Patents

Literature

197results about How to "Guaranteed tight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

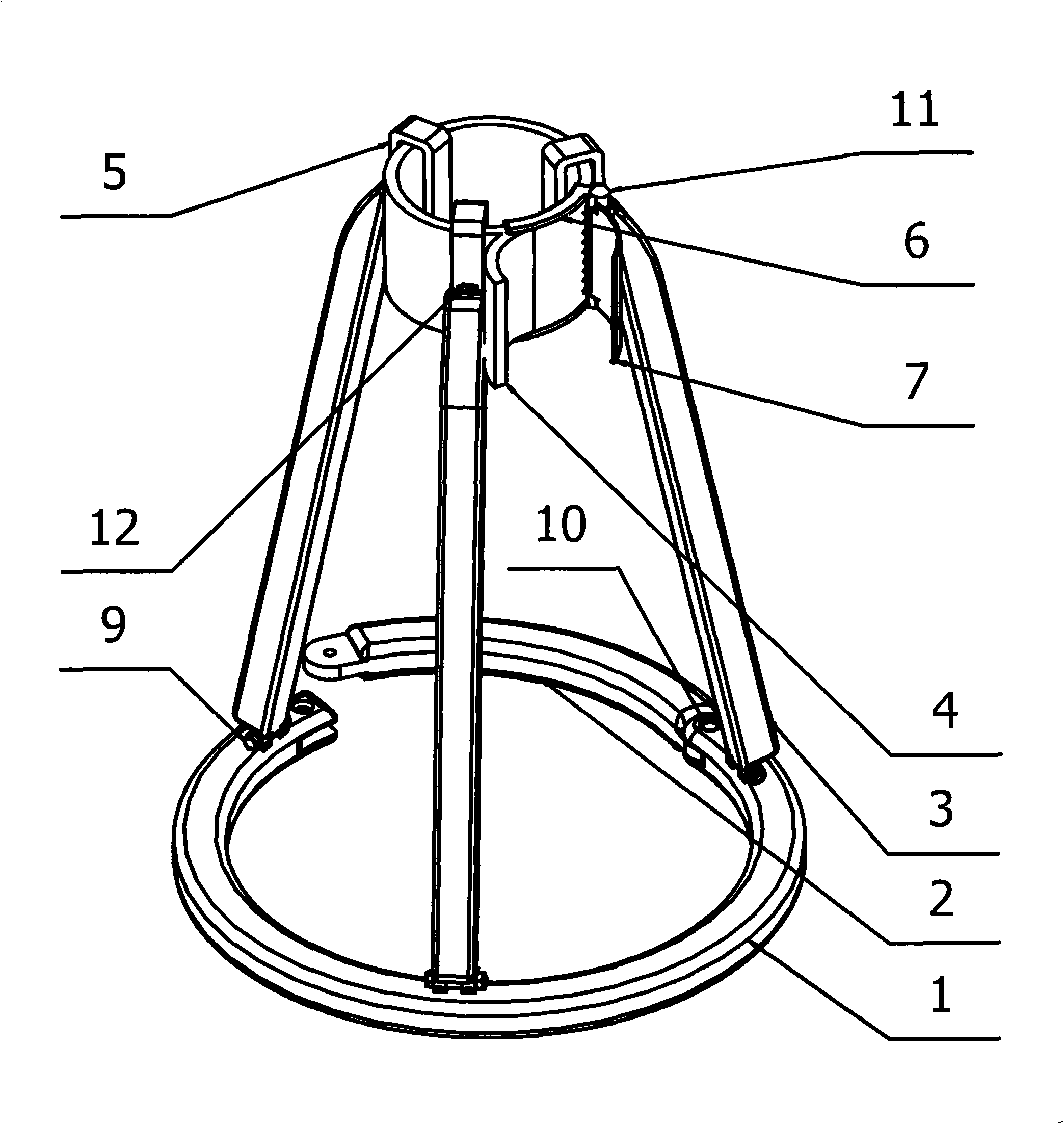

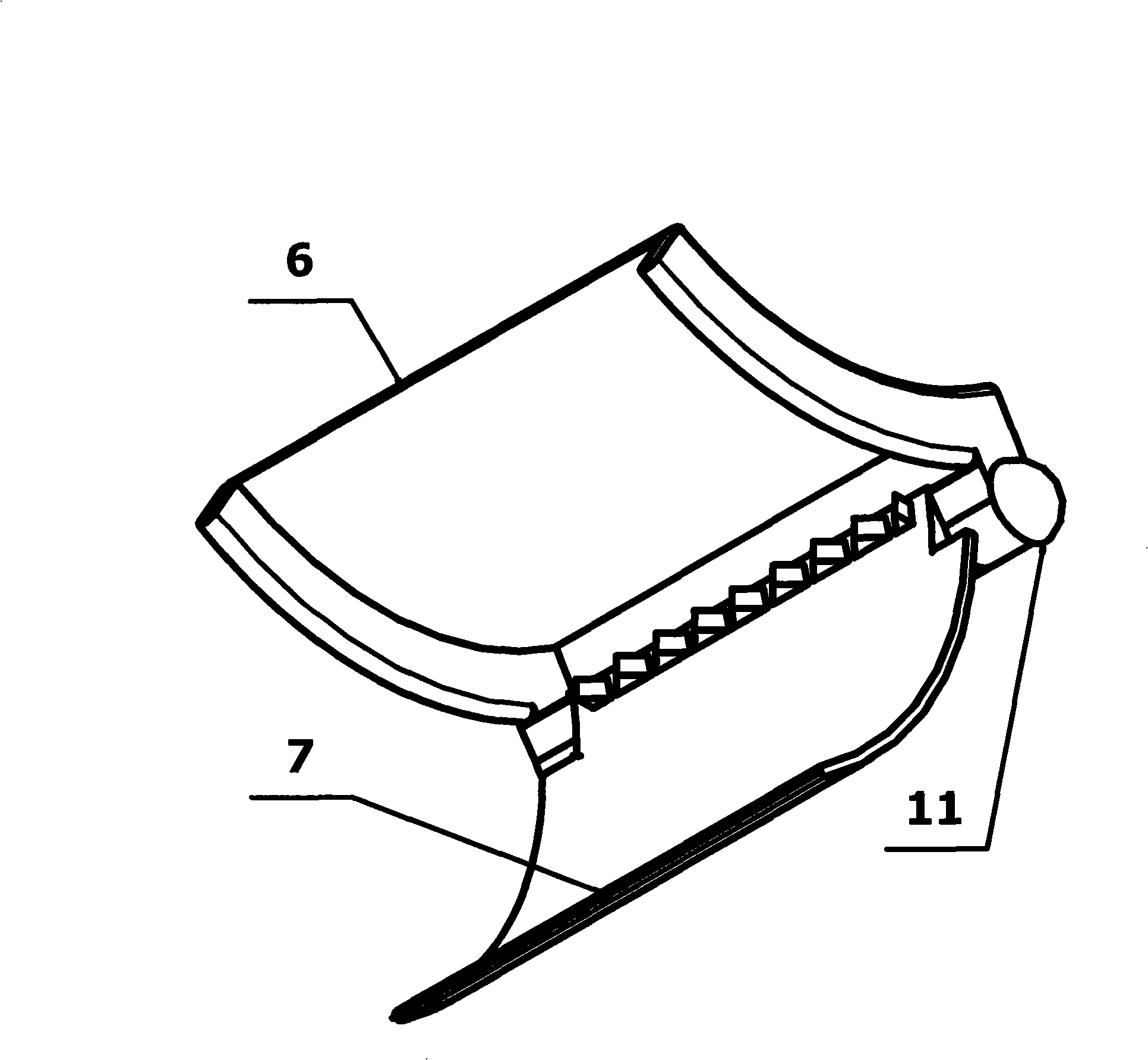

Frame work for assuring tree vertical growth at transplant early

InactiveCN101258826ASimple structureLow costCultivating equipmentsForestryEngineeringVertical growth

The invention provides a structural frame which guarantees the straight growing of trees in initial stages after being transplanted. The structural frame comprises a base, support bars which are installed on the base and clamping mechanisms which are installed on the support bars. The base is an open annular base, three support bars are installed on the base by a fixedly rotary hinge, the clamping mechanisms are composed of movable tappings installed on the top end of each support bar, fastener bottom cuts and tooth form clips installed on the top end of a support bar through a fastener rotating shaft, and bandages threaded in the movable tappings. The structural frame which guarantees the straight growing of trees in initial stage after being transplanted of the invention has simple structure, can be assembled and dissembled and make self-adjustment to adapt to trees with diameters within a certain size range. The structural frame is essentially applied to helping the straight growing of the trees at the initial stage after being transplanted and can be dismantled, recycled and reused after the root systems of the trees are stable, thereby having low cost but good effect.

Owner:HARBIN ENG UNIV

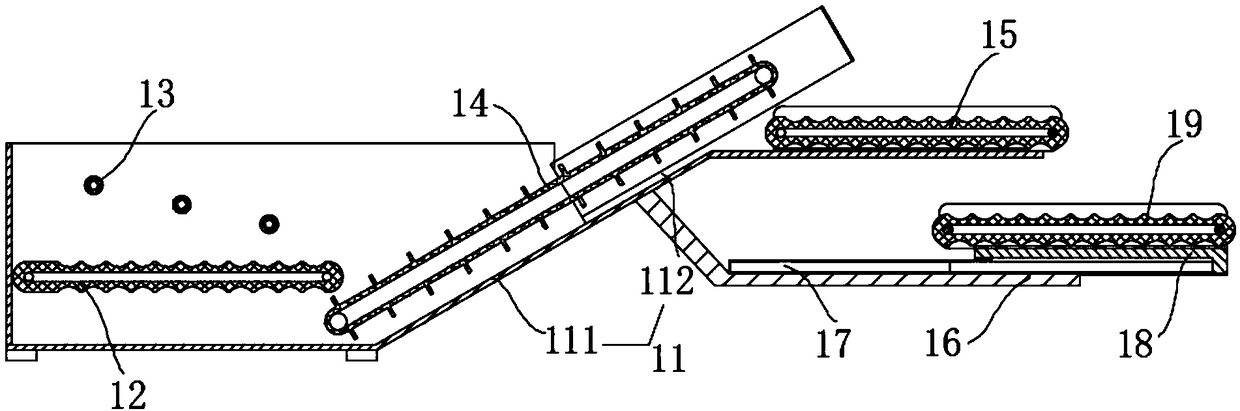

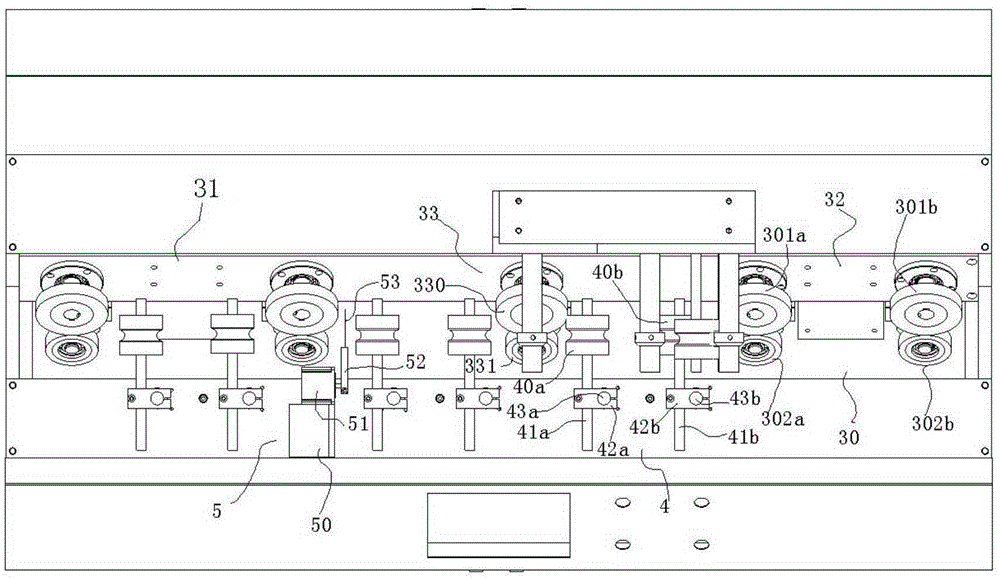

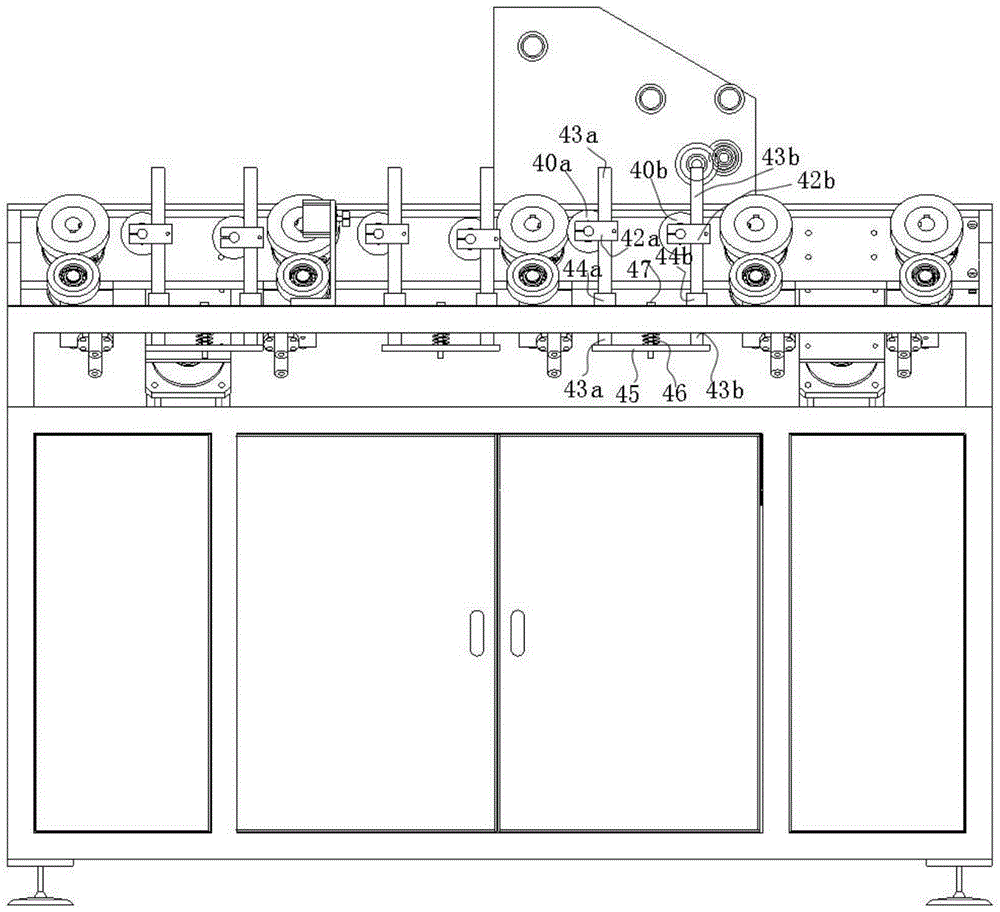

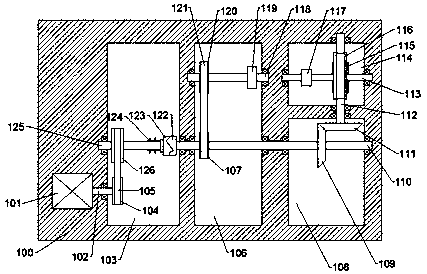

Agricultural product lotus root slice processing automatic production line

The invention discloses an agricultural product lotus root slice processing automatic production line which comprises a lotus root section feeding device, a lotus root section slicing mechanism, a lotus root slice cleaning device, a turning device, a blanching device, a critic acid solution tank, a lotus root slice stirring device and a lotus root slice sequencing and sorting device. According tothe agricultural product lotus root slice processing automatic production line disclosed by the invention, only lotus root sections are manually put into the lotus root section feeding device, primarily cleaning and sequentially feeding lotus root sections can be automatically finished by equipment, the lotus root sections can be automatically sliced and automatically conveyed into lotus root slice cleaning equipment, cleaning of the lotus root slices can be automatically finished by equipment, the lotus root slices are automatically conveyed to the blanching device for blanching, the lotus root slices after blenching are automatically conveyed to the critic acid solution tank, the lotus root slices are automatically conveyed to the lotus root slice stirring device, complete lotus root slices can be automatically screened out later, and the lotus root slices can be automatically separated according to size; thus, the lotus root slices can be conveniently packaged in a concentrated mode; furthermore, labor is saved, and a production efficiency is improved.

Owner:徐丽亚

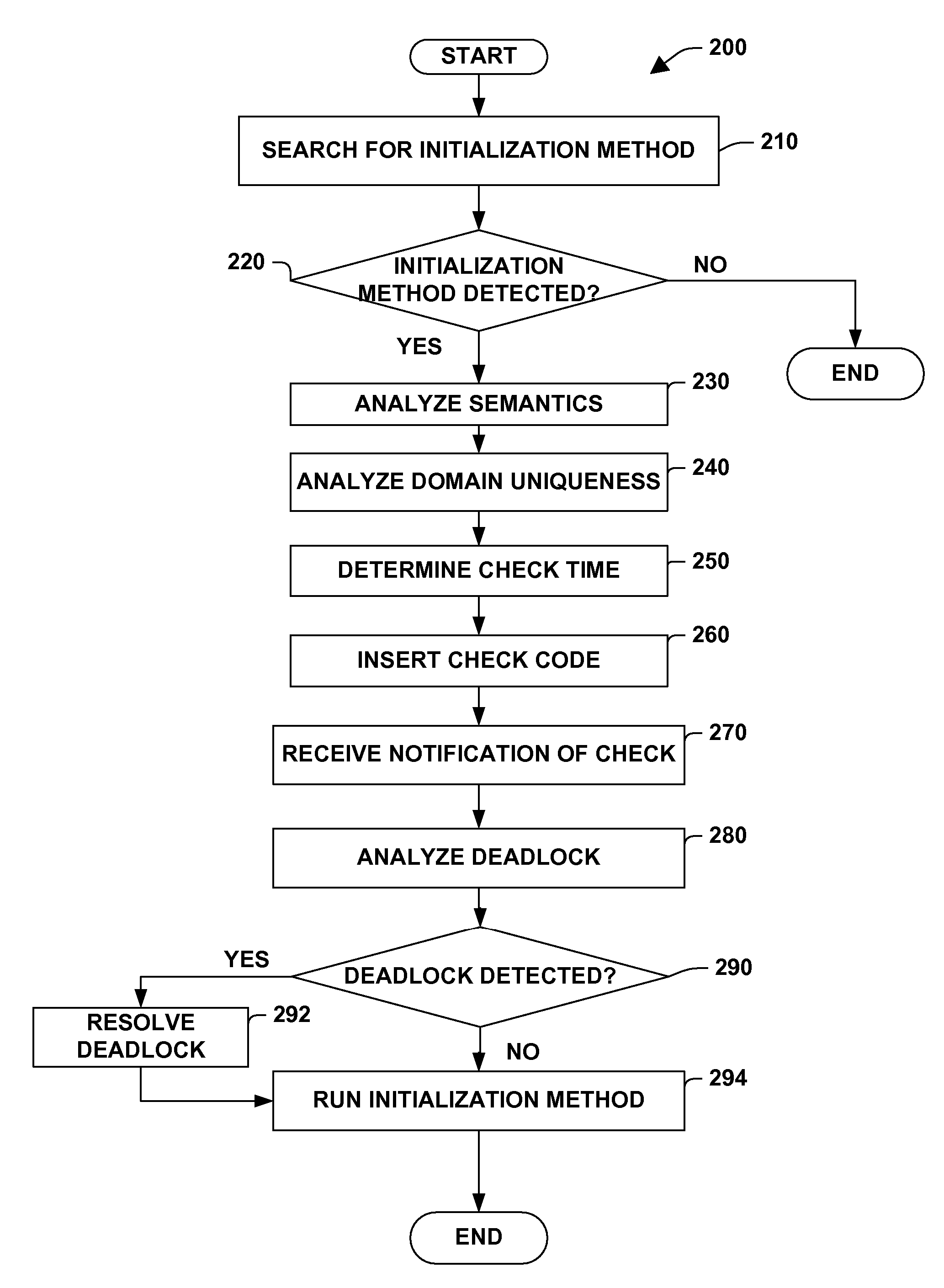

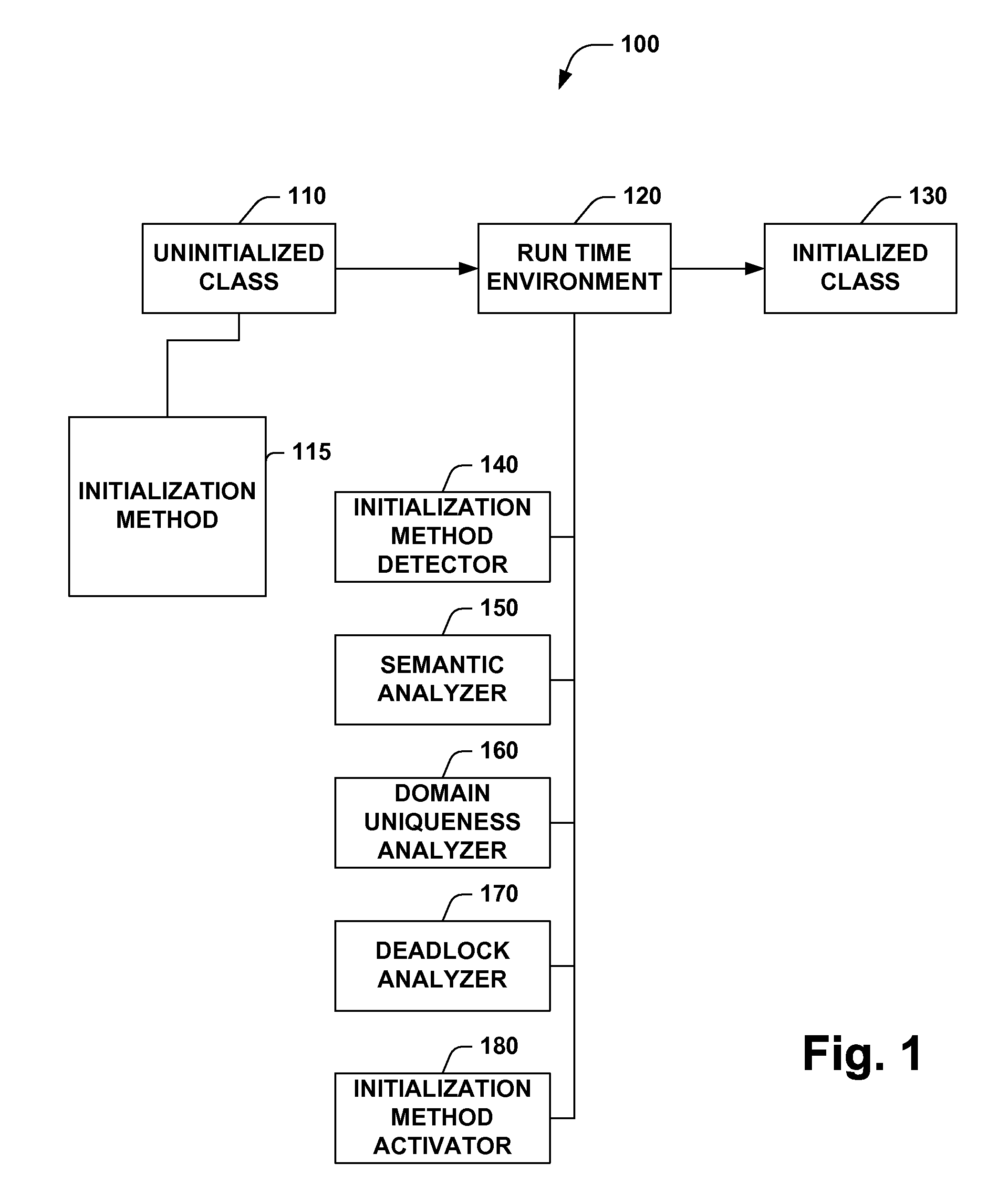

Class initialization method semantics

InactiveUS20070006198A1Easy to detectReduce decreaseDigital computer detailsMultiprogramming arrangementsSemanticsA domain

A system and method for mitigating problems associated with automatic execution of initialization code is provided. The system includes an initialization method activator that can call a class initialization method at a pre-determined execution point. The system also includes a deadlock analyzer that can determine whether calling the initialization method will create a deadlock, and, if a deadlock is detected that can resolve such a deadlock. The system also includes a semantic analyzing component that can analyze a semantic type associated with the initialization method and a domain uniqueness analyzer that can analyze the uniqueness of the domain with which the class will interact, to facilitate determining where to place code that will check whether a class is initialized, and if the class is not initialized that will invoke the class initializing method.

Owner:MICROSOFT TECH LICENSING LLC

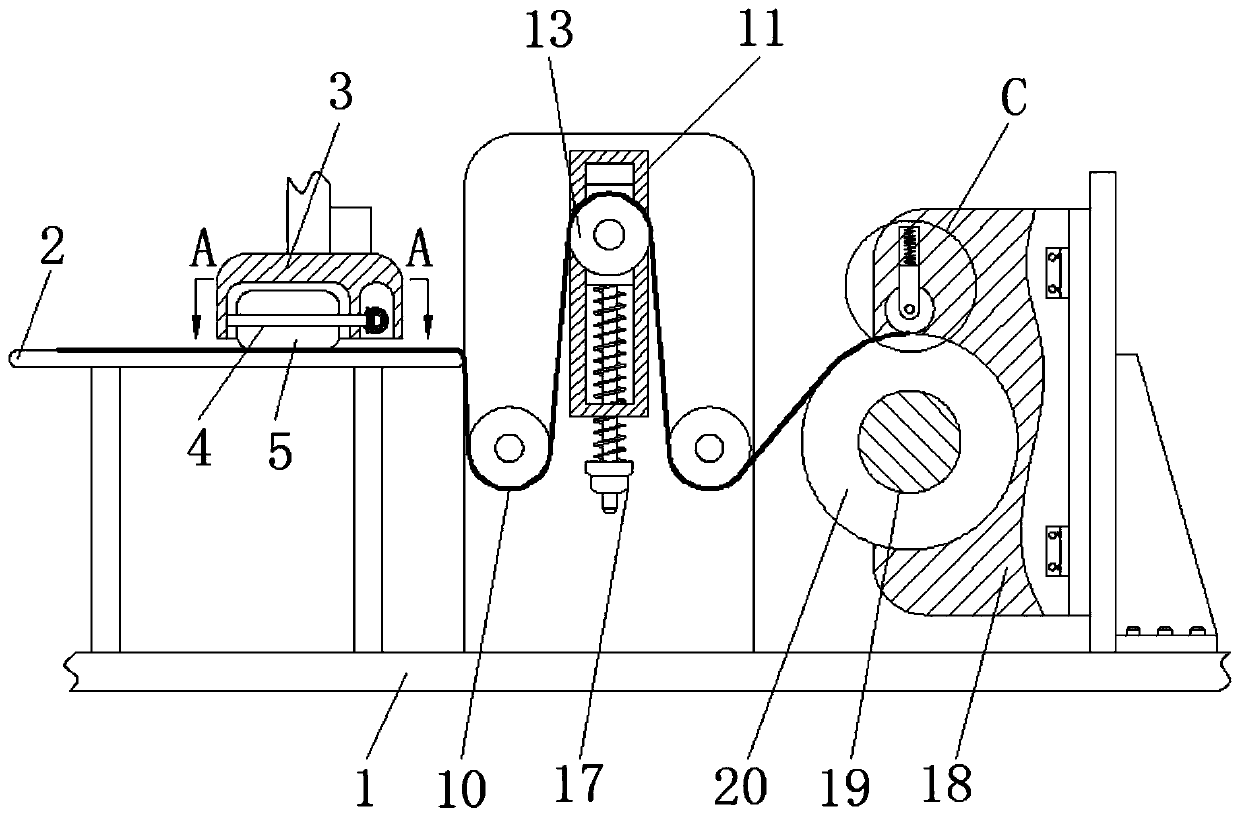

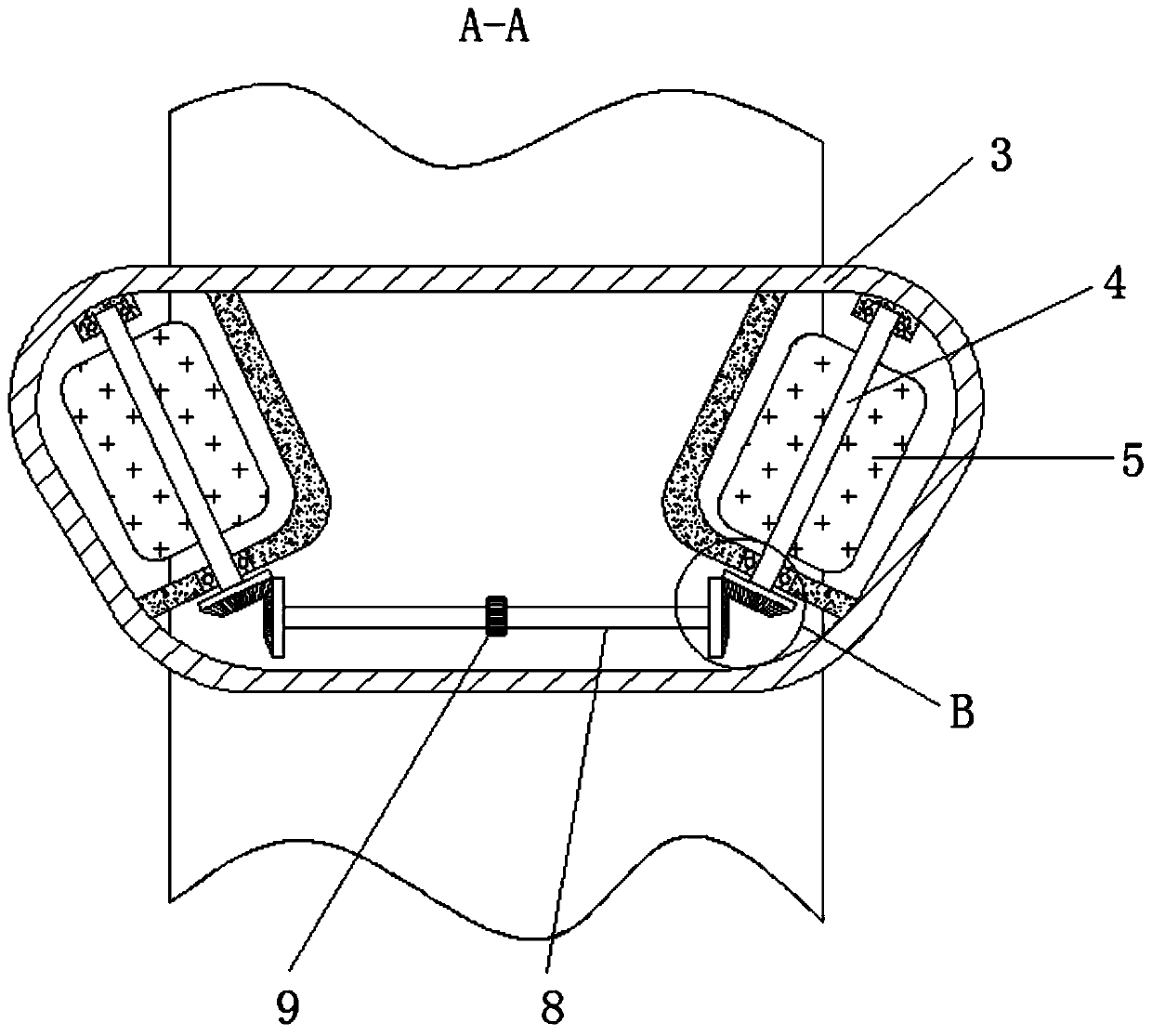

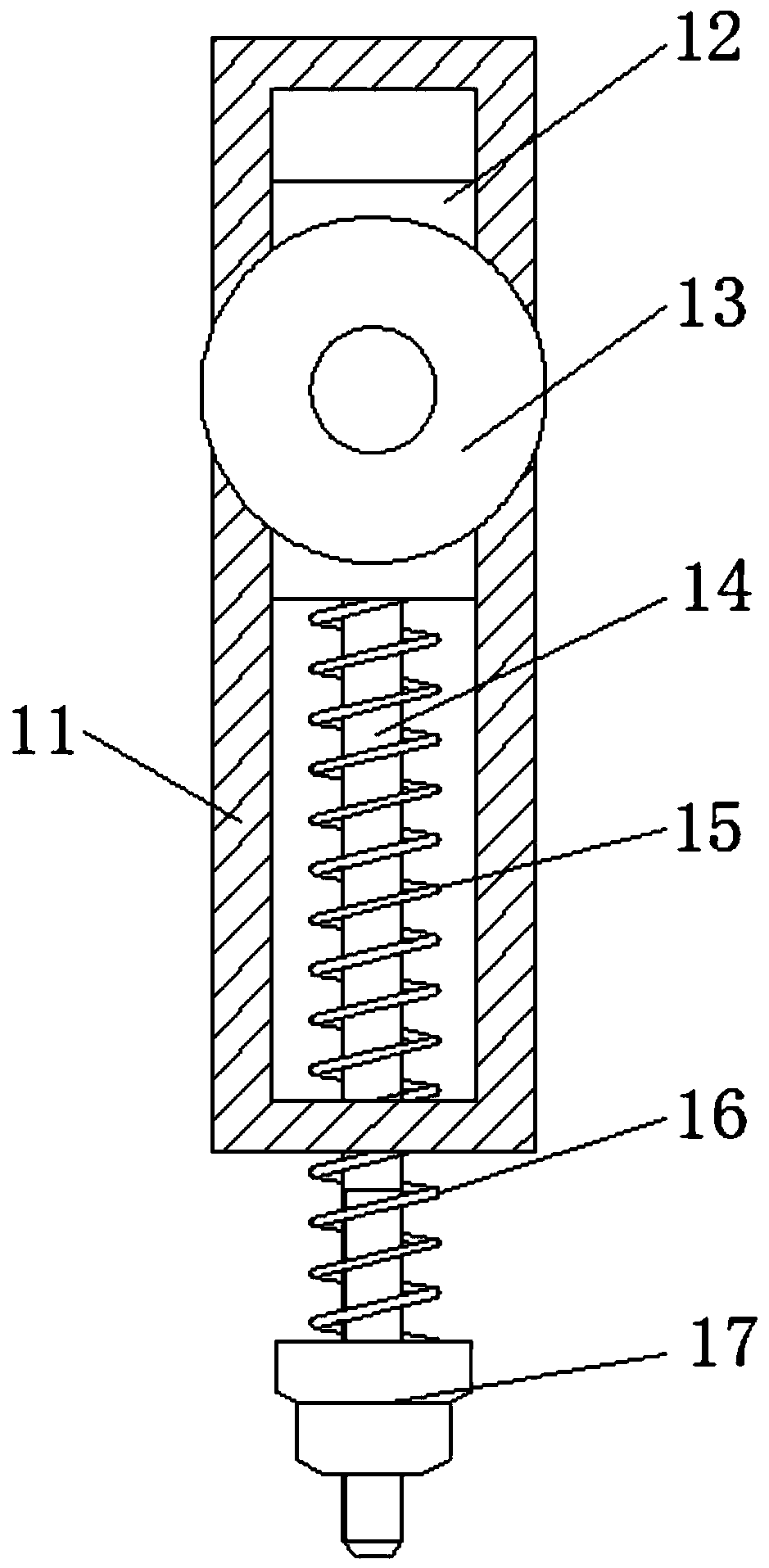

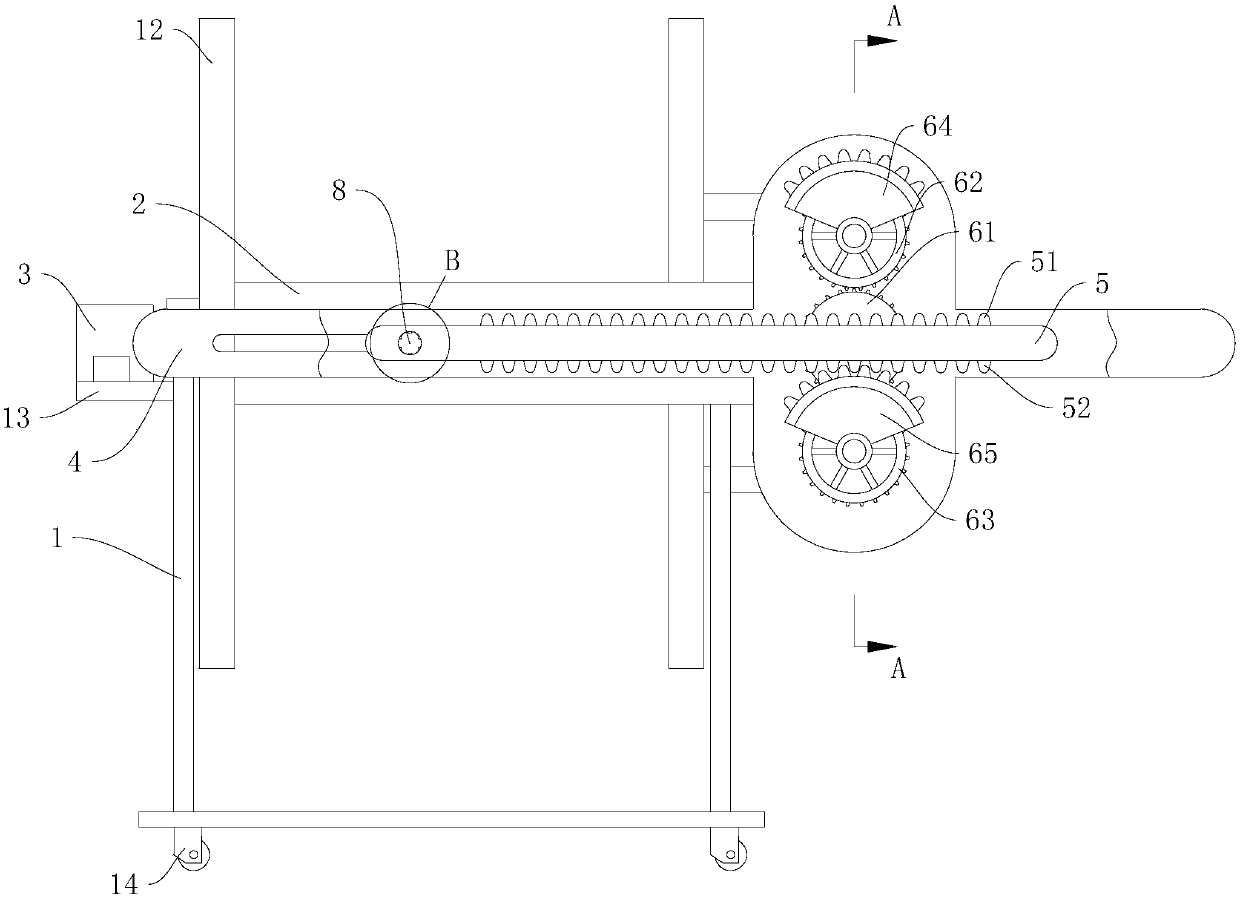

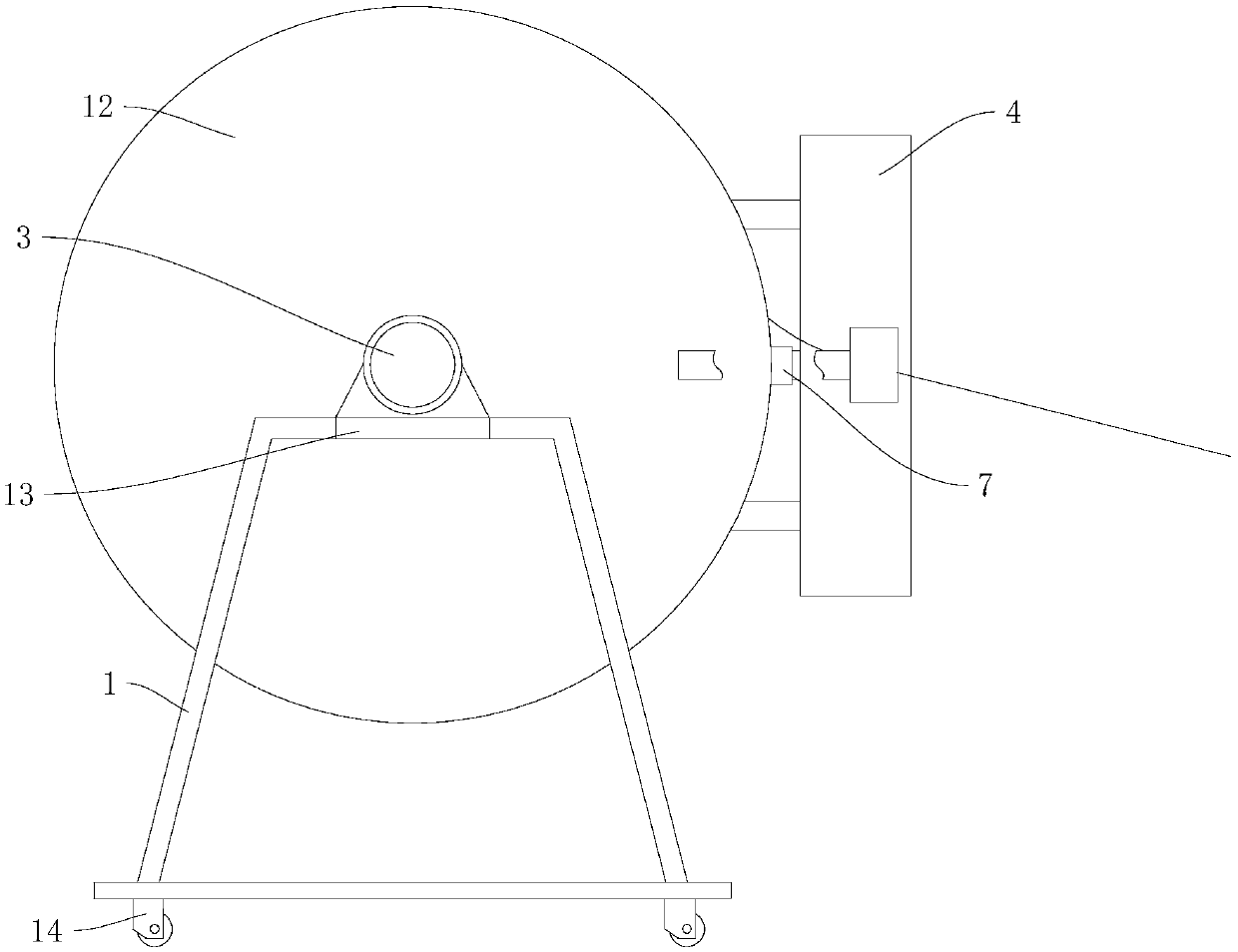

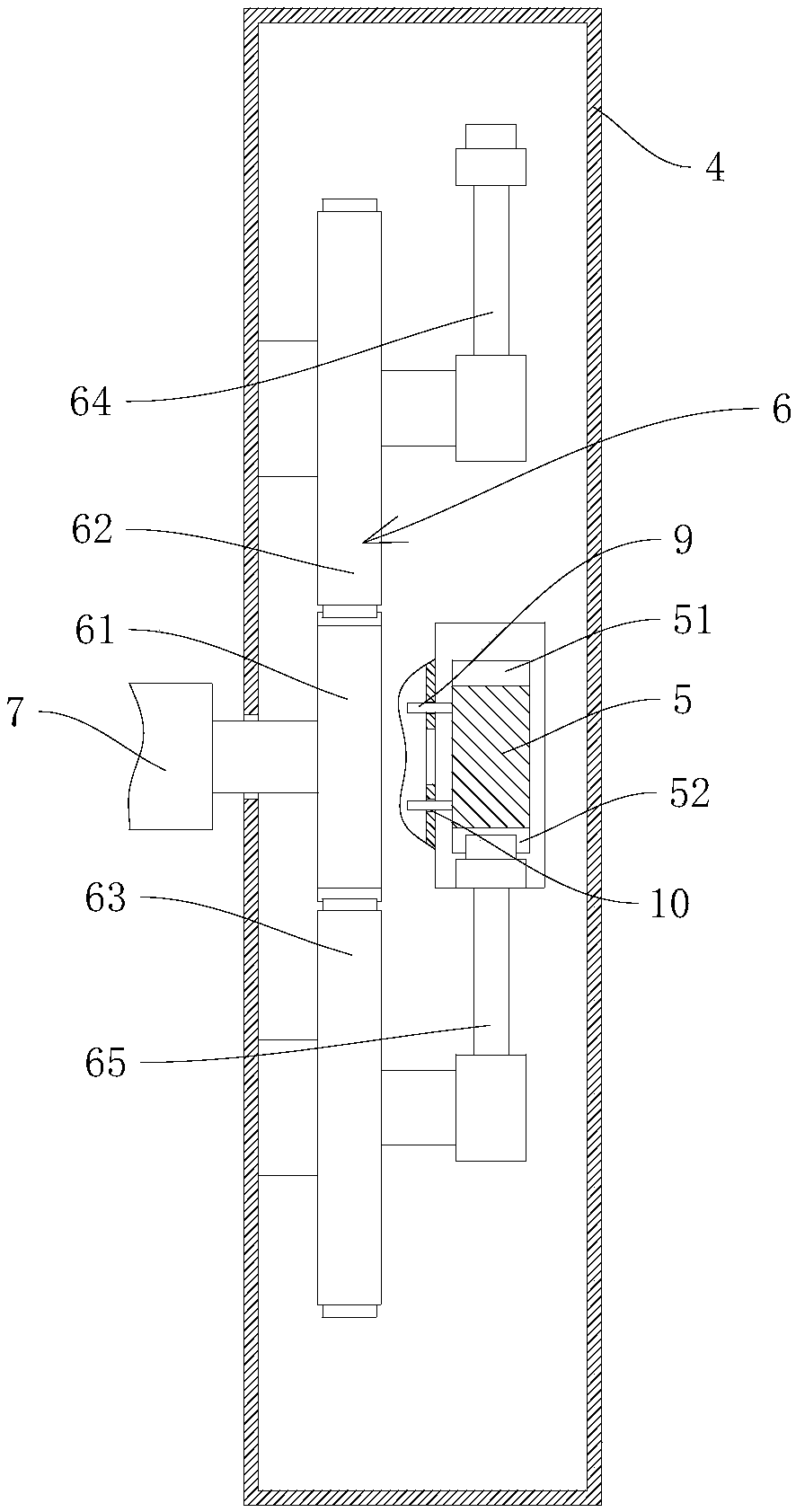

Tension-adjustable textile fabric winder based on Hooke law principle

The invention relates to the technical field of textile fabrics, and discloses a tension-adjustable textile fabric winder based on a Hooke law principle. The tension-adjustable textile fabric winder based on the Hooke law principle comprises a support frame, wherein a cloth guiding plate is fixedly connected to the inner part of the support frame; an unfolding frame is movably connected to the toppart of the cloth guiding plate; an unfolding shaft is movably connected to the inner part of the unfolding frame; an unfolding wheel is fixedly connected to the outer part of the unfolding shaft; afirst bevel gear is fixedly connected to the outer part of the unfolding shaft; a second bevel gear is connected to the outer part of the first bevel gear in a meshing way; a rotary shaft is fixedly connected to the inner part of the second bevel gear; a main gear is fixedly connected to the outer part of the rotary shaft; and a fixed cloth guiding roller is movably connected to the inner part ofthe support frame. Through the cooperative use of the cloth guiding plate and the unfolding wheel, a fabric is fully ensured to be unfolded and spread on the surface of the cloth guiding plate in therotation process of the unfolding wheel, the fabric is effectively prevented from being wrinkled and imprinted, and the fabric is fully ensured to be wound flatly.

Owner:陕西秦塬纺织有限公司

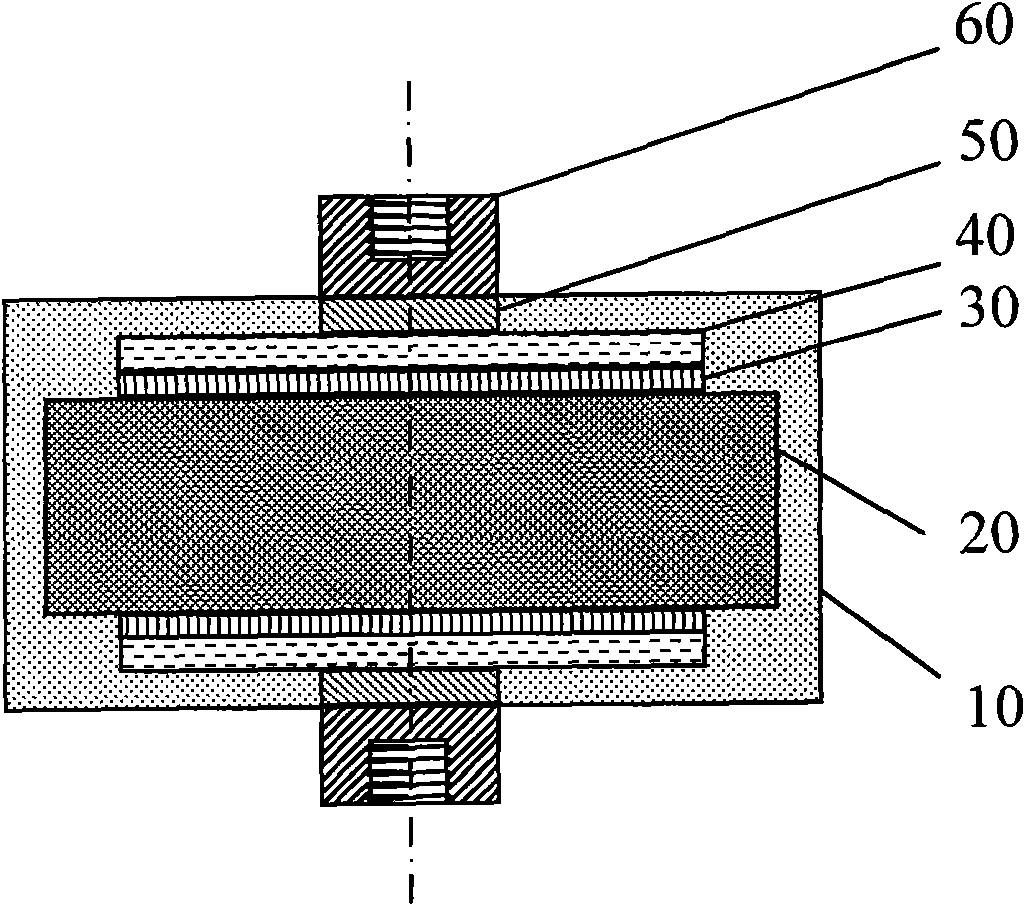

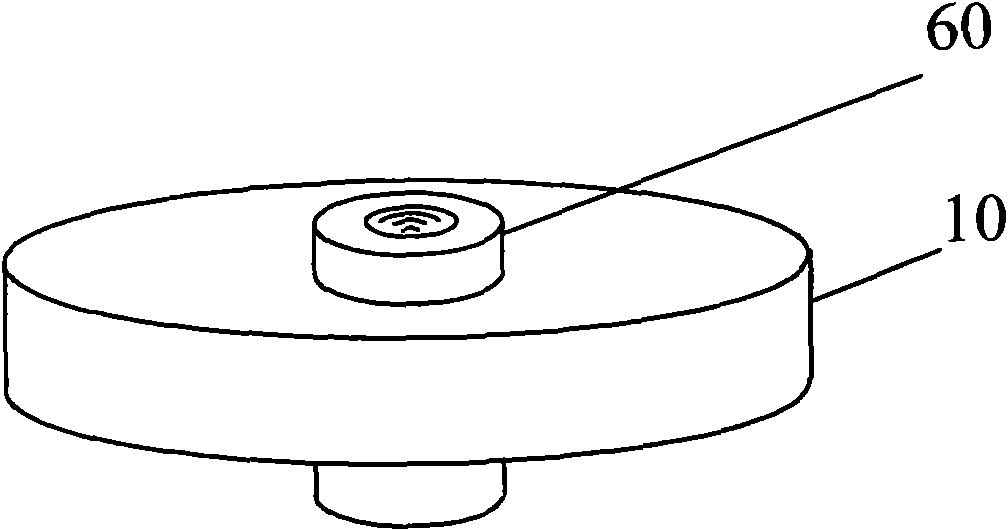

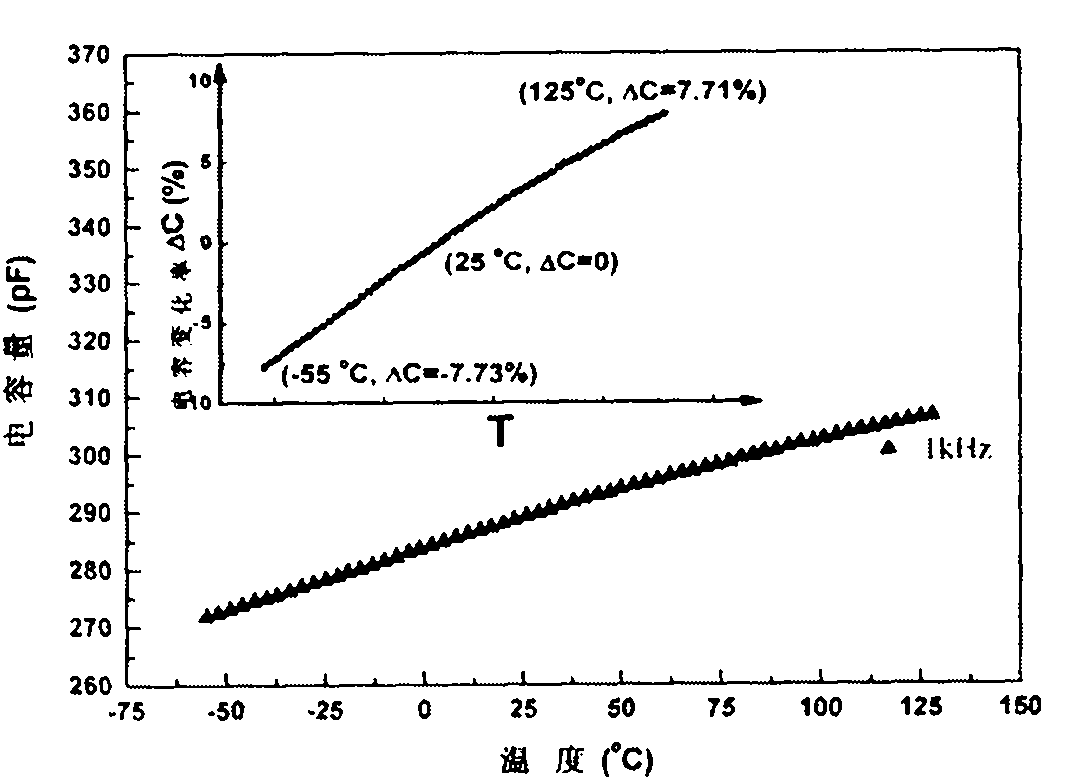

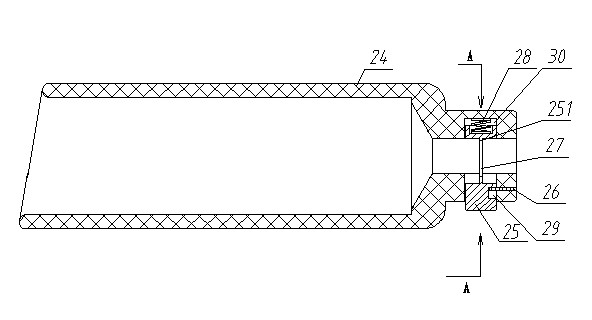

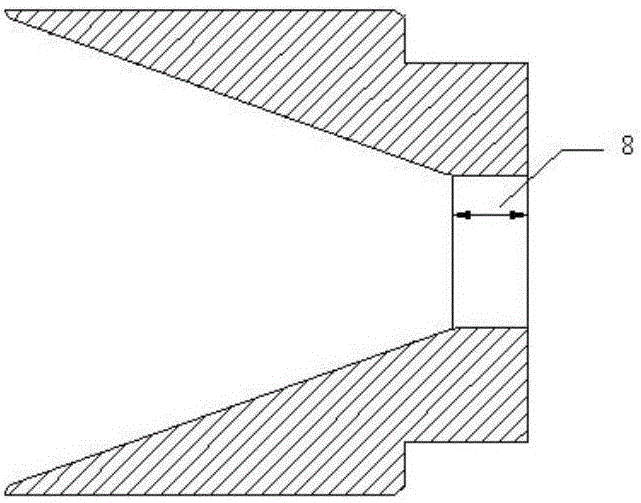

Miniature high-voltage capacitor and making method thereof

InactiveCN102054585AReduce volumeGuaranteed compactness and continuityFixed capacitor electrodesFixed capacitor dielectricCapacitanceGold film

The invention relates to a miniature high-voltage capacitor and a making method thereof. A dielectric layer is made of glass-ceramic materials, an electrode comprises a gold film inside electrode, a silver paste transition electrode, an In-Sn 50 alloy slice and an outside electrode end of a red copper sheet in sequence from inside to outside, and encapsulating material is epoxy resin. The invention provides the miniature high-voltage capacitor which has the diameter phi of 10-25mm, the thickness of 1-2mm, the nominal capacitance of 10pF-1nF, the rated direct-current voltage 10-20kV and the temperature characteristic of X7R. In the capacitor, the volume is greatly reduced, and an inside and outside electrode design technology is adopted, thereby ensuring the compactness and the continuity of the inside electrode, also weakening the electrode edge effect, enhancing the voltage-resisting strength of the capacitor, eliminating the influence of brittle fracture of lamellar medium materials caused in the welding process and supplying a novel design idea and making method for miniaturization and slice for the high-voltage capacitor.

Owner:有研科技集团有限公司

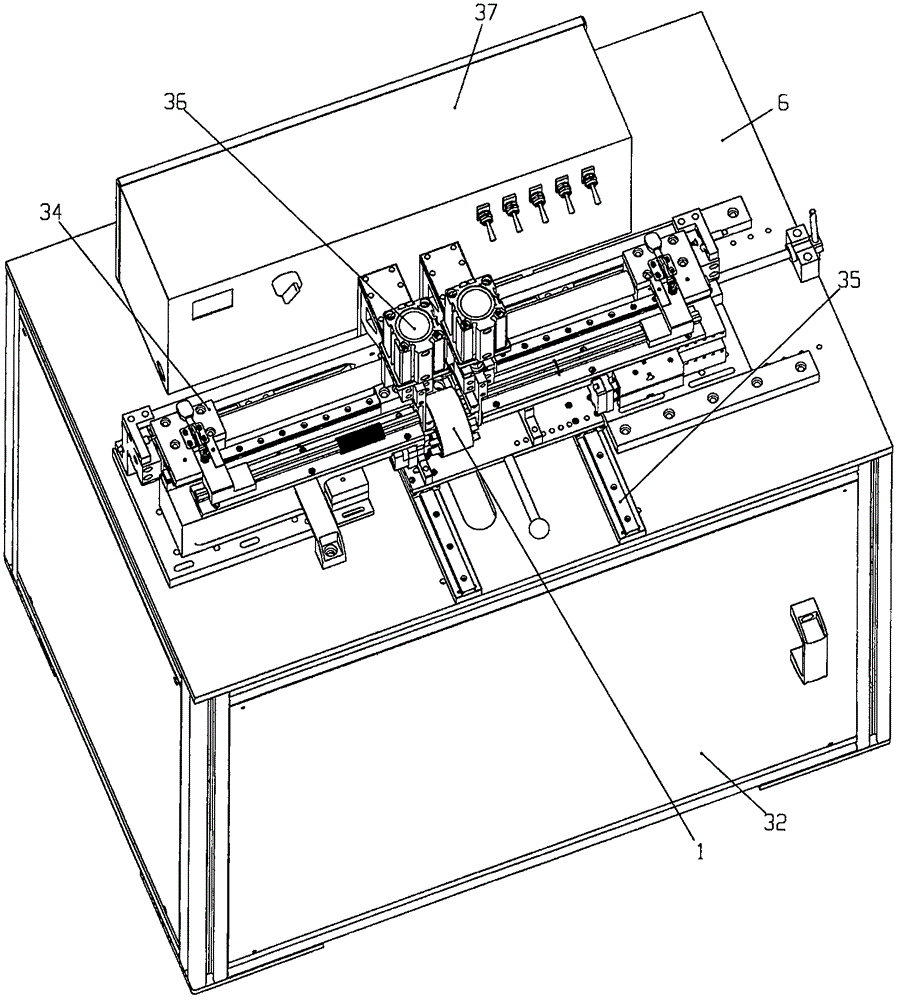

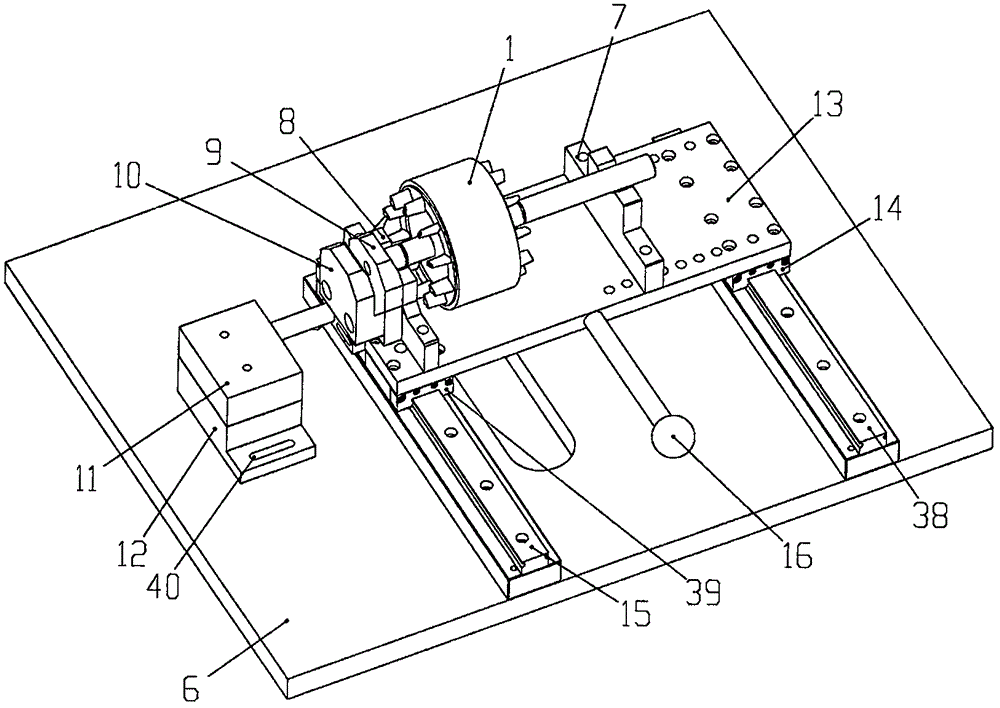

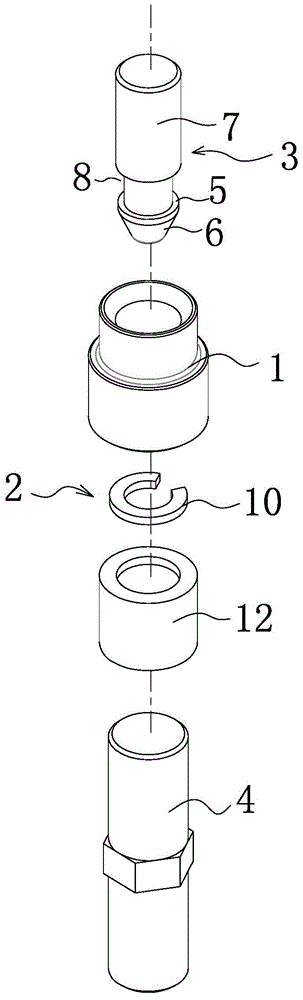

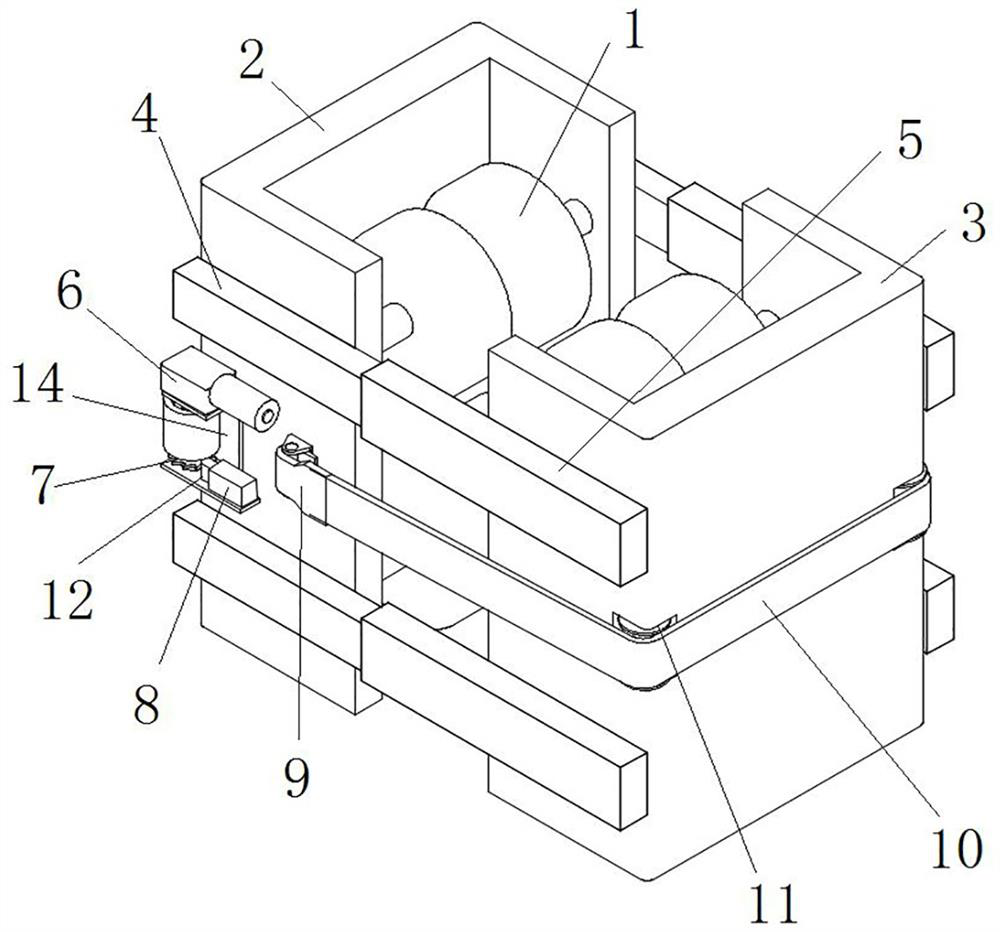

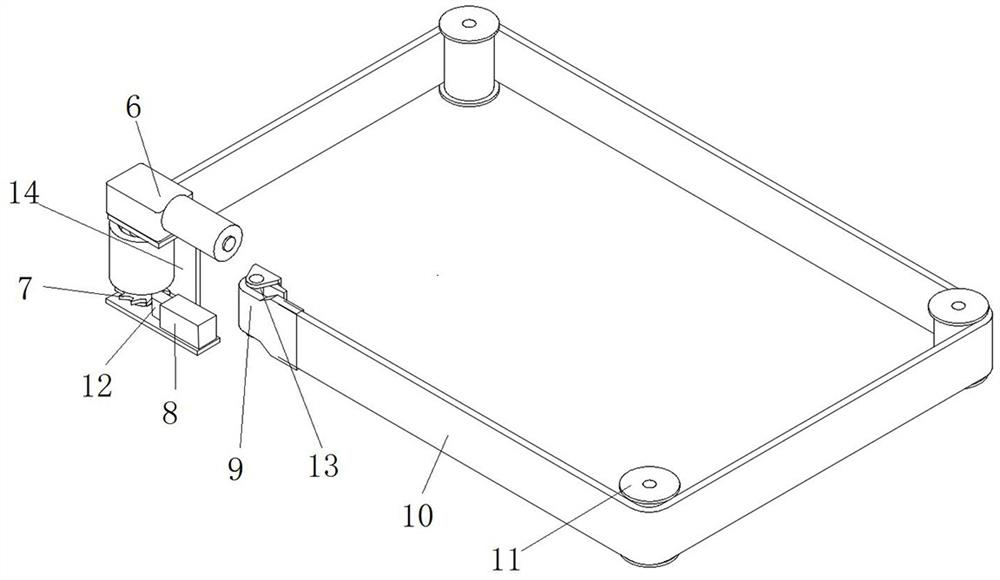

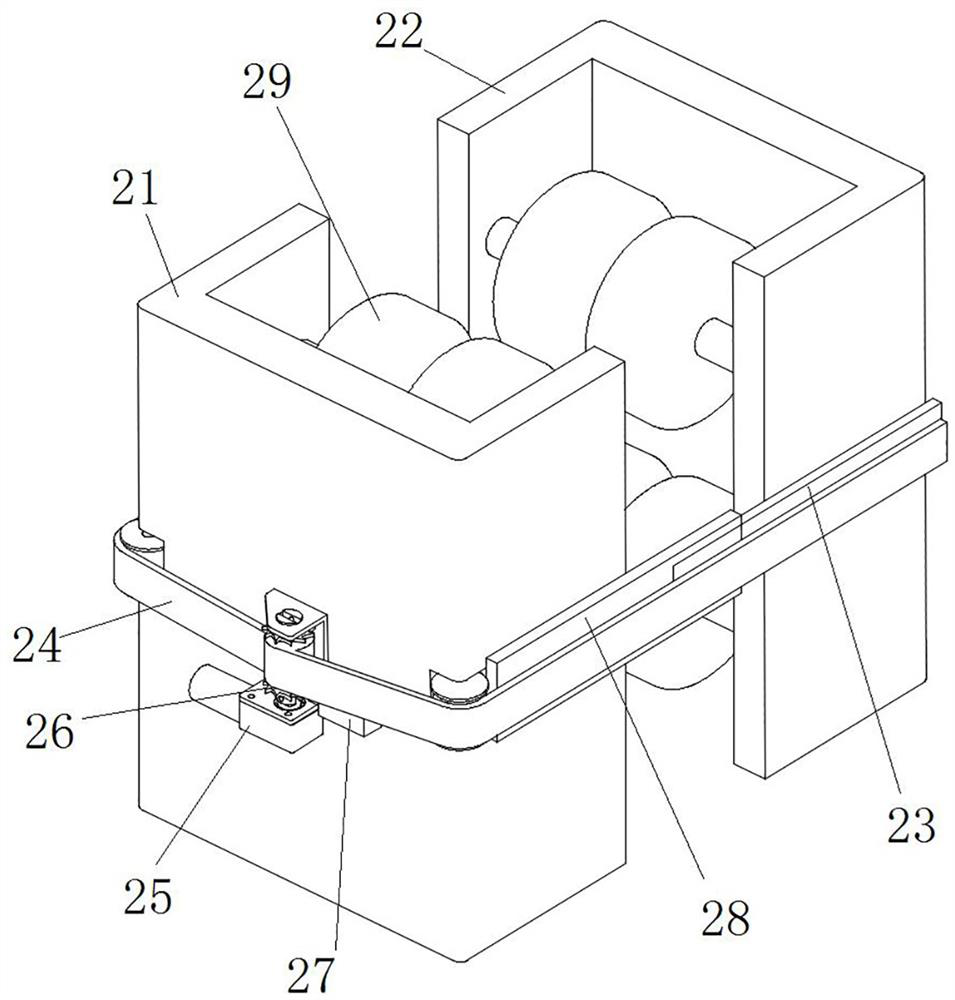

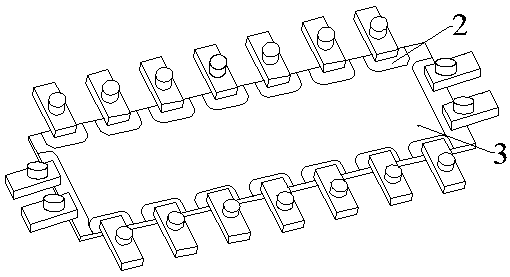

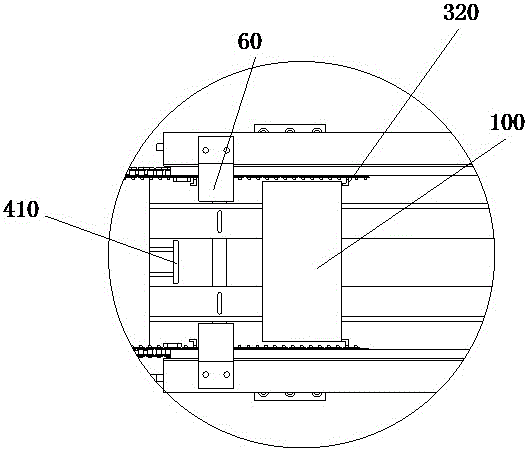

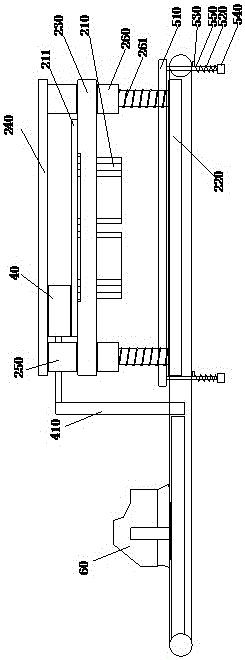

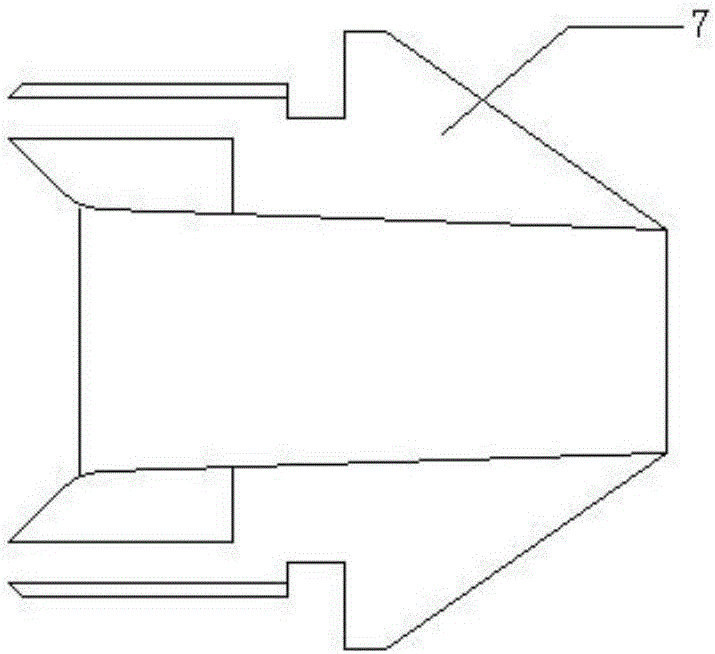

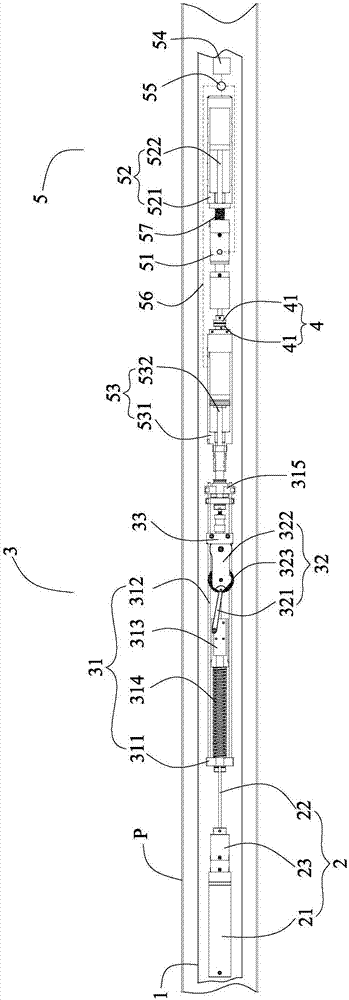

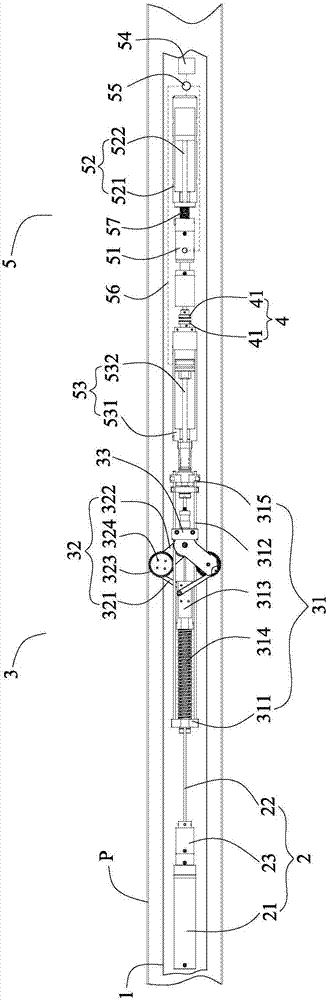

Device for automatically assembling snap spring on engine rotor

ActiveCN106271549AGuaranteed tightGuaranteed fixed effectMetal working apparatusEngineeringMechanical engineering

Owner:安徽创研新材料有限公司

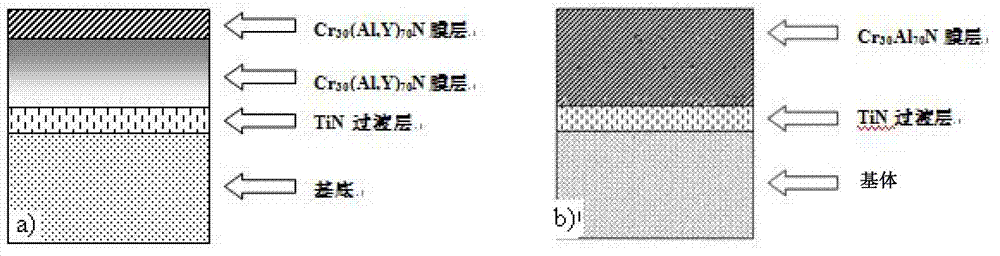

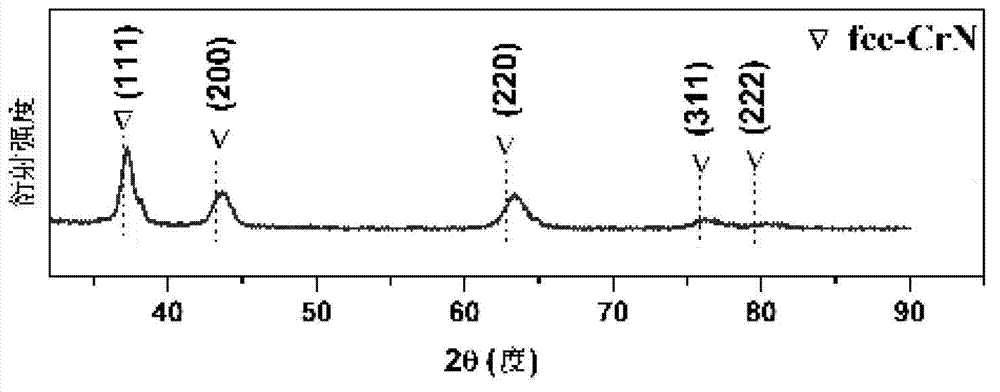

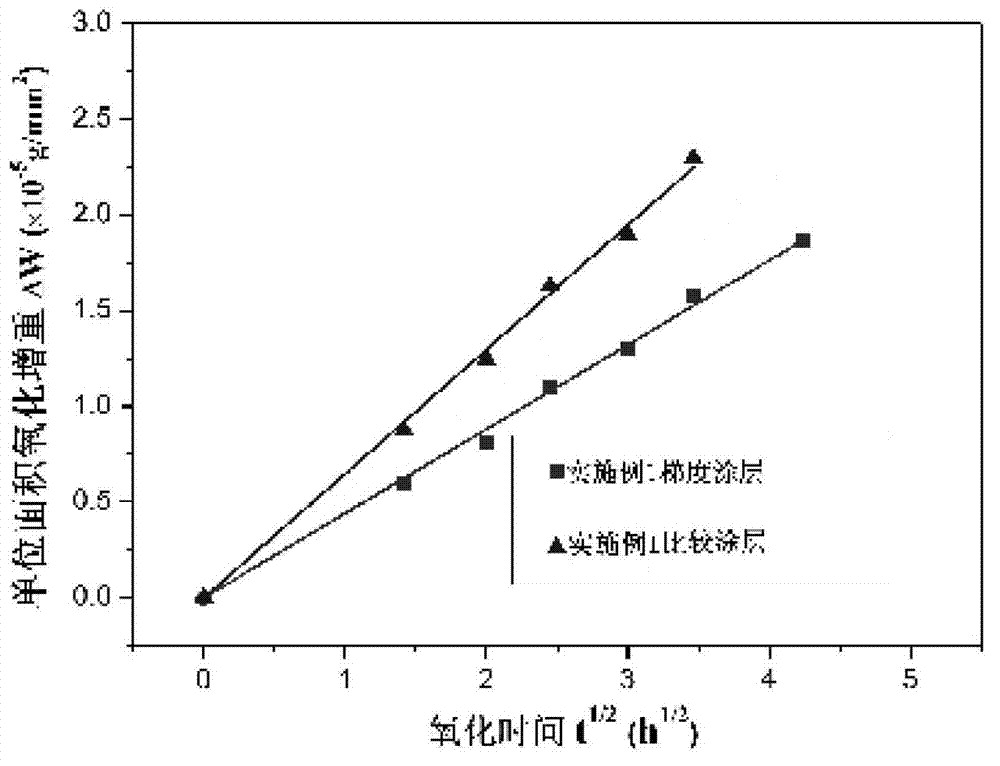

AN/Crl-xAlxN/Cr30 (Al, Y) 70N hard gradient coating and preparation method thereof

ActiveCN102766846AImprovement ingredientsGood compatibilityVacuum evaporation coatingSputtering coatingAlloyOxidation resistant

The invention discloses an AN / Crl-xAlxN / Cr30 (Al, Y) 70N hard gradient coating and a preparation method of the AN / Crl-xAlxN / Cr30 (Al, Y) 70N hard gradient coating. The coating is prepared on hard alloy or a steel base body, and the structure of the coating consists of three parts, wherein the first part is a CrN or TiN film layer which is taken as a bonding layer and a transition layer; the second part is a Crl-xAlxN gradient film layer, the aluminum content X in a structural formula from the inside to the outside of the gradient film layer linearly transits to 0.7 from 0.1; and the outer layer of the third part of the coating is a Cr30 (Al, Y) 70N film layer containing yttrium. The preparation method of the AN / Crl-xAlxN / Cr30 (Al, Y) 70N hard gradient coating comprises the steps of preprocessing the surface of a workpiece, preheating, cleaning and etching the surface, preparing a transition layer, preparing the gradient film layer and preparing the Cr30 (Al, Y) 70N film layer. According to the AN / Crl-xAlxN / Cr30 (Al, Y) 70N hard gradient coating and the preparation method of the AN / Crl-xAlxN / Cr30 (Al, Y) 70N hard gradient coating, due to the design of the coating structure and the adoption of the hollow cathode and ion plating combined preparation technology, the Cr-Al-N series coating with excellent mechanical property and high-temperature oxidation resistance can be obtained.

Owner:SOUTH CHINA UNIV OF TECH +1

Clamping structure of circuit board

InactiveCN108012498AEasy take-out and feed-inEasy to install and fixSupport structure mountingSoftware engineering

Owner:曹诗晴

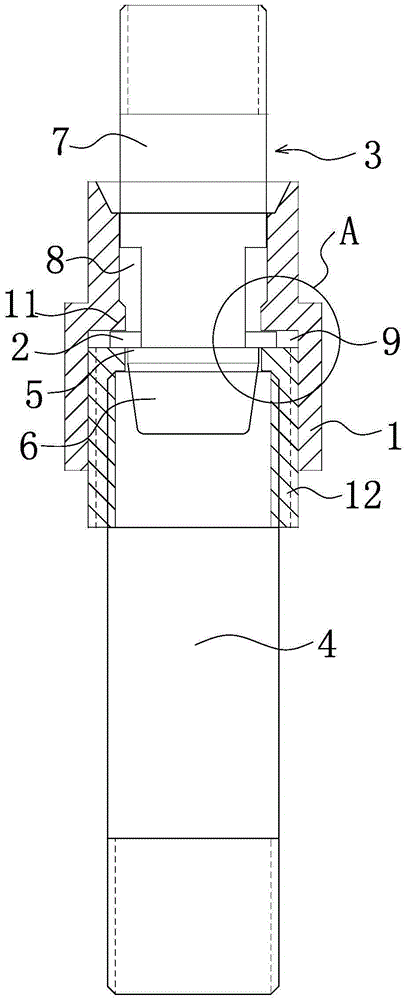

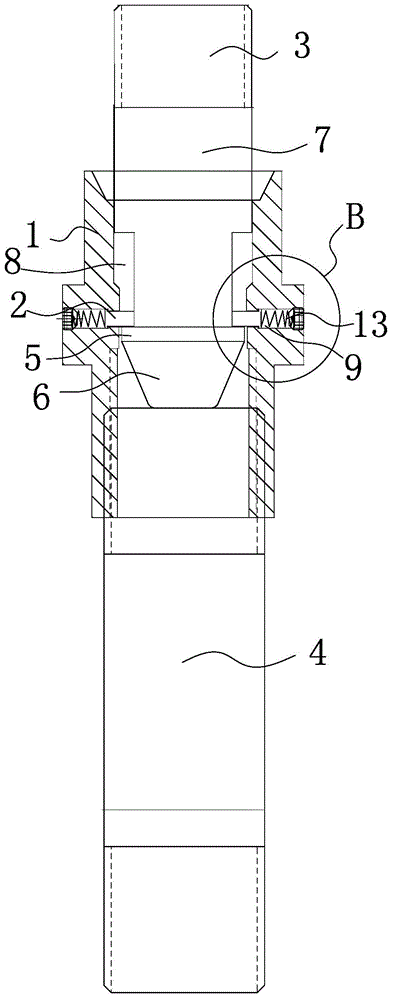

Elastic clamping type connecting piece

The invention belongs to the technical field of buildings and relates to an elastic clamping type connecting piece. The elastic clamping type connecting piece comprises a connecting nut, wherein the upper end and the lower end of the connecting nut are through. An elastic clamping part is movably connected into the connecting nut. A connector clip is inserted in one end of the connecting nut. The other end of the connecting nut is in screw joint with a screw joint part. The connector clip is provided with a clamping platform. When the connector clip is inserted into the clamping part, the clamping part can move in the direction far from the axis line of the connecting nut; when the clamping platform on the connector clip passes through the clamping part, the clamping part can move in the direction close to the axis line of the connecting nut to make the clamping part clamp the clamping platform. The elastic clamping type connecting piece can be used for connection of two objects and is convenient to assemble, convenient and fast to connect and firm and reliable in connection.

Owner:浙江兆弟技术有限公司

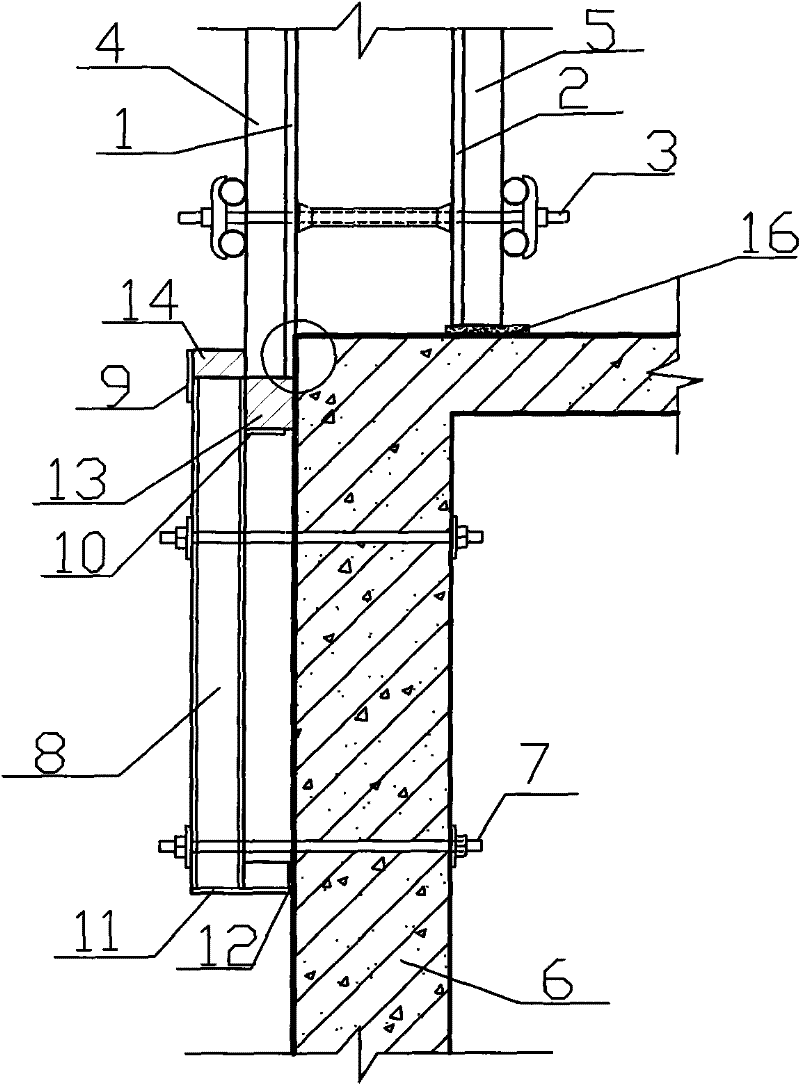

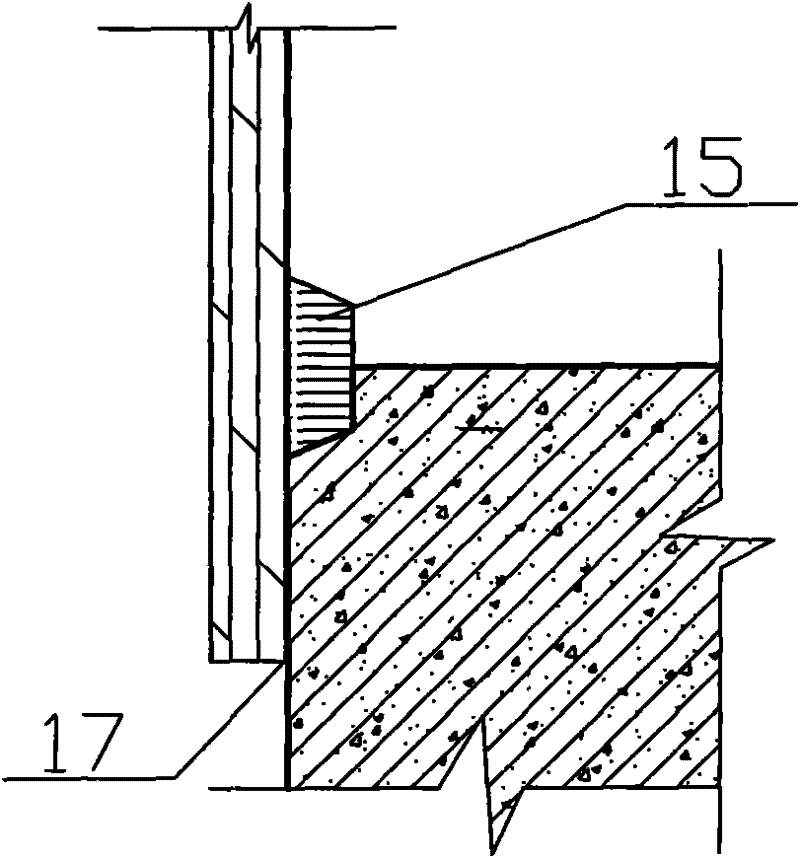

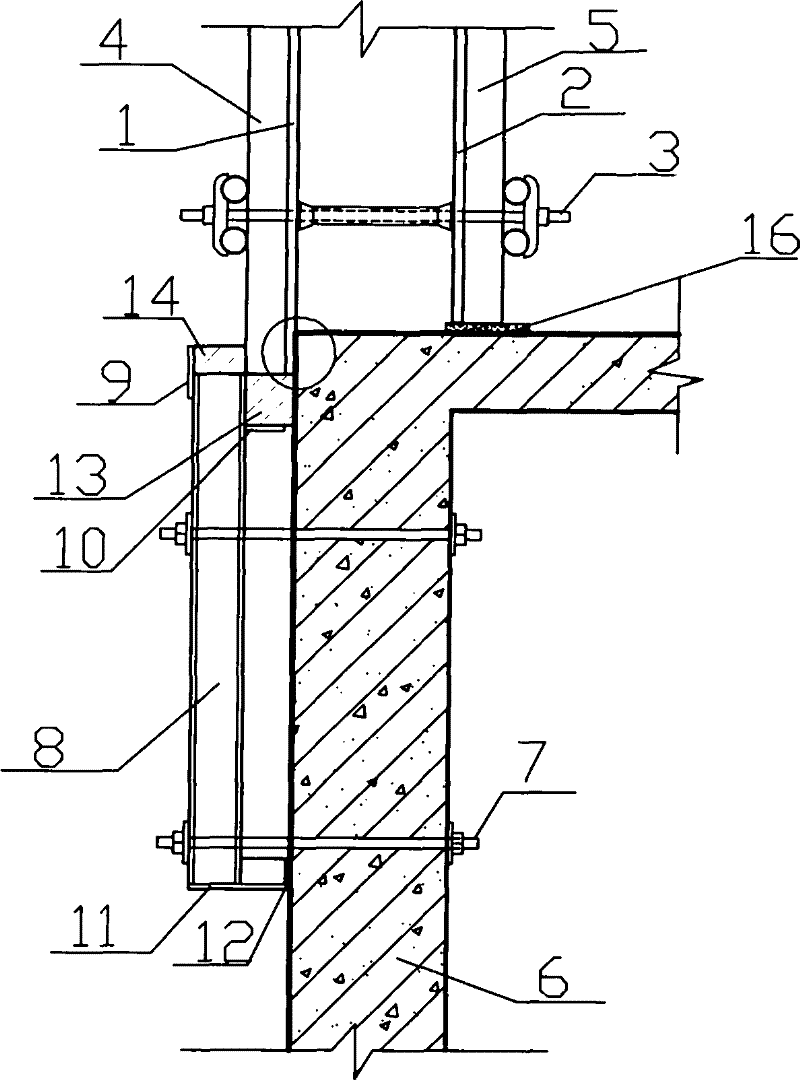

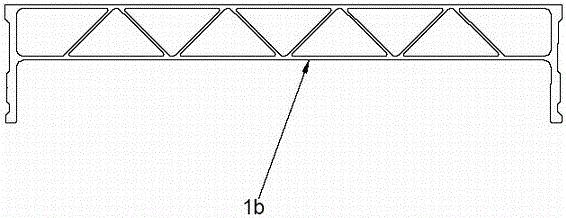

Connecting layer structure of fair-faced concrete outer wall template

InactiveCN101748891AGuaranteed tightEnsure stabilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineeringEngineering

The utility model discloses a connecting layer structure of a fair-faced concrete outer wall template, which comprises a template. The template consists of an outer wall template and an inner wall template which are fixed together by a split bolt; long battens are arranged on both outer sides of the outer wall template and the inner wall template; channel steel is fixedly arranged on the outer side of a lower wall body through a wall penetrating bolt; a steel gasket is arranged on the outer side at the upper part of the channel steel, and a support bracket is arranged on the inner side; a steel gasket is arranged on the inner side at the lower part of the channel steel; a sponge cushion is arranged between the steel gasket and the lower wall body; the bottom part of the outer wall template is fixed on a batten on the support basket of the channel steel, the inner side of the bottom part of the outer wall template is propped against the lower wall body, and a batten is arranged between the long batten on the outer side at the bottom part of the outer wall template and the steel gasket on the outer side at the upper part of the channel steel. In the invention, a connecting layer part of the outer wall template is mainly and specially designed, so that the tightness and the solidness at the connecting layer of the outer wall template are ensured, the mortar leakage and other quality defects at the connecting layer of the outer wall template can be effectively solved, and the forming effect and the apparent mass of fair-faced concrete for the outer wall are ensured.

Owner:QINGJIAN GRP CO LTD

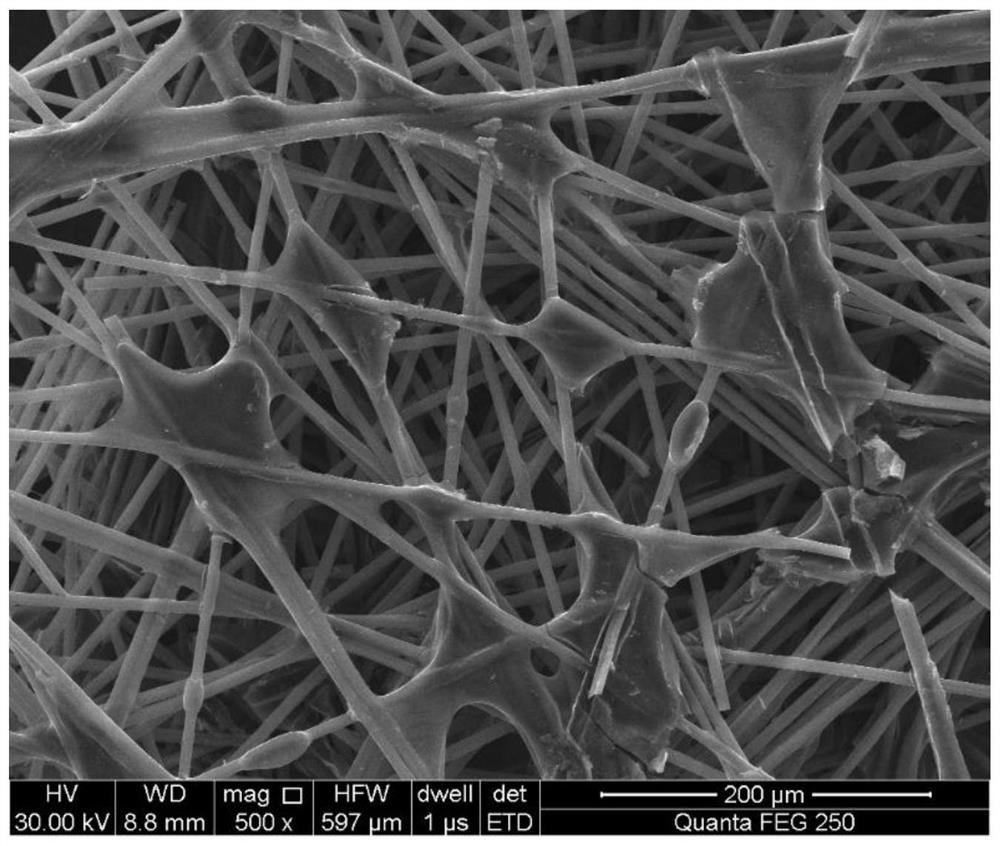

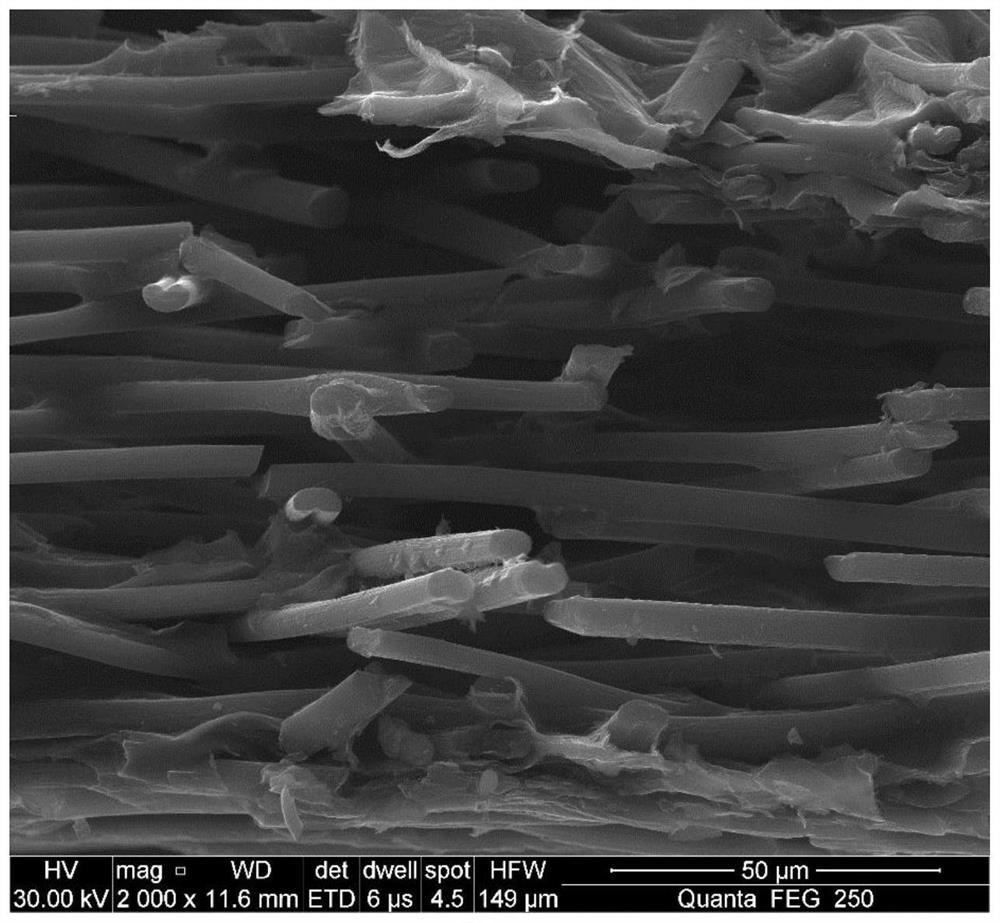

Preparation method of gradient pore structure carbon paper

ActiveCN113322713AEnhanced mass transferImprove heat transfer performanceCell electrodesSynthetic cellulose/non-cellulose material pulp/paperFiberCarbon fibers

The invention discloses a preparation method of carbon paper with a gradient pore structure, which comprises the following steps: separately degumming and oxidizing carbon fibers with different length-diameter ratios, and respectively dispersing the treated carbon fibers in a dispersant solution to form carbon fiber slurry with different length-diameter ratios; sequentially carrying out gradient layering and inclined net forming on the carbon fiber slurry according to the length-diameter ratio of carbon fibers from high to low to obtain a carbon felt precursor with a three-dimensional net structure; dipping the carbon felt precursor in a resin solution, taking out the dipped precursor, and conducting drying to obtain a carbon felt; and firstly hot-pressing the carbon felt into carbon paper body paper, and then conducting carbonization and graphitization treatment to obtain the gradient pore structure carbon paper. According to the invention, gradient layering is carried out in sequence from high to low according to the length-diameter ratio of the slurry carbon fiber, so that the prepared carbon paper has a gradient pore structure, communicating pores are formed in the carbon paper, the pore diameter changes in a gradient manner along the normal direction on the plane of the carbon paper, a pressure gradient is formed in a diffusion channel, the gas conveying efficiency can be improved, and the mass transfer and heat transfer performances of the carbon paper are effectively improved.

Owner:CENT SOUTH UNIV

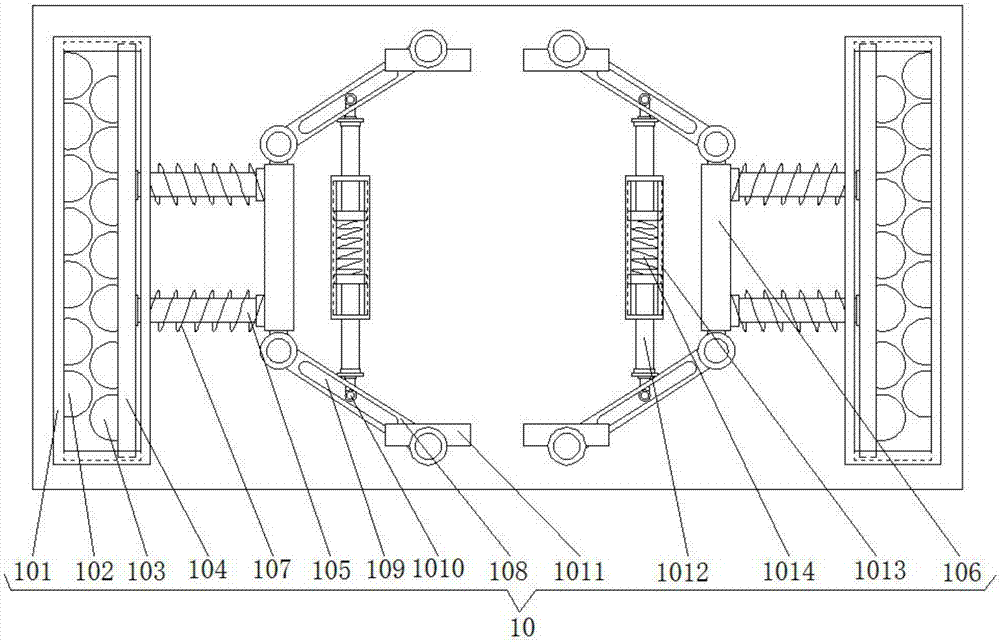

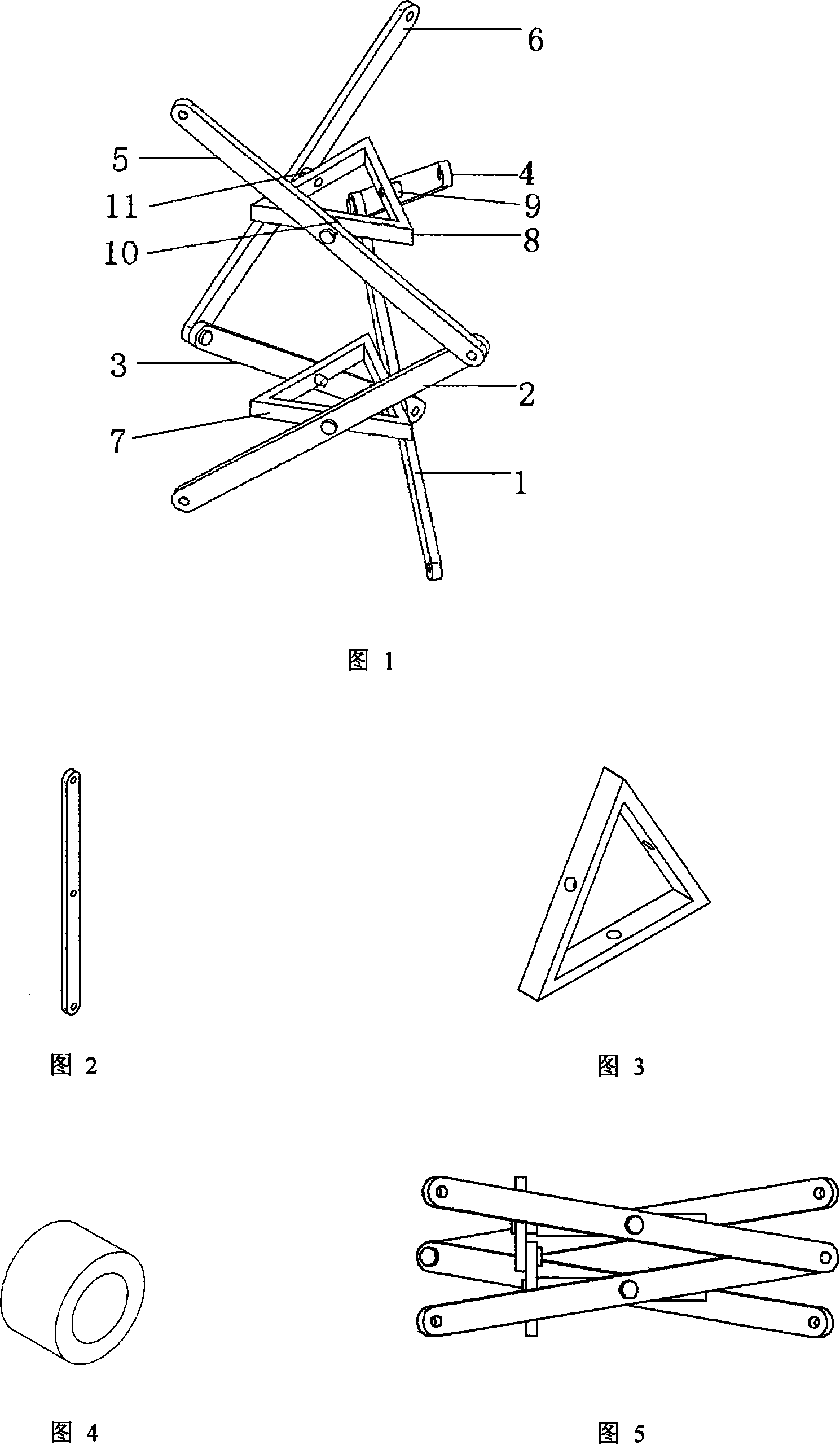

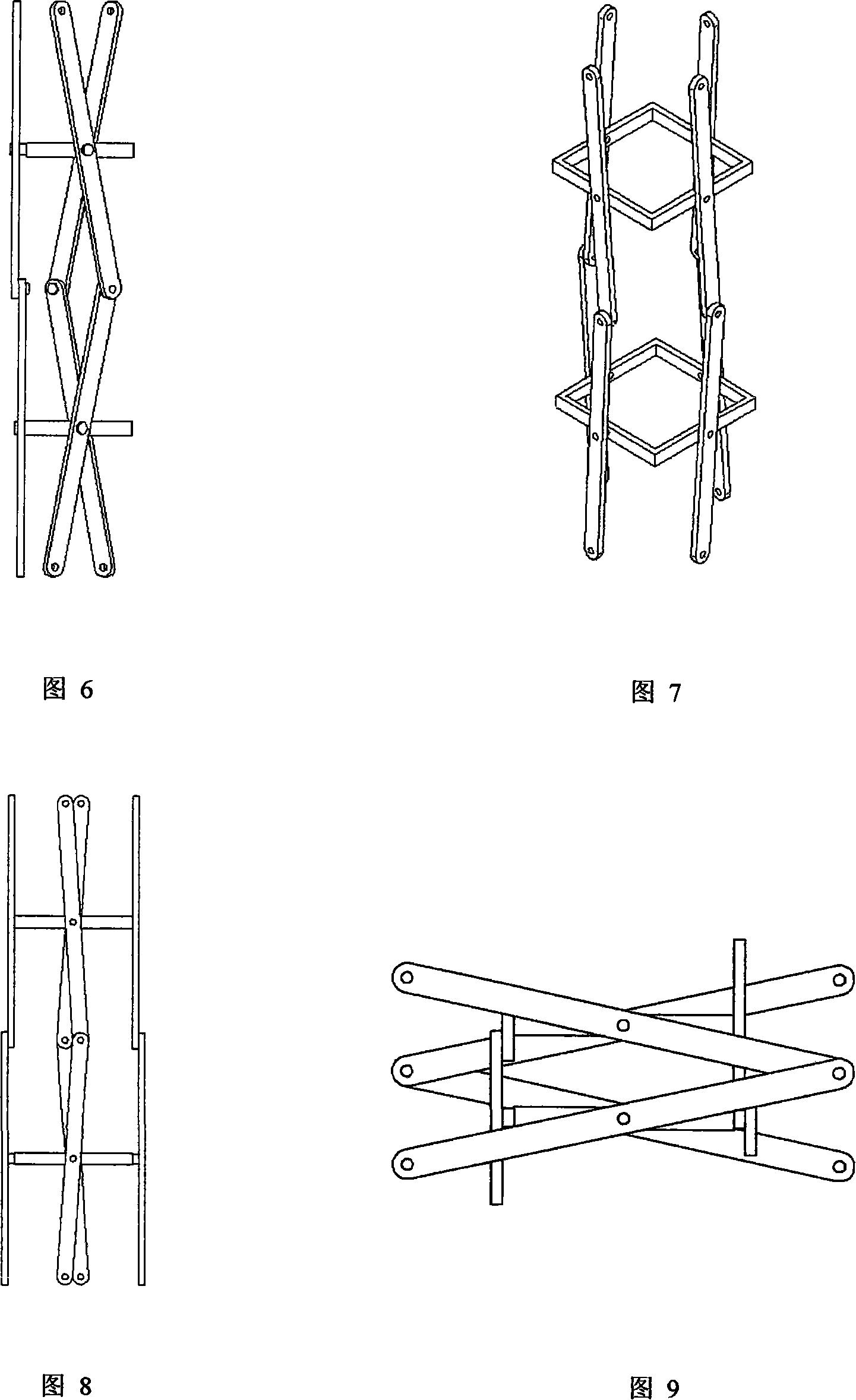

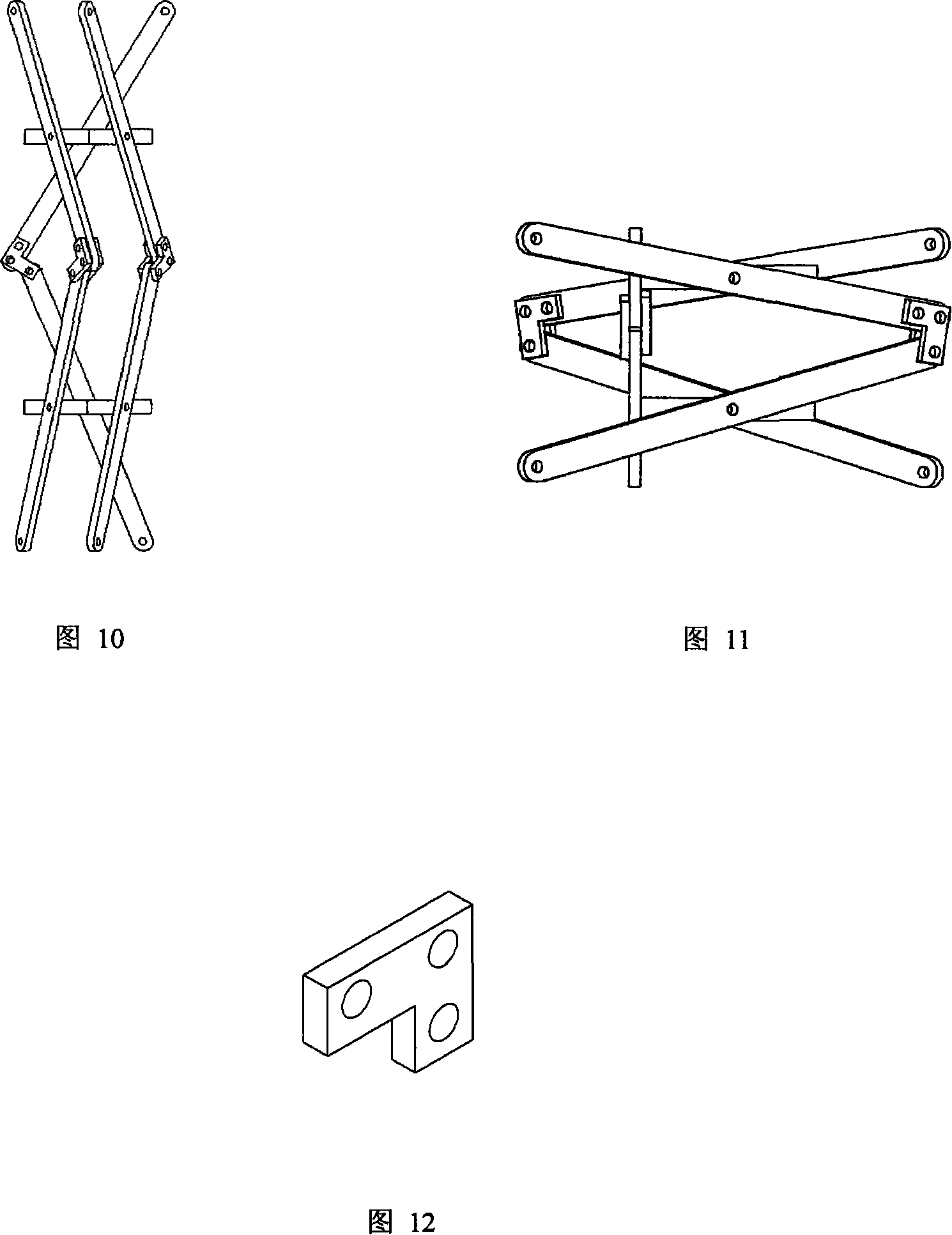

Zigzag rod space telescopic mechanism

InactiveCN101140005AGuaranteed tightLess materialGripping headsRod connectionsMaterial consumptionInterference problem

The invention relates to a zigzag member space telescoping mechanism which comprises a member and a middle bracket and is formed by the series connection of a plurality of layers of same component units. When the mechanism extends or contracts, the members are mutually staggered, which can overcome the interference problem. The arrangement mode of the member and the middle bracket of the mechanism can greatly reduce the occupancy space, which can make the mechanism compact while keeping a large telescopic ratio. When the member length is less than the side length of the middle bracket, the cross section of the mechanism can always remain unchanged. Due to the space symmetry of the mechanism itself, the mechanism has the comparatively uniform distribution of the bearing capacity of the different directions in the space. The mechanism has the advantages of the less material consumption, the large telescopic amplitude, the good stress performance, the strong stability, the wide application range and the simple manufacturing process.

Owner:BEIJING JIAOTONG UNIV

Cable automatic take-up device

Owner:STATE GRID CORP OF CHINA +2

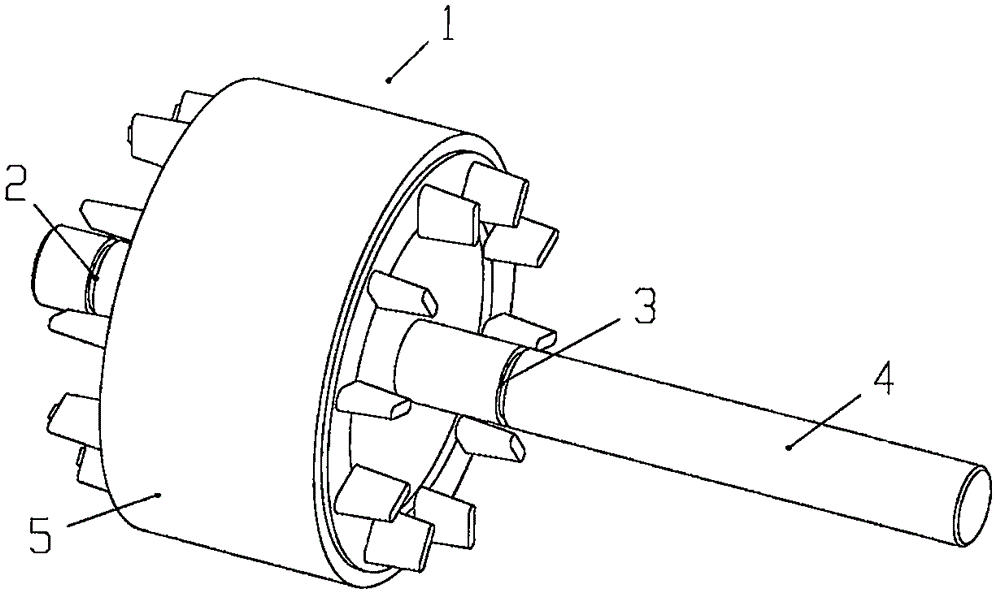

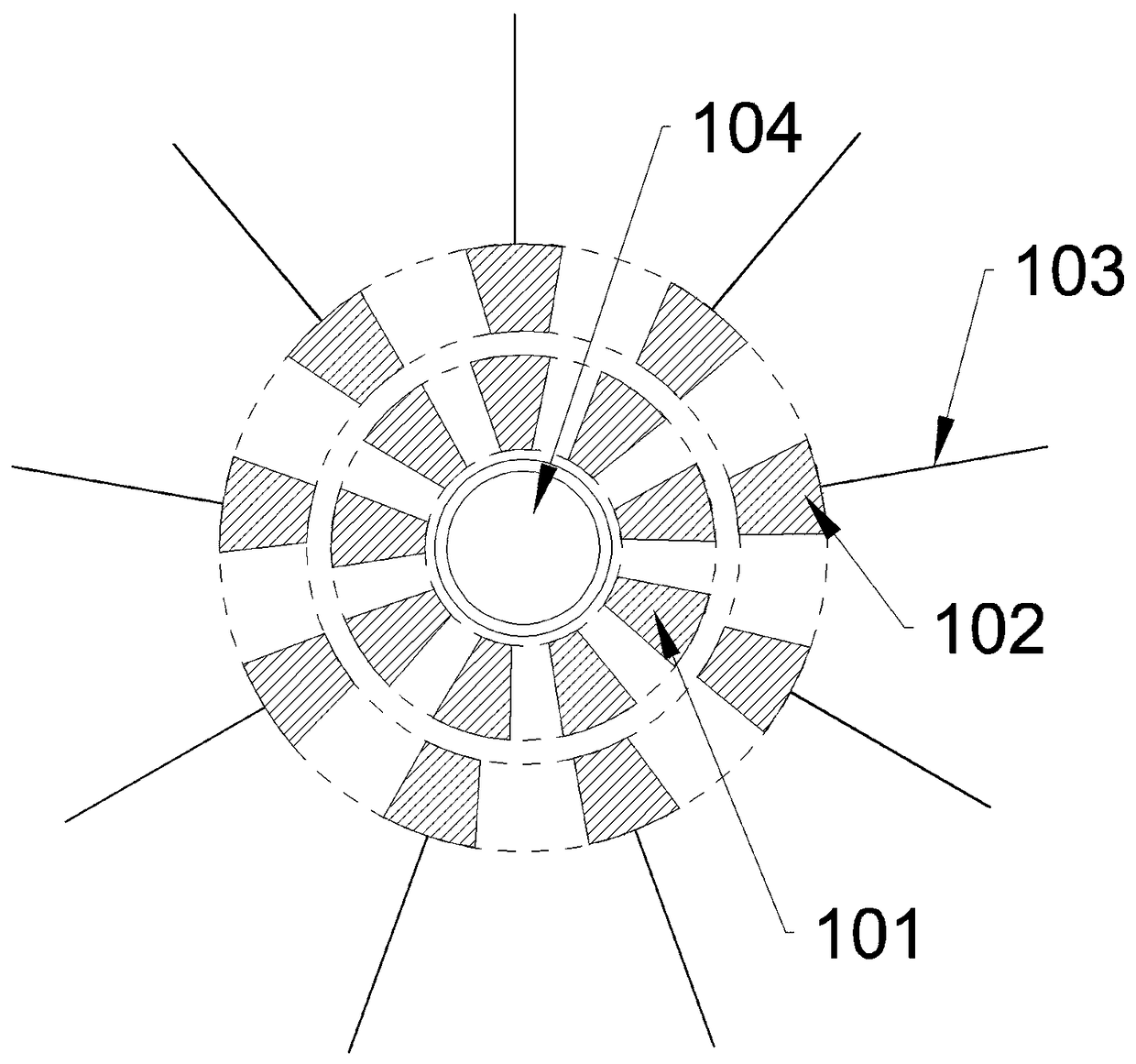

Pole-climbing robot

The invention relates to a pole-climbing robot. The pole-climbing robot comprises at least two climbing blocks, a flexible hooping piece and a tightening driving device, wherein the at least two climbing blocks are used for being distributed in the circumferential direction of a pole piece to be clamped, climbing wheels are arranged on the sides, which face the pole piece, of the climbing blocks,at least one climbing wheel is a driving wheel, and the driving wheel is in transmission connection with a wheel driving mechanism; a guiding telescopic structure is arranged between any two adjacentclimbing blocks and used for guiding the two corresponding climbing blocks to get close to each other in the opposite direction to press the pole piece and guiding the two corresponding climbing blocks to get away from each other in the opposite direction to release the pole piece; the flexible hooping piece extends in the distribution circumferential direction of all the climbing blocks, the flexible hooping piece is hooped on all the climbing blocks during tensioning, the tensioned flexible hooping piece applies hooping acting force to all the climbing blocks to drive all the climbing blocksto get close to each other, and then the climbing wheels of all the climbing blocks are pressed on the pole piece; and the tightening driving device is arranged on the corresponding climbing blocks and is in transmission connection with the flexible hooping piece so as to be used for tensioning the flexible hooping piece.

Owner:临颍县爬杆机器人有限公司

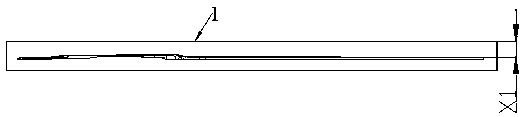

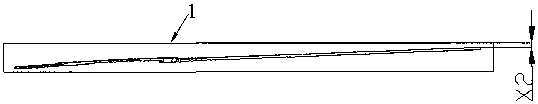

Machining method for controlling thickness of stainless steel sheet part

The invention discloses a machining method for controlling the thickness of a stainless steel sheet part. The method comprises the following steps: firstly tightly pressing a blank of a sheet part toform all pressure plate grooves, wherein the pressure plate grooves are more than 0.2mm lower than a reference surface to be corrected; then tightly pressing the blank, carrying out rough machining and fine machining on a first surface, and when a web plate after fine machining is in place, correcting the reference surface under the situations of the same working step, the same tight pressing state and the same tool so as to reduce the the error between the actual distance and the theoretical distance between the sheet part and the reference surface; and during machining of a second surface, it is guaranteed that the reference surface and a positioning surface are tightly attached so as to effectively control the thickness of the sheet part. According to the machining method for controlling the thickness of the stainless steel sheet part, the machining errors of the stainless steel sheet part can be effectively reduced, the ultrathin phenomenon of the stainless steel sheet part is avoided, the machining efficiency of the sheet part is improved, and the machining quality and stability of the sheet part are ensured.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

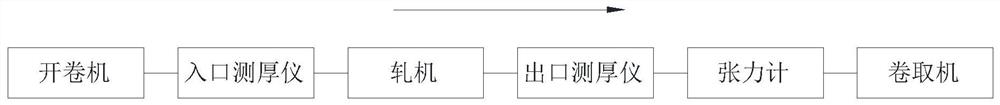

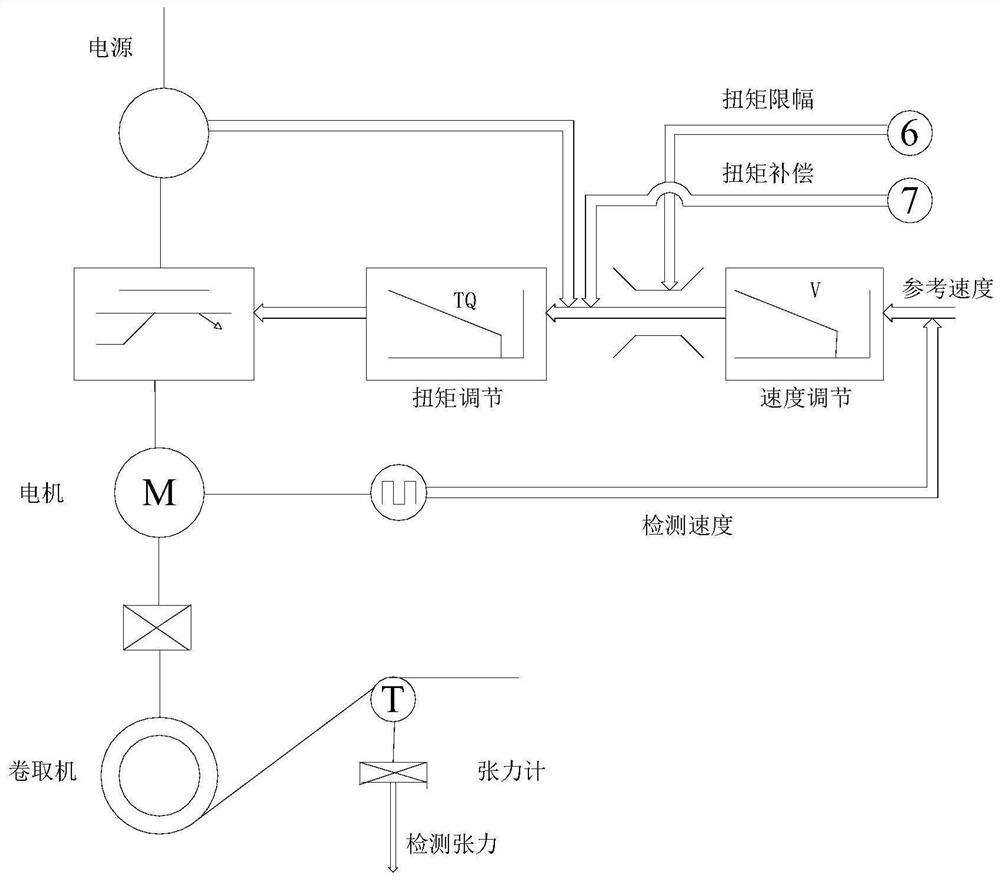

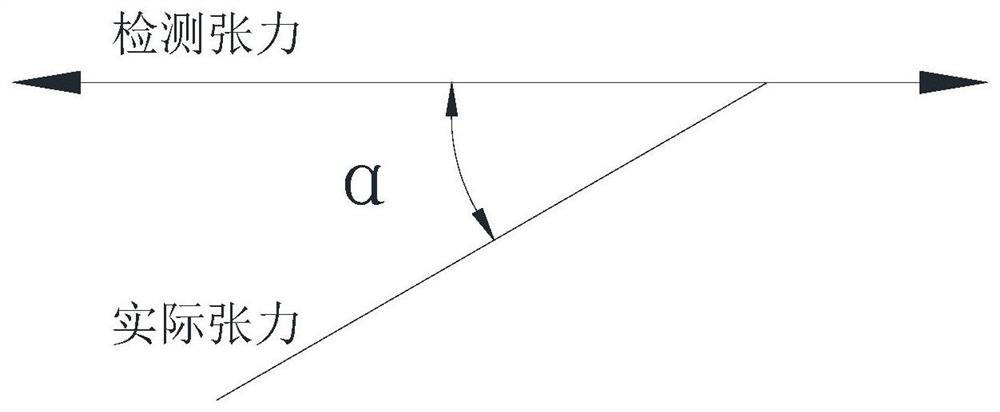

Ultra-thin steel strip coiling tension control method

ActiveCN113042540AGuaranteed tightGuaranteed to rollTensioning/braking arrangementsTension/compression control deviceFriction torqueLoad torque

The invention relates to an ultra-thin steel strip coiling tension control method. The technical problem that tension is difficult to control in the ultra-thin steel strip rolling process is solved. The tension control method comprises the following steps that firstly, static tension is established for an uncoiler and a coiler before a steel rolling unit operates; secondly, after the steel rolling unit operates, a tension value of a steel belt is detected, and a detection result is used for adjusting the output torque of a motor of the coiler; and thirdly, in the ultra-thin steel strip rolling process, torque compensation is conducted on the coiler, the tension of the steel strip is made to be constant, and the load torque MZ of the coiler comprises the steel strip tension torque MF, the rotational inertia torque MD, the steel strip bending torque Mw and the transmission system friction torque Mf. According to the technical scheme provided by the invention, strip drawing and strip breakage are avoided in the ultra-thin steel strip coiling process, so that a steel coil can be tightly and neatly coiled, the performance requirement of a product is met, and the production efficiency is also improved.

Owner:SHANXI TAIGANG STAINLESS STEEL PRECISION STRIP CO LTD

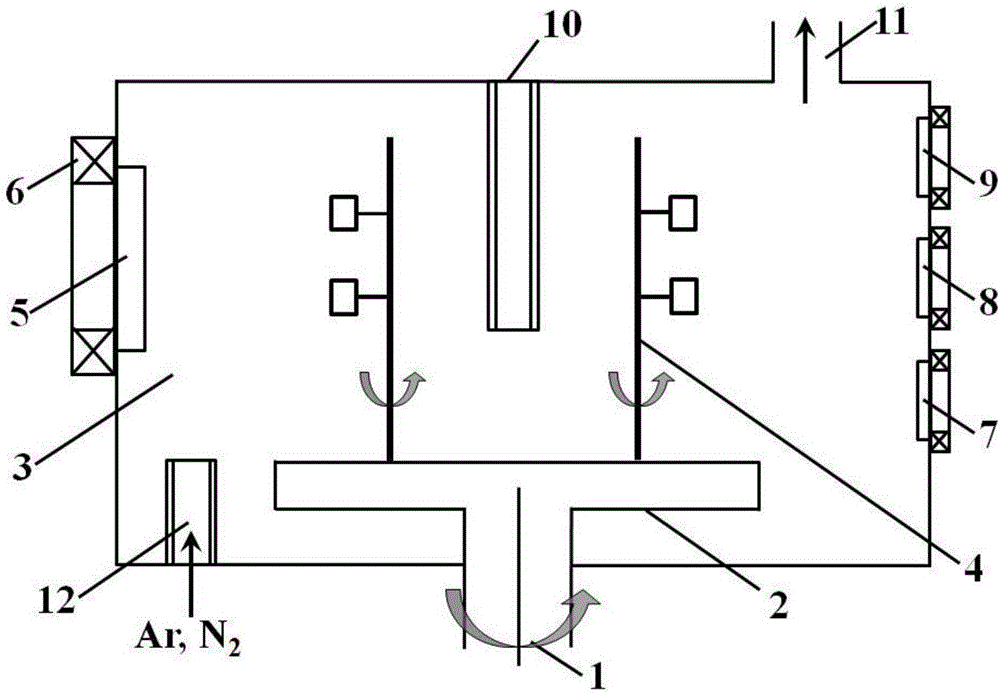

Method for preparing high-temperature alloy cutting tool coating in ion source enhanced arc ion plating mode

InactiveCN106835031ASolve cleaningSolve etchingVacuum evaporation coatingSputtering coatingOxidation resistantSuperalloy

The invention discloses a method for preparing a high-temperature alloy cutting tool coating in an ion source enhanced arc ion plating mode. The method comprises the steps that a high-temperature alloy cutting tool is pretreated and then placed to a rotating stand rod in a vacuum chamber of ion source enhanced arc ion plating equipment, a rectangular arc Ti target serves as a bottom Ti source, and the sputtering rate of the arc Ti target is controlled by adjusting the current of the arc Ti target; a round arc CrAl target serves as a Cr and Al element source for preparing aCrAlN coating, and the sputtering rate of the arc CrAl target is controlled by adjusting the current of the arc CrAl target; high-purity Al and high-purity N2 enter the vacuum chamber through the ion sources, wherein the Ar serves as the ionizing gas, and an effective glow discharging process is guaranteed; and the N2 serves as the reaction gas and is ionized to be combined with Cr and Al elements, and the CrAlN coating is formed on the surface of the high-temperature alloy cutting tool in a deposition mode. According to the prepared CrAlN coating, the anti-oxidization temperature of the coating is 1000 DEG C, the microhardness is Hv3500, and requirements of the high-temperature alloy cutting tool for the abrasion resistance, the thermal fatigue resistance and the anti-oxidization performance can be well met.

Owner:XI AN JIAOTONG UNIV

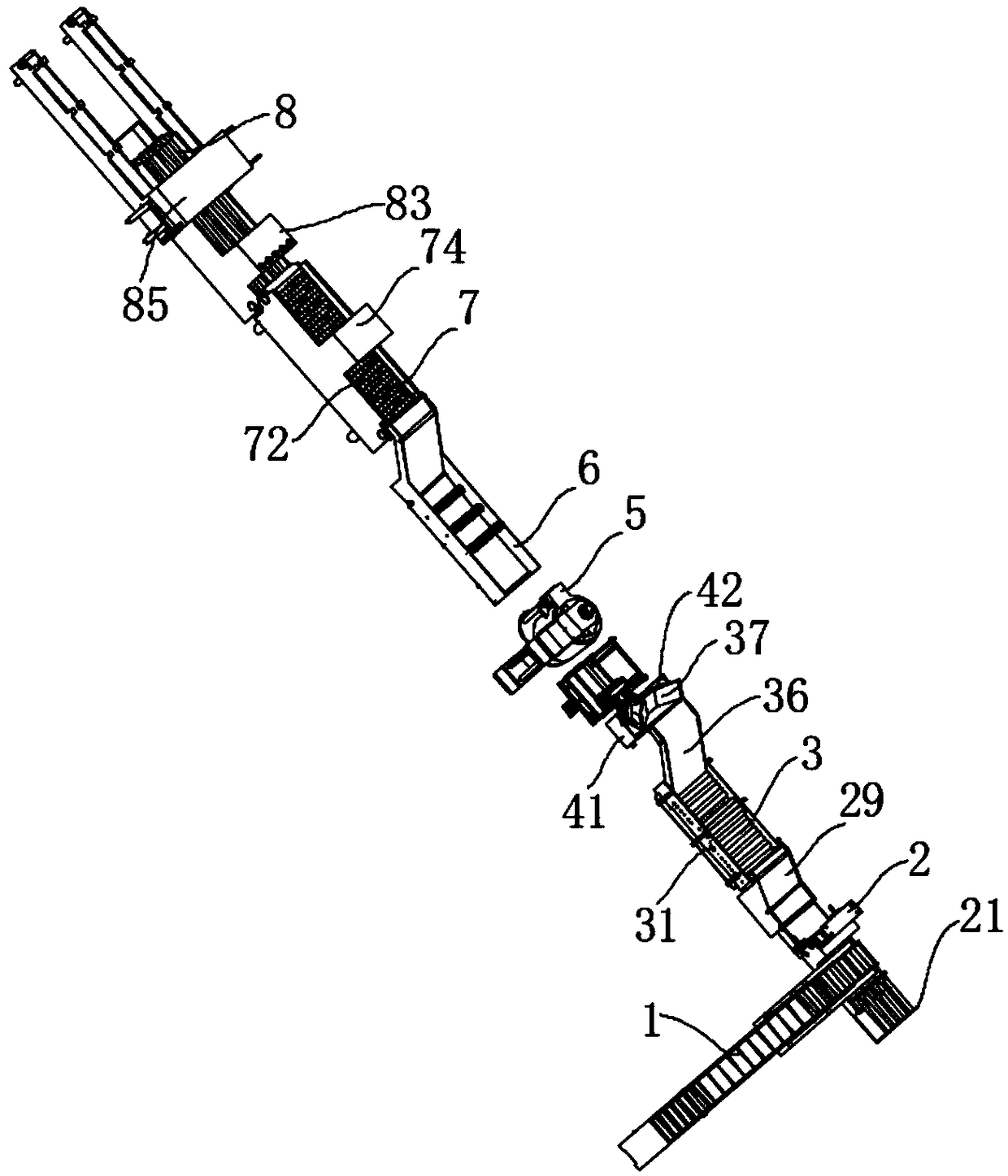

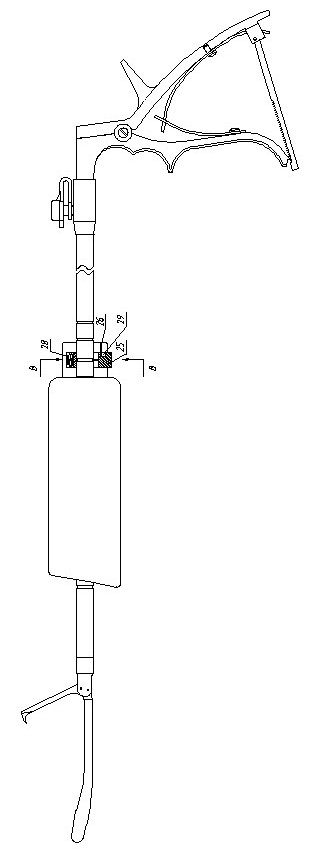

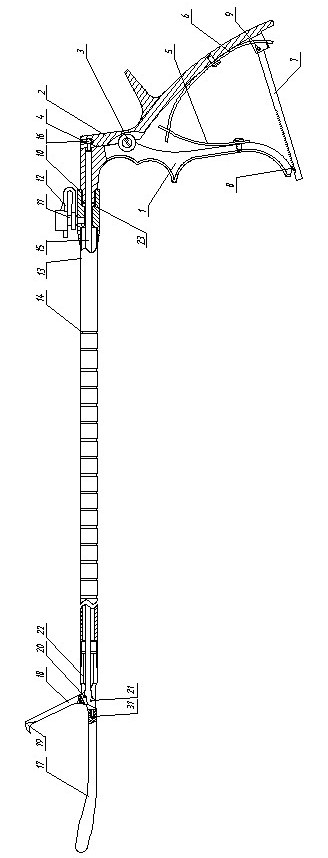

Pair of special pliers for uterus resection operations

ActiveCN102357041AGuaranteed tightReasonable structural designObstetrical instrumentsSurgical forcepsCervix partEngineering

The invention discloses a pair of special pliers for uterus resection operations, which comprises a cervix uteri pliers assembly and a cervix uteri cup assembly, wherein the cervix uteri pliers assembly is provided with a fixed handle, a movable handle, a first return spring, a second return spring, a toothed plate, a pliers seat, a flushing seat, a seal cover, a pliers rod, a pull rod, a pull rod seat, a uterus lifting head, a cervix uteri pliers clamp, cervix uteri clamp teeth, a pliers clamp seat and a seal ring. The first return spring and the second return spring are pressed tightly in acrossed mode and fixed on the fixed handle and the movable handle respectively, the second return spring is connected with the toothed plate, the toothed plate is connected with clamping teeth, and the pliers seat is connected with the flushing seat and connected with the fixed handle. The pliers rod is provided with an adjusting groove which is matched with the cervix uteri cup assembly, the uterus lifting head is fixed on the pliers clamp seat, the cervix uteri pliers clamp is fixed on the pliers clamp seat and fixed at one end of the pull rod, the other end of the pull rod is connected with the pull rod seat which is clamped into a pull rod groove, and the pliers clamp seat is connected with the pliers rod. The pair of special pliers is simple in structure, and a cervix uteri cup is appropriately located through the adjusting groove, thereby being convenient and safe in operation application.

Owner:HANGZHOU KANGJI MEDICAL INSTR

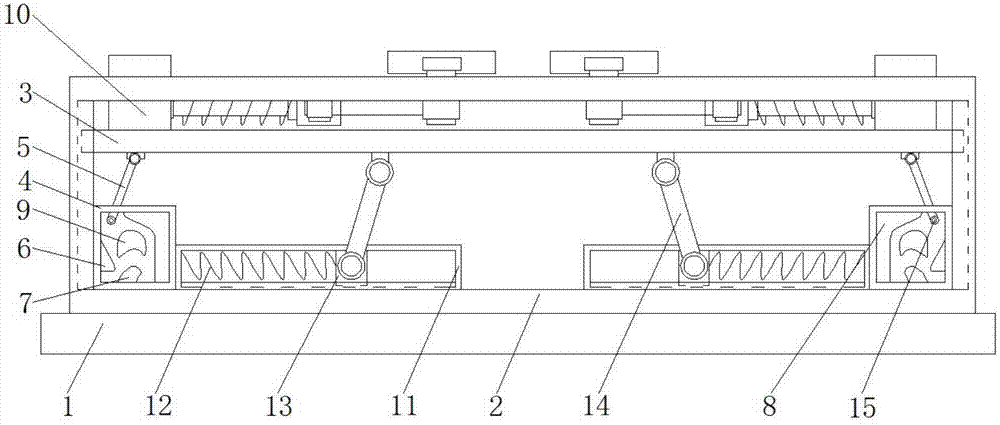

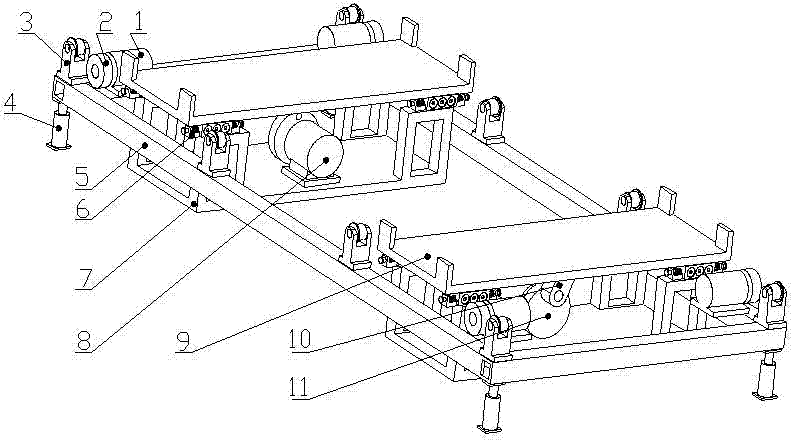

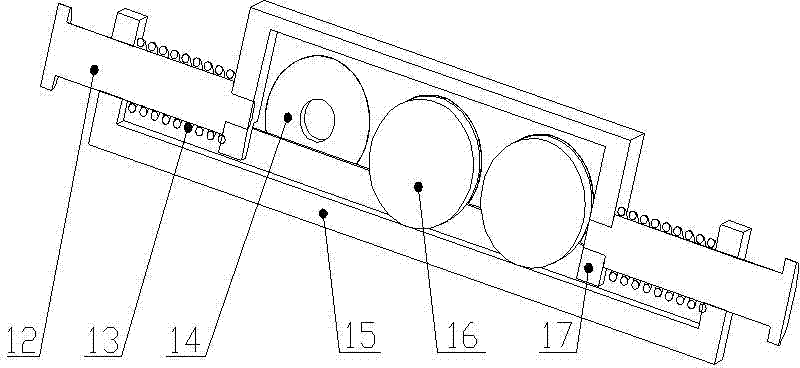

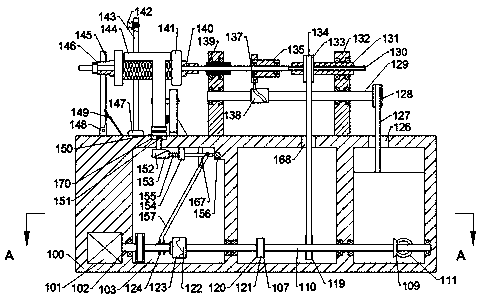

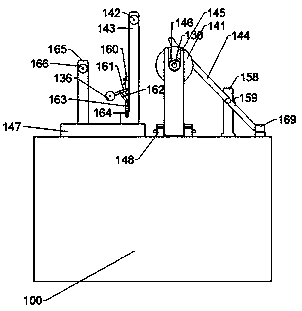

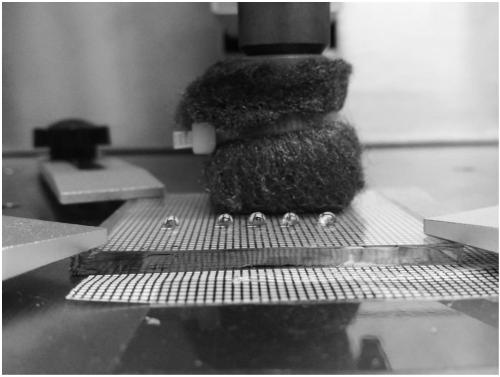

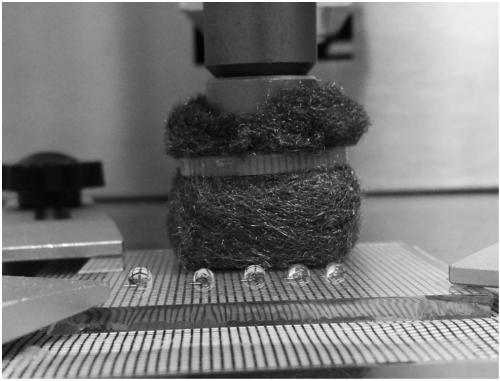

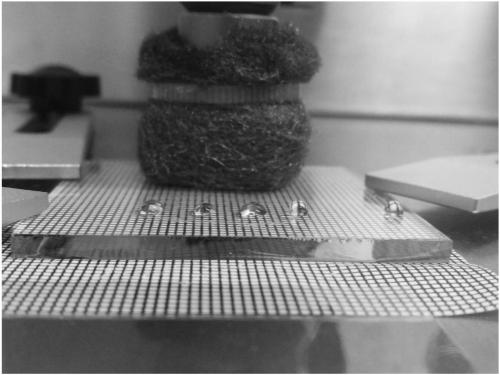

Prefabricated slab vibration tamping device

ActiveCN103522387AAchieve productionKeep the inside tightCeramic shaping apparatusEngineeringIdler-wheel

The invention discloses a prefabricated slab vibration tamping device and belongs to the technical field of industrial manufacturing. The device is used for vibration tamping after concrete is poured on a prefabricated slab. The device comprises a transmission motor, a rubber idler wheel, a driven idler wheel, a lifting oil cylinder, a universal support, an elastic support, a vibration bottom plate, a vibration motor, a vibration supporting plate, a vibration rocking bar and a vibration crank. According to the device, a crank rocking bar mechanism is used for achieving plane vibration tamping after prefabricated slab pouring, vibration is stable, air bubbles cannot be generated easily, inner compaction of the prefabricated slab after concrete pouring is guaranteed, bearing capacity is improved, and meanwhile the idler wheels for conveying a table slab are arranged, the supporting design capable of lifting is used, the continuity of production processes is guaranteed, and flow line production of the prefabricated slab is achieved.

Owner:HUANGSHAN ZHONGYOU CHAIN MFG CO LTD OF ANHUI

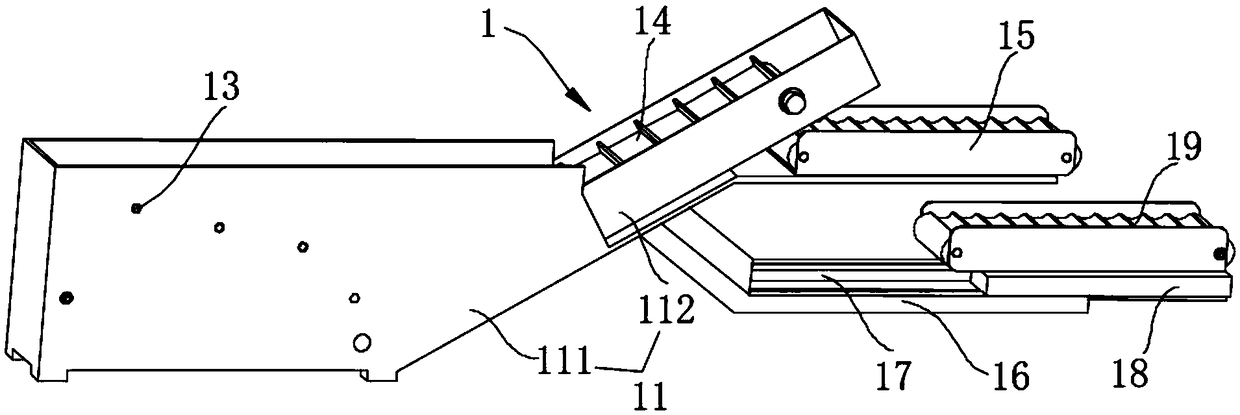

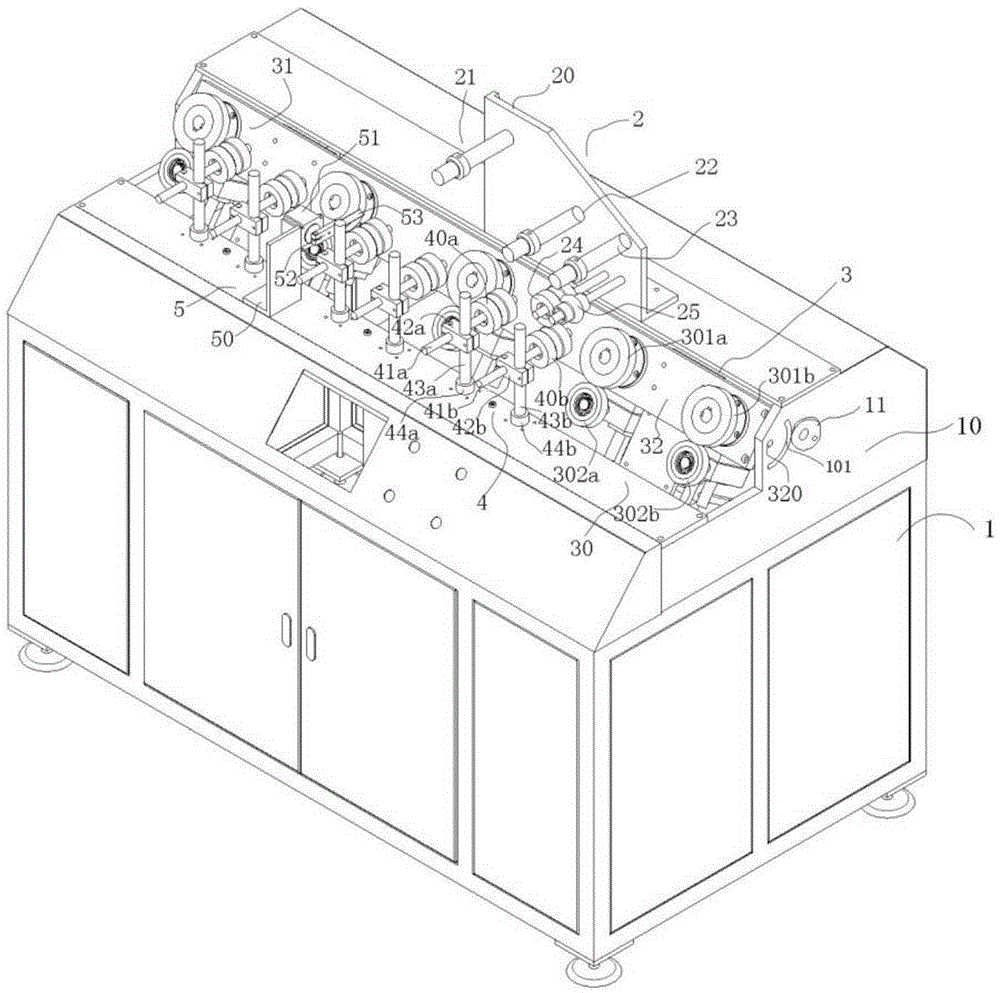

A film sticking machine

A film sticking machine is disclosed. The film sticking machine comprises a rack, a film fixing and conveying device, a stainless steel or aluminum section conveying device, film pressing wheel devices and a film cutter device. The film fixing and conveying device comprises a fixing plate, a first runner for mounting and fixing a film coil, a second runner, a third runner, a fourth runner and a fifth runner, with the second to fifth runners being used for straightening and conveying film. The stainless steel or aluminum section conveying device comprises a section feeding wheel device, a section discharging wheel deice and a feeding wheel device fixing plate. Each of the film pressing wheel devices comprises a first pressing wheel, a second pressing wheel, a first pressing wheel shaft, a second pressing wheel shaft, a first shaft connecting block, a second shaft connecting block, a first fixing bar, a second fixing bar, a first bar sleeve, a second bar sleeve, a connecting plate, a spring and a spring loop bar. The angle of the feeding wheel device fixing plate can be adjusted. The film sticking machine is advantageous in that the angle of the section conveying device can be adjusted, and the film pressing wheel devices ensure that film is tightly pressed on the surface of a section all the time.

Owner:广东原创力量新媒体产业有限公司

Three-phase motor stator winding equipment

The invention discloses three-phase motor stator winding equipment. The equipment comprises a driving mechanism, a transmission mechanism is arranged on the right side of the driving mechanism, and the driving mechanism comprises a clutch left mold. The transmission mechanism comprises a clutch right mold, and the transmission mechanism is connected with the driving mechanism through the clutch left mold and the clutch right mold. The transmission mechanism is provided with a fourth transmission shaft and a sixth transmission shaft. The equipment is simple in structure and convenient to operate, the transmission power of the motor is transmitted to the transmission mechanism through the driving mechanism, and the transmission mechanism transmits the power to a winding mechanism through a belt. Wires are evenly wound on a bobbin, synchronous winding can be achieved through the cooperation of a cam, tightening of the wires is ensured by a tensioning mechanism, and the winding quality and speed are greatly ensured.

Owner:江苏锡安达防爆股份有限公司

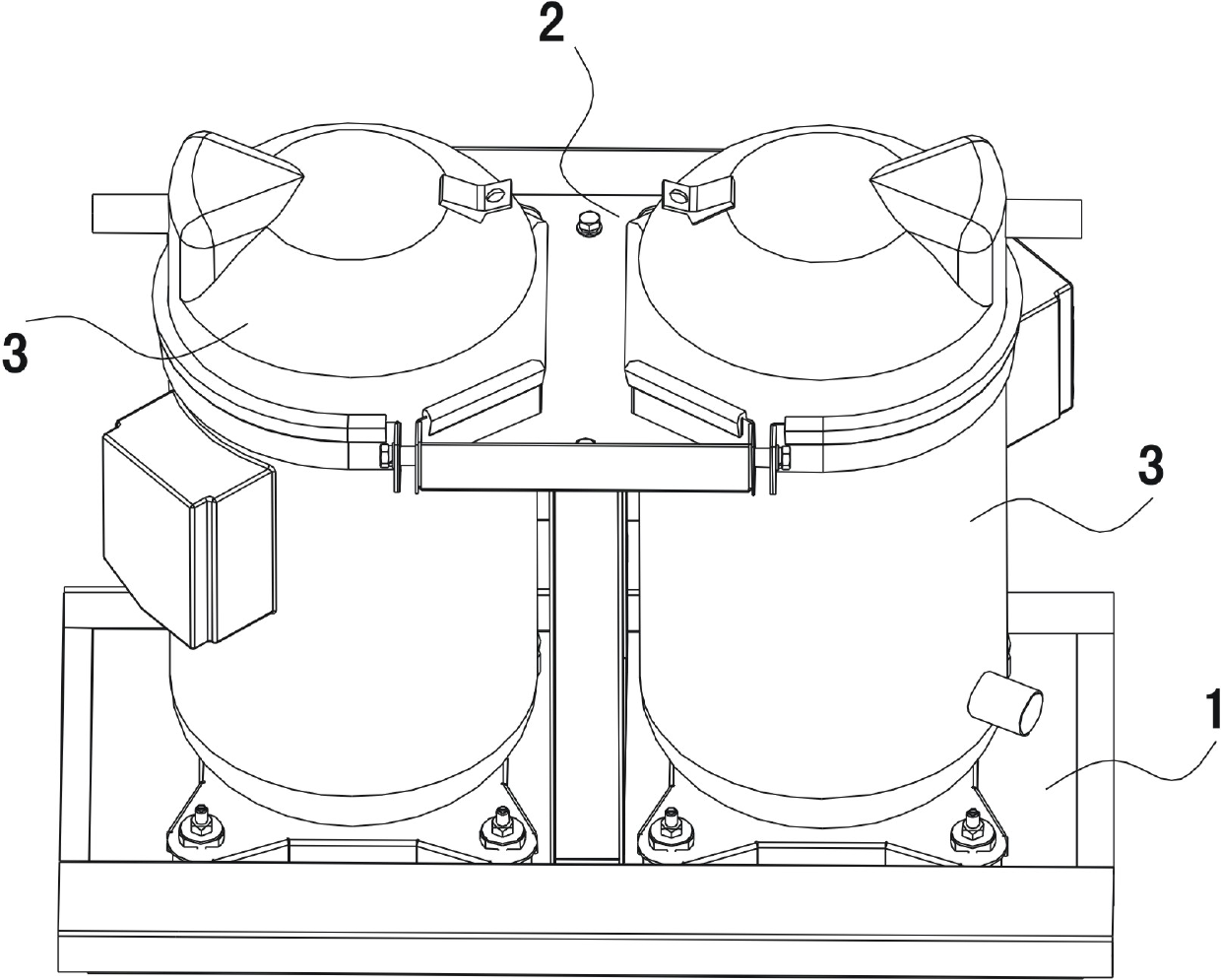

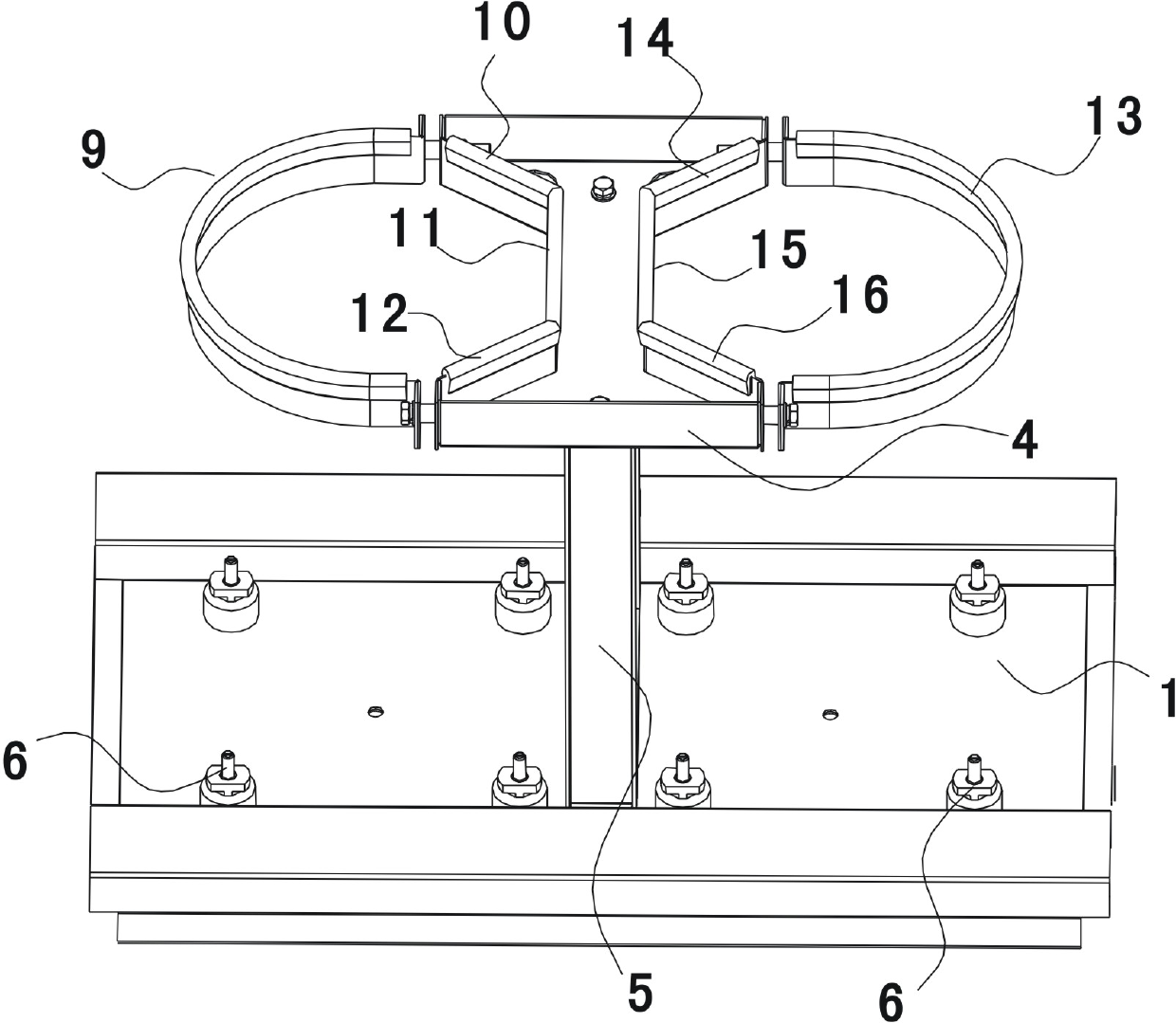

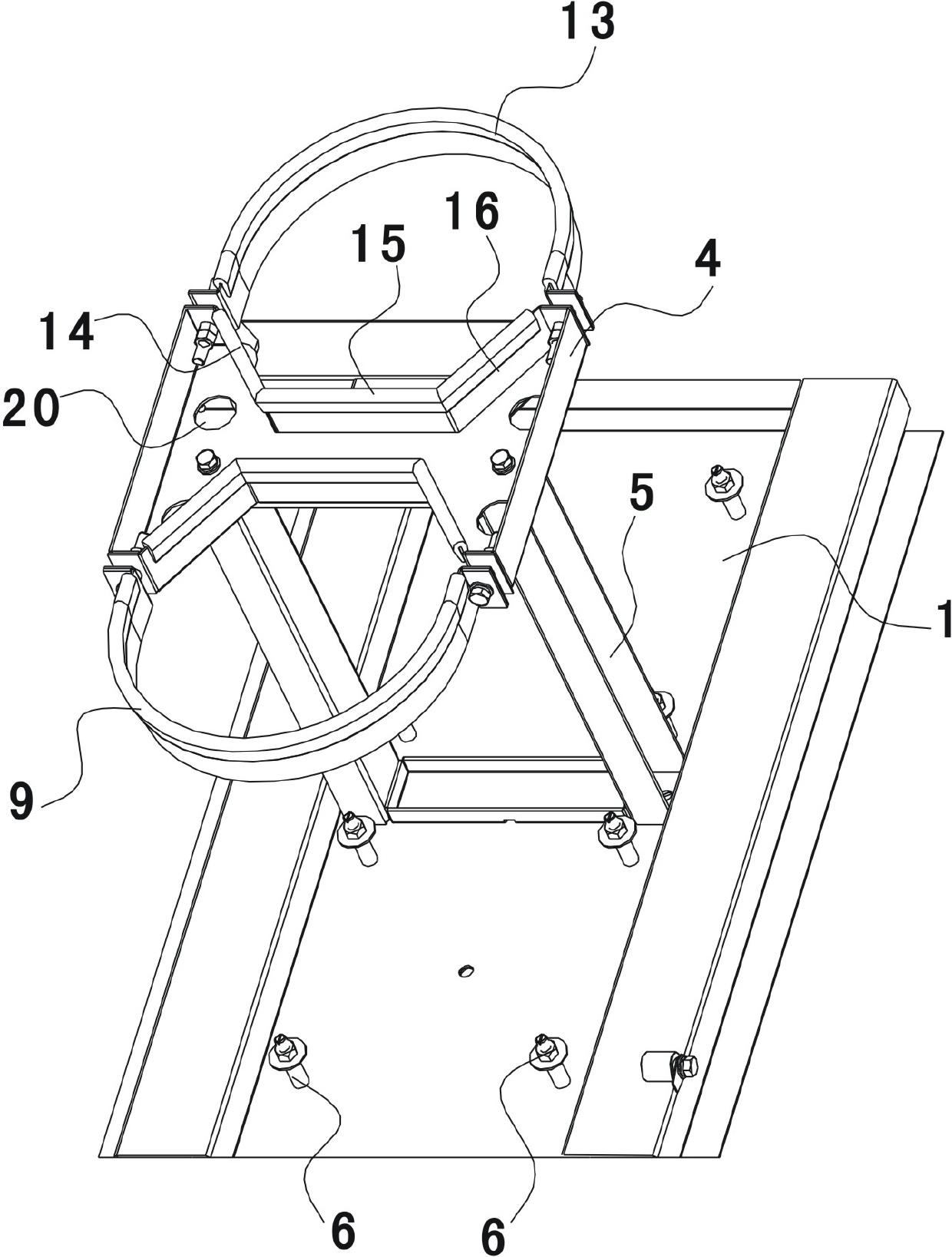

Compressor fixing device and compressor fixing structure

ActiveCN102562520ANot easy to lodgingEasy to fixPositive displacement pump componentsLighting and heating apparatusEngineeringMechanical engineering

Owner:GREE ELECTRIC APPLIANCES INC

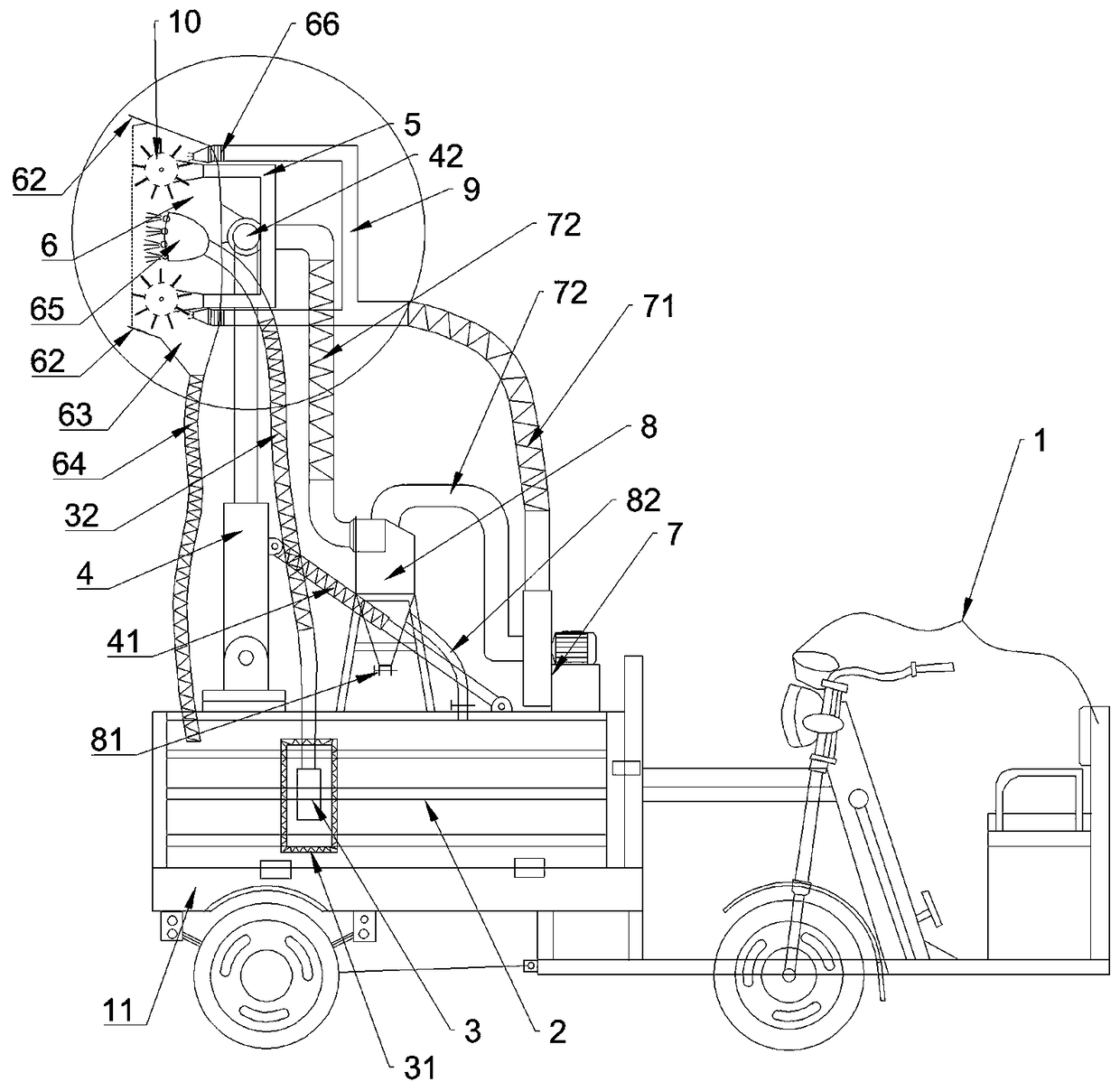

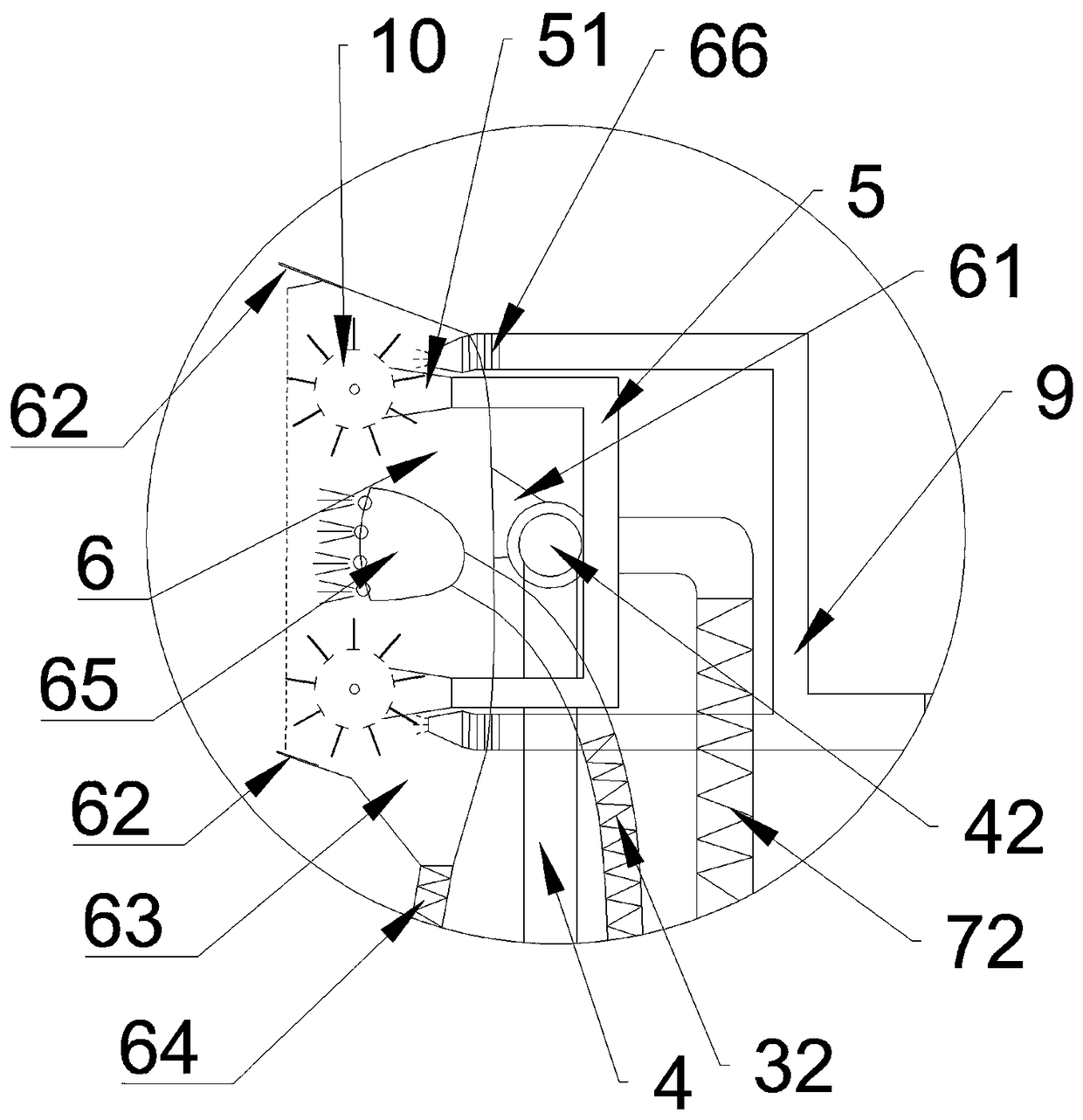

Wall surface cleaning device with function of water-wind circulation and working method thereof

The invention discloses a wall surface cleaning device with a function of water-wind circulation and a working method thereof. The device comprises a driving vehicle body, wherein a vehicle frame in rear of the driving vehicle body is fixedly provided with a box body, a lifter is arranged above the box body, one side of the lifter is provided with a tensioner arranged aslant, the upper end of thelifter is hinged with a connector on the back of a cleaning cover through a rotating shaft, the inner portion of the cleaning cover is provided with a cleaning roller supported through a supporting piece and close to a front opening, the cleaning roller is driven by a power device to rotate, the surface of the cleaning roller is provided with evenly arranged blades made from a rubber material, andrubber baffles located at the front opening are arranged above and below the cleaning cover respectively. The cleaning device utilizes the lifter to adjust the height of the cleaning cover, the cleaning cover tightly abuts the wall surface through the tensioner, the cleaning roller with the blades made from the rubber material is driven by the power device to clean away the wall surface continuously, the rubber baffles can block the discharge of cleaned-away dirt, and can also ensure that the cleaning cover tightly abuts the ground, by adopting the method, the pollution and waste can be avoided, and the cleaning effect is good.

Owner:湖北欣兴洁环境技术有限公司

Automatic cover punching machine and method thereof

ActiveCN106583524AAchieve positioningAchieve dischargeMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention provides an automatic cover punching machine and a method thereof. The automatic cover punching machine comprises a workbench and a transmission mechanism arranged on the workbench, wherein a punching mold for punching a cover is arranged on the upper part of the front end of the transmission mechanism; the punching mold comprises an upper mold and a lower mold; the upper mold is fixed on an upper mold base and positioned above the transmission mechanism; the lower mold is fixed on the workbench and positioned below the transmission mechanism; the upper mold base is fixed on an upper panel; a pressing plate is arranged on the upper panel; the pressing plate is fixedly connected with the upper panel through a fixed guide column; an air cylinder is arranged between the pressing plate and the upper panel; and the telescopic end of the air cylinder is connected with a top plate arranged longitudinally. The automatic cover punching machine is simple in structure, can guarantee that blanks are fed in place in the transportation process by utilizing the top plate and can guarantee that the blank punching is conducted orderly.

Owner:FUJIAN YINGHAO CULTURAL & CREATIVE CO LTD

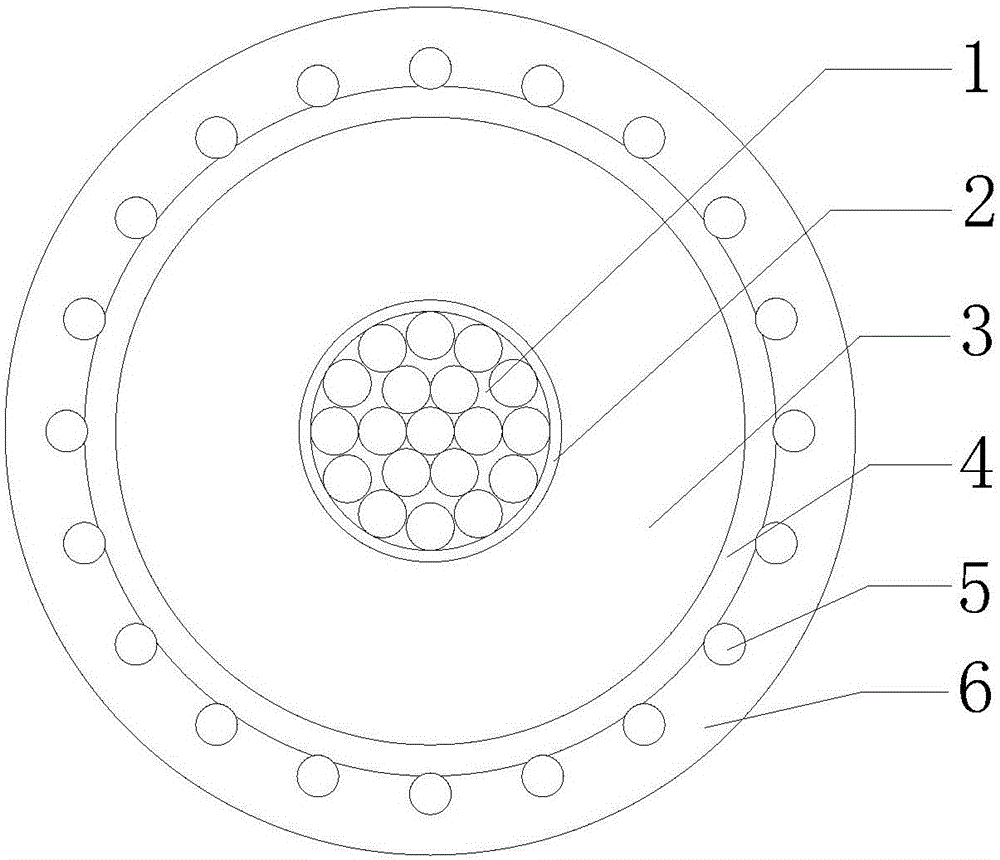

Smart energy water resistant tree-shaped intermediate voltage cable and production technology

InactiveCN106098239ACompact structureImprove waterproof performancePower cables with screens/conductive layersInsulated cablesLinear low-density polyethyleneElectrical conductor

Owner:FAR EAST CABLE +2

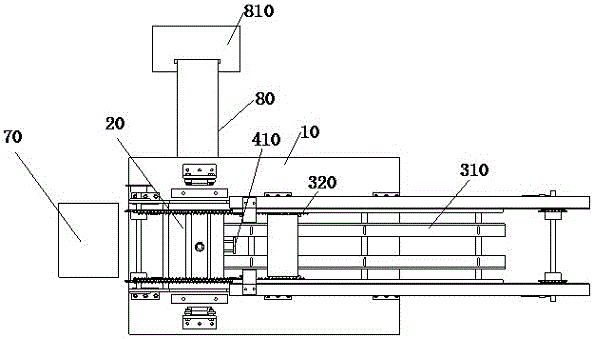

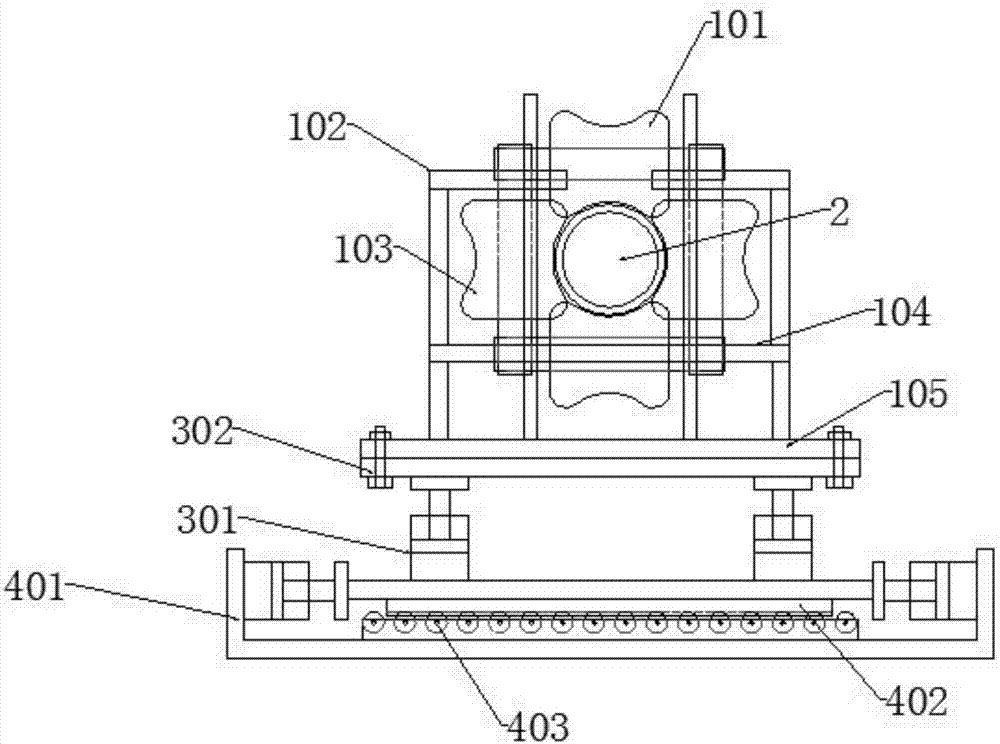

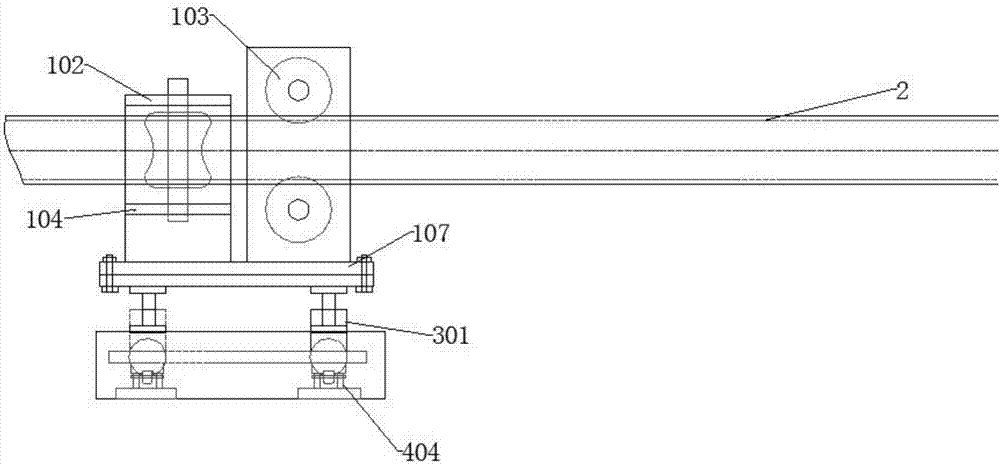

Numerical control complete-set pipe making machine

ActiveCN107470486AGuaranteed straightnessNo horizontalMetal-working feeding devicesPositioning devicesNumerical controlEngineering

The invention provides a numerical control complete-set pipe making machine. The numerical control complete-set pipe making machine comprises a pipe making machine body, a cutting machine, a feeding frame and a deviation rectifying device. The pipe making machine body and a cutting machine body are connected through the feeding frame, and the deviation rectifying device is installed on the feeding frame. The numerical control complete-set pipe making machine is characterized in that the deviation rectifying device comprises a clamping connection device, a vertical deviation rectifying device and a transverse deviation rectifying device. The clamping connection device sleeves a metal pipe, the bottom of the clamping connection device is arranged above the vertical deviation rectifying device, and the transverse deviation rectifying device is installed below the vertical deviation rectifying device. The numerical control complete-set pipe making machine has the advantages that due to the fact that the deviation rectifying device is additionally arranged in the numerical control complete-set pipe making machine, the straightness of the large-span metal pipe is guaranteed, and the transverse or vertical deviation and the rotation angle of the metal pipe cannot be caused in the conveying process.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

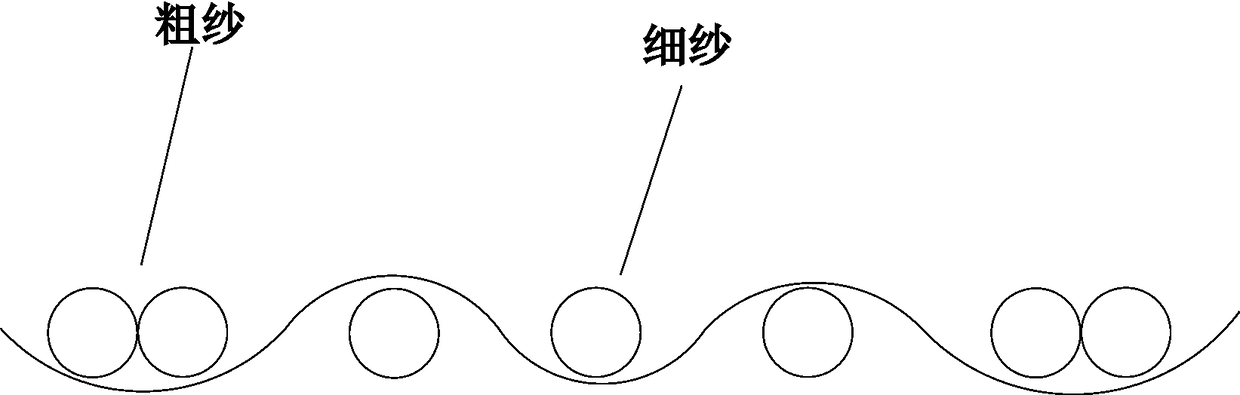

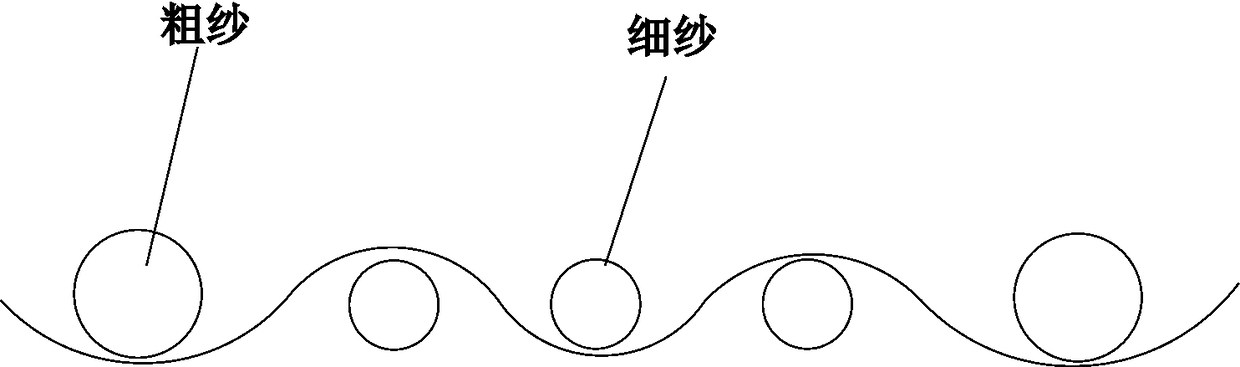

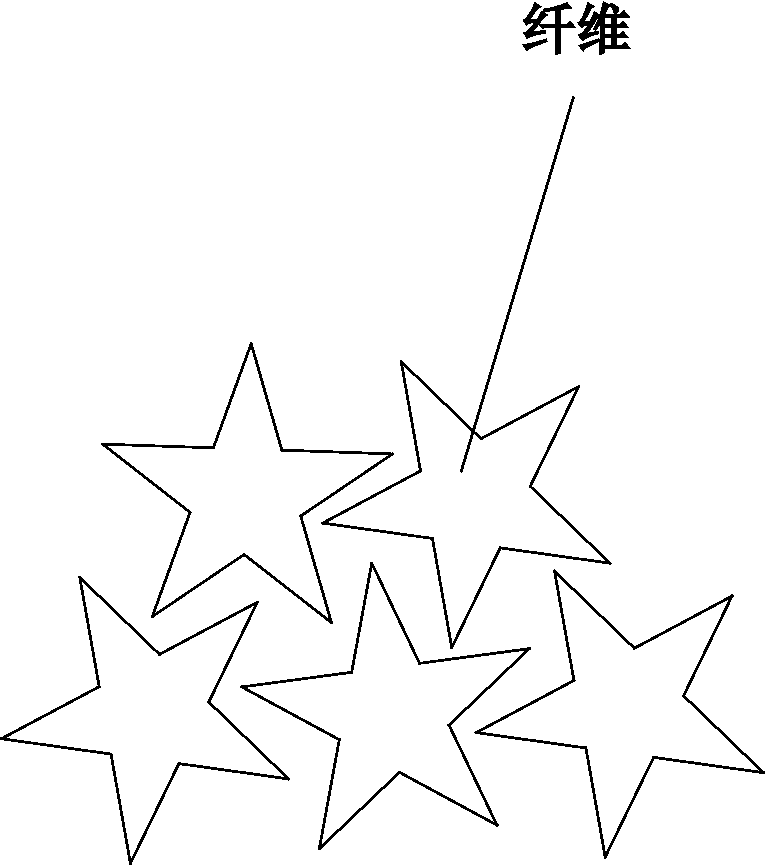

Breathable cool ultraviolet ray proof woven fabric

The invention discloses a breathable cool ultraviolet ray proof woven fabric, and relates to a woven fabric. The fabric is formed by interlacing warp yarns and weft yarns, at least one of the warp yarns or the weft yarns has a structure in which roving and spun yarns are uniformly mixed and arranged, the warp yarns and the weft yarns are interlaced to form a uniformly distributed and convex line structure or mesh structure on the fabric surface, the cross sections of fibers in the warp yarns and the weft yarns are polygons with a plurality of lobes, and the adjacent fibers conform to each other. Compared with the prior art, special weaving is conducted on the yarns with special structures, so that the fabric is provided with a concave-convex structure, does not fully fit a human body, canmaintain the ventilation between the fabric and the human body, and has the effect of quick sweat absorption and perspiration, the special structures of the yarns also keep the tightness between the yarns, and prevent ultraviolet rays from irradiating, and the fabric has the effect of isolating the ultraviolet rays.

Owner:MAXWIN CHINA CO LTD

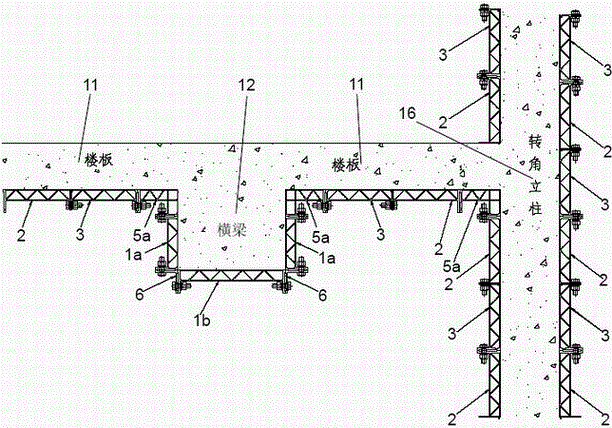

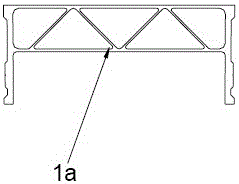

Beam, floor and corner uptight column composite structure of building aluminium alloy templates

PendingCN106677520ALarge operating spaceSave man hoursForms/shuttering/falseworksForming/stuttering elementsSupporting systemMaterials science

The invention relates to a beam, floor and corner uptight column composite structure of building aluminium alloy templates. Edge plates used for connecting of fastening pieces are arranged on all the aluminium templates. The aluminium templates are connected and combined through the fastening pieces, subjected to concreting and then constitute the beam, floor and corner uptight column composite structure. The sixth aluminium template, the first aluminium template A, the fifth corner template aluminium template A, the third aluminium template and the second aluminium template are connected and arranged on the left side and the right side of a beam correspondingly. Concreting is conducted on the first aluminium template B, and the first aluminium template B and the aluminium templates on the two sides of the first aluminium template B constitute the beam. Concreting is conducted on the multiple aluminium templates, and a floor is constituted. The floor and the beam are combined into a whole. A corner upright column is arranged on one side of the beam, and concreting is conducted between the vertical inner faces of the aluminium templates and the vertical outer faces of the aluminium templates. Concreting construction is conducted by using the aluminium alloy building templates, so that the beam, floor and corner uptight column composite structure has the advantages that the quality of the surface of poured concrete is high, the average using cost is low, carbon is low, emission is reduced, formaldehyde emission does not exist, and a supporting system is simplified.

Owner:肇庆南亚金属研制有限公司

Antibacterial glass and preparation method thereof

ActiveCN109502988AReduce energy consumptionLess waste waterCoatingsComposite materialWeather resistance

The invention relates to antibacterial glass and a preparation method of the antibacterial glass. The antibacterial glass comprises a glass substrate, wherein a transparent coating is arranged on at least one lateral surface of the glass substrate, the transparent coating comprises a first coating layer and a second coating layer, the first coating layer is formed by baking a mixed solution of a colorless nano-silver solution and polyethylene glycol after applying onto one lateral surface of the glass substrate, the second coating is formed by carrying out ultraviolet curing on a mixture of ethoxylated trimethylolpropane triacrylate and UV resin, and the second coating is located at the outermost layer of the antimicrobial glass. The antibacterial glass is colorless, transparent, long-lasting in antibacterial effect, resistant to ultraviolet radiation, scrub-resistant, good in weather resistance and wide in practical range; the manufacturing method of the antibacterial glass is short in operation process, high in production efficiency, low in cost, long-lasting in effect, and good in market application prospects.

Owner:晋大纳米科技(厦门)有限公司

Single-motor and hydraulic-clutch driven horizontal well crawl device

InactiveCN107882520ASimple structureImprove reliabilitySurveyConstructionsHydraulic cylinderLine tubing

The invention provides a single-motor and hydraulic-clutch driven horizontal well crawl device comprising a shell, a power mechanism, a travelling mechanism, a clutch mechanism and a hydraulic mechanism. The shell contains the power mechanism, the travelling mechanism, the clutch mechanism and the hydraulic mechanism. The power mechanism comprises a motor and a transmission shaft driven by the motor, the travelling mechanism comprises an opening and closing assembly and two traction assemblies, and each traction assembly comprises a connecting rod, a supporting arm and an idler wheel. The opening and closing assembly drives the two supporting arms through the connecting rods to be closed up towards the center or expanded towards the two opposite sides, and the idler wheels move out of theshell when the two supporting arms are expanded. The clutch mechanism comprises two oppositely-arranged matched tooth discs, and one matched tooth disc is fixed to a transmission shaft. The hydraulicmechanism comprises a hydraulic pump, a clutch hydraulic cylinder, an opening and closing hydraulic cylinder, an energy storage, a control valve and a hydraulic pipeline. The other matched tooth discof the clutch mechanism is fixed to the hydraulic pump, the clutch hydraulic cylinder comprises a first cylinder body and a first piston rod, and the opening and closing hydraulic cylinder comprises asecond cylinder body and a second piston rod.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com