Preparation method of gradient pore structure carbon paper

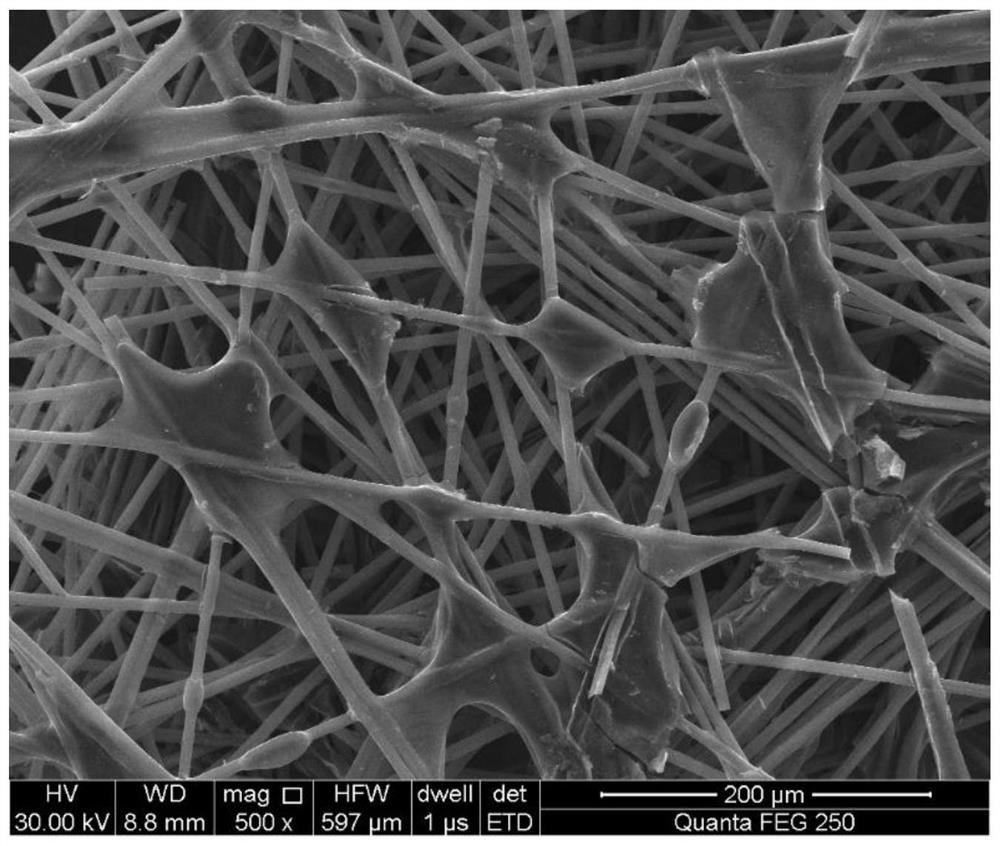

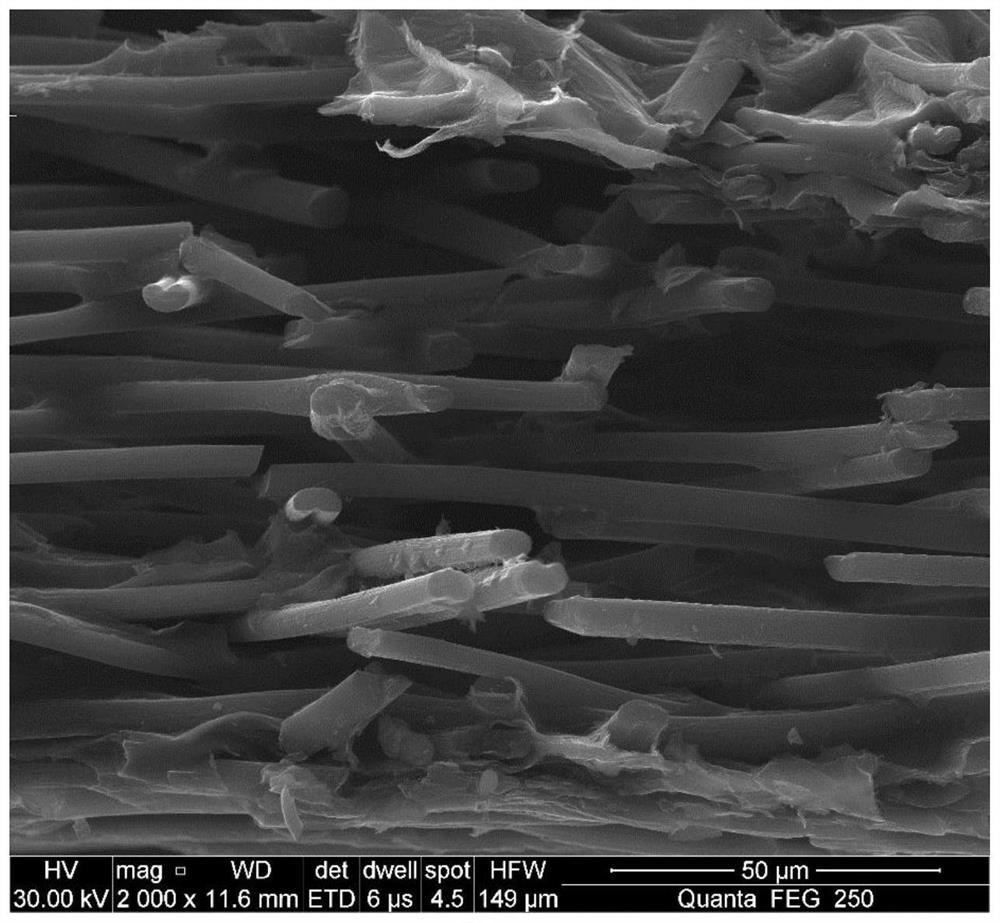

A gradient pore and carbon paper technology, applied to structural parts, papermaking, physical treatment of paper, etc., can solve the problems of strength, electrical conductivity decrease, increase in effective lap between fibers, and decrease in mass transfer efficiency, so as to improve electrical conductivity and Effects of mechanical strength, improvement of mass transfer and heat transfer performance, and maintenance of fiber lap strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of the gradient pore structure carbon paper of the present invention, comprising the following steps:

[0041] (1) Degumming: Polyacrylonitrile-based carbon fibers with different aspect ratios (7 microns in diameter and 5, 7, 9, and 11 mm in length) were first washed with alkali, and then heat-treated at 850 °C for 2 hours in a nitrogen atmosphere. , after cooling with the furnace, immerse in absolute ethanol for ultrasonic treatment for 15 minutes, and finally wash with deionized water and dry.

[0042] (2) Oxidation: The degummed carbon fibers were soaked in concentrated nitric acid, condensed and refluxed at 95°C for 4 hours, then washed with deionized water until the pH was neutral to obtain modified carbon fibers, and dried for later use.

[0043] (3) Dispersion: Put the modified carbon fibers with different aspect ratios into the pre-prepared dispersant solution (0.05wt% polyethylene oxide containing molecular weight 4 million, 0.015wt% polyvi...

Embodiment 2

[0051] A preparation method of the gradient pore structure carbon paper of the present invention, comprising the following steps:

[0052] (1) Degumming: polyacrylonitrile-based carbon fibers with different aspect ratios (7 microns in diameter, 3, 5, 7, 9, and 11 mm in length) were first washed with alkali, and then placed in a nitrogen atmosphere at 850 ° C Heat treatment for 2 hours to remove the surface sizing agent, after cooling with the furnace, immerse in absolute ethanol for ultrasonic treatment for 15 minutes, and finally wash with deionized water and dry.

[0053] (2) Oxidation: Soak the degummed carbon fibers in concentrated sulfuric acid at 60°C for 12 hours, then wash with deionized water until the pH is neutral to obtain modified carbon fibers, and dry them for later use.

[0054] (3) Dispersion: Put the pretreated carbon fibers with different aspect ratios into the pre-prepared dispersant solution (0.05wt% of polyethylene oxide with a molecular weight of 4 milli...

Embodiment 3

[0061] A preparation method of the gradient pore structure carbon paper of the present invention, comprising the following steps:

[0062] (1) Degumming: Polyacrylonitrile-based carbon fibers with different aspect ratios (7 microns in diameter and 3, 6, 9, and 12 mm in length) were first washed with alkali, and then heat-treated at 850 °C for 2 h in a nitrogen atmosphere. Remove the surface sizing agent, after cooling with the furnace, immerse in absolute ethanol for ultrasonic treatment for 15 minutes, and finally wash with deionized water and dry.

[0063] (2) Oxidation: The degummed carbon fibers were subjected to surface oxidation treatment, air oxidized at 450° C. for 1 h in a muffle furnace, rinsed with ethanol, washed with deionized water, and dried for later use.

[0064] (3) Dispersion: Put the pretreated carbon fibers with different aspect ratios into the pre-prepared dispersant solution (0.1wt% polyethylene oxide containing molecular weight 6 million, 0.02wt% polyvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com