Antibacterial glass and preparation method thereof

A technology of antibacterial glass and glass substrate, applied in the direction of coating, etc., can solve the problems of poor antibacterial effect of antibacterial glass, non-wear-resistant film layer, etc., and achieve the effect of widening the application range, good washing resistance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

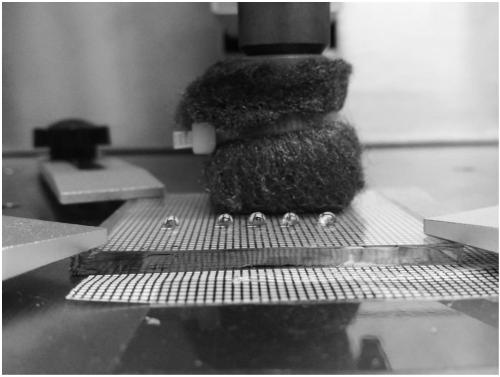

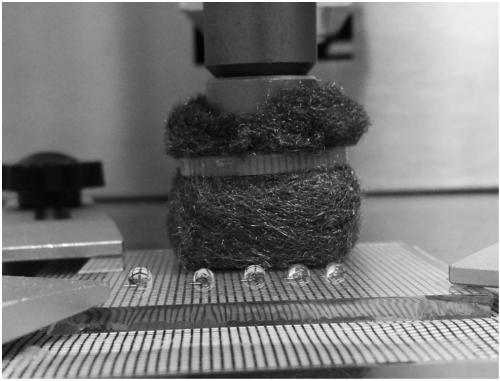

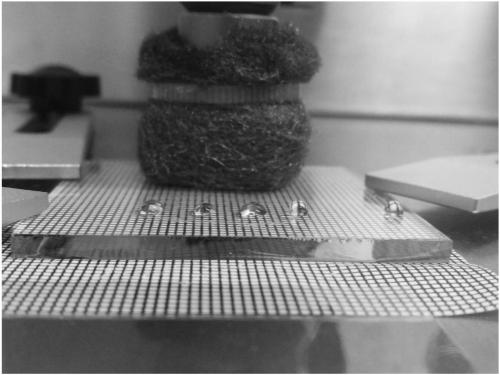

Image

Examples

Embodiment 1

[0053] Prepare antibacterial glass, the method is as follows:

[0054] Step 1: Take a piece of 4*4cm ordinary glass, soak it in 5% NaOH solution for 12 hours, then ultrasonically wash it in acetone, absolute ethanol and deionized water for 15 minutes, then dry it at room temperature and set it aside.

[0055] Step 2: Prepare a colorless nano-silver solution composite solution. Weigh 50 mL of commercially available colorless nano-silver solution and mix it with PEG-2000 at a mass ratio of 15:1, wherein the silver ion content is 5%. Brush the prepared colorless nano-silver solution composite solution evenly on the glass to form a first coating of 1 μm, and then bake it at 120°C for 30 minutes, and set it aside.

[0056] Step 3: The glass in the above step 2 is painted with UV resin containing 5% ethoxy-modified TMPTA, and cured by ultraviolet radiation to obtain a transparent and dense second coating. The ultraviolet irradiation curing adopts conventional ultraviolet irradiati...

Embodiment 2

[0058] Prepare antibacterial glass, the method is as follows:

[0059] Step 1: Take a piece of 4*4cm ordinary glass, soak it in 5% NaOH solution for 12 hours, then ultrasonically wash it in acetone, absolute ethanol and deionized water for 15 minutes, then dry it at room temperature and set it aside.

[0060] Step 2: Prepare a colorless nano-silver solution composite solution. Weigh 50 mL of commercially available colorless nano-silver solution and mix it with PEG-2000 at a mass ratio of 20:1. Brush the prepared colorless nano-silver solution composite solution evenly on the glass to form the first coating of 5 μm, and then bake it at 120°C for 30 minutes, and set it aside.

[0061] Step 3: Paint the glass in the above step 2 with a UV resin containing 10% ethoxy-modified TMPTA, and cure with ultraviolet radiation to obtain a transparent and dense second coating. The ultraviolet irradiation curing adopts conventional ultraviolet irradiation conditions.

Embodiment 3

[0063] Prepare antibacterial glass, the method is as follows:

[0064] Step 1: Take a 4*4cm piece of ordinary glass, soak it in 5% NaOH solution for 12 hours, then ultrasonically wash it in acetone, absolute ethanol and deionized water for 10 minutes, then dry it at room temperature and set it aside.

[0065] Step 2: Prepare a colorless nano-silver solution composite solution. Weigh 50 mL of commercially available colorless nano-silver solution and mix it with PEG-2000 at a mass ratio of 5:1. Brush the prepared colorless nano-silver solution composite solution evenly on the glass to form a first coating of 8 μm, and then bake it at 120°C for 30 minutes, and set it aside.

[0066] Step 3: Paint the glass in the above step 2 with a UV resin containing 15% ethoxy-modified TMPTA, and cure with ultraviolet radiation to obtain a transparent and dense second coating. The ultraviolet irradiation curing adopts conventional ultraviolet irradiation conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com