel roller driving motor, a conveying steel roller and a machining operation platform; and the touch screen clamping base assembly with the protection function is connected to the right side of the upper portion of the machining operation platform through screws. The sealing performance of the touch screen film covering equipment is high, sweeps on the film covering surface can be cleaned, the film covering quality and efficiency are guaranteed, materials can be conveniently taken through the arrangement of multiple cabinet doors of a sealed box body, and the machining process is observed under the action of a tempered glass window; and static electricity attached to a touch screen can be eliminated at any time, and electric appliance elements in the touch screen are protected in the film covering process.

Owner:湖南兴悦科技有限公司

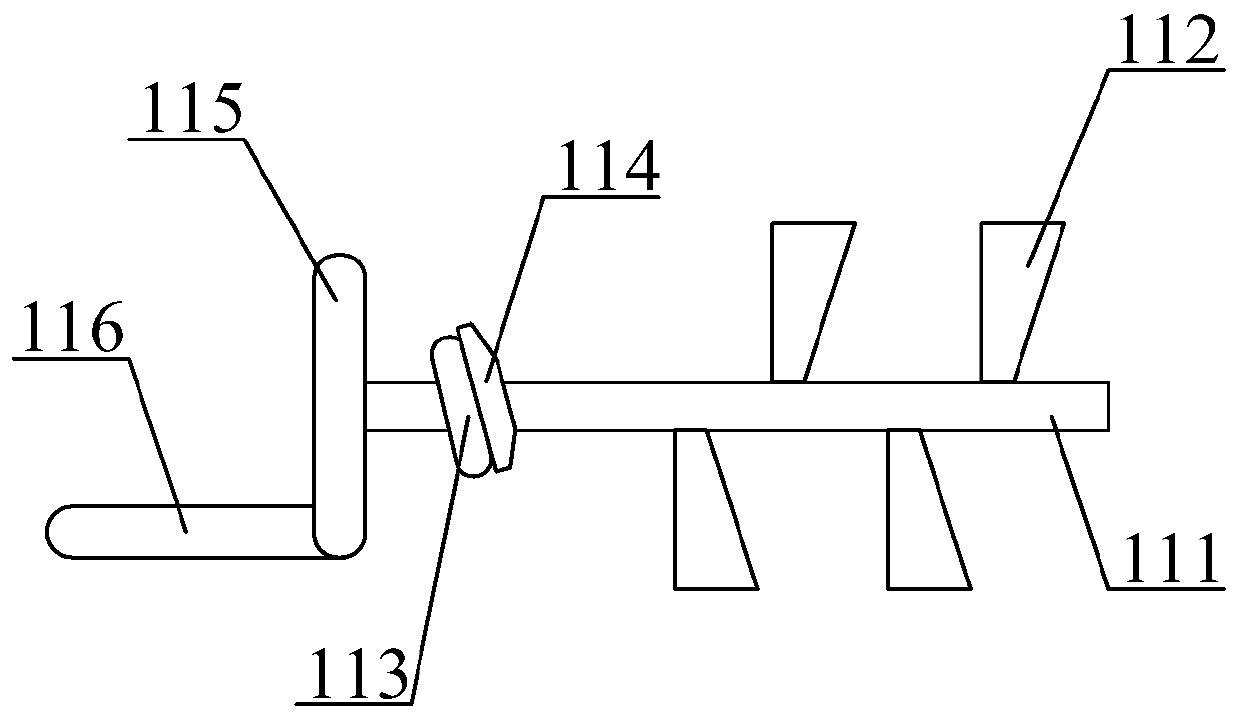

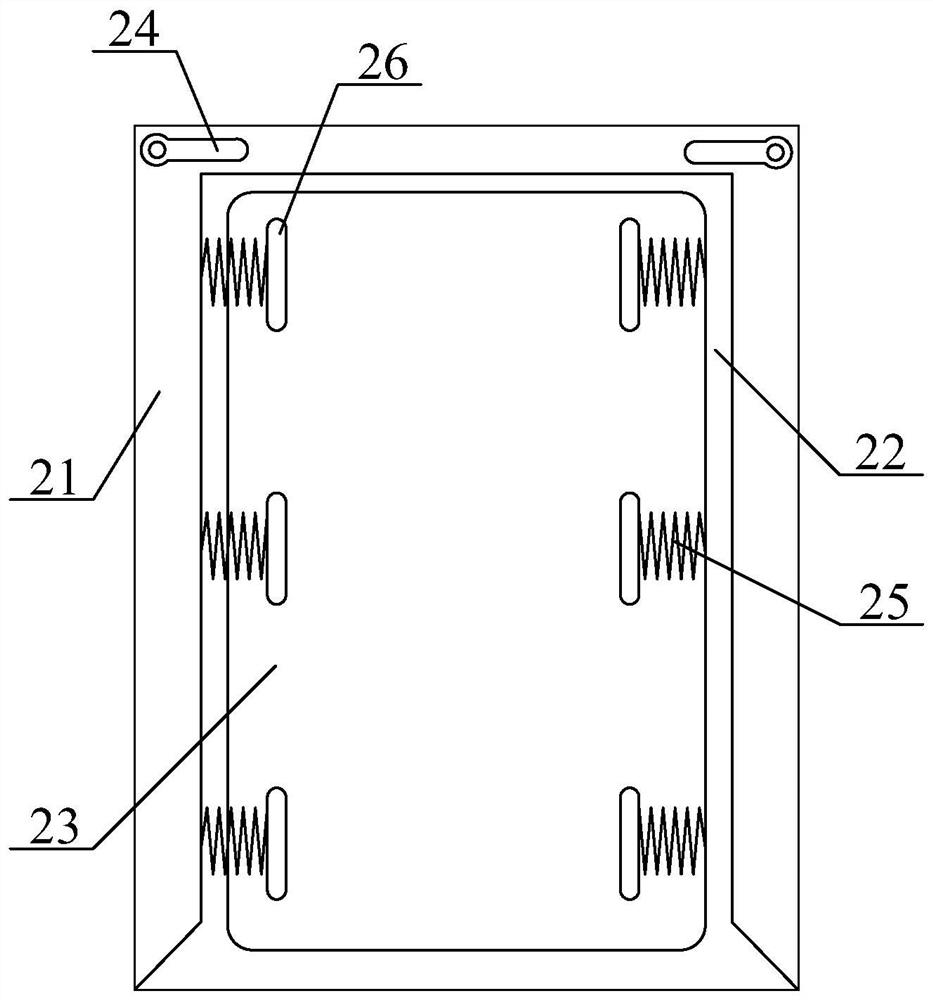

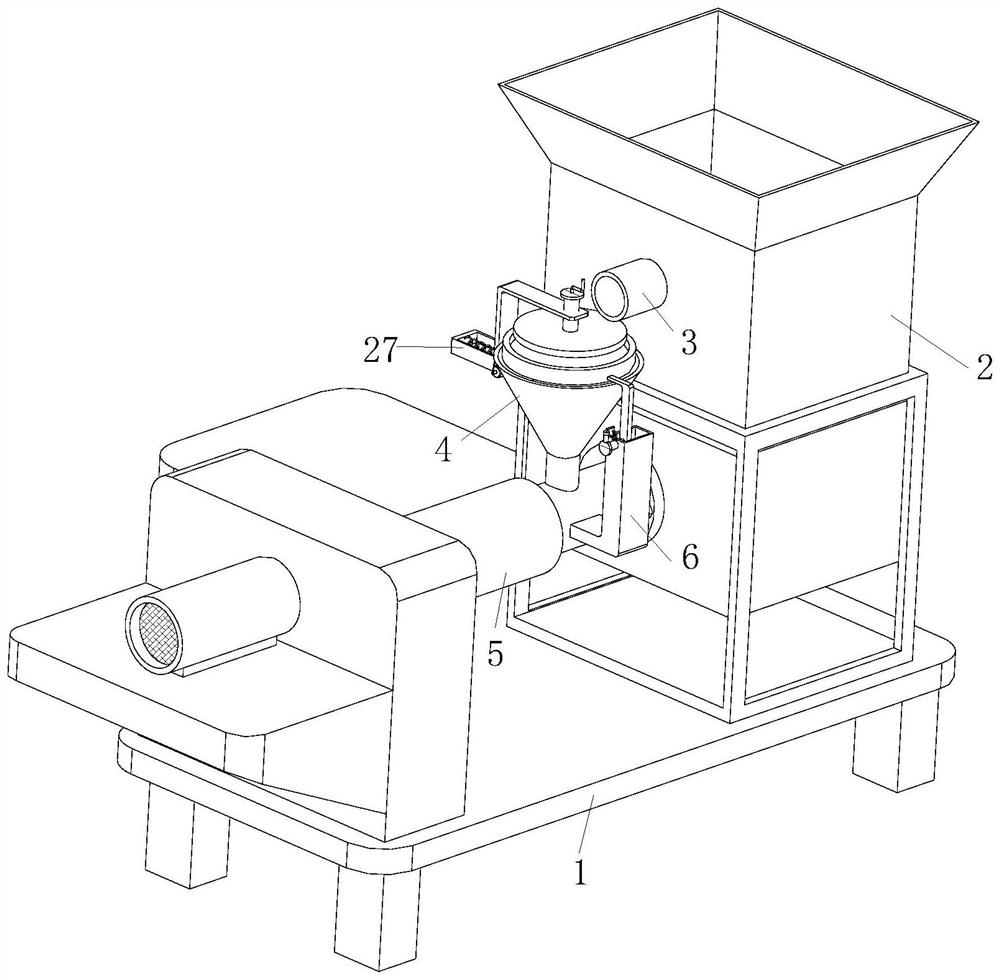

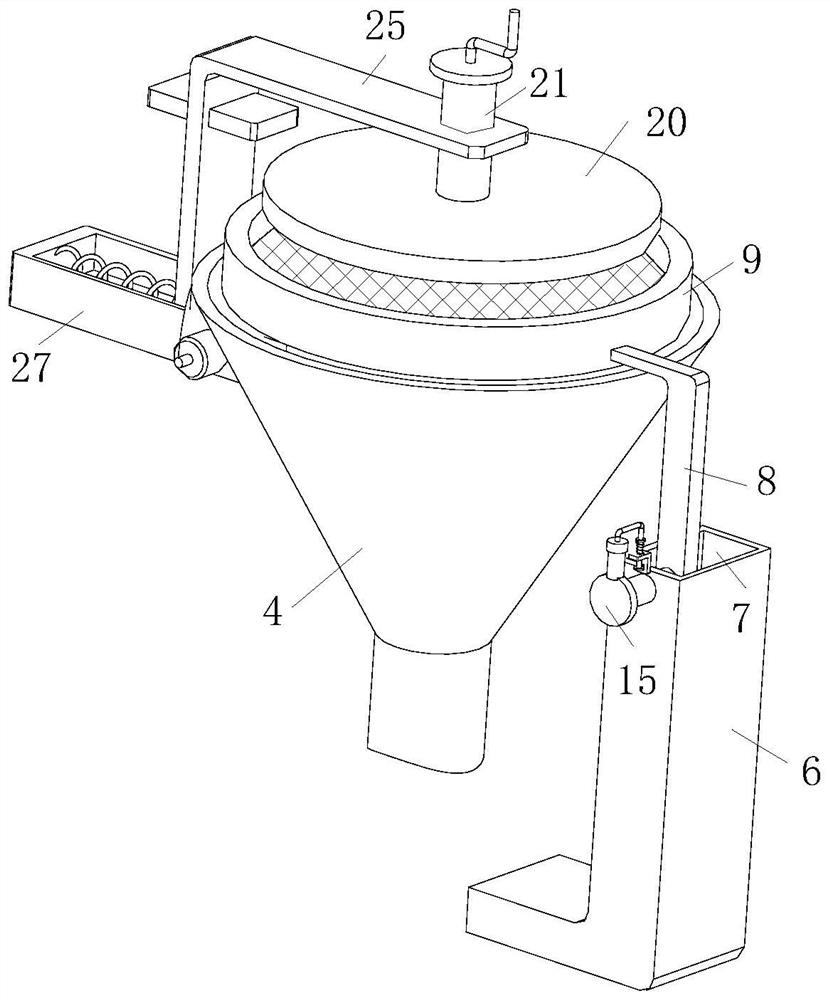

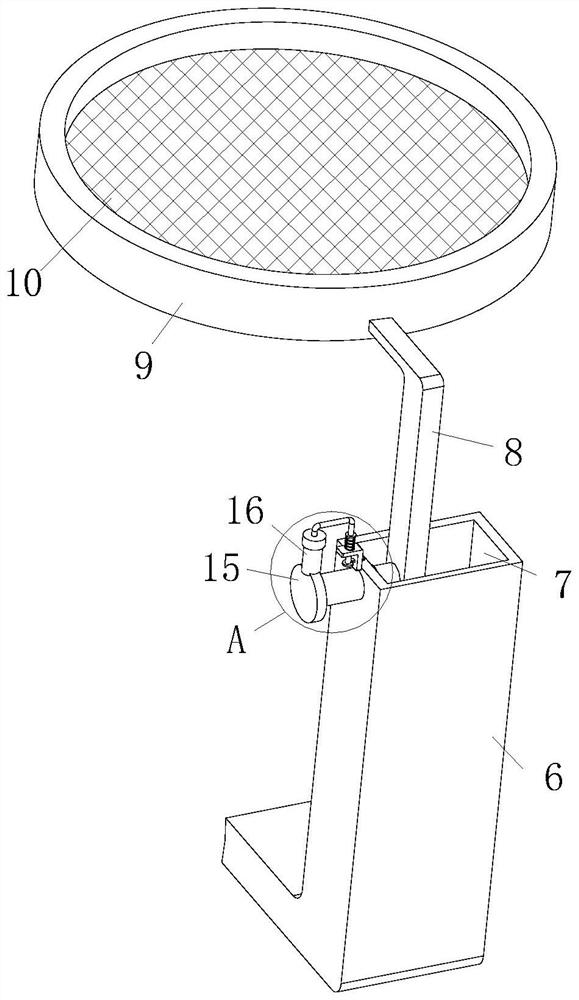

Feed processing and puffing device

The invention belongs to the field of feed processing, and particularly relates to a feed processing and puffing device. The feed processing and puffing device comprises a bottom plate and a stirring machine, wherein the stirring machine is installed at the top end of the bottom plate through a support; one side of the stirring machine communicates with a discharging port and a material conveying pipe; a hopper communicates with the interior of the material conveying pipe; a surface of the material conveying pipe is fixedly connected with a supporting block; the supporting block is L-shaped; a sliding groove is formed in a long arm end of the supporting block; and a sliding block is slidably connected to an inner wall of the sliding groove. According to the invention, by starting an electric telescopic rod, the electric telescopic rod drives the sliding block to slide in the sliding groove, a connecting ring can slide along with the sliding block, and at the moment, a screen enables caked raw materials on the screen to shake due to movement of the sliding block, so that the caked feed raw materials on the screen are screened and scattered and fall into the hopper, the effect of screening the caked feed raw materials is achieved, the situation that the hopper is blocked is avoided, and the use efficiency of the hopper is improved.

Owner:江西博美莱生物科技有限公司

Removable bridge cleaning integrated maintenance device

InactiveCN109113011AEasy to useIncrease contactBridge structural detailsRoad cleaningCouplingWater storage tank

The invention provides a removable bridge cleaning integrated maintenance device comprising a bottom plate, a moving wheel, a pusher, a water storage tank, a water delivery pipe, a water spray pipe, ahigh-pressure spray head, a connecting plate, a motor, a coupling, a threaded rod, a first vertical rod, a horizontal plate, a first bearing, a cleaning rod structure, a collecting bag structure, a maintenance cylinder structure, a stirring cylinder structure and a placing rack structure, wherein the moving wheels are respectively welded to left and right sides and longitudinal middle parts of the lower surface of the bottom plate; the pusher and the water storage tank are respectively welded on the upper right part of the bottom plate. The invention has the advantages that: by cleaning the arrangement of the rod structure, the invention is favorable for cleaning the bridge columns through a cleaning brush, thereby increasing the cleaning effect of the equipment. The arrangement of the collecting bag structure is favorable for conveniently placing chemical substances such as crack glue and the like, and meanwhile, the maintenance work of the bridge can be easily carried out through the maintenance barrel structure.

Owner:滨州市坤颂光伏设备有限公司

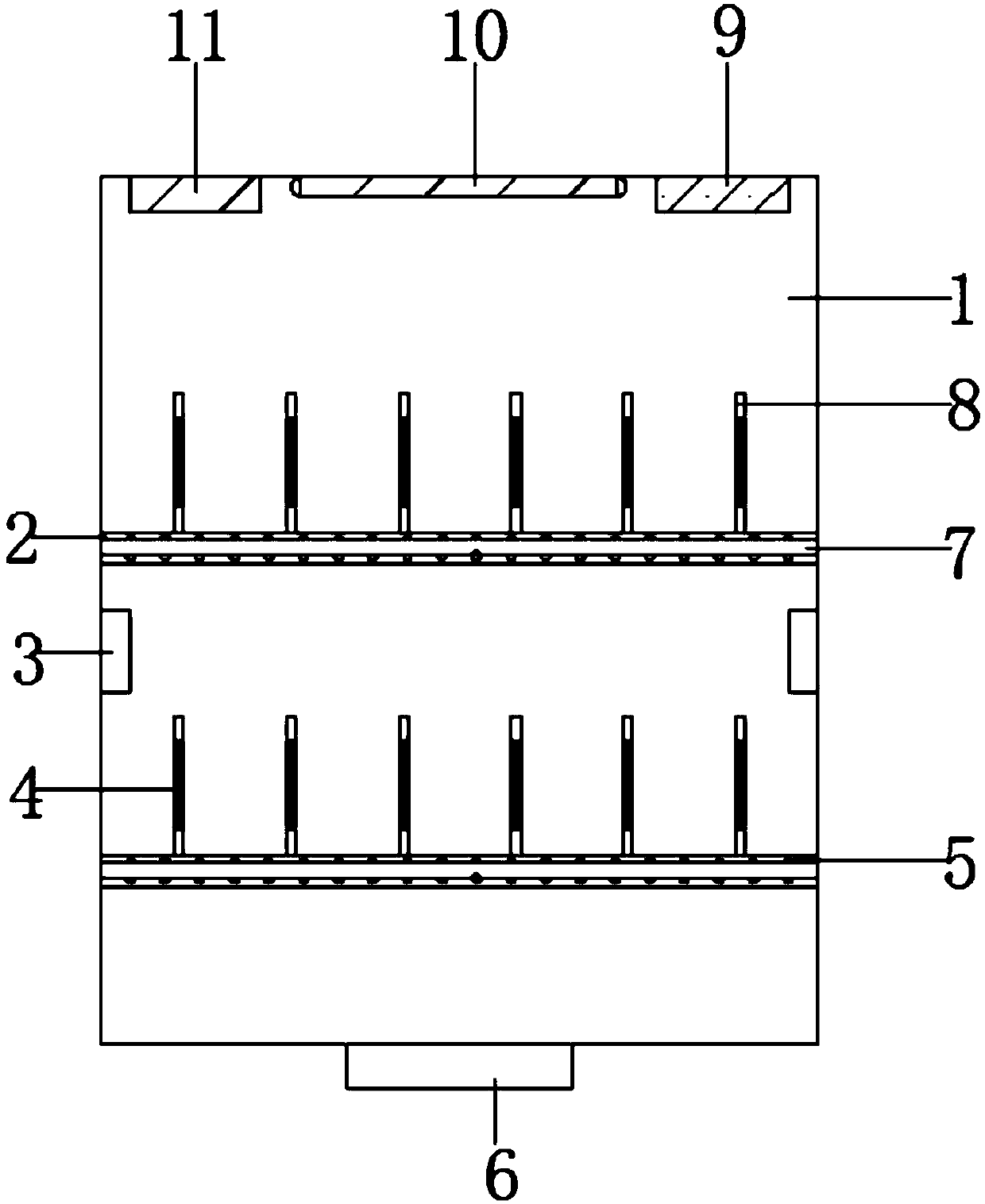

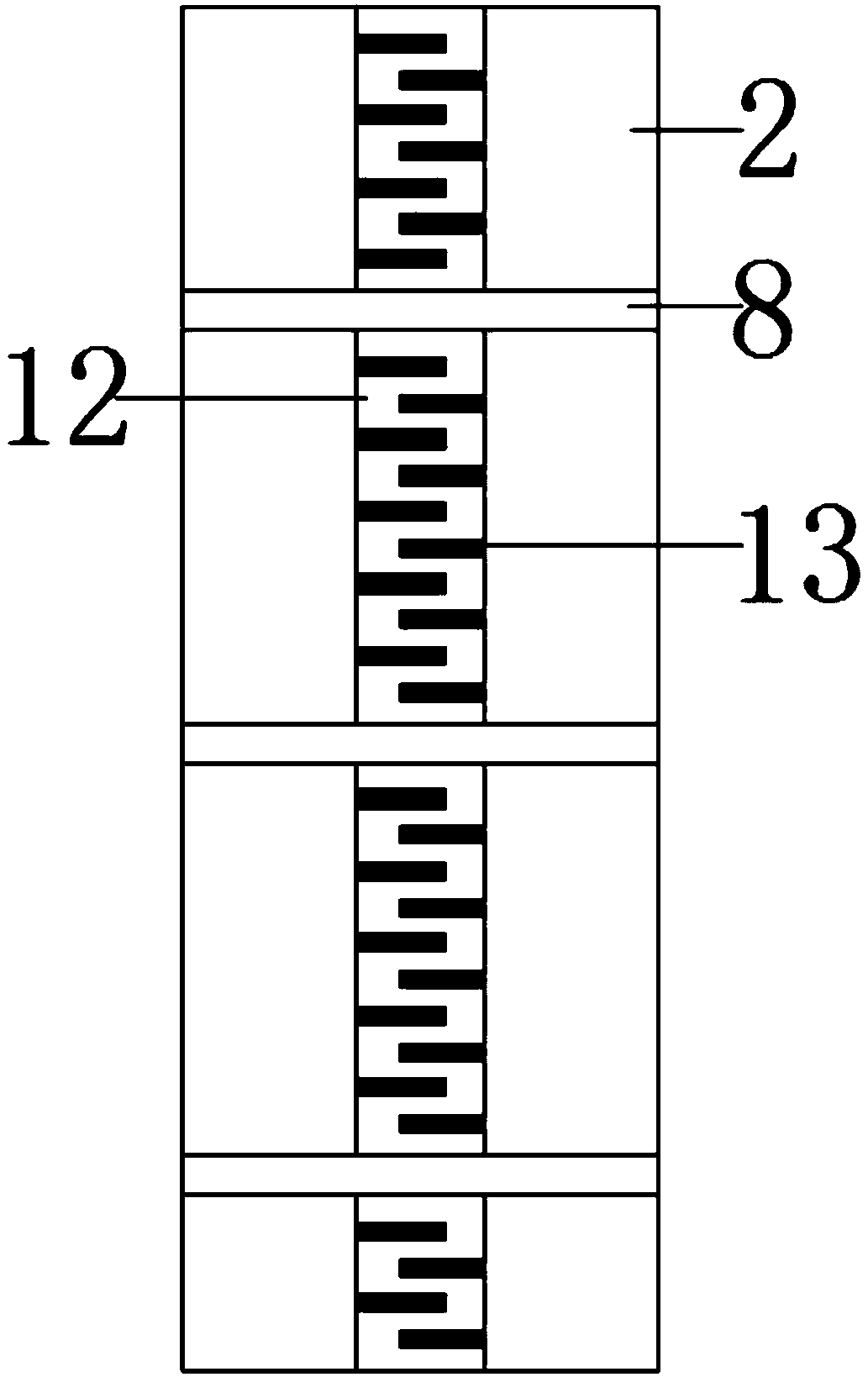

Multi-stage filtering split type air filter and working method thereof

ActiveCN113634052APlay a role in cleaning upEasy to cleanDispersed particle filtrationAir filterEngineering

The invention provides a multi-stage filtering split type air filter and a working method thereof, and relates to the technical field of air cleaners. The multi-stage filtering split type air filter comprises a filter body, the filter body comprises a filter shell, and two compressible filter element assemblies which are oppositely distributed are contained in an inner cavity of the filter shell; and each filter element assembly is composed of a plurality of filter element layers capable of elastically stretching out and drawing back in the length direction of the filter shell, a pressure applying assembly capable of intermittently applying pressure in one direction is arranged between every two adjacent filter element assemblies, each pressure applying assembly comprises a pressure applying plate capable of reciprocating in the length direction of the filter shell, and the pressure applying plates make elastic contact with the filter element assemblies. The filter element assemblies are compressed and recovered to drive the filter element layer to move, so that the filter element layers can be cleaned, dust attached to the surfaces of the filter element layers is reduced, the filter element layers are cleaned, and the cleaning effect of the filter element layers is improved.

Owner:高博集团有限公司

Carton moistureproof storage device

InactiveCN107839972AEasy to storeEasy to fixContainers for heating foodShock-sensitive articlesCross connectionSurface cleaning

The invention discloses a carton moisture-proof storage device, which comprises a cavity, the interior of the cavity is fixedly connected to a horizontal plate, the upper part of the horizontal plate is fixedly connected to a fixing rod, both sides of the inner wall of the cavity are fixedly connected to an incense box, the cavity The top of the body is connected with an ultraviolet sterilizing lamp, one side of the ultraviolet sterilizing lamp is provided with a heating plate, the other side of the ultraviolet sterilizing lamp is provided with a temperature regulator and the temperature regulator is connected with the heating plate, and the inside of the fixed rod is connected with a vibrating rod. The invention is convenient for dislocation of fixed cartons, easy to clean the cartons, easy to remove the cartons, and can dry the cartons to ensure the surface of the cartons is dry, and the cartons can be sterilized by ultraviolet germicidal lamps Disinfection can clean the surface of the carton and ensure the cleanliness of the inside of the cavity. It can change the smell of the carton and avoid the smell infection between the cartons.

Owner:WUXI ZHONGHUAN PACKAGING

Textile fabric wetting device for textile production

InactiveCN112127066APlay a role in cleaning upSmall footprintMechanical cleaningPressure cleaningTextile technologyActivated carbon

The invention discloses a textile fabric wetting device for textile production, and relates to the technical field of textiles. A first extrusion plate is fixedly connected to the telescopic end of ahydraulic rod, a second extrusion plate is hinged to one side of the first extrusion plate through a hinge, a plurality of sets of brushes are fixedly installed at the positions, not making contact with a water passing hole, of the bottom of the second extrusion plate, and the interior of a waste water collecting box is divided into a first cavity and a second cavity through a filter plate; and aplurality of sets of supporting rods are clamped in the waste water collecting box and located above the filter plate, reset springs are fixedly installed at the two ends of the interior of each supporting rod, the exterior of each supporting rod is sleeved with an activated carbon filter element, and an abutting column is fixedly installed at one end of each reset spring. In the using process, excess water on a textile fabric can be squeezed out, so that next processing operation is facilitated; and the structure is simple, manual operation is not needed, more time and labor are saved, the working efficiency is improved, used water can be recycled again, and water resources are saved.

Owner:郭建召

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com