Air-conditioner machining method, self-foaming production system and air-conditioner

A processing method and production system technology, which is applied in the field of air conditioner processing, self-foaming production system and air conditioner, can solve the problems that the parts of the top cover of the outdoor unit cannot be automatically produced, the sponge mounting process is complicated, and the required man-hours are many. , to achieve the effect of realizing online automatic production, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below, and the embodiments described with reference to the accompanying drawings are exemplary and are only used to explain the present invention, and should not be construed as limiting the present invention.

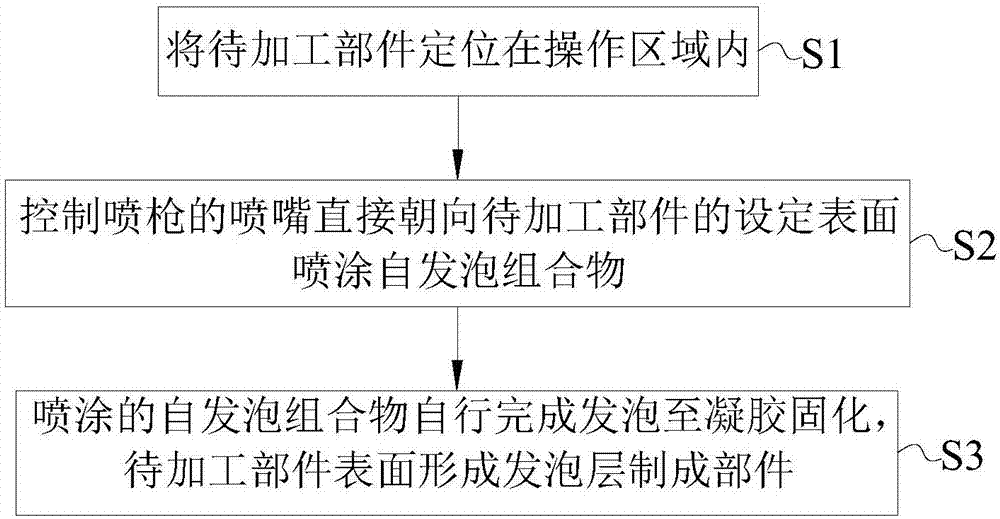

[0028] Refer below figure 1 A method of manufacturing an air conditioner according to an embodiment of the present invention will be described.

[0029] In the embodiment of the present invention, the surface of at least one part of the air conditioner is provided with a foam layer formed by covering the self-foaming composition, foaming, and curing the gel.

[0030] According to the air conditioner processing method of the embodiment of the present invention, the processing steps for this part are as follows:

[0031] S1: Position the parts to be processed in the operating area;

[0032] S2: controlling the nozzle of the spray gun to spray the self-foaming composition directly towards the set su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com