Macroporous and microporous hybrid starch granule and preparation method and application thereof

A technology of starch granules and microporous starch, which is applied in applications, tobacco, food science, etc., can solve problems such as unsatisfactory adsorption of harmful gas phase components, reduced smoking quality of flue-cured cigarettes, and difficult regulation of molecular sieve structure, etc. Effects of tar and carbon monoxide delivery, enhanced selective adsorption capacity, improved sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

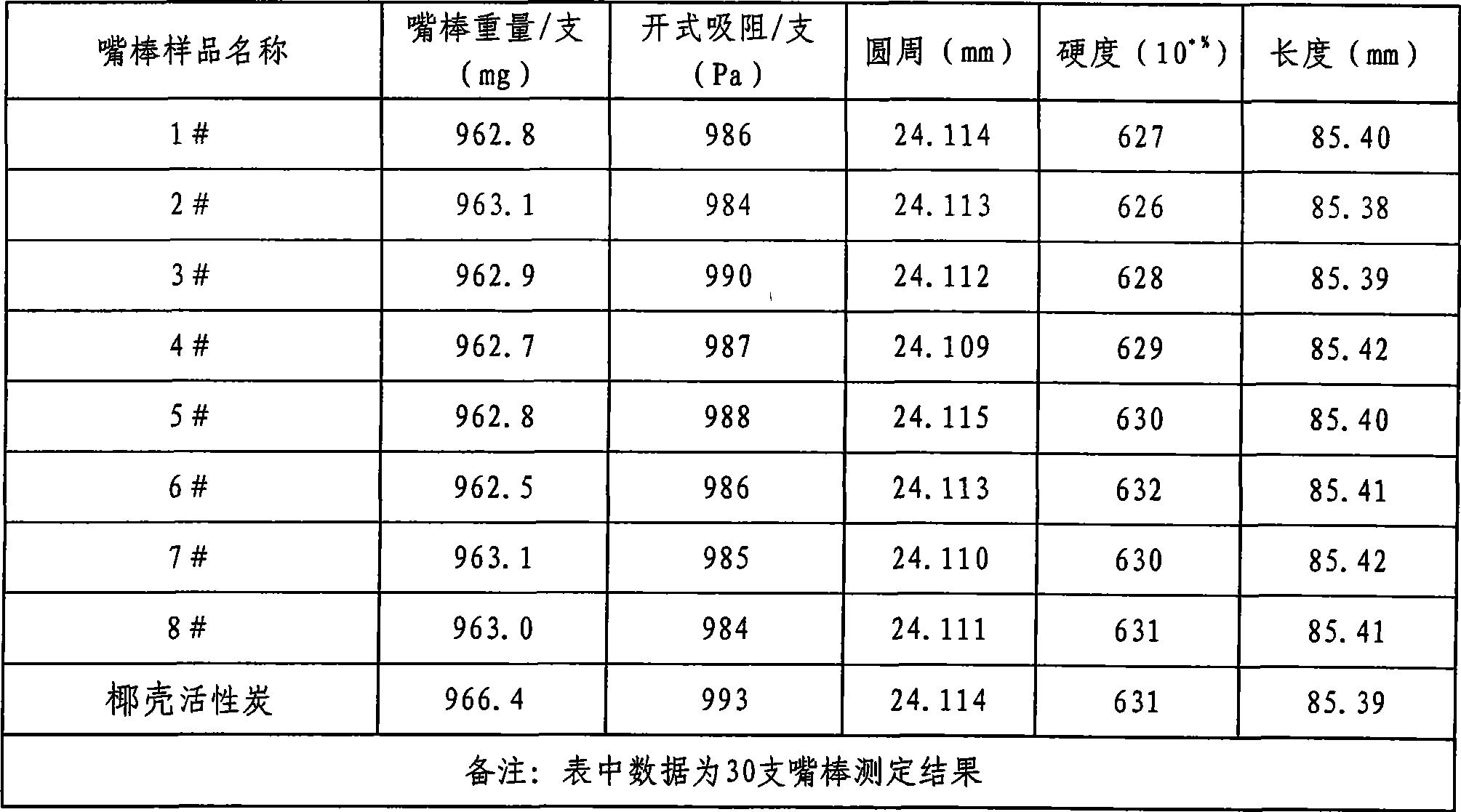

Image

Examples

Embodiment 1

[0033] Take 20g of cornstarch, add 50ml of acid buffer solution with a concentration of 0.1mol / L and a pH value of 5.0, and stir evenly at 50°C to prepare a mixed starch milk. 0.2 g of glucoamylase was added, and after 20 hours of enzymolysis with constant temperature and stirring at 50° C. and pH value of 5.0, 1 ml of 4% sodium hydroxide solution was added to terminate the reaction. Centrifuged to obtain slurry-like porous starch. After drying the slurry porous starch at 50°C, the macroporous cornstarch YSQ with a pore diameter in the range of 0.5um to 1.5um can be prepared. Take another 20g of cornstarch, add 0.2g of α-amylase to liquefy and pre-hydrolyze, then add 0.2g of cyclodextrin glucosyltransferase to ferment, and after the fermentation product is dried, microbes with a pore size in the range of 6A° to 6.5A° can be obtained. Hole Cornstarch HH. Mix the prepared YSQ and HH in a weight ratio of 0.5:1, spray 5 grams of water per kilogram of starch to moisten it, dry it...

Embodiment 2

[0035] Repeat Example 1 with the following difference: the YSQ and HH prepared are mixed in a weight ratio of 1:1. Pass through a 50 mesh sieve.

Embodiment 3

[0037] Repeat Example 1 with the following difference: the YSQ and HH prepared are mixed in a weight ratio of 1.5:1. Pass through a 60 mesh sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com