Automatic positioning inner barrel control method

A technology of automatic positioning and control method, applied in the field of washing machines, can solve problems such as shortened service life, wear and tear, water leakage, and inability to function, and achieve the effects of extending service life, avoiding water leakage, and saving water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

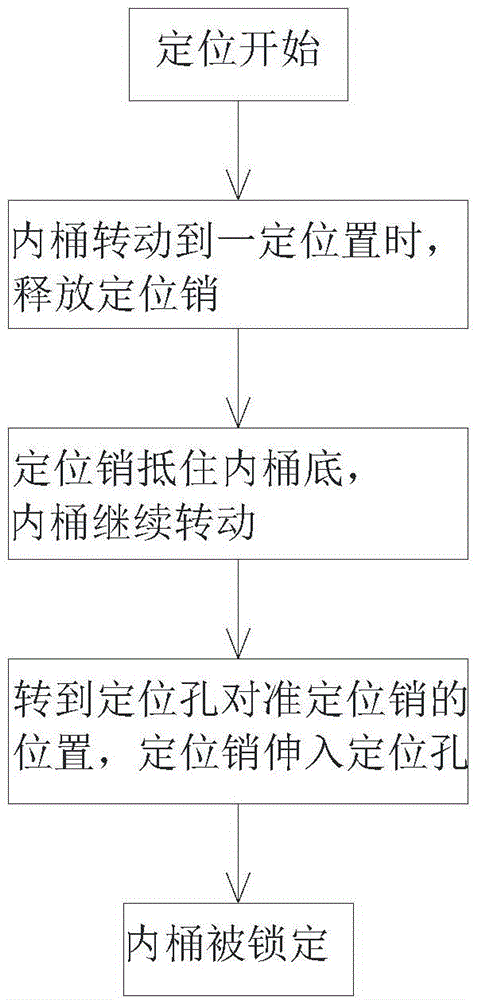

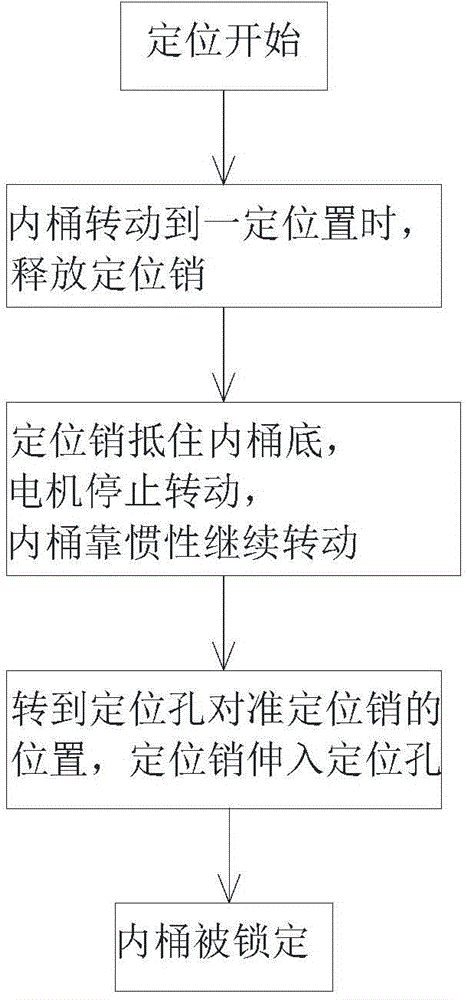

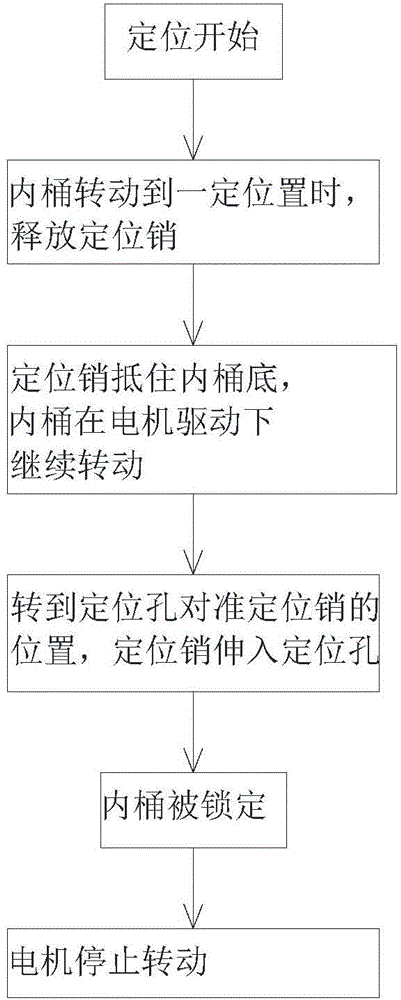

[0030] The washing machine of the present invention is a fully automatic washing machine, the inner tub does not rotate during washing, and the pulsator rotates. In order to prevent the inner tub from shaking with the rotation of the pulsator, a positioning hole is provided at the bottom of the inner tub, and a positioning pin is provided at the bottom of the outer tub. A structure that can drive the positioning pin to expand and contract, and the positioning pin automatically extends into the positioning hole to realize the positioning of the inner barrel.

[0031] Or there is no water between the inner and outer tubs when the washing machine of the present invention is washing, the washing machine includes an inner tub and an outer tub, the inner tub has no leaking holes connected to the outer tub, the bottom of the inner tub is provided with at least one first drainage hole, and the upper part of the inner tub is provided with a Circle the second drainage hole. When washing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com