Reinforced anti-crack diatom mud material containing PVA (polyvinyl alcohol) fiber and preparation method of material

A technology of diatom mud and mud materials, applied in the field of environmentally friendly building interior wall materials, can solve the problems of insufficient reinforcement effect, easy to drop powder, and can not be used alone, etc., to achieve cheap raw materials and environmental protection, improve bonding strength, adjust The effect of humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

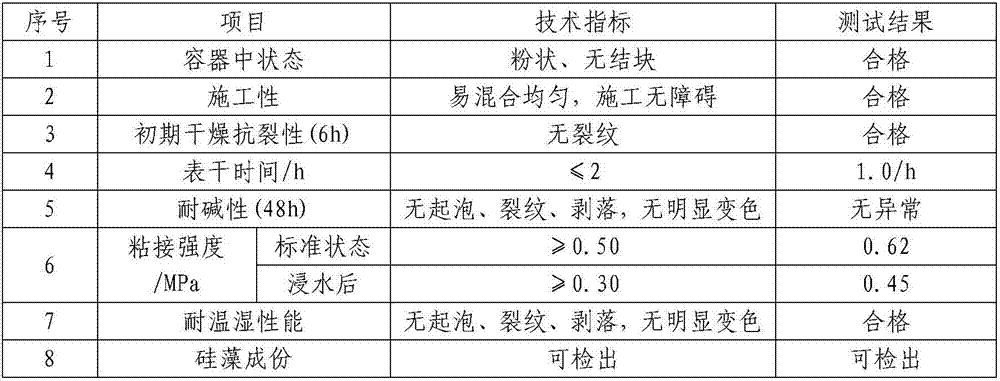

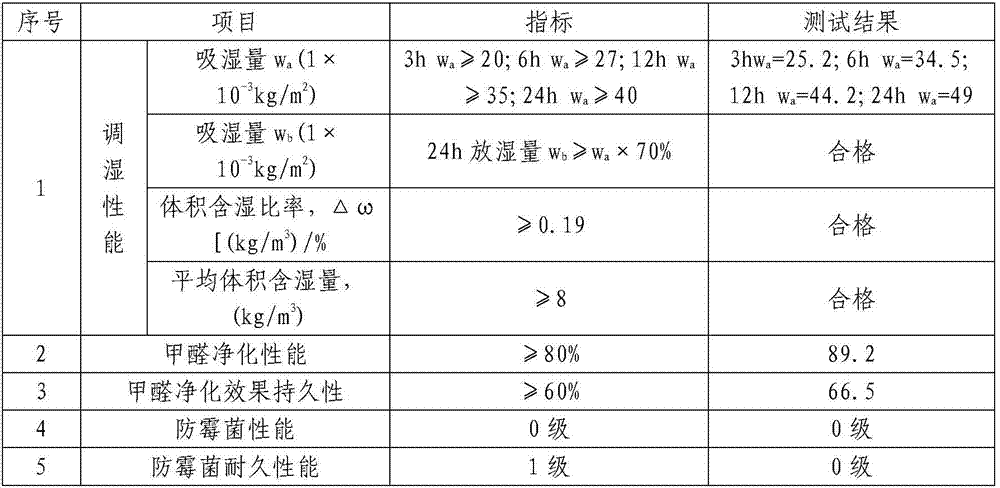

Examples

Embodiment 1

[0022] A kind of preparation of fiber-reinforced diatom mud material not containing organic adhesive: diatomite is mixed with 28%, heavy calcium 30%, ash calcium 18%, quartz sand 16%, negative ion powder 3%, cellulose ether 1.5% and Pre-gelatinized starch 0.3%, pre-mixed evenly for later use, the percentage in this embodiment is the mass percentage.

[0023] Among them, the silicon dioxide content in diatomite is ≥ 90%, the particle size of heavy calcium and ash calcium is 325 mesh; the particle size of quartz sand is 80 mesh; the anatase nano-titanium dioxide is selected and configured into an aqueous solution, and the particle size of negative ion powder is 4000 mesh; The cellulose ether is selected from hydroxypropyl methylcellulose with a viscosity of 75,000; the pre-gelatinized starch is selected from cassava pre-gelatinized starch, and its fineness (passing through a 80 mesh sieve) is ≥ 90%; the diameter of the PVA fiber is 20 μm, and the length is 10mm.

[0024] Ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com