Air heating tunnel and fabric drying apparatus incorporating the same

A technology for air heating and drying equipment, which is used in household dryers, textiles and papermaking, washing devices, etc., and can solve problems such as energy waste, reduced air heating efficiency, and heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

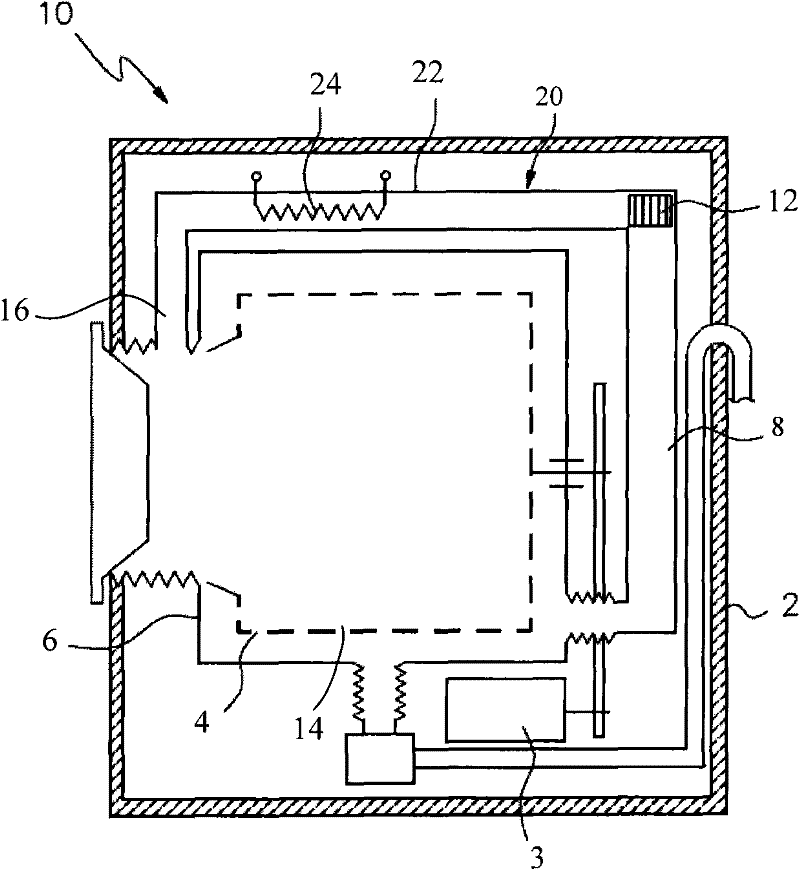

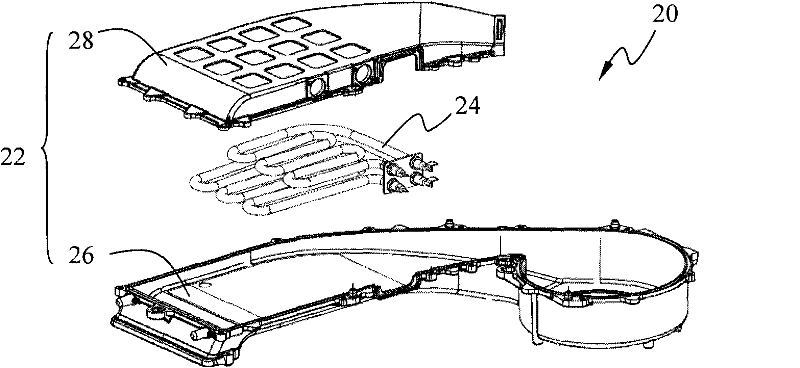

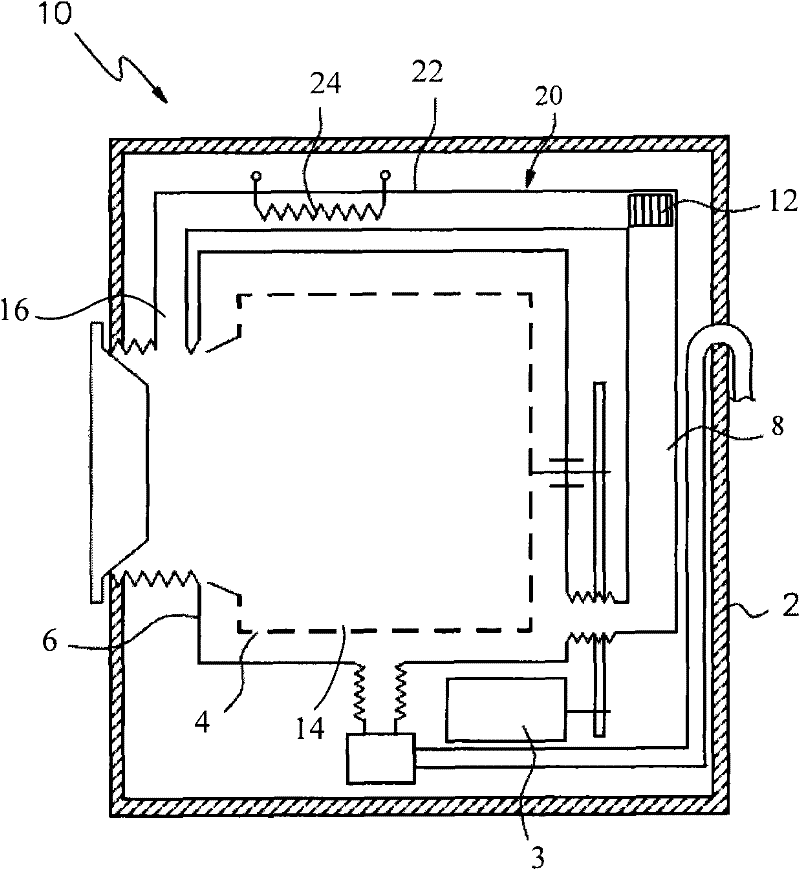

[0009] like figure 1 As shown, the fabric drying equipment 10 includes a drum 4 arranged in the box body 2 for storing the fabric to be dried and driven by the motor 3 to rotate, and an outer tub 6 for accommodating the drum 4 . A large number of through holes 14 are distributed on the drum 4, so as to communicate with the tub 6 in space. The outer tub 6 is sequentially connected with the condensing device 8 , the blower device 12 and the air heating channel 20 , and the outlet end 16 of the air heating channel 20 is connected with the outer tub 6 to form an air circulation cycle.

[0010] During the process of drying the fabric by the fabric drying equipment 10 , the air heating channel 20 heats the air and sends it into the outer tub 6 and the drum 4 . The hot air takes away part of the moisture after contacting the wet fabric in the drum 4, and enters the condensation device 8 through the outer tub 6. In the condensing device 8, the moisture in the air is separated from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com