Patents

Literature

176results about How to "Easy recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

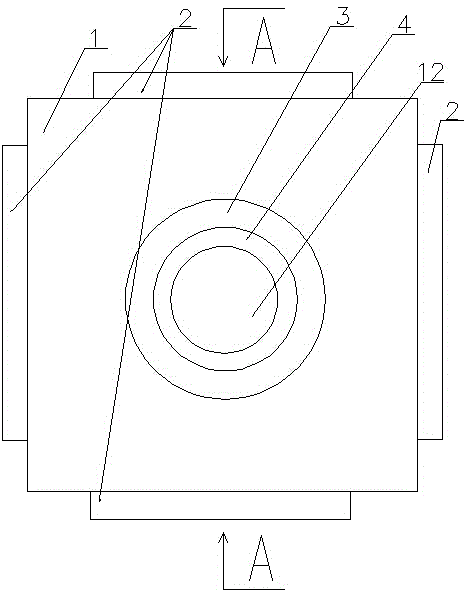

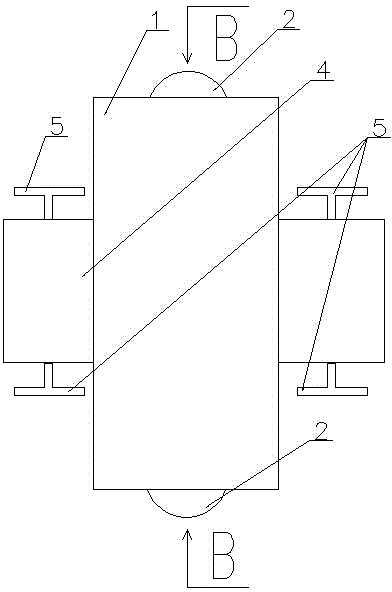

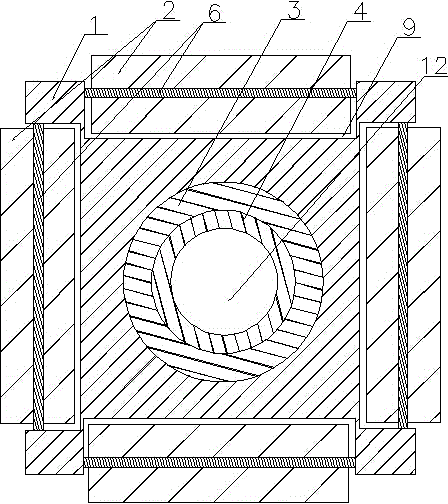

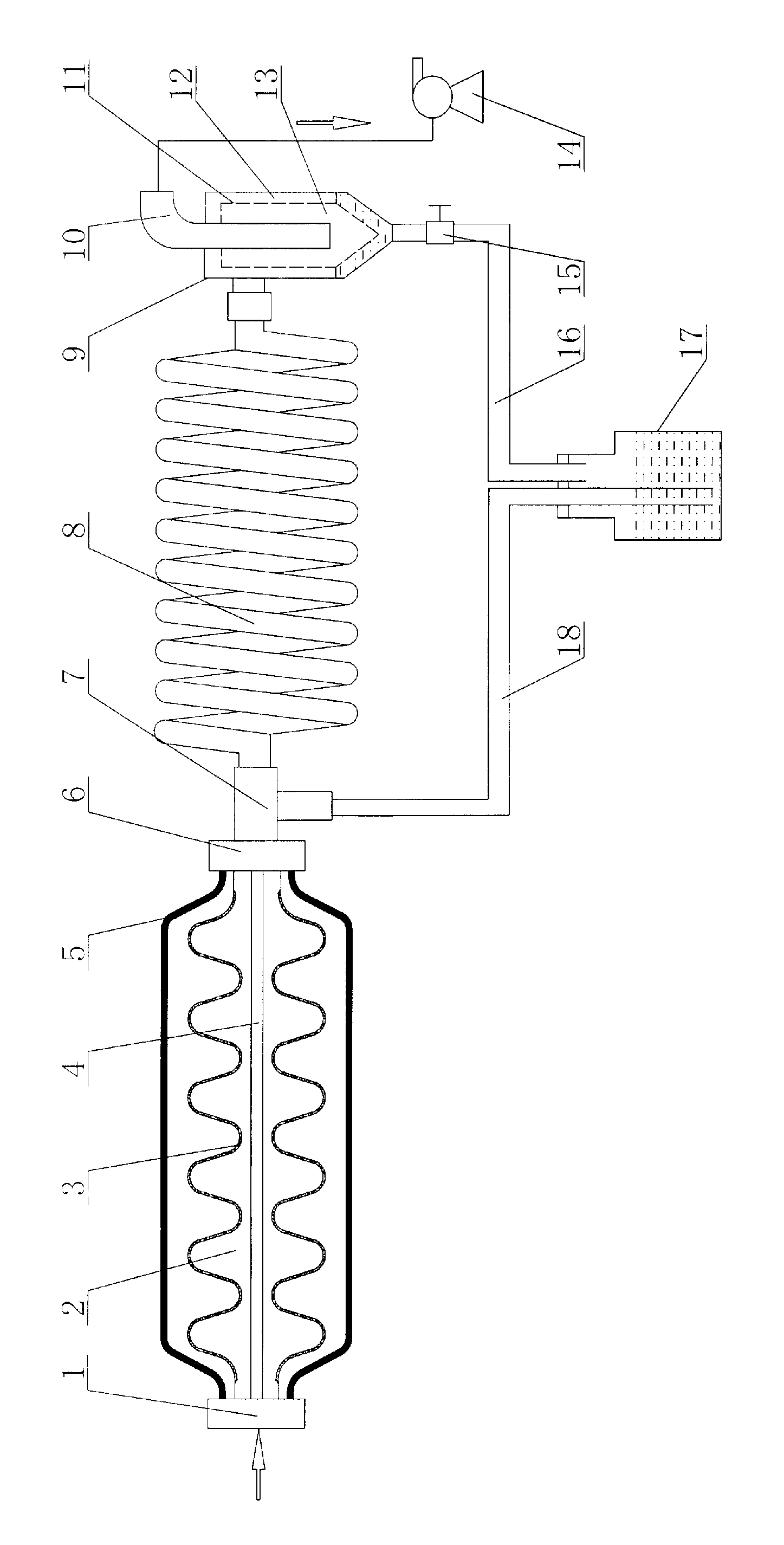

Apparatus for reclaiming sewerage nitrogen and phosphor by ammoniomagnesium phosphate crystal method and method thereof

InactiveCN101298324AHigh recovery rateStir wellWater/sewage treatmentPhosphorus compoundsPhosphate crystalsPhosphor

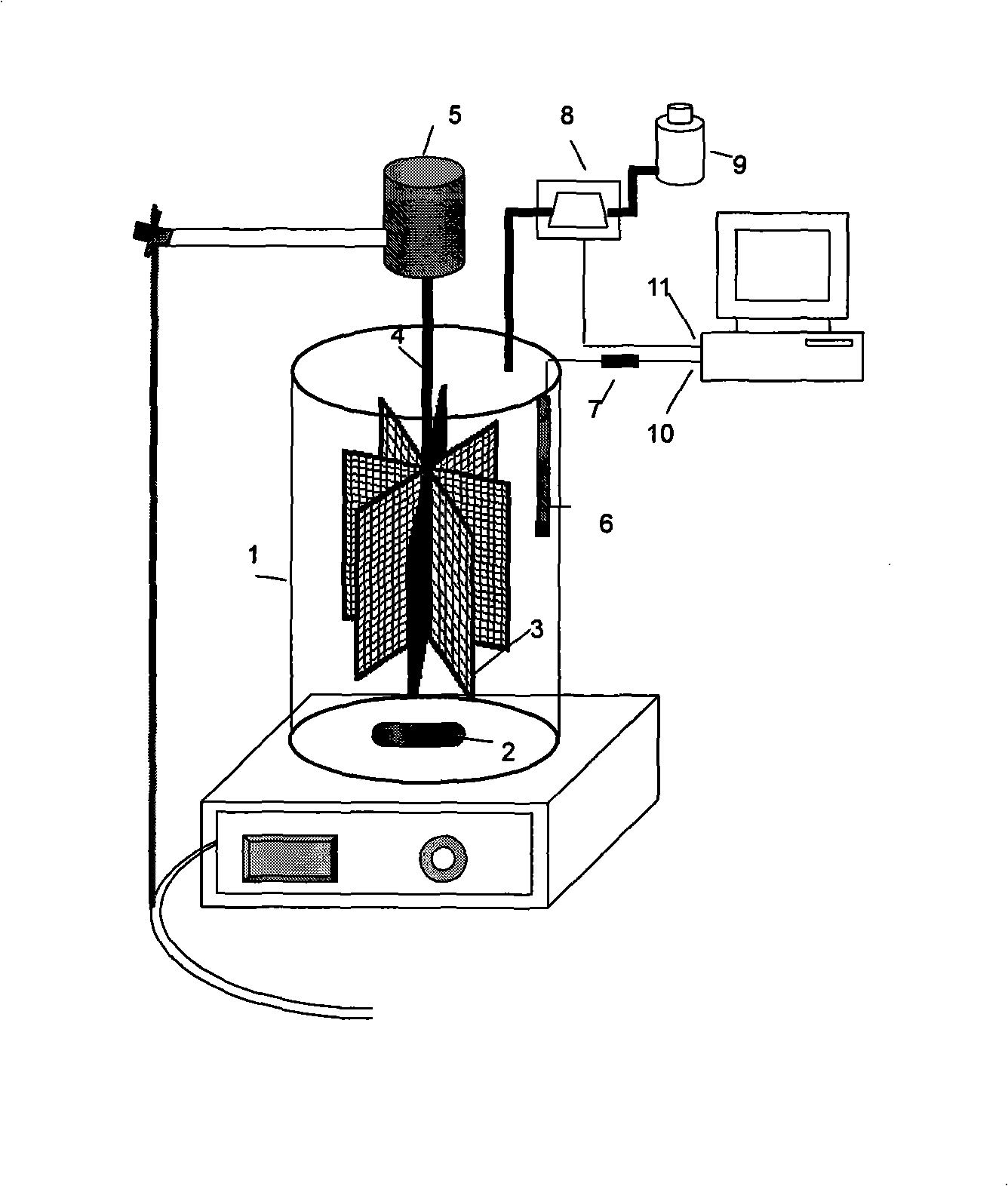

The invention discloses a device and method for recovering nitrogen and phosphor in the wastewater by the ammoniomagnesium phosphate crystal method. The invention adopts an MAP nitrogen and phosphor recovery device which has a two-stage agitation of a magnetic stirring apparatus and a deposit catcher, then the wastewater of 3 / 5 to 4 / 5 of the volume of the device is added as the reactant liquor, then add magnesium source and phosphorus source regulation reaction liquor with the ration of NH4<+>: PO4<3->: Mg<2+> equal to 1:1:1 to 1:1.2:1.2, then alkali liquor is dropped continuously to maintain the PH value of the reaction liquor at 9.0 plus / minus 0.1, the magnetic stirring apparatus rotates at the speed of 400-600 r / m and the deposit catcher is driven by a motor stirrer and agitates continuously at the speed of 40-60 r / m, and finally the MAP can be obtained. The invention overcomes the problem that the activity of the crystal-forming ions drops when the PH value decreases during the crystallization process, promotes the MAP crystallization process and improves the MAP recovery rate; the magnetic stirring apparatus and the deposit catcher adopted in the MAP recovery device reduces the stirring dead area in the reactor, the reaction liquor is stirred more sufficiently, which is favorable for the MAP crystal-forming ions to form crystal; the deposit catcher that is designed to catch MAP is favorable to improve the MAP purity in the recovered products.

Owner:ZHEJIANG UNIV

Method for preparing isosorbide taking supported heteropoly acid as catalyst

InactiveCN101691376AHigh selectivityEasy to separateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHeteropoly acidFixed bed

The invention discloses a method for preparing isosorbide by taking supported heteropoly acid as a catalyst. Sorbitol from a biological radical is used as a raw material to prepare the isosorbide directly through dehydration reaction. The method comprises the following steps: putting the catalyst into a constant temperature section of a fixed-bed reactor; introducing a reactant sorbitol solution into a reactor, and performing reaction through a catalyst bed after gasification; and separating a mixture obtained after the reaction to obtain the isosorbide. The method has simple operation process of the reaction, low production cost and light environmental pollution; the selectivity and yield of the isosorbide reaches up to 75.2 percent and 71.4 percent respectively, and the catalyst is easy to separate and recycle; and the method is a novel method which meets industrial demands and has strong practicality.

Owner:NANJING UNIV OF TECH

Method for synthesizing polyatomic alcohol fatty acid ester

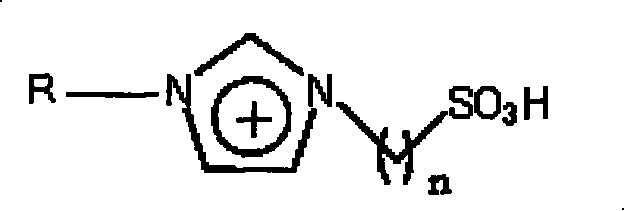

InactiveCN101456813AEsterification reaction temperature is lowImprove conversion rateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolyolAlcohol

The invention discloses a method for synthesizing polyol fatty acid ester. The method comprises: fatty acid and polyol are used as reactants; functionalized ionic liquid is used as catalyst; under operational conditions of normal pressure, a reaction temperature of between 80 and 200 DEG C and reaction time of between 0.5 and 8 hours, the polyol fatty acid ester is synthesized. The method has the advantages of simple working procedure, mild reaction condition, high esterification rate, good stability of the catalyst and recyclability.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

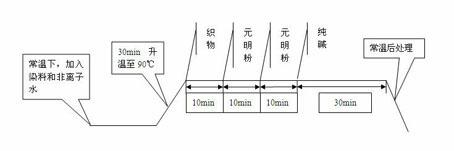

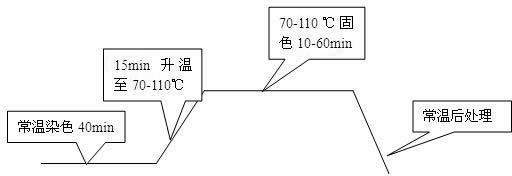

Dyeing process of pure cotton fabric

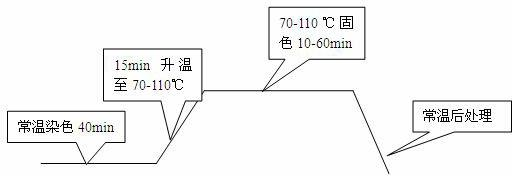

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric tofully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

Purification method for separation of cozymase Q10

InactiveCN101429108AHigh content of active ingredientsEasy recyclingQuinone separation/purificationPurification methodsAlcohol

The invention relates to a method for purifying coenzyme Q10. The method comprises the following steps: an upper column solution containing the coenzyme Q10 is subjected to chromatography through a silica gel column; and a mixed solvent of n-hexane and low-grade alcohol or a mixed solvent of n-hexane and low-grade ketone is subjected to elution to obtain eluent; and the eluent is decompressed, is condensed to be dried and is added with ethanol to obtain the coenzyme Q10. Through an elution mode, the method greatly reduces the difficult degree of the reclaiming operation of a subsequent solvent; and simultaneously, the content of effective ingredients of the coenzyme Q10 is improved.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

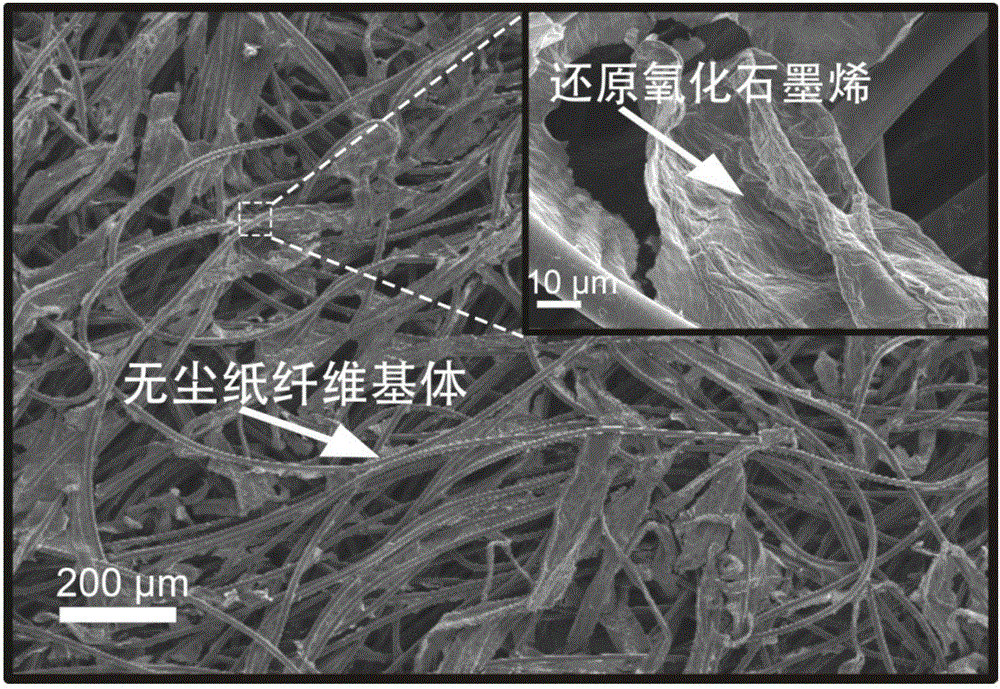

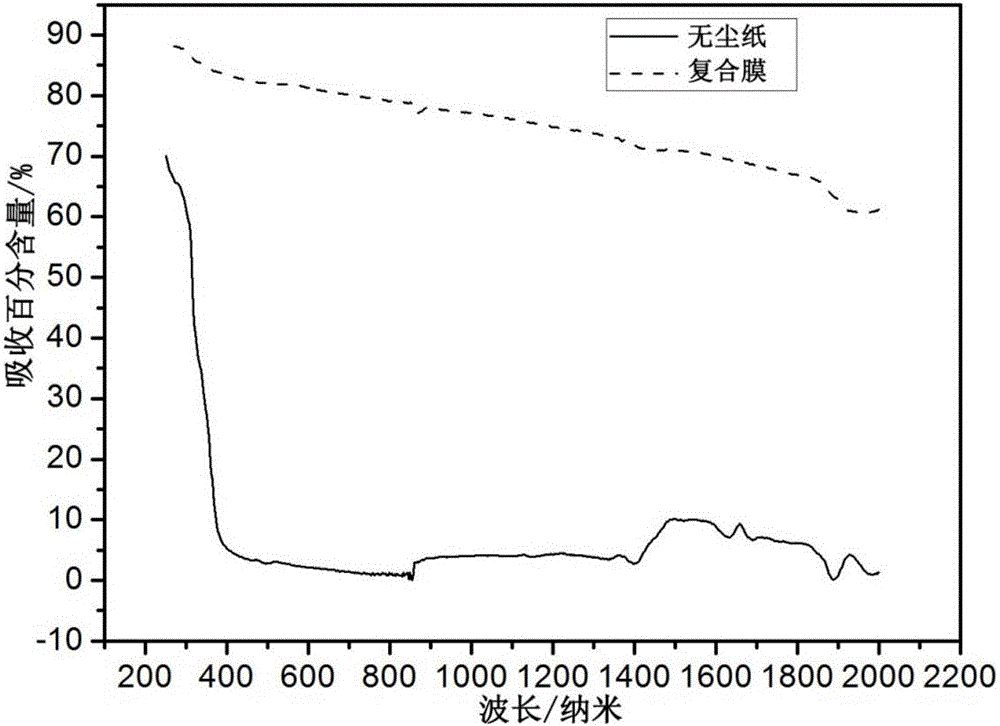

Composite thin film integrating photothermal conversion performance and adsorption characteristics as well as preparation and application of composite thin film

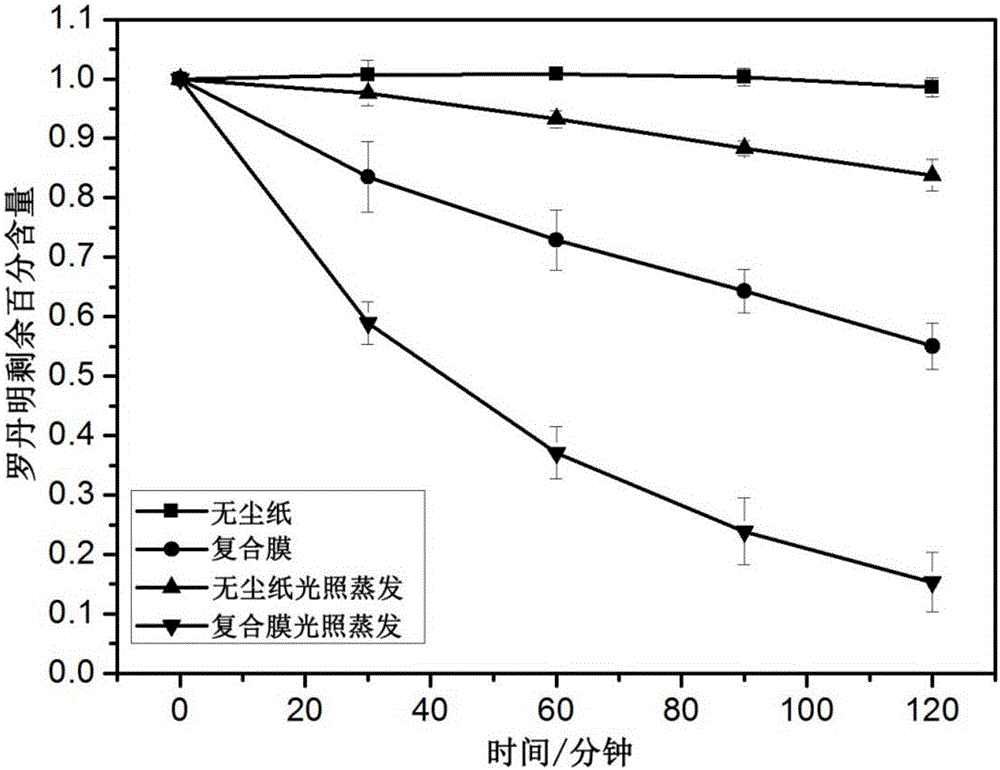

ActiveCN106000362AFacilitated DiffusionAccelerate the rate of adsorption and purificationOther chemical processesHeat-exchange elementsMicro nanoComposite film

The invention relates to a composite thin film integrating photothermal conversion performance and adsorption characteristics as well as preparation and application of the composite thin film. The composite thin film comprises a substrate and a functional film which is deposited on the substrate and integrates the photothermal conversion performance and the adsorption characteristics, wherein the substrate is a micro-nano thin film with a porous structure; the functional film is made of nonmetal inorganic substances integrating the photothermal conversion performance and the adsorption characteristics. The composite thin film is placed on the upper surface of a to-be-adsorbed solution and is enabled to float on an interface of the solution and air and be sufficiently contacted with the solution, the functional film effectively adsorbs pollutants in the solution, and the purpose of adsorbing the pollutants is achieved; meanwhile, the floating composite thin film is illuminated, a photothermal conversion effect of the nonmetal inorganic substances in the composite thin film is triggered, a local heating effect is generated at the interface of the solution and air, and rapid evaporation of a solvent is promoted, so that the pollutants are accelerated to be diffused into and adsorbed by the composite thin film. The method adopting the composite thin film for sewage purification has the advantages of high adsorption capacity, high adsorption rate, high interface heating and evaporating speed and the like.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method and using method of human mesenchymal stem cell exosome freeze-dried powder

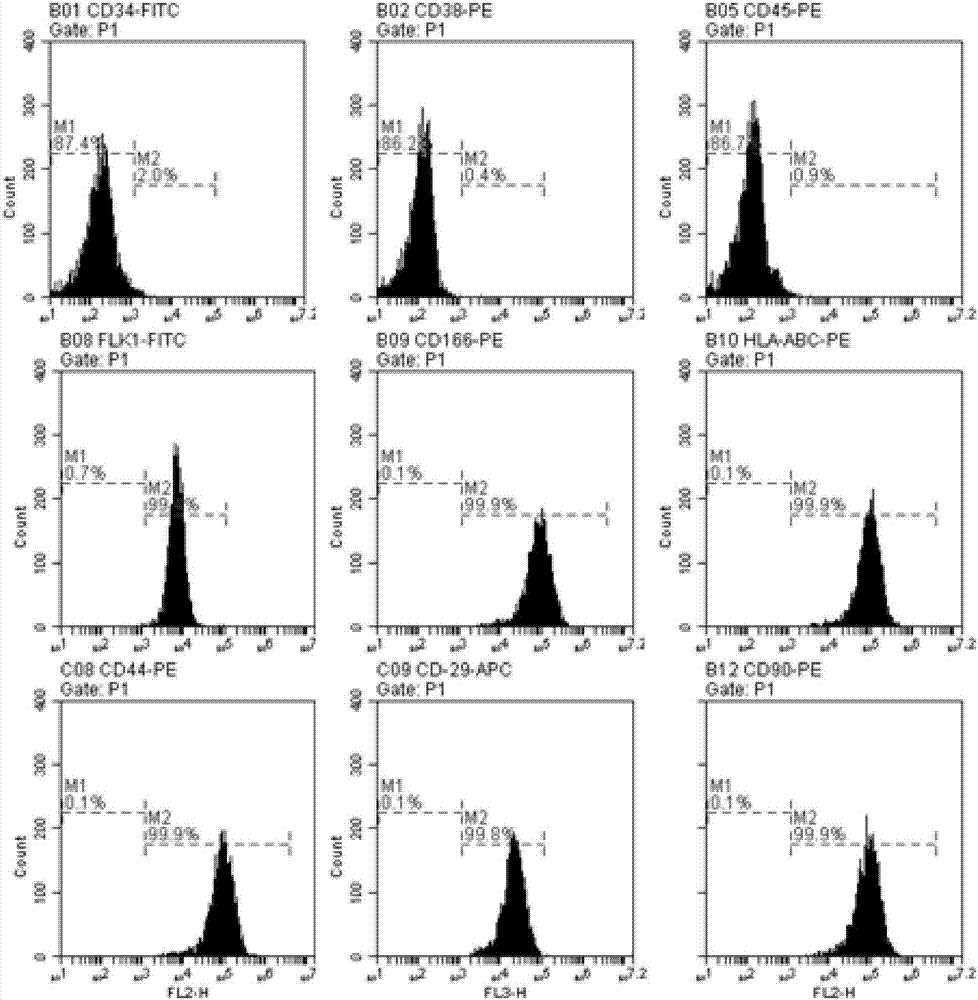

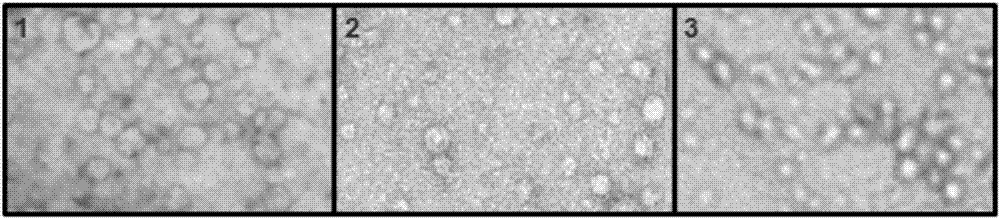

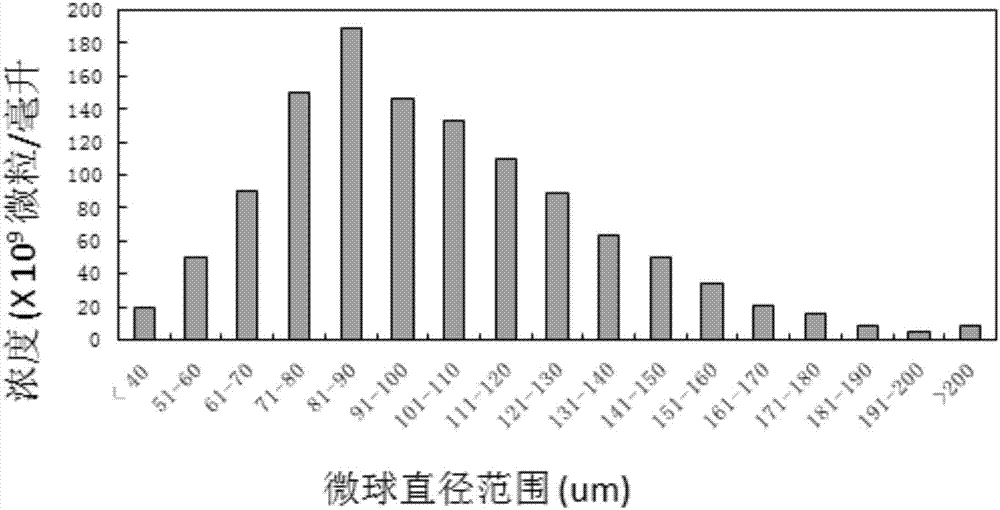

ActiveCN107245472AEasy recyclingImprove cortexPowder deliveryCulture processUltrafiltrationPlastic surgery

The invention provides a preparation method and a using method of human mesenchymal stem cell exosome freeze-dried powder, used for solving the problems of exosome such as low separation and recovery quantity, poor quality and low efficiency. The preparation method of the human mesenchymal stem cell exosome freeze-dried powder comprises the following steps: 1) performing culture, purification and passage on human mesenchymal stem cells; 2) inducing large-scale synthesis of the human mesenchymal stem cells and secreting functional exosome; 3) performing ultrafiltration and concentration on the exosome of the human mesenchymal stem cells, preparing a concentrated culture solution, and refrigerating; 4) preparing the freeze-dried powder from the refrigerated concentrated culture solution, and adding complex liquid into the freeze-dried powder for preserving. According to the method disclosed by the invention, synthesis of the human mesenchymal stem cells and secretion of the exosome can be effectively induced to the greatest degree, and the active ingredients are obtained on a large scale and are conveniently and directly used for various aspects of massive health, such as diagnosis and treatment of diseases and cosmetic plastic surgery of the human body.

Owner:北京智能宝生物科技有限公司

Preparation method of hexamethylenediamine

InactiveCN107805203AReduce usageHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHexamethylenediamineOxide composite

The invention discloses a preparation method of hexamethylenediamine. Hexane dinitrile is used as a raw material, and a nano-nickel and magnesium oxide composite material is used as a catalyst to prepare the hexamethylenediamine through liquid phase hydrogenation. The preparation method of the hexamethylenediamine comprises the following steps: dipping a porous carrier by using nickel acetate andmagnesium nitrate aqueous solutions at different concentrations at first, and carrying out in-situ reduction to obtain an immobilized nickel and magnesium oxide based composite catalyst under different conditions; adding raw materials, the catalyst and a solvent in a reaction kettle in proportion, sealing the reaction kettle, removing air in the kettle by a hydrogen substitution method, starting aheating power supply, applying set pressure to hydrogen after the temperature in the kettle is raised to the set reaction temperature, then starting a magnetic stirrer, and beginning to time reaction; and after the reaction is finished, filtering out the catalyst, and distilling and separating under reduced pressure. The yield of a target product is high, the yield of the hexamethylenediamine isgreater than 70%, and the solvent and the catalyst are recyclable.

Owner:SHANGHAI INST OF TECH

Process for preparing alkylated oil

InactiveCN101210192AImprove thermal stabilityLess corrosiveOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionFiberStrong acids

The invention discloses an alkylate preparation method in petrochemical field, in particular to a method for preparing alkylate by using an ionic liquid as a catalyst. The method can prepare the alkylate with high octane number by selecting the ionic liquid as the catalyst and the mixture of isobutane and C4 olefin as the reactants and by intermittent or continuous operation of a tank reactor or a fiber membrane reactor at 30 to 85 DEG C, in the presence or absence of reaction auxiliary agent and under a pressure that can ensure the reactants are liquid. The catalytic activity and C8 selectivity of the invention reach or exceed the level of industrial production of alkylate, and the ionic liquid catalyst has almost no corrosion and can form a two-phase system with the alkylate, so that the alkylate product can be easily separated from the catalyst. The ionic liquid catalyst can be used for substituting for liquid strong acid, and the method is a green and clean alkylation process at scale and is suitable for large-scale industrial continuous production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Protection device and protection method for cable sheath in power construction process

InactiveCN104158110AAvoid damageEasy to twist and twistCable installation apparatusMechanical engineeringElectric power

The invention discloses a protection device for a cable sheath in the power construction process. The protection device comprises a shell, wherein one or more rolling mechanisms are arranged at the upper end of the shell; a through hole axially perpendicular to a rotating shaft of each rolling mechanism is formed in the shell; a bearing is arranged in the through hole; an inner pipe is sleeved by the bearing; two ends of the inner pipe stretch out of the through hole; a conducting wire adjusting and fixing mechanism is arranged at each of the two ends of the inner pipe. By the adoption of the bearing arranged inside the shell, the cable moves forwards under the action of a dragger, a conducting wire is easy to automatically rotate due to the dead weight per se, and a twisted conducting wire is loosened to greatly facilitate moving or recycling of the conducting wire without damaging the wire sheath.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

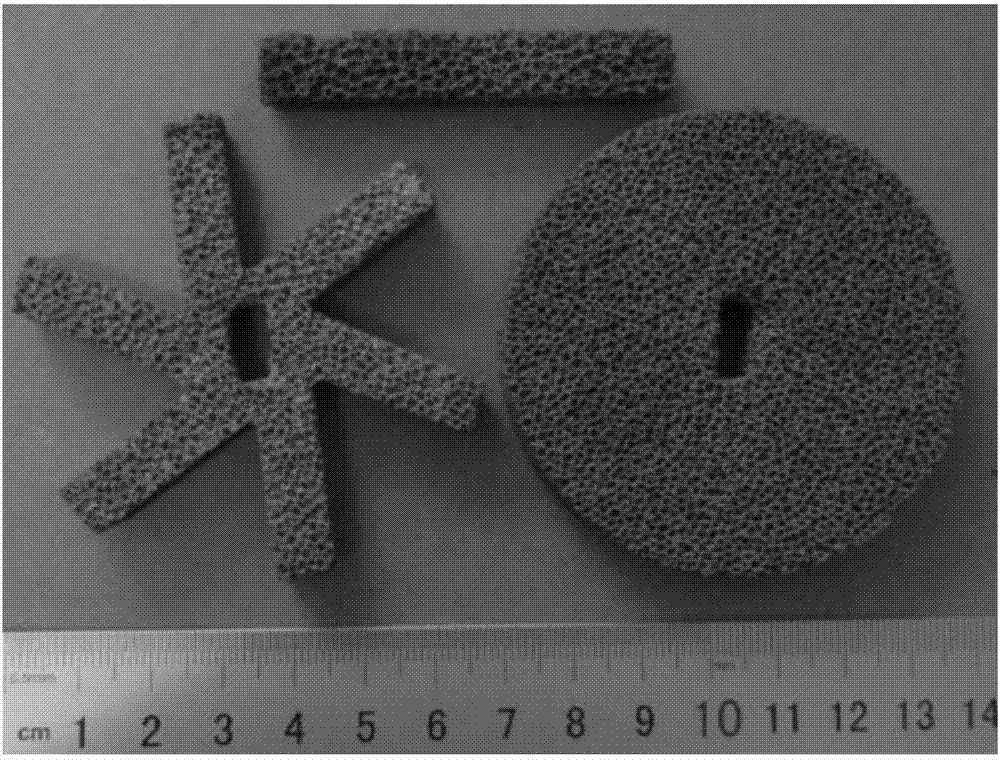

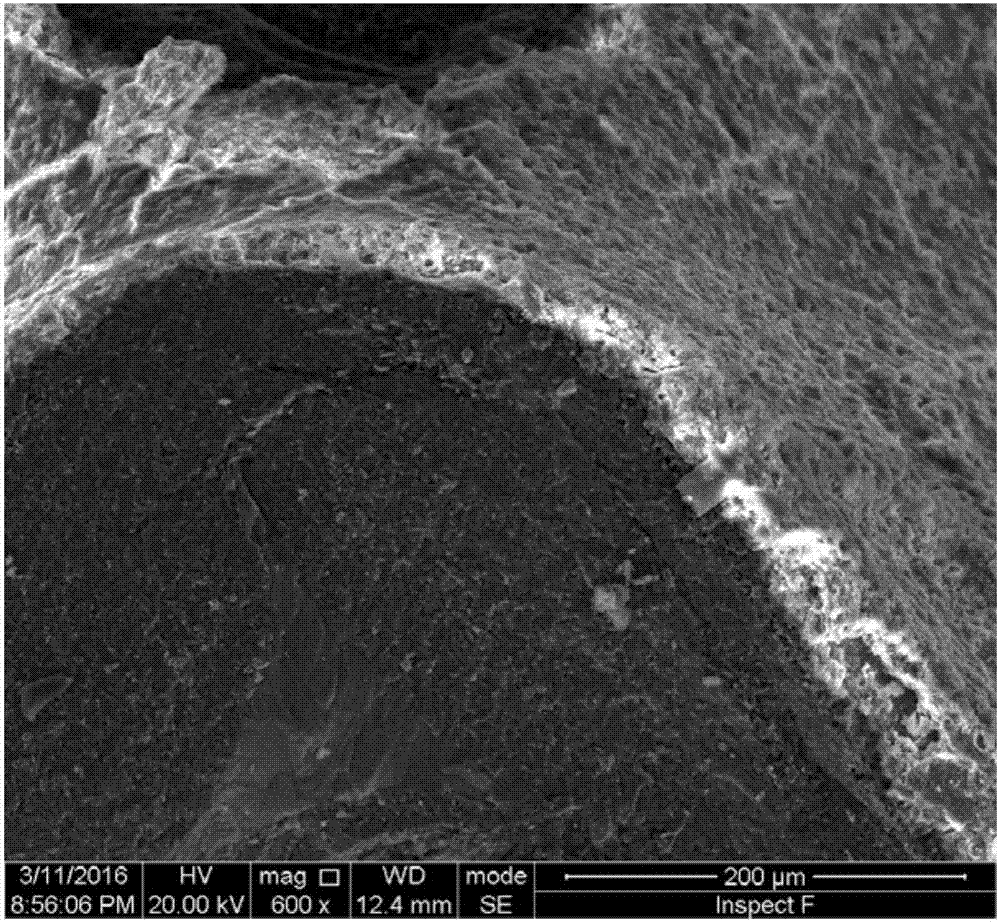

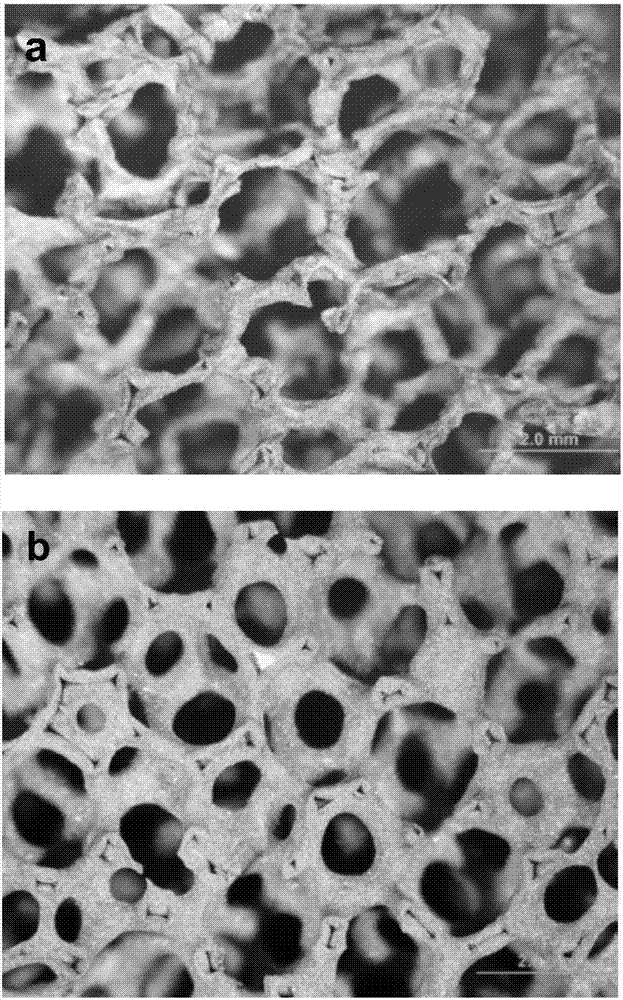

Foam-structure catalyst used in reaction for preparing benzyl alcohol from benzaldehyde through hydrogenation and preparation thereof

InactiveCN107442149AHigh catalytic activityAvoid wear and tearOrganic compound preparationHydroxy compound preparationPtru catalystBenzaldehyde

The present invention relates to the field of structured catalytic materials, in particular to a foam-structure catalyst used in a reaction for preparing benzyl alcohol from benzaldehyde through hydrogenation and a preparation method thereof. The objective of the invention is to overcome the problems that conventional granular catalysts are prone to wearing; the catalysts are difficult to separate from reaction products; recovery processes are complex; etc. The foam-structure catalyst in the invention is of a three-dimensional interconnected network foam structure; the main structure of the catalyst is composed of a foam ceramic material used as a first carrier, a coating (used as a second carrier), a catalytically active component and the like, wherein the second carrier uniformly coats the surfaces of foam ribs of the first carrier, and the catalytically active component is uniformly supported in the second carrier with a high specific surface area. The foam-structure catalyst of the invention is used for a reaction for preparing benzyl alcohol from benzaldehyde through liquid-phase hydrogenation; technology is simplified; and complicated equipment is not needed. The foam-structure catalyst can enhance the mass transfer process of a chemical reaction while avoiding catalyst wearing and simplifying a separation process, and has the advantages of high mass transfer efficiency, good catalytic activity, high benzyl alcohol selectivity and good stability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

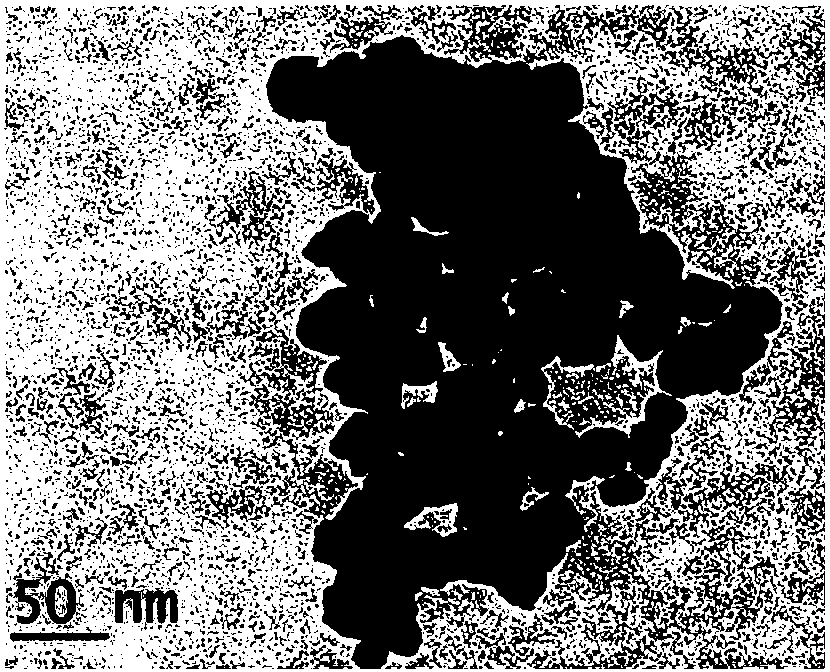

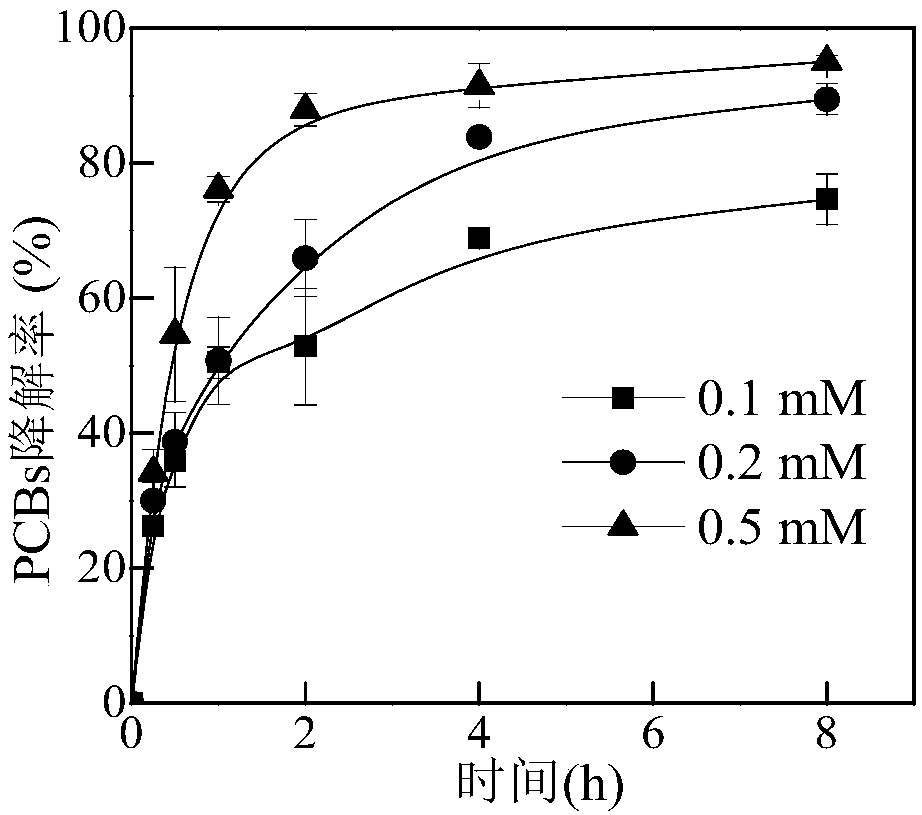

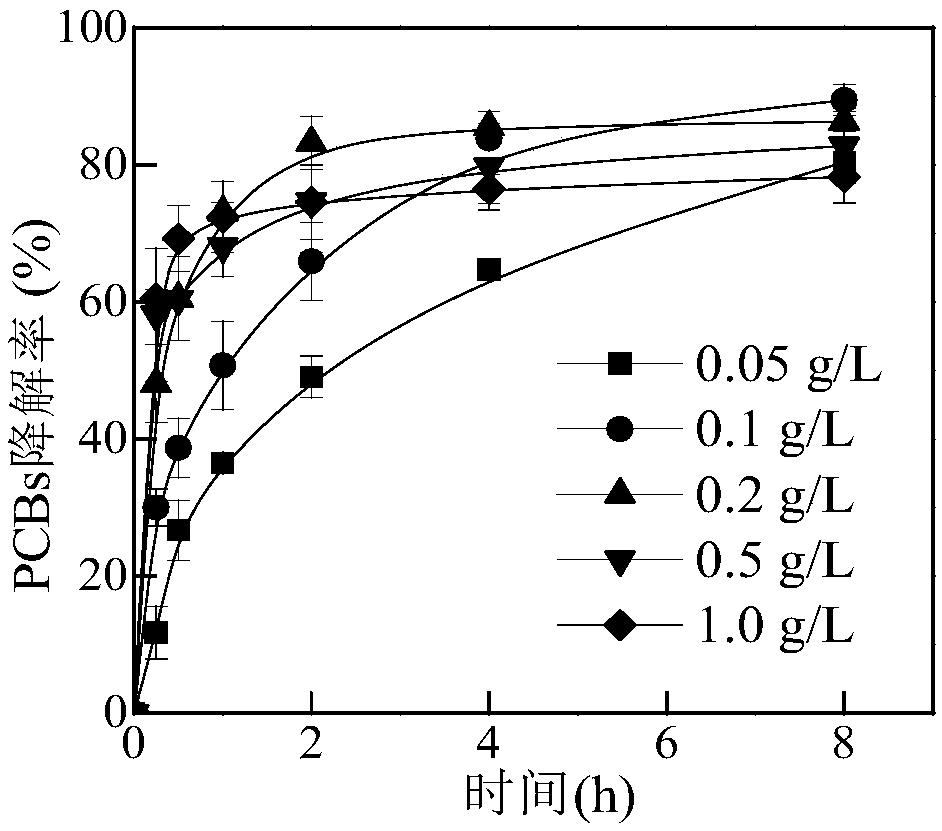

Application of activating mono-persulfate based on copper ferrite nano-powder

InactiveCN108341479ASolve the problem of difficult recycling and easy to cause secondary pollutionEasy to prepareWater contaminantsWater/sewage treatment by magnetic/electric fieldsPersulfateCopper oxide

The invention discloses application of activating mono-persulfate based on copper ferrite nano-powder. Nanometer copper ferrite particles are put into a solution containing persistent organic pollutants, then, mono-persulfate is put to perform a reaction, after the reaction is ended, and a magnetic separation method is performed for recycling an activating agent. Compared with other activating systems, such as metal ions (Fe2+ / Cu2+) or nanometer copper oxide, the adopted nanometer copper ferrite is higher in activating efficiency, the mono-persulfate can be efficiently and continuously activated for generating sulfate radials and hydroxyl radicals, and the purpose of degrading the persistent organic pollutants is achieved.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

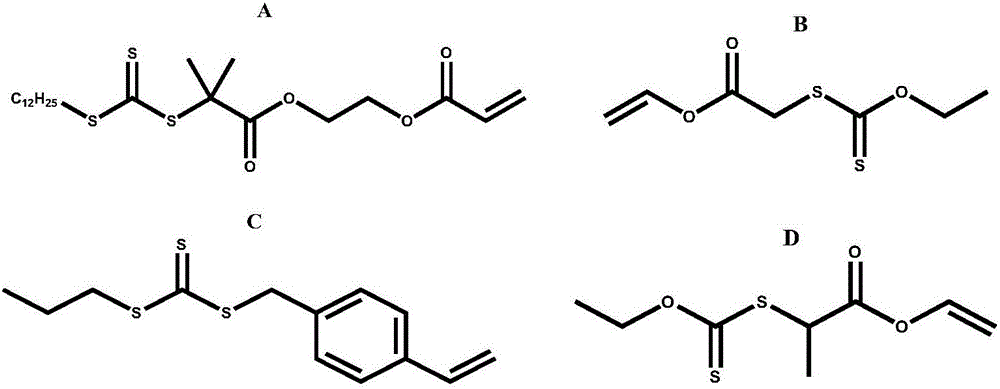

Load type chiral catalyst and preparation method thereof

InactiveCN102909070AHigh activityGood dispersionOrganic-compounds/hydrides/coordination-complexes catalystsAsymmetric synthesesStructural formulaSilicon dioxide

The invention discloses a load type chiral catalyst and a preparation method thereof. The load type chiral catalyst is characterized in that the load type chiral catalyst is proline-loaded hair-shaped silica nano particle obtained by forming a functional group on the surface of nano silica in a finishing manner, triggering chiral N-p-vinyltoluene sulfonyl-Boc-L-proline amide to polymerize by an reversible-breakage-chain transfer polymerization method, grafting a chiral polymer chain on the surface of the nano silica and further deprotecting, and the structural formula of the load type chiral catalyst is shown as follow. The invention discloses the preparation method of the load type chiral catalyst. The load type chiral catalyst can realize the advantages of separability and recyclability besides being capable of obtaining high-stereoselectivity chiral products in asymmetric catalyzing reaction, and production cost is reduced.

Owner:HENAN NORMAL UNIV

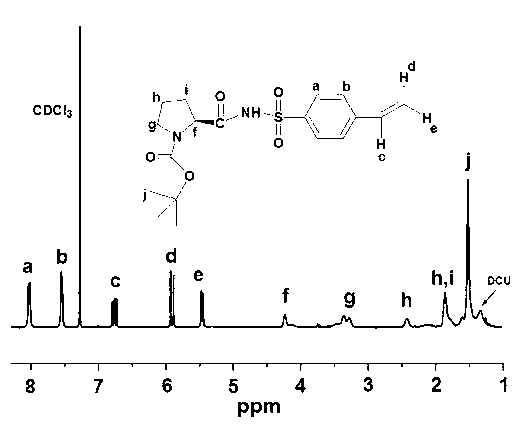

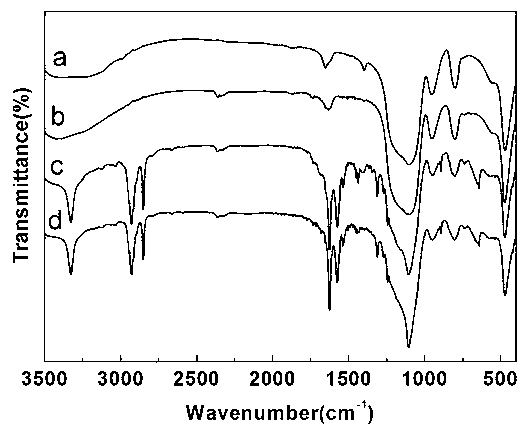

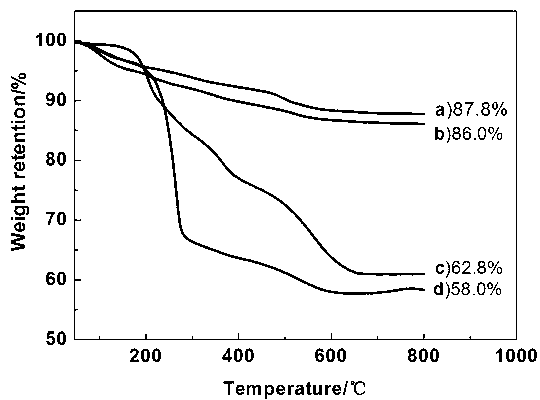

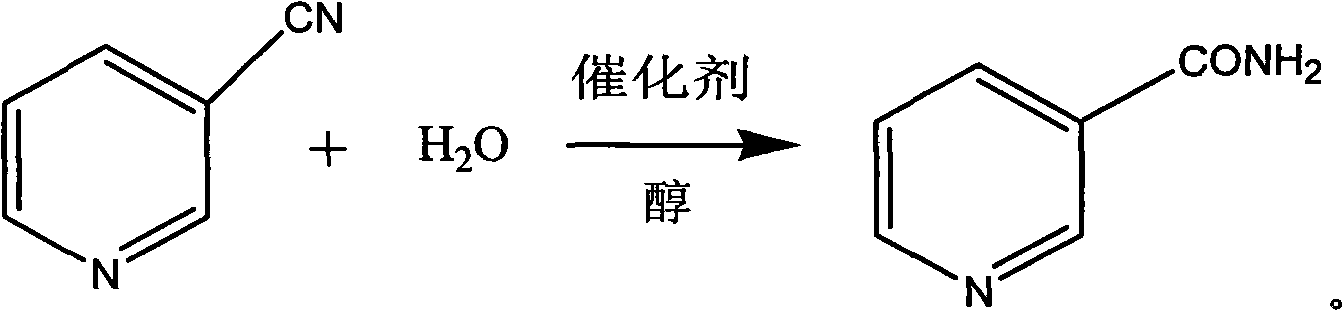

Method for preparing nicotinamide

The invention discloses a method for preparing nicotinamide, which comprises the following steps: dissolving 3-cyanopyridine in alcohol; adding water and a catalyst to perform a hydrolysis reaction; and performing posttreatment on the reaction product to obtain the nicotinamide. The method avoids introducing auxiliary reagents, is highly economic, ensures mild reaction conditions, easy product separation, high product purity and high yield, generates little waste gas, liquid and solid, and is favorable for industrial production.

Owner:浙江新赛科药业有限公司

Absorbing emulsion of volatile organic compounds (VOCs) and preparation method of absorbing emulsion

InactiveCN103463935AEasy to prepareImprove stabilityDispersed particle separationAir quality improvementInorganic saltsEmulsion

The invention discloses a formula of an absorbing emulsion of volatile organic compounds (VOCs). The absorbing emulsion is a W / O / W (Water / Oil / Water) multiple emulsion and comprises the main components: white oil, water, emulsifying agents (Tween-80 and Span-80) and inorganic salt (sodium silicate, sodium phosphate and sodium carbonate), wherein the volume ratio of the white oil to the water is 1: (3 / 7-7 / 3), the total mass of the emulsifying agents (Tween-80 and Span-80) is 1-10% (g / ml) of the total volume of mineral oil-water, and the total mass of the inorganic salt is higher than the total volume of the mineral oil-water by less than 1% (g / ml). According to the formula, the absorbing emulsion of the VOCs has the advantages of simple preparation method, high absorption rate of the VOCs, good dispersibility, regeneration, low regeneration cost and the like. The invention also discloses a preparation method of the absorbing emulsion.

Owner:NANJING UNIV

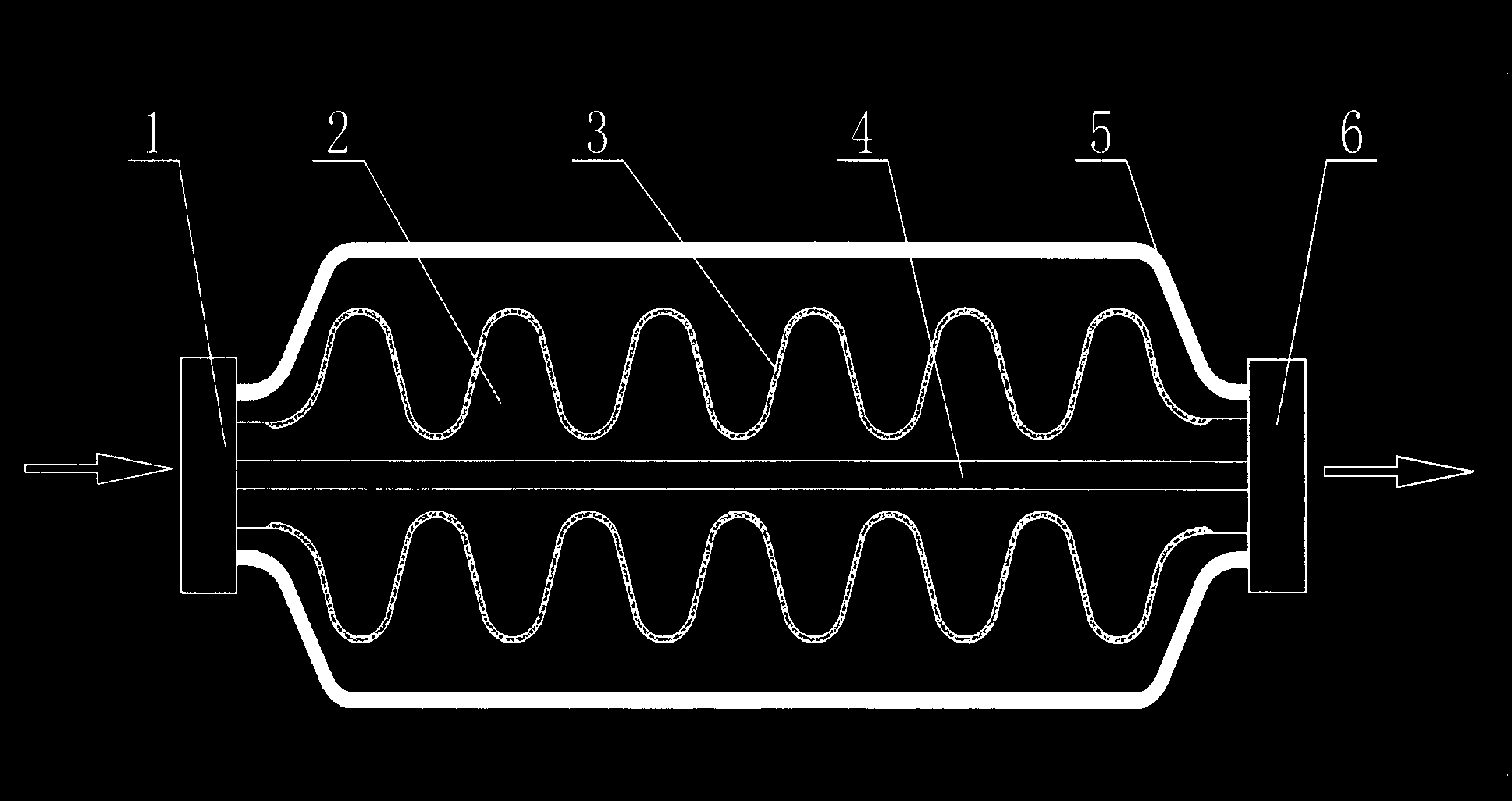

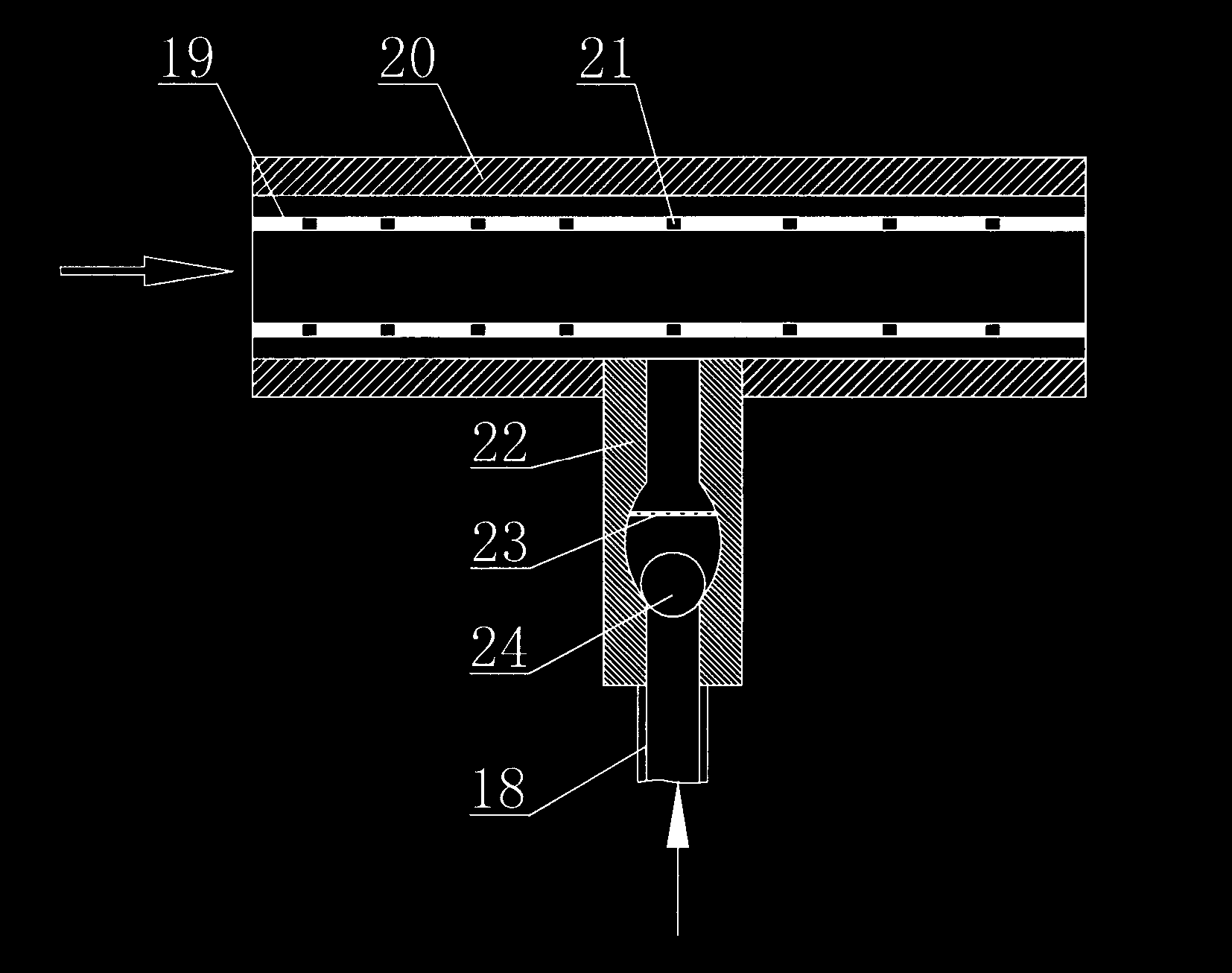

Method for producing ammonium polyphosphate by using stepwise reaction and polymerization

The invention discloses a method for producing ammonium polyphosphate by using a stepwise reaction and polymerization, relates to a method for producing ammonium polyphosphateproducts with different polymerization degrees in the same set of device, in particular to a production method of ammonium polyphosphate with high purity, high polymerization degree and the average polymerization degree larger than 1000. The method comprises the following steps in sequence: a. adding a polycondensation agent into polyphosphoric acid as a raw material in the weight ratio of 1:1 and mixing evenly; b. adding the material obtained by the step a into a continuous synthetic reactor for reacting; and c. further polymerizing products obtained in the step b for 30-300 minutes at the pressure of 0.00MPa-0.6MPa and the temperature of 120DEG C-500DEG C to obtain the high-purity ammonium polyphosphate products with the polymerization degree of 10-1,800. The invention has the advantages of convenient production and control, high yield, low energy consumption and benefit for large-scale continuous industrial production.

Owner:YUNNAN CHEM RES INST

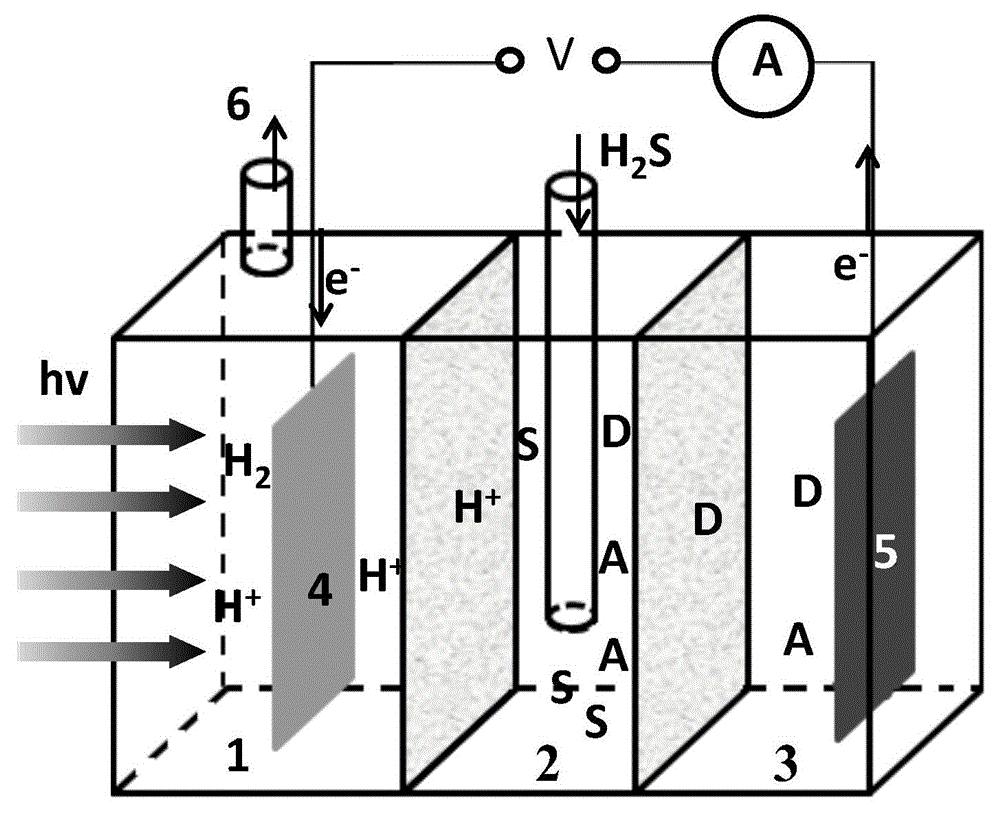

Method for coupled decomposition of hydrogen sulfide through photocatalytic/electrocatalytic-chemical ring reaction

The invention discloses a method for the coupled decomposition of hydrogen sulfide through a photocatalytic / electrocatalytic-chemical ring reaction, which relates to a hydrogen sulfide conversion method and a hydrogen sulfide conversion device. The hydrogen sulfide conversion method disclosed by the invention is implemented in two steps, and used for decomposing hydrogen sulfide into elements sulfur and hydrogen. In the first step, protons are subjected to photoelectrocatalytic or electrocatalytic reduction so as to produce hydrogen, and an oxidation-state redox couple is obtained on an anode; and in the second step, the redox couple is reacted with hydrogen sulfide so as to obtain an element sulfur and hydrogen ions, the hydrogen ions are transferred to a cathode to participate in the first step, and the element sulfur can be separated and recycled. The approach provided by the invention can be used for decomposing hydrogen sulfide.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of foamed polypropylene beads

The invention discloses a preparation method of foamed polypropylene beads. The method comprises the following steps that 1, polypropylene resin, an active filler and auxiliaries are added into a high-speed mixing machine and mixed to be uniform at the temperature of 10-20 DEG C, and a polypropylene foaming material is obtained; 2, the polypropylene foaming material is added into a triple-screw extruder, plastification and mixing are conducted, a supercritical fluid is injected, the mouth mold pressure is controlled to be 5-25 MPa, the mouth mold temperature is 110-160 DEG C, instant pressure release is conducted through a mouth mold, foaming is conducted, and super-fine hole foamed polypropylene is obtained; 3, super-fine hole foamed polypropylene is subjected to mold surface water-ring hot-cutting granulation, drying and sieving, and the foamed polypropylene beads are obtained. The method is low in production cost, high in capacity, safe and environmentally friendly, no foaming agent decomposed residue exists in the prepared foamed polypropylene beads, secondary foaming can be conducted, the foaming ratio can be adjusted, the rebound resilience of a finished product is high, decomposing and recycling are easy, and the foamed polypropylene beads can be widely used in the fields of plastic packaging, transportation industry, military aerospace, office supplies and the like.

Owner:湖北聚石新材料科技有限公司

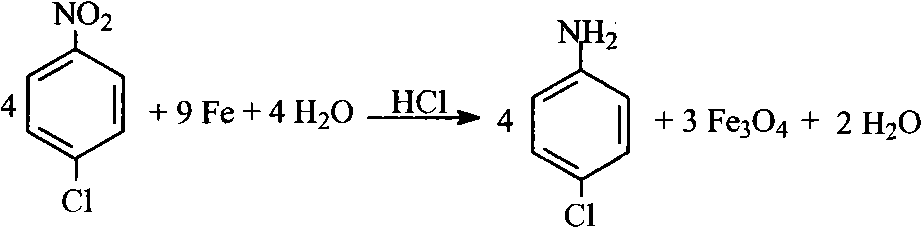

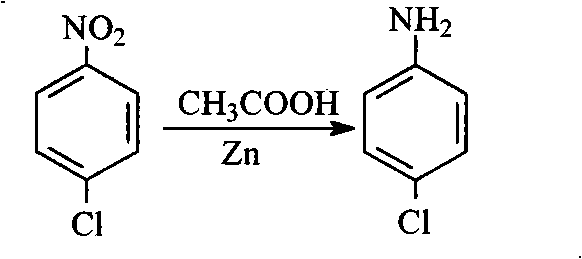

Support catalysts for p-chloronitrobenzene selective hydrogenation and preparation method thereof

InactiveCN101342487AHigh catalytic activityImprove catalytic selectivityOrganic compound preparationAmino compound preparationHydrogenation reactionSolvent

The invention relates to a method to prepare a load catalyst of parachloroaniline used to prepare parachloronitrobenzene hydrogenation and an application method thereof. During preparation of the catalyst, AlO(OH), r-Al<2>O<3>, SiO<2> and SBA-15 are used as carriers respectively to compare the performances of Ru catalyst after loading different carriers. Because the AlO(OH) has excellent dispersing performance in water, Ru nano particles are dispersed evenly, during the reaction for preparing parachloroaniline by using parachloronitrobenzene hydrogenation, excellent catalytic activity is achieved. The temperature and the solvent are changed during the process of catalyst preparation, and ultrasonic assistance is introduced to optimize the method of catalyst preparation. The catalyst has high activity, high selectivity, and has the advantages of that the stability is high, the separation technique is easy and the precious metal is easy to reclaim; the method is applicable to the reaction for preparing parachloroaniline by using parachloronitrobenzene hydrogenation, and excellent hydrogenation activity and selectivity are achieved during the reaction.

Owner:NANKAI UNIV

Device and method for purifying indoor air

InactiveCN101927025AFully contactedPromote absorptionDeodrantsRadiationLiquid storage tankEnvironmental engineering

Owner:HENAN UNIV OF URBAN CONSTR

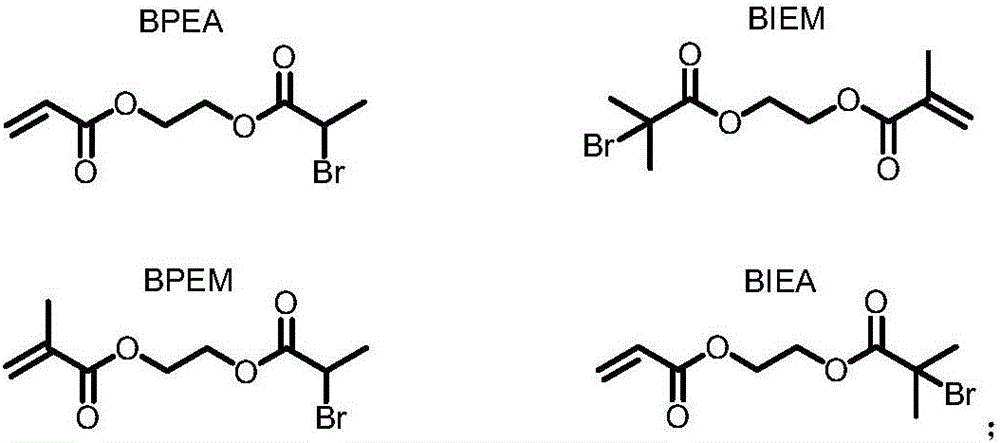

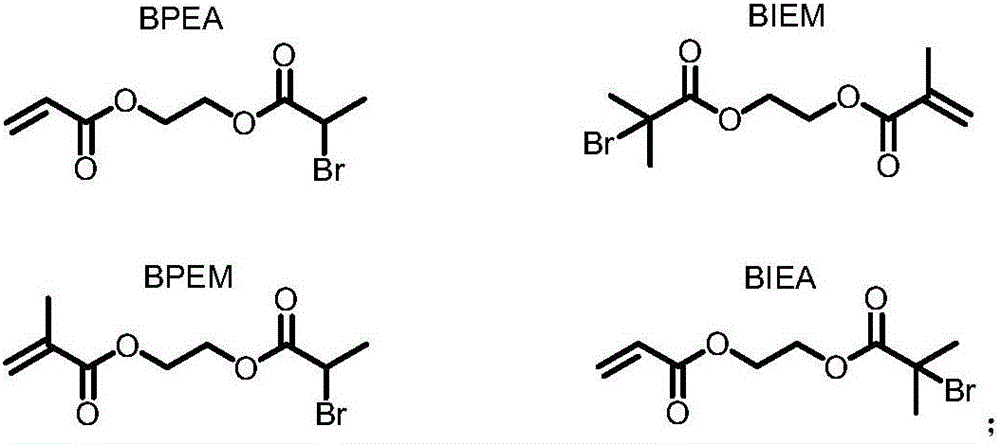

CO2 responsive hyperbranched polymer and preparation method and application thereof

ActiveCN106046247AEasy recyclingReduce energy consumptionGeneral water supply conservationSeawater treatmentCo2 responsiveSolvent

The invention provides a CO2 responsive hyperbranched polymer. The polymer is prepared through one of the following methods. According to the first method, CO2 responsive monomers, a catalyst, ligand, initiator monomers and solvent serve as raw materials, and the target product is prepared through the ATRP method. According to the second method, CO2 responsive monomers, chain transfer agent monomers, initiator and solvent serve as the raw materials, and the target product is prepared through the RAFT. The CO2 responsive hyperbranched polymer can serve as forward osmosis extract solute, and is specifically applied to the forward osmosis seawater desalination process; CO2 is introduced into an extraction solution, the polymer is dissolved in water to form a high-osmotic-pressure extraction solution, water flux is large, counter diffusion is small, N2 is introduced into the extraction solution, polymer will precipitate and be separated out, the polymer is filtered and recycled to be used for forward osmosis next time, the extraction solute is easy to recycle, energy consumption is low, and the extraction solute can be repeatedly used.

Owner:ZHEJIANG UNIV OF TECH

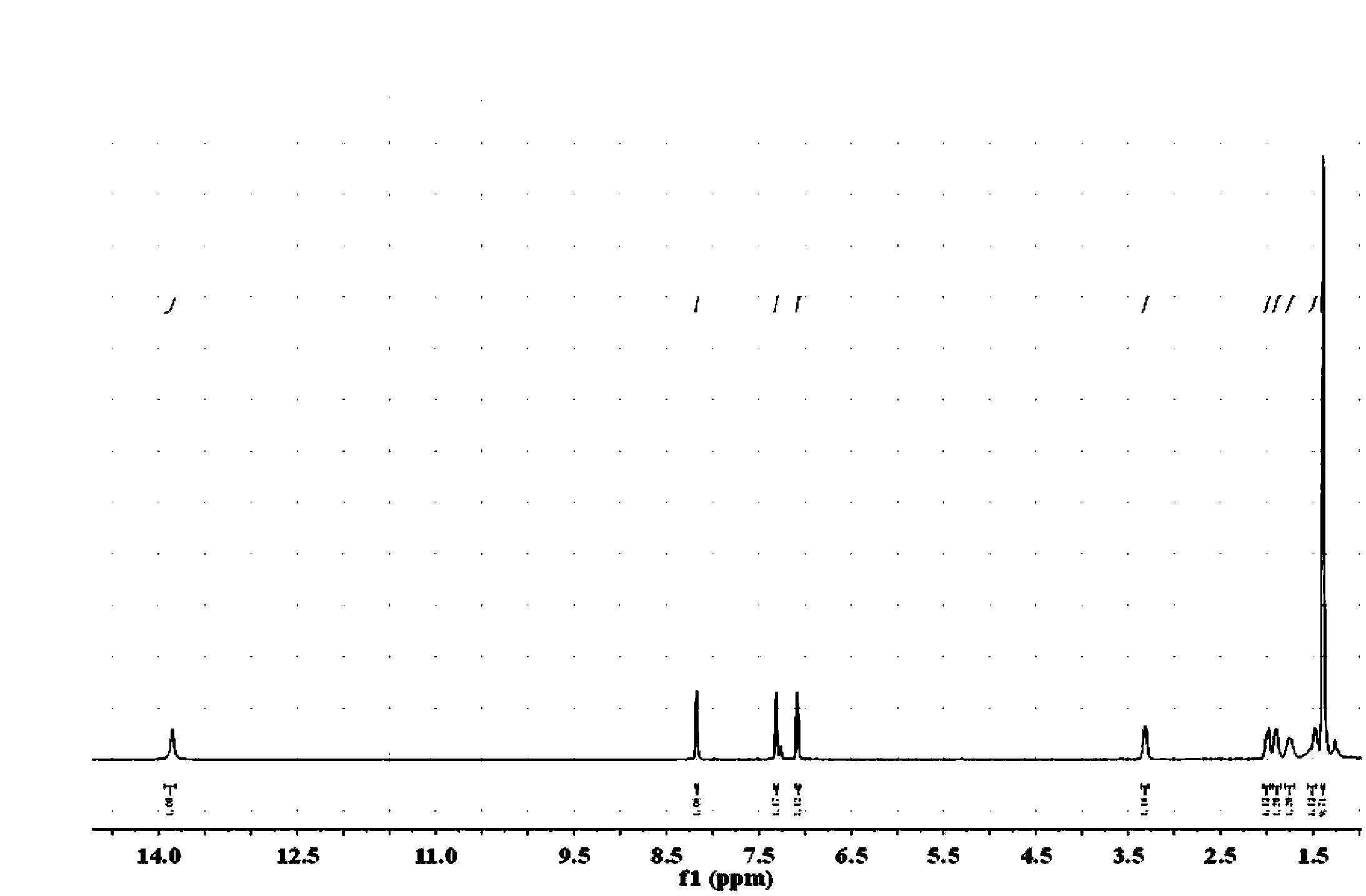

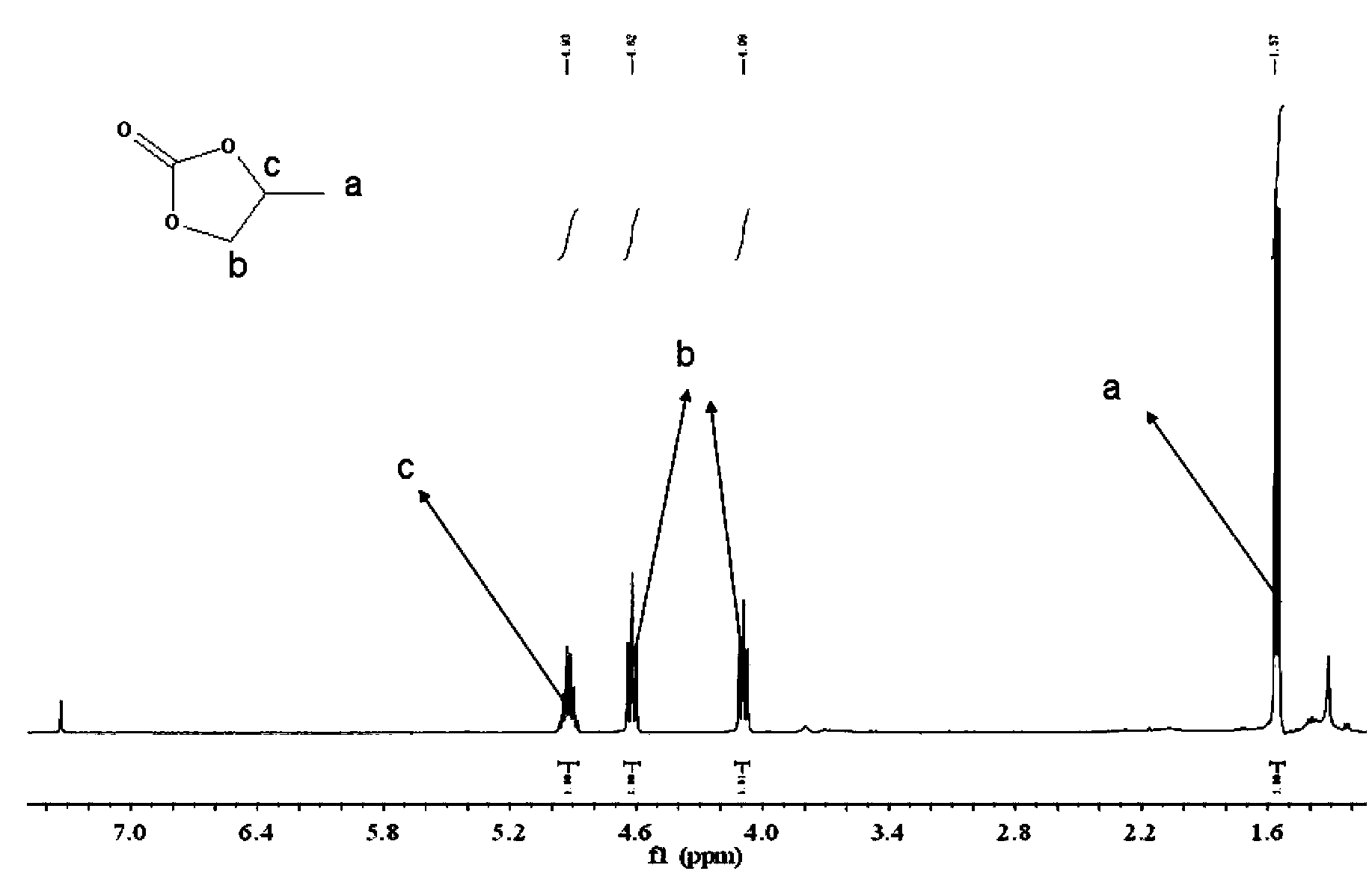

Chromium, zinc or copper complexed conjugated microporous polymer catalysts, as well as preparation method and application thereof

ActiveCN103566970AIncrease profitYield has no effectOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyAlkane

The invention develops novel catalysts which can be used for catalyzing the cycloaddition of CO2 and epoxy alkane at 0-160 DEG C and 0.1-6MPa to generate corresponding cyclic carbonates and a preparation method thereof. The catalysts provided by the invention are metal chromium, zinc or copper complexed conjugated microporous polymer (CMP) catalysts, wherein CMP-1 is one type of metal chromium complexed polymers, CMP-2 is one type of metal zinc complexed polymers, and CMP-3 is one type of metal copper complexed polymers; by using the polymer catalysts complexed by different metals to catalyze the reaction of CO2 and epoxy alkane at normal temperature and normal pressure, the yield of the obtained corresponding cyclic carbonates is 35-38%, the recovery of the catalysts is simple and convenient to operate, and the reuse of the catalysts can not affect the yield; meanwhile the reaction conditions are controlled, and the yield can achieve above 90% when the reaction is performed at the temperature of 50-120 DEG C and the CO2 pressure of 2-6MPa for 1-3 hours.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

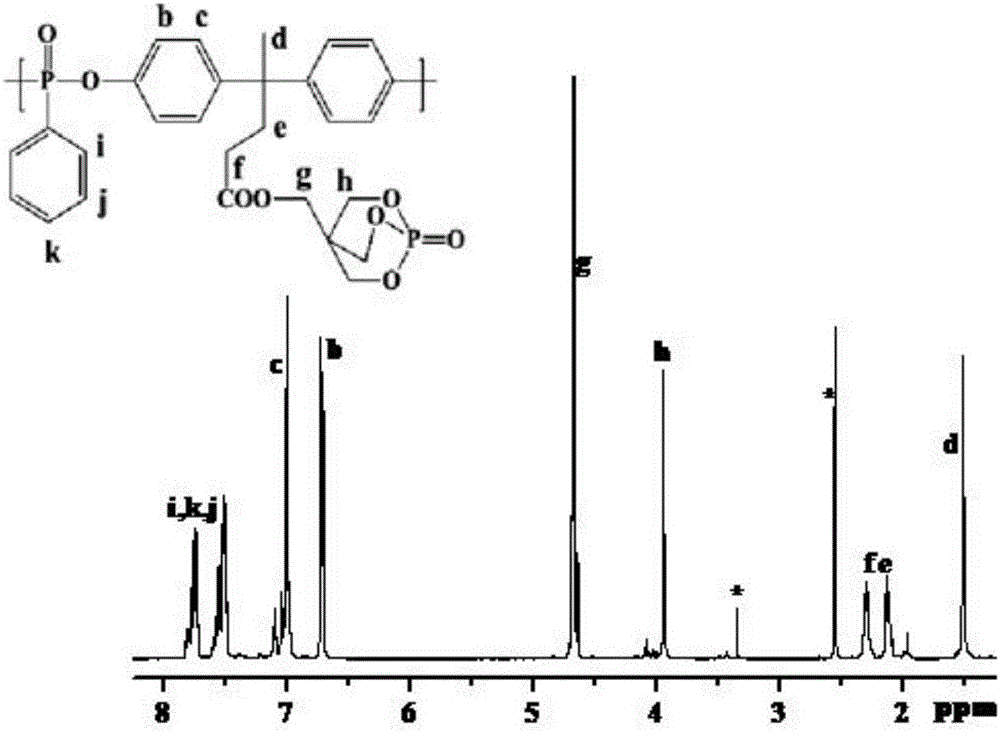

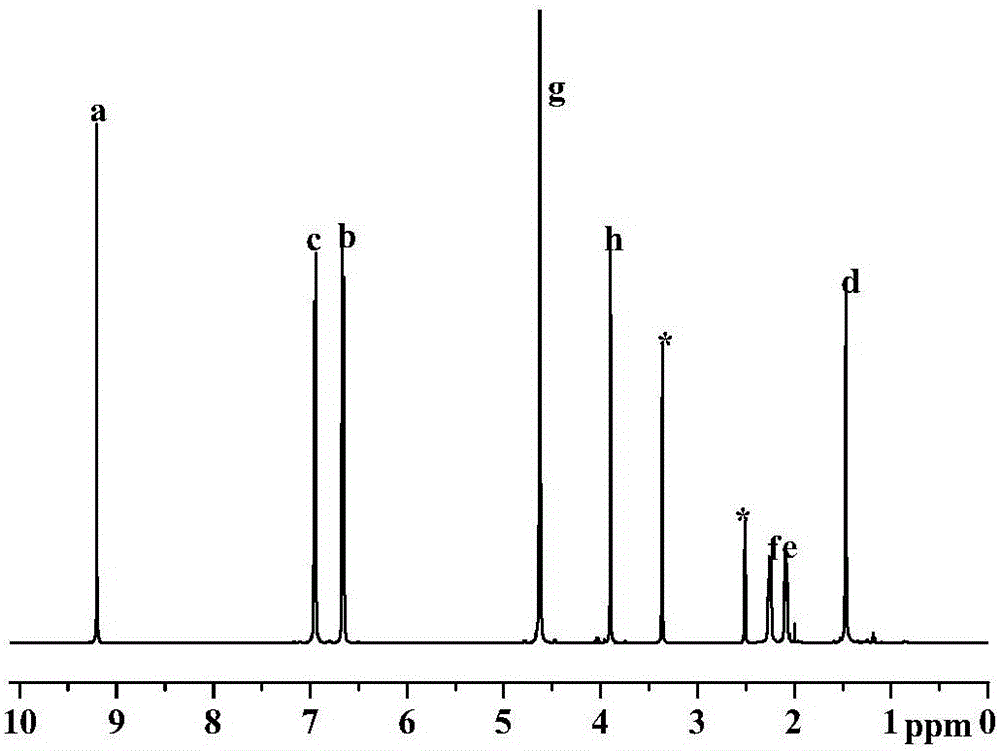

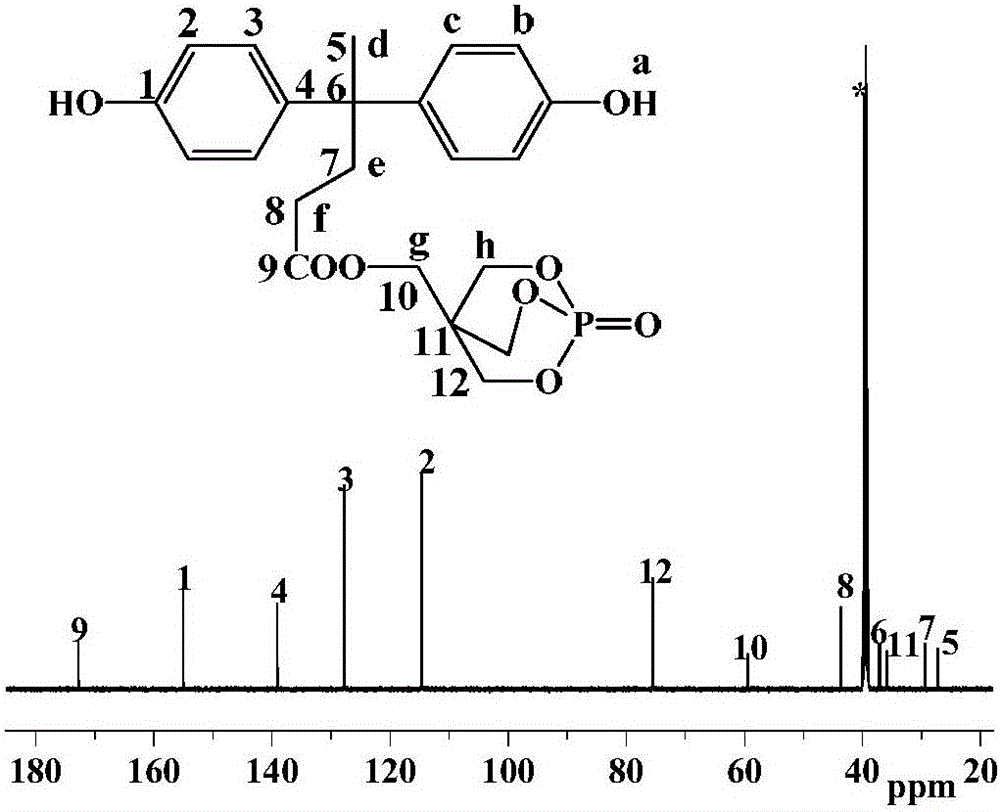

High-efficiency polyphosphate ester fire retardant and preparation method thereof

InactiveCN105838389AHigh in phosphorusGuaranteed mechanical propertiesGroup 5/15 element organic compoundsEnvironmental resistancePhosphate

The invention provides a high-efficiency polyphosphate ester fire retardant. The fire retardant is characterized by having a structure general formula (I) defined in the description, wherein n is 2-20, and R group is phenyl group or phenoxy group. The prepared phosphate ester has high phosphorus content by means of molecular structure design, and the additive amount of the phosphate ester is less than 10 wt% to reach a quite good flame retardant efficiency, which is much less than the additive amount of the traditional phosphorus based flame retardant. The phosphate ester is a high-efficiency green and environmentally-friendly fire retardant. The high-efficiency phosphate ester fire retardant overcomes the disadvantages of the traditional fire retardant such as deliquescence and migration, and has advantages such as strong water resistence, and good compatibility with the matrix, and is halogen-free and difficult to migrate.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

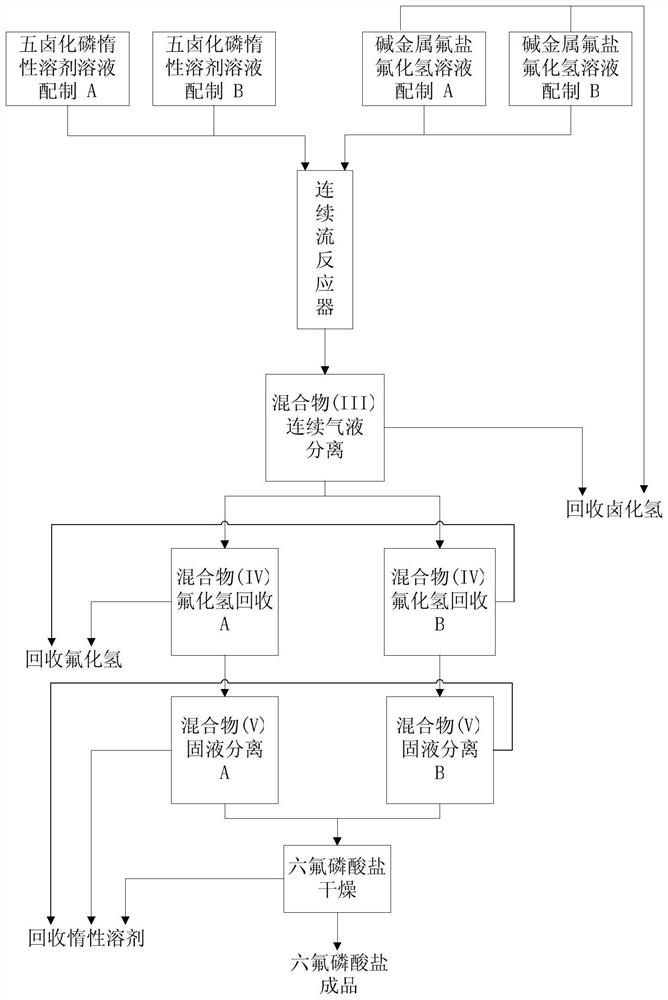

Synthetic method of hexafluorophosphate

ActiveCN114132912APrecise control of feed rateAccurate control precisionLithium hexafluorophosphatePhosphorus compoundsHydrogen fluorideHydrogen halide

The invention discloses a synthesis method of hexafluorophosphate, which belongs to the technical field of chemical synthesis, and is characterized by comprising the following steps: dissolving phosphorus pentahalide in an inert solvent to obtain a phosphorus pentahalide inert solvent solution, dissolving alkali metal halide salt in anhydrous hydrogen fluoride to obtain an alkali metal villiaumite hydrogen fluoride solution, the method comprises the following steps: inputting hexafluorophosphate, hydrogen fluoride, an inert solvent and hydrogen halide into a reactor in proportion for reaction to obtain a mixture consisting of the hexafluorophosphate, the hydrogen fluoride, the inert solvent and the hydrogen halide, firstly removing hydrogen halide gas through gas-liquid separation, then recovering the hydrogen fluoride through heating evaporation, finally recovering the inert solvent through solid-liquid separation, and drying a solid to obtain the hexafluorophosphate, the synthesis method disclosed by the invention has the advantages of simplicity in operation, good safety, high reaction yield, excellent product quality, capability of realizing continuous production and the like.

Owner:ZHEJIANG ZHONGXIN FLUORIDE MATERIALS CO LTD +1

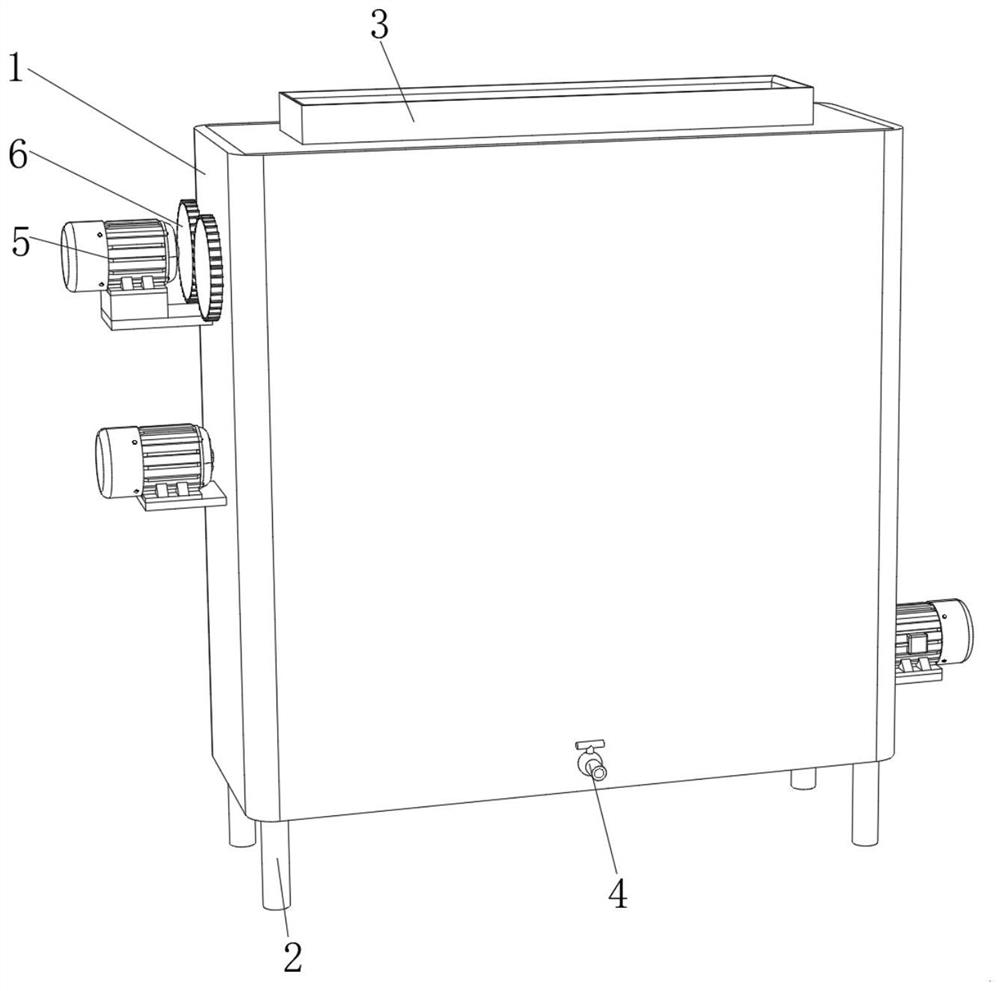

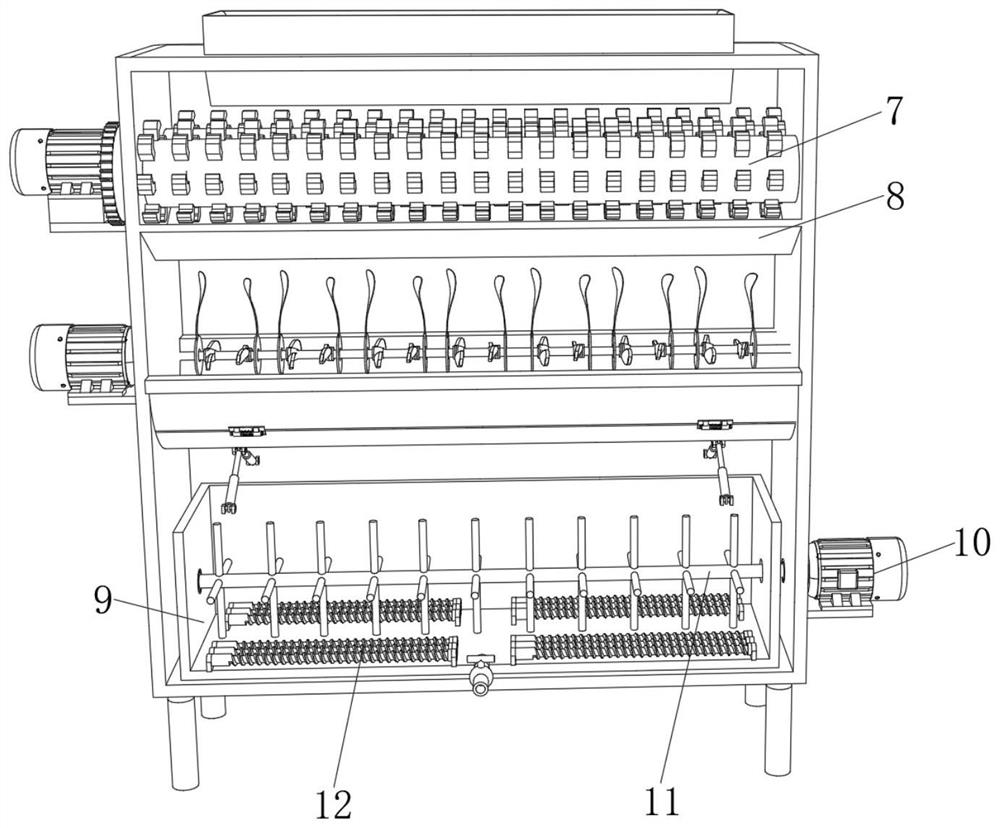

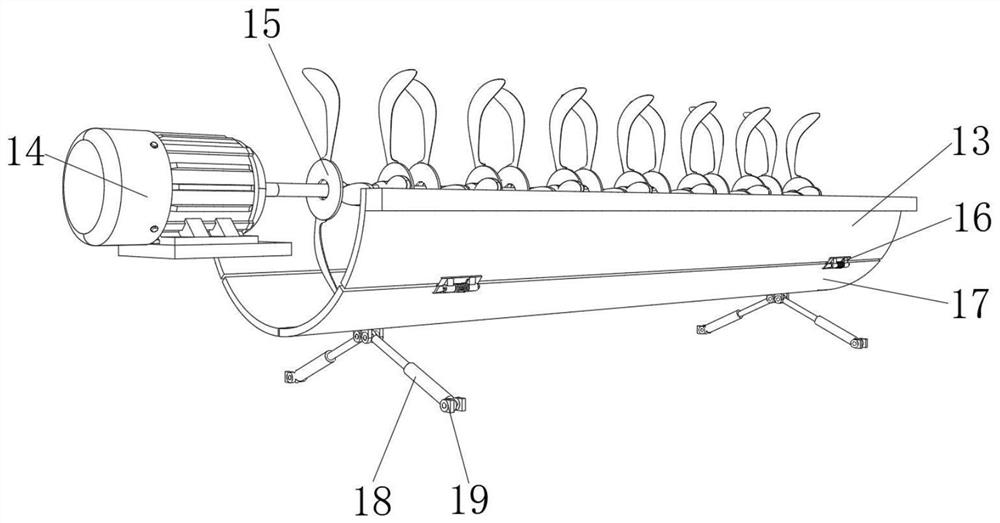

Convenient-collect waste paper recycling device

InactiveCN112246399AEasy to collectEasy to crushTransportation and packagingMixer accessoriesPaper recyclingElectric machine

The invention relates to the technical field of paper recycling and discloses a convenient-collect waste paper recycling device which comprises a smashing box, supporting legs are fixedly connected tothe four corners of the lower surface of the smashing box, a feeding inlet is formed in the upper surface of the smashing box, and a discharging valve communicates with the bottom of the front face of the smashing box. The top of the left side face of the smashing box is fixedly connected with a driving motor, and the output end of the driving motor is fixedly connected with an opposite rotatinggear. According to the convenient-collect waste paper recycling device, a rotary motor drives a smashing cutter to rotate to be matched with a rotary arc plate to conduct two-stage deep smashing on waste paper, a better smashing effect on the waste paper is achieved, the waste paper can be better smashed, melting and recycling of the waste paper are more convenient, and better recycling of the waste paper is facilitated. The waste paper is prevented from being discarded everywhere to damage the surrounding environment, the waste paper recycling efficiency is further improved, and the use convenience is greatly improved.

Owner:新邵县金龙纸业有限责任公司

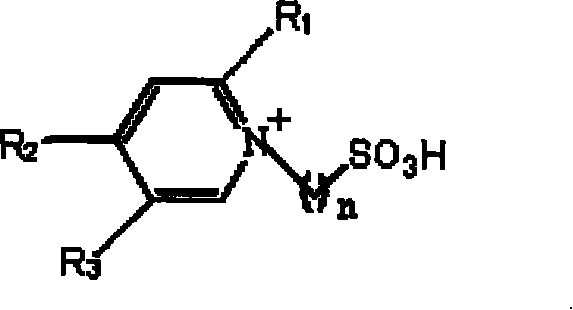

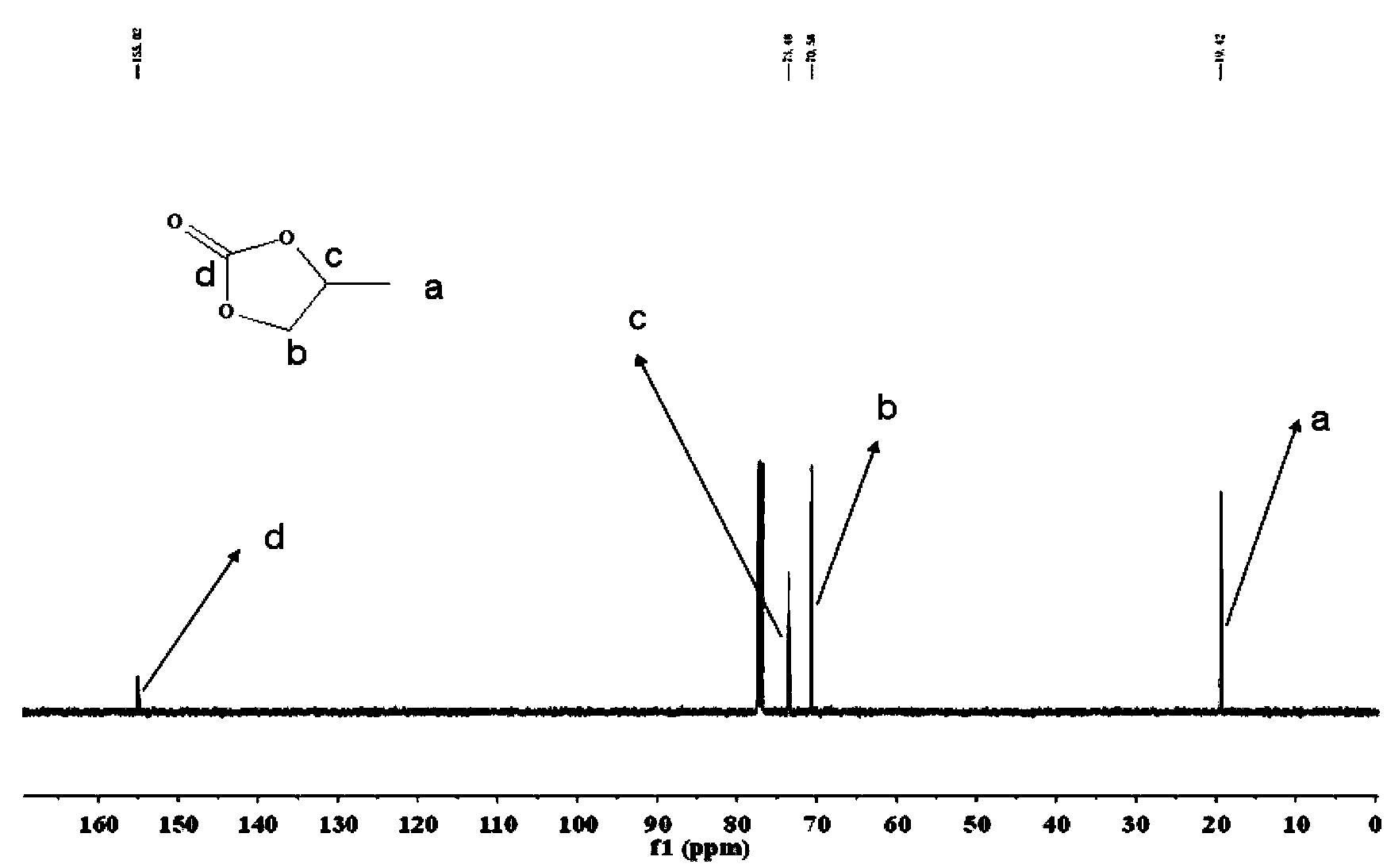

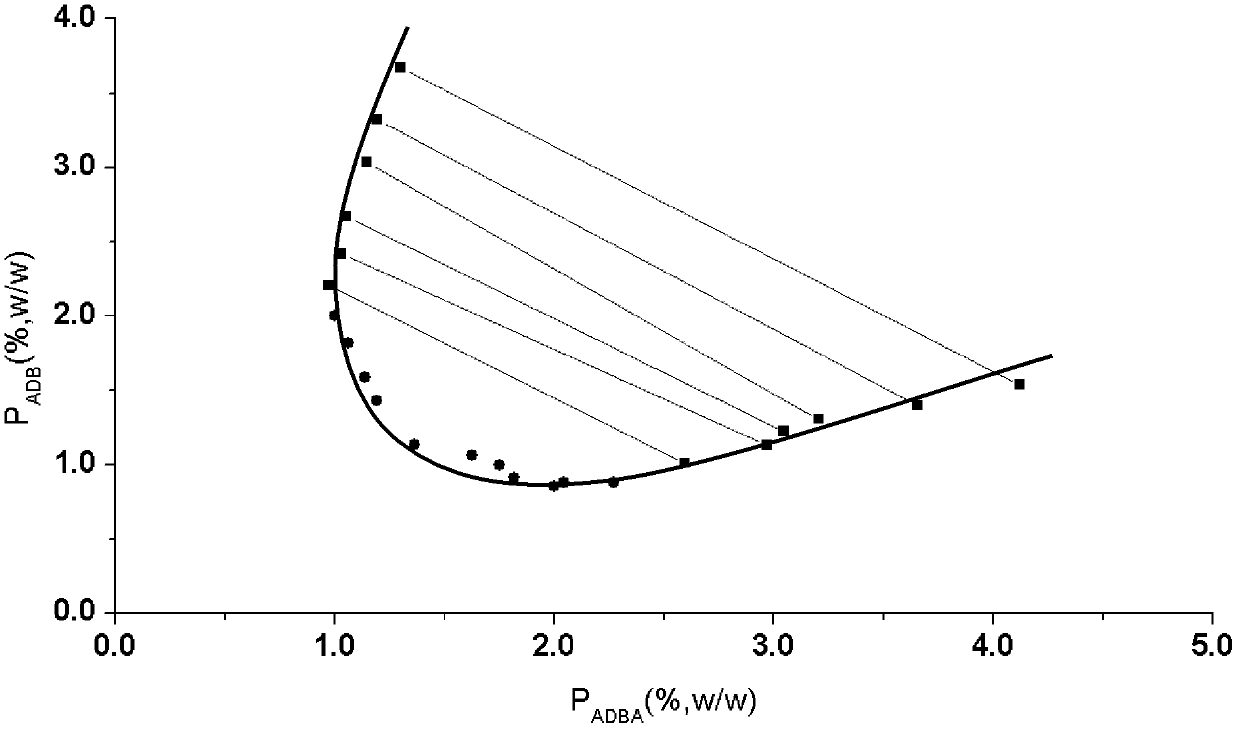

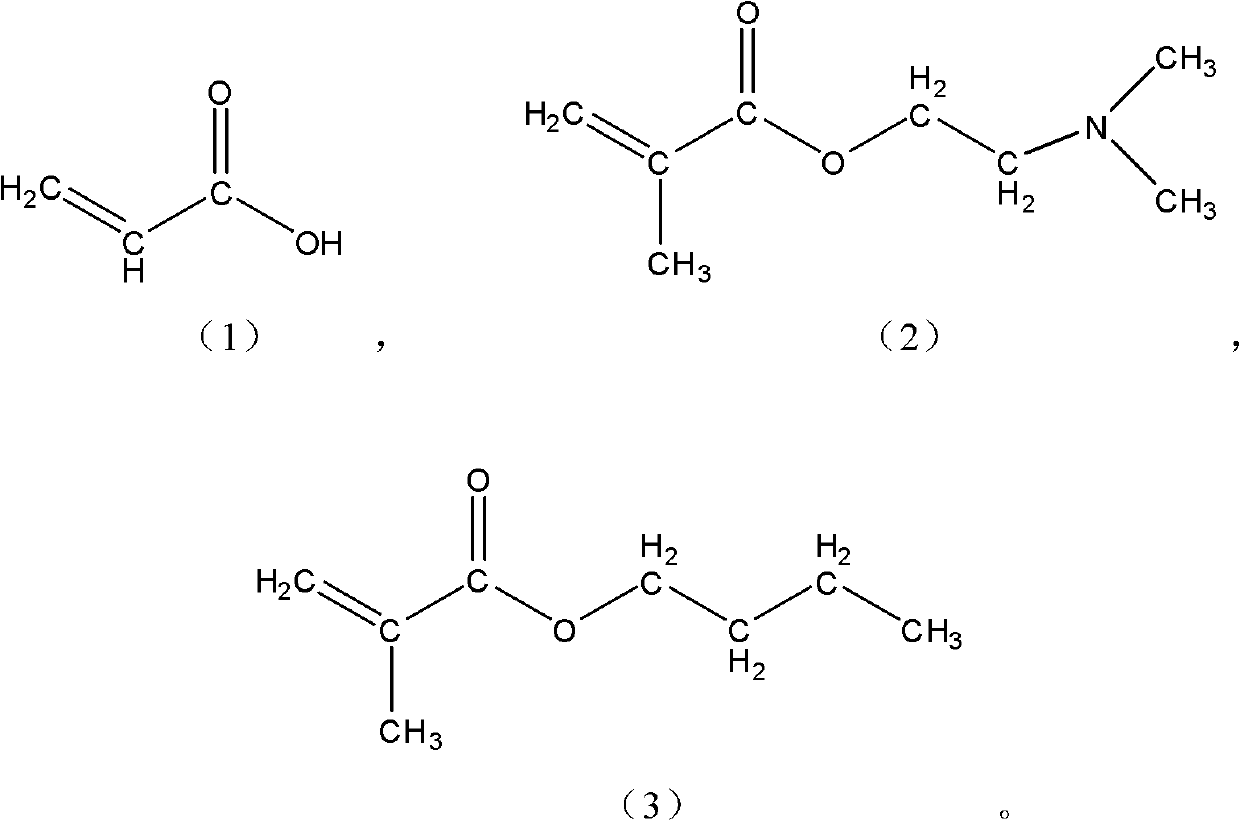

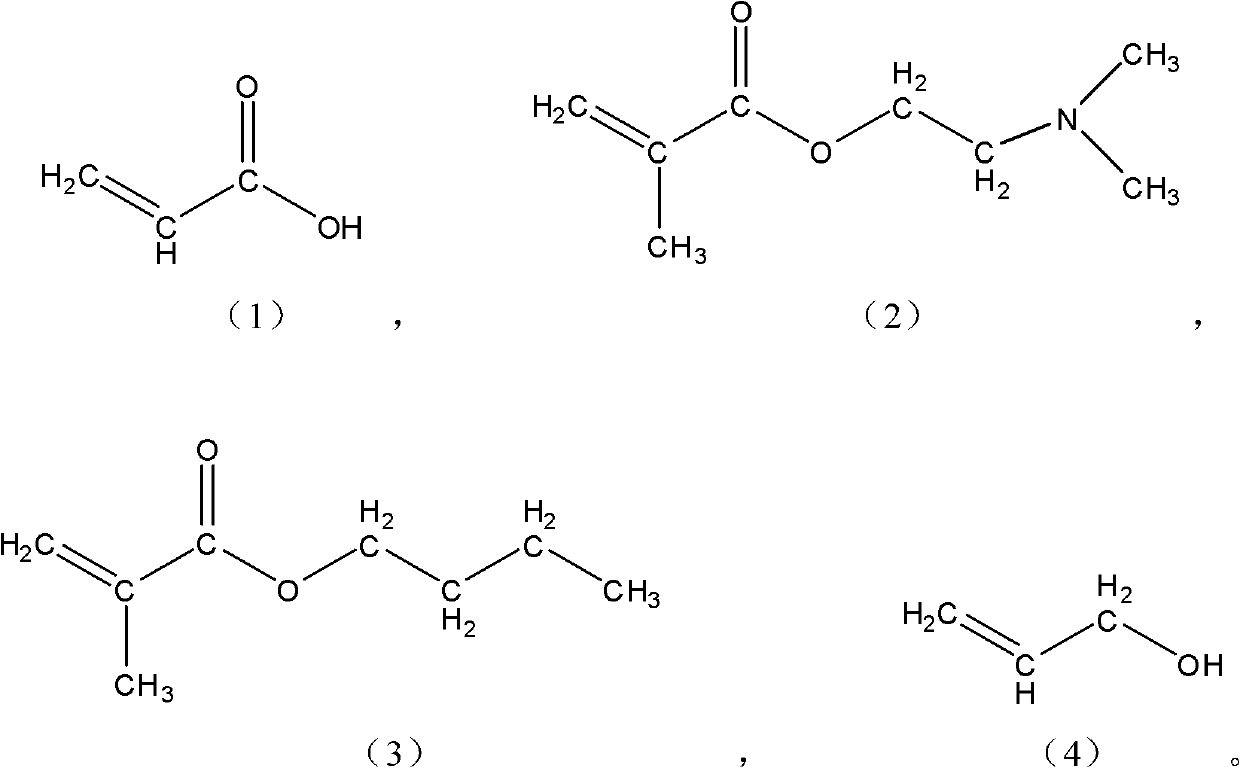

Two types of pH sensitive regenerated polymers and preparation method thereof, as well as regenerated aqueous two-phase system formed by pH sensitive regenerated polymers and application of regenerated aqueous two-phase system

InactiveCN102344520AReduce use costEasy recyclingLiquid solutions solvent extractionPolymer scienceAqueous two-phase system

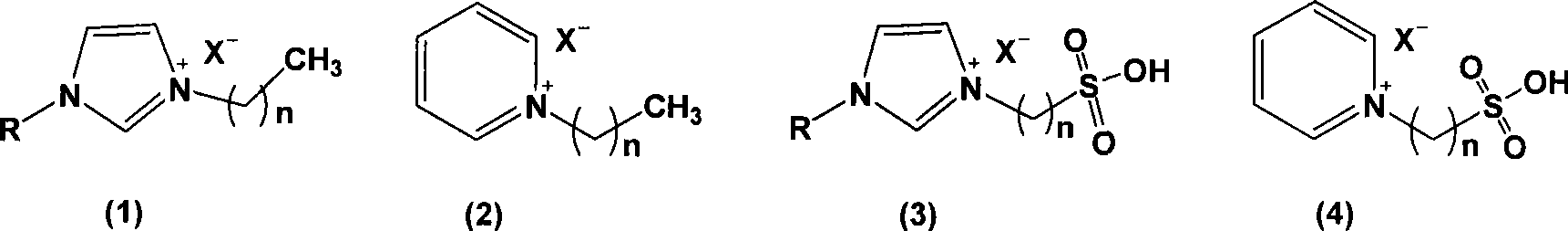

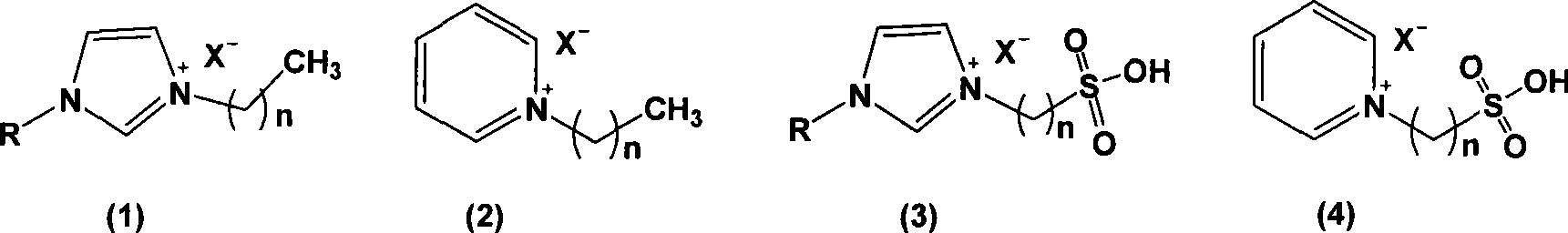

The invention relates to pH sensitive regenerated polymers I and II. In the polymer I, the viscosityaverage molecular weight is 2.93*10<6>g / mol, the isoelectric point is 2.87, the recovery rate is 98.87 percent, the polymer I is randomly copolymerized by compounds shown in formulae (1), (2) and (3), and the molar ratio of feeding is 23:2:1. In the polymer II, the viscosityaverage molecular weight is 3.37*10<5>g / mol, the isoelectric point is 3.91, the recovery rate is 97.18 percent, the polymer I is randomly copolymerized by compounds shown in formulae (1), (2), (3) and (4), and the molar ratio of feeding is 23: 8: 1: 6. The invention also relates to a related preparation method, an aqueous two-phase system formed by the pH sensitive regenerated polymers, as well as an application of the aqueous two-phase system. The two types of polymers are pH sensitive and reversely soluble, the formed regenerated aqueous two-phase system is pH sensitive, and twenty percent of the two types of phase-forming polymers can be efficiently retrieved, so that the use cost is greatly reduced, the retrieving is simple and convenient, and the pH sensitive regenerated polymers provided by the invention is suitable for large-scale popularization and application.

Owner:EAST CHINA UNIV OF SCI & TECH

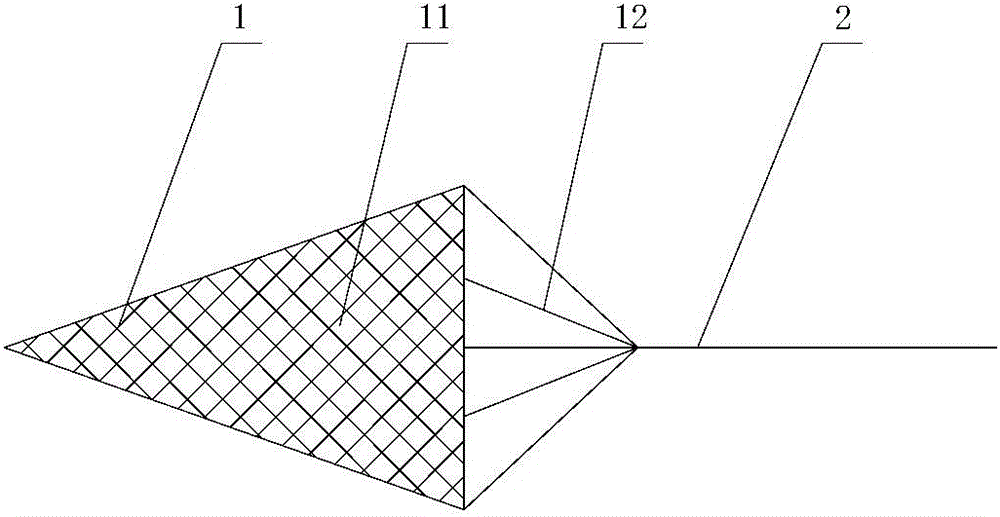

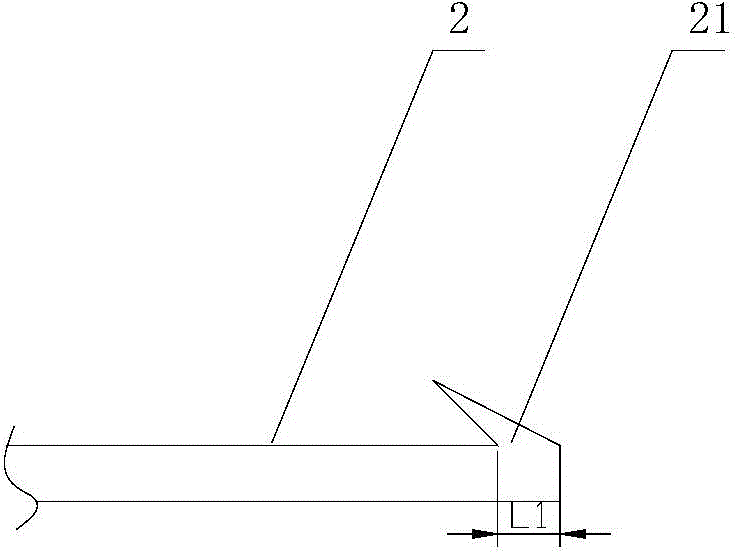

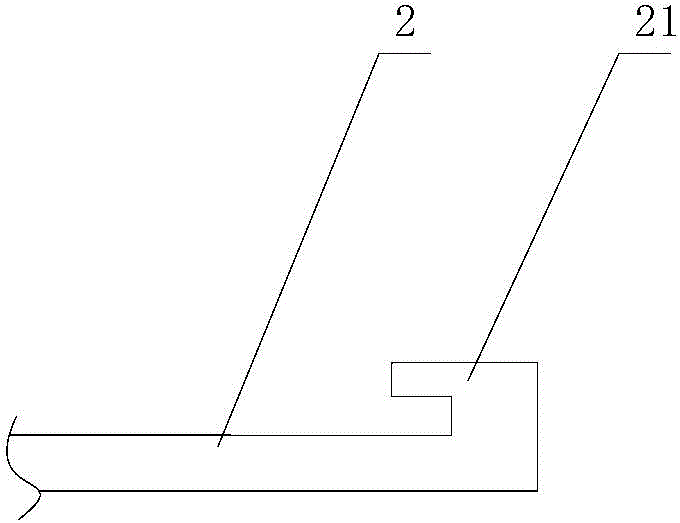

Recyclable blood vessel filter component

The invention provides a recyclable blood vessel filter component. The recyclable blood vessel filter component comprises a guide-in system and a recovery system. The guide-in system comprises a filter body and a retention guide wire, the recovery system comprises a lengthened guide wire and a recovery sheath, the filter body is fixedly connected with the retention guide wire, and during recovery, the retention guide wire is connected with the lengthened guide wire, and the filter body can retract back into the recovery sheath. The recyclable blood vessel filter component is simple in structure and convenient to use and recover and has a long recovery time window.

Owner:GENERAL HOSPITAL OF PLA

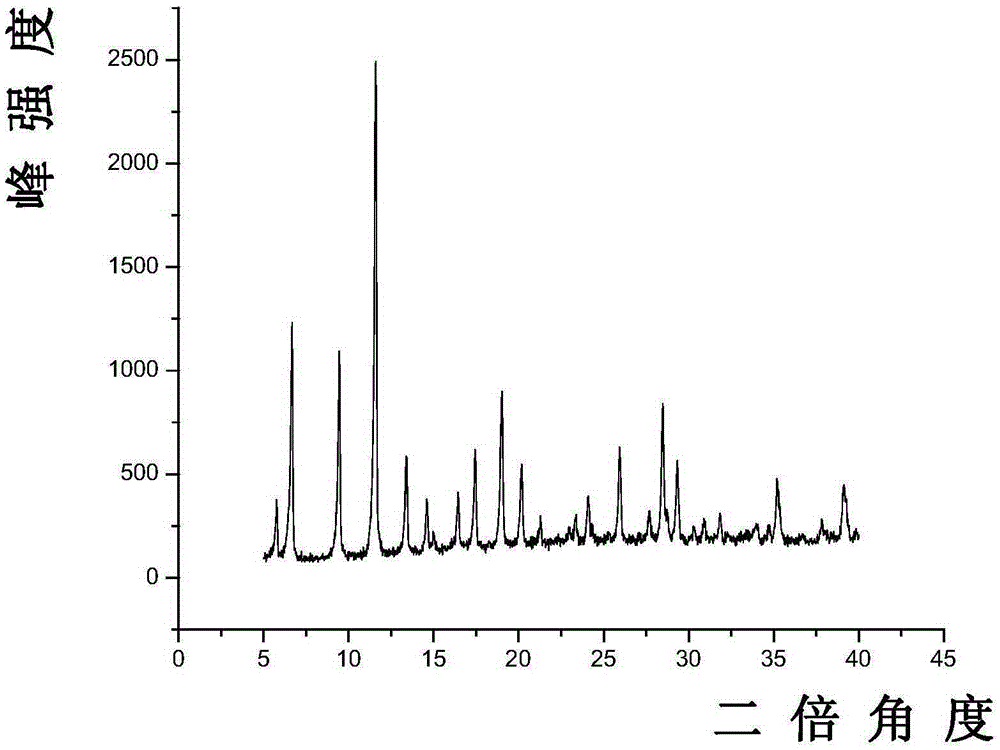

Method for synthesizing Cu-BTC material by utilizing deep-eutectic solvent as solvent

InactiveCN105294741AHigh boiling pointImprove solubilityIon-exchange process apparatusOther chemical processesOrganic solventDesorption

The invention provides a method for synthesizing a Cu-BTC material through a solvothermal method by utilizing a deep-eutectic solvent as a solvent. The Cu-BTC material prepared by virtue of the method is capable of effectively adsorbing dibenzothiophene in a normal octane solvent of dibenzothiophene; the Cu-BTC material is high in adsorptive property, strong in selectivity and good in deep desorption degree of dibenzothiophene; after being cleaned and dried, the Cu-BTC material which adsorbs dibenzothiophene can be recycled; the recycling operation is simple, no toxic organic solvent is used, and the operation conditions are mild and environmentally friendly.

Owner:DALIAN UNIV

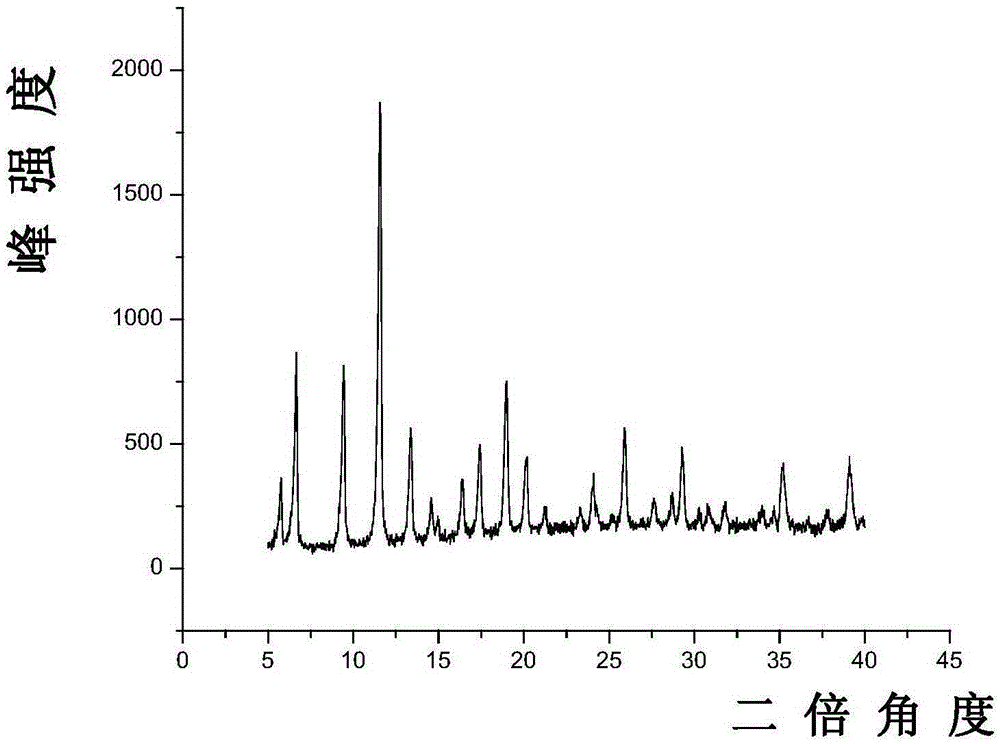

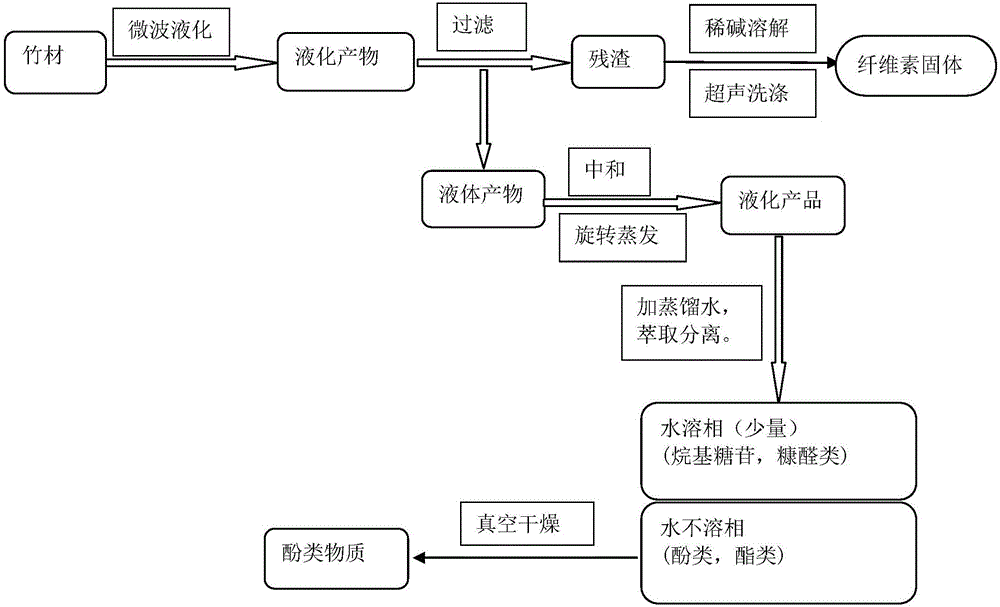

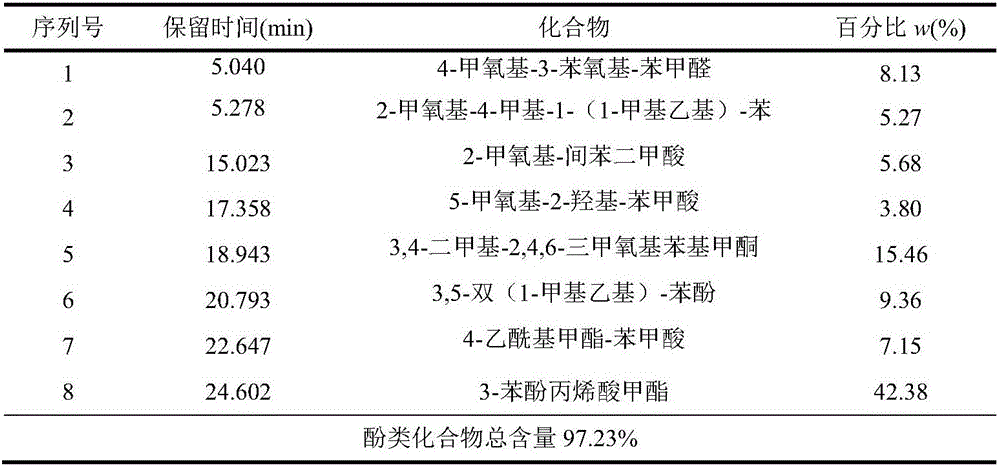

Method for directional liquefaction of woody biomass to obtain high value-added chemicals and comprehensive utilization of liquefaction residue

InactiveCN106495990AImprove conversion rateEasy recyclingOrganic chemistryOrganic compound preparationCelluloseFiber

The invention relates to a method for directional liquefaction of woody biomass to obtain high value-added chemicals and comprehensive utilization of liquefaction residue. The method includes: step 1, directional liquefaction reaction of woody fiber biomass: subjecting a biomass raw material, low carbon alcohol and an acidic catalyst to alcoholysis liquefaction reaction in a microwave liquefaction reaction system; step 2, a process of directional extraction separation to obtain chemicals: filtering the direct liquefaction product to obtain residue and filtrate, neutralizing the filtrate with a NaOH solution, and subjecting the neutralization solution to rotary evaporation of solvent to obtain a liquefaction product, adding distilled water into the liquefaction product, and performing extraction separation to obtain a phenol compound; and step 3, a process of comprehensive utilization of residue: adding low carbon alcohol into the liquefaction residue, performing stirring to dissolve the surface lignin degradation product components into the low carbon alcohol solvent, and filtering the solvent to obtain an off-white solid, and further performing cleaning by a dilute alkali solution and conducting ultrasonic washing, thus obtaining a white cellulose solid.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

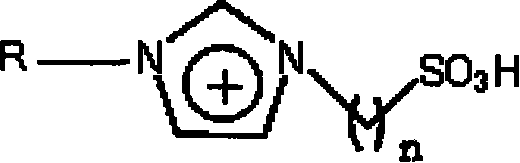

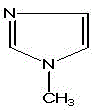

Method for catalyzed synthesis of lubricating base oil from supported ionic liquid

InactiveCN105541612AHigh activityEsterification reaction time is shortOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureSolvent

The present invention discloses a method for preparing lubricating base oil from supported ionic liquid. The method is characterized by using oleic acid and pentaerythritol as raw materials, and using a supported imidazole ionic liquid as a catalyst and a solvent. The present invention employs a dipping method or a sol-gel method for preparing the supported ionic liquid catalyst: addition amount of catalyst of 0.5%-3% of the total mole number of alcohol and acid, the reaction temperature of 130-160 DEG C, atmospheric pressure, and reaction time of 0.5-3 h. The method is characterized by no usage of concentrated sulfuric acid and hydrofluoric acid, which are pollute the environment. Compared to the traditional inorganic acid as an alcohol acid esterification catalyst, the supported ionic liquid has the advantages of mild reaction conditions, high catalytic activity, short reaction time, high esterification rate, simplified production process, simple catalyst recycling operation and reusability.

Owner:NANJING POLYTECHNIC INSITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com