Patents

Literature

51results about How to "With sound insulation and noise reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

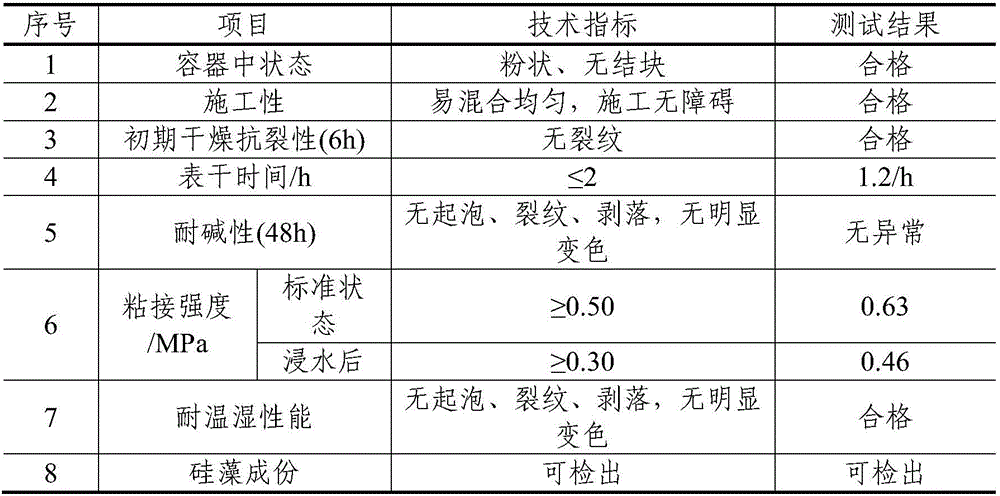

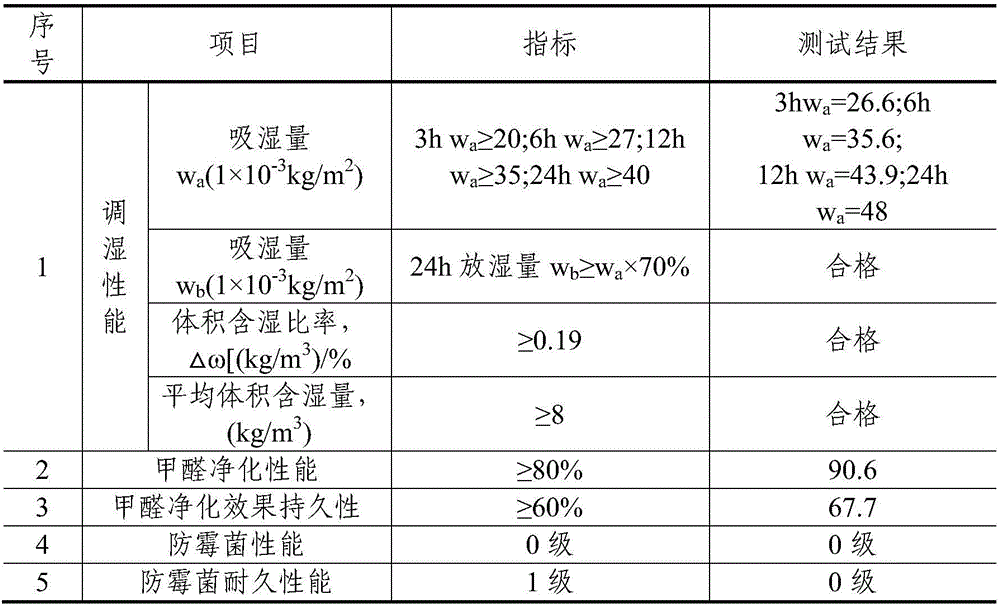

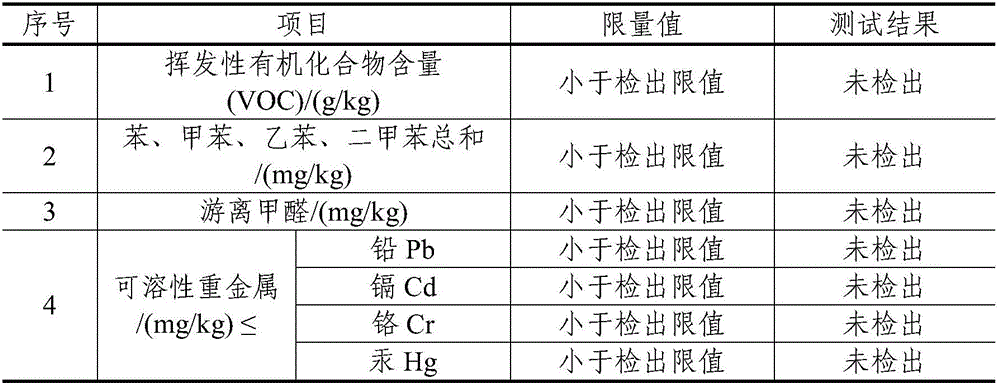

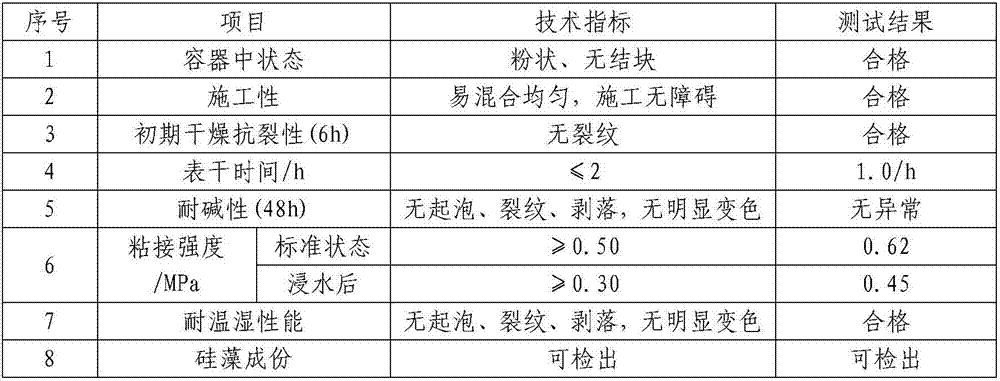

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190BStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberSodium Bentonite

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

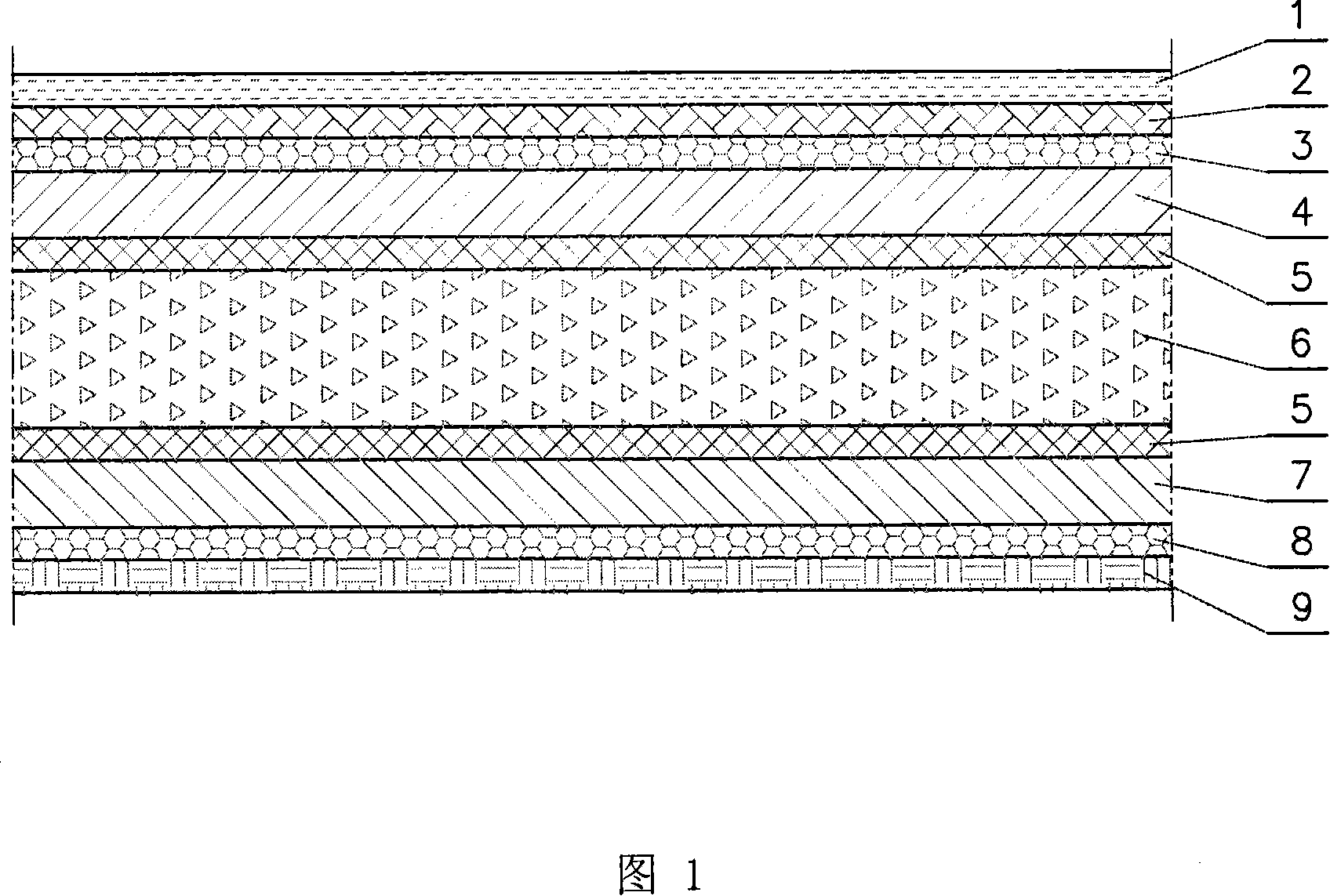

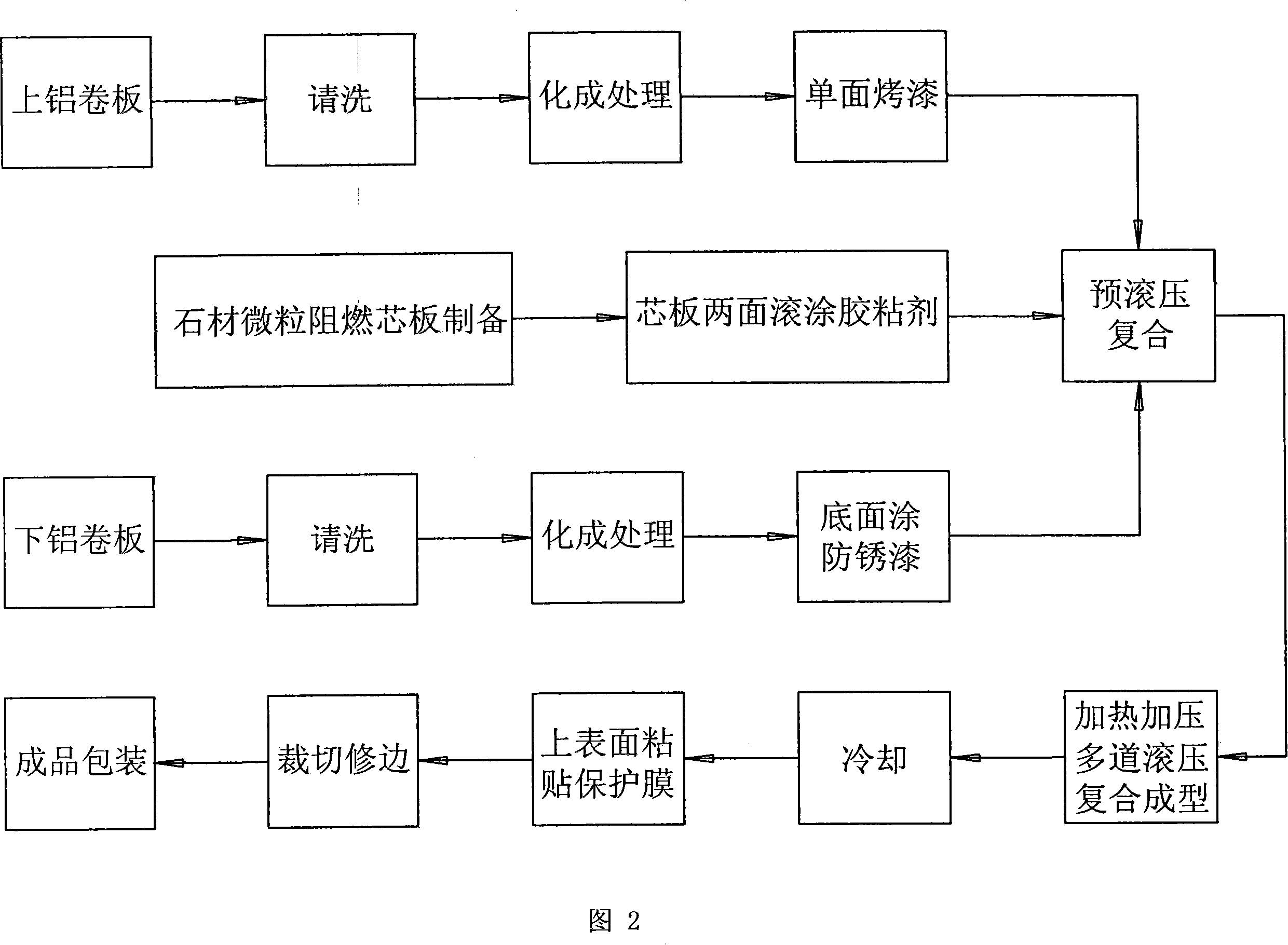

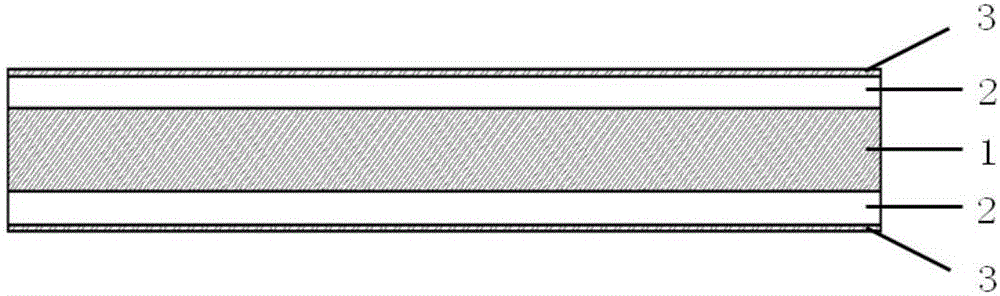

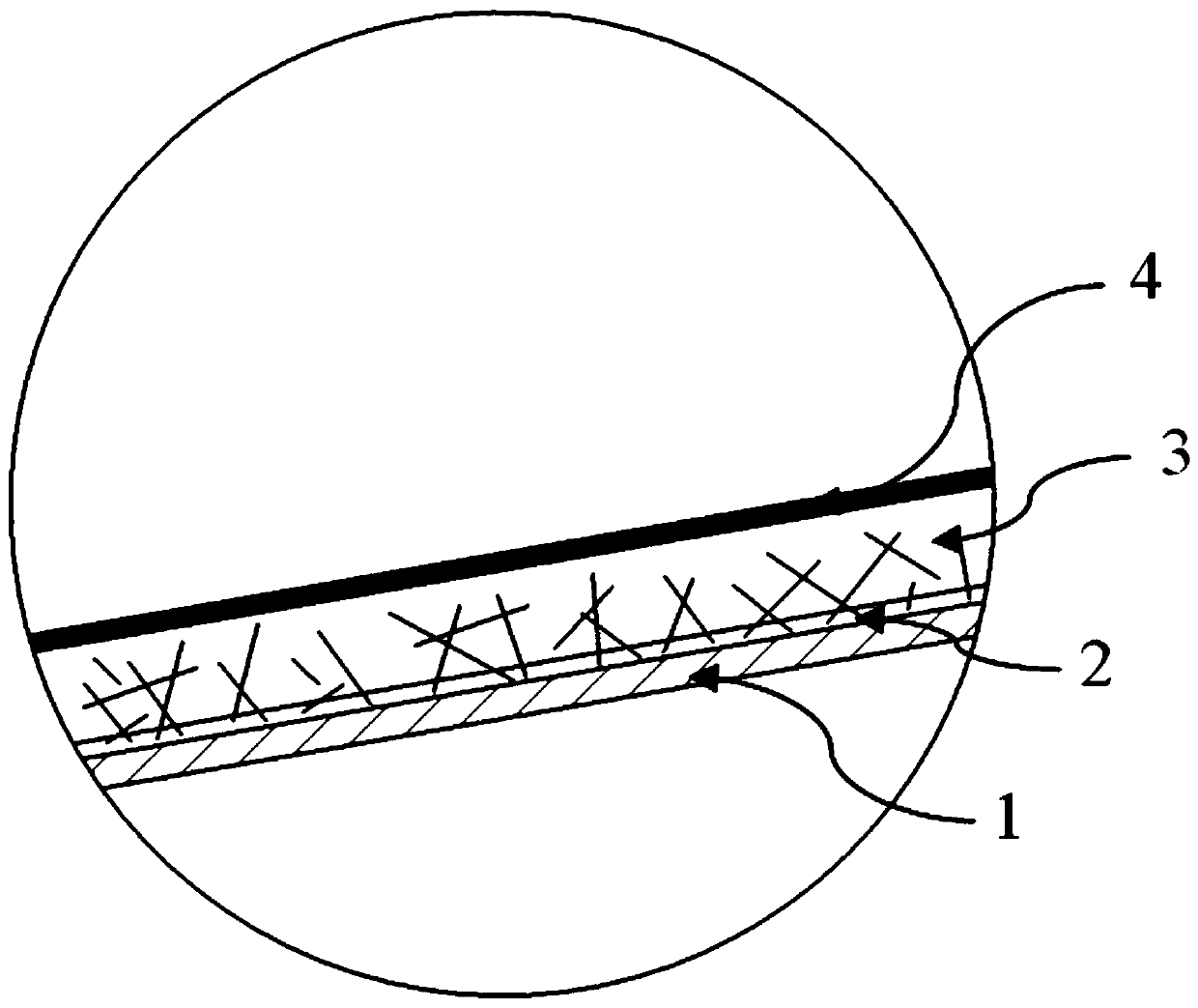

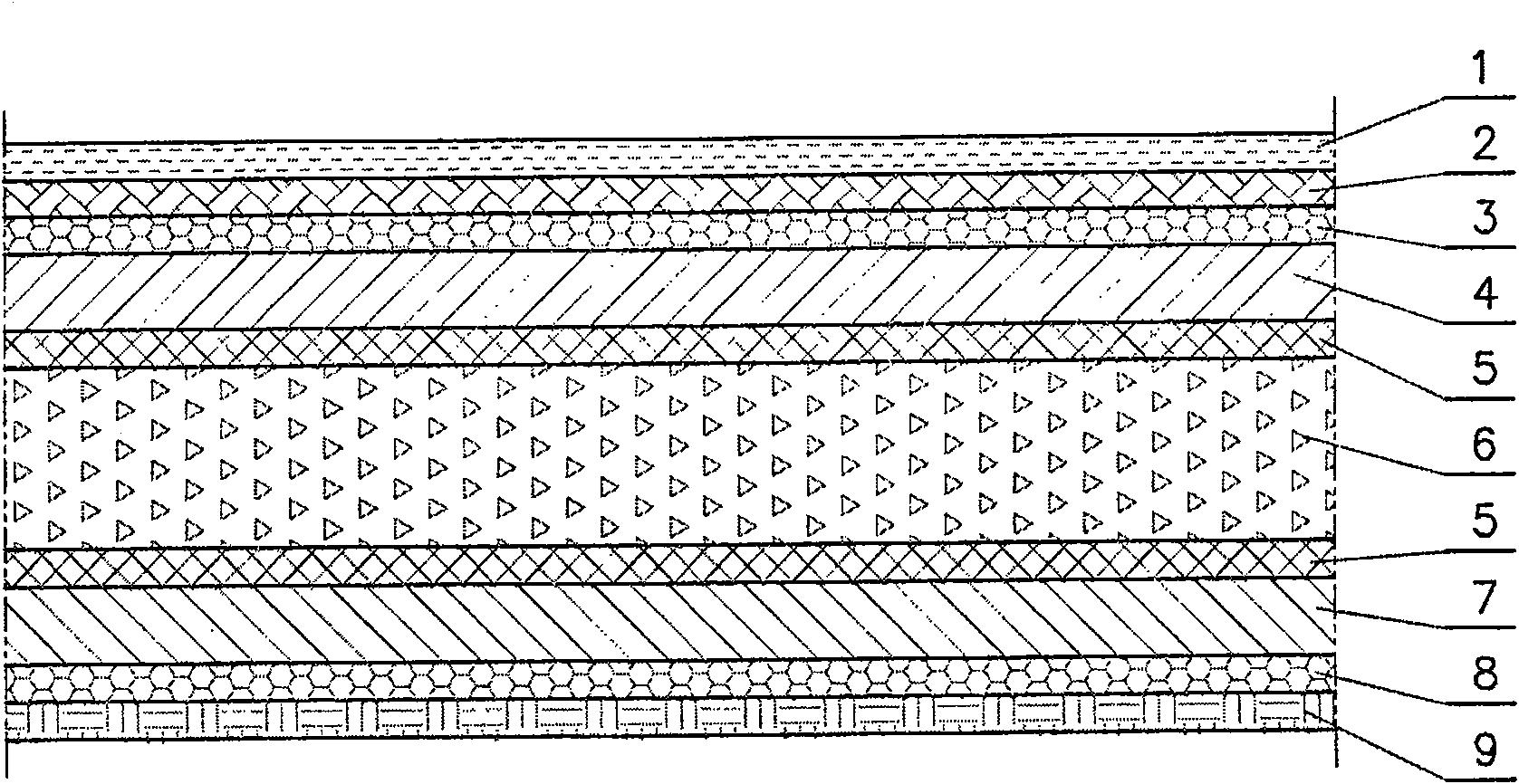

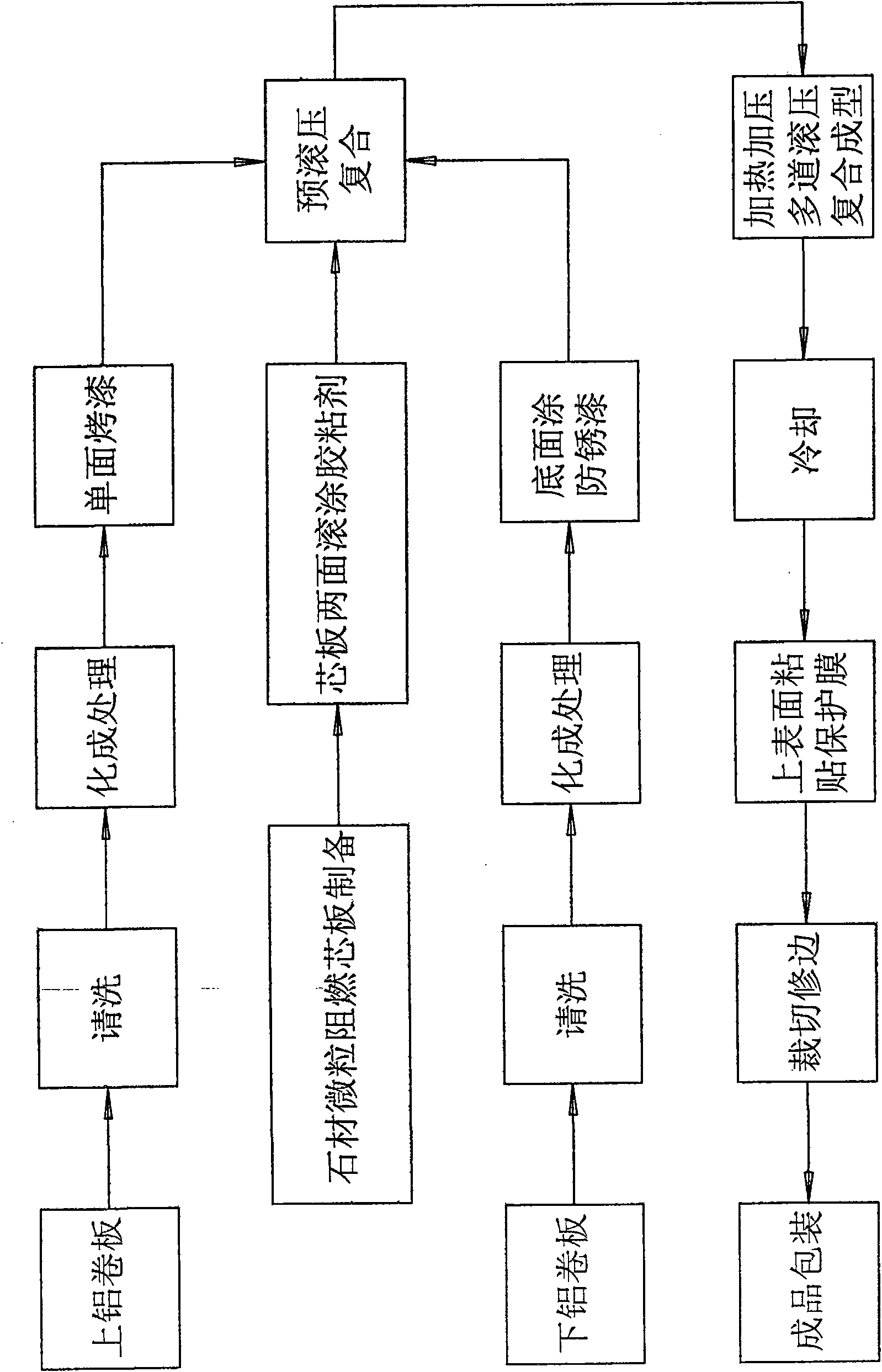

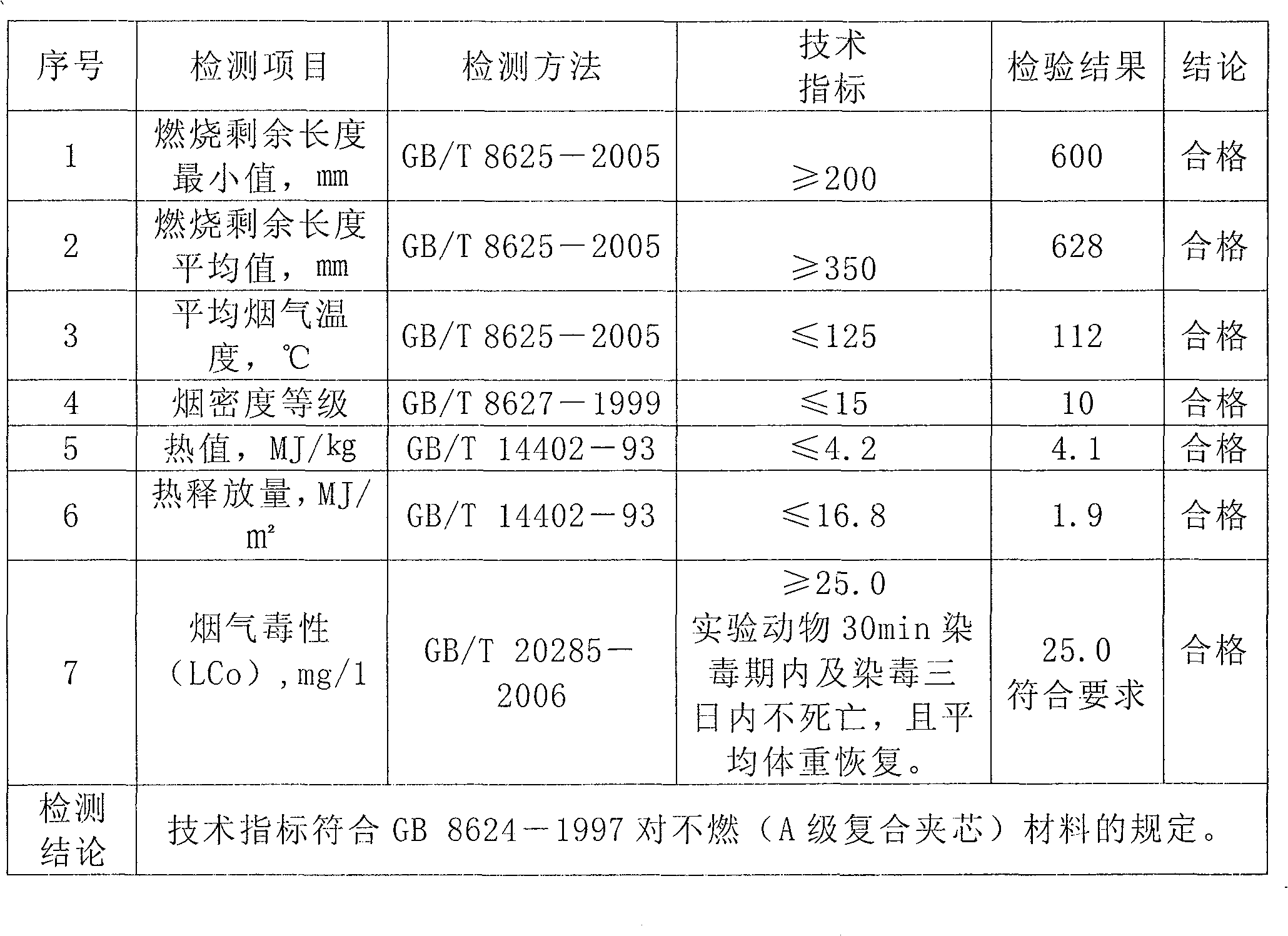

Metal composite plate with fireproof interlayer and manufacturing method thereof

ActiveCN101148936AWon't happenWith thermal insulationCovering/liningsLamination ancillary operationsTectorial membraneAdhesive

The present invention is one kind of composite metal plate with sandwiched fireproof layer and its making process. The composite metal plate with sandwiched fireproof layer consists of a protecting film layer, a baking varnish layer, a first chemically formed film layer, a first metal sheet, a first adhesive layer, a sandwiched fireproof layer, a second adhesive layer, a second metal sheet, a second chemically formed film layer and an antirust primer layer superposed successively and compounded integrally. Its making process includes the steps of: hot pressing the mixture of fine ore grains, fire retardant, coupling agent and adhesive to form the fireproof core board; treating the first metal sheet to form the first film layer and the baking varnish layer, and treating the second metal sheet to form the second film layer and the antirust primer layer; painting adhesive to two sides of the core board and hot pressing to combine the core board and two metal sheets; adhering the protecting film layer and cutting.

Owner:江阴新泓泰复合材料有限公司

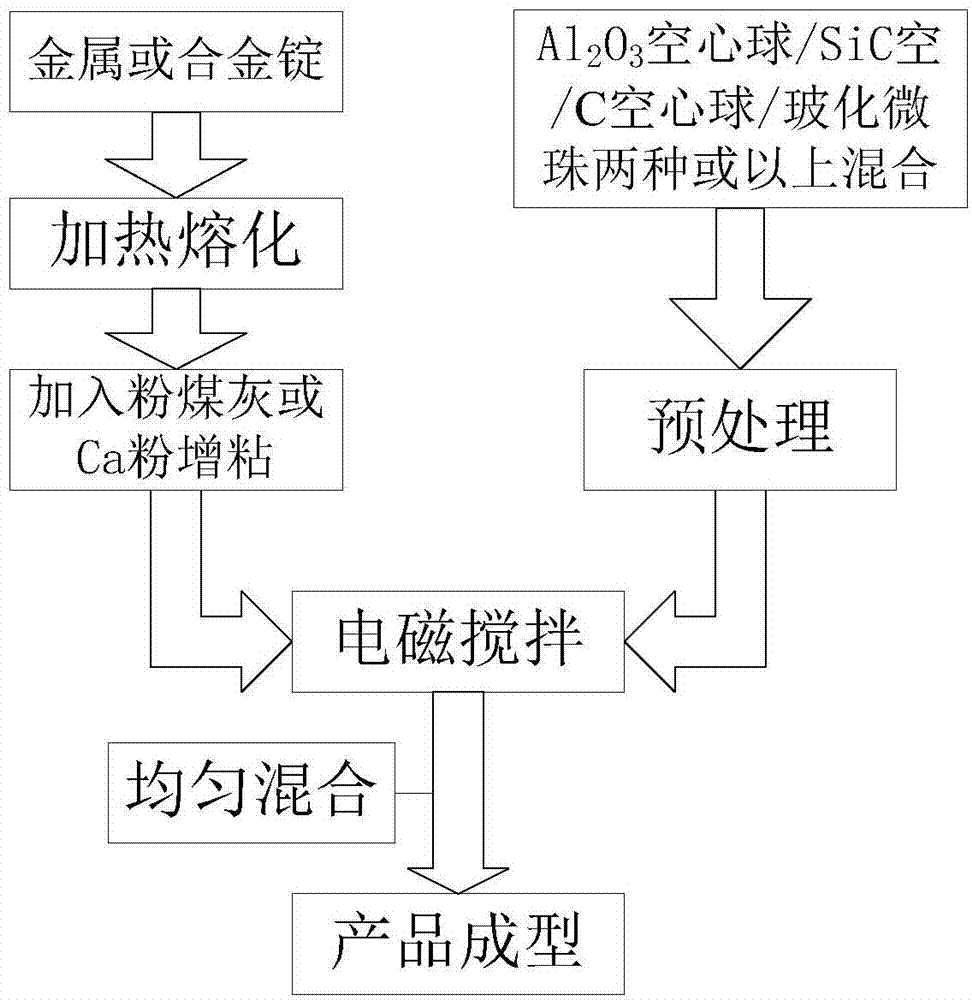

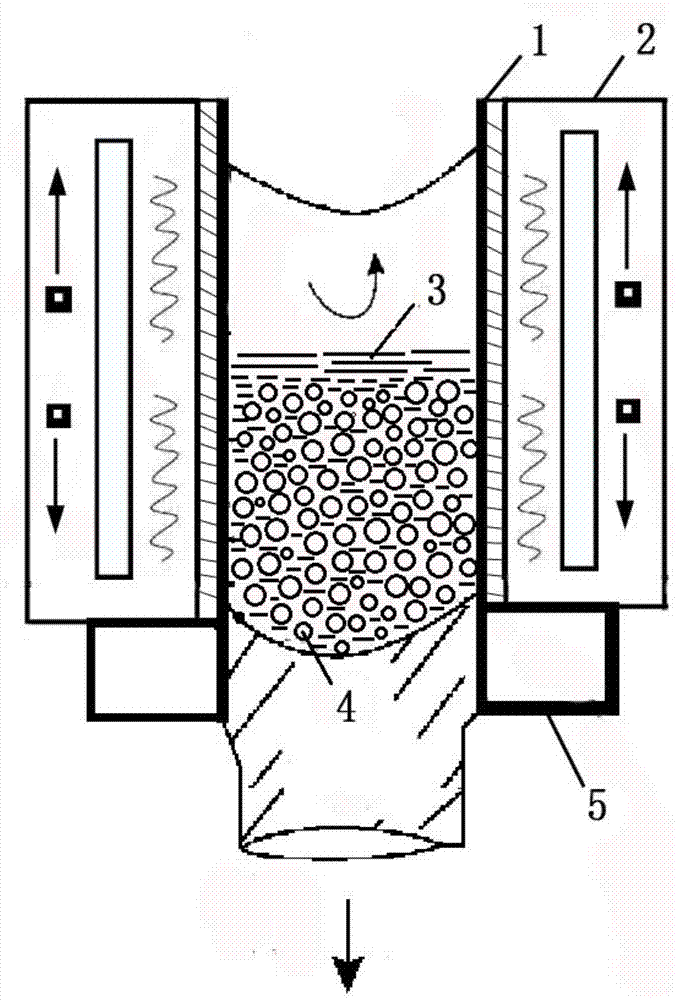

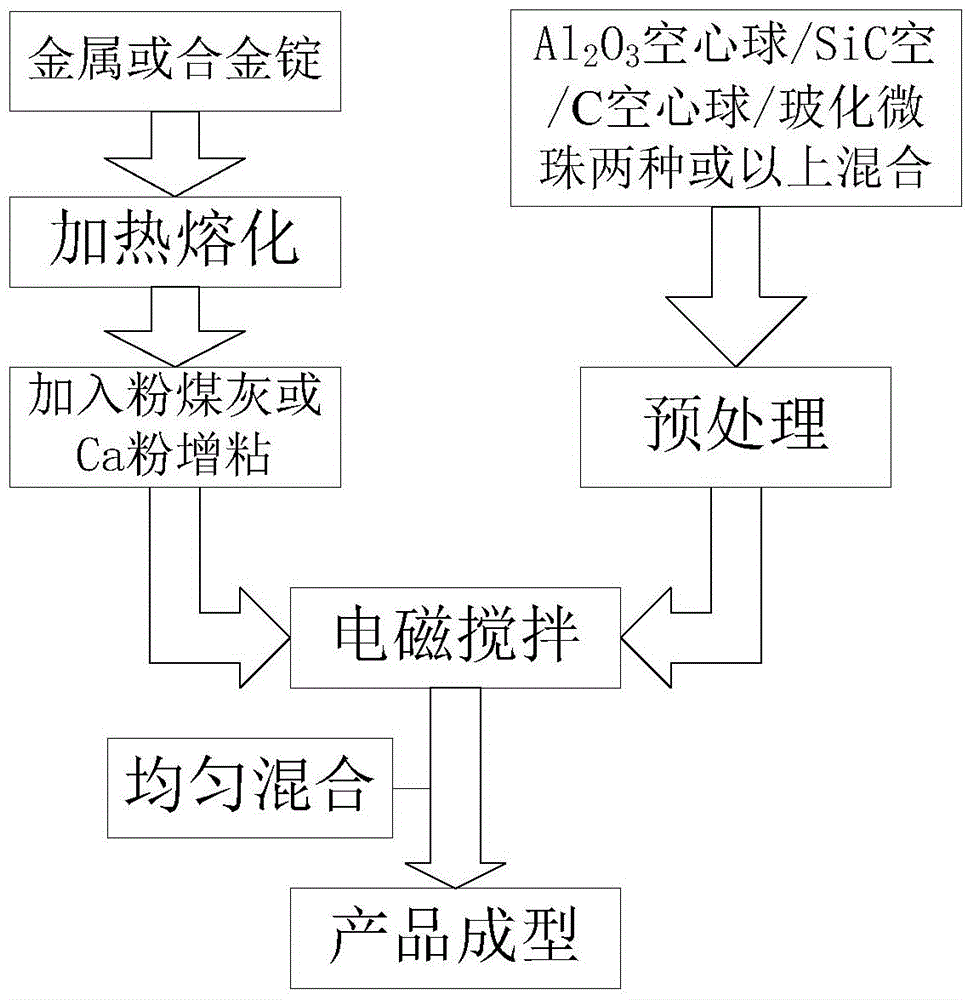

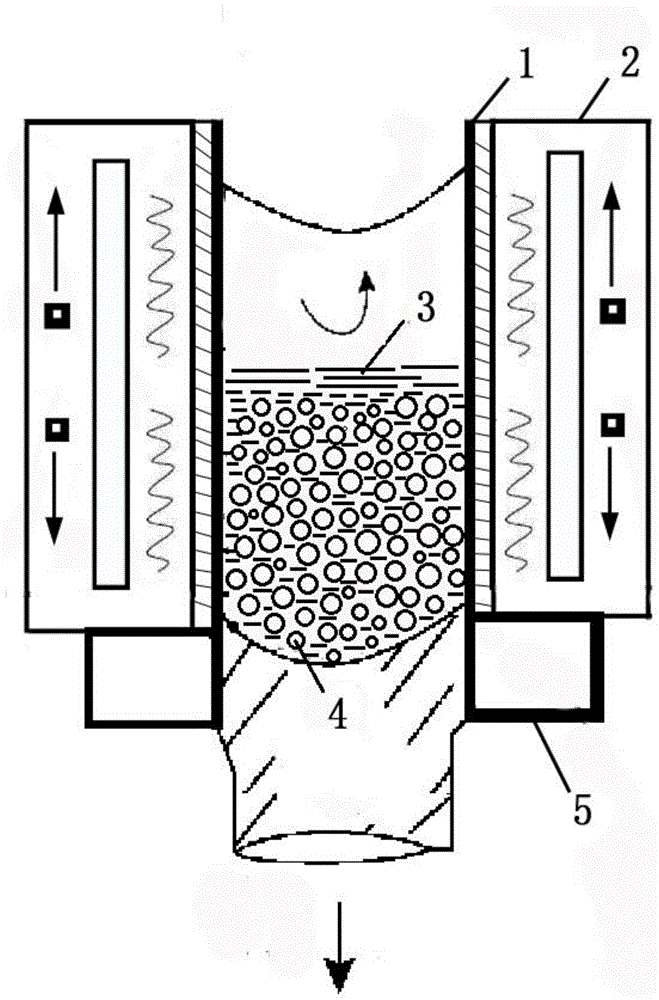

Preparation method of hybrid hollow sphere metal-matrix lightweight composite material

The invention relates to a preparation method of a hybrid hollow sphere metal-matrix lightweight composite material. A metal-matrix composite material containing closed bubble holes is formed by filling hollow spheres into metal matrix; the hollow spheres are SiC hollow spheres, Al2O3 hollow spheres, C hollow spheres or two or more hybrid hollow spheres which are the same or different in diameter and are mixed at any ratio in glass beads; and the metal matrix is commercially available aluminum, magnesium, zinc, copper, titanium and iron or aluminum alloy, magnesium alloy, zinc alloy, copper alloy, titanium alloy and iron alloy. The porosity of the hybrid hollow sphere metal-matrix lightweight composite material prepared by the method is over 50%; the density is significantly reduced; the compression strength of the material can be kept, and thus high strength and light weight are achieved; and meanwhile, the hybrid hollow sphere metal-matrix lightweight composite material has a plurality of functions of damping shock absorption, sound-insulated noise reduction, energy absorption and the like, and also has the advantages of low cost, simple process, and wide application range on hollow sphere varieties and dimensions, and can be continuously produced, and thus the production efficiency is greatly improved.

Owner:TONGJI UNIV

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190AStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberAdhesive

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

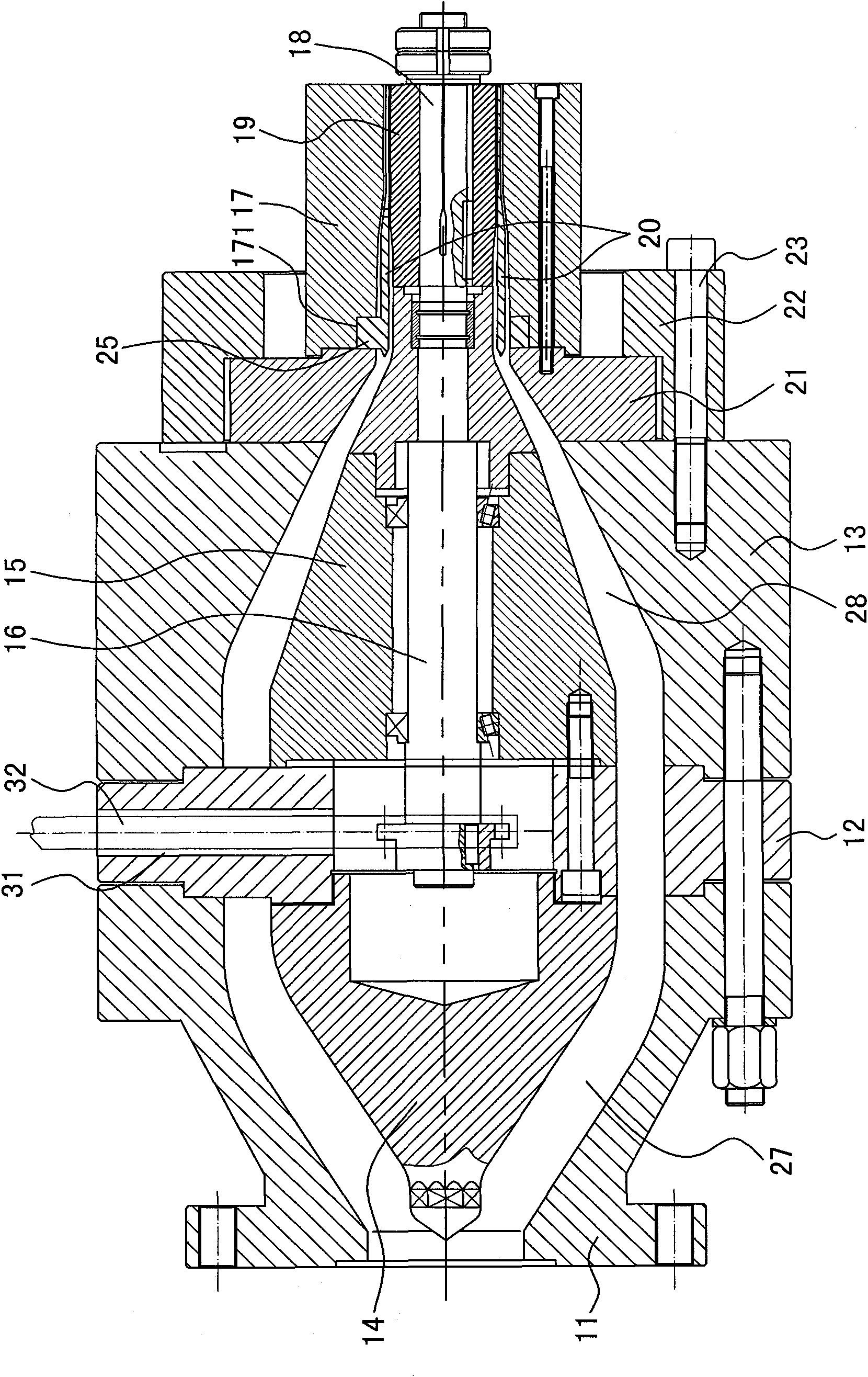

Multipurpose thimbleshaped valve respiration valve

The invention discloses a multipurpose cap-shape valve respiratory valve, comprising a valve seat, a valve core and a fixed sleeve; the valve core is of cap shape and made of elastic rubber; the cap rim of the valve core is fixed between the valve seat and the fixed sleeve; the cap body is sheathed in the central hole of the valve seat or the fixed sleeve; furthermore, the top of the cap of the valve core is provided with at least two lancings so that at least one valve clack is formed at the top of the cap. the lancings are distributed all around in a radial pattern from the axle center projected at the top of the cap to form a taper angle shape valve clack, or a C shape, V shape, U shape or opening polygon shape valve clack to cause the end part projected at the top of the cap to form a flip-shell valve clack or cause the lateral side projected at the top of the cap to form at least two valve clacks. The invention has the advantages of simple structure, few faults, long service life, low manufacturing cost, multiple functions and extensive usage, is favorable for environment protection, and has good social and economical benefits.

Owner:刘景福

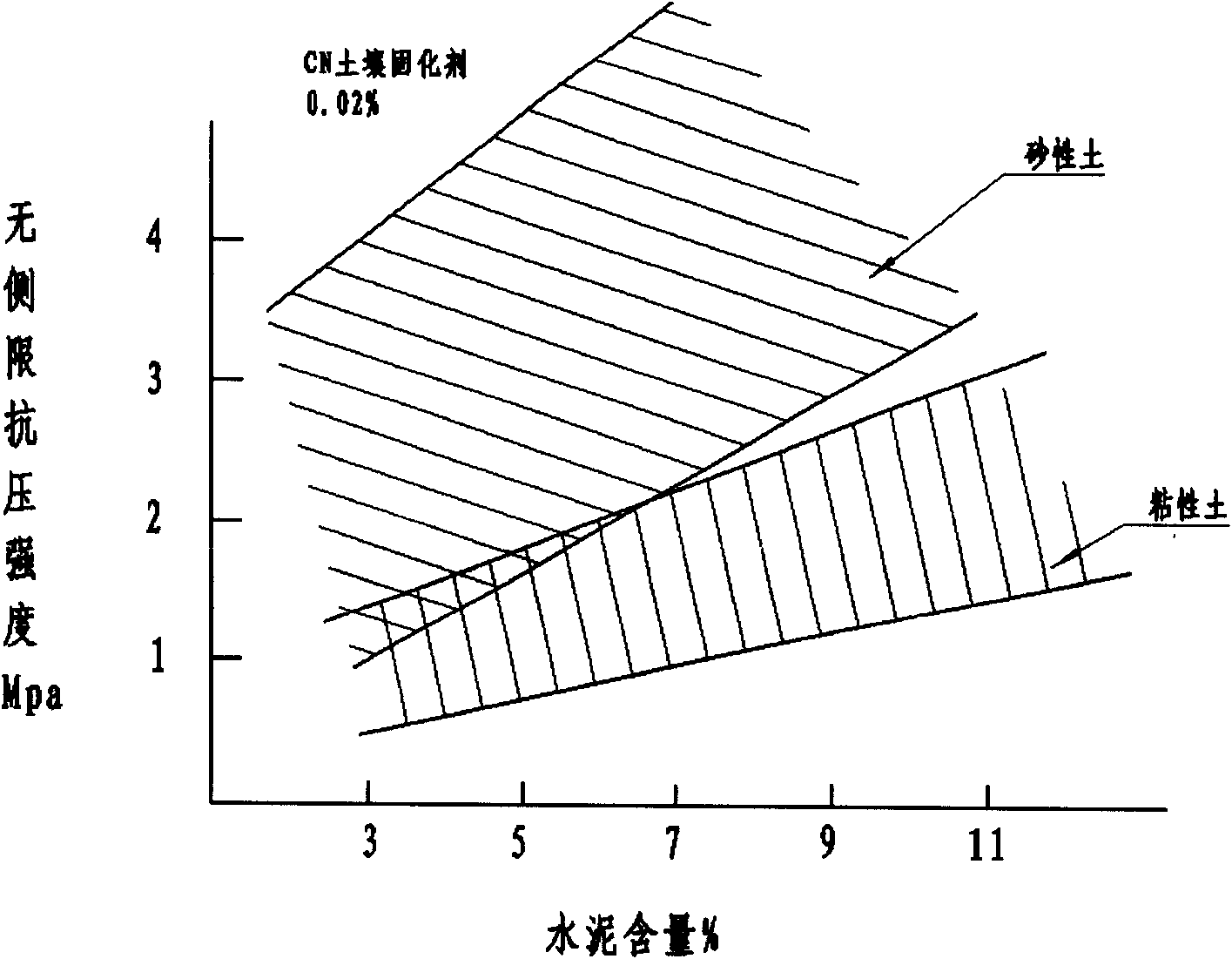

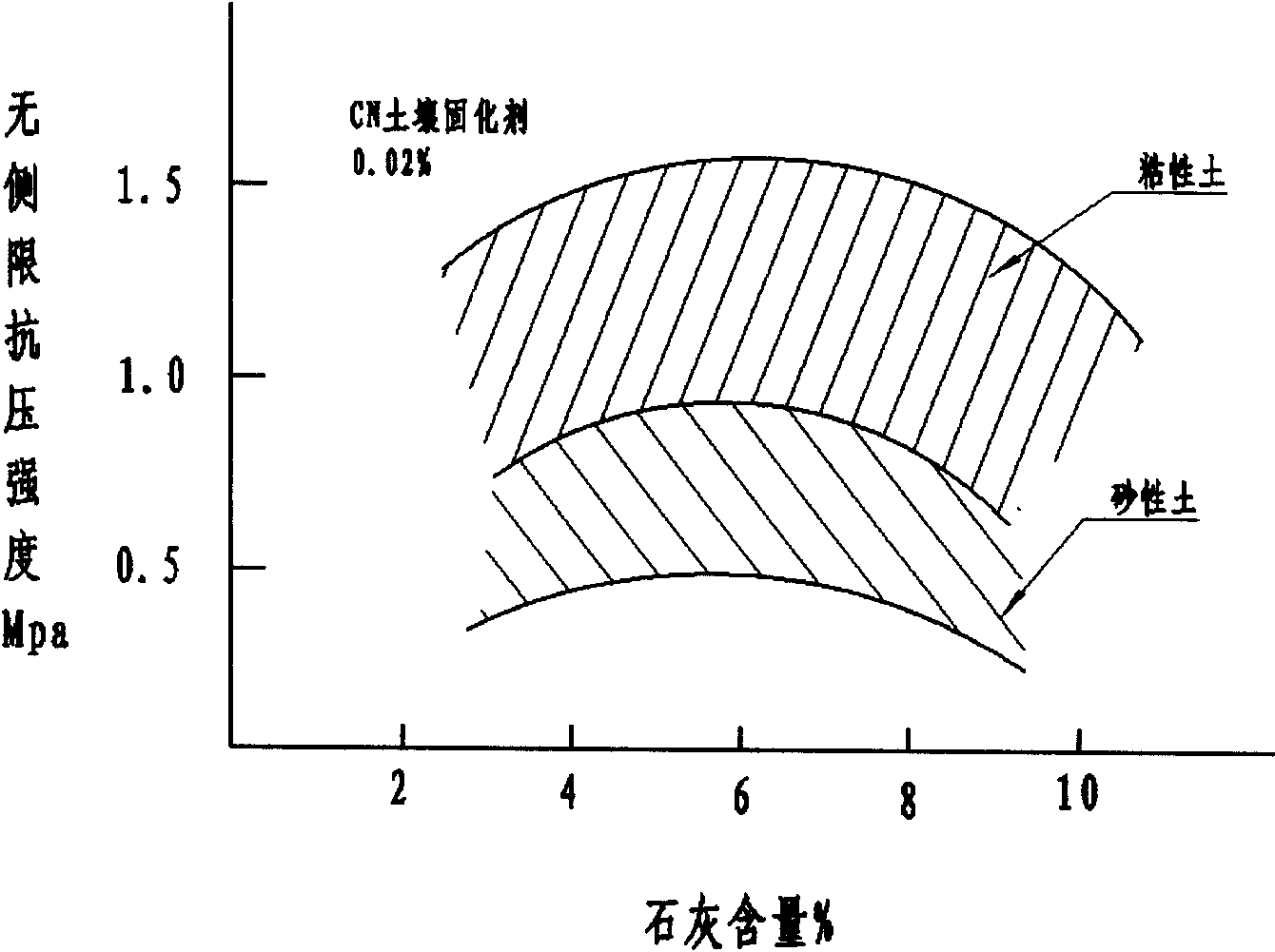

Soil chemical stabilizer formula and application

InactiveCN101684409AImprove compaction efficiencyImproved resistance to water immersionRoadwaysWallsWater contentChemistry

The invention discloses a soil chemical stabilizer formula and an application. The formula is characterized by comprising raw material components in parts by weight: 70-93 parts of sulfuric acid, 3-30parts of rosin oil, 1-6 parts of wetting agent, 0.5-1.7 parts of dispersing agent and 0.3-1.5 parts of thickening agent. Soil and the soil chemical stabilizer are stirred evenly for compaction and maintenance under the condition of the optimum water content, wherein the addition amount of the soil chemical stabilizer accounts for 0.01-0.04% of the soil; the soil chemical stabilizer can be used independently, while a little of concrete or lime needs to be added in many cases; the construction of the stabilizer adopts traditional equipment, and the construction method is the same as the conventional process. The soil chemical stabilizer has the characteristics of low cost, excellent performance and environmental friendly materials, and can be widely applied in the fields, such as subgrade construction, water conservancy construction, country roads, temporary sites, low cost road pavements, wall building and brick making and the like.

Owner:孙建国

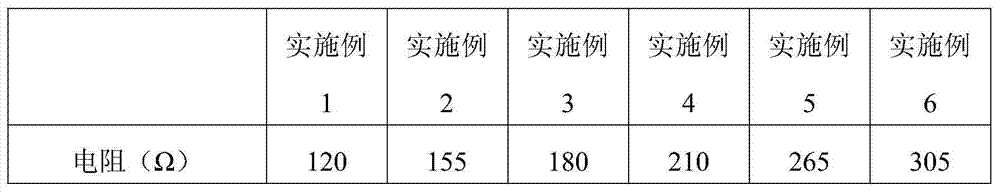

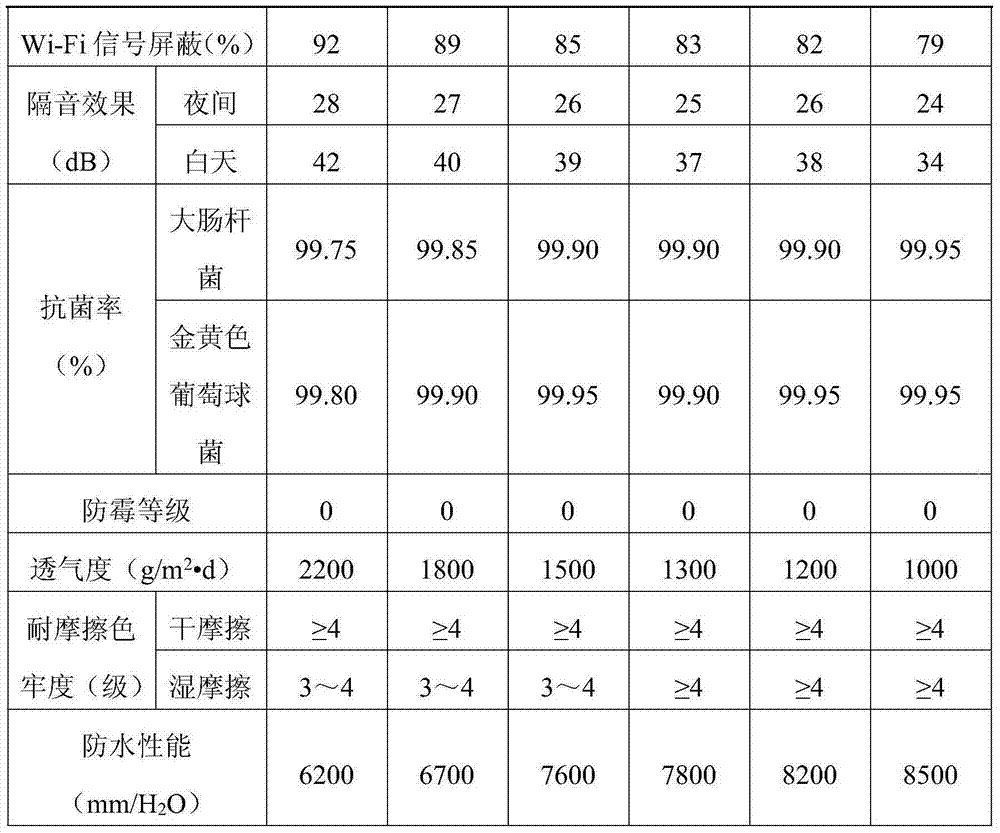

Multifunctional wallpaper capable of shielding Wi-Fi signals and production method thereof

InactiveCN103924758AConductiveWith sound insulation and noise reductionAntifouling/underwater paintsLamination ancillary operationsWater basedElectricity

The invention relates to multifunctional wallpaper capable of shielding Wi-Fi signals and a production method thereof. The multifunctional wallpaper comprises a base, a multifunctional layer on the base, and a pattern layer printed on the multifunctional layer. The production method of the multifunctional wallpaper includes the steps of selecting base material; preparing material of the multifunctional layer; preparing evenly-dispersed slurry; preparing uniform water-based paint; preparing the multifunctional layer; printing the multifunctional layer; producing a finished product. The multifunctional wallpaper has the functions of shielding Wi-Fi signals, conducting electricity, insulating, decreasing noise, inhibiting bacteria, preventing molds, proofing moisture and the like, human, equipment and information security can be protected, and application range of the wallpaper is widened.

Owner:宋旭 +1

Antimicrobial radiation-preventing formaldehyde-degrading ecological diatom wall material

The invention discloses a wall material belonging to the field of building decoration, and specifically relates to antimicrobial radiation-preventing formaldehyde-degrading ecological diatom wall material paint and a preparation process and construction process of the wall material. The wall material is prepared from the following components in percentage by weight: 21-29% of kieselguhr, 15-20% of quartz sand, 0.1% of fiber, 7-8.6% of bentonite, 3-5% of attapulgite, 12-17% of sierozem, 6-8% of water-retaining agent, 8-12% of nano titanium dioxide, 3-6.1% of nano zinc oxide, 3-5% of zeolite, 3-5% of micro silicon powder, 3-5% of grammite and 3-7% of anion powder. The wall material disclosed by the invention has the effects of adsorbing toxic and harmful gas, resisting bacteria, preventing radiation and degrading formaldehyde, and diatom ooze enables the product to have the powerful characteristics of breathing, conditioning and purifying air; and the wall material has the functions of fire resistance, flame retardance, sound insulation, noise reduction, warm keeping and heat insulation. Thus, the wall material is an ideal wall decoration material combining an environmental protection function and artistic modeling.

Owner:广东太氧谷环保科技有限公司

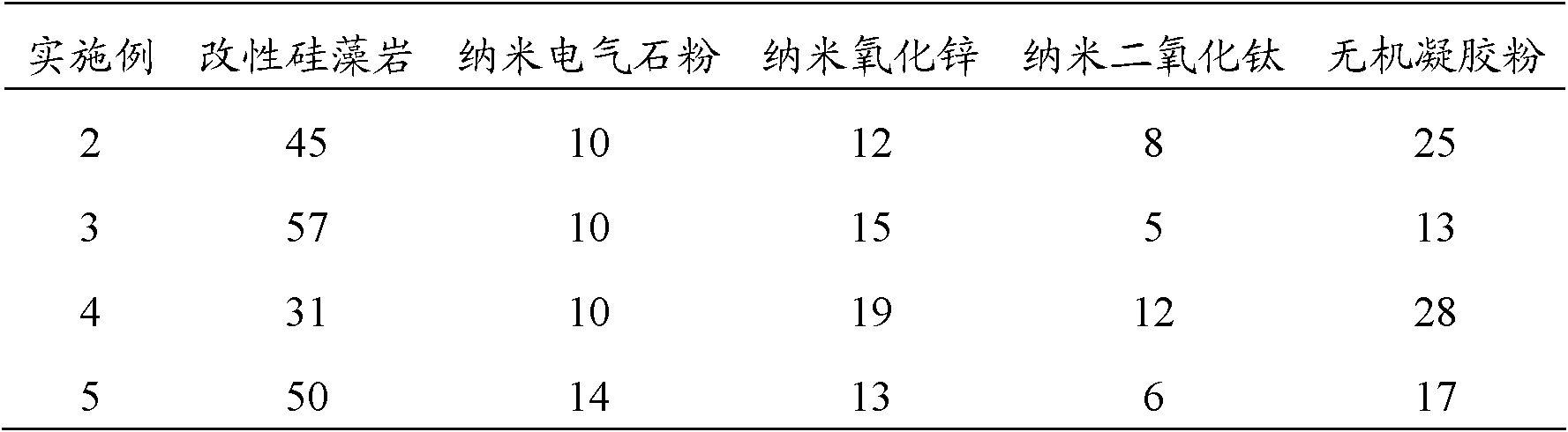

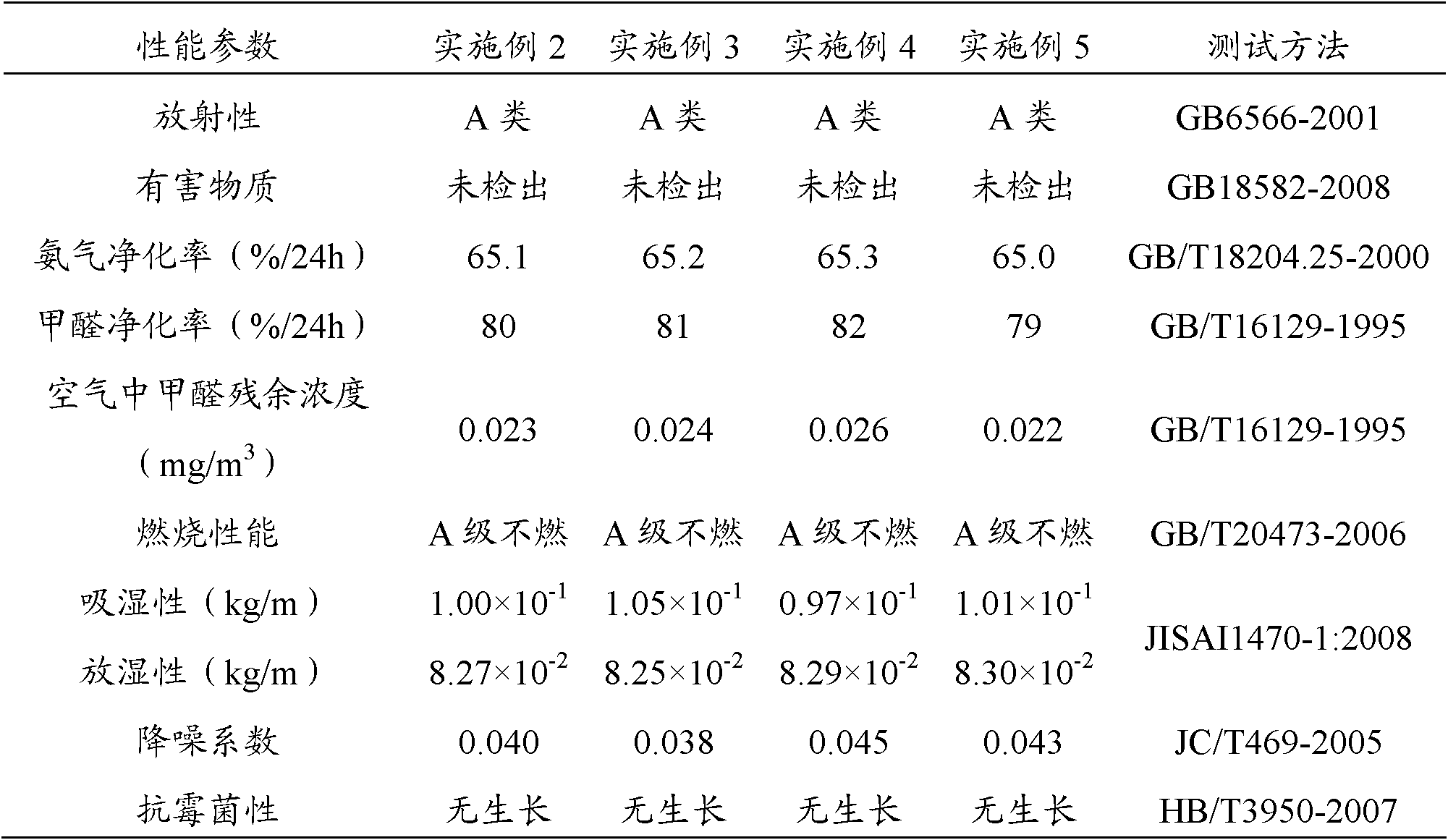

Tripoli composition

InactiveCN102320784AImprove humidity control performanceImprove noise immunityHazardous substanceNano zinc oxide

The invention provides a tripoli composition which comprises the following components in percentage by weight: 30-60 percent of octadecanoic acid modified tripoli, 5-15 percent of nano tourmaline powder, 5-20 percent of nano zinc oxide, 3-15 percent of nano titanium dioxide and 10-40 percent of inorganic gel powder. The tripoli composition provided by the invention has decorative effect, favorable air permeability, wet regulation and noise resistance and favorable air purifying capability. Tests indicate that the tripoli composition provided by the invention has no harmful substances or radioactivity and has the 24h ammonia purifying efficiency of higher than 65 percent, 24h formaldehyde purifying efficiency of higher than 75 percent and the noise reducing coefficient of 0.04 or so.

Owner:董卜祯

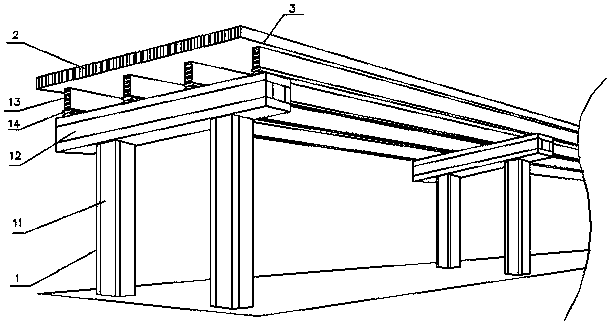

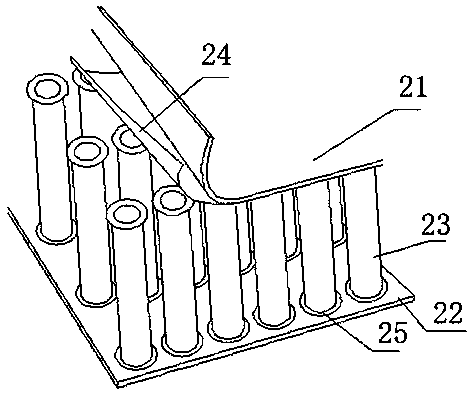

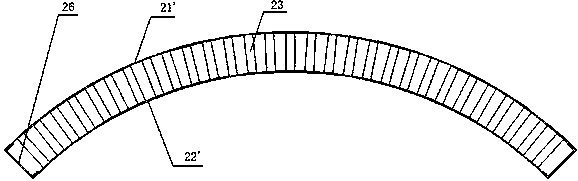

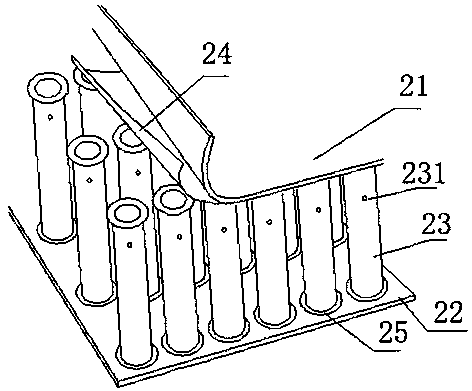

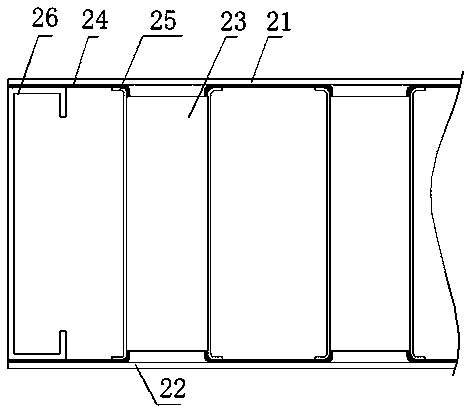

Viaduct structure

InactiveCN109403210AReduce stressIncrease the welding areaBallastwayDoors/windowsEngineeringTemperature resistance

A viaduct structure comprises a deck and a supporting body used for supporting the deck. The viaduct structure is characterized in that the deck and / or the supporting body is made of a metal plate; the metal plate comprises a first panel, a second panel and multiple hollow pipes, wherein the multiple hollow pipes are arranged between the first panel and the second panel; brazing layers are arranged between the hollow pipe and the first panel and between the hollow pipe and the second panels; and a turned-up edge is arranged at at least one end of each hollow pipe. The viaduct structure has theadvantages of light deadweight, high strength, stable structure, high pressure bearing capacity, sound insulation and noise reduction, high temperature resistance, vibration resistance, long servicelife and the like, and the viaduct structure can also be conveyed and spliced.

Owner:张跃

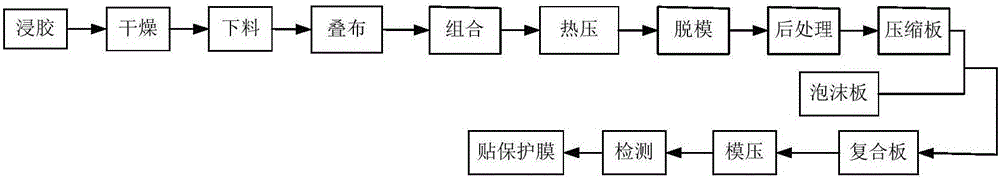

Basalt fiber reinforced foam base composite heat-preservation layer and producing method thereof

InactiveCN106337508AExcellent heat insulation, noise prevention and flame retardant performanceImproved heat insulation and noise reductionSynthetic resin layered productsLaminationOptoelectronicsNoise reduction

The invention relates to a production method for a basalt fiber reinforced foam base composite heat-preservation layer. The production method is characterized by comprising the following steps: 1, producing a compressed plate; 2, arranging a heat-preservation layer on the compressed plate; 3, performing detection and aftertreatment. By adopting the production method provided by the invention, compressed plates made of basalt fiber fabrics / needled felt in a compressing manner are added on two sides of a foam plate, so that the properties of heat insulation, noise reduction and flame retardancy improvement, of the heat-preservation layer can be improved, the loss caused by fire hazard can be reduced, a comfortable and quiet rest environment can be provided for people in daily life, and meanwhile, the strength of the heat-preservation layer is improved to a certain extent when being compared with that of a pure foam plate heat-preservation layer.

Owner:HUNAN UNIV

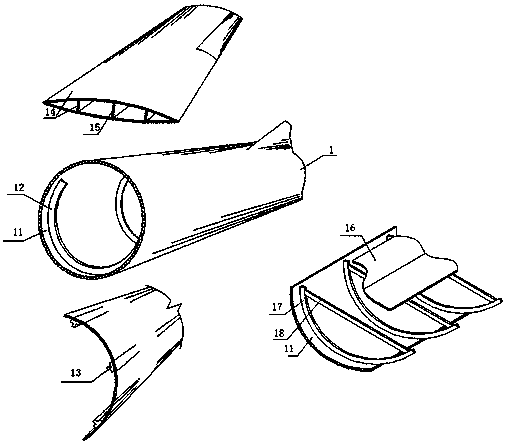

Aerial vehicle structure

An air vehicle structure comprises a framework structure and a skin connected with the framework structure, wherein at least one of the framework structure and the skin is made of plate metal; the plate metal comprises a first panel, a second panel as well as a plurality of hollow tubes arranged between the first panel and the second panel, and brazing layers are arranged between the hollow tubesand the first panel as well as between the hollow tubes and the second panel; a turning edge is arranged at at least one end of the hollow tubes. The aerial vehicle structure has the advantages of being small in self-weight, high in strength, stable in structure, high in impact resistance, capable of insulating sound and reducing noise, resistant to high temperature, corrosion and vibration, longin service life, capable of being carried and spliced and the like.

Owner:张跃

Polyester fiber reinforced anti-cracking diatom ooze material, and preparation method thereof

The invention discloses a polyester fiber reinforced anti-cracking diatom ooze material, and a preparation method thereof. The polyester fiber reinforced anti-cracking diatom ooze material comprises, by mass, 15 to 35 parts of diatomite, 20 to 40 parts of heavy calcium carbonate, 8 to 20 parts of ash calcium powder, 8 to 20 parts of quartz sand, 2 to 5 parts of nanometer titanium dioxide, 1 to 4 parts of tourmaline, 0.5 to 2.5 parts of cellulose ether, 0.1 to 0.5 part of pregelatinized starch, and 0.1 to 2 parts of polyester fiber. According to the preparation method, diatomite, heavy calcium carbonate, ash calcium powder, quartz sand, nanometer titanium dioxide, tourmaline, and polyester fiber are taken as the raw materials, nontoxic and renewable adhesives cellulose ether and pregelatinized starch are also added, so that the obtained polyester fiber reinforced anti-cracking diatom ooze material possesses excellent cracking resistance and anti-pulverization ability; the preparation method is safe, and is friendly to the environment; production cost is low; and large-scale production can be realized easily.

Owner:东莞市爱乐居环保科技有限公司

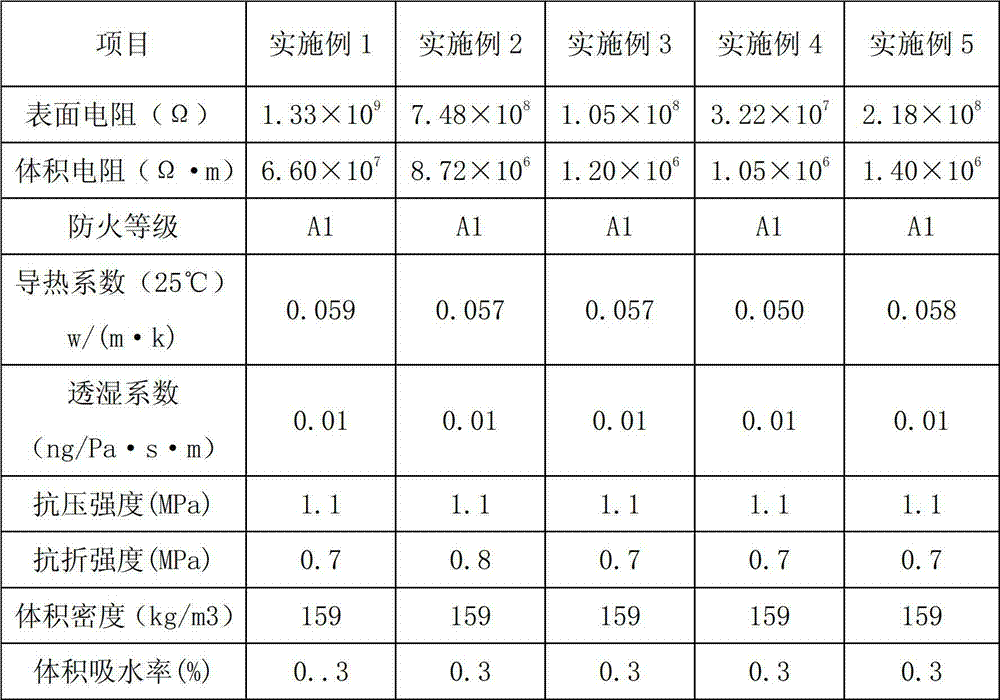

Anti-static foam glass heat insulation and cold insulation material and preparation method thereof

InactiveCN102923959AFireproofWith sound insulation and noise reductionGlass shaping apparatusCombustionThermal insulation

The invention discloses an anti-static foam glass heat insulation and cold insulation material and a preparation method thereof. The preparation method comprises the steps of: carrying out ultra-refining fusion permo-treatment on a special high-temperature resistant conductive metallurgical powder material and a metal oxide serving as adding materials for realizing phase modification; controlling the combustion atmosphere by using a special process, expanding at a high temperature and sintering for forming; and finally, annealing and cooling to prepare the anti-static foam glass heat insulation and cold insulation material. The anti-static foam glass heat insulation and cold insulation material maintains the advantages of water prevention, heat insulation, cold insulation, water and moisture prevention, good chemical stability, sound insulation, noise reduction and the like of foam glass, and has a permanent conductive (static) and static dissipative function. The use space and the application range of the foam glass material are expanded.

Owner:JIANGSU SUNPOWER TECH

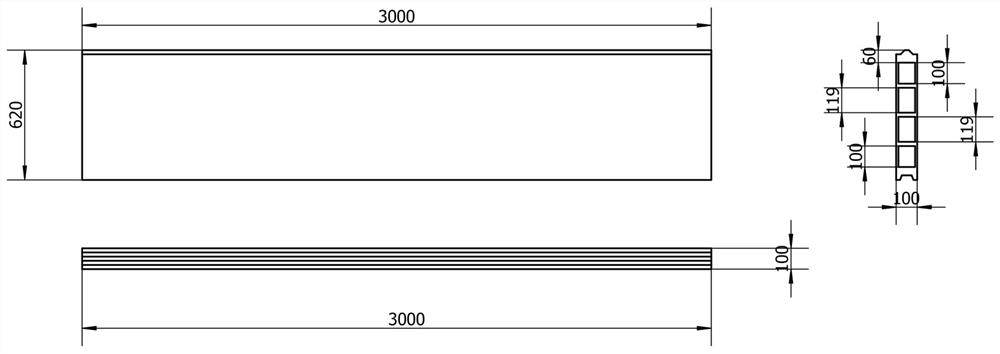

Method for preparing stoneware batten for fabricated building by utilizing industrial solid waste

PendingCN113387681ALightweight and high strengthWith sound insulation and noise reductionCeramic materials productionClaywaresHeat conservationProcess engineering

The invention relates to a method for preparing a stoneware batten for a fabricated building by utilizing industrial solid waste. The stoneware batten is formed by mixing solid powder and water according to the weight ratio of 1: (0.1-0.25), and comprises the following components in percentage by weight: 75%-95% of solid waste raw materials; 3%-15% of raw mineral materials; and 2%-10% of chemical raw materials. The method comprises the following steps: preparing formula raw materials; mixing and stirring; homogenizing and aging; performing vacuum pugging; performing extrusion molding; drying the green body; sintering at high temperature; and processing. The technical problems that a traditional wall material is large in volume weight, poor in waterproof effect and poor in energy-saving and heat-preserving effect are well solved.

Owner:SHENYANG POLYTECHNIC UNIV

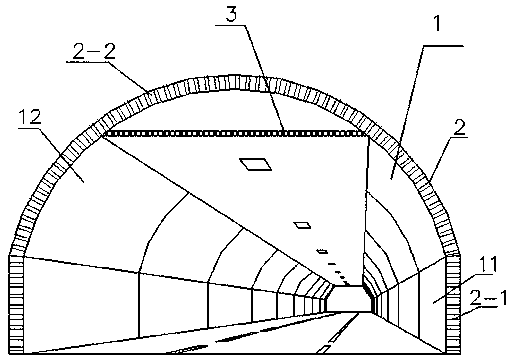

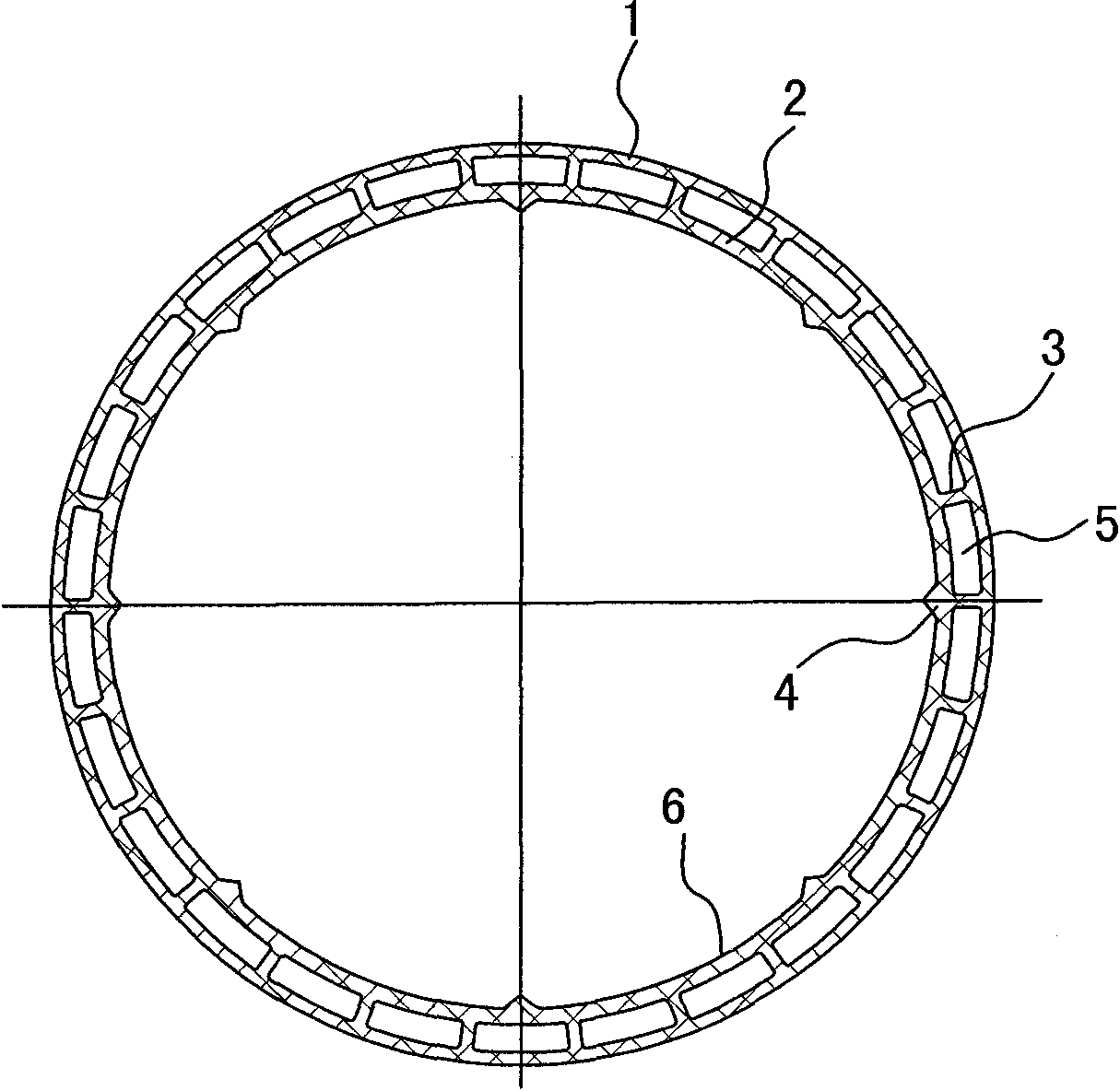

Tunnel structure

The invention discloses a tunnel structure. The tunnel structure comprises a tunnel body, and the tunnel body is formed by spicing a plurality of metal plates. The metal plates comprise first panels,second panels and a plurality of hollow pipes, wherein the hollow pipes are arranged between the first panels and the second panels. Brazing layers are arranged between the hollow pipes and the firstpanels as well as the second panels, and flangings are arranged at least one ends of the hollow pipes. The tunnel structure has the advantages of light self-weight, high strength, stable structure, sound insulation and noise reduction, high temperature resistance, vibration resistance, long service life, capability to be carried and assembled, short building period and the like.

Owner:张跃

A kind of preparation method of mixed hollow sphere metal matrix lightweight composite material

The invention relates to a preparation method of a hybrid hollow sphere metal-matrix lightweight composite material. A metal-matrix composite material containing closed bubble holes is formed by filling hollow spheres into metal matrix; the hollow spheres are SiC hollow spheres, Al2O3 hollow spheres, C hollow spheres or two or more hybrid hollow spheres which are the same or different in diameter and are mixed at any ratio in glass beads; and the metal matrix is commercially available aluminum, magnesium, zinc, copper, titanium and iron or aluminum alloy, magnesium alloy, zinc alloy, copper alloy, titanium alloy and iron alloy. The porosity of the hybrid hollow sphere metal-matrix lightweight composite material prepared by the method is over 50%; the density is significantly reduced; the compression strength of the material can be kept, and thus high strength and light weight are achieved; and meanwhile, the hybrid hollow sphere metal-matrix lightweight composite material has a plurality of functions of damping shock absorption, sound-insulated noise reduction, energy absorption and the like, and also has the advantages of low cost, simple process, and wide application range on hollow sphere varieties and dimensions, and can be continuously produced, and thus the production efficiency is greatly improved.

Owner:TONGJI UNIV

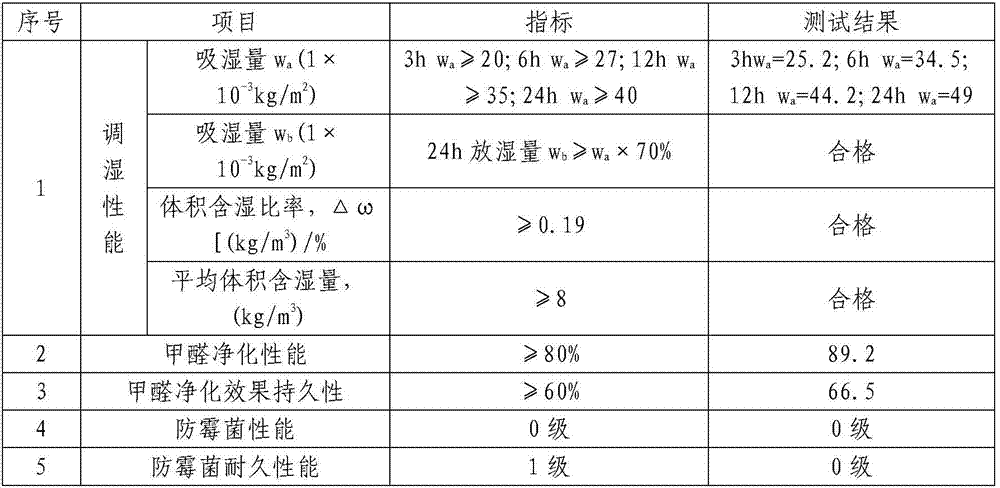

Composite roller blind door/window

InactiveCN104295216ASteady parkingHigh degree of intelligenceLight protection screensHeat transferAlloy

The invention discloses a composite roller blind door / window. The composite roller blind door / window comprises a bridge cutoff aluminum alloy door / window, an aluminum alloy roller blind window and a screen window, and is integrally designed; covers of the aluminum alloy door / window and the roller blind window both prevent heat transfer through an insulation bridge cutoff technology so as to keep the indoor temperature to achieve an energy-saving effect. The roller blind window is mounted outside glass of the aluminum alloy door / window for adjusting the indoor lighting. When the screen window is opened, mosquitoes are prevented from entering inside. The lifting and the overturning of roller blinds are controlled by a driving mechanism; an electric remote controller is prepared; and a controller can enable the roller blinds to be stopped and locked in any position without dropping, so that the stopping is stable. Meanwhile, the composite roller blind door / window further comprises a temperature / humidity induction probe for intelligently controlling the opening and closing of the outer sunshading and energy-saving roller blind window according to the value of external temperature / humidity, so that the composite roller blind door / window is more energy-conserving and environment-friendly.

Owner:湖州新峰塑业有限公司

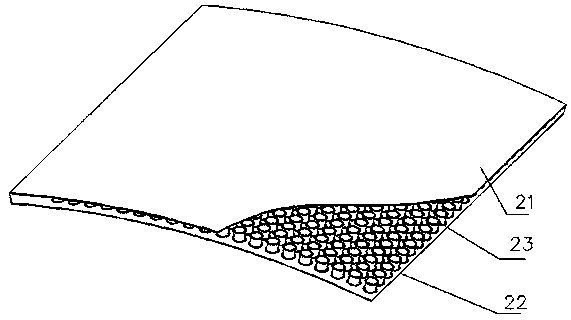

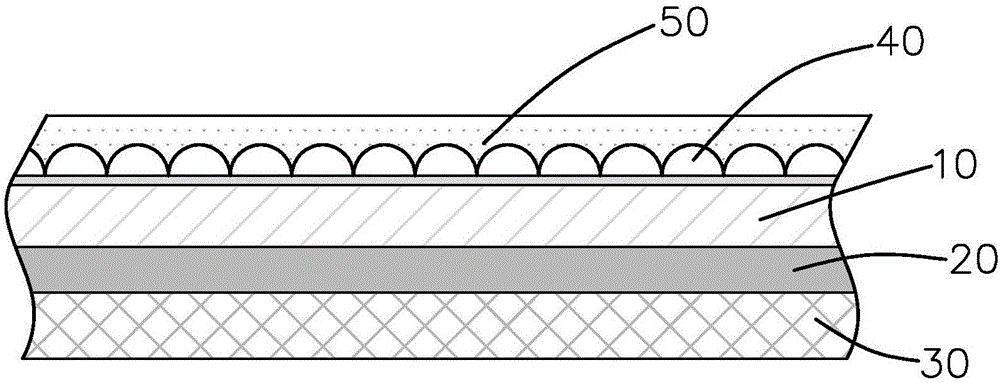

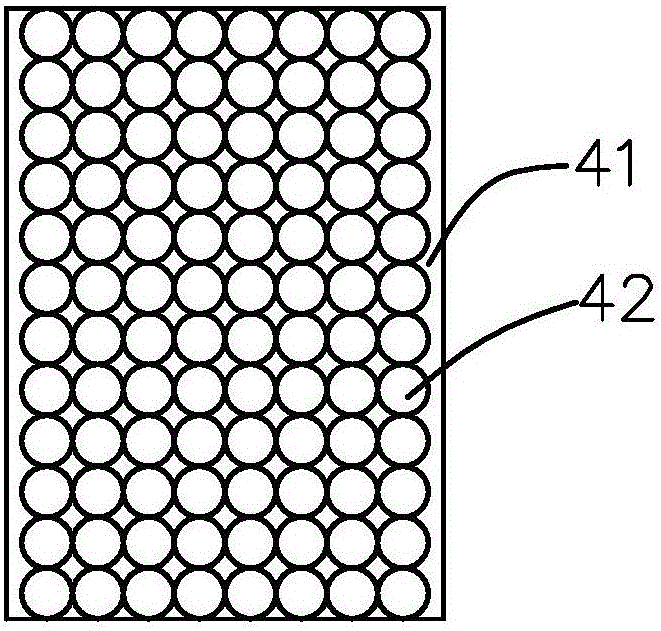

Soundproof sterilizing PVC composite board

InactiveCN106836704ALow costDecibel reduction functionCovering/liningsFlooringEngineeringNoise reduction

The invention discloses a soundproof sterilizing PVC composite board which sequentially comprises a PVC layer, a bonding layer, a substrate layer and a photocatalytic nano layer, wherein two sides of the bonding layer are bonded to the PVC layer and the substrate layer in a covering manner separately; a soundproof layer also covers the surface of the PVC layer; the soundproof layer comprises a bottom plate and a plurality of hemispherical soundproof shells, wherein the hemispherical soundproof shells are densely distributed on the surface of the bottom plate uniformly; the back surface of the bottom plate covers the PVC layer; and the photocatalytic nano layer covers the surface of the soundproof layer and fills the gap in the soundproof shell. The soundproof sterilizing PVC composite board has the advantages of moisture protection, sterilization, sound insulation, noise reduction and firm structure, and is suitable for being used as a wall decorating plate for home decoration.

Owner:张彩银

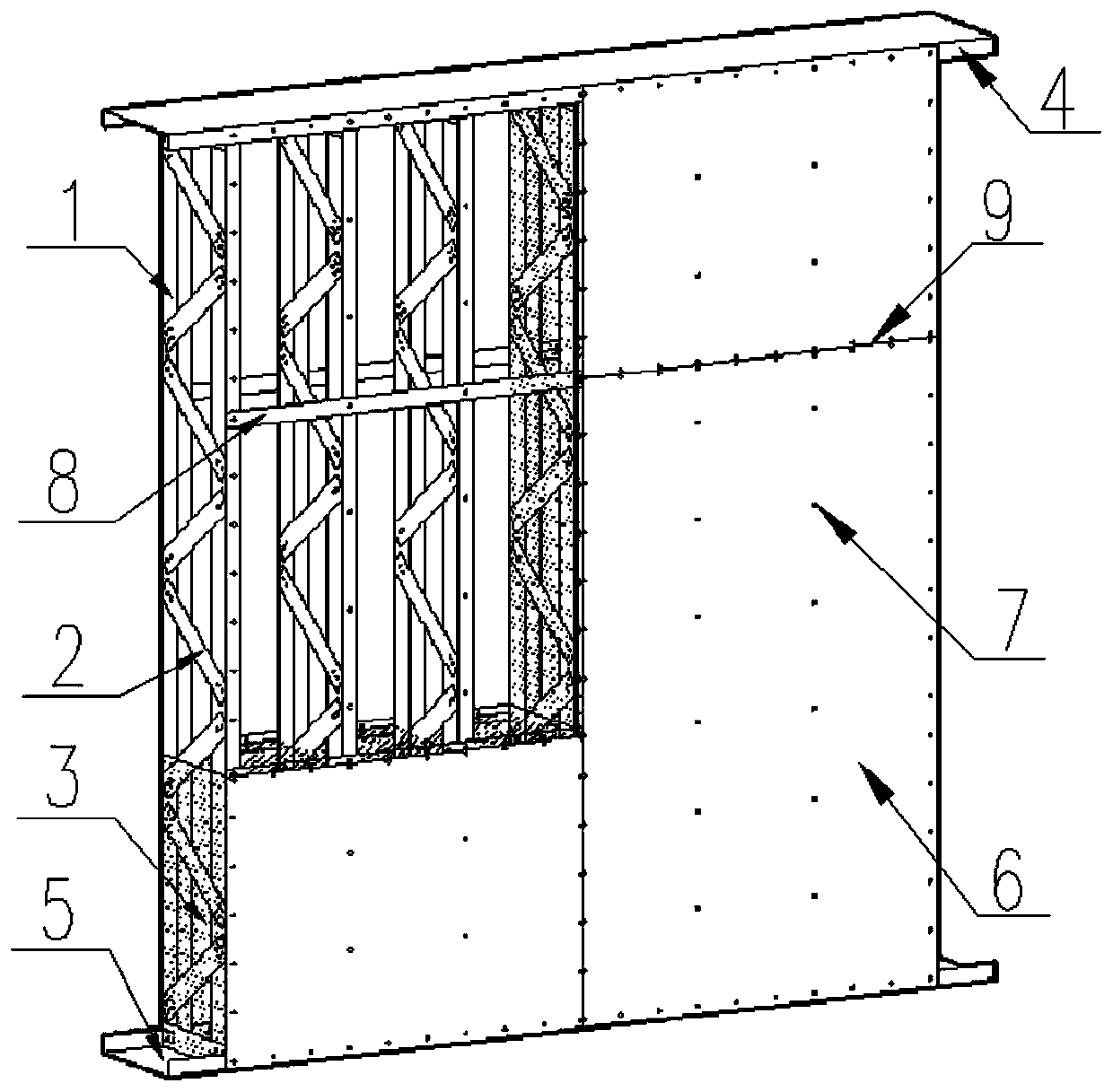

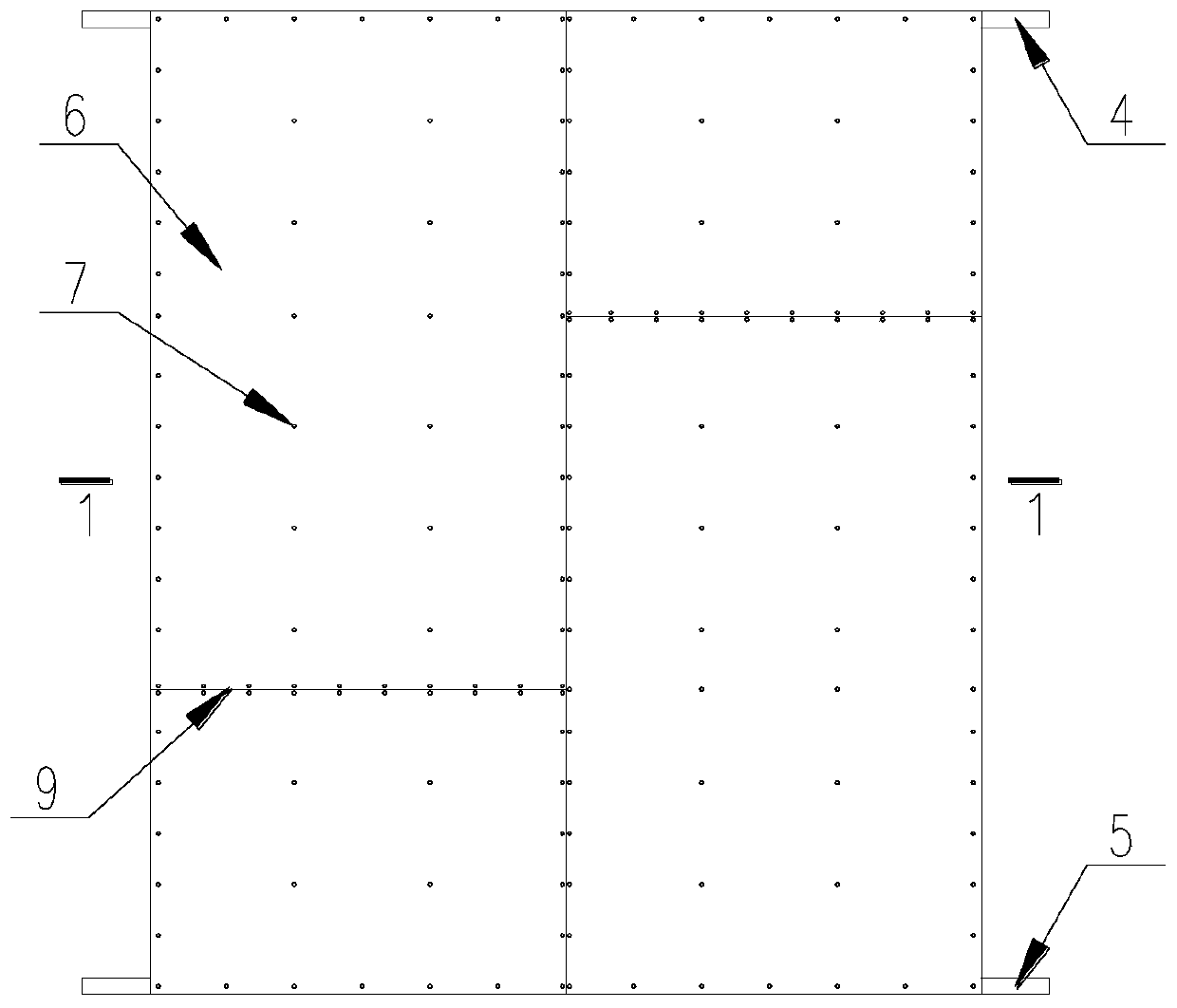

Cold-bending thin-walled steel lattice column composite wall with built-in straw grass brick

PendingCN109944365AHas viscoelastic propertiesWith thermal insulationWallsProtective buildings/sheltersBrickThermal insulation

The invention discloses a cold-bending thin-walled steel lattice column composite wall with a built-in straw grass brick. The wall comprises a composite wall skeleton formed by a cold-bending thin-walled steel lattice column and a top guide rail and a bottom guide rail, the composite wall skeleton is filled with the straw grass brick, and cover panels are fixed to both sides of the composite wallskeleton. The wall has high shear resistance and compression bearing capacity and large out-of-plane stiffness, provides convenience for the combination wall to absorb and dissipate seismic energy, has the advantages of green environmental protection, thermal insulation, sound insulation and noise reduction, and achieves structural heat insulation integration. In a low-rise and multi-story steel structure building, the strength, stiffnes and ability to absorb and dissipate the seismic energy of the structure can be significantly improved, it is convenient to manufacture and process, the wall can be prefabricated and produced in a plant, and on-site assembly and construction are achieved; waste is turned into a treasure, which can produce good social and economic benefits, help to protect the environment, promote the sustainable development of green buildings and has broad application prospects.

Owner:TIANJIN UNIV

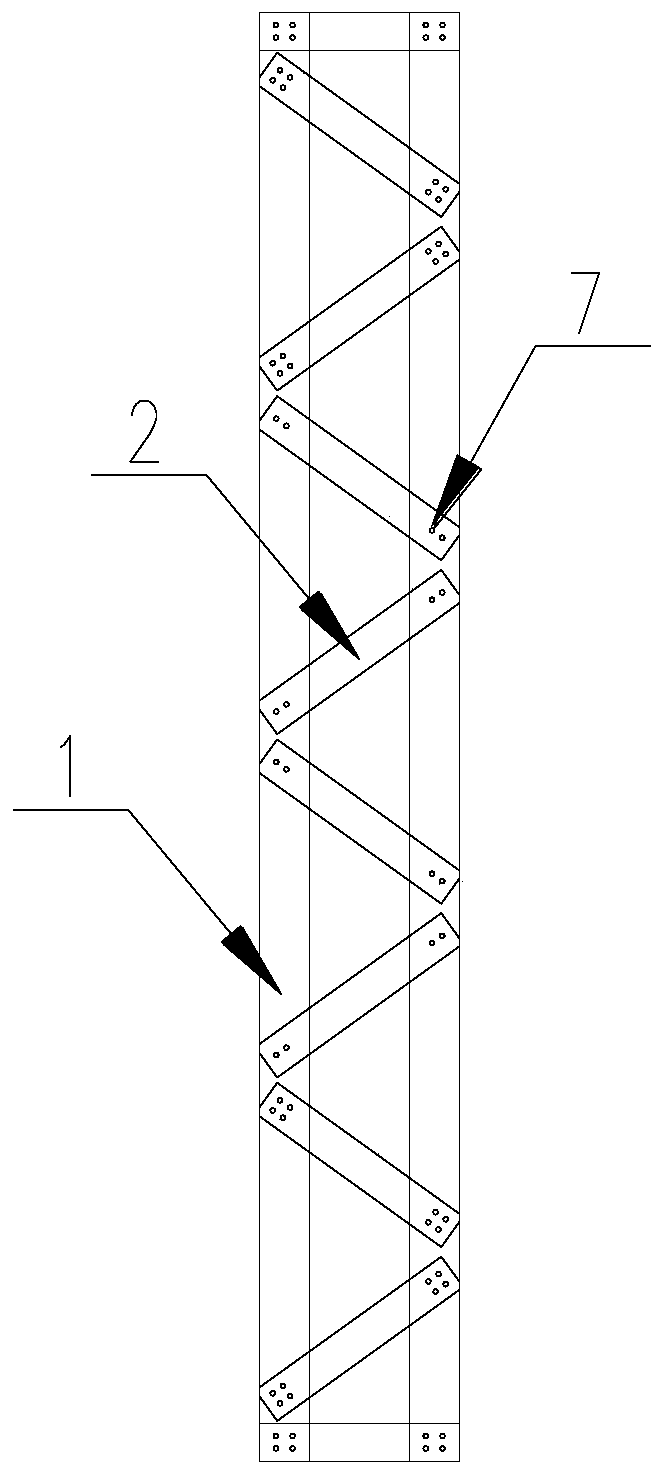

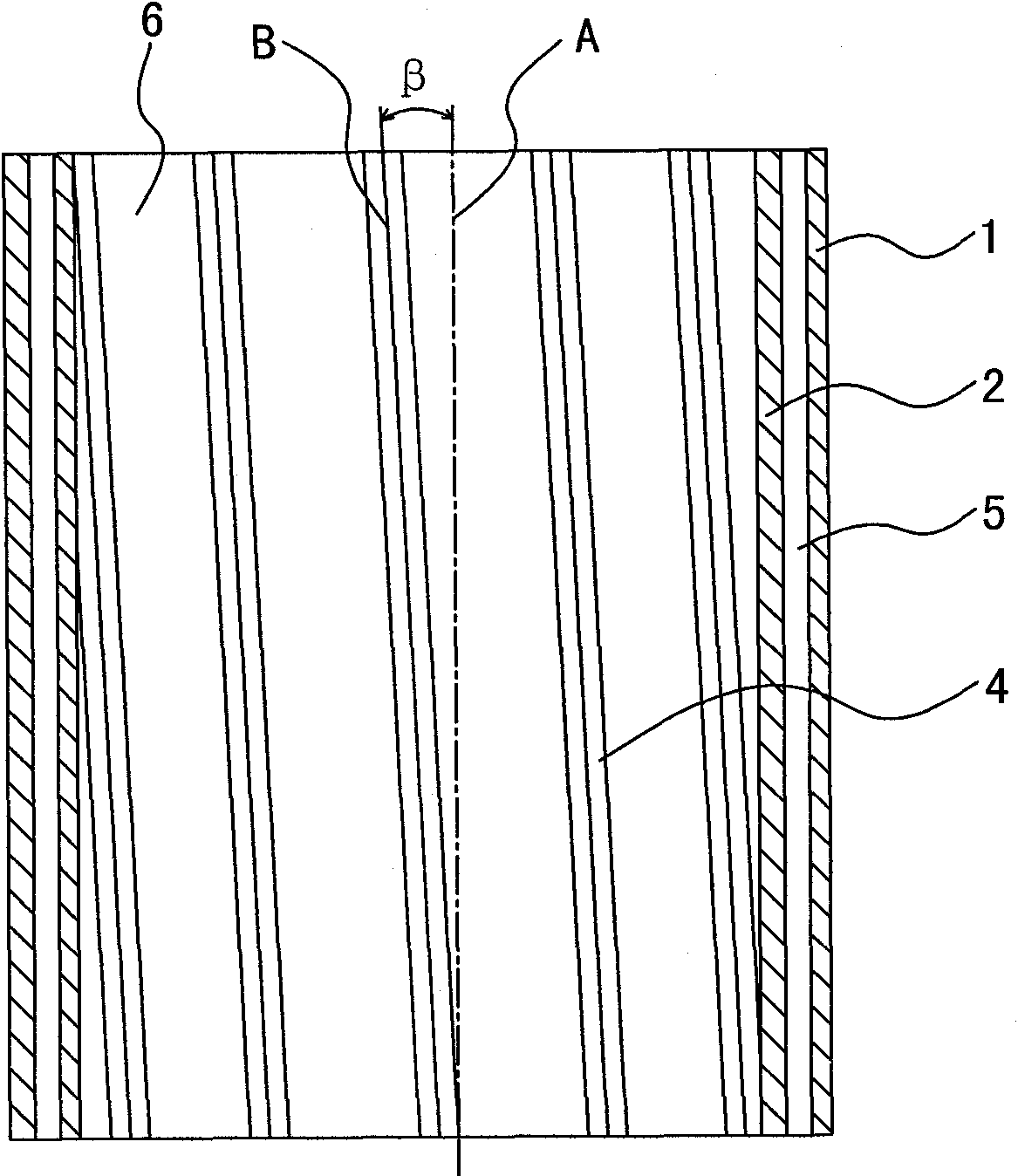

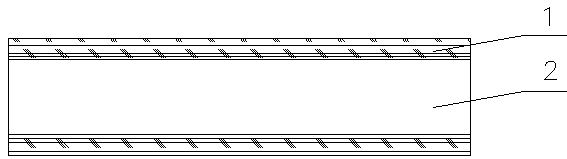

Oblique-straight helical water guide rib pipe and processing method thereof

ActiveCN101776193AWith sound insulation and noise reductionTo achieve the purpose of silencePipe elementsWater flowEngineering

The invention discloses an oblique-straight helical water guide rib pipe, which is composed of an inner layer and an outer layer which are interconnected via ribs, wherein the inner wall of the inner layer of the pipe is provided with helical ribs which are evenly distributed in an oblique-straight way, and an included angle between a central line B of the helical ribs and a central line A of the pipe is 12 to 30 degrees. In the proposal, the pipe is composed of the inner layer and the outer layer which are interconnected via the ribs to form a pipe, in particularly, the inner wall of the inner layer of the pipe is provided with helical ribs which are evenly distributed in an oblique-straight way, and under the guide of the helical ribs, water streams flow downwards along the inner wall of the inner layer of the pipe according to the oblique-straight trend of the helical ribs during drainage in order to avoid the water streams causing strong impact to the inner wall of the inner layer of the pipe, thereby achieving the purpose of lowering noise.

Owner:YONGGAO CO LTD

Gypsum board with composite glass fiber veneering felts on surfaces

InactiveCN108166695AAct as a skeleton supportHigh tensile strengthCovering/liningsGlass/slag layered productsPolyesterGlass fiber

The invention discloses a gypsum board with composite glass fiber veneering felts on surfaces, and relates to decorative boards for buildings. The gypsum board is mainly composed of a gypsum board core layer and the composite glass fiber veneering felts which are attached to the outer sides of the gypsum board core layer, and the composite glass fiber veneering felts comprise following raw materials of, by weight, 35-50 parts of glass fiber chopped wires, 30-45 parts of polyester fibers, and 10-25 parts of wood fibers; and the glass fiber chopped wires have a diameter of 30-35 mu and a lengthof 30-35 mm, the polyester fibers have a diameter of 20-30 mu and a length of 30-35 mm, and the wood fibers have a diameter of 14-20 mu and a length of 20-30 mm. According to the gypsum board with thecomposite glass fiber veneering felts on the surfaces, various fiber materials such as glass fibers, the polyester fibers and the wood fibers to form the composite glass fiber veneering felts with the effects of fire retardant, sound proofing and noise reduction and water proofing and mould proofing; and the composite glass fiber veneering felts are combined with a gypsum board core, or special materials are added into the gypsum board core, so that the effects of the fire retardant, the sound proofing and noise reduction and the water proofing and mould proofing are improved, and the servicelife is prolonged.

Owner:TAISHAN GYPSUM CO LTD

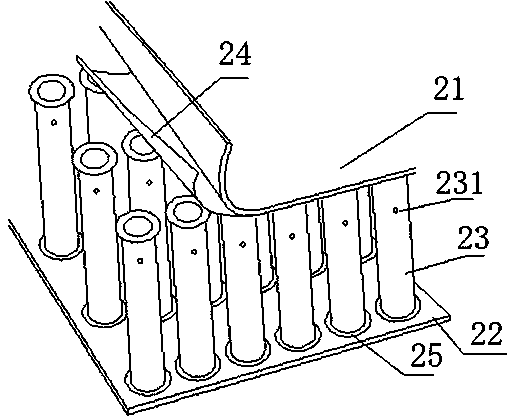

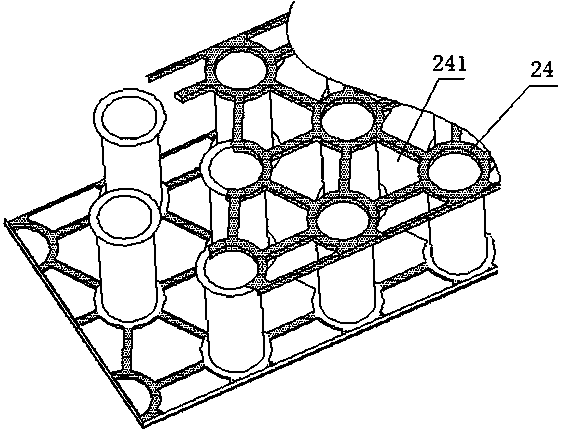

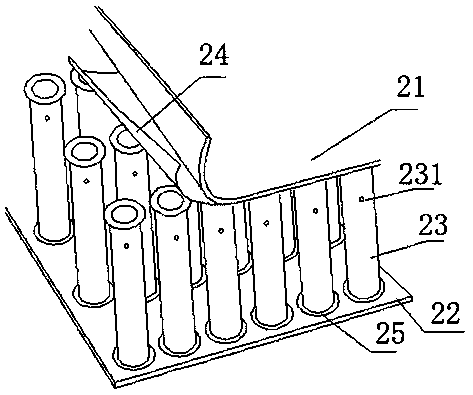

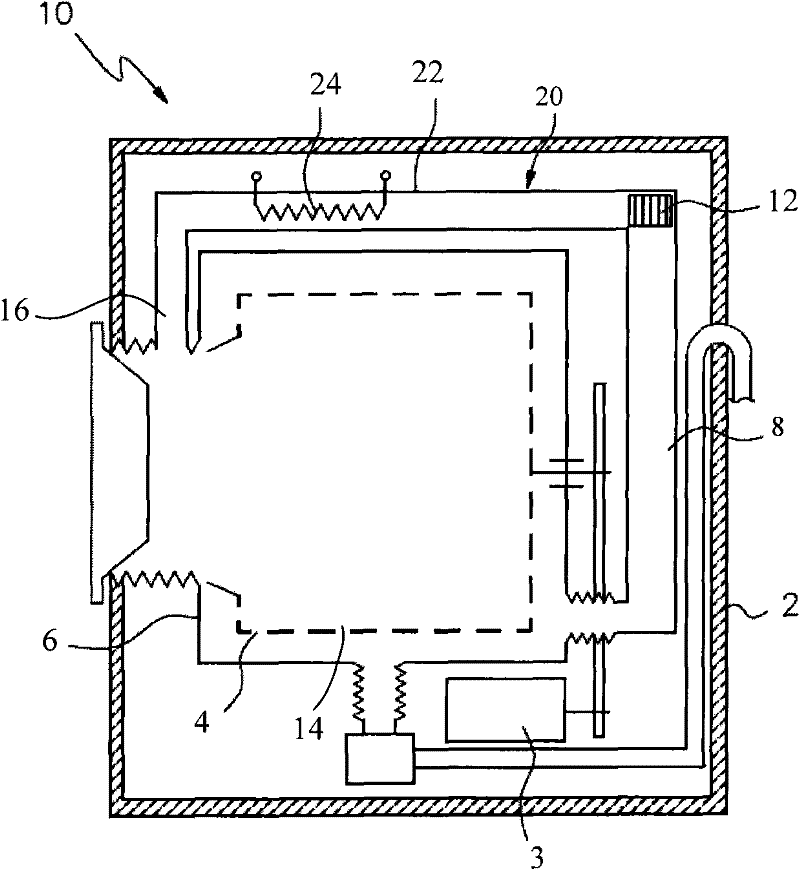

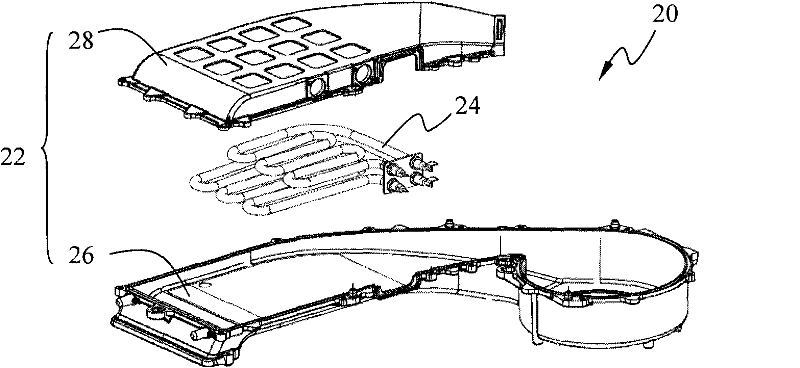

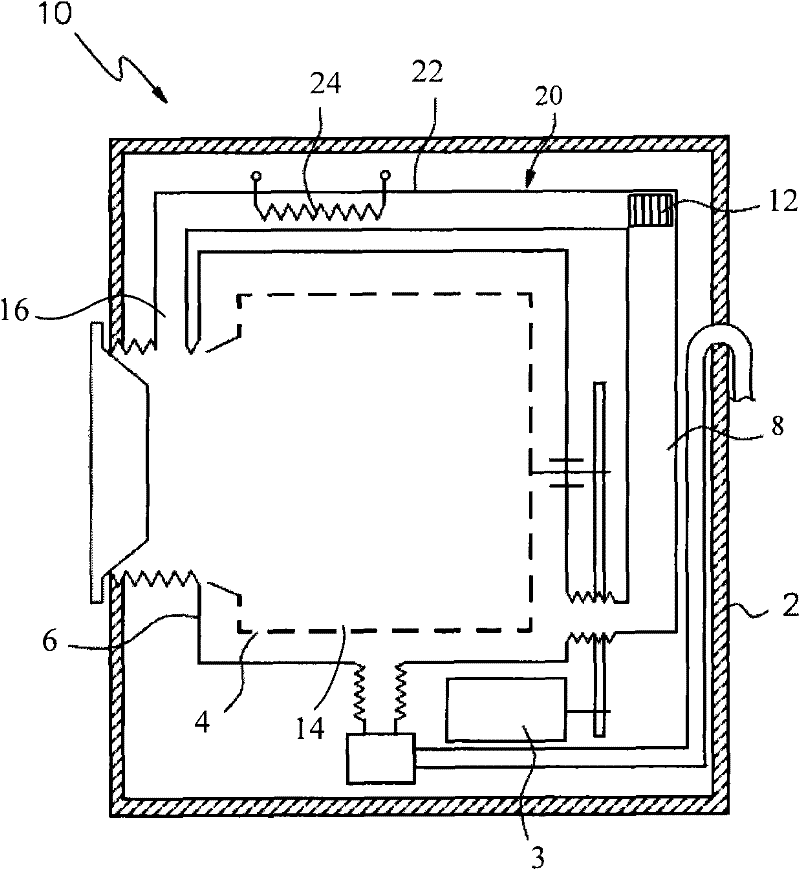

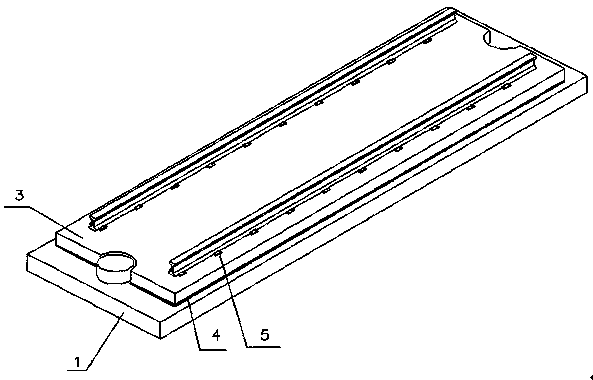

Air heating tunnel and fabric drying apparatus incorporating the same

InactiveCN102277713AReduce lossesWith sound insulation and noise reductionTextiles and paperLaundry driersAir heatingElectrical and Electronics engineering

An air heating passage (20) is provided, which includes a passage (22) allowing air to flow through and a heating device (24) installed in the passage (22) for heating the air passing through the passage (22), whereby at least one part of the passage (22) is made of a foam material. A fabric drying apparatus (10) is also provided, which includes a rotatable drum (4) for accommodating fabrics and the air heating passage (20) for heating air and sending the heated air into the drum (4).

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

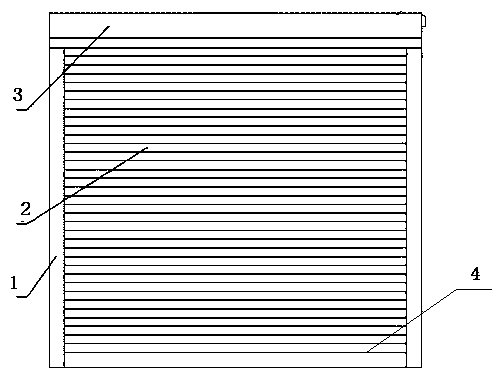

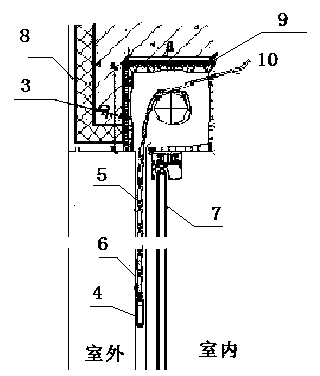

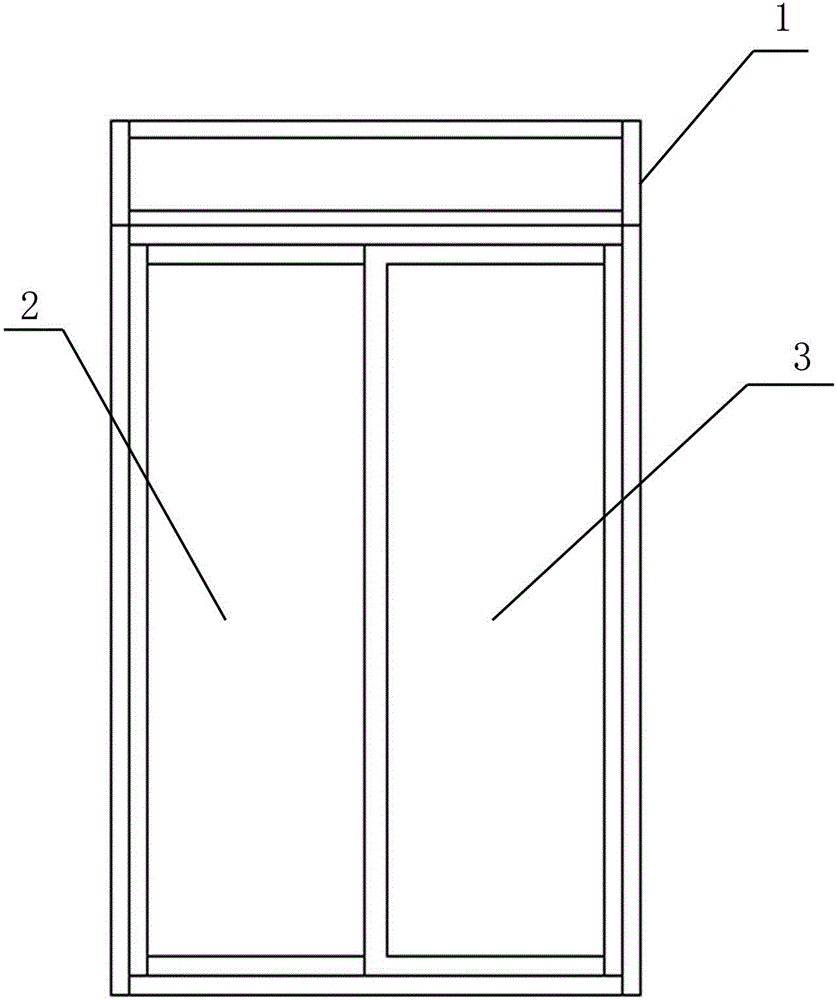

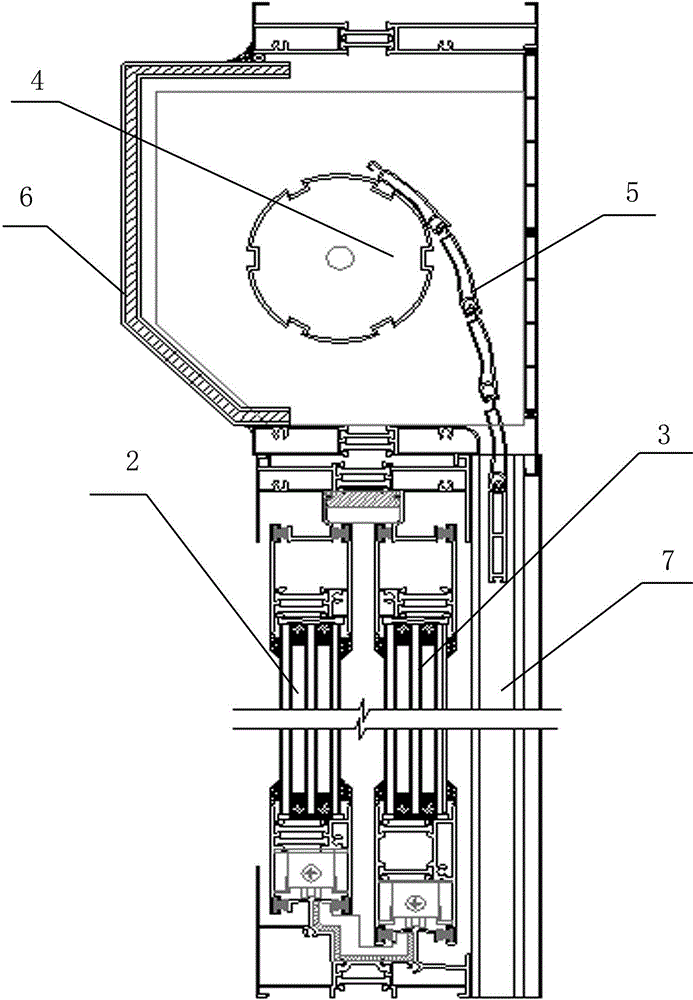

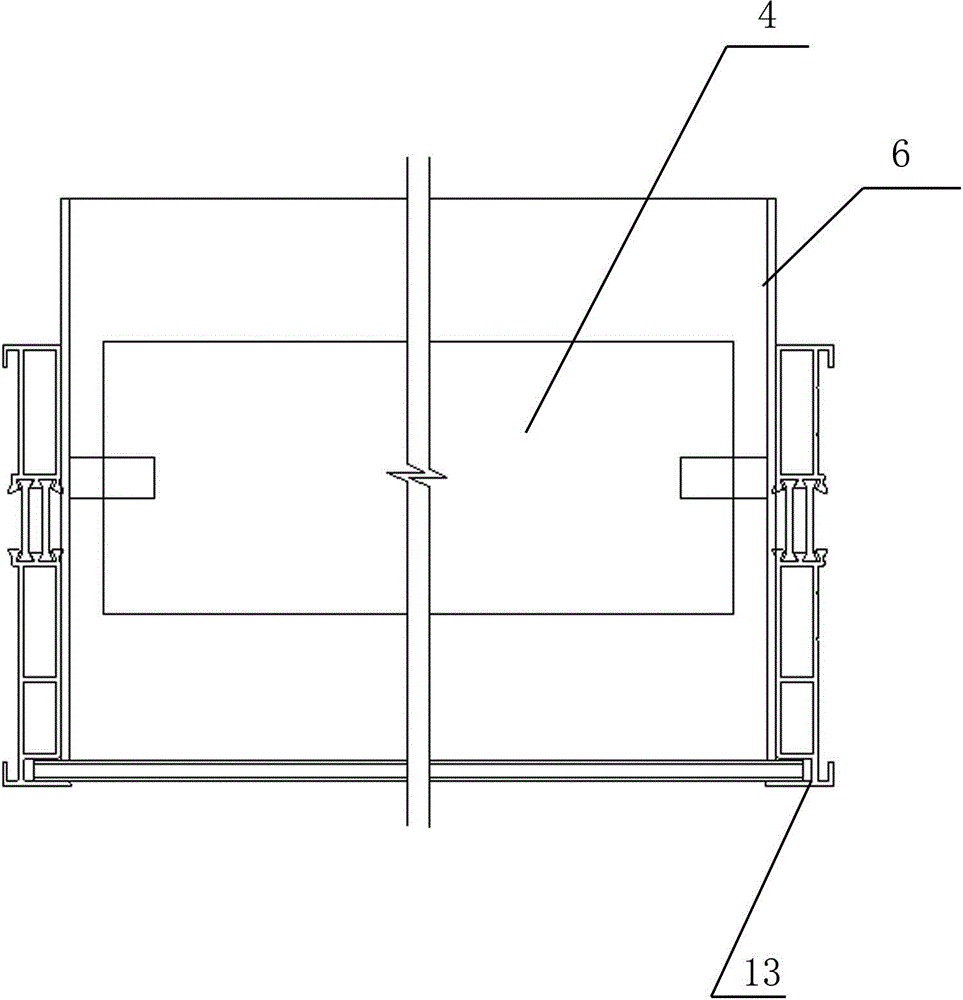

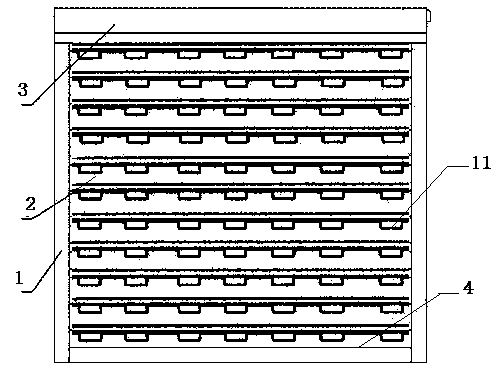

Integrated glass window with built-in metal roller blind

InactiveCN104563828ANo operational hazardLower installation feesShutters/ movable grillesPower-operated mechanismArchitectural engineeringMetal

The invention discloses an integrated glass window with a built-in metal roller blind. The integrated glass window comprises a metal roller blind window, wherein the metal roller blind window comprises a motor, a rotating shaft (4) and a metal sunshade curtain sheet (5); the motor and the rotating shaft (4) are positioned in a roller blind box (6) arranged on the top of a window frame (1) and are in transmission connection; the metal sunshade curtain sheet (5) is wound on the rotating shaft (4); a left curtain sheet guide slot (7) and a right curtain sheet guide slot (8) are respectively formed in the left side and the right side of the window frame (1) and are integrated with the window frame (1); the left side and the right side of the metal sunshade curtain sheet (5) are respectively positioned in the left curtain sheet guide slot (7) and the right curtain sheet guide slot (8); the motor drives the rotating shaft (4) to rotate; the rotating shaft (4) drives the metal sunshade curtain sheet (5) to be coiled or uncoiled; the two sides of the metal sunshade curtain sheet (5) move up and down in the left curtain sheet guide slot (7) and the right curtain sheet guide slot (8).

Owner:泰州市同裕节能门窗有限公司

Ballastless track structure

A ballastless track structure includes a foundation and a track slab. The foundation and / or the track slab is made of metal plates; each metal plate comprises a first panel, a second panel and a plurality of hollow tubes arranged between the first panel and the second panel, and brazing layers are arranged between the hollow tubes and the first and second panels correspondingly; and at least one end of each hollow tube is provided with a flange. On the one hand, the ballastless track structure has the advantages of light dead weight, large strength, stable structure, high bearing capacity, sound insulation and noise reduction, high temperature resistance, vibration resistance, long service life, portability, assembly and the like; and on the other hand, the ballastless track structure canincrease the speed of rail vehicles such as high-speed trains and bullet trains.

Owner:张跃

Engine bottom guard plate and production process thereof

InactiveCN110481127AGuaranteed molding effectAvoid wrinklesSynthetic resin layered productsVehicle componentsCompression moldingMulti material

The invention belongs to the technical field of automobile part preparation, and discloses an engine bottom protection plate which is composed of a continuous fiber reinforced thermoplastic material and a light thermoplastic reinforced material, which are in fusion connection through resin. The invention further discloses an inspection process of the engine bottom protection plate. The engine bottom protection plate is formed through steps of: baking and heating, rapid transfer, stacking, compression molding, and cutting in later period. According to the production process of the multi-material composite engine bottom protection plate, the problem of connection strength among multiple materials is solved through material preheating temperature control and transfer duration optimization, and the prepared engine bottom protection plate has the advantages of being good in strength region designability, excellent in impact resistance, light in weight and the like.

Owner:CHINA FIRST AUTOMOBILE

Metal composite plate with fireproof interlayer and manufacturing method thereof

ActiveCN100580203CWon't happenWith thermal insulationCovering/liningsLamination ancillary operationsTectorial membraneAdhesive

The present invention is one kind of composite metal plate with sandwiched fireproof layer and its making process. The composite metal plate with sandwiched fireproof layer consists of a protecting film layer, a baking varnish layer, a first chemically formed film layer, a first metal sheet, a first adhesive layer, a sandwiched fireproof layer, a second adhesive layer, a second metal sheet, a second chemically formed film layer and an antirust primer layer superposed successively and compounded integrally. Its making process includes the steps of: hot pressing the mixture of fine ore grains, fire retardant, coupling agent and adhesive to form the fireproof core board; treating the first metal sheet to form the first film layer and the baking varnish layer, and treating the second metal sheet to form the second film layer and the antirust primer layer; painting adhesive to two sides of the core board and hot pressing to combine the core board and two metal sheets; adhering the protecting film layer and cutting.

Owner:江阴新泓泰复合材料有限公司

Reinforced anti-crack diatom mud material containing PVA (polyvinyl alcohol) fiber and preparation method of material

The invention discloses a reinforced anti-crack diatom mud material containing PVA (polyvinyl alcohol) fiber and a preparation method of the material. The diatom mud material is prepared from components in percentage by mass as follows: 15%-35% of diatomite, 20%-40% of heavy calcium, 8%-20% of ash calcium, 8%-20% of quartz sand, 2%-5% of nano titania, 1%-4% of negative ion powder, 0.5%-2.5% of cellulose ether, 0.1%-0.5% of pregelatinized starch and 0.1%-2% of the PVA fiber. The diatom mud material prepared with the method has the functions of regulating humidity, insulating sounds, reducing noise, preventing fire, retarding flame, purifying air, contributing to health and the like.

Owner:东莞市爱乐居环保科技有限公司

Composite energy-saving roller blind door/window

InactiveCN104295218ASimple shapeAvoid bright lightLight protection screensWindow/door framesWindow coveringEngineering

The invention discloses a composite energy-saving roller blind door / window. The composite energy-saving roller blind door / window comprises an aluminum alloy door / window, an aluminum alloy roller blind window and a screen window, and is integrally designed; covers of the aluminum alloy door / window and the roller blind window both can prevent heat transfer through adoption of an insulation bridge cutoff technology so as to keep the indoor temperature to achieve an energy-saving effect. In addition, the roller blind window is mounted outside glass of the aluminum alloy door / window for adjusting the indoor lighting. When the screen window is opened, mosquitoes are prevented from entering inside. Roller blinds of the roller blind window are once formed by aluminum alloy blades with high heat reflectivity, are simple in shape, and can be randomly selected according to hobbies and colors of buildings; and a polyurethane insulation foam material is filled in the middle of a sectional material for effectively preventing the strong light irradiation and the ultraviolet radiation. The composite energy-saving roller blind door / window has such functions as sun protection, heat insulation, sound insulation, noise reduction, lighting, ventilation, theft prevention and mosquito prevention, and has the advantages of simple structure and convenience for mounting and use. The on-site installation difficulty is reduced, and the coordination problem between a window body and the sun protection is solved.

Owner:湖州新峰塑业有限公司

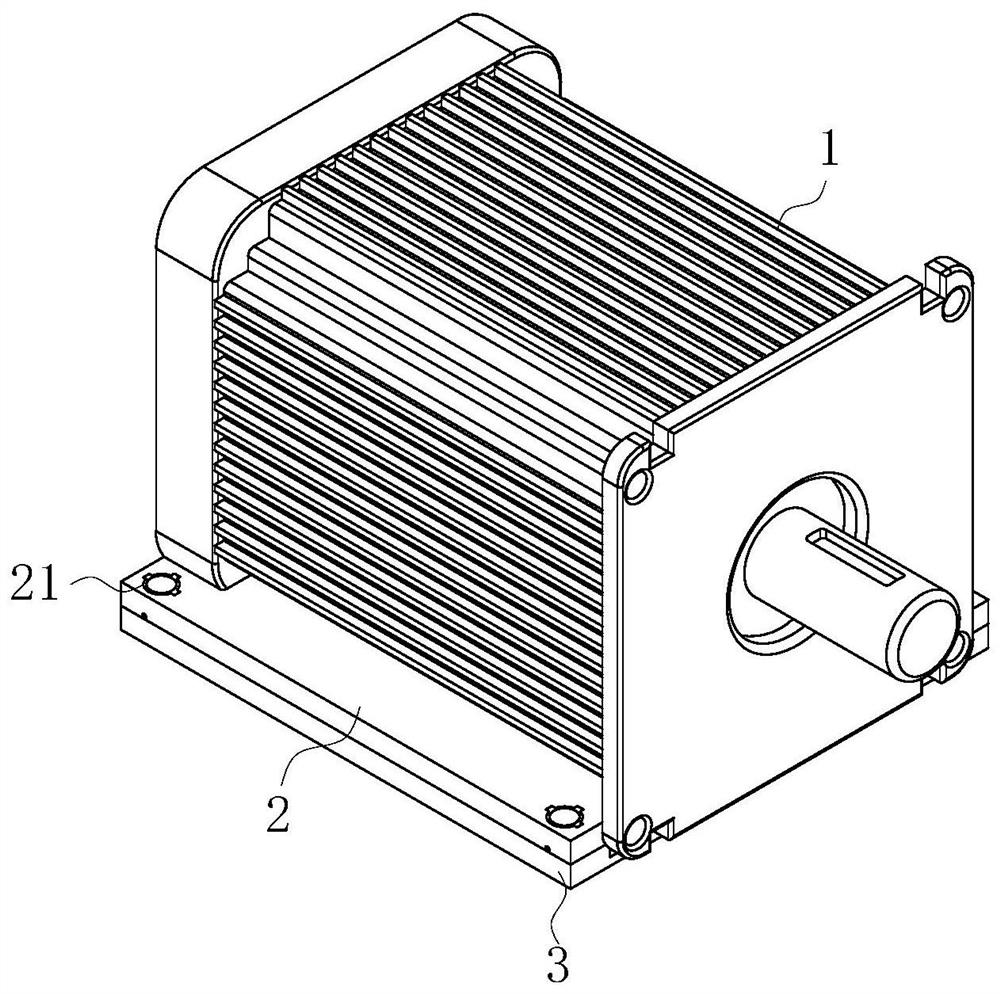

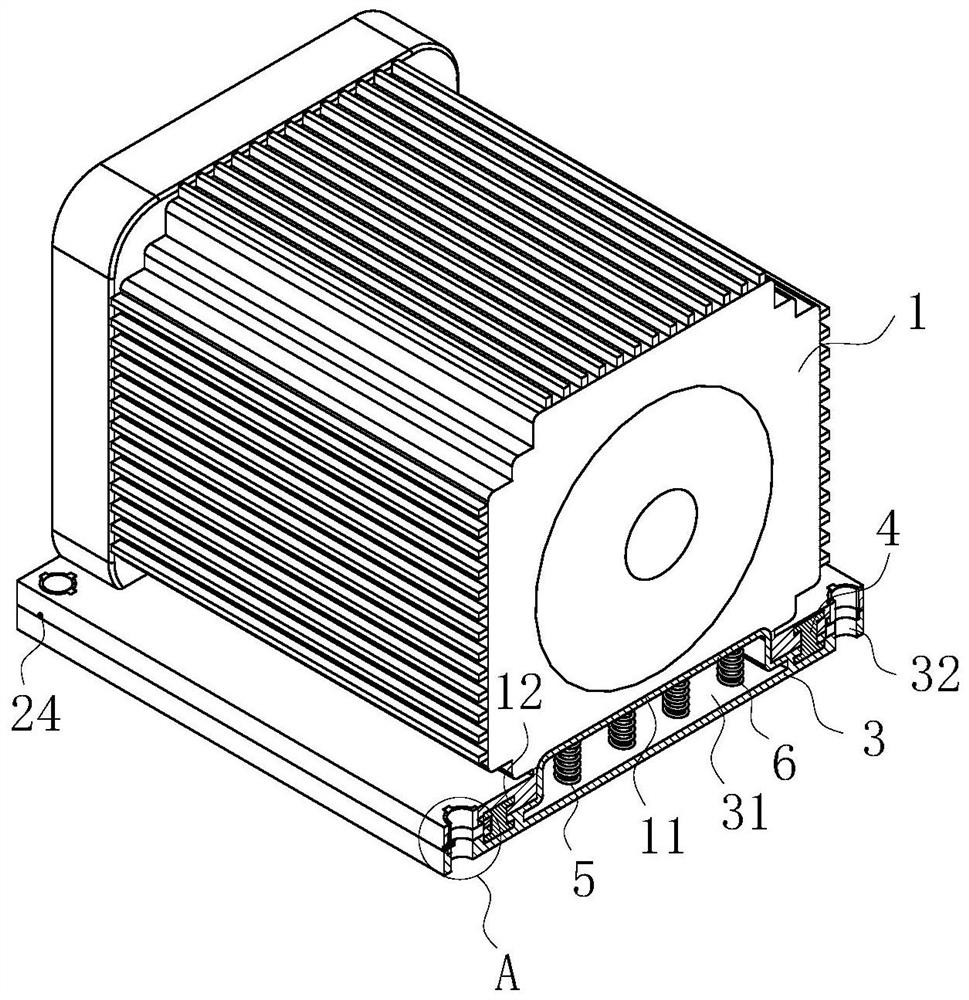

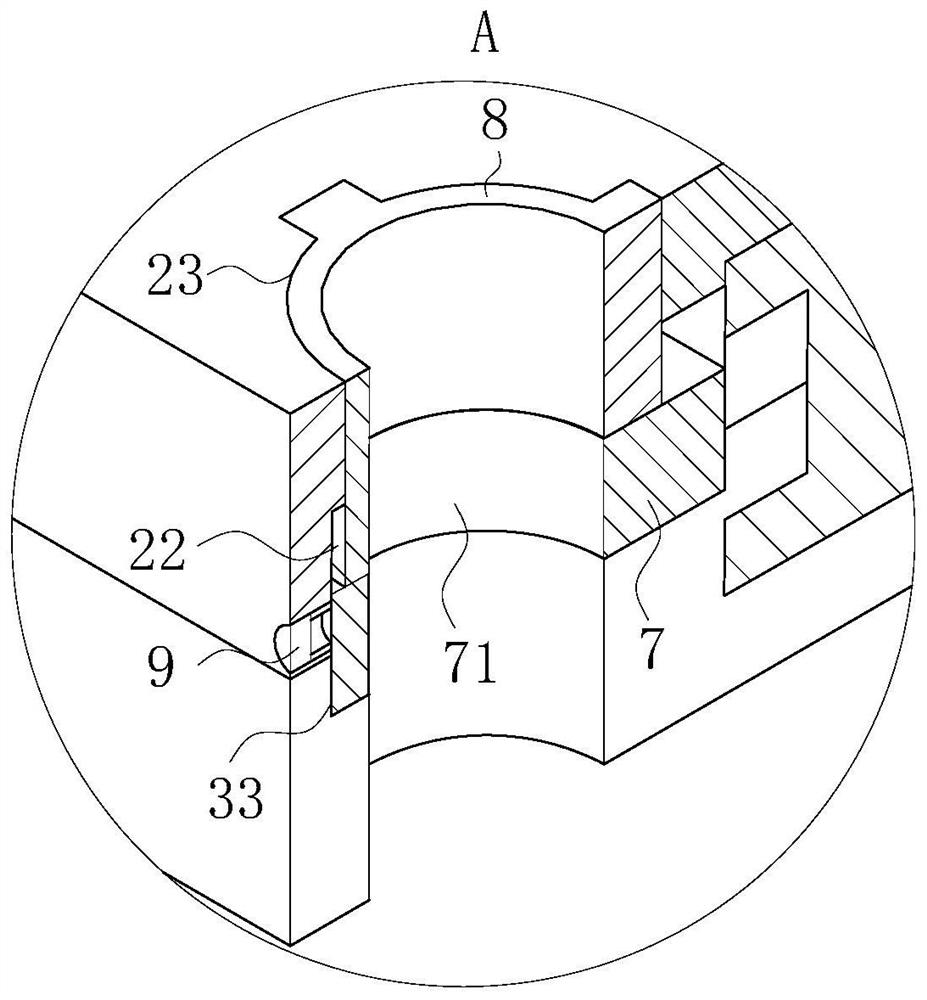

Permanent magnet brushless direct current motor

InactiveCN111934478ALow densityHigh shock absorption capacitySupports/enclosures/casingsPhysicsDC - Direct current

The invention belongs to the technical field of motors, and particularly relates to a permanent magnet brushless direct current motor. The permanent magnet brushless direct current motor comprises a motor shell, wherein a rotor assembly is arranged in the motor shell and arranged outside a rotating shaft in a sleeving mode to drive the rotating shaft to rotate around the axis of the rotating shaft; a sliding groove cavity is formed in the lower end face of the motor shell, and mounting plates are arranged on the two sides of the sliding cavity; a T-shaped sliding groove is formed in the bottomend face of the mounting plate, and a plurality of connecting holes are formed in the mounting plate; a fixed base is slidably inserted into the sliding cavity, and the upper end faces of the two sides of the fixed base make sliding contact with the lower surface of the mounting plate; I-shaped sliding strips are arranged on the upper end faces of the two sides of the fixed base, and the upper ends of the I-shaped sliding strips are inserted into the T-shaped sliding groove in a sliding mode; a damping cavity is formed in the fixed base, and a damping spring is arranged in the damping cavityin the vertical direction; an elastic buffer column is inserted into the damping spring; the fixed base is made of a closed-cell foamed aluminum material; and the damping spring arranged in the fixedbase can play a role in buffering and damping the brushless direct current motor.

Owner:姚宇翔

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com