Waste cable recovery device

A waste cable, recycling device technology, applied in the direction of cable installation device, cable installation, equipment for dismantling/armored cable, etc. The effect of collecting and winding copper wire, increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

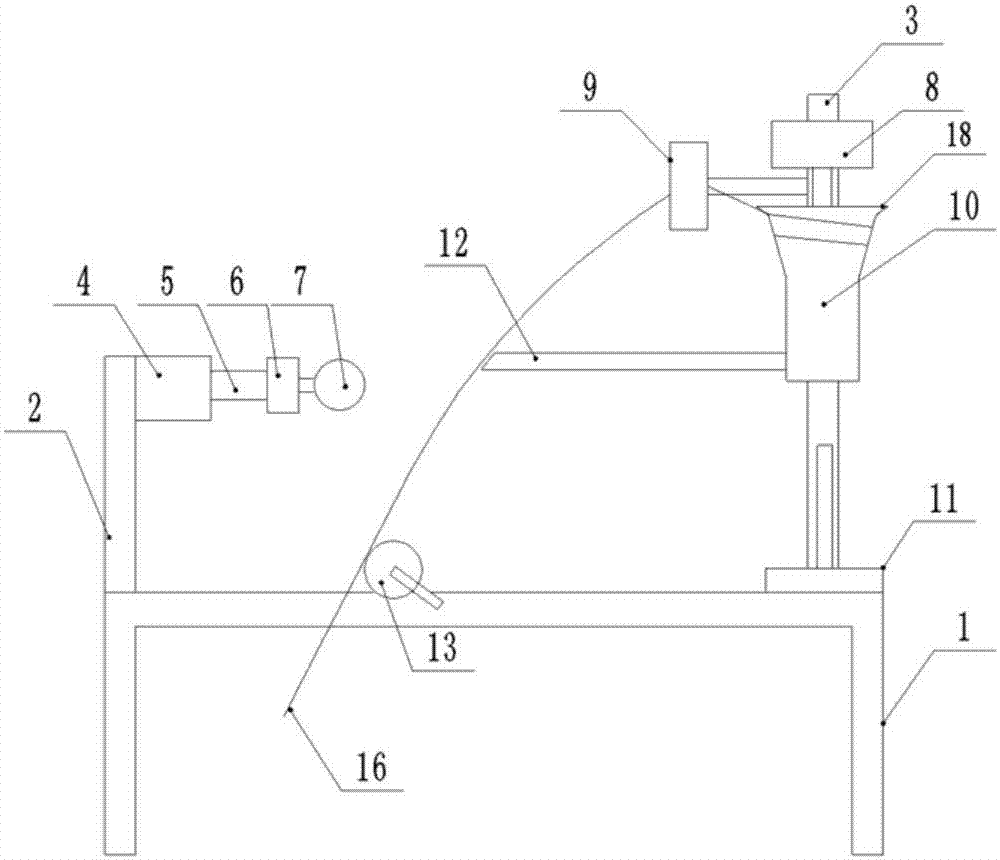

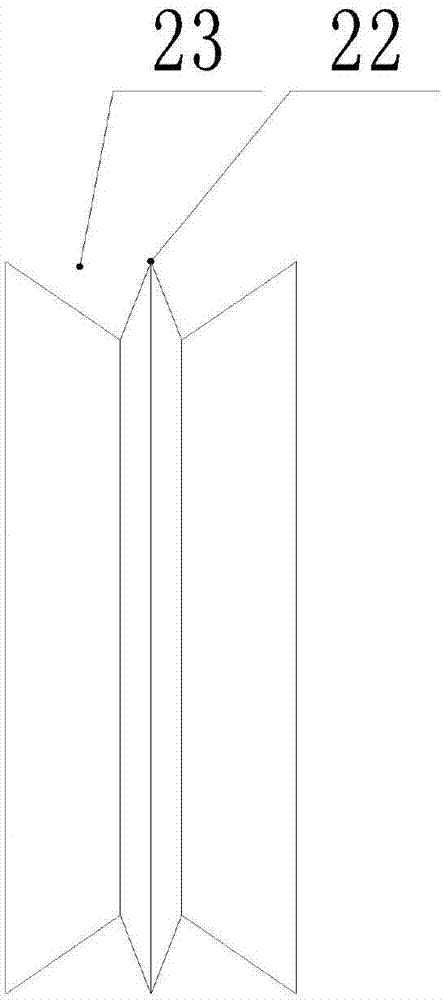

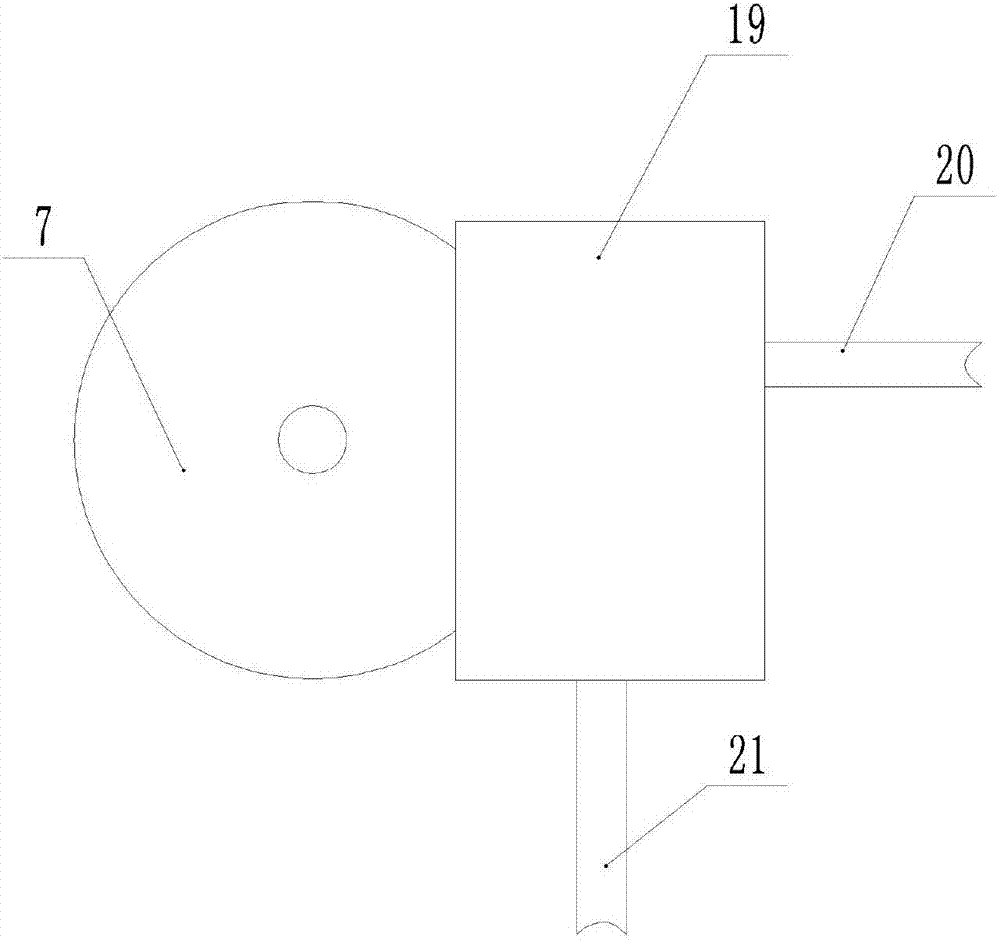

[0024] Such as figure 1 As shown, the waste cable recovery device includes a frame 1, the left end of the frame 1 is fixedly connected with a support rod 2 by welding or bolts, the right end of the frame 1 is welded with a bracket 3, and the cylinder 4 is installed on the upper end of the support rod 2 by welding, The expansion link 5 of cylinder 4 faces rightward, and first motor 6 is welded on the expansion link 5, and cutting knife 7 is fixed by bolt and nut on the output shaft of first motor 6; figure 2 As shown, the cutting knife 7 is provided with an inwardly recessed knife groove 23 along the circumference, and the bottom of the knife groove 23 is processed with an annular blade 22; image 3As shown, the left side of the cutting knife 7 is equipped with an inwardly sunken hot water chamber 19, and the hot water chamber 19 is provided with a hot water tank inwardly. The water pipe 20 and the hot water outlet pipe 21; the upper end of the support 3 is welded with a seco...

Embodiment 2

[0027] Such as Figure 4 As shown, on the basis of Embodiment 1, the left end of the scraper 12 is welded with a horizontal shaft, a support frame 17 is installed on the horizontal shaft, a torsion spring is installed between the horizontal shaft and the support frame 17, and a rotating connection is installed on the support frame. Roll top roller 15, under the action of torsion spring, roll top roller 15 is leaned against on the cable wire 16, when lead moves, can make roll top roller 15 rotate under the frictional force drive of lead wire and roll top roller, can simultaneously The insulating skin that scraper 12 peels off is wound on the volume skin roller 15; Figure 6 As shown, on the upper surface of the winding roller 10 and the right side of the guide wheel 9, the meshing gears are processed, the rotation of the winding roller 10 can drive the guide wheel 9 to rotate, and the sponge is pasted on the inside of the guide hole, and the guide wheel 9 rotates The surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com