Oblique-straight helical water guide rib pipe and processing method thereof

A processing method and straight-spiral technology, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of noise pollution of the surrounding environment, the pipes cannot be silenced, and the material consumption is too much, so as to save materials and costs. Low, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

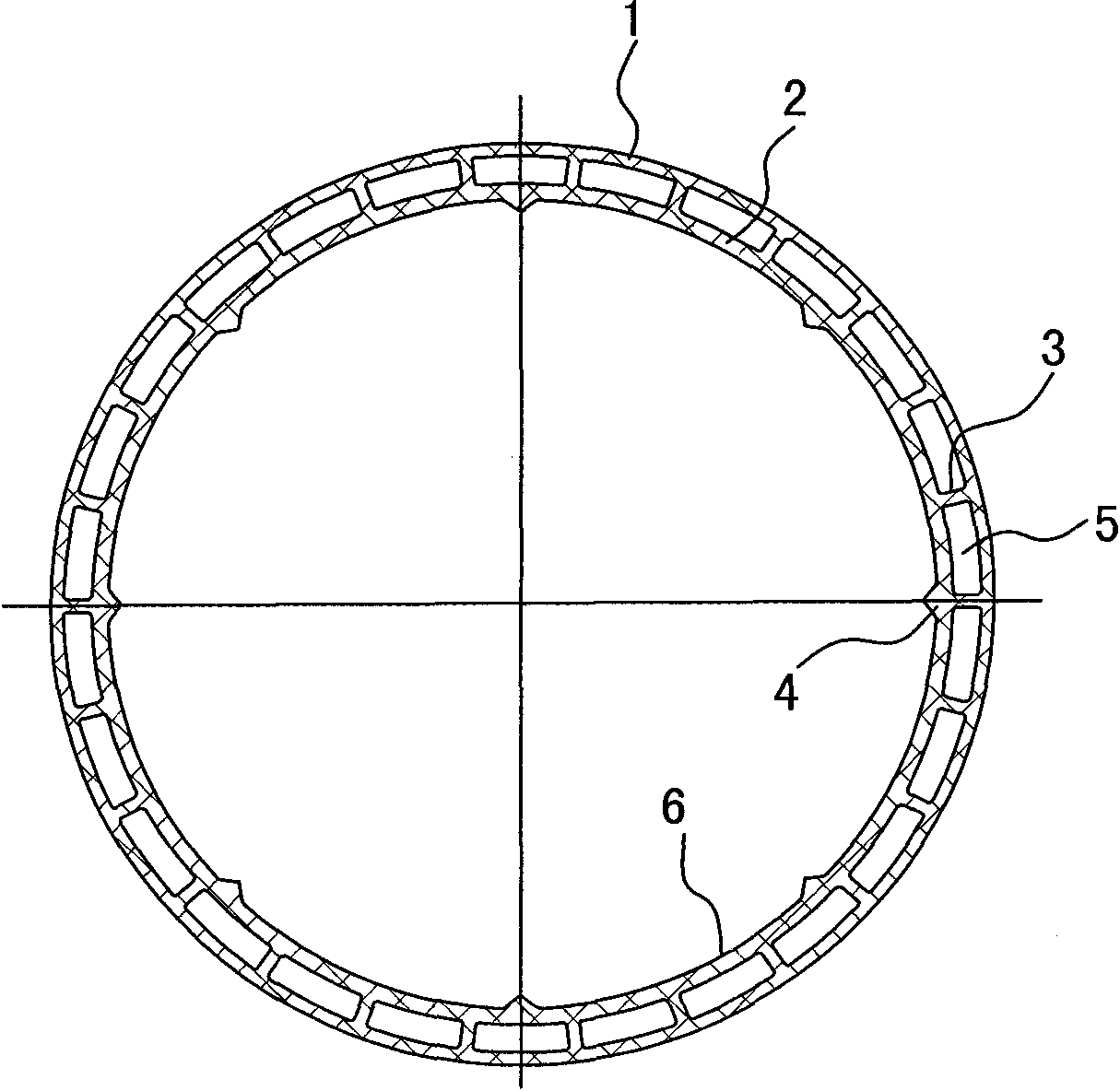

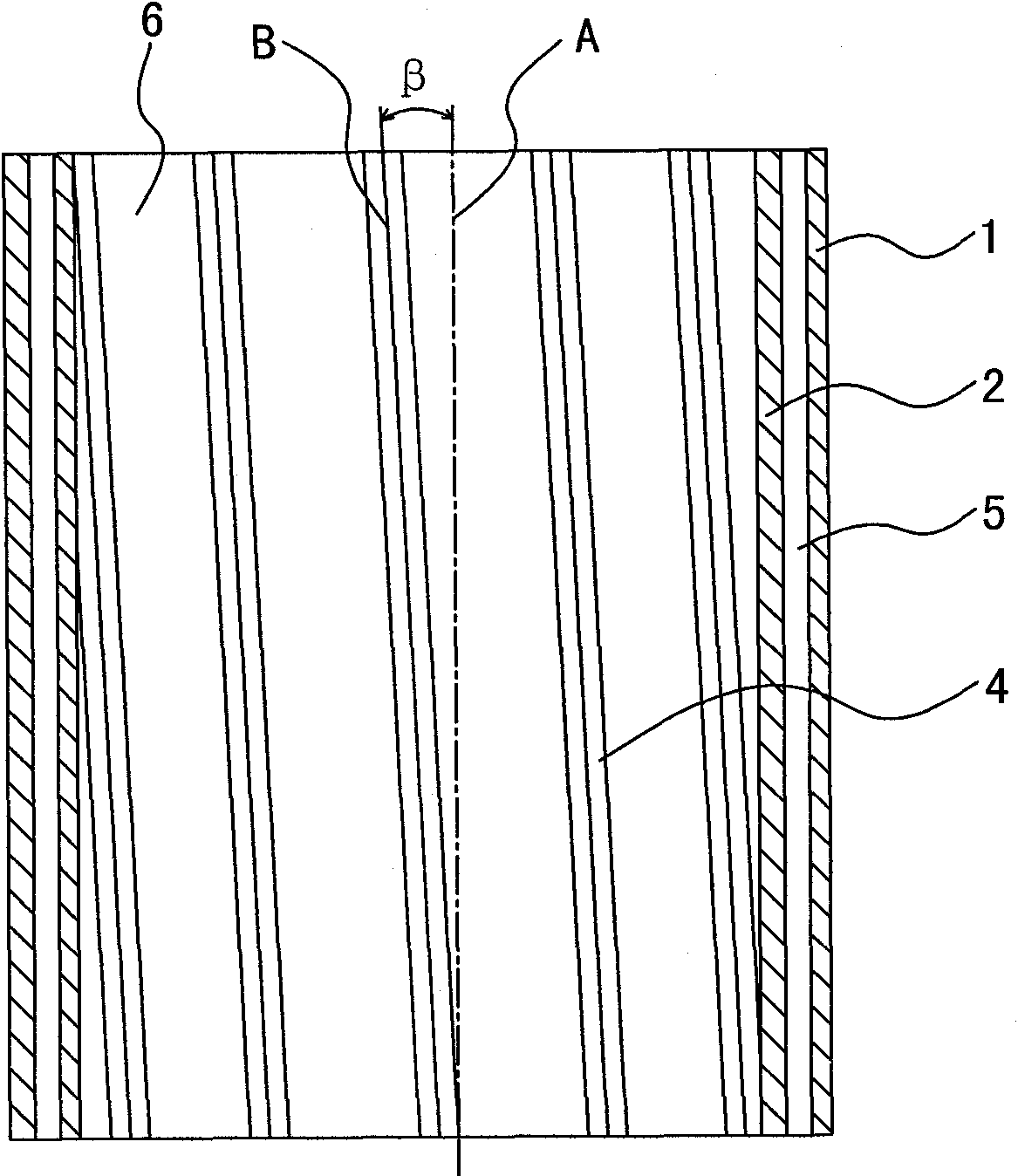

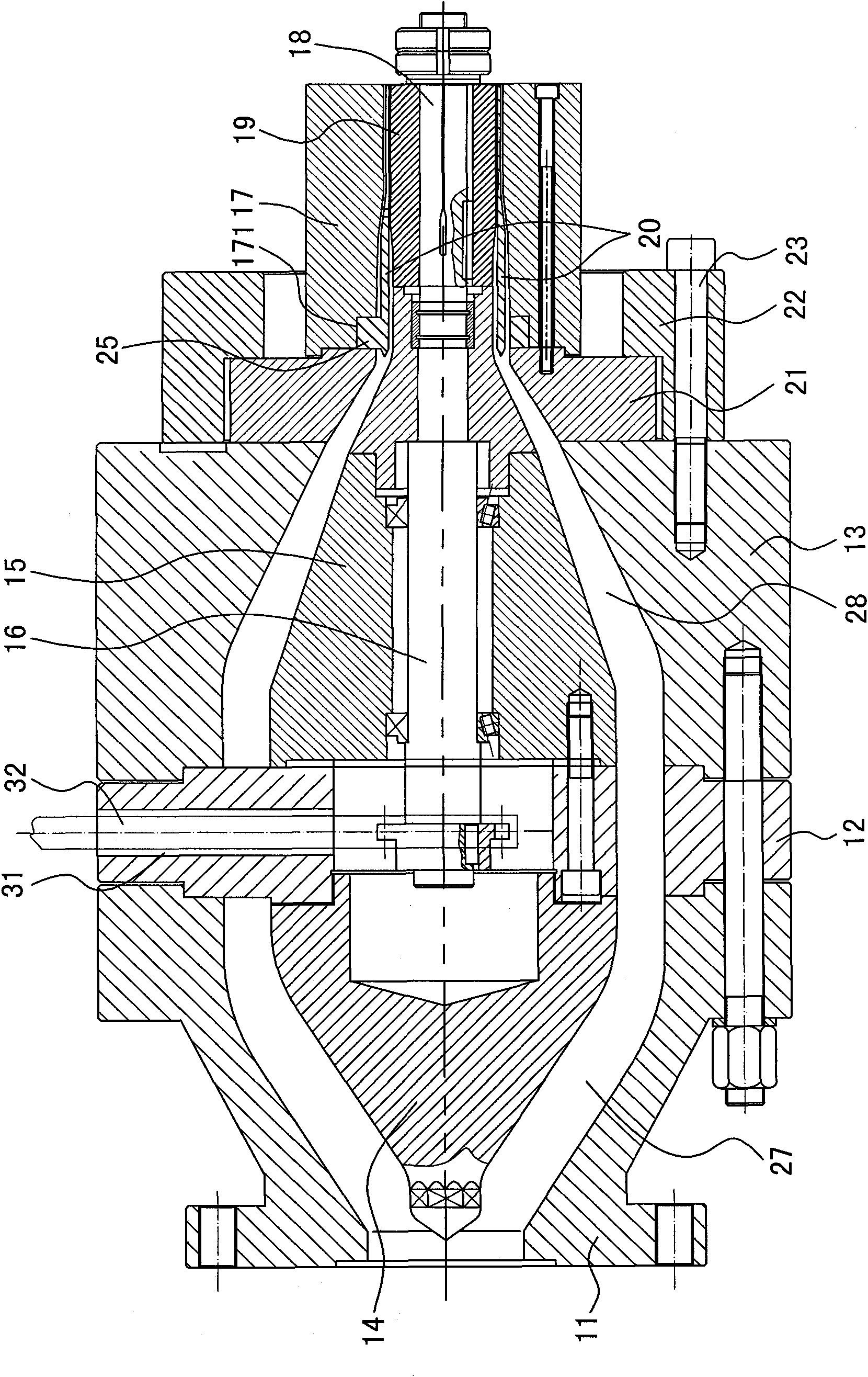

[0015] The present invention relates to an oblique straight spiral water diversion bar pipe material and a processing method for the oblique straight spiral water diversion bar pipe material, such as figure 1 , figure 2 As shown, the oblique straight spiral water diversion rib pipe material is composed of an inner layer 2 and an outer layer 1, and the inner layer 2 and the outer layer 1 are connected by a rib 3, which is characterized in that the inner wall 6 of the inner layer 2 of the pipe material Spiral ribs 4 are formed on the top, and the spiral ribs 4 are uniformly distributed in a straight line and obliquely. The angle β between the centerline B of the spiral ribs 4 and the centerline A of the pipe is 12°-20°. In this technical solution, on the inner wall 6 of the inner layer 2 of the pipe material, spiral ribs 4 are uniformly distributed in a straight line and obliquely. The inner wall 6 of the inner layer 2 flows downward to avoid strong impact of the water flow on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com