Beam, floor and corner uptight column composite structure of building aluminium alloy templates

A technology of aluminum alloy formwork and corner columns, which is applied in the combined structure of floor slabs and corner columns, building aluminum alloy formwork, and beams. It can solve the problems of increased basic cost, high material cost, labor and materials, and reduce unnecessary costs. , high surface quality and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

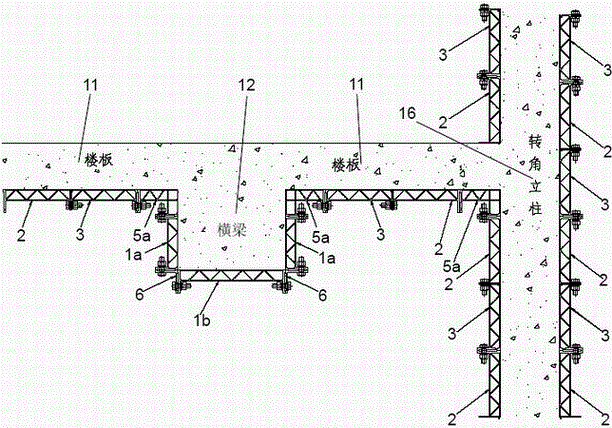

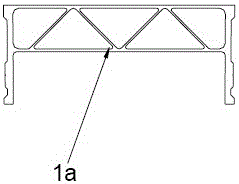

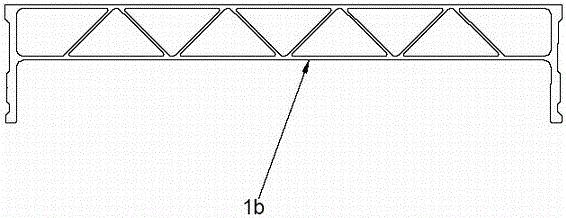

[0049] see Figure 1 to Figure 7 , the present invention provides a combination structure of beams, floor slabs and corner columns of building aluminum alloy formwork, which mainly consists of aluminum formwork A (1a), aluminum formwork B (1b), aluminum formwork two 2, aluminum formwork three 3, aluminum formwork Template five A (5a) and aluminum template six 6 composition. The aluminum formworks are all provided with side plates for fastener connection, and each aluminum formwork is combined by fasteners and poured with concrete to form a combined structure of beams 12 , floor slabs 11 and corner columns 16 .

[0050] The left end and the right end of the two ends of the aluminum formwork 1 B (1b) are respectively connected to the aluminum formwork 6 6 by fasteners, and the two aluminum formwork 66 are right-angled formworks, and the fasteners are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com