Autonomous cooling polishing and grinding robot

A polishing and grinding, robot technology, applied in the field of workpiece processing, can solve the problems of no drying device, unfavorable automatic production, unable to form a process, etc., to achieve the effect of improving polishing and grinding efficiency and facilitating automatic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

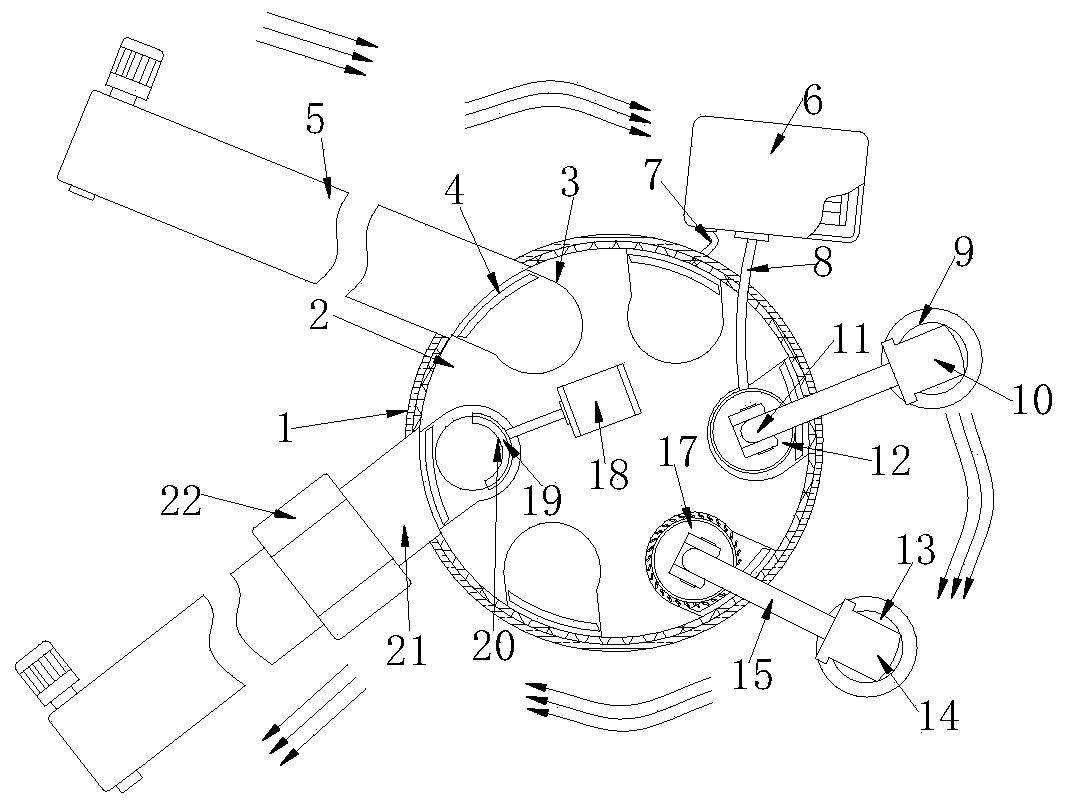

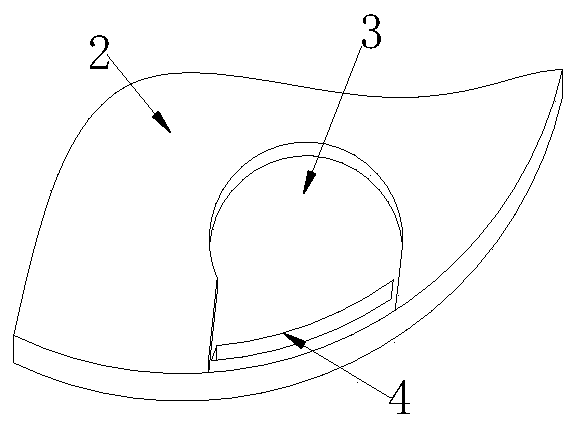

[0034] Such as figure 1 , Figure 4 and Figure 6 shown;

[0035] figure 1 It is a structural schematic diagram of the present invention;

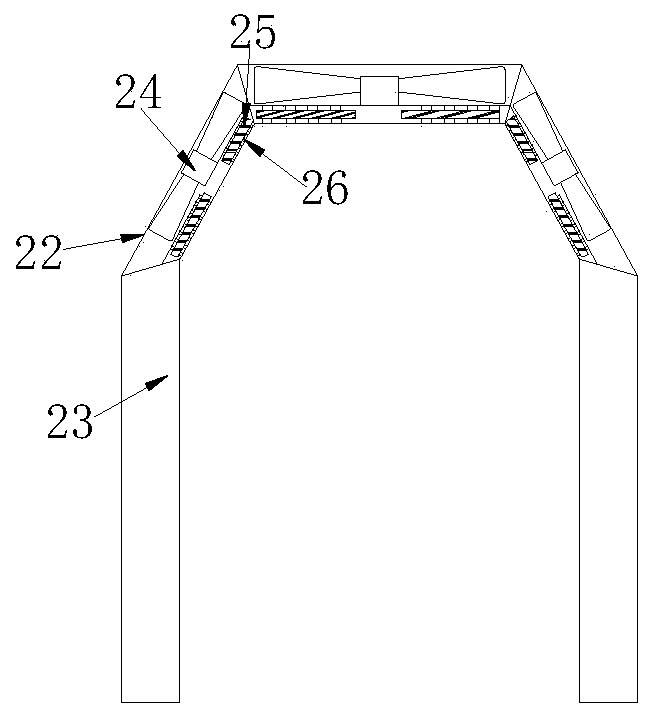

[0036] Figure 4 It is a connection side view of the fixed barrel and the rotating disk in the present invention;

[0037] Figure 6 is a flow chart in the present invention;

[0038]An autonomous cooling and polishing robot, comprising a turntable 2, a first base 9 is installed on one side of the turntable 2, a first telescopic rod 10 is installed on the upper surface of the first base 9, and the outer wall of the first telescopic rod 10 is fixedly connected with a second A rotary plate 11, the bottom surface of the first rotary plate 11 is rotatably connected with a grinding piece 12, the bottom surface of the rotary plate 2 is equipped with a fixed barrel 1, and the upper surface of the rotary plate 2 is provided with a plurality of concave placement grooves 3, the outer side of the rotary plate 2 The wall is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com