Tunnel structure

A tunnel structure and tunnel technology, applied in the direction of tunnel lining, superstructure sub-assembly, track, etc., can solve the problems of difficult transportation of materials, poor thermal insulation effect, long construction period, etc., to achieve easy handling and assembly, short construction period, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

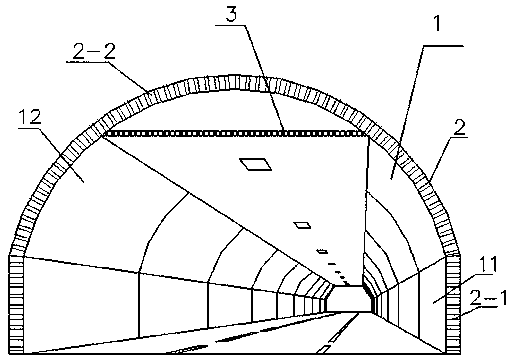

[0050] Such as figure 1 Shown: a tunnel structure, including a tunnel body 1, the tunnel body 1 is spliced by a plurality of metal plates 2; the number of metal plates depends on the length of the tunnel body 1. In this embodiment, the metal plates used for the two side walls 11 of the tunnel body 1 are planar metal plates 2-1, and the metal plates used for the ceiling 12 of the tunnel body 1 are arc-shaped metal plates 2-2.

[0051] A partition 3 is arranged above the interior of the tunnel body 1, and the partition 3 is also spliced by a plurality of planar metal plates 2-1. The partition plate 3 is connected with the inner chamber of the tunnel body 1 by bolts.

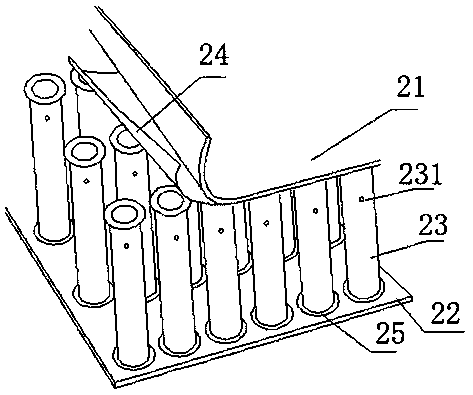

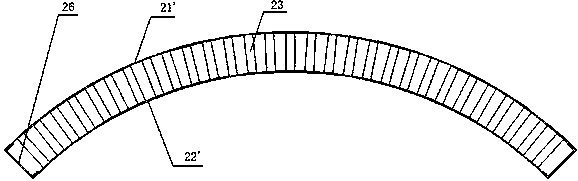

[0052] Such as figure 2 and image 3 Shown: In this embodiment, the metal plate includes a first panel, a second panel and a plurality of hollow tubes 23 arranged between the first panel and the second panel, and the hollow tube 23 is connected to the first panel and the second panel. A brazing layer is pr...

Embodiment 2

[0063] The difference from Embodiment 1 is that the metal plate used for the ceiling of the tunnel body is also a plane metal plate.

[0064] Other structures are with embodiment 1.

Embodiment 3

[0066] The difference from Embodiment 1 is that the two side walls and the ceiling of the tunnel body are made of a single piece of metal plate, and the length of the tunnel body is made of multiple pieces of metal plates spliced together. The metal plate is a curved plate, and the lines of the curved plate The shape is semicircular.

[0067] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com