Machining method for controlling thickness of stainless steel sheet part

A technology of thickness control and processing method, applied in aircraft assembly and other directions, can solve the problems of relative position relationship not meeting theoretical requirements, increasing the difficulty of thickness and size, etc., to solve large and uncontrollable deformation, reduce grinding workload, and reduce manual intervention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

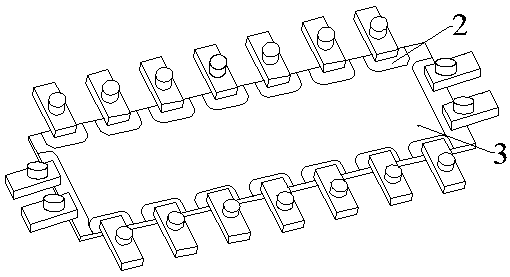

[0028] A processing method for thickness control of stainless steel thin plate parts, processing a milling sheet 3 for Boeing E-767 aircraft, the processing thickness of the milling sheet 3 is 7mm, mainly comprising the following steps:

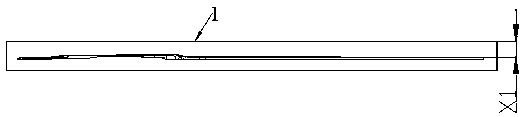

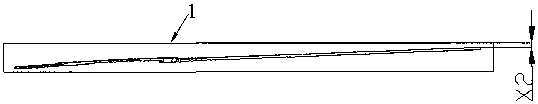

[0029] Step S1, clamp the blank of the milling sheet 3, and open all the pressure plate grooves 2 on the blank; the pressure plate groove 2 is 0.3mm lower than the reference plane 1 to be repaired; press the blank by clamping the pressure plate groove 2 to press the blank. Processing, it is convenient to adjust the reference plane 1, so that the deformation of the milling surface 3 and the reference plane 1 are synchronized;

[0030] Step S2: if figure 1 As shown, press the pressure plate groove 2 of the milling sheet 3 to rough and finish the first surface of the milling sheet 3; after finishing the web of the milling sheet 3 in place, repair the reference plane in the same step 1. Rough machining, finishing first surface, and reference pla...

Embodiment 2

[0037] A processing method for thickness control of stainless steel thin plate parts, processing a face milling sheet 3 for Boeing E-767 aircraft, the processing thickness of the face milling sheet 3 is 5mm, mainly comprising the following steps:

[0038] Step S1, clamp the blank of the milling sheet 3, and open all the pressure plate grooves 2 on the blank; the pressure plate groove 2 is 0.2mm lower than the reference plane 1 to be repaired; by clamping the pressure plate groove 2, the blank is pressed against the milling surface. The surface piece 3 is processed to facilitate the adjustment of the reference plane 1, so that the deformation of the milled surface piece 3 and the reference plane 1 are synchronized;

[0039] Step S2: Press the pressing plate groove 2 of the blank, and perform rough machining and finishing machining on the first surface of the milling sheet 3; after finishing the web of the milling sheet 3 in place, repair the reference plane 1 in the same step; ...

Embodiment 3

[0046] A processing method for thickness control of stainless steel thin plate parts, processing a face milling sheet 3 for Boeing E-767 aircraft, the processing thickness of the face milling sheet 3 is 10mm, mainly comprising the following steps:

[0047] Step S1, clamp the stainless steel blank, and open all the pressure plate grooves 2 on the blank; the pressure plate groove 2 is 0.5mm lower than the reference plane 1 to be repaired; by clamping the pressure plate groove 2, the blank is pressed to perform milling sheet 3 Processing, it is convenient to adjust the reference plane 1, so that the deformation of the milling surface 3 and the reference plane 1 are synchronized;

[0048] Step S2: Press the pressing plate groove 2 of the blank, and perform rough machining and finishing machining on the first surface of the milling sheet 3; after finishing the web of the milling sheet 3 in place, repair the reference plane 1 in the same step; Carry out rough machining, finish machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com