Patents

Literature

819results about How to "Highly selective adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190BStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberSodium Bentonite

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

Method for preparing metal ion imprinting adsorbent with underwater selective recognition performance

InactiveCN102626611ASimple regeneration methodLow costOther chemical processesWater/sewage treatment by sorptionCross-linkIndustrial waste water

The invention provides a method for preparing a metal ion imprinting adsorbent with an underwater selective recognition performance. The method comprises the steps of: preparation of an amino functional material: dispersing a nuclear body material into a methanol solution, slowly adding 3-propylaminoethoxy silane, uniformly stirring, and then, continuously adding a cross-linking agent and a stabilizer to form the amino functional material; and preparation of the metal ion imprinting adsorbent: dispersing the amino functional material in the methanol solution, and exposing to ultrasound to obtain a solution A; dissolving isonicotinic acid and metal template ions in deionized water to form a solution B; dripping the solution B into the solution A, and reacting to obtain a white sol-like product; and eluting the metal template ions: performing Soxhlet extraction by using an acetic acid-methanol solution, then eluting the metal template ions by using a hydrochloric acid, and drying to obtain the metal ion imprinting adsorbent. The metal ion imprinting adsorbent disclosed by the invention can be widely applied to advanced treatment of drinking water as well as enrichment recovery or rapid analysis detection of metal ions in different water bodies, such as industrial waste water, aquaculture water and seawater.

Owner:HARBIN ENG UNIV

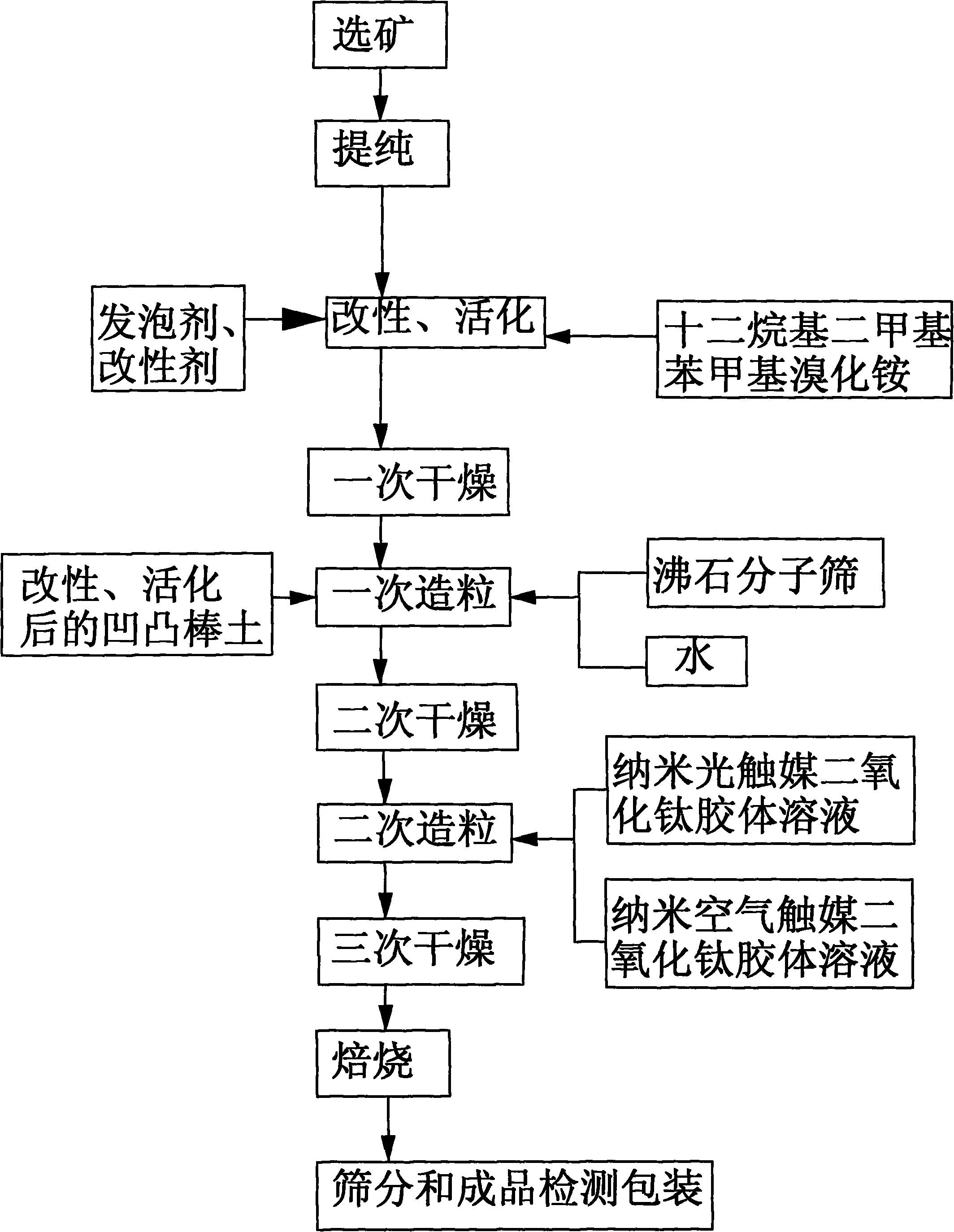

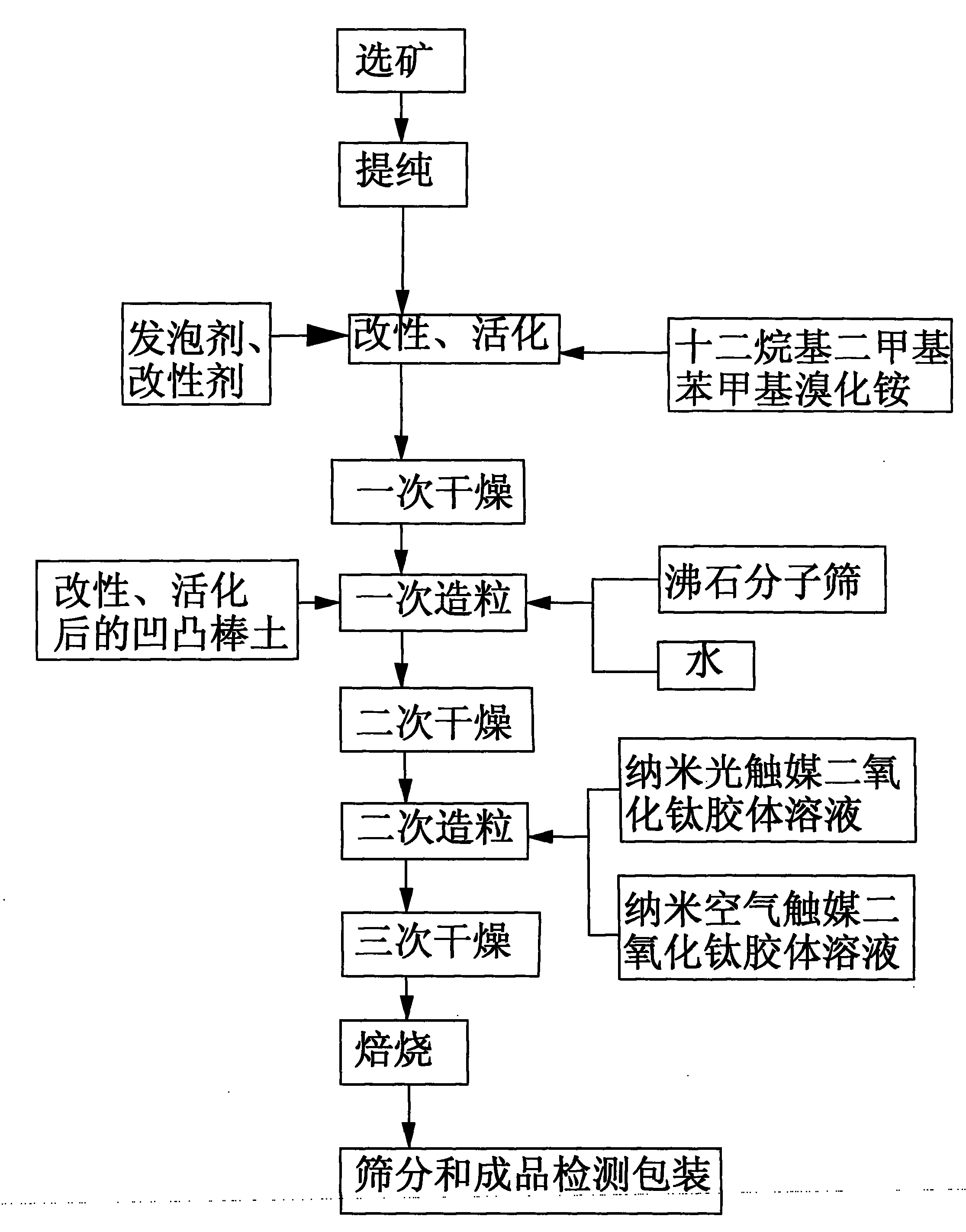

Composite air purificant containing nanometer mineral matters and preparation method thereof

ActiveCN101780288AWill not polluteProcess environmental protectionPhysical/chemical process catalystsDispersed particle separationSodium bicarbonateDecomposition

The invention provides a composite air purificant containing nanometer mineral matters, which contains 47wt% to 78wt% of attapulgite as a natural mineral, 20wt% to 50wt% of synthetic zeolite molecular sieve as a molecular sieve, 0.5wt% to 5wt% of sodium carbonate or sodium chloride or sodium fluoride or sodium hydrogensulfite as a modifier, 0.5wt% to 5wt% of ammonium bicarbonate or sodium bicarbonate or aluminum sulfate as a foaming agent, 0.5wt% to 2wt% of dodecyldimethylbenzylammonium chloride as a surface active agent, 0.2wt% to 2wt% of nanometer photocatalyst titanium dioxide colloidal solution as a photocatalyst and 0.1wt% to 1wt% of nanometer aircatalyst titanium dioxide colloidal solution as photochemical catalysts. The composite air purificant is prepared by first drying, first pelleting, second drying, second pelleting, third drying, baking and finish product detection and package. The invention has high alternative adsorbability and high decomposition efficiency for organic pollutants in the air.

Owner:宁波市沧海新材料开发有限公司

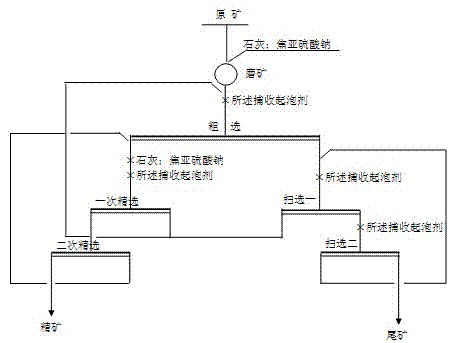

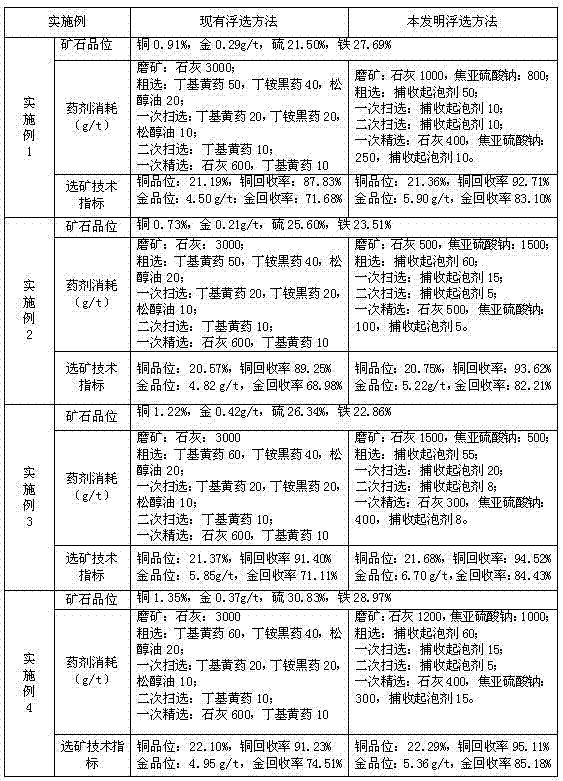

Method for floating high-sulfur gold-bearing copper ore

ActiveCN103691569AEnhanced inhibitory effectImprove beneficiation indexFlotationPropionitrileEthyl group

The invention discloses a method for floating high-sulfur gold-bearing copper ore, which aims at solving the problems that the existing beneficiation method is lower in copper and gold recovery rate under high-alkali condition, and problems that xanthate and black powder are adopted as high-sulfur gold-bearing copper ore collecting agents, the collecting power is stronger, the selectivity is poor, the separation difficulty of copper and sulfur can be aggravated and the consumption of inhibitors is increased. The method comprises the steps of by adopting lime and sodium metabisulfite as an ore pulp pH regulator and a pyrite inhibitor, and the mixture of isopropyl xanthogen propionitrile ester, black powder acid and ethyl dithiocarboxyl propionitrile ester according to certain proportion as a collecting foaming agent, carrying out ore grinding, rough concentration, primary scavenging, secondary scavenging, primary concentration, and secondary concentration on a crude ore, thus realizing the high-efficiency recovery on copper and gold in the high-sulfur gold-bearing copper ore. According to the method, through reasonable combination and addition of medicaments, the selective adsorption of the collecting agent on target mineral-copper pyrite and other copper sulfide minerals and gold minerals can be reinforced, and the copper recovery rate and the gold recovery rate can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

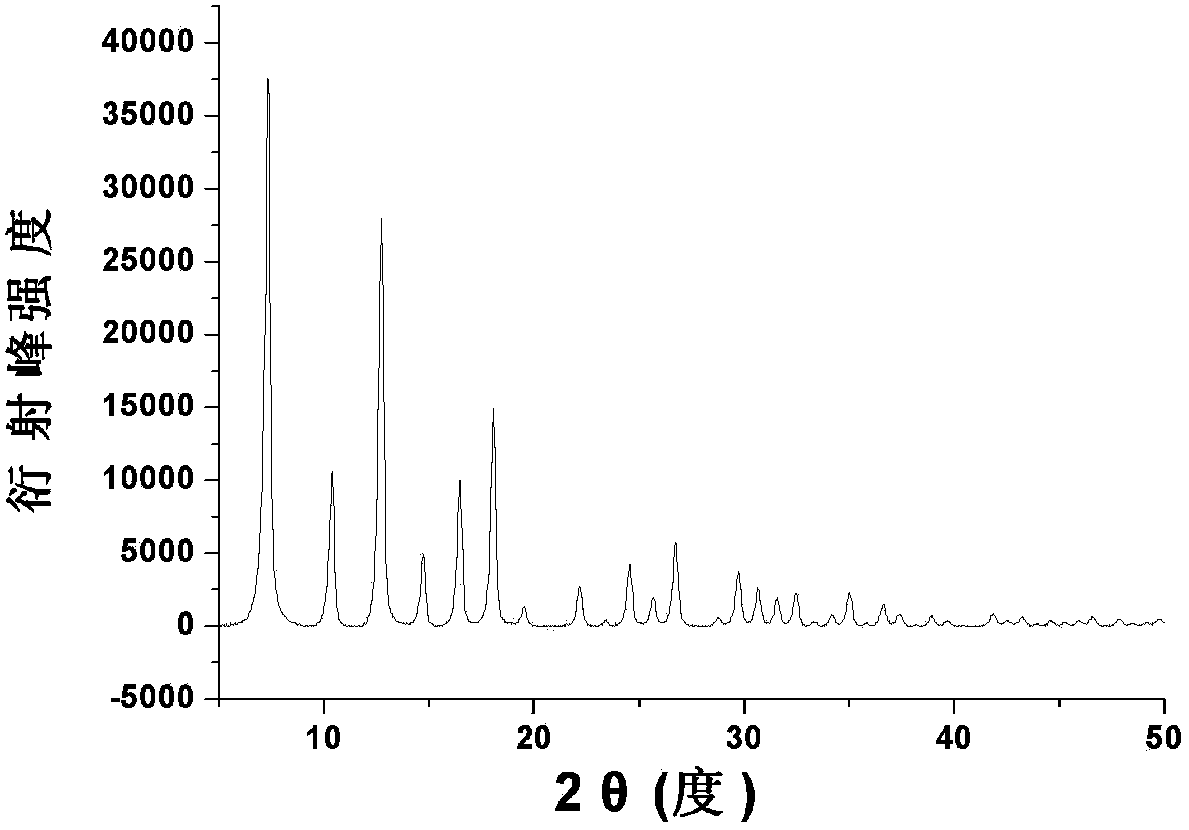

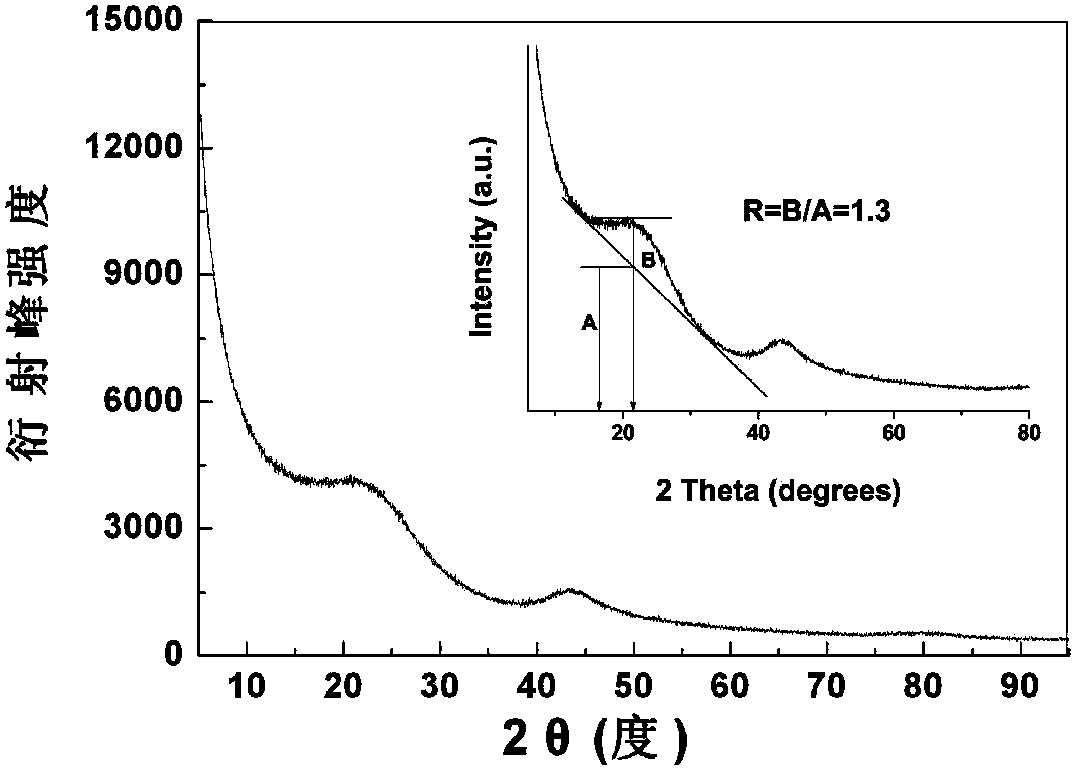

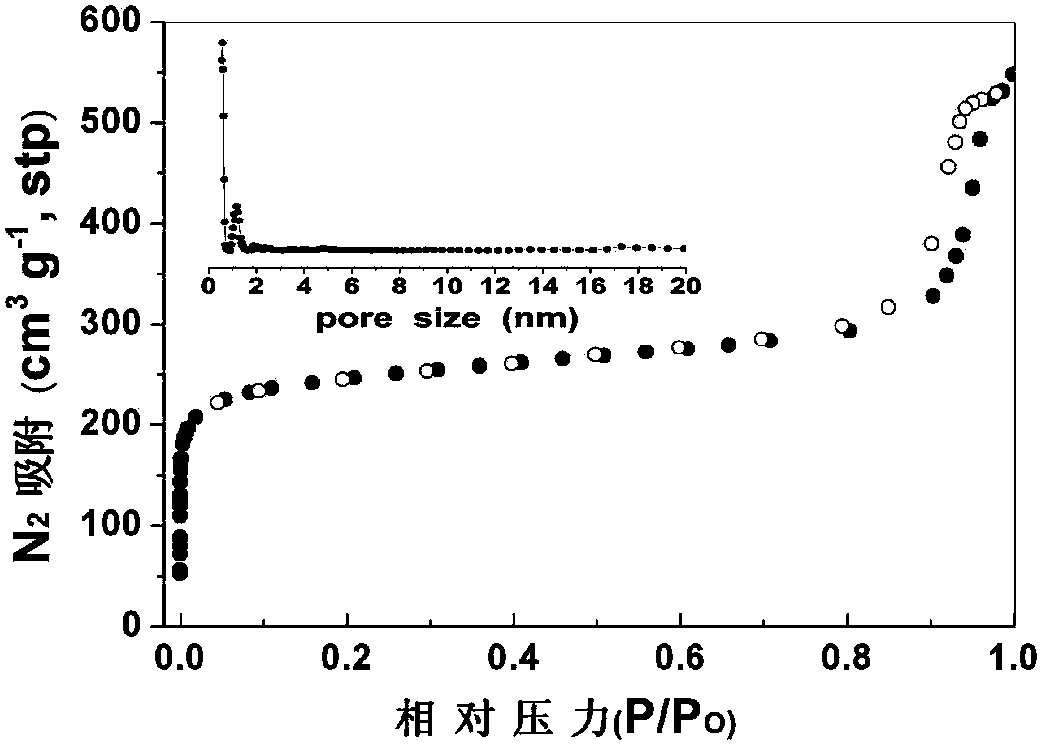

Preparation method of boron/nitrogen-doped microporous carbon material

InactiveCN103508434AGood hydrogen storage performanceStrong selective adsorption performanceOther chemical processesCarbon preparation/purificationArgon atmosphereNitrogen gas

The invention relates to a preparation method and gas adsorption properties of a boron / nitrogen-doped microporous carbon material, particularly a boron / nitrogen-doped microporous carbon material prepared by using metal organic framework ZIF-8 (zeolitic imidazolate framework-8) and boron nitrogen compounds as precursors by a high-temperature sintering method and gas adsorption properties of the boron / nitrogen-doped microporous carbon material for hydrogen, carbon dioxide, nitrogen and the like. The preparation method comprises the following steps: 1) preparing the porous metal organic framework ZIF-8; 2) limiting the boron nitrogen compounds (such as ammonia borane) to the inside of the pores of the metal organic framework ZIF-8 by a solution impregnating method; and 3) carrying out high-temperature sintering on the composite material in an argon atmosphere to obtain the boron / nitrogen-doped microporous carbon material. The preparation technique is simple; and the prepared carbon material implements simultaneous doping of boron and nitrogen and centralized distribution of micropore sizes, and has favorable adsorption property for hydrogen and selective adsorption property for carbon dioxide.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Macroporous and microporous hybrid starch granule and preparation method and application thereof

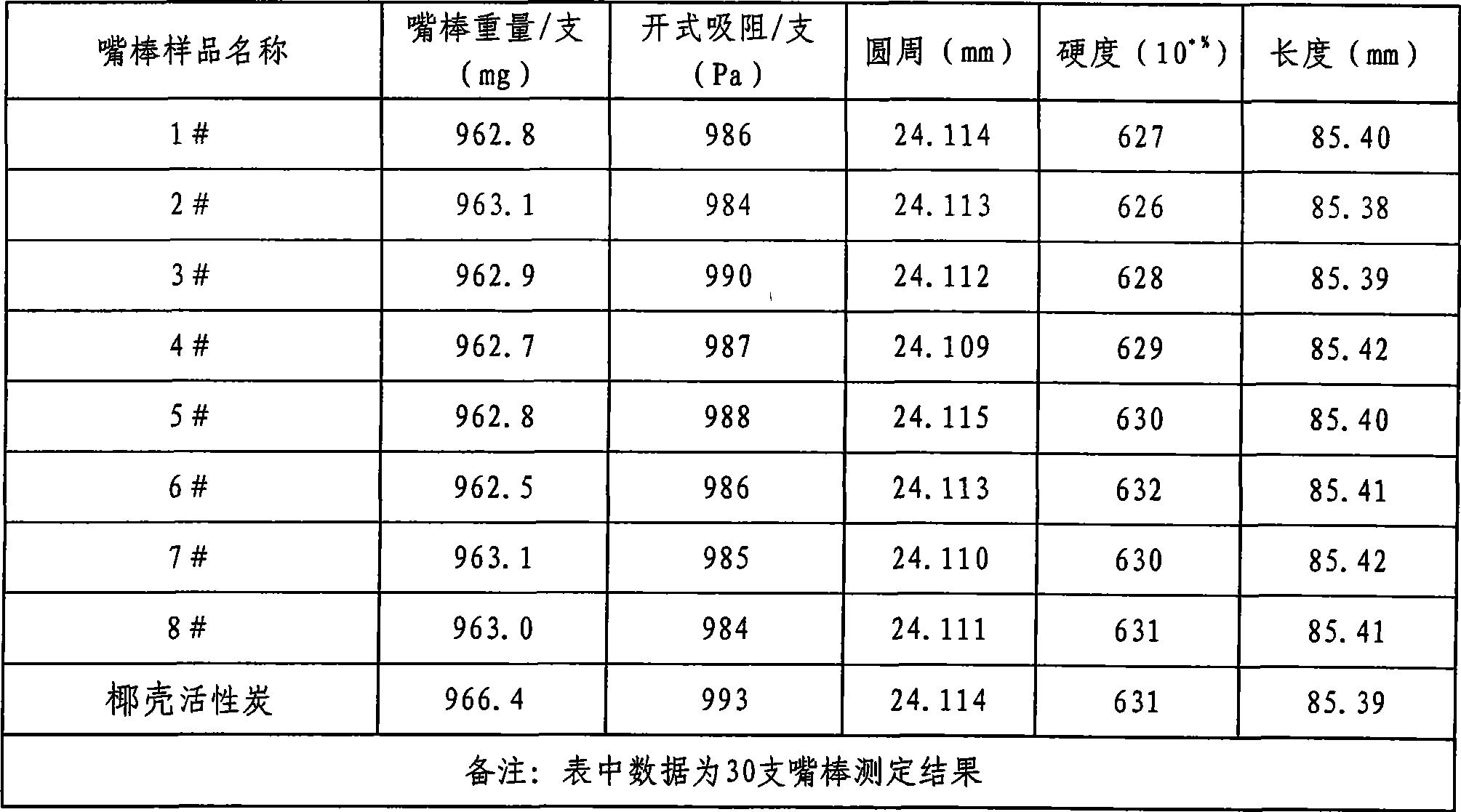

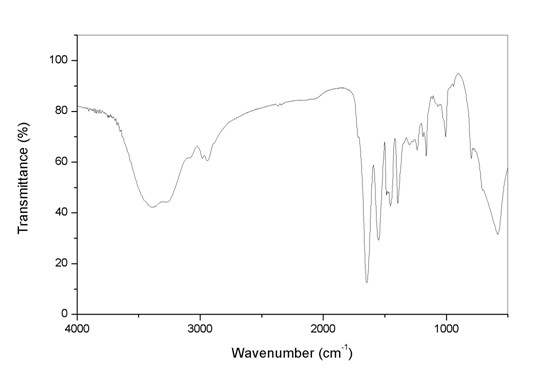

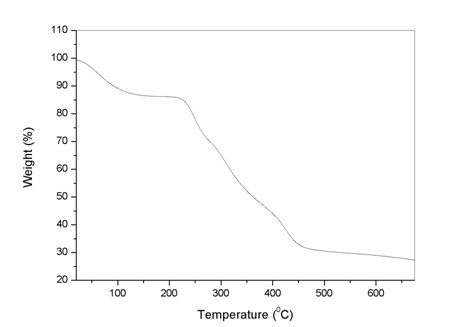

InactiveCN101531779AHigh specific surface areaHigh selective adsorption capacityTobacco smoke filtersPolymer scienceCyclodextrin

The invention discloses a macroporous and microporous hybrid starch granule and a preparation method and an application thereof; wherein, the method comprises the following steps: mixing the macroporous starch with pore diameter ranging from 0.5umm to 1.5umm with microporous starch with pore diameter ranging from 6A degree to 6.5 A degree according to the weight proportion of 0.5-4;1; then wetting, microwave drying, crashing and sifting are carried out on the mixture, thus obtaining the hybrid starch granule; the additive is superior to single modified cornstarch granule (YSQ) or beta- cyclodextrin (HH) in terms of absorption property; dualistic or ternary composite filter prepared by adding the additive to a filter element of a cigarette filter can effectively reduce delivery volume of tar, phenol, hydrocyanic acid and carbon monoxide in smoke gas and improve organoleptic quality of the cigarette, effectively improve sensory comfort of the cigarette, enhance intensity of cigarette aroma, thus enjoying good application prospect.

Owner:YUNNAN RES INST OF TOBACCO SCI

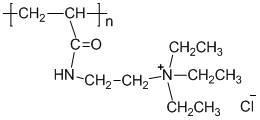

Magnetic microsphere resin for removing nitrate nitrogen selectively, and preparation method thereof

ActiveCN102430433AHigh base exchange capacityAccelerated settlementWater/sewage treatment by ion-exchangeAnion exchangersOil phaseStructural formula

The invention discloses magnetic microsphere resin for removing nitrate nitrogen selectively, and a preparation method thereof, and belongs to the field of ion exchange resin. The resin consists of a resin skeleton, and magnetic granules wrapped in the resin skeleton; and the resin skeleton has a basic structural formula shown in the specification, wherein B is a quaternary ammonium salt group for adsorbing the nitrate nitrogen selectively, the saturation magnetization intensity of the quaternary ammonium salt group is between 5 and 30 emu / g, the exchange capacity of strong base is between 3.0 and 4.5 mmol / g, the exchange capacity of weak base is between 0.5 and 1.5 mmol / g, and the average grain diameter of the resin is between 50 and 500 micrometers. The resin is synthesized by a suspension polymerization method; acrylate monomers are mixed with a pore-forming agent and an initiator to form an oil phase; after being mixed with the magnetic granules uniformly, the mixture is subjectedto suspension polymerization with an aqueous phase mixed with a dispersing agent to form the magnetic polymer granules, and the magnetic polymer granules are subjected to aminolysis and alkylation toform the resin serving as a finished product. The resin can adsorb negative ions such as nitrates, nitrites and the like in a water body selectively, so the magnetic microsphere resin has a bright application prospect in fields of drinking water treatment, groundwater remediation and the advanced treatment of urban domestic sewage.

Owner:NANJING UNIV +1

Method for preparing magnetic powder heavy metal ion blotting chitosan compound adsorbing agent

InactiveCN101301604AThe synthesis process is simpleEasy to separate and recycleOther chemical processesIonMagnetic powder

The present invention provides a preparation of a chitosan compound adsorbent for absorbing magnetic powder heavy metal ion imprint. The chitosan is employed as a imprinting matrix material, the nanometer magnetic powder Fe3O4 is employed as a magnetic component, the epichlorohydrin is employed as a crosslinking agent, the sodium tripolyphosphate is employed as a curing agent, after steps of ion imprinting, magnetic powder embedding and curing and template ion eliminating, the magnetic metal ion imprinting chitosan compound adsorbent is obtained. The compound absorbent prepared by the present invention can be separated from the solution after absorption efficiently and rapidly under the external magnetic field to realize the rapid efficient reclaim of the adsorbent. The compound absorbent has high mechanical strength and selective absorbability of imprint Cr(VI) or Zn (II), avoids the swelling loss of the chitosan in acidity solution and improves the absorption capacity of Cr(VI) or Zn (II). The preparation of the present invention has simple reaction conditions and has no rigorous limit of the experiment conditions. The preparation of the present invention can be used to process the heavy metal waste water containing Cr(VI) or Zn (II), also reclaim Cr(VI) or Zn (II).

Owner:HARBIN ENG UNIV

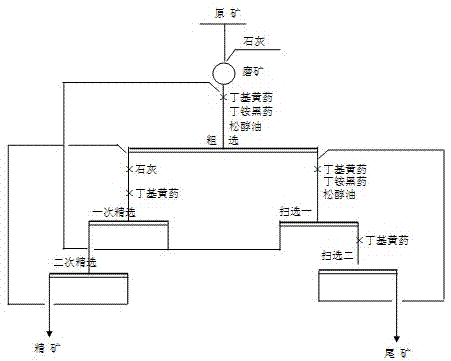

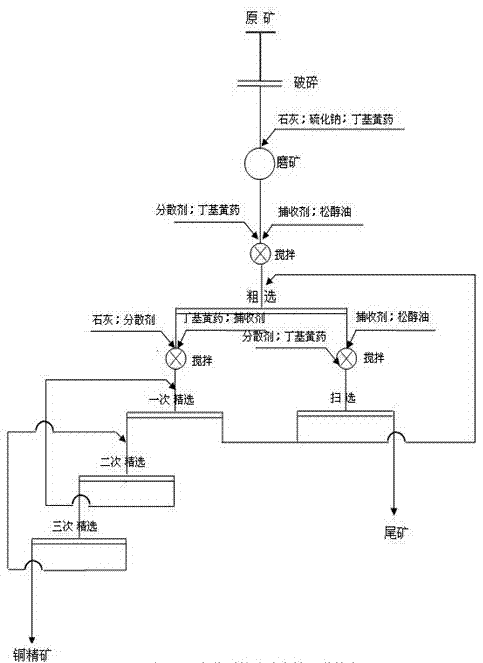

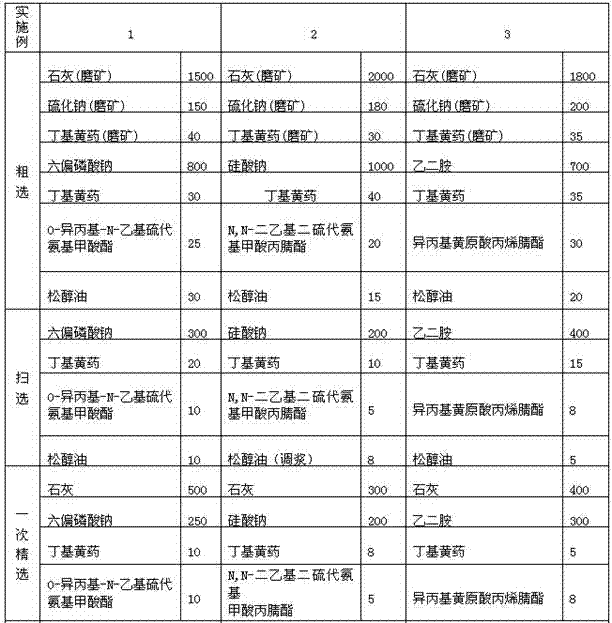

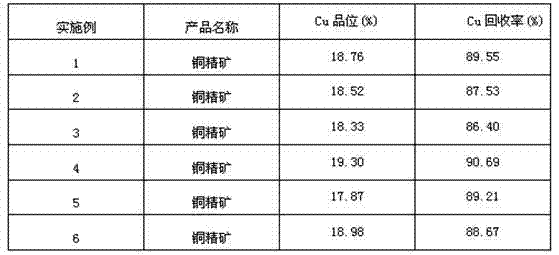

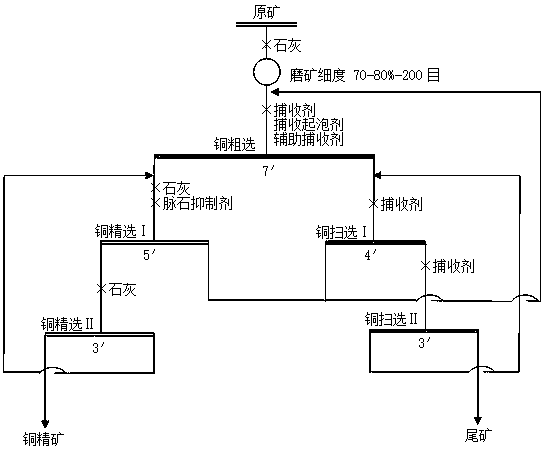

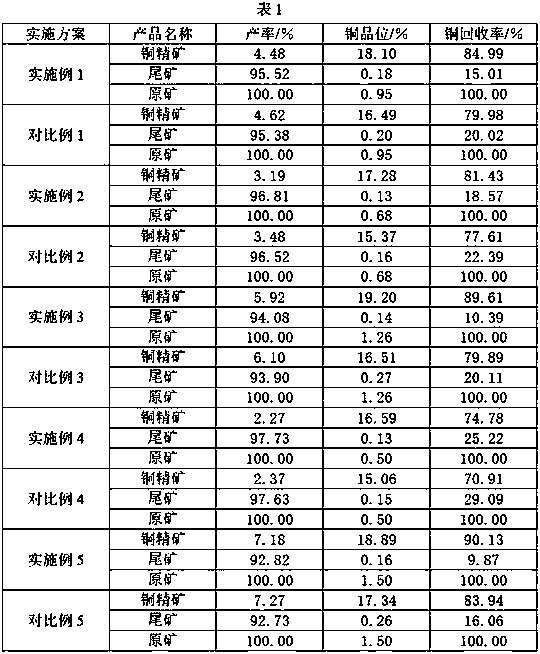

Beneficiation method for copper sulfide ore containing easily-sliming gangue minerals

The invention relates to a beneficiation method for copper sulfide ore containing easily-sliming gangue minerals. According to the method, lime is adopted as pH regulator and pyrite depressant of flotation pulp of the copper sulfide ore containing the easily-sliming gangue minerals; sodium sulfide serves as activator of a small number of copper oxide minerals in the ore; sodium hexametaphosphate, sodium silicate or ethylenediamine serves as gangue slurry dispersant; a combination of butyl xanthate and other collectors serves as a collector of copper sulfide minerals; terpernic oil serves as foaming agent. The ore is subjected to primary grinding, primary roughing, primary scavenging and three-time concentration; the ore pulp is subjected to strong stirring and pulp mixing before starting to be subjected to primary roughing, primary scavenging and primary concentration, so that copper contained in the ore is efficiently recovered. According to the method, through reasonable combination and addition of chemicals, the ore grinding and pulp mixing process is strengthened, the adverse influence of gangue slurry on copper sulfide mineral floatation is eliminated, the surface characteristics of copper sulfide minerals are improved, the preferential adsorption of the collector on the surfaces of the copper sulfide minerals is enhanced, and accordingly, compared with a conventional method, the copper grade and the copper recovery rate of copper concentrate are substantially increased.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

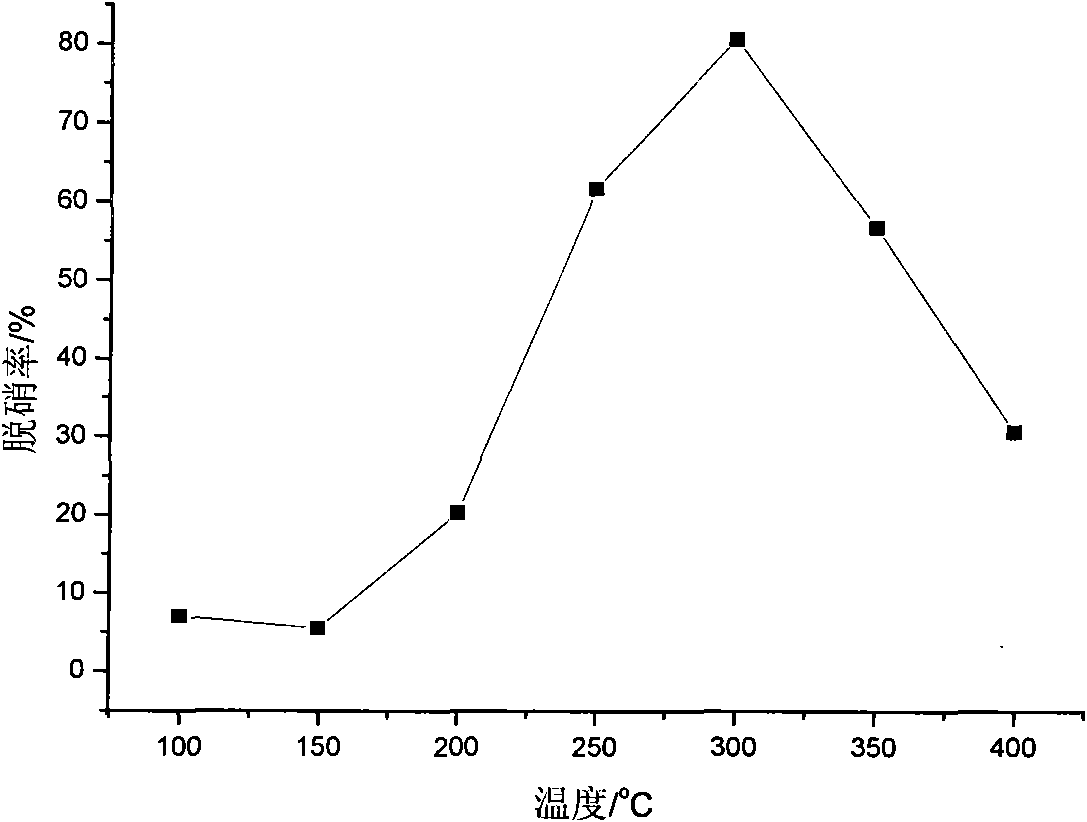

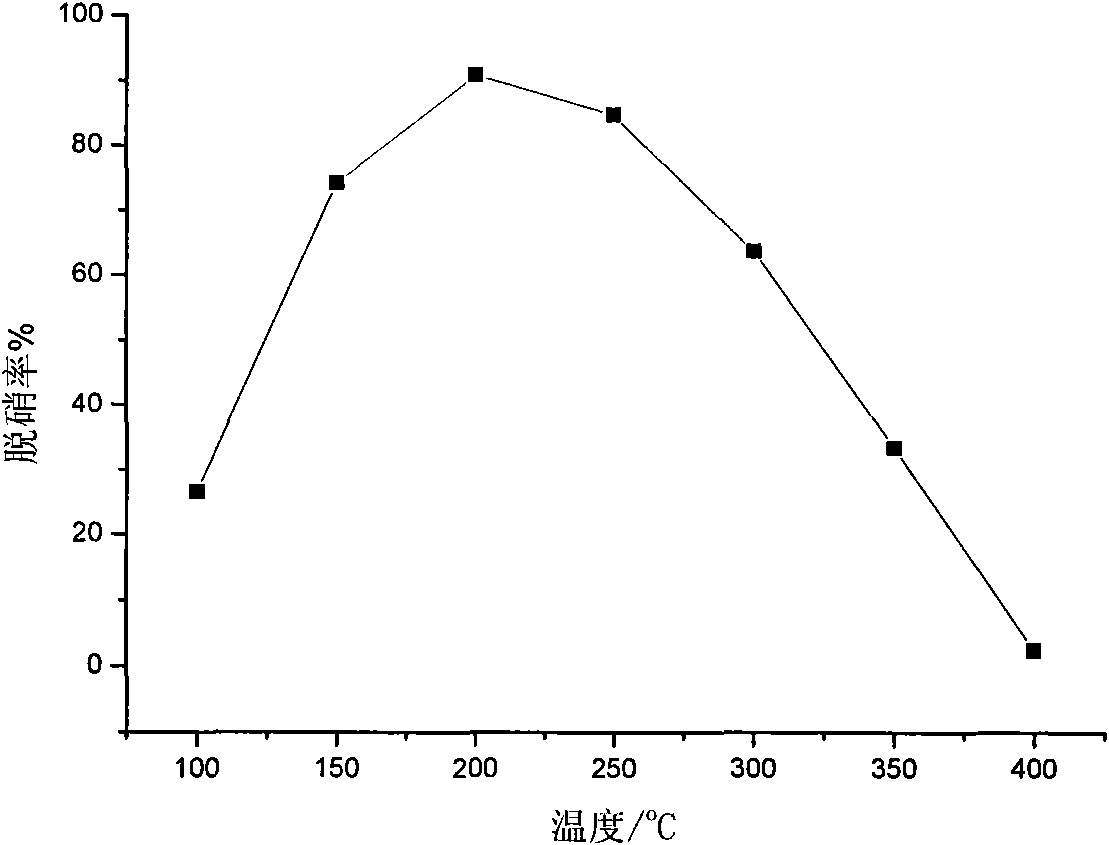

Coal ash and attapulgite compound SCR denitration catalyst and preparation method thereof

InactiveCN102000564AHigh mechanical strengthImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceActive component

The invention discloses a coal ash and attapulgite compound SCR denitration catalyst and a preparation method thereof. Coal ash and attapulgite compound are used as catalyst carriers for carrying the compound material of manganese oxide. The preparation method comprises the following steps: mixing the coal ash with the attapulgite, making the mixture into coal ash and attapulgite compound catalyst carrier by scoring, molding, drying and burning, using the isopyknic immersion method to carry the compound carrier on the catalyst precursor, drying and burning so as to acquire the finished product. In the invention, the coal ash and the attapulgite cheaply obtained are used as the catalyst carriers, so the cost of the catalyst and the environmental loading of the catalyst are reduced, the mouldability and the heat stability are better, and the low-temperature activity of the catalyst is better because of the loading of manganese active component.

Owner:HEFEI UNIV OF TECH

Ozone-assisted method for catalytic decomposition of volatile organic pollutants in high-temperature flue gas

ActiveCN102814108AHighly selective adsorptionHigh selectivityDispersed particle separationCarbon nanotubeCatalytic decomposition

The invention discloses an ozone-assisted method for catalytic decomposition of volatile organic pollutants in high-temperature flue gas. According to the invention, ozone gas is introduced into a fixed bed reactor of a catalytic reaction. According to the catalyst in the fixed bed reactor, carbon nano-tubes, activated carbon, titanium dioxide, silica, or a composition thereof is adopted as a carrier; and Mn2O3, MnO2, CeO2, CuO, Cu2O, V2O5, Fe2O3, FeO, or a composition thereof is adopted as an active component. The active component accounts for 1-50% of total mass of the catalyst. The concentration of the introduced ozone gas is in a range of 0.1-50mg / L. According to the invention, a strong oxidant ozone is introduced in a catalytic decomposition process, such that active oxygen in the system is increased, catalytic decomposition of pollutant molecules is promoted, catalytic decomposition efficiency of the catalyst upon the volatile organic pollutants is substantially improved, and carbon dioxide selectivity is greatly improved. Therefore, an optimal effect of volatile organic pollutant low-temperature catalytic decomposition is achieved.

Owner:ZHEJIANG UNIV

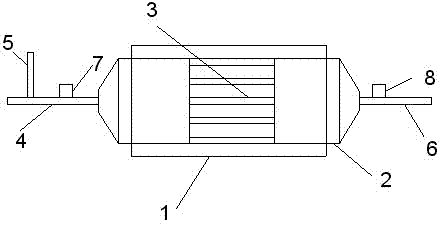

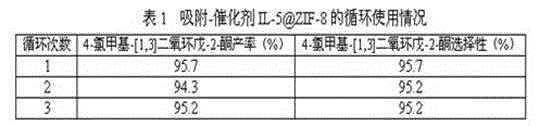

ZIF-8 encapsulated amino ionic liquid type carbon dioxide adsorbing-catalyzing agent

ActiveCN105149002ALarge capacityHigh activityProductsOrganic chemistryMetal-organic frameworkIonic liquid

The invention discloses a ZIF-8 encapsulated amino ionic liquid type carbon dioxide adsorbing-catalyzing agent. The ZIF-8 encapsulated amino ionic liquid type carbon dioxide adsorbing-catalyzing agent is prepared according to the following steps: taking the metal organic framework material ZIF-8 as a carrier; taking the amino-group functionalized ionic liquid 1-(3-aminopropyl)-3-methylimidazole chloride as an active component; immobilizing the amino-group functionalized ionic liquid in the super-cages of the ZIF-8 carrier in an in-situ manner during preparation of ZIF-8, wherein 1.5 to 5 mmol of the amino-group functionalized ionic liquid is immobilized in each gram of the adsorbing-catalyzing agent. The adsorbing-catalyzing agent integrates the functions of selective adsorbing and catalyzing into a whole, and can be used for synchronously adsorbing and converting carbon dioxide, so as to reduce the cost of the CUU technology.

Owner:TAIYUAN UNIV OF TECH

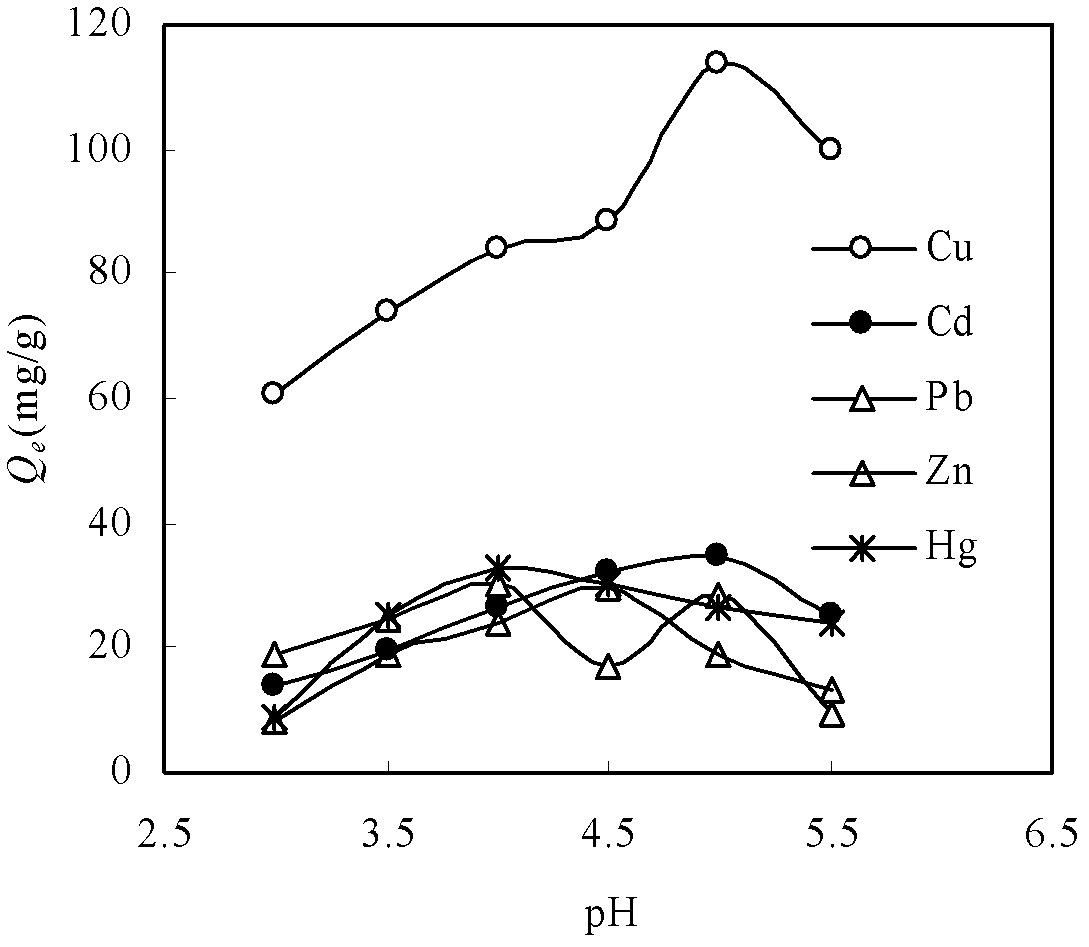

Collagen fiber solidified tannin adsorptive material and its preparation method and its adsorption and separation of metallic ion

InactiveCN1410157AEliminate solubilityEliminate strengthOther chemical processesWater/sewage treatment by sorptionFiberTannin

An adsorbing collagen fibre-solidified tannin material for adsorbing and separating metallic ions (Pb, Cd, Hg, Cr and Cu) is prepared from animal skin through preparing collagen fibre membrane or granules, adding the said collagen fibres along with the aqueous solution of tannin to a reactor, reacting at 10-45 deg.c for 6-24 hr, laying aside for 12-24 hr, filtering, washing to remove excessive tannin, adding cross-linking agent, reacting at 20-70 deg.c for 2-8 hr, filtering, washing and drying at 60 deg.c for 12-24 hr. It has very high adsorption selectivity.

Owner:SICHUAN UNIV

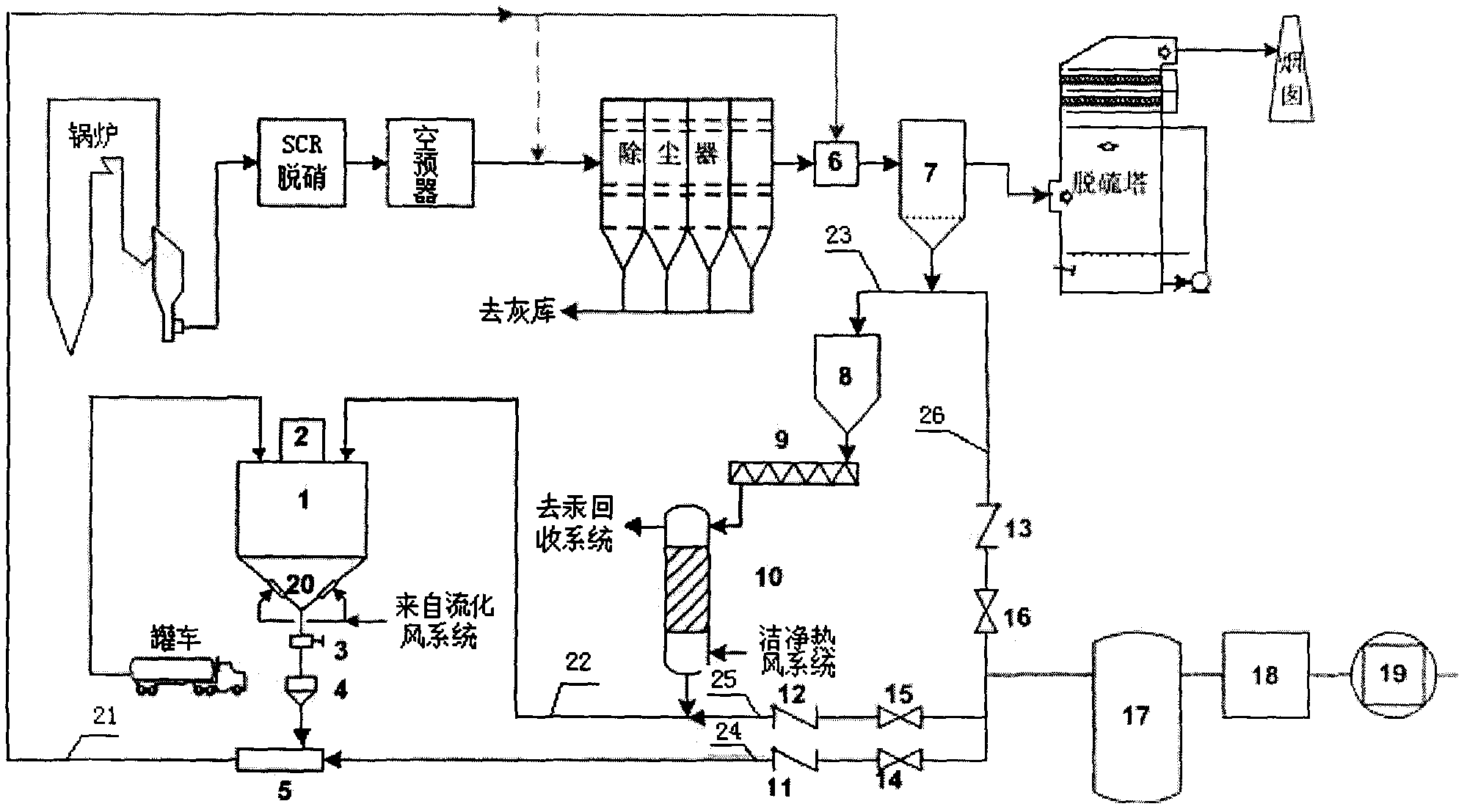

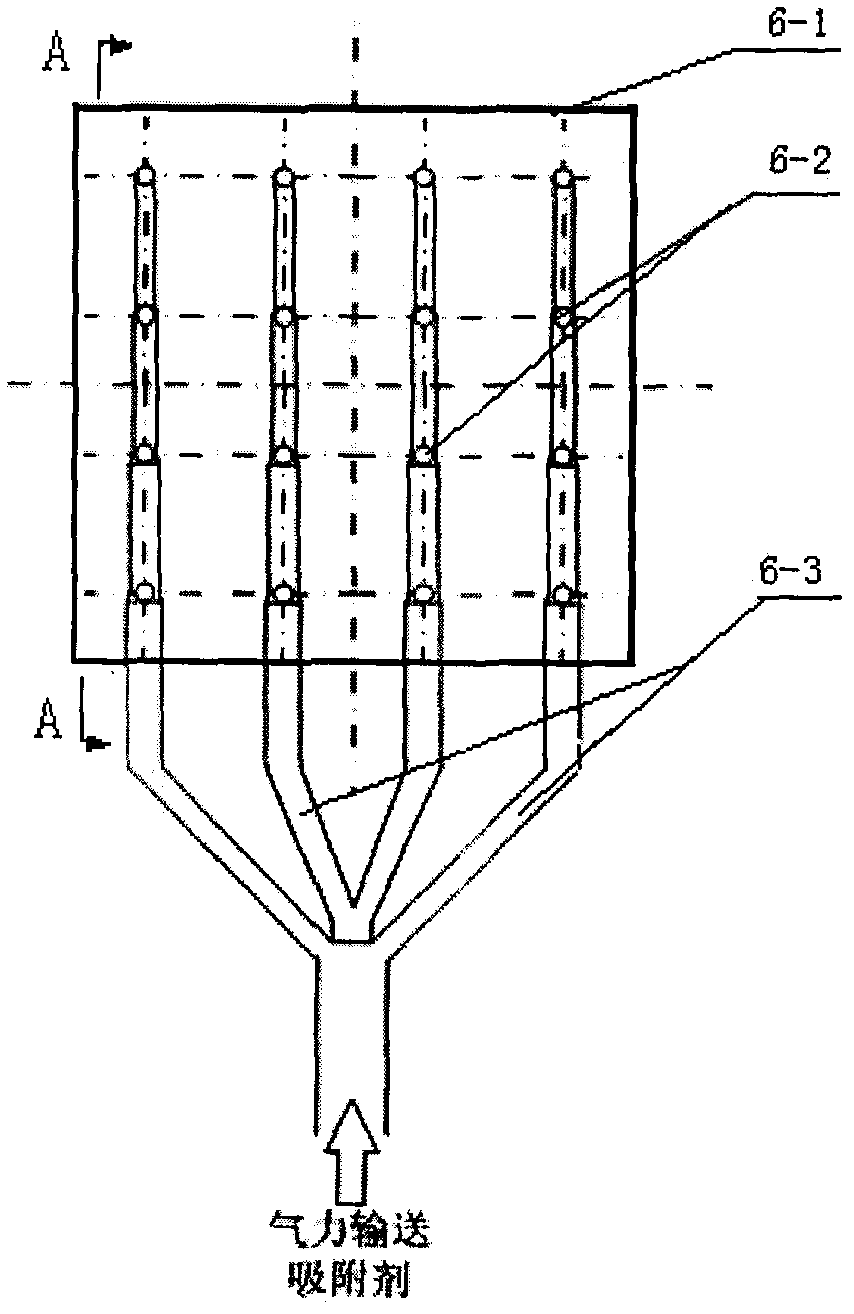

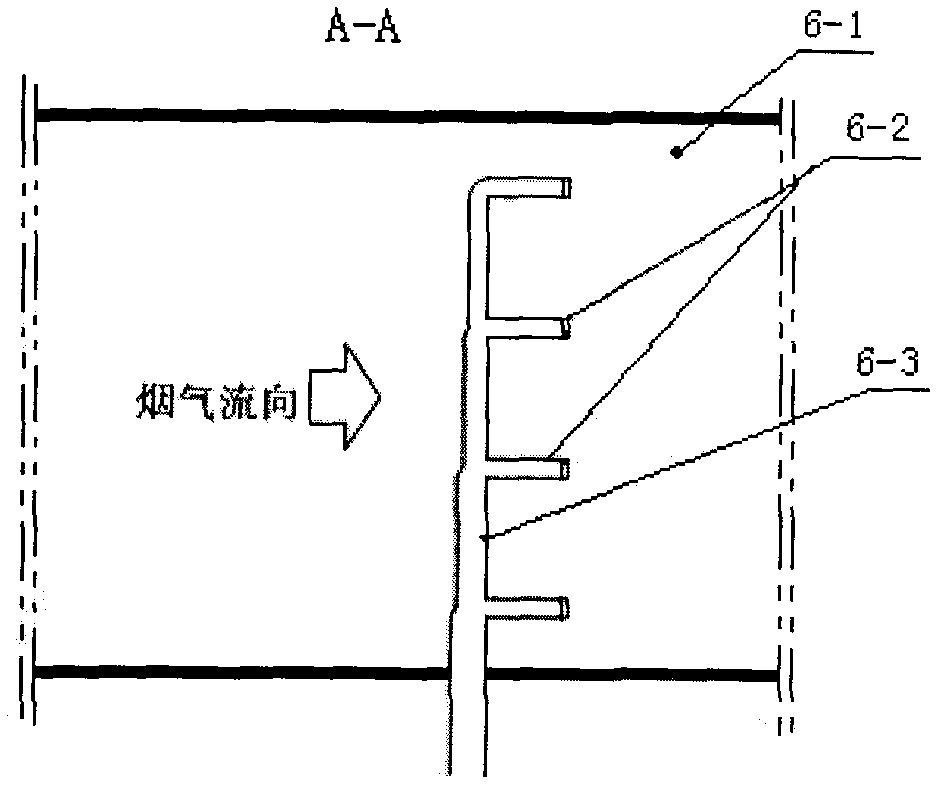

Coal flue gas mercury adsorbing removal process capable of recovering adsorbent and device utilizing same

InactiveCN102489116ARealize automatic controlActivateDispersed particle separationActivated carbonSorbent

The invention relates to a coal flue gas mercury adsorbing removal process capable of recovering adsorbent and a device utilizing the same. The coal flue gas mercury adsorbing removal process includes steps of firstly, delivering powdered activated carbon which serves as adsorbent into a flue gas pipeline between a flue gas dust collector and an inlet of a desulfurizing tower, and spraying the powdered activated carbon by a spray gun so that the powered activated carbon is dispersed in flue gas sufficiently and capable of adsorbing mercury in the flue gas; secondarily, filling the flue gas mixed with the activated carbon into a cloth bag type filter so as to realize gas and solid separation; and thirdly, delivering and recovering the activated carbon after the activated carbon is regenerated. When gas and solid separation is realized in the second step, flue gas without mercury enters the next desulfurizing process through the cloth bag type filter, the activated carbon retained by the cloth bag type filter is captured, desorbed and regenerated at the temperature ranging from 130 DEG C to 800 DEG C under protection of nitrogen gas, and mercury gas is released and then sent to a recovery system. The coal flue gas mercury adsorbing removal process capable of recovering the adsorbent and the device utilizing the same have the advantages that mercury removal efficiency is high, usage of the adsorbent is low, and the adsorbent can be recovered so that cost is reduced; further, since the adsorbent is separated from fly ash, the subsequent use value of fly ash is ensured, while recovery of mercury source is realized.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

Active carbon used for adsorbing and removing sulfides in gasoline, and preparation method thereof

ActiveCN102188954AHighly selective adsorptionLow ashOther chemical processesHydrocarbon oils refiningHydration reactionAdhesive

The invention relates to active carbon used for absorbing and removing sulfides in gasoline, and a preparation method thereof. The active carbon is composed of the following components in percentage by weight: 40-70% of petroleum coke, 10-50% of coal, 10-30% of adhesive, 0.1-10% of pore forming agent and 0.1-10% of amodifier, wherein the ash content of the petroleum coke is less than 1%; the coalis anthracite or bituminous coal with volatile content less than 35%; the adhesive is one of or the mixture of coal pitch, coal tar, vacuum residue, coked condensed oil, ethylene cracked residue, catalytic slurry, petroleum pitch and petroleum pitch oxide; the pore forming agent is one of or the mixture of carbon black containing active functional groups and active elements, furfural residue, ferrocene, furfuryl alcohol and potassium; and the modifier is a hydrate nitrate of Cr, Fe, Co, Ni, Mo, Ti, Cu or Zn. The active carbon has the characteristics of low ash content, high strength, high selectivity, excellent adsorption performance and the like.

Owner:PETROCHINA CO LTD

Burn-free coal-ash-based geological polymer high performance adsorbing material preparation method

InactiveCN106362680AHigh specific surface areaHigh selective adsorptionOther chemical processesAluminium silicatesPhenolEnergy conservation

The invention provides a burn-free coal-ash-based geological polymer high performance adsorbing material preparation method which comprises the following steps: a, preprocessing a solid raw material; b, preparing a base material, wherein solid waste coal ash containing rich aluminosilicate is utilized as the solid raw material, an alkali activator is utilized as a liquid raw material, and the solid raw material and the liquid raw material are evenly mixed to react at a temperature of 20 to 100 DEG C to form a base; c, forming a base material, i.e., forming the evenly-mixed solid and liquid raw materials into a base sample through granulation molding or casting molding or extrusion molding; d, maintaining the base sample; e, washing and drying. The method can save energy, is simple in preparation technology, can reduce production cost, can be used to produce a high performance geological polymer adsorbing material in a large scale, and the waste coal ash of coal-fired power plants is utilized as a raw material to prepare the adsorbing material at a room temperature; thus, the problem of coal ash stack and waste and the environmental problems caused by the coal ash stack and waste are solved, and industrial organic waste gas and waste water containing phenol can be treated in a mode of using waste to treat waste.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN

Porous solid supported ionic liquid for adsorption of HCl gas

InactiveCN107651651AHigh adsorption rateHigh purityChlorine/hydrogen-chloride purificationGas treatmentPhosphoniumCarbon nanotube

The invention disclosed a porous solid supported ionic liquid and application thereof in adsorption of HCl gas, the porous solid supported ionic liquid comprises a porous solid support and an ionic liquid supported on the support, the porous solid support is activated carbon, mesoporous carbon, carbon nanotubes, silicon oxide, aluminum oxide, titanium oxide, a molecular sieve, a metal organic framework compound or a covalent organic framework compound; the ionic liquids is imidazole, pyridine, quaternary phosphonium and pyrrolidinium ionic liquid, the Ionic liquid loading amount is 1 to 50% based on the mass of the porous solid support. The porous solid supported ionic liquid can be used for adsorbing of the HCl gas, and is used in typical occasions for adsorbing of the HCl gas in industrial exhaust gas of vinyl chloride synthesis by HCl / C2H2 mixed gas and ethyne hydrochlorination for enriching or separating recovering of the HCl. The adsorption rate of the HCl is up to 99.97%, and thepurity of HCl thus obtained is high, up to 99.999%.

Owner:ZHEJIANG UNIV OF TECH

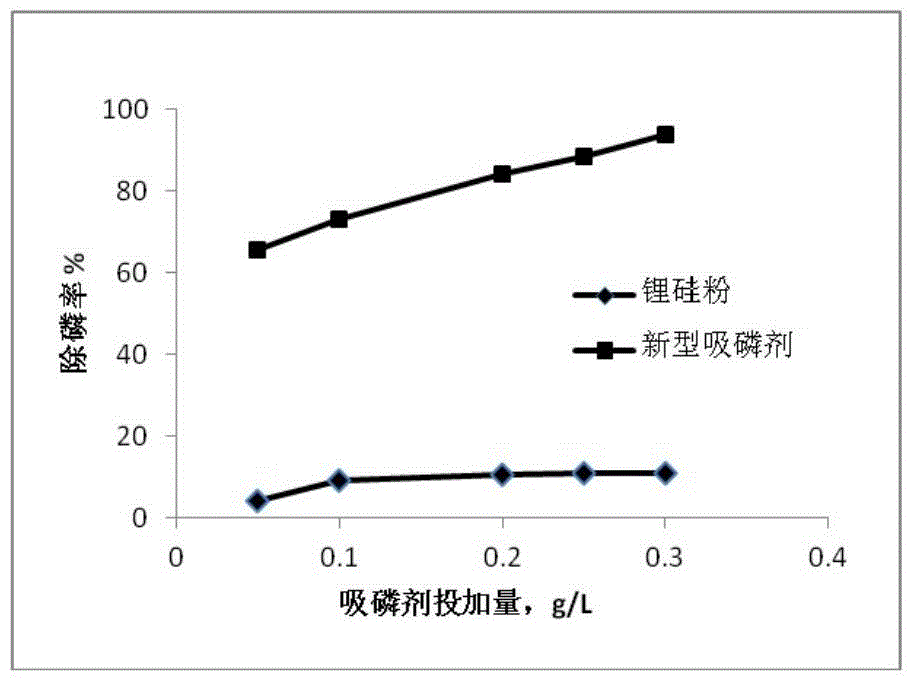

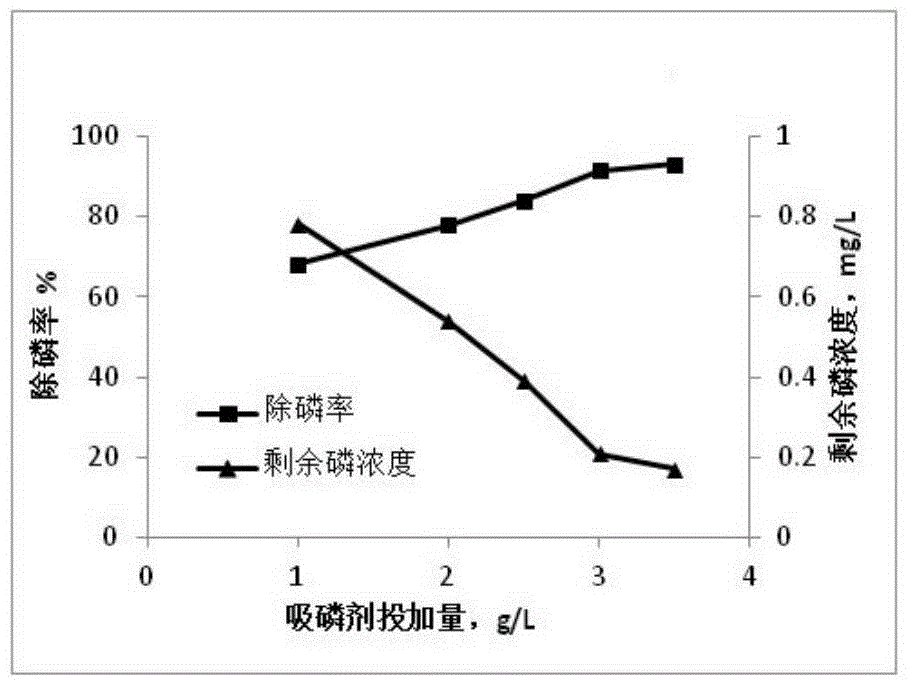

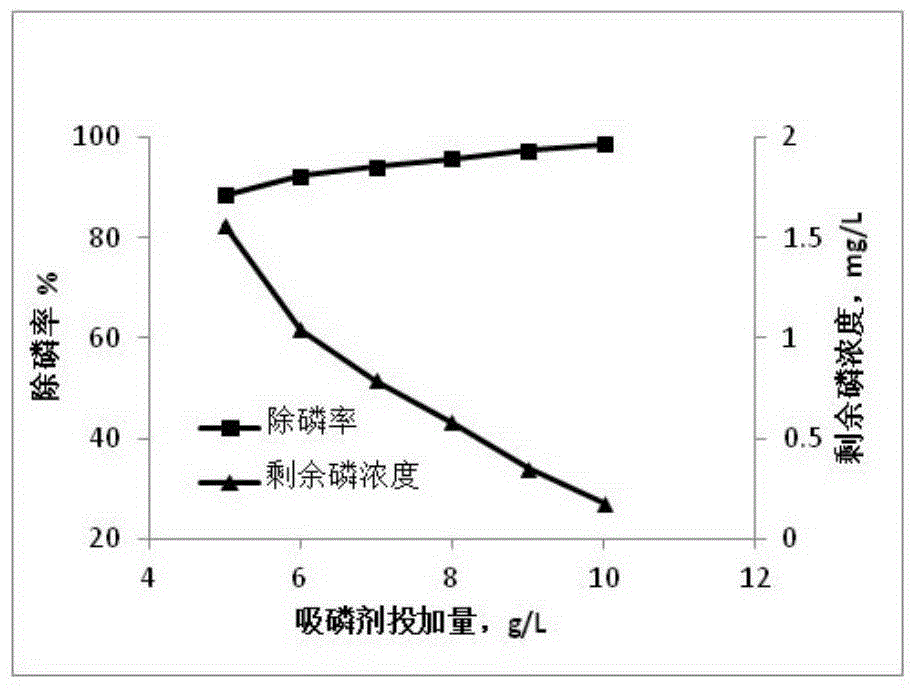

Absorbent used in sewage phosphorus removal, and preparation method thereof

InactiveCN104525090AWell-developed pore structureObvious pleatsOther chemical processesWater contaminantsAbsorption capacitySlag

The invention discloses an absorbent used in sewage phosphorus removal. A carrier of the absorbent is industrial lithium-silicon powder waste slag with a size no lower than 150 meshes. Lanthanum ions are loaded on the carrier. With the absorbent, the removal rate upon phosphorus in phosphorus-containing sewage and wastewater or natural water body with a total phosphorus concentration of 1mg / L and a pH value of 3-8 is always higher than 86%. The invention also discloses a preparation method of the absorbent. According to the invention, the carrier raw material lithium-silicon powder adopted by the absorbent is selected from industrial waste slag, such that the source is wide, and cost is low. With a developed pore structure, the carrier can provide sufficient active absorption points. Only trace of rare earth lanthanum used for modification is needed to be added. The obtained absorbent has excellent phosphorus absorption effects in natural water bodies, sewage and wastewater. With the absorbent, an absorption capacity is high, absorbent stability in water body is high, no water body secondary pollution is caused, and cost is low. The absorbent has a good application prospect.

Owner:SICHUAN UNIV

Metal ion imprinted hydrogel adsorbing material with interpenetrating polymer network (IPN) structure and preparation method for metal ion imprinted hydrogel adsorbing material

ActiveCN102824899AImprove mechanical propertiesImprove adsorption capacityOther chemical processesCross-linkUltraviolet

The invention discloses a metal ion imprinted hydrogel adsorbing material with an interpenetrating polymer network (IPN) structure and a preparation method for the metal ion imprinted hydrogel adsorbing material. The material is obtained by the following steps of: evenly mixing a component group (1), a component group (2) and metal salt (3) to obtain a mixture; then, performing one-step ultraviolet-induced polymerization on the mixture; and then, removing template ions, wherein the component group (1) comprises an acrylic monomer, an acrylic cross-linking agent and a radical initiator, and the component group (2) comprises a vinethene cross-linking agent and a cationic initiator. The metal ion imprinted hydrogel adsorbing material is excellent in mechanical property, higher in adsorption capacity and stronger in selective adsorptivity. The preparation method for the metal ion imprinted hydrogel adsorbing material comprises the following steps of: dissolving the acrylic monomer, the acrylic cross-linking agent, the radical initiator, the vinethene cross-linking agent, the cationic initiator and the metal salt in a solvent and evenly mixing; then, injecting into a mold; curing for 5 minutes to 1 hour through one-step ultraviolet irradiation; extracting an obtained in a hydrochloric acid solution; and removing the template ions to obtain the metal ion imprinted hydrogel adsorbing material.

Owner:苏州博睿特环保科技有限公司

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190AStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberAdhesive

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

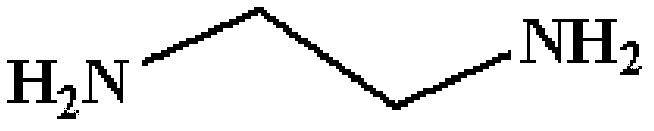

Production method of crosslinked chitosan microsphere heavy metal ion adsorbent

InactiveCN102614838AWide variety of sourcesLow priceOther chemical processesCrosslinked chitosanEthylene diamine

The invention discloses a production method of a crosslinked chitosan microsphere heavy metal ion adsorbent. The method comprises the following steps of: (1) protecting amino on chitosan C2 with formaldehyde by taking chitosan as a material and taking liquid paraffin as an organic dispersion medium, and preparing a crosslinked chitosan microsphere with a reversed phase suspension crosslinking method; and (2) chemically grafting the crosslinked chitosan microspheres by taking the crosslinked chitosan microsphere as a parent body and taking ethylene diamine as a ligand to obtain the crosslinked chitosan microsphere heavy metal ion adsorbent. The crosslinked chitosan microsphere heavy metal ion adsorbent produced with the method has high selective adsorption on Cu<2+> ions.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Thallium-containing wastewater strongly oxidizing, coagulating, adsorbing and recovering process

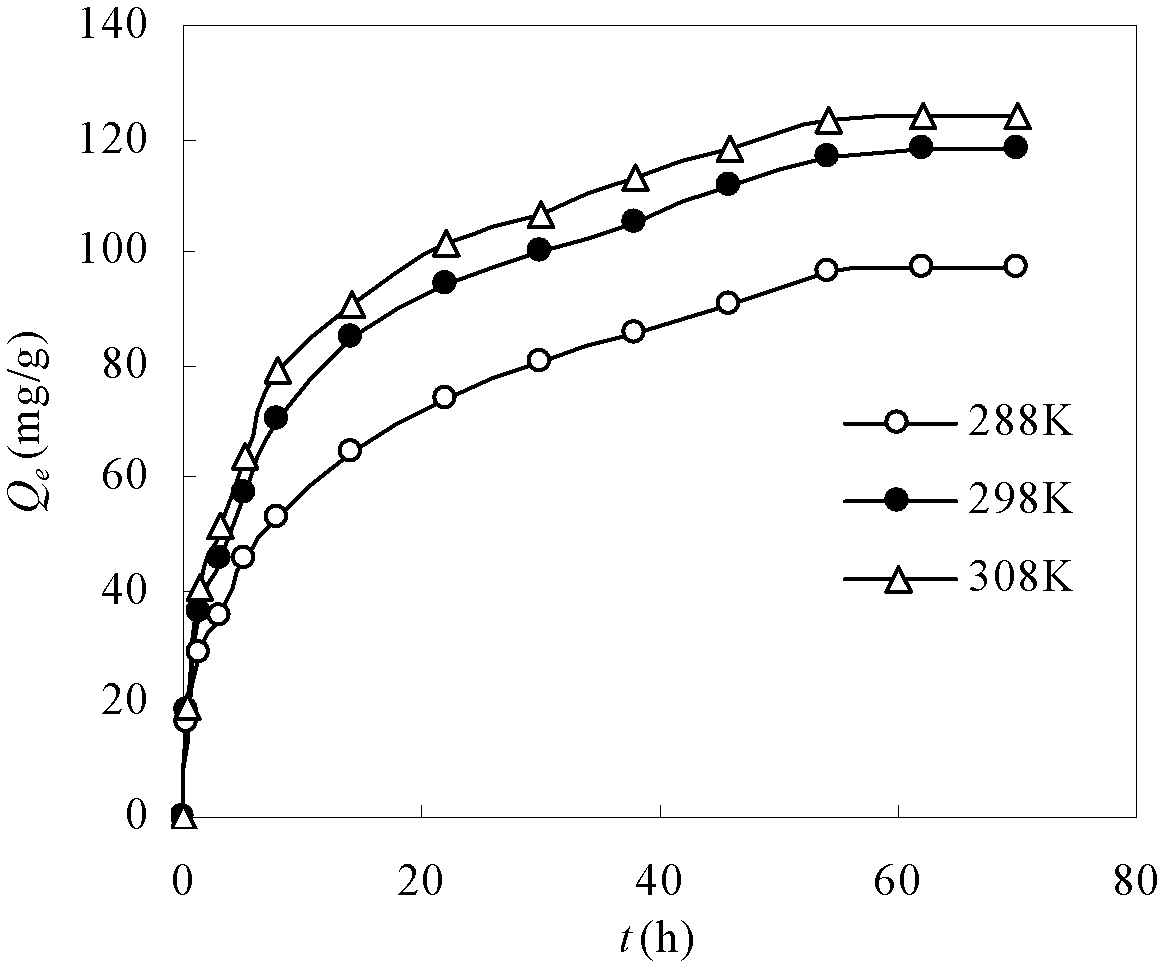

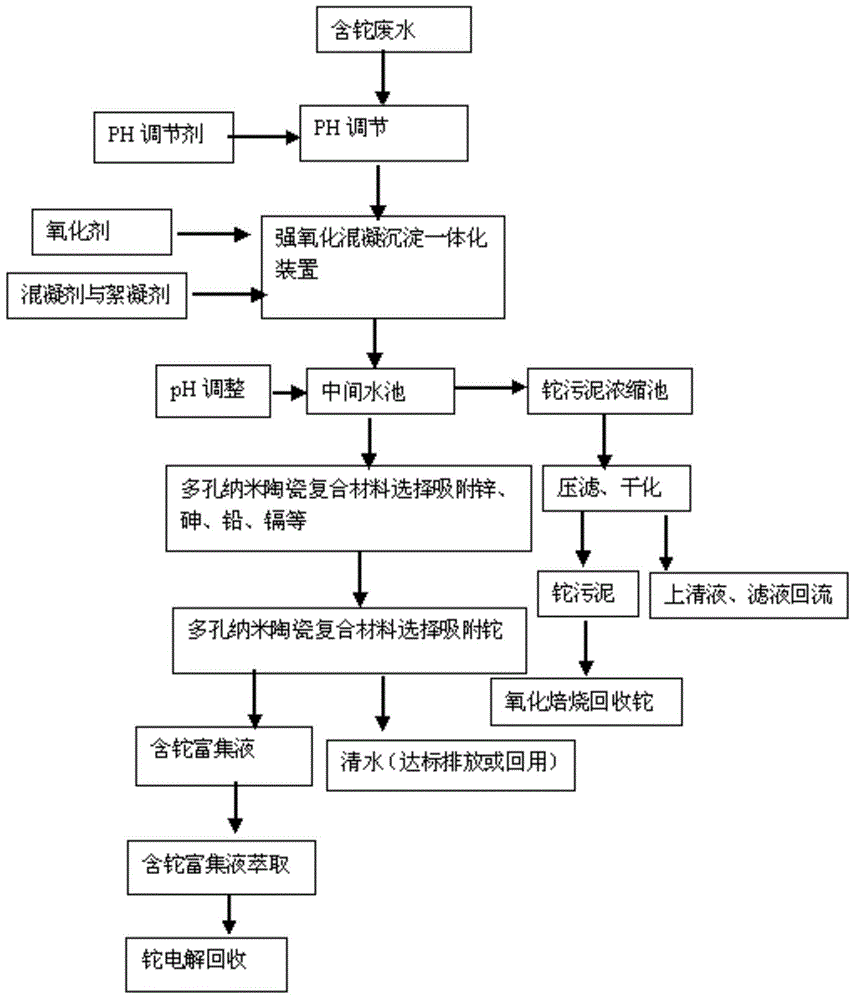

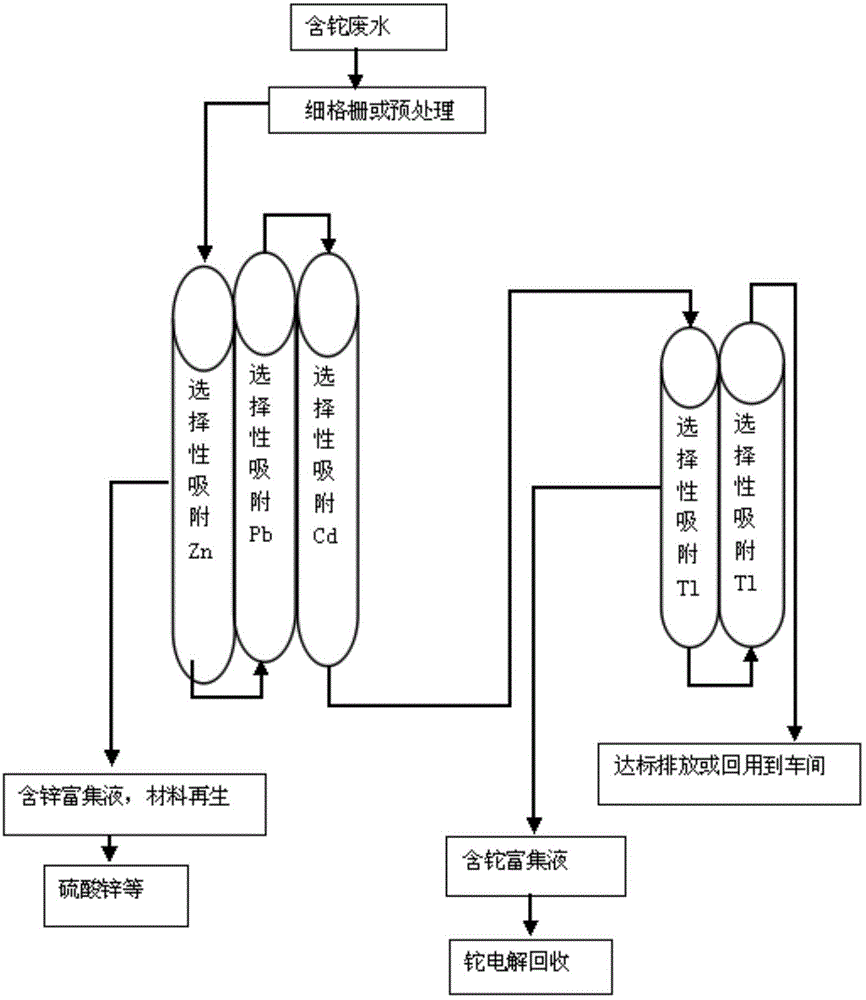

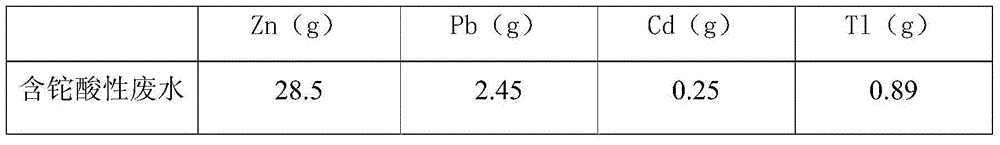

ActiveCN104310672AHighly selective adsorptionLarge specific surface areaWater treatment parameter controlSludge treatmentFiltrationSludge

The invention provides a thallium-containing wastewater strongly oxidizing, coagulating, adsorbing and recovering process. The process includes the following procedures: thallium-containing wastewater concentration, pH regulation, strong oxidization, coagulation, flocculation, precipitated sludge treatment, pH regulation, solid impurity filtration, removal of Zn, Pb, Cd and Tl, and the like. The process has the beneficial effects that the process has the advantages of advanced technology, maturity, good effluent quality, stability in operation, conciseness in process, strong practicability, easiness in start and stop, convenience in maintenance and management, small investment, low operating cost, small floor area for construction, short construction period and large application ranges of projects; treatment of heavy metal ion polluted sewage is not limited by temperatures; the limitation that a biological method can not be used in cold regions in the north can be overcome.

Owner:HUNAN JINGYUAN ENVIRONMENTAL ENG

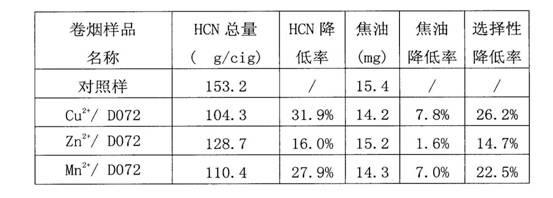

Metal complexing material and preparation method thereof, and application of metal complexing material to cigarettes

The invention relates to a metal complexing material and a preparation method thereof, and application of the metal complexing material to cigarettes. The invention is characterized in that: the complexing material is obtained by complexing a porous carrier with large specific surface area, such as ion exchange resin, ion exchange fibers, macroporous adsorption resin and the like, and different metal ions, and is applied to the cigarettes in a form of a binary composite filter stick; 10 to 40mg of complexing material is added into each cigarette, so that hydrogen cyanide (HCN) in mainstream smoke can be selectively reduced by over 25 percent; meanwhile, the complexing material does not have negative effects on the sensory quality of the cigarettes. The porous carrier in the material has large specific surface area, so smoke can be effectively contacted with the functional group of the material when passing through the material; meanwhile, the metal ions on the surface can be subjectedto complexing reaction with the HCN, so that the HCN in the smoke of the cigarettes is selectively removed.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Magnetic adsorbent for removing heavy metal in water and method for preparing magnetic adsorbent

InactiveCN105664884AHigh mechanical strengthImprove physical and chemical propertiesOther chemical processesWater contaminantsPolyvinyl alcoholSorbent

The invention relates to the technical field of water treatment, and specifically discloses a magnetic adsorbent for removing heavy metals in water and a preparation method thereof. The adsorbent is prepared by sequentially modifying magnetic chitosan-polyvinyl alcohol microspheres through glutaraldehyde cross-linking modification and carbon disulfide modification; wherein the magnetic chitosan-polyvinyl alcohol microspheres are made of chitosan, polyvinyl alcohol Vinyl alcohol and nano-magnetic iron are prepared as raw materials; the mass ratio of chitosan, polyvinyl alcohol and nano-magnetic iron is 1:1:1. The present invention makes the adsorbent magnetic by adding nano-magnetic iron, and uses glutaraldehyde and carbon disulfide to modify the magnetic chitosan-polyvinyl alcohol microspheres to enhance the mechanical strength of the adsorbent and the adsorption effect on heavy metal ions, so that The prepared adsorbent has the characteristics of large adsorption capacity, high removal rate of various heavy metal ions, magnetic separation under an external magnetic field, and renewable recycling, and can be used to remove heavy metals in domestic sewage, industrial wastewater and natural water.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

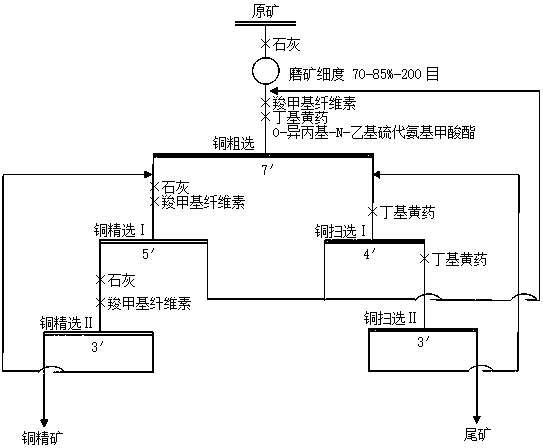

Gangue inhibitor and beneficiation method of copper sulfide ore containing easily floated gangue minerals

The invention discloses a gangue inhibitor and a beneficiation method of copper sulphide ore containing easily floated gangue minerals, belongs to the technical field of flotation, and solves the problem that gangue minerals have very adverse effects on flotation of copper sulphide ore. The gangue inhibitor comprises sodium polyacrylate, carboxymethyl cellulose, Arabic gum, sodium silicate, sodiumtripolyphosphate, anhydrous sodium sulfite, sodium lignosulfonate and anhydrous zinc sulfate. The method comprises the following steps: adding lime for ore grinding, and adding water for size mixing;sequentially adding a collecting foaming agent, an auxiliary collecting agent and a collecting agent into obtained ore pulp for roughing; adding a collecting agent into obtained roughing tailings, and scavenging for the first time; adding a collecting agent into the scavenging tailings, and carrying out secondary scavenging; sequentially adding pH regulator lime and the gangue inhibitor into an obtained roughing concentrate, and carrying out primary concentration; and adding pH regulator lime into an obtained primary concentration concentrate for secondary concentration. The gangue inhibitoris capable of reducing the floatability of gangue minerals greatly; the method is capable of improving the copper grade and the copper recovery rate of rough concentrate.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

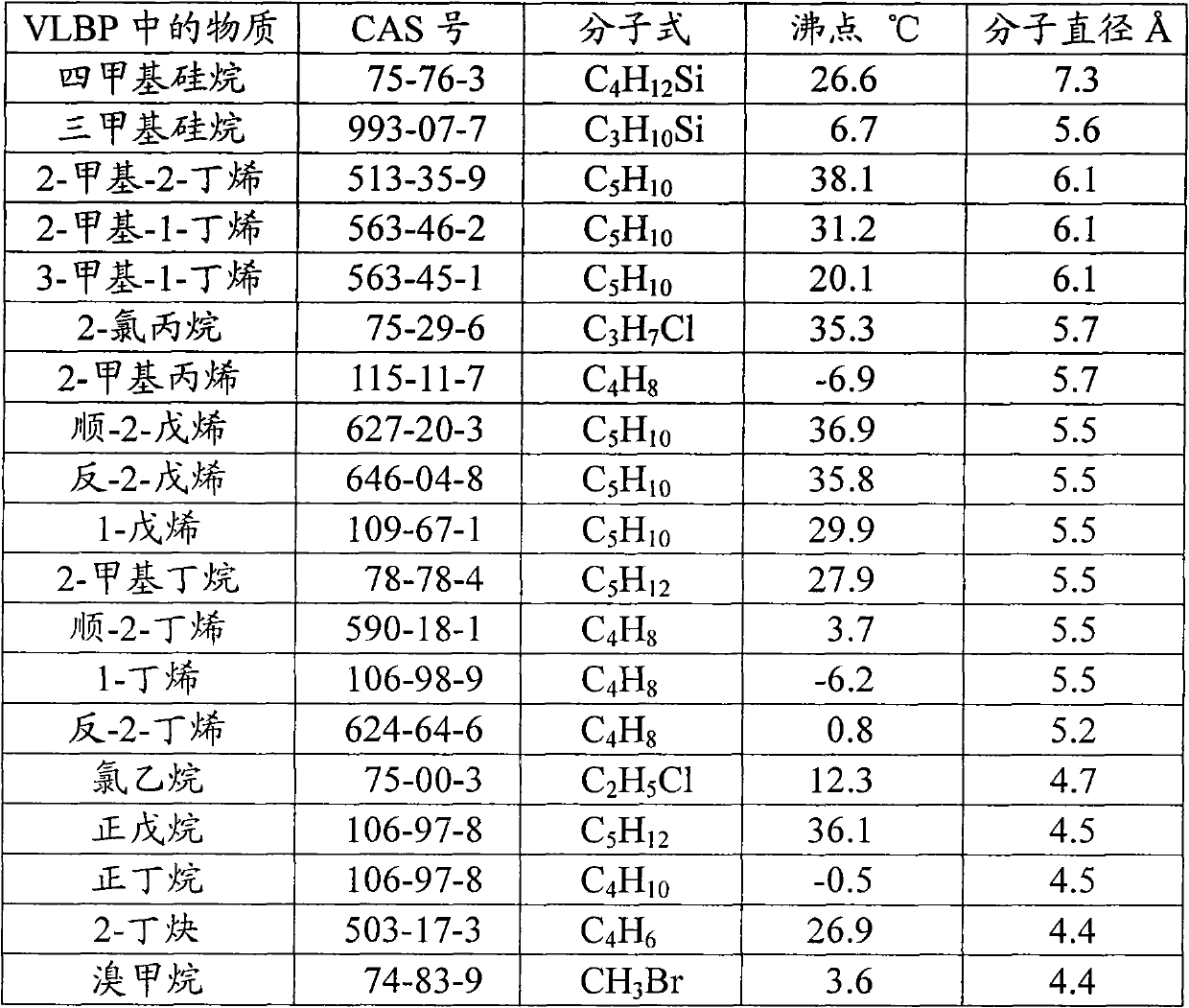

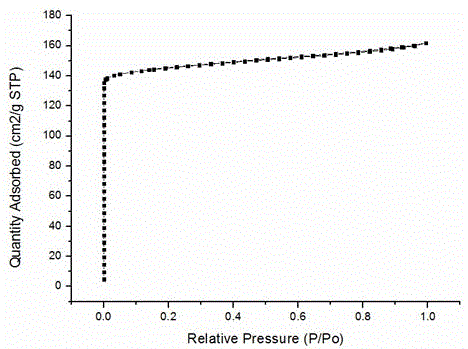

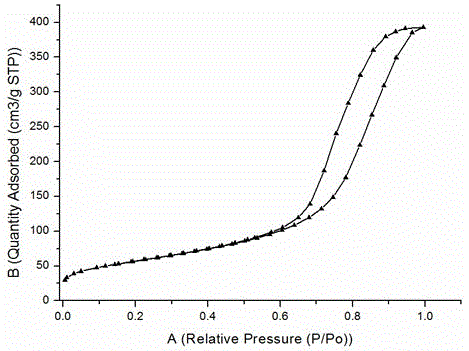

Process for purifying tetramethylsilane

ActiveCN101955496ALow costHighly selective adsorptionSilicon organic compoundsDispersed particle separationMolecular sieveAlkane

The invention discloses a process for purifying tetramethylsilane, which comprises the following steps of: (1) pretreating fractions of a low-boiling-point substance after synthesizing methyl chlorosilane by a direct method and separating to remove a compound containing a Si-Cl bond; and (2) adsorbing impurities in separated fractions in the step (1) by using a molecular sieve and purifying to obtain the tetramethylsilane, wherein the channel diameter of the molecular sieve is 4.5 to 7.2 angstroms. The impurities in the fractions of the low-boiling-point substance are adsorbed by the molecular sieve; the molecular sieve has good selective adsorption effect on alkane, olefin, chloroalkane and trimethylsilane in the fractions of the low-boiling-point substance; the tetramethylsilane can be purified to have high purity and other impurities are not introduced; in addition, the molecular sieve can be reused after being activated and has low cost.

Owner:JIAXING UNITED CHEM +1

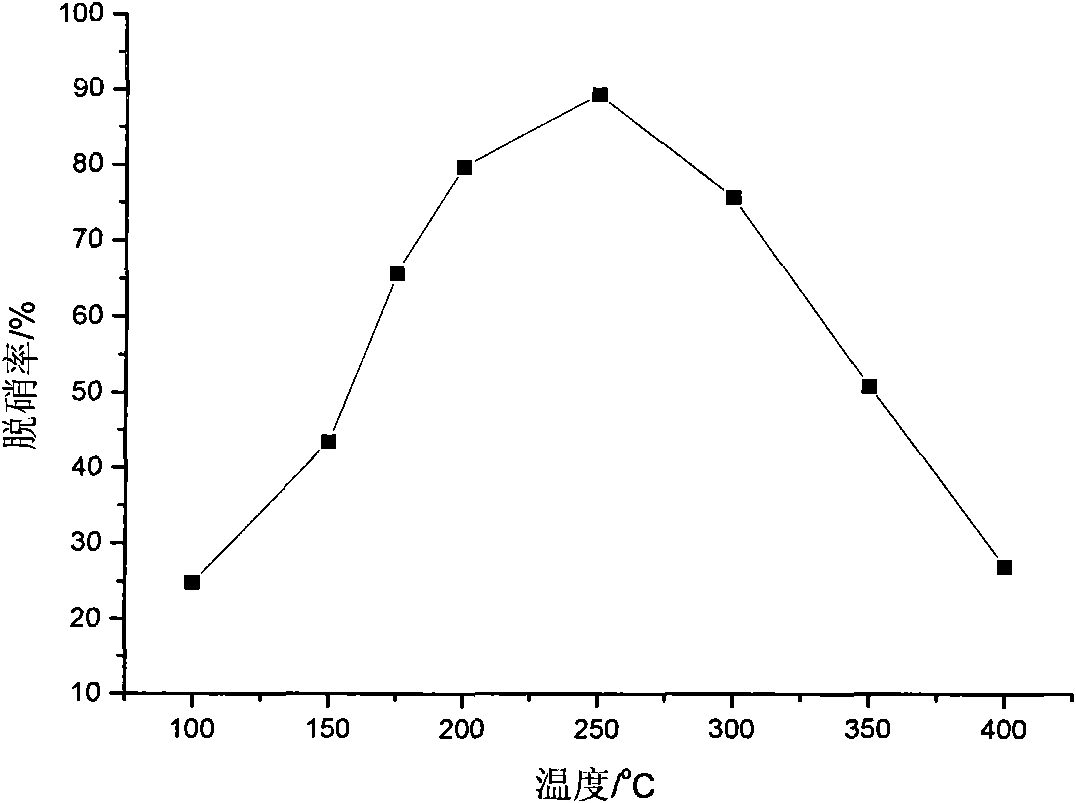

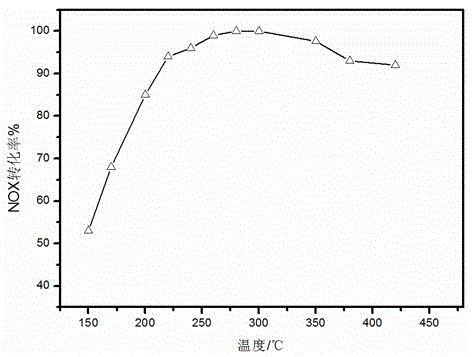

Ion exchange/impregnation continuous preparation Fe-based molecular sieve SCR catalyst

InactiveCN105413737AImprove production efficiencyImprove conversion efficiencyMolecular sieve catalystsMolecular sieveActive component

The invention relates to an ion exchange / impregnation continuous preparation Fe-based molecular sieve SCR catalyst. The ion exchange / impregnation continuous preparation Fe-based molecular sieve SCR catalyst is characterized in that a specific preparation method of the catalyst comprises the following specific steps: dissolving a compound containing ferric salt in dissolved water and preparing into a metal salt solution with a certain concentration; adding a dispersing agent; adding a molecular sieve material in the solution, adding a co-catalyst metal compound material to form a solution, and increasing the solid content of an ion exchange solution to form an excessive impregnation state; heating and concentrating under the state of high-speed stirring, dehydrating and drying an aged catalyst raw material, grinding into a certain grain size, and calcining at high temperature to obtain the Fe-based molecular sieve SCR catalyst without NOx. The ion exchange-impregnation combined method is adopted, and an active component guiding-in agent and a dispersing agent are added so that the metal active components Fe are uniformly distributed in molecular sieve holes and surfaces of the molecular sieve holes; and moreover, during calcination of an iron compound, Fe has abundant valence states, and NOx conversion efficiency is high.

Owner:CHINA FIRST AUTOMOBILE

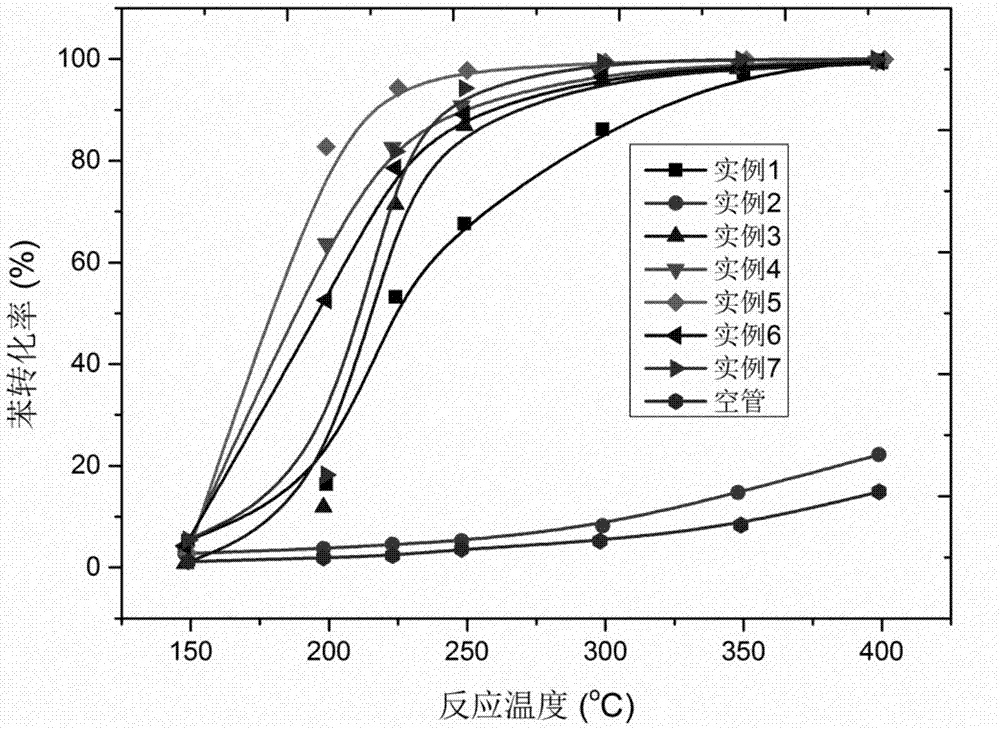

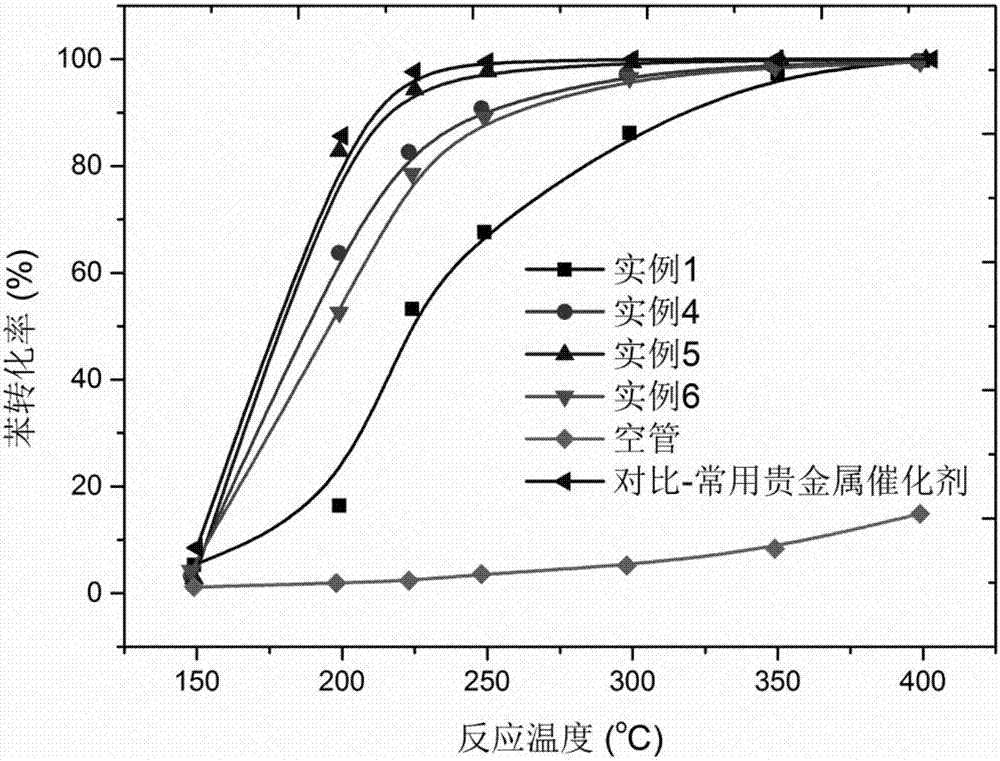

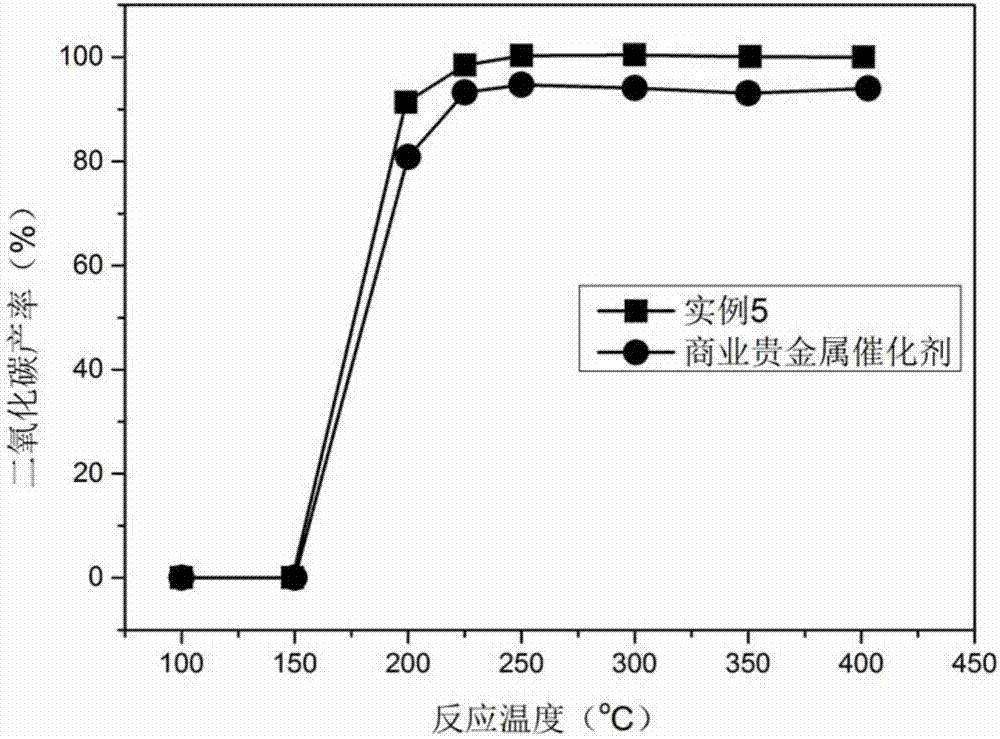

Cryptomelane-based composite metal element catalyst, and preparation method and application thereof

InactiveCN107442154AHigh catalytic activityLarge specific surface areaMolecular sieve catalystsIncinerator apparatusPotassiumManganese oxide

The invention provides a cryptomelane-based composite metal element catalyst, and a preparation method and application thereof. The cryptomelane-based composite metal element catalyst is prepared from acryptomelane-containing manganese oxide molecular sieve and a doping metal element, wherein the doping metal element enters a cryptomelane type manganese oxidemolecular sieve framework; the mole ratio of the manganese element in the cryptomelane type manganese oxidemolecular sieve to the doping metal element is (100 to 1) to (10 to 1); the cryptomelane type manganese oxide molecular sieve is obtained through the reaction of septivalence manganese and bivalent manganese; the mole ratio of the septivalence manganese to the bivalent manganese is (2 to 1) to (0.5 to 1). The cryptomelane-based composite metal element catalyst provided by the invention has high catalytic activity, and the usage of precious metal is not needed or reduced, so that the cost of the catalyst is greatly reduced; the catalyst has no need to be activated by utilizing hydrogen reduction, is simple in usage conditions, and can be widely applied in purification treatment of benzene-containing waste gas discharged by fixed sources such as a smelting plant, an oil refinery plant and a chemical plant.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

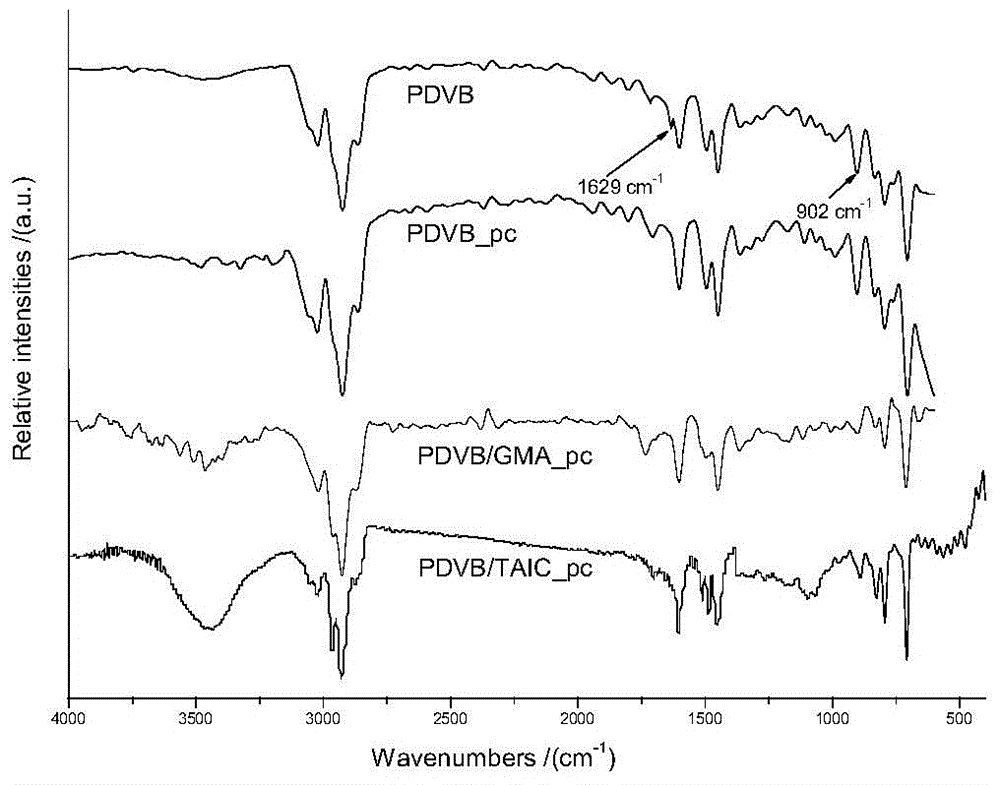

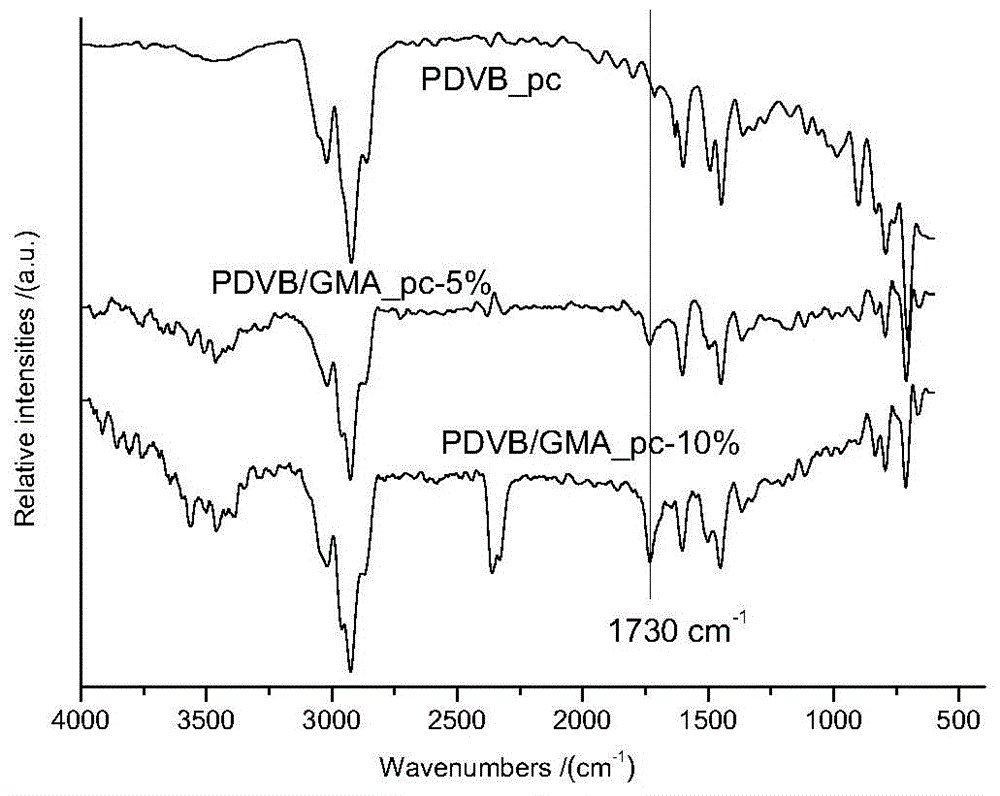

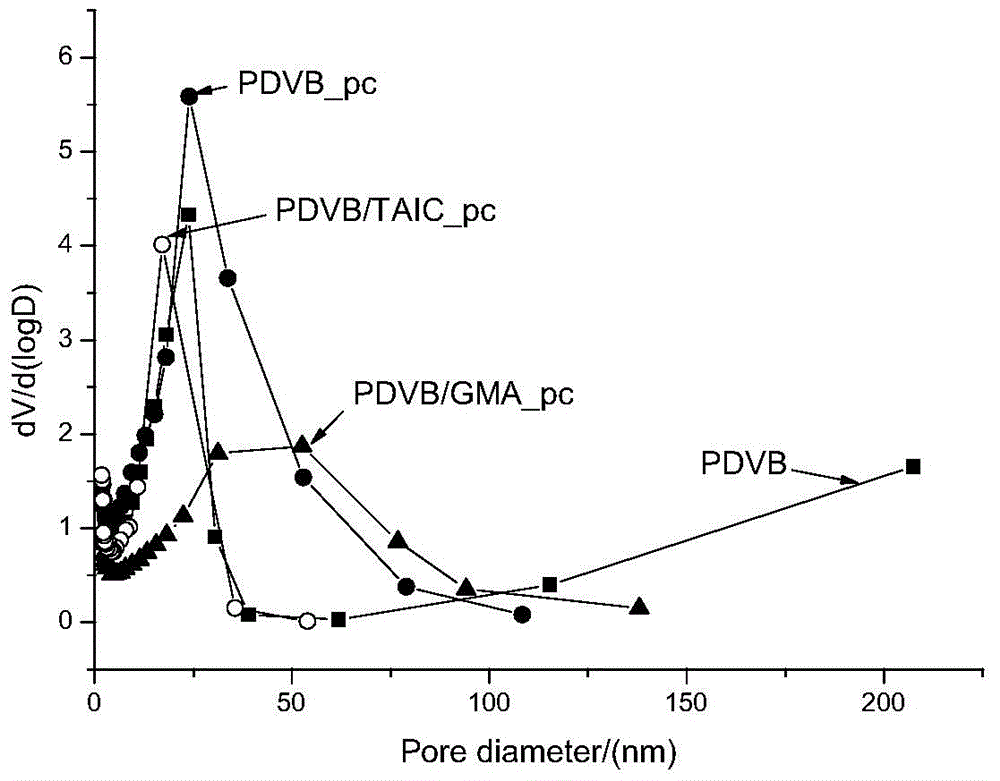

Preparation method and application of polar group-modified pendent double bond post-crosslinked polydivinylbenzene resin

InactiveCN103910823ALarge specific surface areaGood selective adsorptionOther chemical processesWater/sewage treatment by sorptionDouble bondOrganic matter

The invention discloses a preparation method and an application of polar group-modified pendent double bond post-crosslinked polydivinylbenzene resin. The preparation method comprises: firstly performing a polymerization reaction of divinylbenzene monomers, polar monomers, and a pore forming agent to obtain a polar group-modified pendent double bond post-crosslinked polydivinylbenzene resin precursor; performing further crosslinking through a Friedel-Crafts reaction to obtain the polar group-modified pendent double bond post-crosslinked polydivinylbenzene resin. The preparation method is simple, and low in cost, and the prepared post-crosslinked resin has a high specific surface area and a special pore structure; the post-crosslinked resin can be used for adsorbing and removing organic matter in waste water, has the effect of selective adsorption, and especially has obvious selective adsorption effect on Congo red and / or rhodamine B.

Owner:CENT SOUTH UNIV

Magnetic mesoporous silica surface-imprinted polymer adsorbing material and preparation method thereof

InactiveCN106334537AEasy to separate and recycleFacilitate solid-liquid separationIon-exchange process apparatusOther chemical processesRare earth ionsAtom-transfer radical-polymerization

The invention discloses a magnetic mesoporous silica surface-imprinted polymer adsorbing material and a preparation method thereof. The preparation method comprises the following steps: firstly, modifying magnetic mesoporous silica with a silane coupling agent; then grafting an initiator; finally, preparing a surface-imprinted adsorbing material through a surface imprinting technology and an activator generated by electron transfer atom transfer radical polymerization (AGET ATRP). The adsorbing material prepared in the invention is fast to adsorb rare earth ions, strong in selective adsorption, easy to separate and recover, and applicable to the adsorption and separation of the rare earth ions.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com