Petroleum soil cleaning device

A technology for cleaning device and soil, applied in cleaning device, mixer with rotary stirring device, transportation and packaging, etc., can solve the problems of high separation cost, waste of resources, etc., to improve separation efficiency, increase service life, and improve output. The effect of material efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

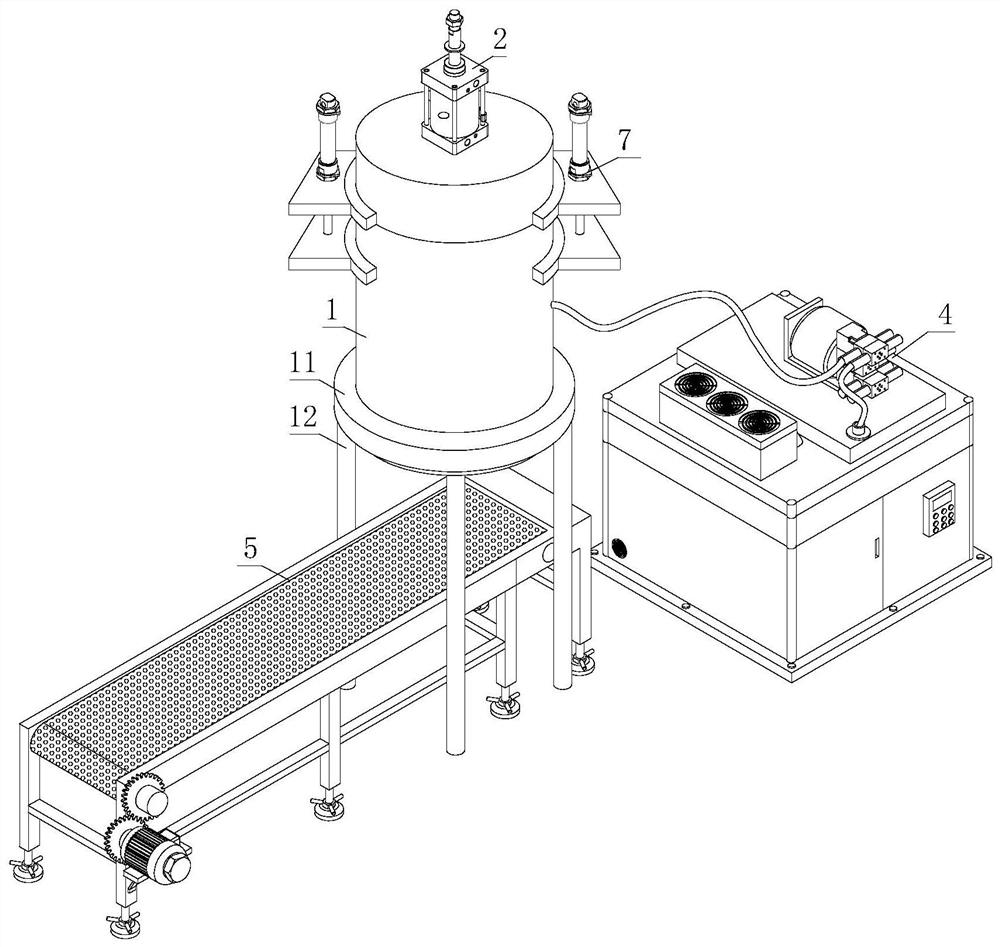

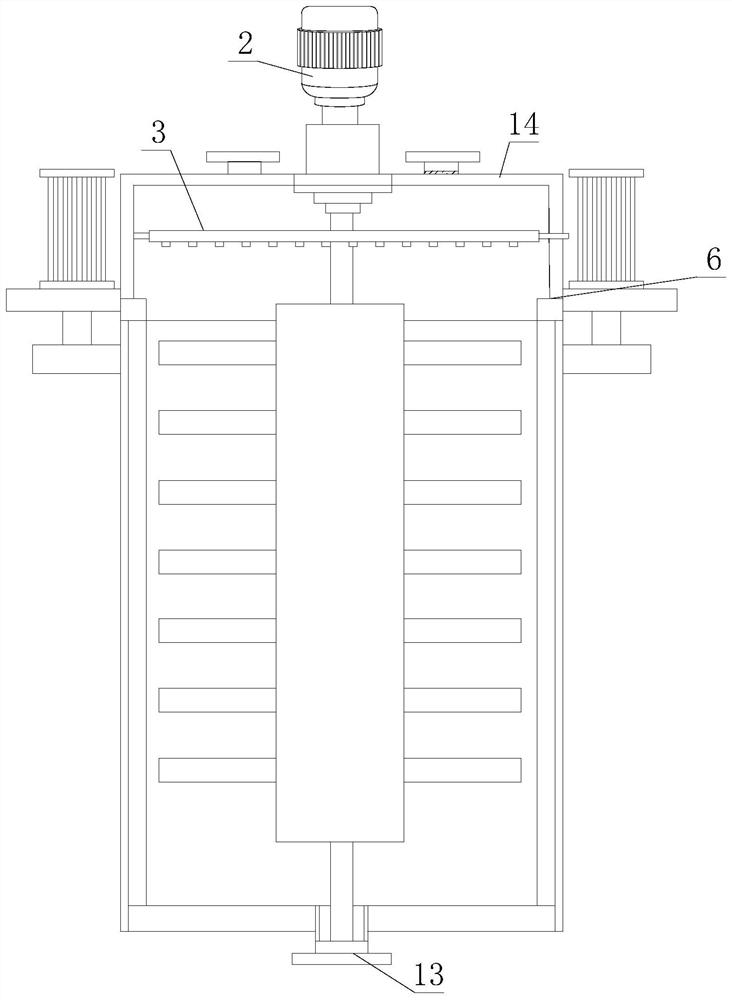

[0039] see Figure 1-Figure 2, a petroleum soil cleaning device, comprising a cleaning tank body 1, an outer hoop ring 11 is sleeved outside the bottom of the cleaning tank body 1, brackets 12 are respectively installed around the bottom of the outer hoop ring 11, and a stirring and separating device is arranged inside the cleaning tank body 1 2. A water injection device 3 is installed above the stirring and separating device 2, a discharge port 13 is provided under the cleaning tank body 1, an oil recovery device 4 is installed at the side end of the cleaning tank body 1, and soil transportation is installed inside the support 12 under the cleaning tank body 1 device 5.

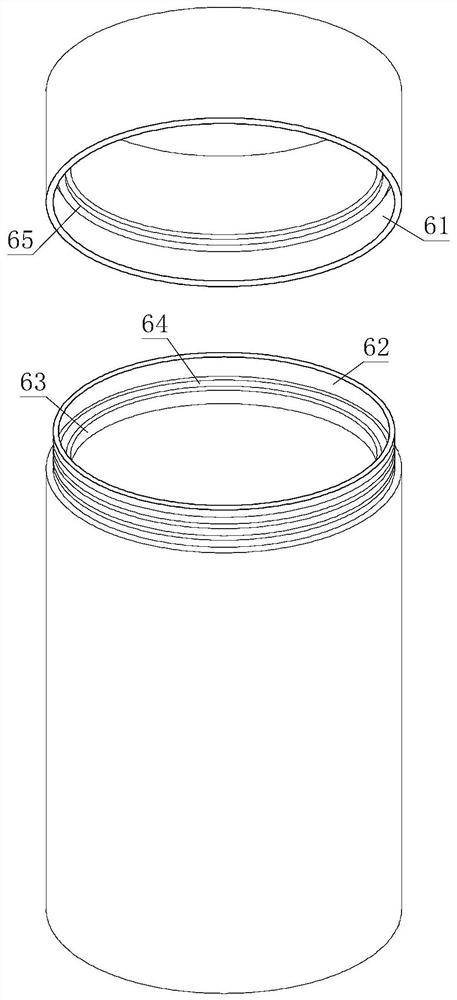

[0040] see image 3 The top of the cleaning tank body 1 is provided with an upper cover 14, and a seal 6 and a lifting device 7 are arranged between the upper cover 14 and the cleaning tank body 1. The seal 6 includes an outer coat layer 61, an inner connection layer 62, a sealing pad seat 63, and a sealing...

Embodiment 2

[0047] see Figure 11 , a petroleum soil cleaning device, comprising a cleaning tank body 1, an outer hoop 11 is sleeved on the outside of the bottom of the cleaning tank body 1, brackets 12 are respectively installed around the bottom of the outer hoop ring 11, and the inside of the cleaning tank body 1 A stirring and separating device 2 is set, and a water injection device 3 is arranged above the stirring and separating device 2. A discharge port 13 is provided under the cleaning tank body 1, an oil recovery device 4 is arranged at the side end of the cleaning tank body 1, and the bottom of the bracket 12 of the cleaning tank body 1 is cleaned. The soil conveying device 5 is arranged inside, and a loam cake 14 is arranged on the top of the cleaning tank body 1, and a sealing member 6 and a lifting device 7 are arranged between the loam cake 14 and the cleaning tank body 1, and the sealing member 6 includes an outer coat layer 61, an inner layer 62, Gasket seat 63, tight join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com