Magnetic microsphere resin for removing nitrate nitrogen selectively, and preparation method thereof

A technology of magnetic microspheres and nitrate nitrogen, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., to achieve the effects of high alkali exchange capacity, good sedimentation performance, and good selective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

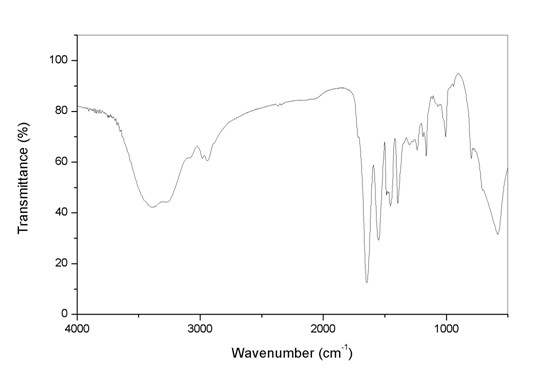

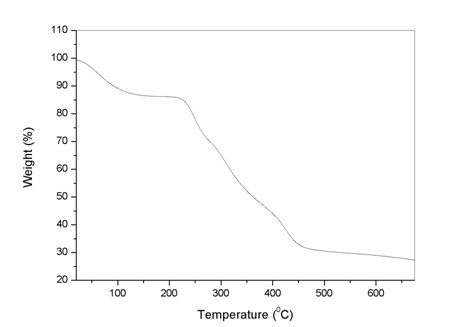

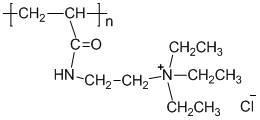

Image

Examples

Embodiment 1

[0036] Dissolve 15g of gelatin and 120g of sodium chloride in 500g of pure water to prepare an aqueous phase and add it to a three-necked flask. Add 98g capsules of 80g methyl acrylate, 20g acrylic acid, 10g ethylene glycol dimethacrylate, 0.5g benzoyl peroxide, 0.5g azobisisobutyronitrile, 80g toluene and 25g ethyl acetate Mix ferroferric oxide magnetic particles with a diameter of about 0.1 μm evenly, control the stirring speed at 100~150rpm, add it to the water phase, and raise the temperature to 55°C, keep it for 6 hours, raise the temperature to 85°C, keep it for 10 hours, and then discharge ; Wash with methanol and dry it, add N,N-diethylethylenediamine 3 times the mass of the resin, heat it at 150°C for 6 hours, and discharge it, wash it with methanol and pure water, add alkaline aqueous solution, and add 180g of ethyl bromide was discharged at 65°C for 18 hours, washed with methanol and pure water successively and transformed with sodium chloride solution to obtain a m...

Embodiment 2

[0040] Dissolve 2g of polyvinyl alcohol and 50g of sodium chloride in 500g of pure water to prepare an aqueous phase and add it to a three-necked flask. 90g methyl methacrylate, 10g methacrylic acid, 10g trimethylolpropane trimethacrylate, 1.0g azobisisobutyronitrile, 50g toluene, 10g 200 # Add 50g of ferroferric oxide magnetic particles with a particle size of about 0.1 micron to the mixed solution of solvent oil, mix evenly, control the stirring speed at 200~250 rpm, add it to the water phase, and raise the temperature to 50°C, keep it for 4 hours, then raise the temperature to 90°C, keep it for 4 hours, and discharge it; wash it with methanol and dry it, add N,N-diethylpropylenediamine 4 times the mass of the resin, keep it at 200°C for 12 hours, and discharge it; use methanol, pure After washing with water, add alkaline aqueous solution, and add 350g of bromopropane, heat it at 100°C for 12 hours, then discharge, wash with methanol and pure water in turn, and transform wit...

Embodiment 3

[0044] 4.5g of gull gum and 80g of sodium chloride were dissolved in 500g of pure water to prepare an aqueous phase and added to a three-necked flask. 80g ethyl acrylate, 5g acrylic acid, 5g ethylene glycol dimethacrylate, 5g triallyl cyanurate, 1.2g benzoyl peroxide, 1.5g azobisisobutyronitrile, 25g xylene, 25g of isobutanol mixture, add 16g of ferroferric oxide magnetic particles with a particle size of about 0.1 microns and mix evenly, control the stirring speed at 300~350 rpm, add it to the water phase, and raise the temperature to 60°C and keep it for 10 hours , heated up to 88°C, kept for 2 hours, and discharged; washed with ethanol and dried, added N,N-diethylpropylenediamine 5 times the mass of the resin, kept at 160°C for 8 hours, and discharged; 1. After washing with pure water, add alkaline aqueous solution, and add 500g bromobutane, heat it at 110°C for 20 hours, then discharge, wash with methanol and pure water in turn, and transform with sodium chloride solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com