Method for synthesizing Cu-BTC material by utilizing deep-eutectic solvent as solvent

A deep eutectic solvent and solvent technology, applied in the field of adsorption and extraction of dibenzothiophene, can solve the problems of difficult control and implementation, high volatility, environmental pollution, etc., and achieve the effects of easier recovery, high adsorption performance and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

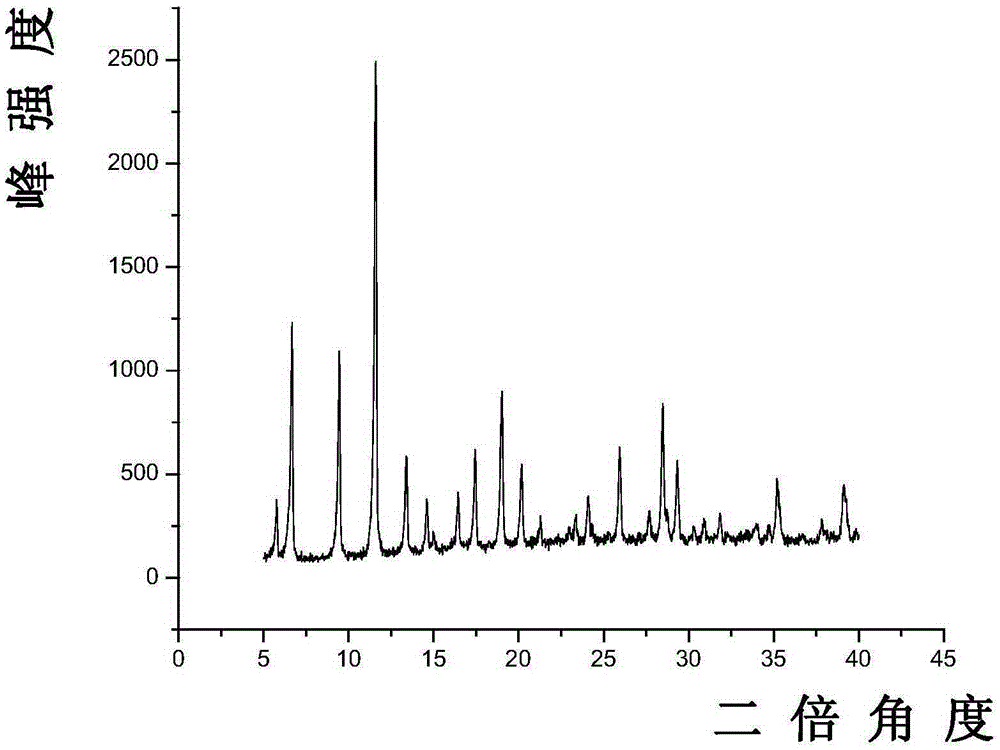

Embodiment 1

[0021] Add choline chloride and ethylene glycol into the reactor at a molar ratio of 1:2, stir in an oil bath at 80°C under reflux condensation until the two raw materials are evenly mixed into a liquid, and continue stirring for 4 hours; The deep eutectic solvent ChCl / ethylene glycol used in this example was obtained by vacuum drying for 24 hours.

[0022] Weigh 1.0531g of trimesic acid and 2.5512g of copper nitrate trihydrate into the reactor, add 10mL of deep eutectic solvent ChCl / ethylene glycol to dissolve, seal the reactor, place it in a constant temperature drying oven, and heat it to 100°C , Reaction 24h. Take out the reactor, wash it twice with deionized water and absolute ethanol (200mL / time) to obtain a solid product, first dry it in a drying oven at 70°C for 5h, and then vacuum dry it in a vacuum oven at 100°C for 24h , to obtain Cu-BTC material. Sealed and stored in dry conditions for later use.

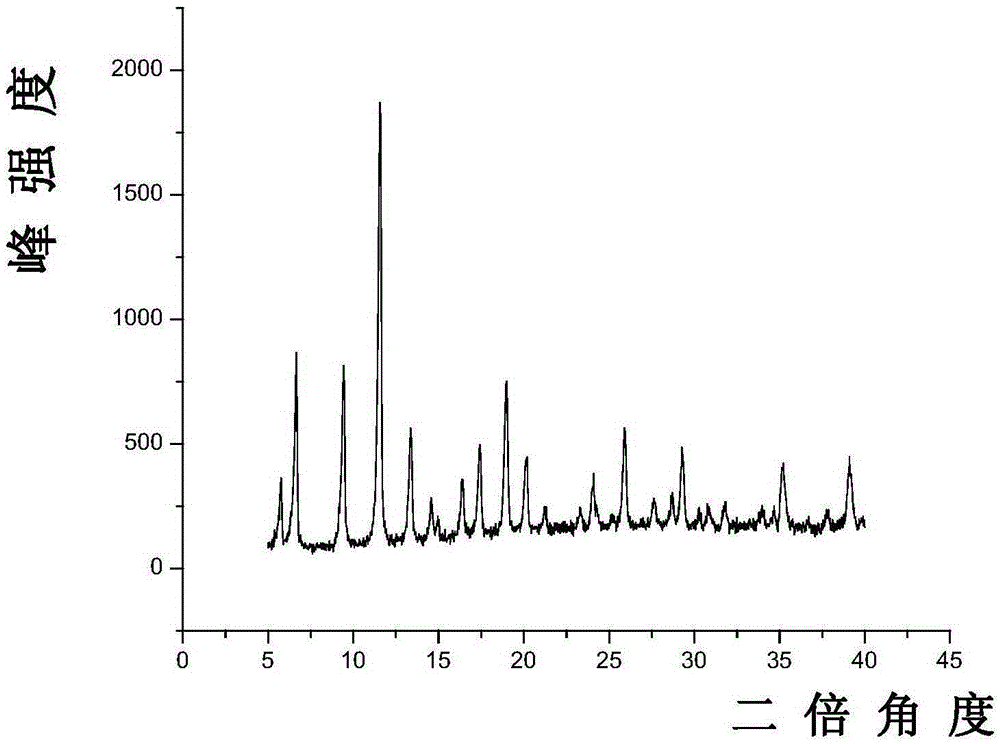

Embodiment 2

[0024] Add choline chloride and ethylene glycol into the reactor at a molar ratio of 1:2, stir in an oil bath at 80°C under reflux condensation until the two raw materials are evenly mixed into a liquid, and continue stirring for 4 hours; The deep eutectic solvent ChCl / ethylene glycol used in this example was obtained by vacuum drying for 24 hours.

[0025] Weigh 2.1012g of trimesic acid and 5.2014g of copper nitrate trihydrate into the reactor, add 15mL of deep eutectic solvent ChCl / ethylene glycol to dissolve, seal the reactor, place it in a constant temperature drying oven, and heat it to 100°C , Reaction 24h. Take out the reactor, wash it twice with deionized water and absolute ethanol (200mL / time) respectively, and dry the solid product at 70°C for 5h in a drying oven, and then vacuum dry at 100°C for 24h in a vacuum drying oven , to obtain Cu-BTC material. Sealed and stored in dry conditions for later use.

Embodiment 3

[0027] Add choline chloride and N,N-dimethylurea into the reactor at a molar ratio of 1:2, stir in an oil bath at 80°C under reflux condensation until the two raw materials are uniformly mixed into a liquid, and then continue to stir for 4 hours; After completion, vacuum-dry at 60° C. for 24 hours to obtain the deep eutectic solvent ChCl / N,N-dimethylurea used in this example.

[0028] Weigh 2.1012g of trimesic acid and 5.2014g of copper nitrate trihydrate into the reactor, add 10mL of deep eutectic solvent ChCl / N,N-dimethylurea to dissolve, seal the reactor and place it in a constant temperature drying oven , heated to 100 ° C, the reaction 24h. Take out the reactor, wash it twice with deionized water and absolute ethanol (200mL / time) respectively, and dry the solid product at 70°C for 5h in a drying oven, and then vacuum dry at 100°C for 24h in a vacuum drying oven , to obtain Cu-BTC material. Sealed and stored in dry conditions for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com