Method for preparing nano-porous magnesium through vapor deposition method

A vapor deposition method and nanoporous technology, applied in nanotechnology, ion implantation plating, coating, etc., can solve the problems of honeycomb nanoporous magnesium ligament thickness, unfavorable hydrogen storage performance, and large hydrogen diffusion path, etc., to achieve the preparation The effect of short time, favorable hydrogen storage performance, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

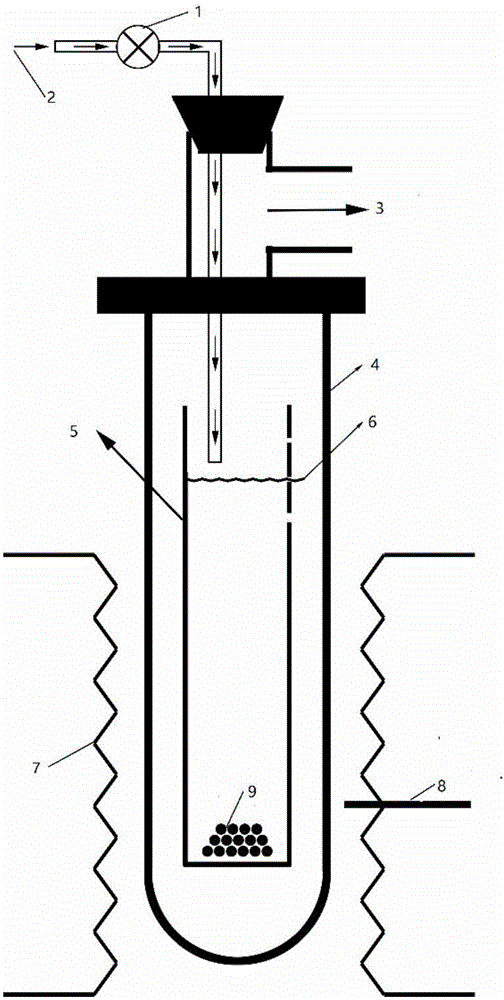

[0033] Such as image 3 As shown, first, 0.5-1.0 g of magnesium powder 9 was placed at the bottom of the stainless steel deposition chamber 5, and the stainless steel mesh substrate 6 was inserted into the stainless steel deposition chamber 5 so that the vertical distance from the magnesium powder 9 was about 120 mm. Put the stainless steel deposition chamber 5 into the quartz tube 4 vertically. Next, put the quartz tube 4 vertically into the heating furnace 7, and adjust the position of the quartz tube 4 so that it is located in the heating zone of the tube furnace. Insert the ventilation pipe so that it is inside the stainless steel deposition chamber 5, above the stainless steel mesh substrate 6, but not in contact with the stainless steel mesh substrate 6. Connect the quartz tube 4 and the mechanical pump 3 with a bellows with a diameter of 25 mm and a length of 1.5 m. The 3rd, open mechanical pump 3, the vacuum degree of quartz tube 4 is pumped to 10 -1 Pa, and then pa...

Embodiment 2

[0035] Such as image 3 As shown, first, 0.5-1.0 g of magnesium powder 9 was placed at the bottom of the stainless steel deposition chamber 5, and the stainless steel mesh substrate 6 was inserted into the stainless steel deposition chamber 5 so that the vertical distance from the magnesium powder 9 was about 120 mm. Put the stainless steel deposition chamber 5 into the quartz tube 4 vertically. Next, put the quartz tube 4 vertically into the heating furnace 7, and adjust the position of the quartz tube 4 so that it is located in the heating zone of the tube furnace. Connect the quartz tube to the mechanical pump with a bellows with a diameter of 25 mm and a length of 1.5 m. During this process, ensure that the ventilation pipe is inside the stainless steel deposition chamber 5 and above the stainless steel mesh substrate 6 , but does not touch the stainless steel mesh substrate 6 . The 3rd, open mechanical pump 3, the vacuum degree of quartz tube 4 is pumped to 10 -1 Pa, a...

Embodiment 3

[0037] Such as image 3 As shown, first, 0.5-1.0 g of magnesium powder 9 was placed at the bottom of the stainless steel deposition chamber 5, and the stainless steel mesh substrate 6 was inserted into the stainless steel deposition chamber 5 so that the vertical distance from the magnesium powder 9 was about 120 mm. Put the stainless steel deposition chamber 5 into the quartz tube 4 vertically. Next, put the quartz tube 4 vertically into the heating furnace 7, and adjust the position of the quartz tube 4 so that it is located in the heating zone of the tube furnace. Insert the ventilation pipe so that it is inside the stainless steel deposition chamber 5, above the stainless steel mesh substrate 6, but not in contact with the stainless steel mesh substrate 6. Connect the quartz tube 4 and the mechanical pump 3 with a bellows with a diameter of 25 mm and a length of 1.5 m. The 3rd, open mechanical pump 3, the quartz tube vacuum degree is pumped to 10 -1 Pa, and then into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com