Zigzag rod space telescopic mechanism

A telescoping mechanism and rod technology, which is applied in the field of zigzag rod space telescopic mechanism, can solve the problems of high manufacturing process requirements, limited telescopic range, poor lateral force, etc., and achieve simple manufacturing process, large telescopic range, and distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

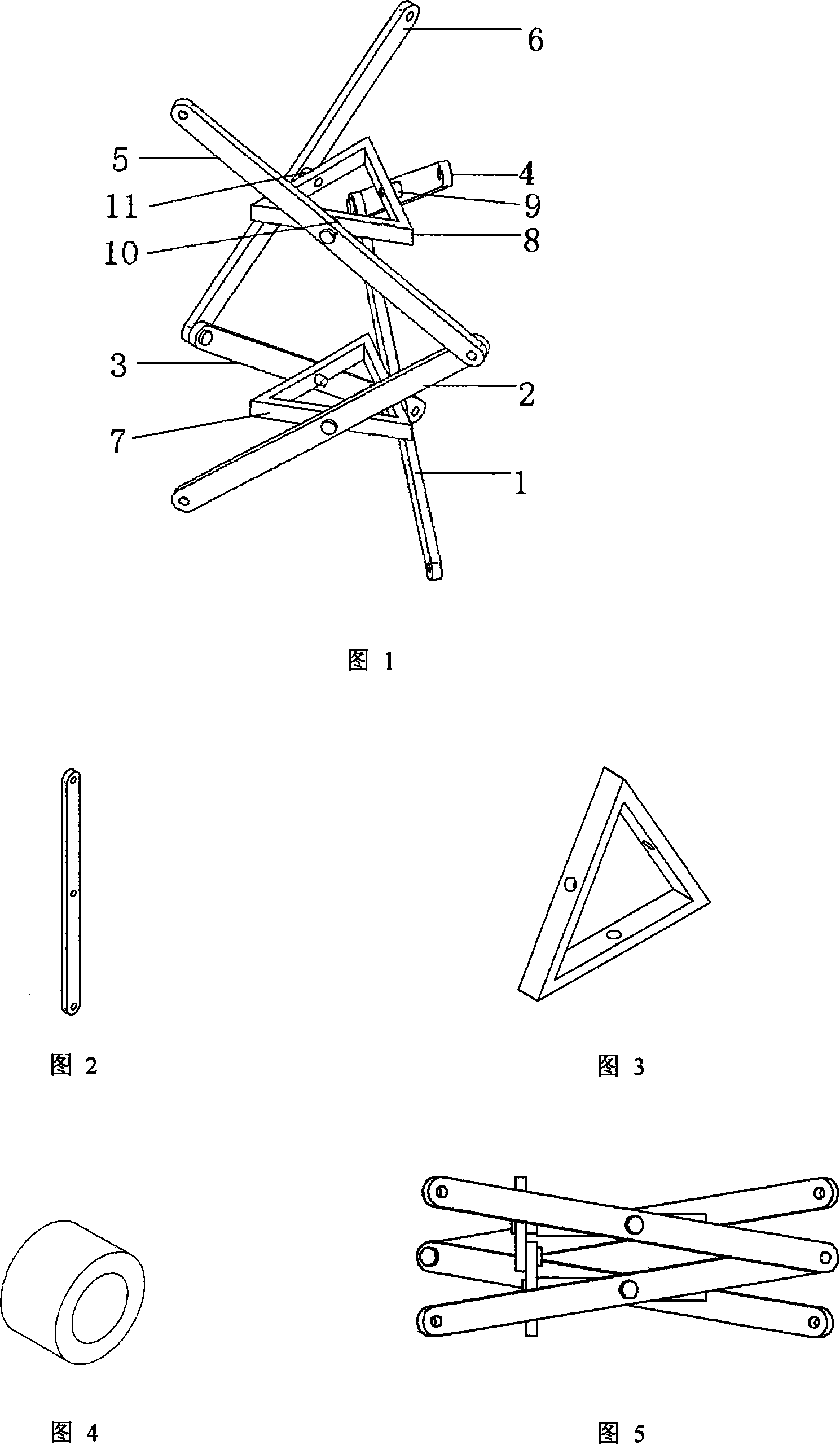

[0033] Embodiment 1: A space telescopic mechanism in which the length of the rod is greater than the side length of the intermediate frame.

[0034] As shown in Figures 1, 5 and 6: the length of the bar is greater than the side length of the intermediate frame, which is beneficial to increase the range of extension. If the point of force is at the end of the mechanism, the mechanism will stretch in one direction. Using this point, it can be made into a folding support mechanism or an arm of a manipulator. In addition, it can also be realized by driving the intermediate frame near the end of the mechanism. E.g:

[0035] 1. Outriggers of telescopic and folding tables and stools.

[0036] The top of the mechanism is connected with the clamping plate fixed on the bottom surface of the desktop. When each apex moves inward synchronously along the chute of the clamping plate, the mechanism is extended, adjusted to the required height, and the clamping point is fixed. The folding o...

Embodiment 2

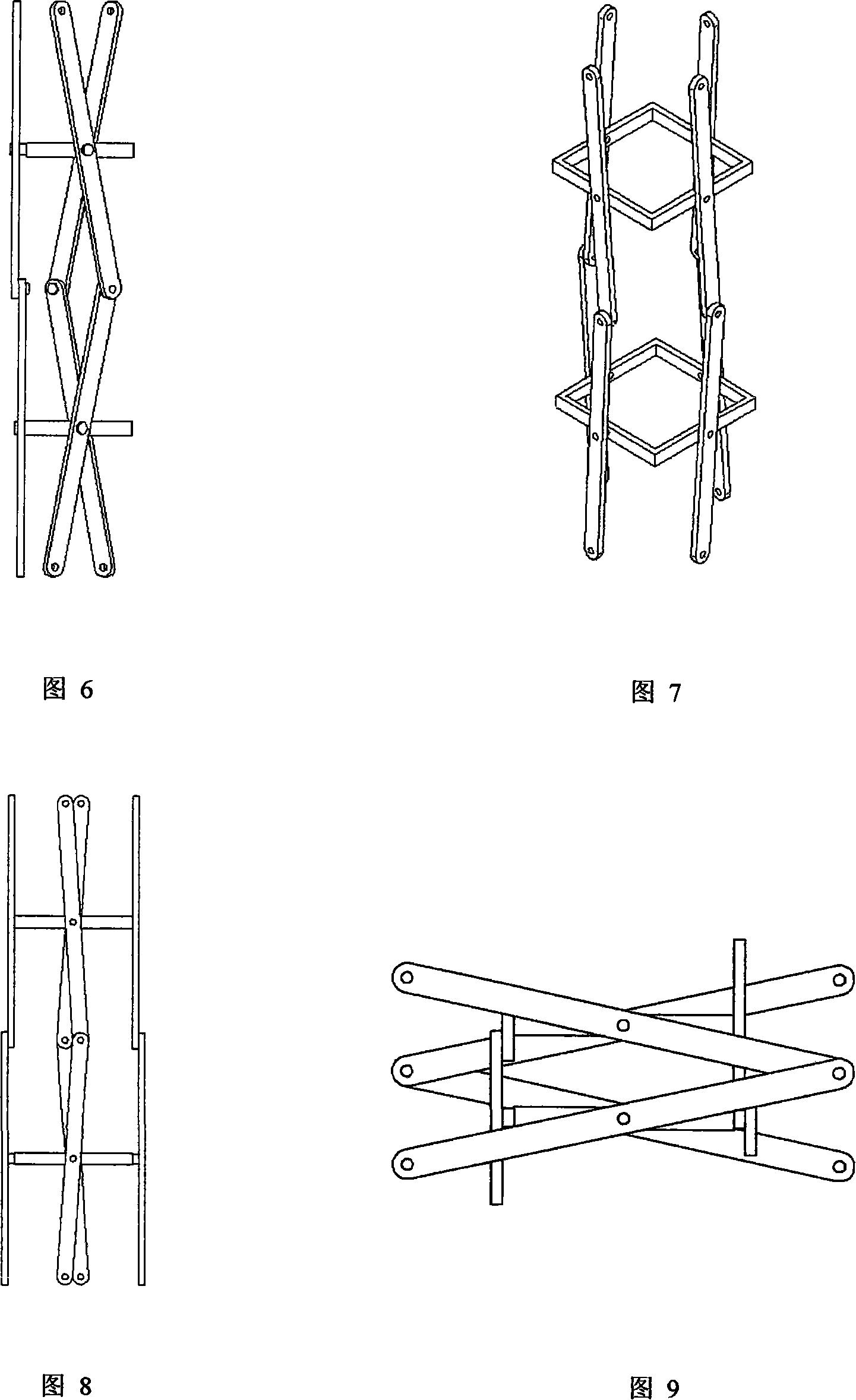

[0041] Embodiment 2: A space telescopic mechanism in which the length of the rod is smaller than the side length of the intermediate frame.

[0042] The space telescopic mechanism whose rod length is less than the side length of the intermediate frame has the characteristic that the cross-sectional area remains constant at any time. The length of the bar is smaller than the side length of the intermediate frame, so that even in the limit position of contraction, the two ends of the bar will not exceed the range of the intermediate frame, and no additional cross-sectional space will be added. Utilizing this property, a space stretching mechanism with a constant cross section can be made.

[0043] Example: retractable wardrobe

[0044]The popular feature of the simple wardrobe with assembly rods on the market is that after the wardrobe rack is spliced first, then a cloth cover is put on. And the feature of applying the retractable wardrobe of the present invention is that it...

Embodiment 3

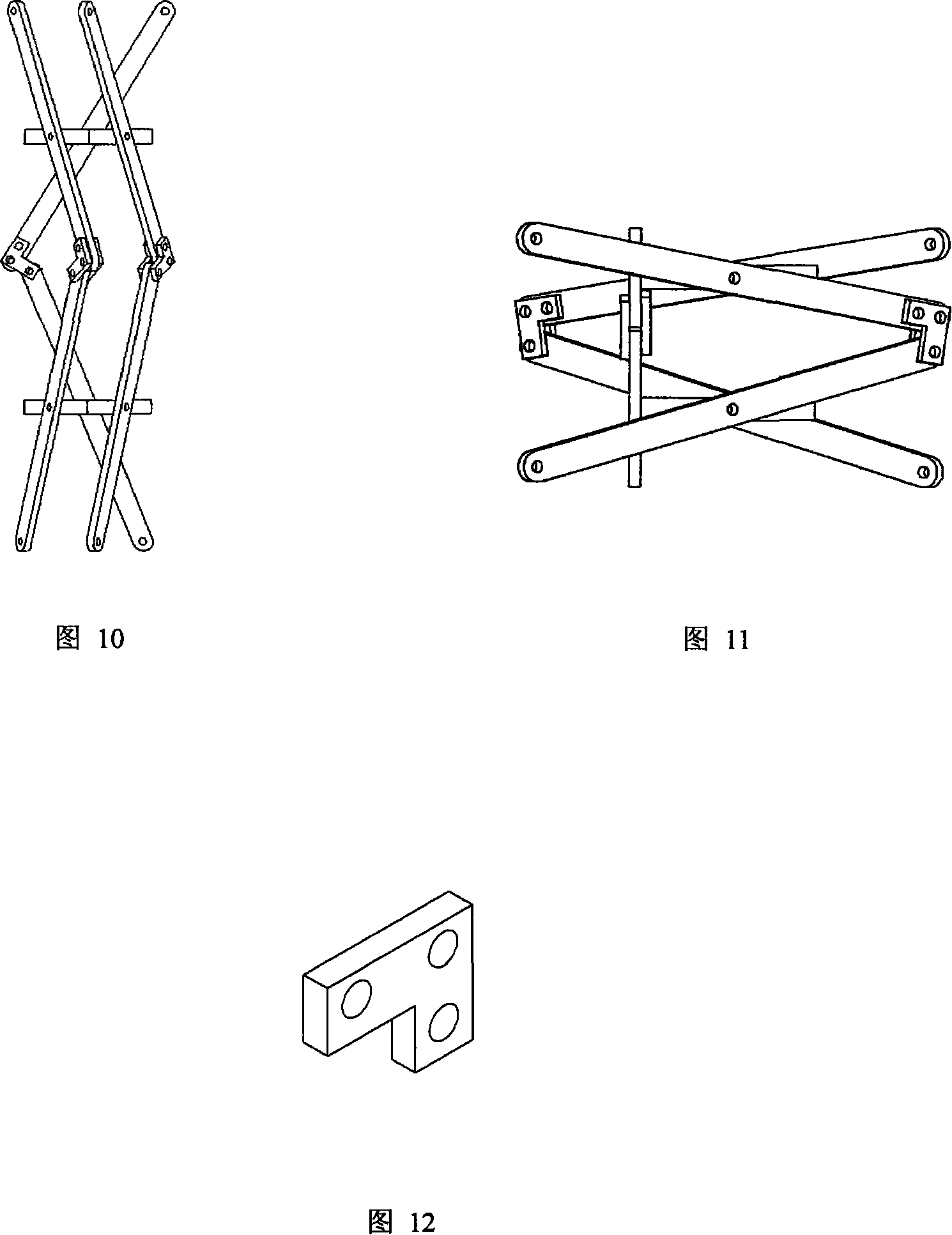

[0045] Embodiment 3: The parallel mechanism of the space stretching mechanism.

[0046] The space telescopic mechanism can be combined into a telescopic mechanism with a larger cross-section through parallel connection in different ways. For example, three intermediate frames are triangular space telescopic mechanisms that can be assembled into a large triangular space telescopic mechanism (as shown in Figures 13 and 14). The three intermediate frames are quadrilateral space telescopic mechanisms that can be assembled into a zigzag space telescopic mechanism.

[0047] Taking the large triangle space telescopic mechanism as an example, in order to avoid interference between the rods, the length of the rods should be smaller than the side length of the intermediate frame. The mechanism formed in parallel has the characteristics of high strength and rigidity, and is more stable when it plays a supporting role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com