Ultra-thin steel strip coiling tension control method

A technology of tension control and steel strip coiling, which is applied in the field of steel rolling, can solve problems such as economic loss, large inclusion size, strip extraction and broken strip, etc., achieve high economic benefits, meet performance requirements, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the purpose, structure and function of the present invention, a method for controlling the coiling tension of an ultra-thin steel strip according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

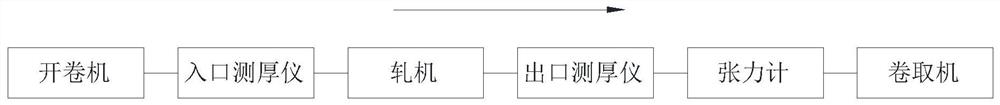

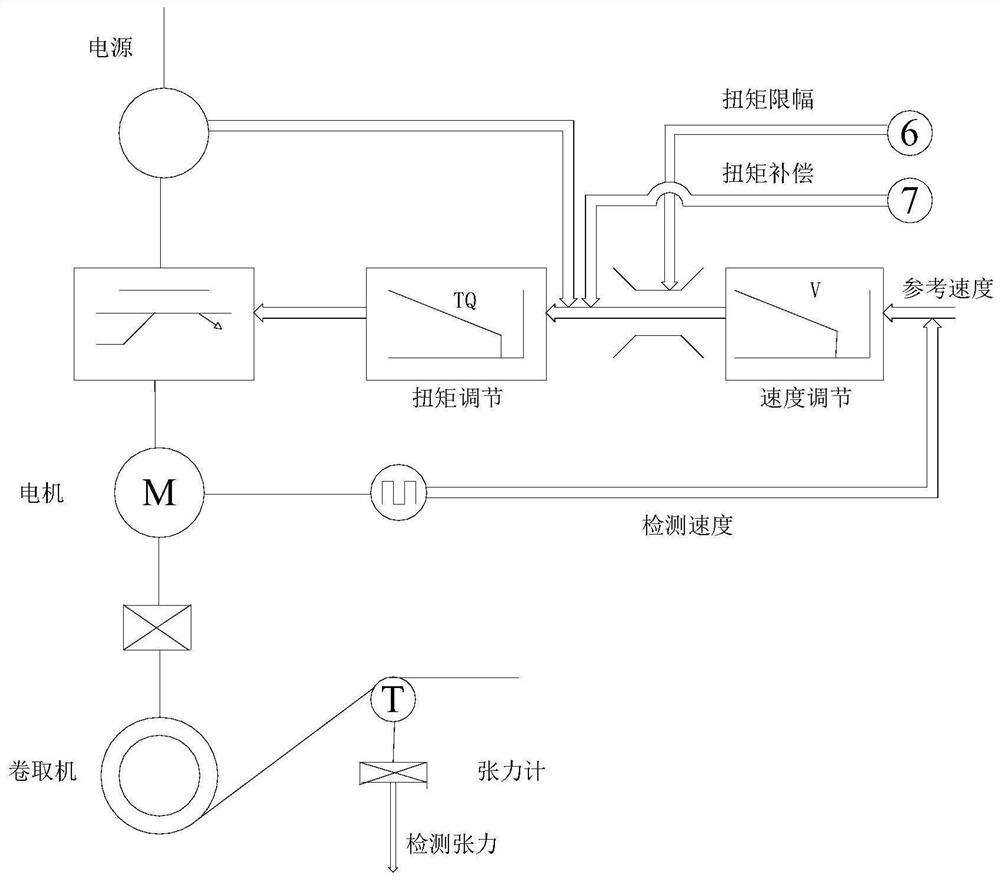

[0038] Such as figure 1 , figure 2 , image 3 , Figure 5 Shown is an embodiment of the invention, figure 1 It is a block diagram of the structure of the rolling mill in the embodiment of the present invention, from figure 1 It can be seen that the rolling unit includes: uncoiler, entrance thickness gauge, rolling mill roll, exit thickness gauge, tension gauge roll, and coiler. The steel strip passes through the entrance thickness gauge, rolling mill roll, exit thickness gauge and tension gauge roll from the uncoiler to the coiler, and the coiler uses a belt coiler to complete the coiling of the steel strip. For the specific structure of each of the above devices, reference may...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com