Ion exchange/impregnation continuous preparation Fe-based molecular sieve SCR catalyst

An SCR catalyst, ion exchange technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of long operation time, poor catalyst durability, and complicated impregnation process, etc., to improve the preparation efficiency. , the effect of improving the load effect and improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 1000g of Fe(NO 3 ) 3 ﹒ 9H 2 O in 2000g of deionized water, stir to dissolve, add 3500g of ZSM-5 molecular sieve, stir for 5 hours; continue to add 1200ml of ammonia water with a mass fraction of 10% to make it evenly stirred, add 150g of ethanol and continue to stir until it is evenly mixed, then statically soak for 2h. Then, put it into a disk and dry it in an oven at 105°C, crush the dried massive solid with a pulverizer, place it in a muffle furnace for calcination at 550°C for 4 hours, and use a grinder to further process the calcined powder It is a powder with a particle size of 0.5 to 1 micron, that is, an iron-based high-activity molecular sieve SCR catalyst is obtained.

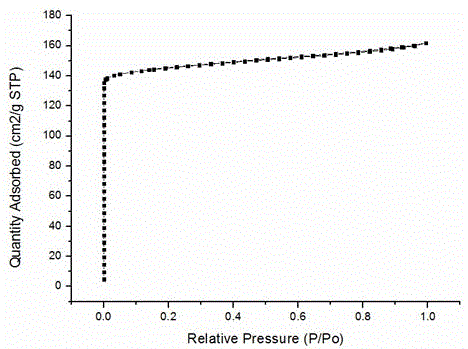

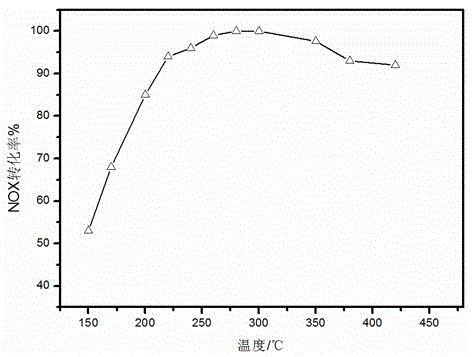

[0039] NH on catalyst powder using a fixed-bed micro-reactor and a five-gas analyzer 3 - SCR conversion efficiency test, the experimental conditions are: space velocity 100000h -1 , NO500ppm, O 2 5%, NH 3 500ppm. The result is as Figure 4 shown. Increase airspeed to 160000h -1...

Embodiment 2

[0041] Weigh 1400g of Fe(NO3) 3 ﹒ 9H 2 O in 2500g of deionized water, stir and dissolve, add 3.5kg of SAPO-34 molecular sieve, stir for 8h; continue to add 1200ml of ammonia water with a mass fraction of 15% to make it evenly stirred, add 350g of ethanol and continue stirring for half until evenly, then stand still Dipping for 24h. Continue to stir and add 100g of 500nm ferric oxide powder. After stirring evenly, put it into a disk and dry it in an oven at 150°C. Crush the dried solid in a pulverizer and place it in a muffle furnace at 520°C. Calcined at ℃ for 6h, the calcined powder was further processed into a powder with a particle size of 2-5 μm by a grinder, and the Fe-based molecular sieve catalyst was obtained.

Embodiment 3

[0043] Weigh 800g of FeCl 3 ﹒ Dissolve 6H2O in 3000g of deionized water, stir to dissolve, add 3000g of β molecular sieve, stir for 3 hours; continue to add 900g of ammonia water with a mass fraction of 20% to make it evenly stirred, then add 180g of 90% ethylene glycol and continue to stir until uniform After that, static dipping for 4h. Continue to stir and add 500g of 1μm ferric oxide and 600g of cerium dioxide powder. After stirring and dispersing evenly, put it into a disk and dry it in an oven at 135°C. Calcined at 500° C. for 5 h in a muffle furnace, and the calcined powder was further processed into a powder with a particle size of 2 microns by a grinder, thereby obtaining an Fe-based molecular sieve catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com