Edge rolling equipment

A kind of equipment and technology for adjusting rollers, applied in the field of machinery, can solve the problems of inconvenient adjustment of roller shafts, simple design, screw misalignment, etc., and achieve the effect of ensuring work efficiency and forming effect, reasonable structural design and good forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] The invention protects a rolling device, which is suitable for bending and forming strips (plates) into required automobile wheel rims.

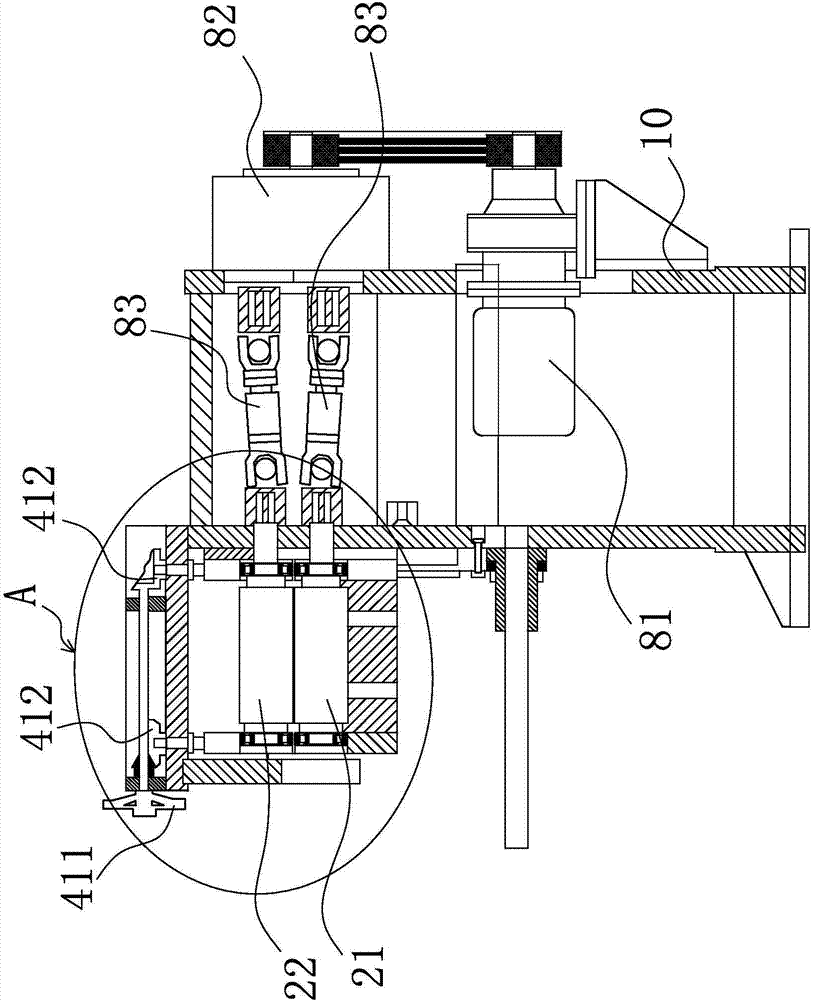

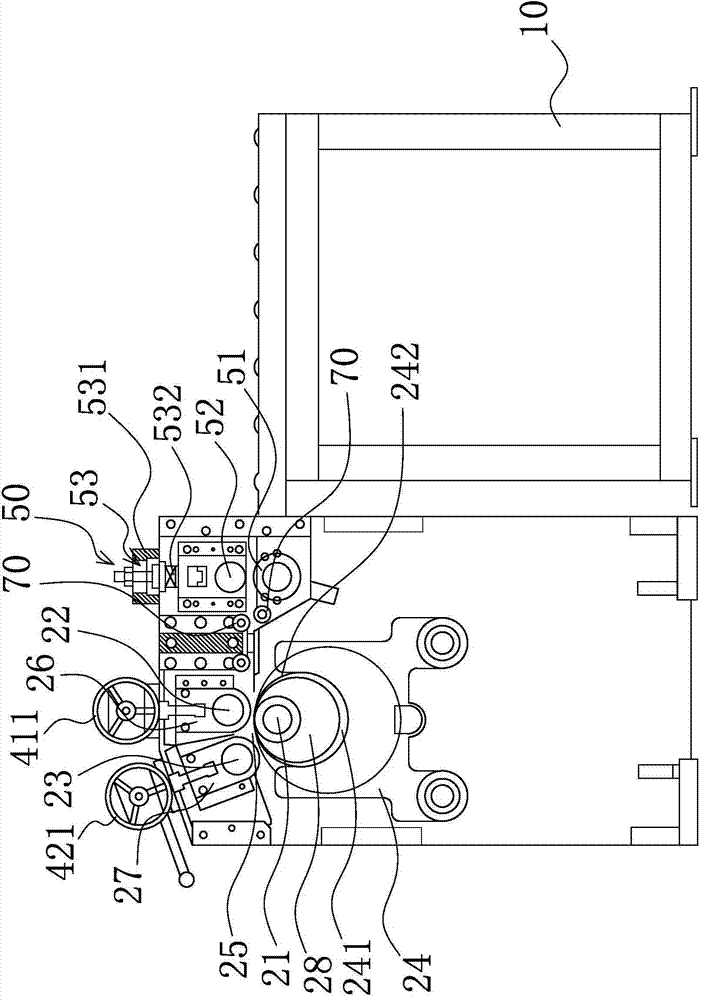

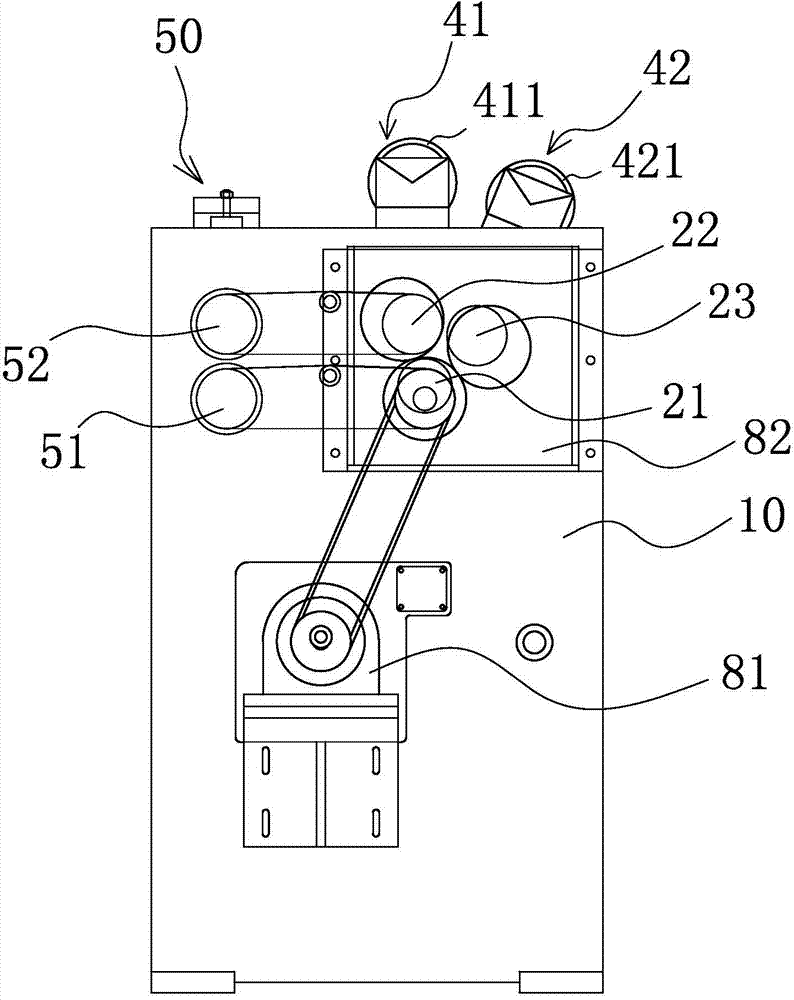

[0024] Such as Figure 1 to Figure 4 As shown, the rolling equipment comprises frame 10, main roll 21, first adjustment roll 22, second adjustment roll 23, movable seat 24, main roll 21, first adjustment roll 22, second adjustment roll 23 three The outer peripheral side is surrounded to form a transition channel 25, and the first adjustment mechanism 41 and the second adjustment mechanism 42 that are connected to the first adjustment roller 22 and the second adjustment roller 23 are respectively arranged on the frame 10, and the first adjustment mechanism 41 can drive the first ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com