CO2 responsive hyperbranched polymer and preparation method and application thereof

A hyperbranched polymer, responsive technology, applied in chemical instruments and methods, water/sewage treatment, general water supply conservation, etc., can solve the problems of low solubility, loss of solute extraction, etc., and achieves simple recovery operation and large water flux. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

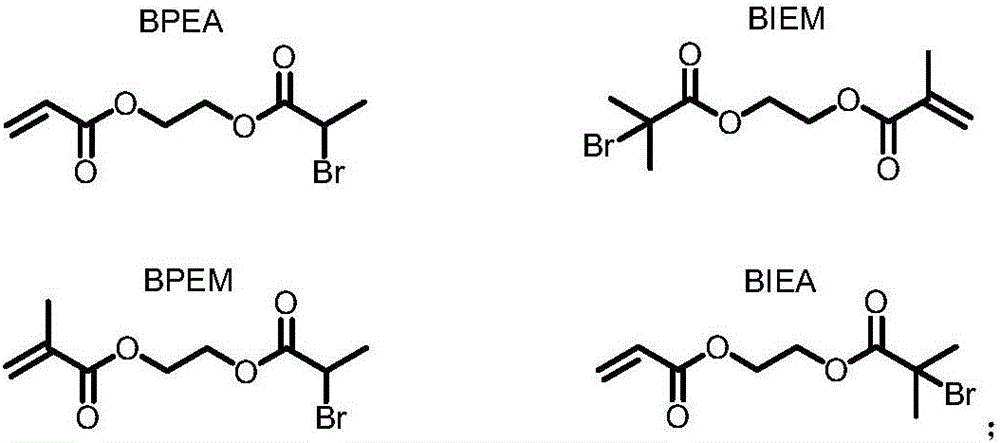

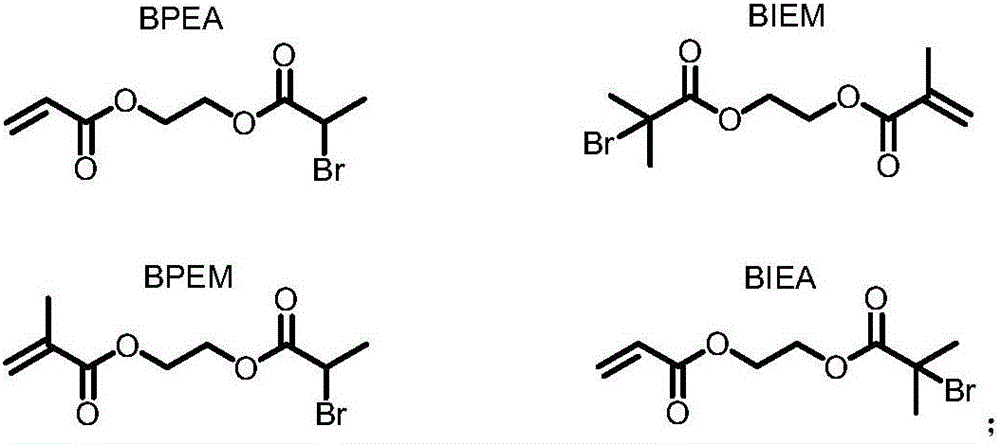

[0042] Add BIEM 0.8g (2.75mmol), diethylaminoethyl methacrylate (DEAEMA) 5.1g (27.5mmol), ethyl acetate 5mL (51.1mmol), PMDTETA 54mg (0.3mmol) in the single-necked flask 1 of 25ml, Magnetic stirring, at room temperature, pass N 2 Divide O 2 . Take another 25ml flask II and add 43.5mg (0.3mmol) of CuBr, at room temperature, pass N 2 Divide O 2 . After 30 minutes, under anaerobic conditions, the liquid mixture in the flask I was added to the flask II, and then the flask II was placed in a constant temperature oil bath at 60° C., and reacted for 12 hours. After the reaction was completed, the reaction solution was added to 90 mL of n-hexane (0° C.), and the precipitate was precipitated. The supernatant was poured out, and the precipitate was dissolved in 10 ml of tetrahydrofuran. 2 o 3 As column filler, 45mL tetrahydrofuran is eluent, and the collected eluent is dialyzed with 3500 molecular weight dialysis bag again, and the retentate in the dialysis bag is lyophilized to o...

Embodiment 2

[0045] Add BIEM 0.8g (2.75mmol), diethylaminoethyl methacrylate (DEAEMA) 10.2g (55mmol), ethyl acetate 10mL (102.3mmol), PMDTETA 100mg (0.58mmol) in 25ml single-necked flask I, magnetic Stirring, at room temperature, pass N 2 Divide O 2 . Take another 25ml flask II and add 83.4mg (0.58mol) of CuBr. 2 Divide O 2 . After 30 minutes, under anaerobic conditions, the liquid mixture in flask I was added to flask II, and then flask II was placed in a constant temperature oil bath at 60°C to react for 12 hours. After the reaction was completed, the reaction solution was added to 160 mL of n-hexane (0° C.), and the precipitate was precipitated, and the supernatant was poured out. 2 o 3 As column packing, 80mL tetrahydrofuran was used as eluent, the eluate was collected and then dialyzed with a dialysis bag with a molecular weight of 8000, and the retentate in the dialysis bag was freeze-dried to obtain 7.8 g of hyperbranched PDEAEMA;

[0046] In this example, the conversion rate...

Embodiment 3

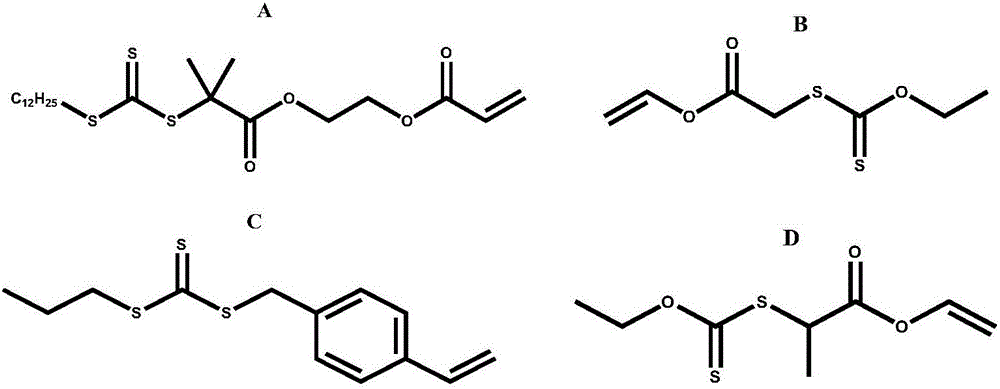

[0048] In a 100ml round bottom flask, add DEAEMA 5.6g (30mmol), 2-[(2-{[(dodecylthio)carbonyl]thio}-2-methylpropionyl)oxy]-acrylic acid ethyl Esters 0.46g (1mmol), AIBN 18mg (0.1mmol), 1,4-dioxane 30ml, and seal the flask with a rubber stopper. Pass N into the flask with a needle 2 Divide O 2 After 30 min, the flask was placed in an oil bath at 70° C. for 24 h. Quench the reaction with liquid nitrogen, add 10 mL of chloroform to dilute, then add the diluted reaction solution into 300 mL of n-hexane (0°C), precipitate out, pour off the supernatant, and vacuum-dry the lower layer to obtain the hyperbranched polymer PDEAEMA6 .6g.

[0049] In this example, the conversion rate of the polymerization system is 82%, the number average molecular weight is 8000, and the molecular weight distribution is 1.7. Take 4g PDEAEMA and put it into 10mL water, introduce CO 2 , PDEAEMA is dissolved in water to form a draw solution with a concentration of 0.4g / g (the raw material solution is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com