Engine bottom guard plate and production process thereof

A bottom guard plate and engine technology, which is applied to layered products, other household appliances, synthetic resin layered products, etc., can solve the problem that the engine bottom guard plate cannot meet high-strength performance and light weight at the same time, and meet operating efficiency required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

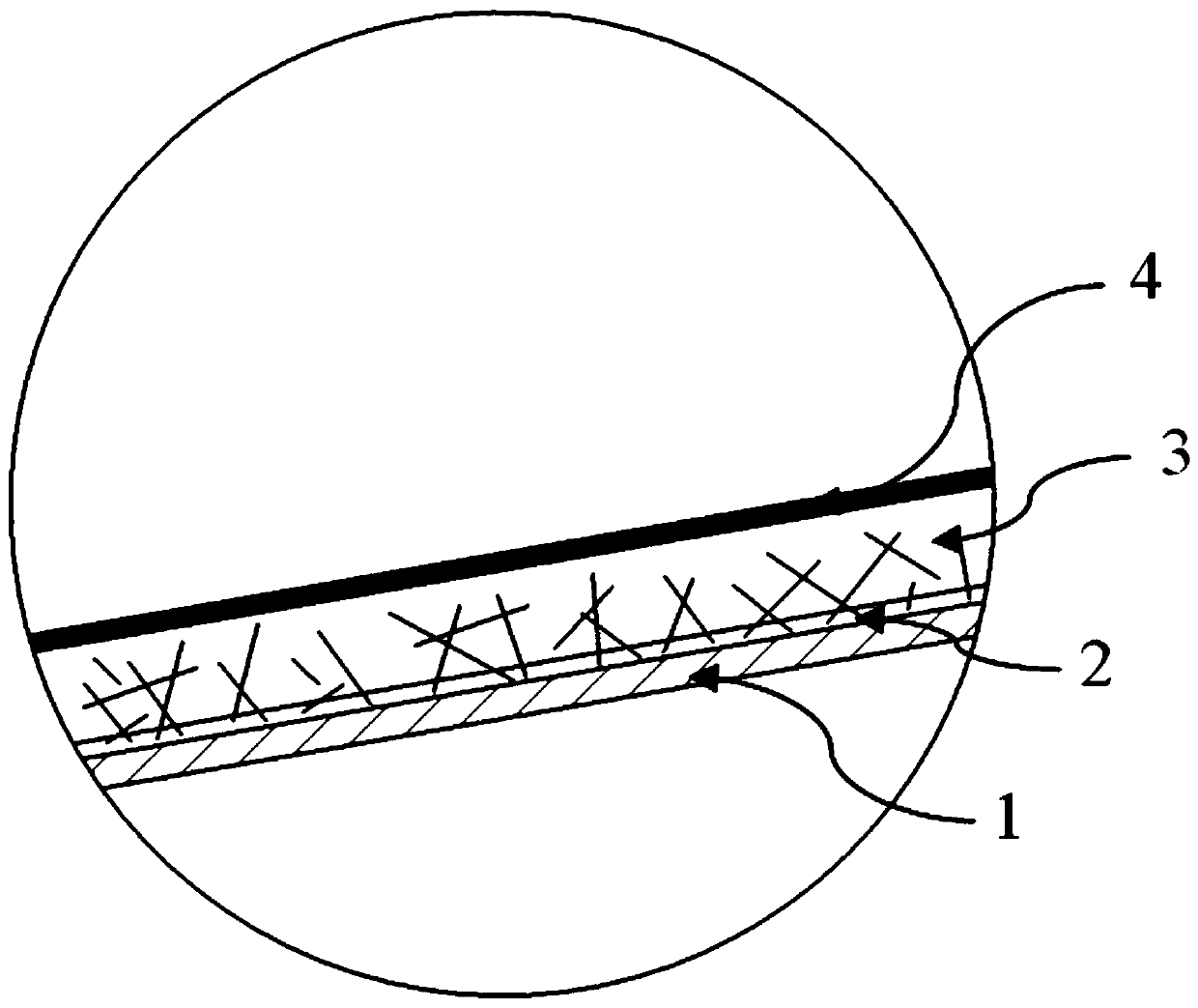

[0026] An engine bottom guard plate and its production process, the engine bottom guard plate is made of continuous fiber reinforced thermoplastic material and lightweight thermoplastic reinforced material (LWRT), comprising the following steps:

[0027] (1) Heating: heat the continuous fiber reinforced thermoplastic material in a heating device, the temperature acting on the surface of the plate is 200°C, and the heating time is 45s; place the lightweight thermoplastic reinforced material (LWRT) in another heating device to heat, The temperature acting on the surface of the plate is 220°C, and the heating time is 60s; further, the heating device uses an infrared heating box, which has obtained a more uniform heating temperature field;

[0028] (2) Transfer: In the first transfer step, the preheated continuous fiber-reinforced thermoplastic material is transferred to the mold through automatic equipment, and the transfer time is 2s; in the second transfer step, the preheated li...

Embodiment 2

[0040] An engine bottom guard plate and its production process, the selected area density is 1200g / m 2 continuous fiber-reinforced thermoplastic material with an area density of 1400g / m 2 The lightweight thermoplastic reinforced material (LWRT), the two kinds of plates are cut to the corresponding size according to the size of the product.

[0041] (1) Heating: Using an infrared heating device, place the continuous fiber reinforced thermoplastic material in the heating device for heating. The temperature acting on the surface of the plate is 210°C, and the heating time is 70s; place the lightweight thermoplastic reinforced material (LWRT) in another Heating in the infrared heating device, the temperature acting on the surface of the plate is 210°C, and the heating time is 60s;

[0042] (2) Transfer: In the first transfer step, the manipulator cooperates with the vacuum suction cup grasping device to transfer the preheated continuous fiber reinforced thermoplastic material to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com