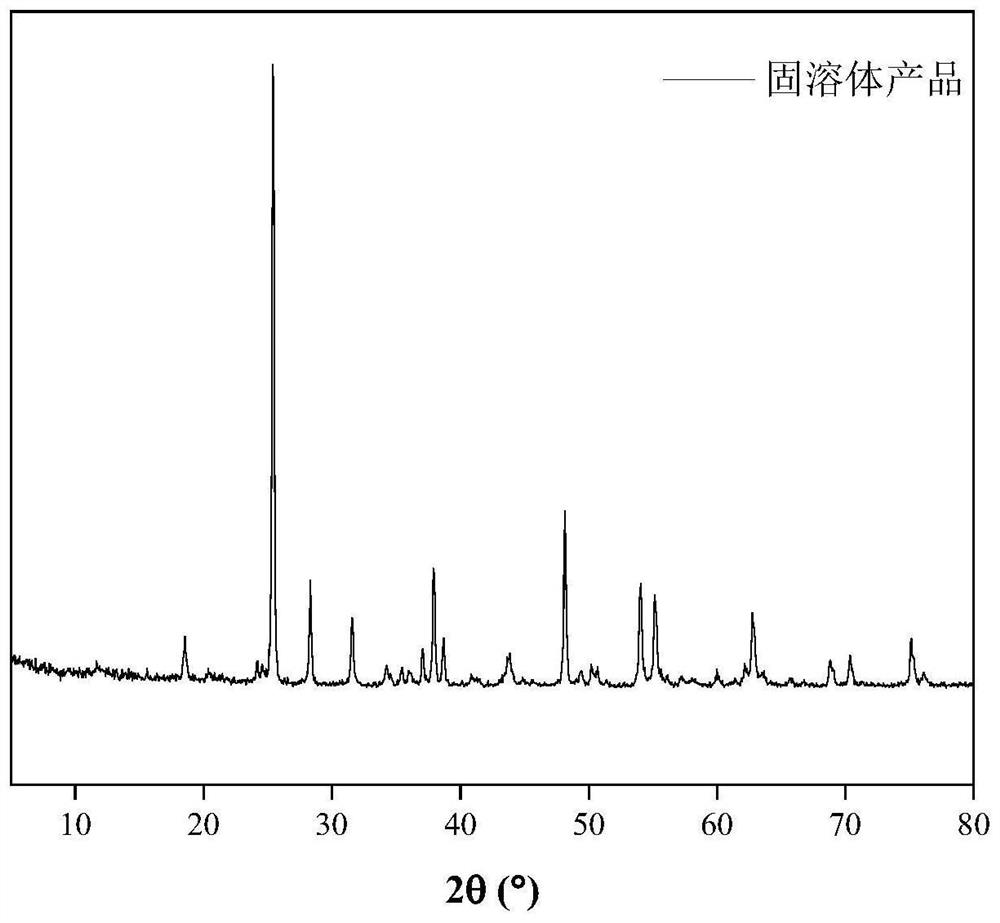

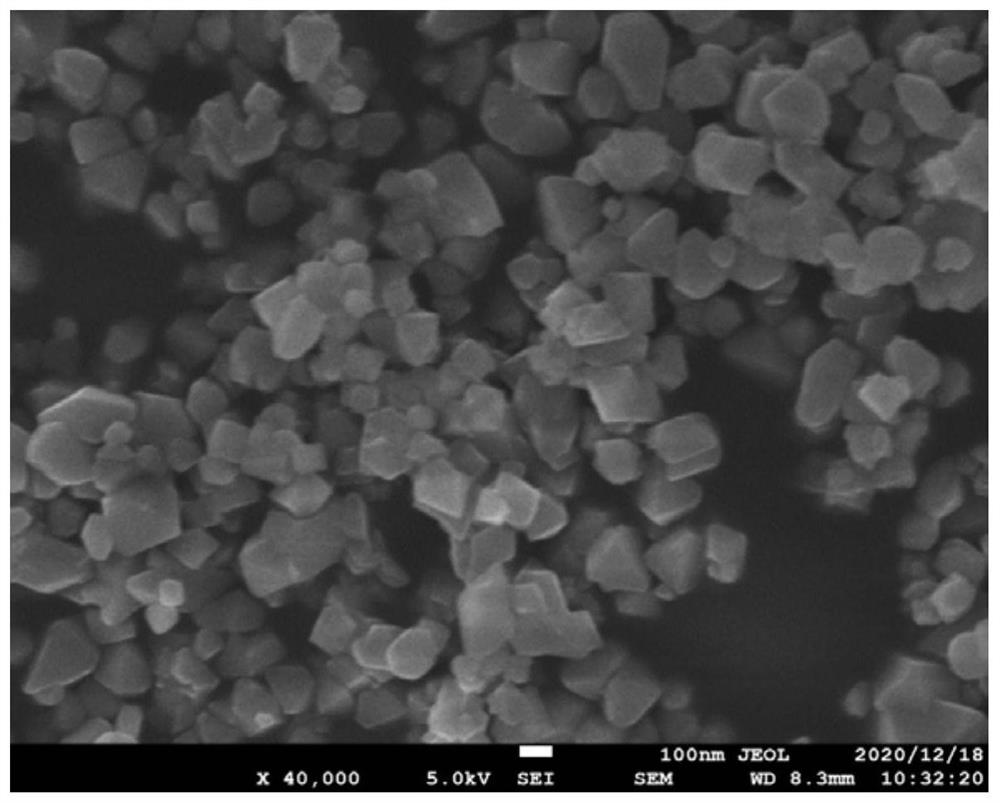

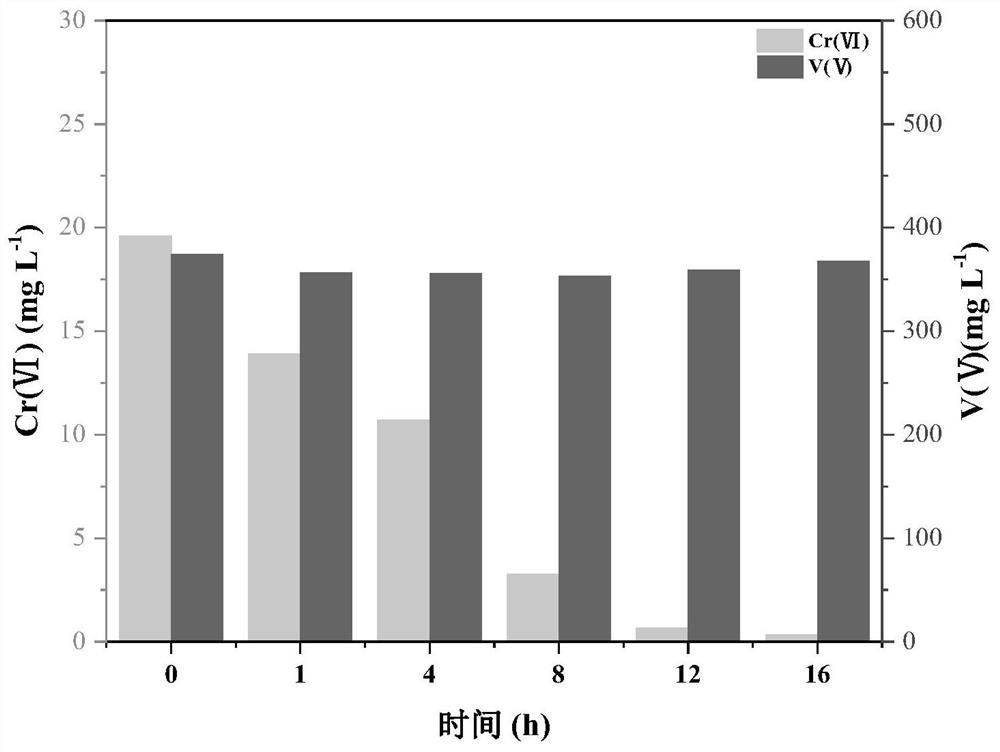

Solid solution structure adsorbent, preparation method and application in separation of Cr (VI) contained in water body

A solid solution and adsorbent technology, applied in the direction of adsorption of water/sewage treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of low cost performance, high energy consumption, complex preparation process, etc., and achieve improved safety and energy consumption The effect of reduction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the steps of preparing the solid solution structure adsorbent are as follows:

[0035] (1) Ingredients and Mixing

[0036] The titanium source is titanium dioxide powder, the zirconium source is zirconium dioxide powder, the nitrogen source is urea powder, the molten salt is lithium chloride powder and potassium chloride powder, and the mass ratio of lithium chloride powder and potassium chloride powder is 1:1, The molar ratio of each raw material component is titanium source: zirconium source: molten salt: nitrogen source=1:0.10:2.96:6.65, and the measured raw materials are uniformly mixed by dry grinding to form a mixture;

[0037] (2) Calcination

[0038] Put the mixture obtained in step (1) into a crucible and put it into a muffle furnace, heat it up to 600 °C for 2 hours at a heating rate of 2 °C / min under normal pressure, and then cool it to room temperature with the furnace to obtain a molten Crude products of salt;

[0039] (3) Washing and...

Embodiment 2

[0044] In this embodiment, the steps of preparing the solid solution structure adsorbent are as follows:

[0045] (1) Ingredients and Mixing

[0046] The titanium source is titanyl sulfate powder, the zirconium source is zirconium sulfate powder, the nitrogen source is thiourea powder, the molten salt is sodium sulfate powder and potassium sulfate powder, and the mass ratio of sodium sulfate powder to potassium sulfate powder is 1:1. The molar ratio of the raw material components is titanium source: zirconium source: molten salt: nitrogen source=1:0.12:1.53:5.26, and the measured raw materials are uniformly mixed by dry grinding to form a mixture;

[0047] (2) Calcination

[0048] Put the mixture obtained in step (1) into a crucible and put it into a muffle furnace, heat it up to 700 °C for 2 hours at a heating rate of 3 °C / min under normal pressure, and then cool it to room temperature with the furnace to obtain a molten Crude products of salt;

[0049] (3) Washing and dry...

Embodiment 3

[0052] In this embodiment, the steps of preparing the solid solution structure adsorbent are as follows:

[0053] (1) Ingredients and Mixing

[0054] Titanium source is titanate powder, zirconium source is zirconium hydroxide powder, nitrogen source is ammonium chloride powder, molten salt is sodium chloride powder and lithium chloride powder, the mass ratio of sodium chloride powder to lithium chloride powder is 1 : 1, the molar ratio of each raw material component is titanium source: zirconium source: molten salt: nitrogen source=1:0.10:2.32:5.33, and each raw material measured is mixed uniformly by dry grinding to form a mixture;

[0055] (2) Calcination

[0056] The mixture obtained in step (1) is put into a crucible and put into a muffle furnace, and is heated to 500 °C for 3 hours at a heating rate of 5 °C / min under normal pressure, and then cooled to room temperature with the furnace to obtain a molten Crude products of salt;

[0057] (3) Washing and drying

[0058]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com