Preparation method of boron/nitrogen-doped microporous carbon material

A technology of element doping and microporous carbon, which is applied in the preparation/purification of carbon, chemical instruments and methods, and other chemical processes. It can solve the problem of small surface area, uneven pore size distribution, and wide pore size distribution of porous carbon materials. problems, to achieve the effects of doping and concentrated micropore size distribution, simple preparation process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

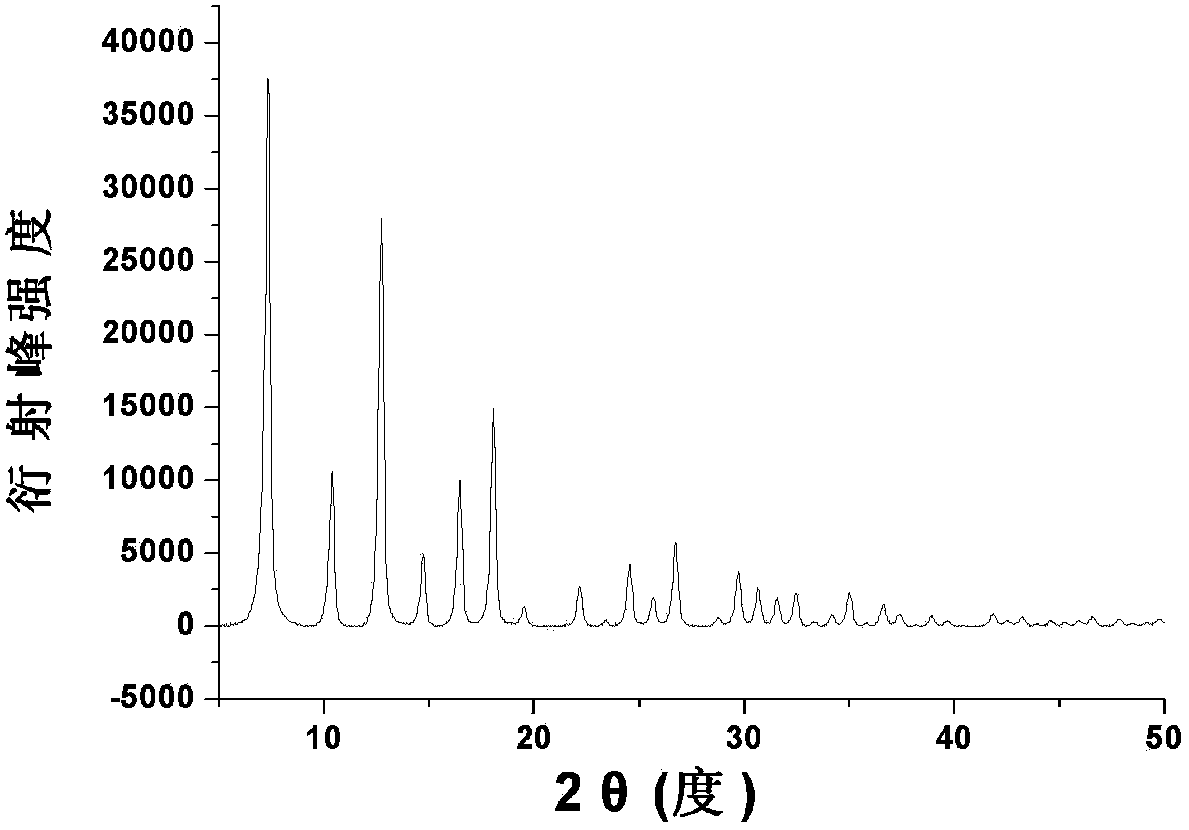

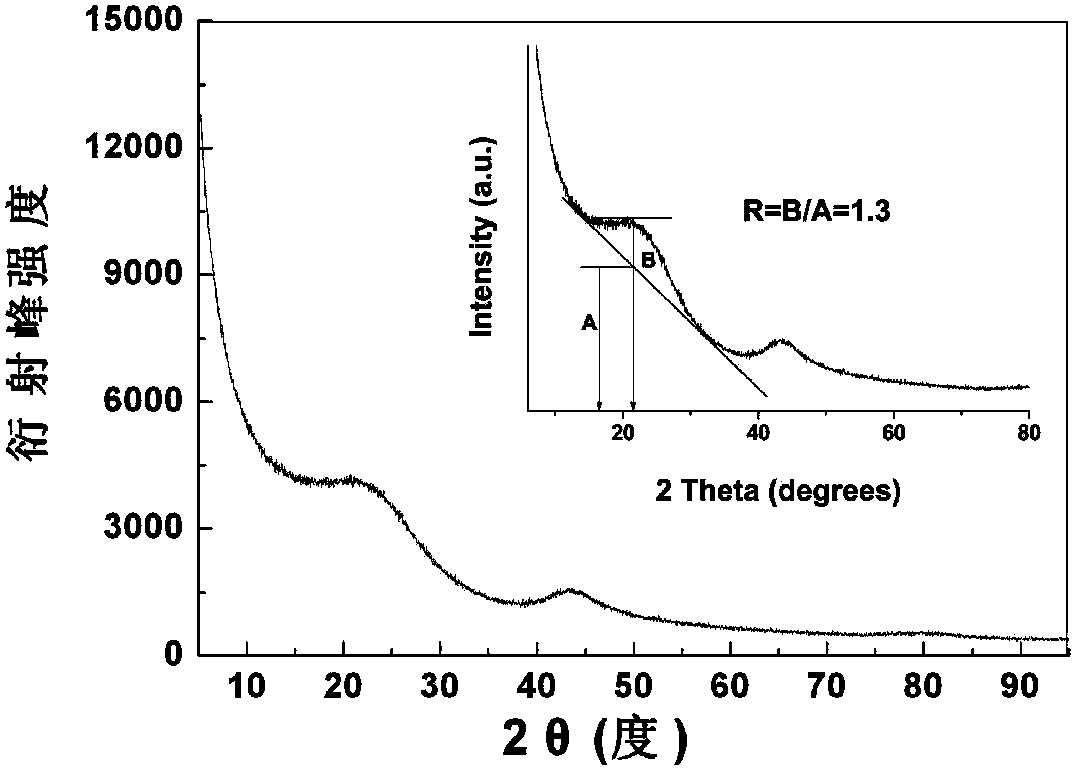

Embodiment 1

[0030] 1. Weigh 2.933g of zinc nitrate hexahydrate and 6.489g of dimethylimidazole and dissolve them in 200ml of methanol solution respectively. Stir vigorously for 3h~6h and stand still overnight. The product was filtered, washed with fresh methanol solution, and vacuumed overnight at 30 °C to prepare a ZIF-8 sample. Apply vacuum at 300°C for 4 hours to obtain the activated ZIF-8 sample.

[0031] 2. Add 3ml, 2mol / L ammonia borane solution to one gram of activated ZIF-8 sample in an argon atmosphere glove box, ultrasonically impregnate for 5h, and vacuum dry overnight at room temperature. A composite material of ammonia borane and metal-organic framework compound ZIF-8 was prepared.

[0032] 3. Put the above composite material into a high-temperature furnace, use an argon atmosphere (gas flow rate is 100-400mL / min), raise the temperature to 800-1200°C at a heating rate of 1-10°C / min, and heat it up at 800-1200 °C was kept for 2-10 hours, and cooled to room temperature in an...

Embodiment 2

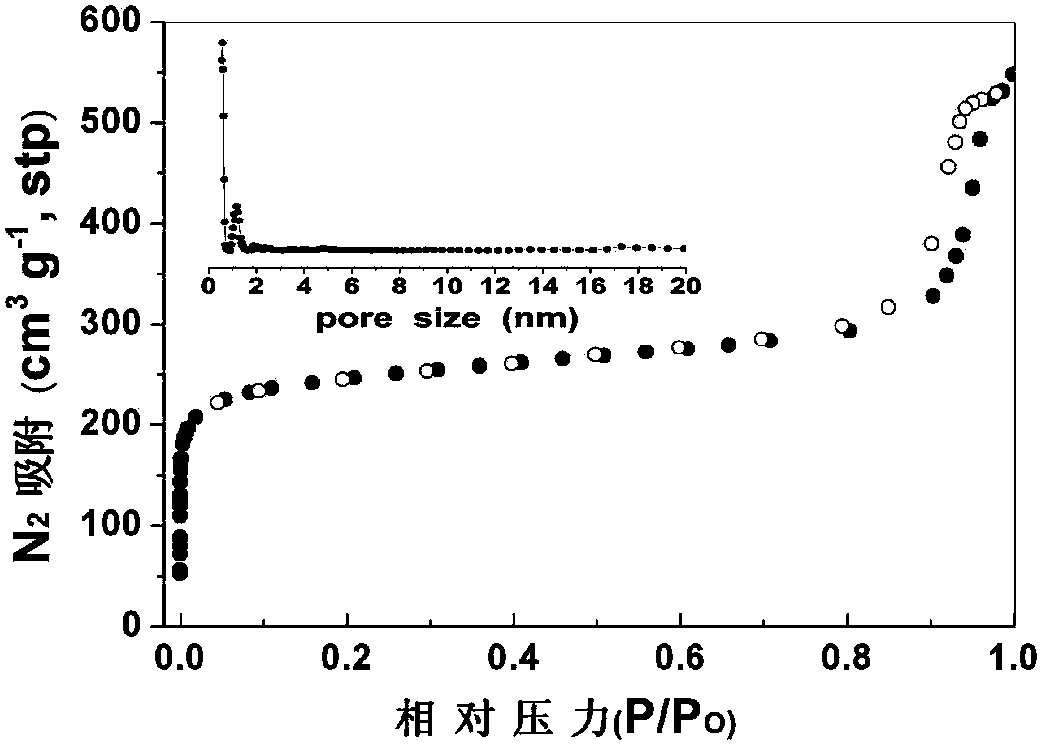

[0035] The 0.4g boron-nitrogen-doped microporous carbon material prepared in Example 1 was placed in a 9mm sample tube of the Absorb-1 physical adsorption instrument of Quanta Corporation, USA, and heated overnight at 200°C in a sealed vacuum. The low-pressure hydrogen adsorption experiment was carried out under two temperature conditions of 77K and 87K.

[0036] Depend on Figure 4 It can be seen that under the hydrogen pressure conditions of 77K and 820mmHg, each gram of boron-nitrogen-doped microporous carbon material can adsorb 204cm 3 Hydrogen, the corresponding mass fraction is 1.83wt%.

Embodiment 3

[0038] The microporous carbon material doped with 0.3 g of boron and nitrogen elements prepared in Example 1 was placed in a 9 mm sample tube of the Absorb-1 physical adsorption instrument of Quanta Corporation, USA, and heated in a sealed vacuum at 200 ° C overnight. Under the constant temperature condition of 273K, the low-pressure carbon dioxide adsorption experiment was carried out.

[0039] Depend on Figure 5 It can be seen that under the pressure conditions of 273K and 780mmHg, each gram of boron and nitrogen doped microporous carbon materials can adsorb 100cm 3 of carbon dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com