A film sticking machine

A film laminating machine and frame technology, which is applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of not being able to guarantee the film at all times, difficult to operate, and tightly pressed on the surface of stainless steel or aluminum profiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

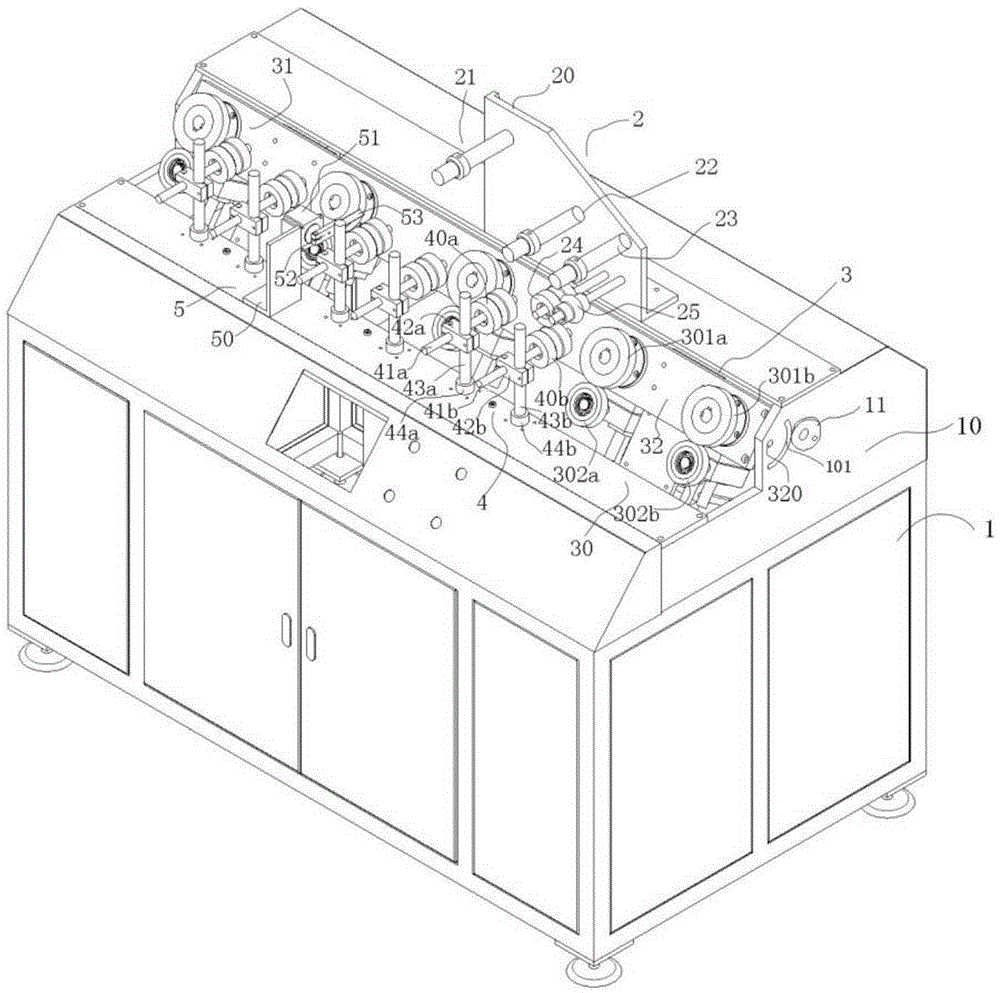

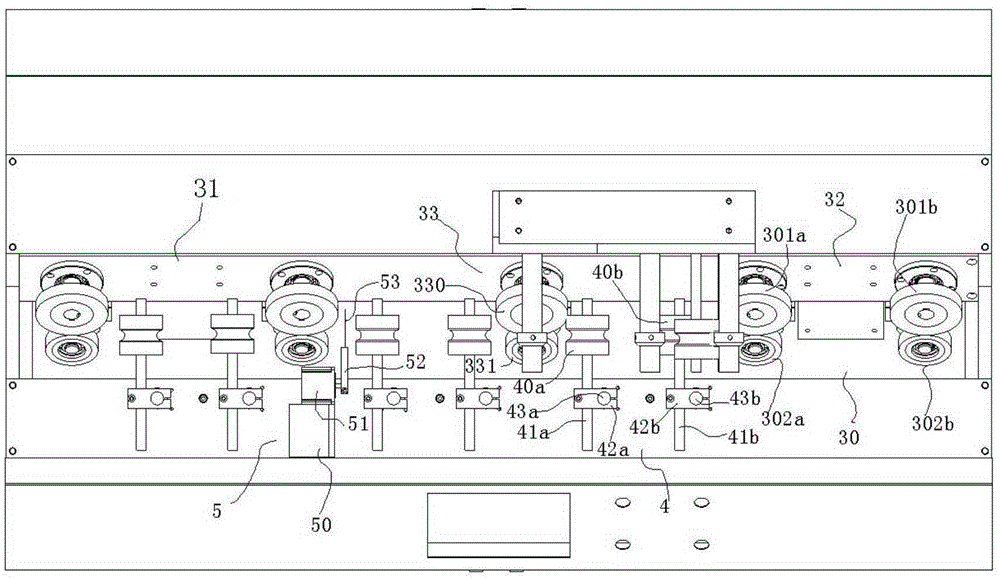

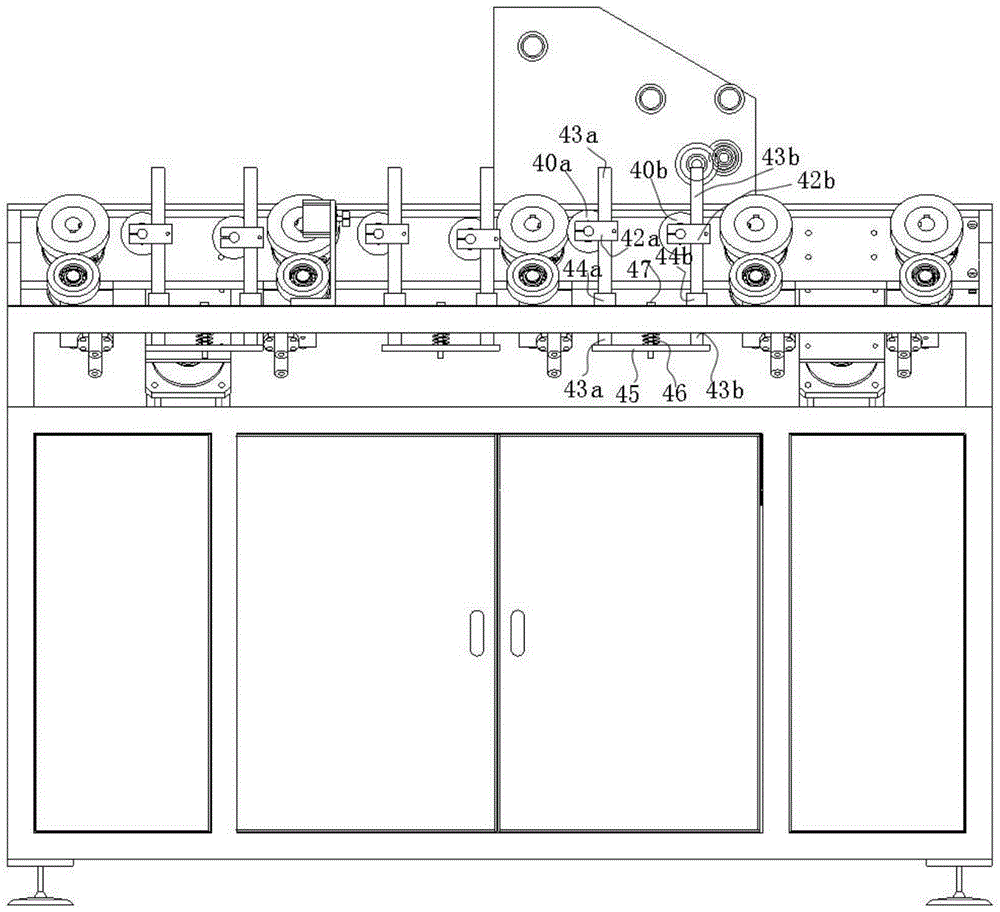

[0018] Such as Figure 1-5 A film laminating machine of the present invention is shown, comprising a frame 1, a film fixing conveying device 2, a stainless steel or aluminum profile conveying device 3, a film pressing wheel device 4 and a film cutter device 5, and the film fixing conveying device 2 includes a fixed plate 20, a first wheel 21 for installing a fixed film coil, a second wheel 22 for straightening and conveying a film, a third wheel 23, a fourth wheel 24 and a fifth wheel 25, the The fixed plate 20 is installed and fixed on the frame 1, the first runner 21 is installed and fixed on the upper left corner of the fixed plate 20, the second runner 22 and the third runner 23 are installed and fixed on the fixed plate 20 at the same height a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com