Ballastless track structure

A ballastless track and track slab technology is applied in the direction of the track, the superstructure sub-assembly, the connection between the superstructure sub-assemblies, etc., which can solve the problems of difficult to transport materials, long construction period, poor vibration isolation performance, etc. To achieve the effect of easy handling and assembly, high work efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

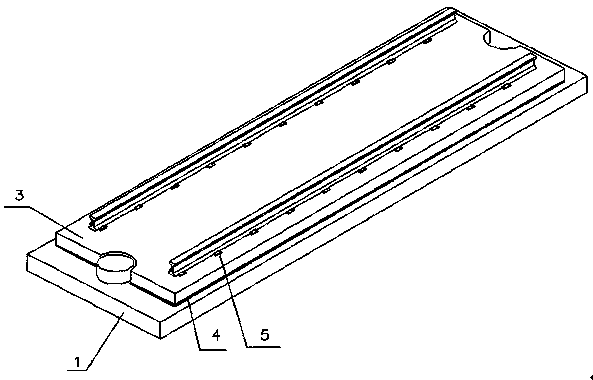

[0045] Such as figure 1 Shown: a ballastless track structure, including a foundation 1 and a track plate 3, both of which are spliced by a plurality of metal plates 2, and the number of metal plates 2 depends on the overall length of the track. The track plate 3 is arranged on the foundation 1 , and the track plate 3 and the base 1 are connected by a flexible adhesive 4 . A fastening system 5 is provided on the track plate 2 .

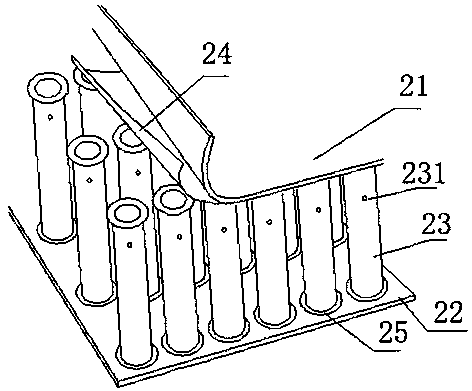

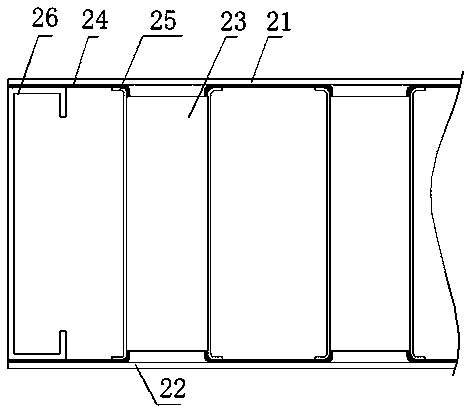

[0046] Such as figure 2 As shown: in this embodiment, the metal plate 2 includes a first panel 21, a second panel 22 and a plurality of hollow tubes 23 arranged between the first panel 21 and the second panel 22, the hollow tubes 23 and the first panel 21 1. A brazing layer is provided between the second panels 22; flanges 25 are provided at both ends of the hollow tube 23, and a circular structure is turned outward. The flanging 25 of the hollow tube is connected to the first panel 21 and the second panel 22 by soldering 24 .

[0047] Both the ...

Embodiment 2

[0053] On the basis of Example 1, all hollow tubes or part of the hollow tubes are filled with foaming materials through air holes, such as polyurethane stock solution, and foamed into foamed polyurethane in the hollow tubes; in addition, the hollow tubes can also be provided with foaming inorganic Particles, on the one hand, are convenient for rapid foaming when filled with polyurethane stock solution, and on the other hand, can improve the heat preservation effect. Filling the hollow tube with foam material not only plays a role of heat preservation, but also reduces the convection in the hollow tube and improves the sound insulation effect; moreover, the filled foam layer can be used as a supporting structure to prevent the hollow tube from bending and increase the The supporting force; and the foam has a long service life, because there is no air inside, cracks and various reactions will not occur.

Embodiment 3

[0055] Such as Figure 4 Shown: the difference with embodiment 1 is that brazing filler metal 24 ' punching flanging, and this flanging is to turn down vertically along the hole of brazing filler metal, so that hollow tube 23 is enclosed within the location on the flanging of brazing filler metal 24 '. The brazing material 24' is provided with a hollow 241' at the non-hollow tube place, so as to avoid the accumulation of the brazing material in the brazing process.

[0056] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com