Patents

Literature

192results about How to "Solve the oil spill problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

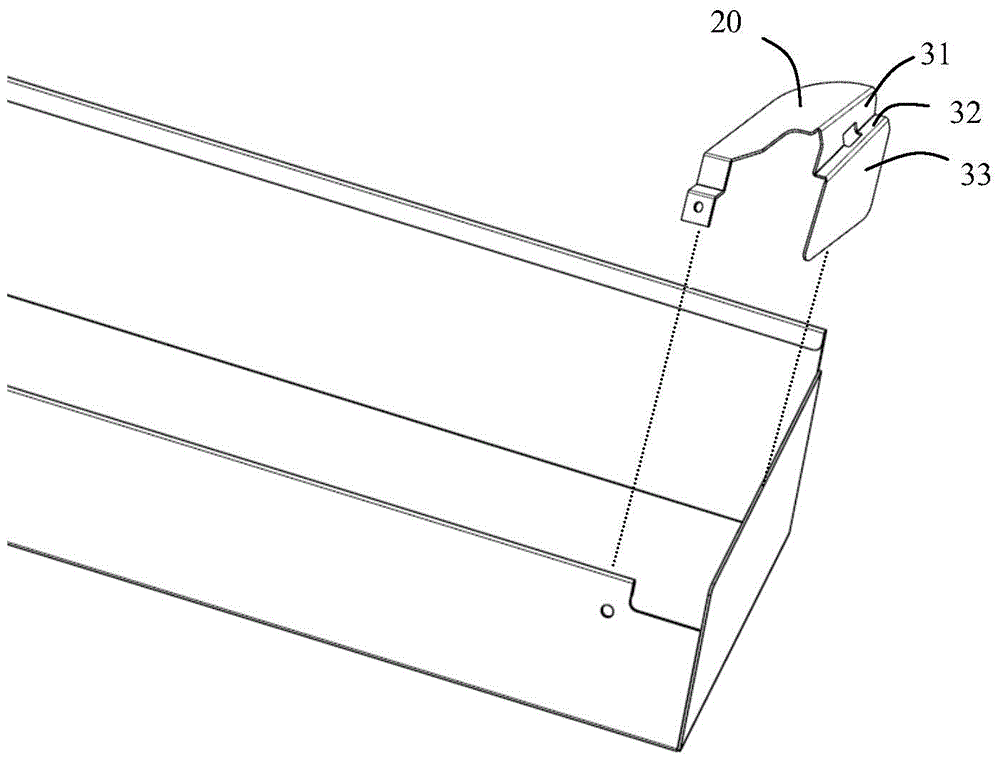

Solid smoke cartridge, electronic cigarette heating component using solid cartridge and electronic cigarette

ActiveCN104207323AOvercome the shortcomings of not pure tasteHarm reductionTobacco treatmentTobacco pipesElectricityCombustion

The invention discloses a solid smoke cartridge, an electronic cigarette heating component using the solid cartridge and an electronic cigarette. The solid smoke cartridge comprises a smoke cartridge body which is formed by adding an atomization agent into tobacco particles, mixing, stirring and performing pressure forming, wherein the atomization agent comprises an edible organic solvent with the atomization temperature of 150-350 DGE C; the electronic cigarette heating component comprises a temperature-resistant shell and a smoke cartridge pipe for utilizing the solid smoke cartridge; one end of the temperature-resistant shell is provided with a smoke adsorbing port, and the other end of the temperature-resistant shell is provided with an opening cavity; the temperature-resistant shell is provided with a first electric connector; the smoke cartridge pipe is inserted into the opening cavity; the exterior of the smoke cartridge pipe is provided with a heating body; one end of the smoke cartridge pipe is provided with a pipe opening; a dust cap is arranged at the pipe opening; a first electric connector is electrically connected with the heating body; the electronic cigarette comprises a shell, wherein a PCB (Printed Circuit board), a battery, a second connector and the heating component are arranged in the shell. The solid smoke cartridge, the electronic cigarette heating component and the electronic cigarette have the advantages of pure taste, low smoke injuries, no oil leakage, convenience in replacement, sanitation in use, completeness in combustion and high smoke amount.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

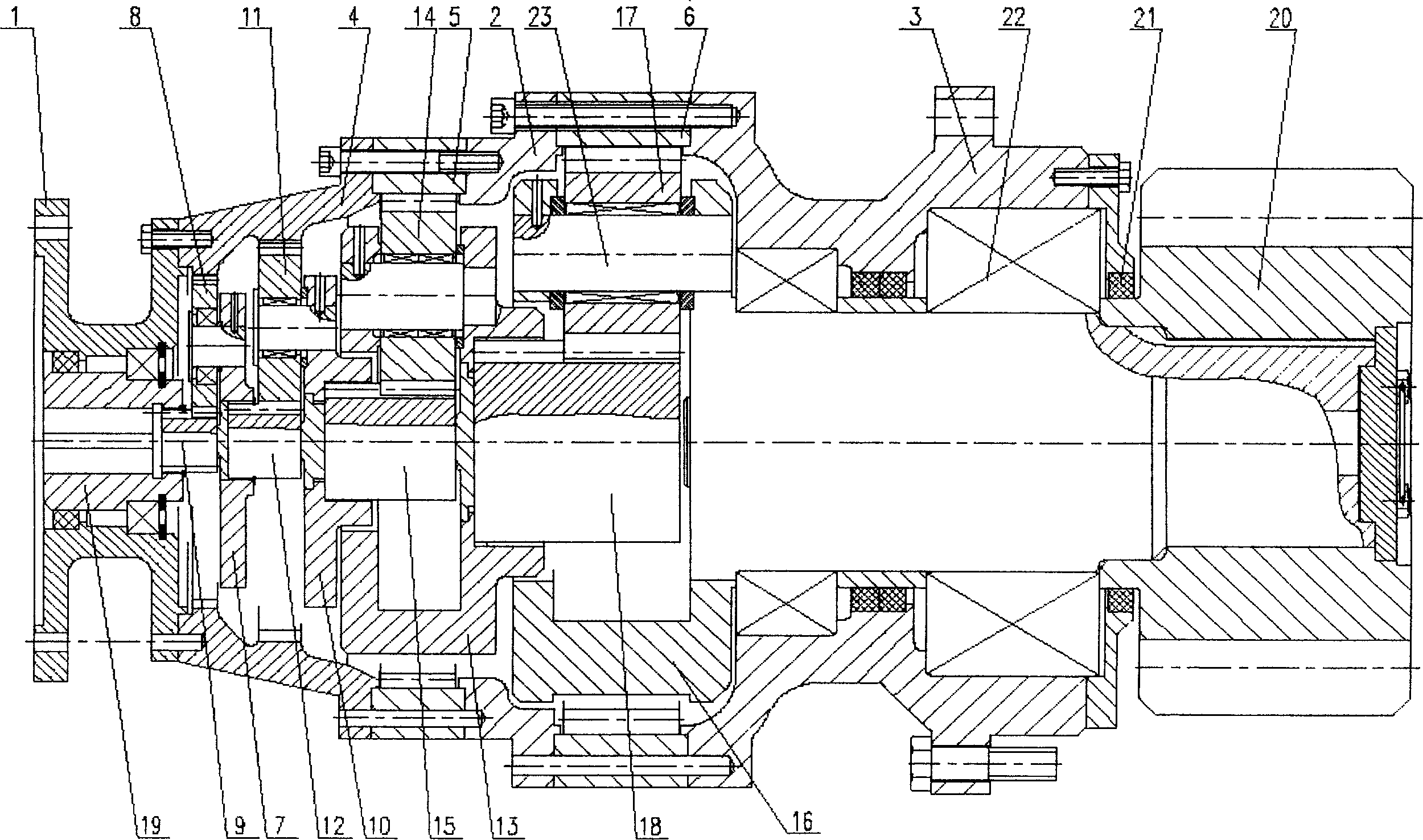

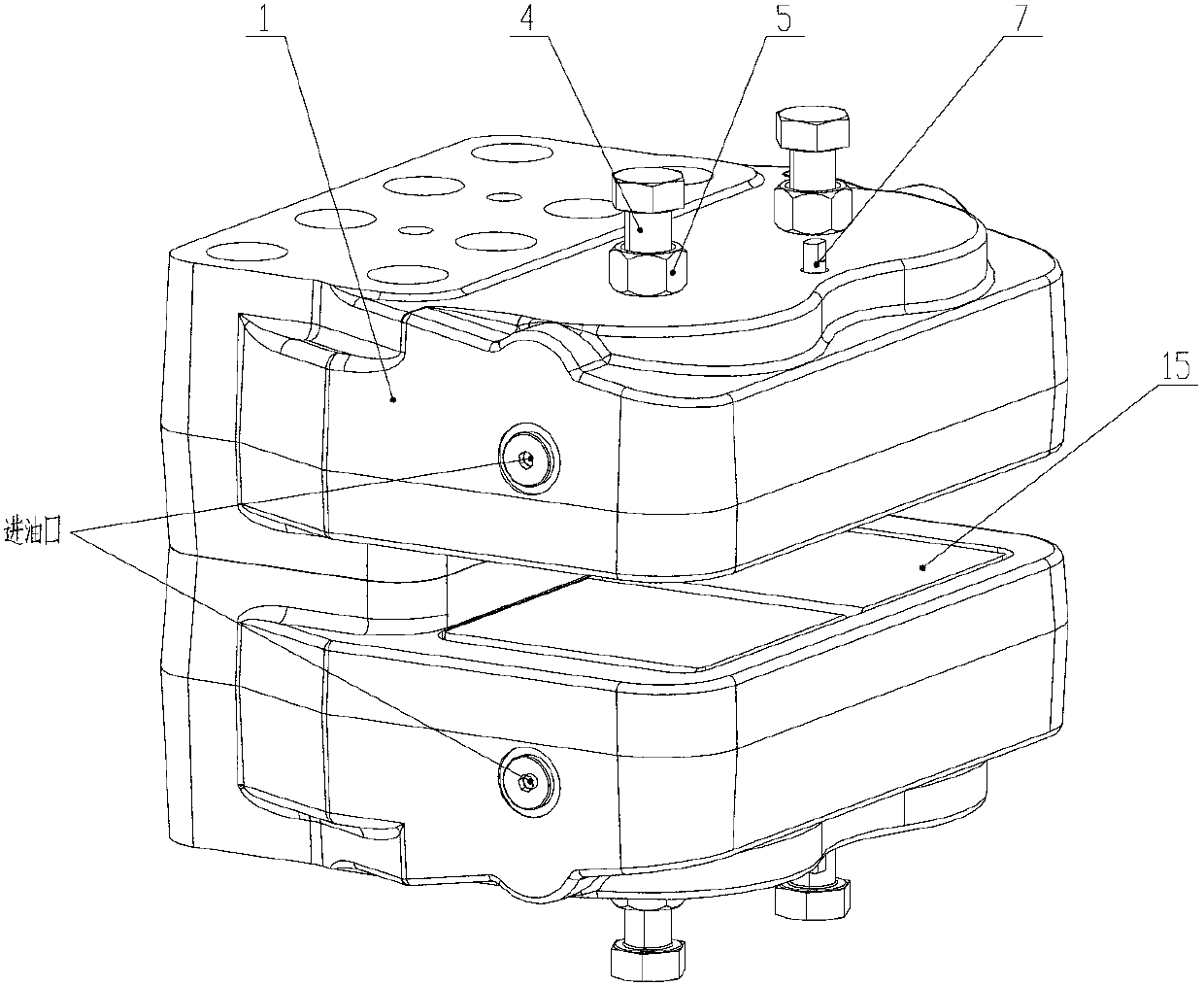

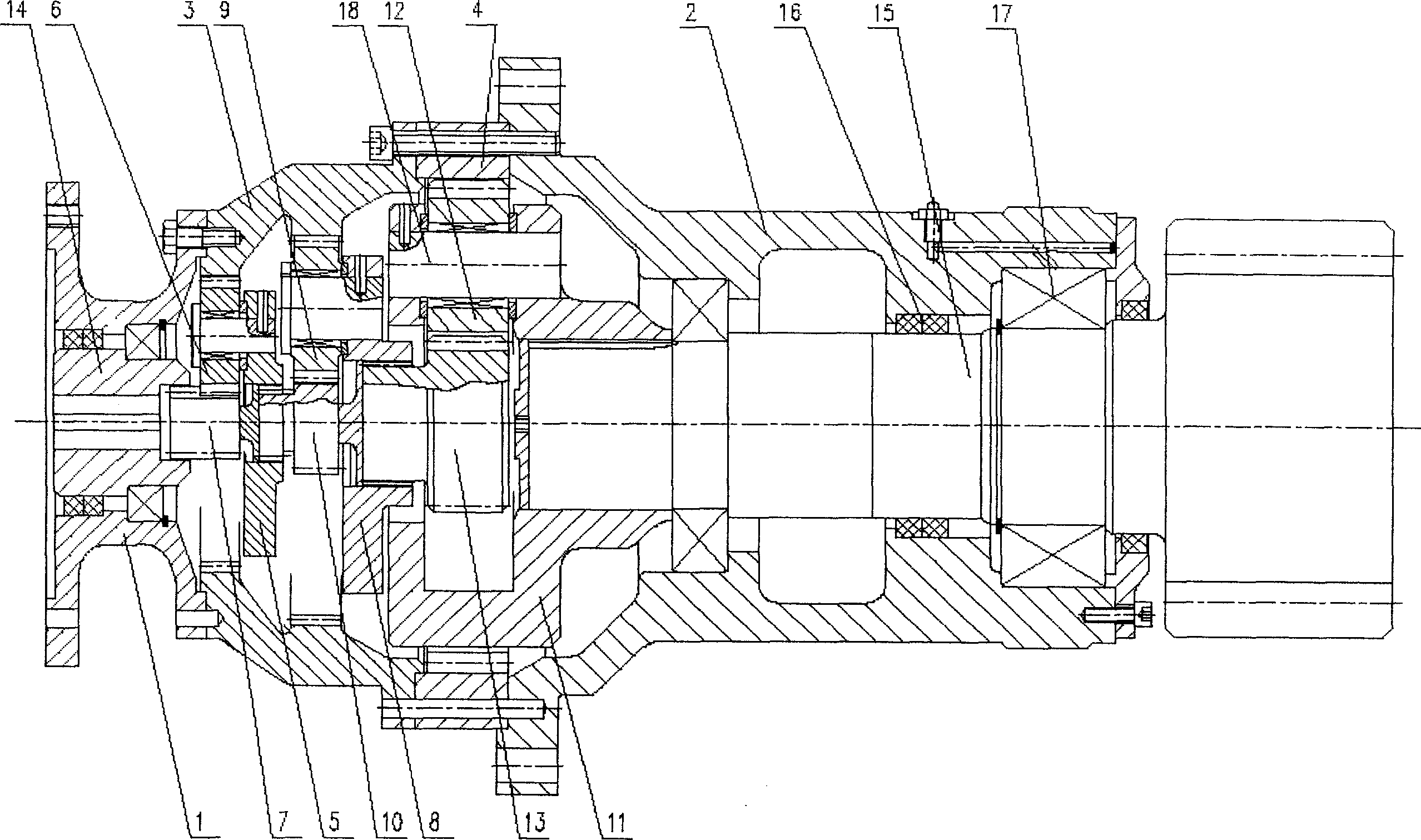

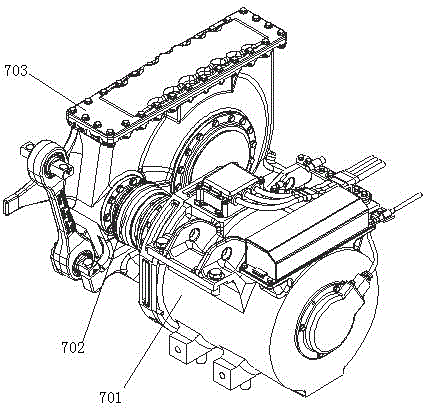

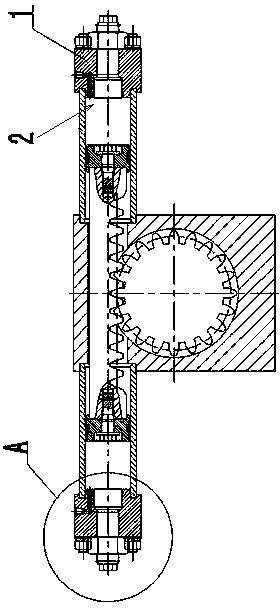

Yaw gearbox for wind power generator

ActiveCN1587681AReduce weightCompact structureToothed gearingsMachines/enginesNeedle roller bearingWind driven

The invention relates to a kind of off-course gear box of wind-driven generator. Between the flange and the middle box body there are the first-grade and the second-grade inner gear cluster, and the third-grade and fourth-grade inner gear circles. On the first and the second grade inner gear cluster there are inner gear circles. Input shaft, planet frames and solar wheels at all levels, output gear shaft axis, the input shaft of connected to the first-grade solar wheel, the planet frames at all levels are connected to the next grade solar wheel. The fourth grade planet frame is fixed on the back box body by the bearing. The end of the frame goes through the back box body and connects with the output gear. Each-grade planet frame has planet wheel, between the input shaft and flange, between the fourth grade planet frame and back box body, there is oil-sealing. Advantages of the invention: take the first and second inner gear circule cluster as a component and make the structure compact; take the gear circle cluster and the inner gear circles at all levels, as a part of the box, reduce the weight, and it is easy to process, convenient to dismantle and fix.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

Electronic cigarette oil bottle with anti-leaking function and electronic cigarette atomizer

ActiveCN104068477AGuaranteed oil capacityIncrease oil storageTobacco devicesElectronic cigaretteBottle

The invention discloses an electronic cigarette oil bottle with an anti-leaking function and an electronic cigarette atomizer. The electronic cigarette oil bottle comprises a bottle provided with an airflow channel tube in the middle, wherein a big oil storing chamber and an oil adding channel are arranged inside the bottle; a small oil storing chamber is arranged on one side, used for mounting an atomizing chamber, of the bottle; the big oil storing chamber is communicated with the small oil storing chamber through the oil adding channel; the electronic cigarette atomizer comprises an electronic cigarette oil bottle, a cigarette holder and the atomizing chamber; one end of the electronic cigarette oil bottle is connected with the cigarette holder and the other end of the electronic cigarette oil bottle is connected with the atomizing chamber; the electronic cigarette oil bottle is the electronic cigarette oil bottle with the anti-leaking function. According to the invention, the electronic cigarette oil bottle provided with both the anti-leaking function and the electronic cigarette atomizer has the advantages of leakage prevention, big oil reserve, cleaning and sanitariness and convenience and comfort for utilization.

Owner:SHENZHEN MIST TECH DEV

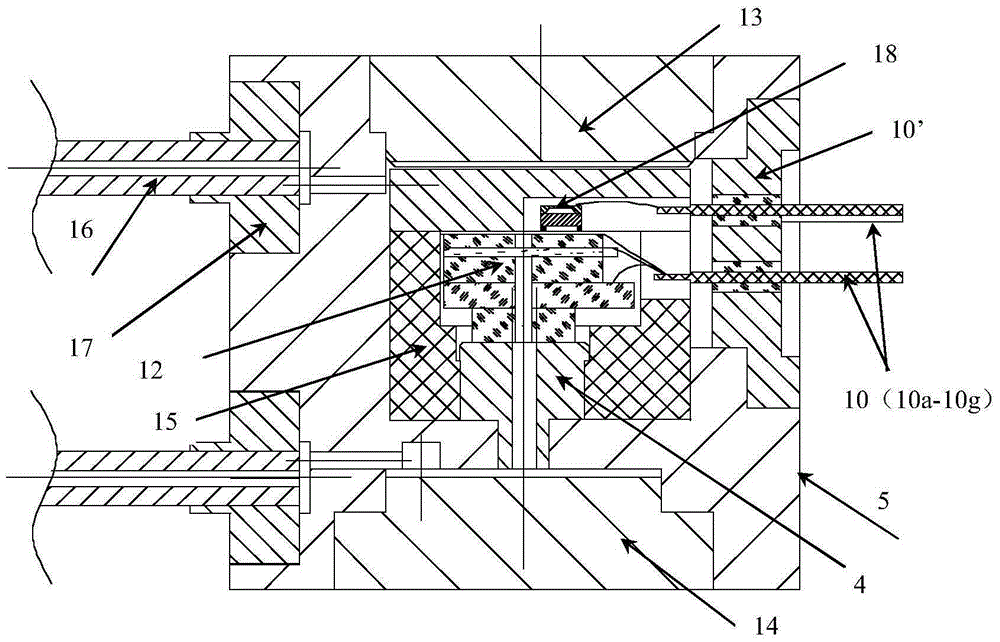

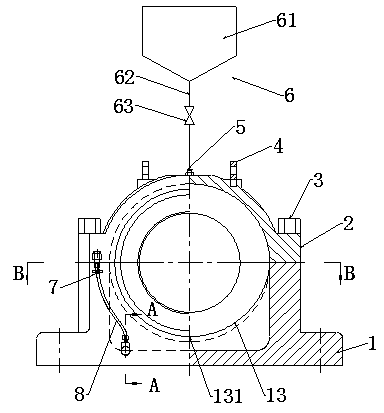

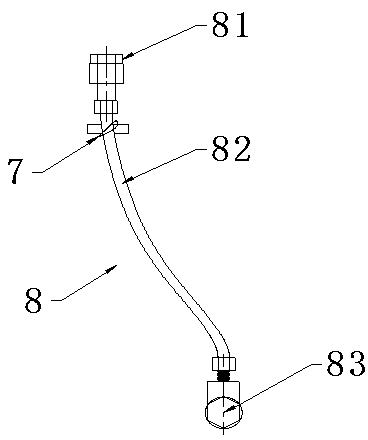

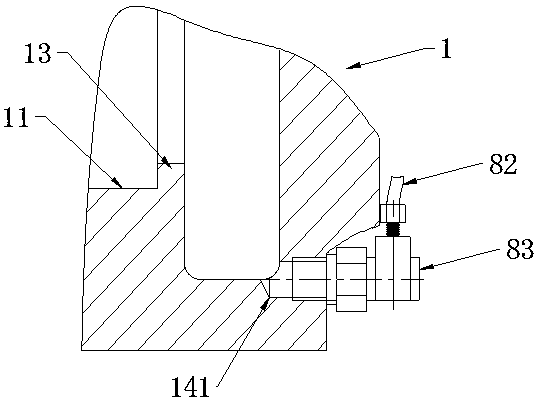

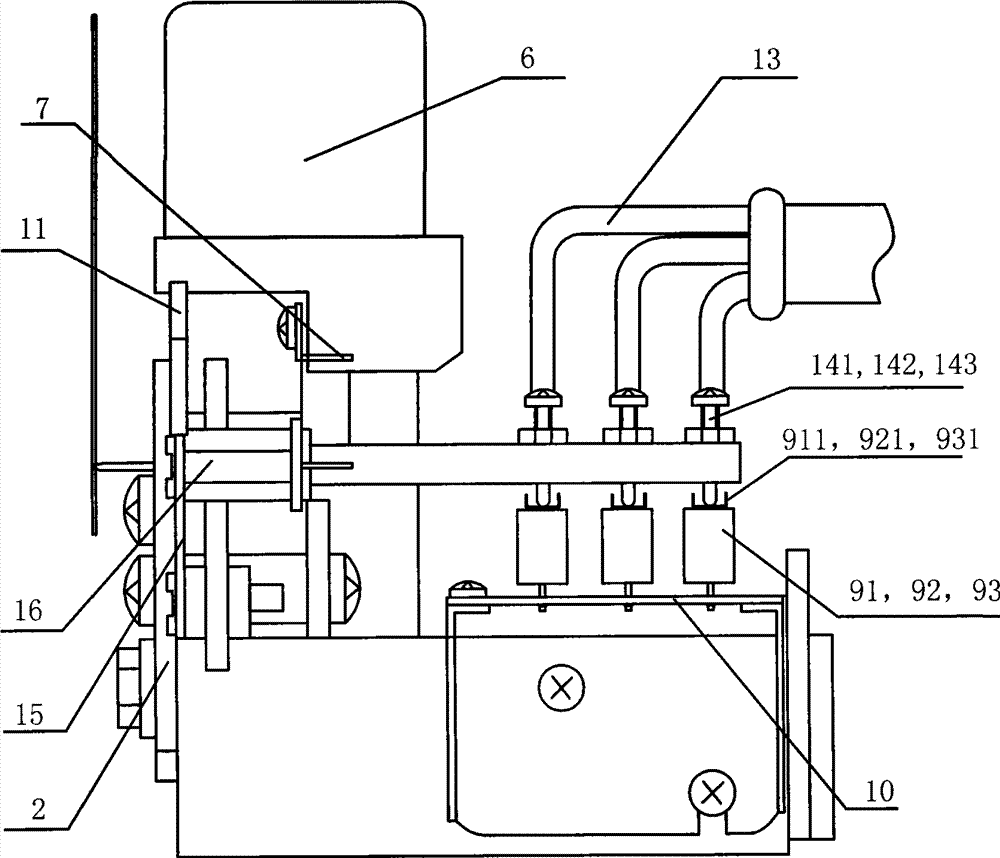

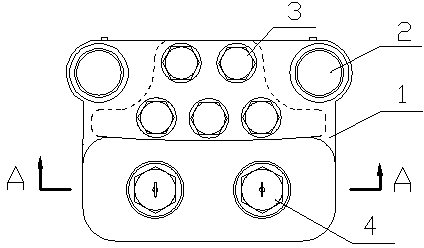

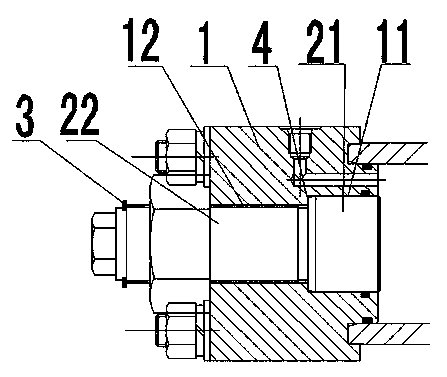

Yaw brake of wind power generation device and controlling method thereof

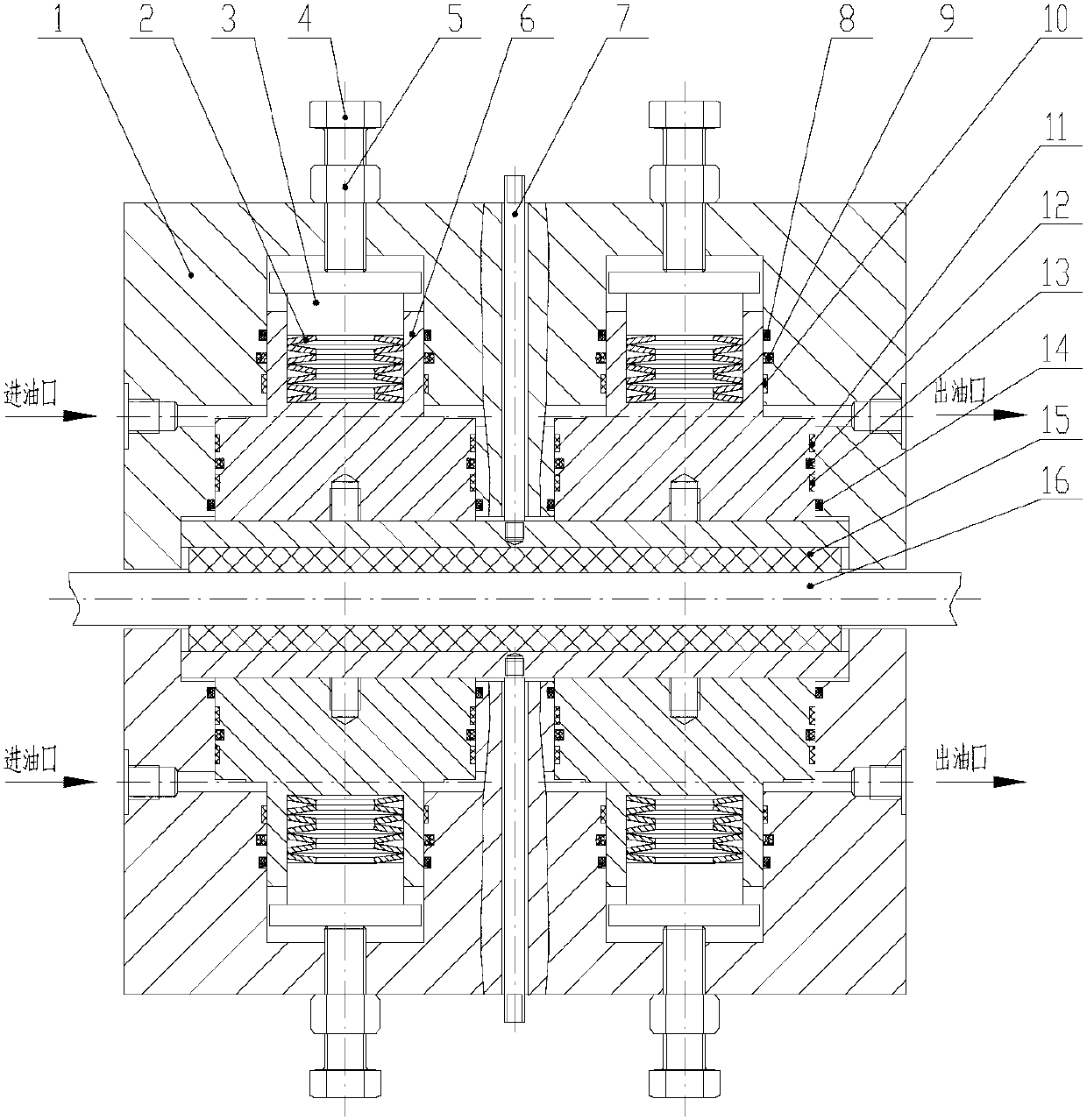

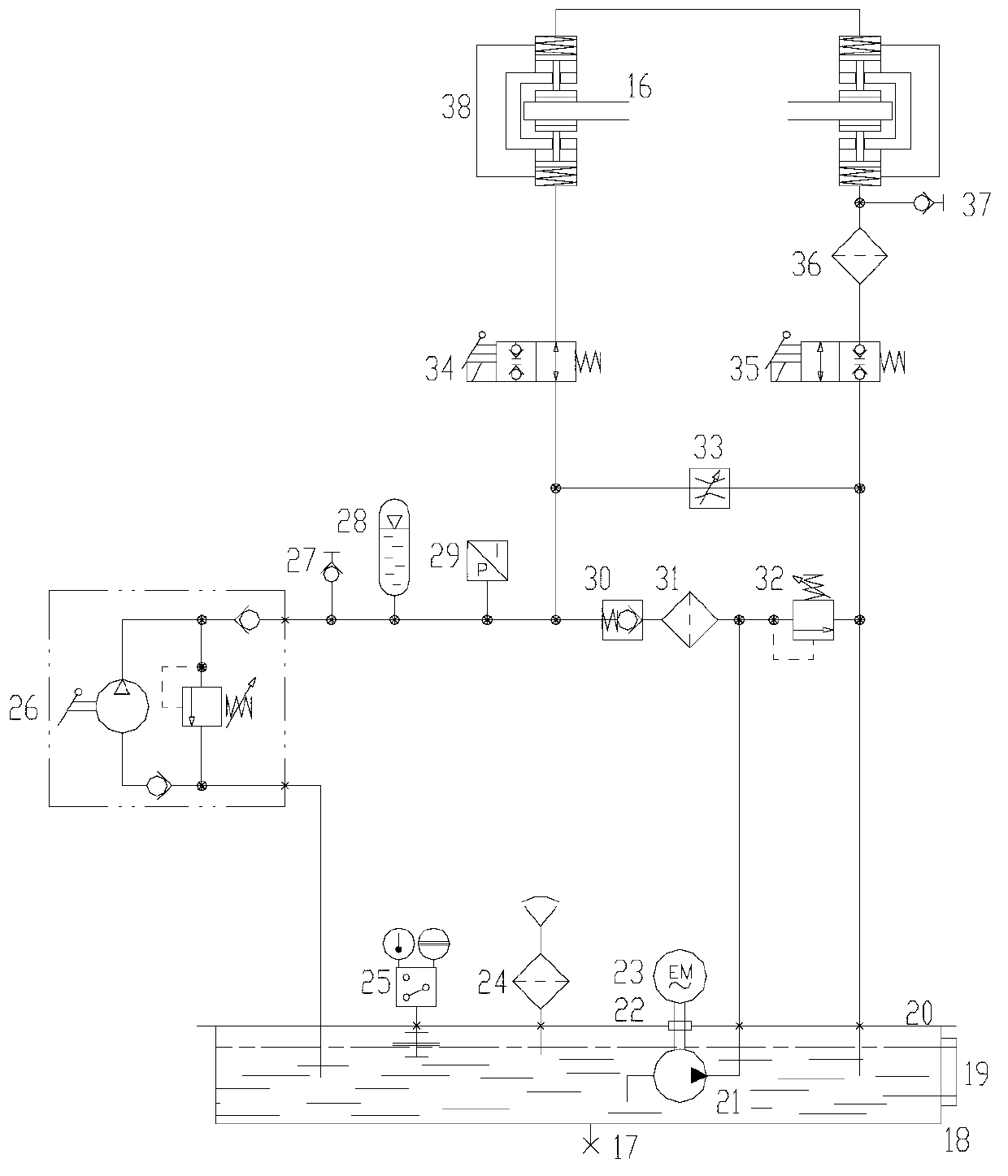

InactiveCN103343789AAvoid damageSolve the oil spill problemAxially engaging brakesBrake actuating mechanismsControl systemTangential force

The invention discloses a yaw brake of a wind power generation device and a controlling method of the yaw brake of the wind power generation device. The yaw brake comprises two brake calipers which are completely same with each other in structure, and the two brake calipers are connected to the left side of a brake disc and the right side of the brake disc respectively in a symmetrical mode through eight high-intensity bolts. Each brake caliper is of a bilateral symmetrical structure, and comprises a brake support, a disc spring set, a guiding block, an adjusting bolt, a locking nut, a piston, an abrasion indicator, a dustproof ring A, a high-pressure sealed ring A, a guiding belt A, a guiding belt B, a high-pressure sealed ring B, a guiding belt C and a dustproof ring B. According to the yaw brake of the wind power generation device, a disc spring hydraulic combined loading mode is adopted, no hydraulic system needs to provide pressure during the yaw process of a fan, the yaw brake force is generated only through the loading of the disc spring force, and a sealing device is prevented from bearing the action of the hydraulic pressure and the tangential force at the same time and being damaged during the yaw process. Multiple sets of guiding belts are adopted, the oil leakage problem is solved, working pressure of a hydraulic controlling system is reduced, and the service life of the sealing device can be effectively prolonged.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

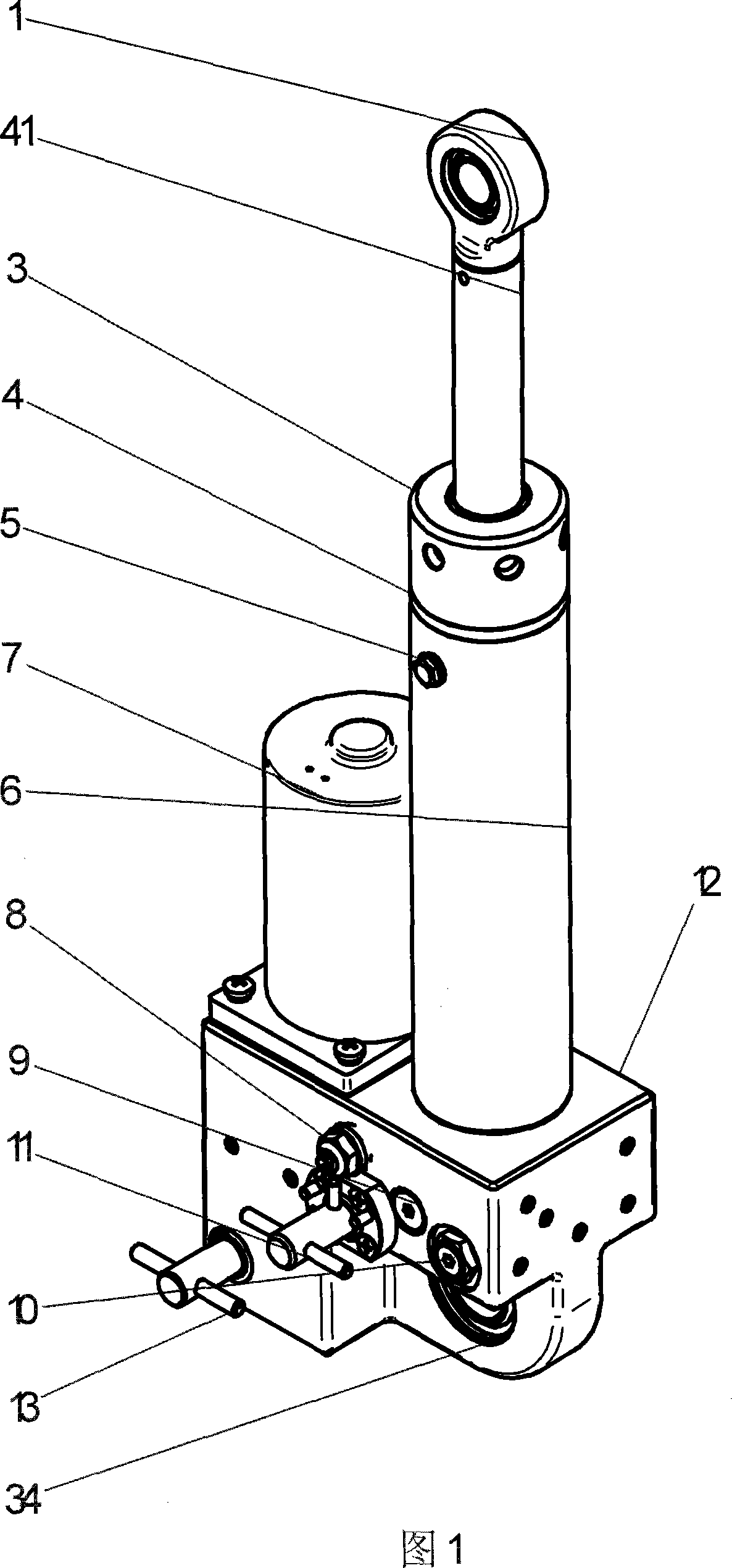

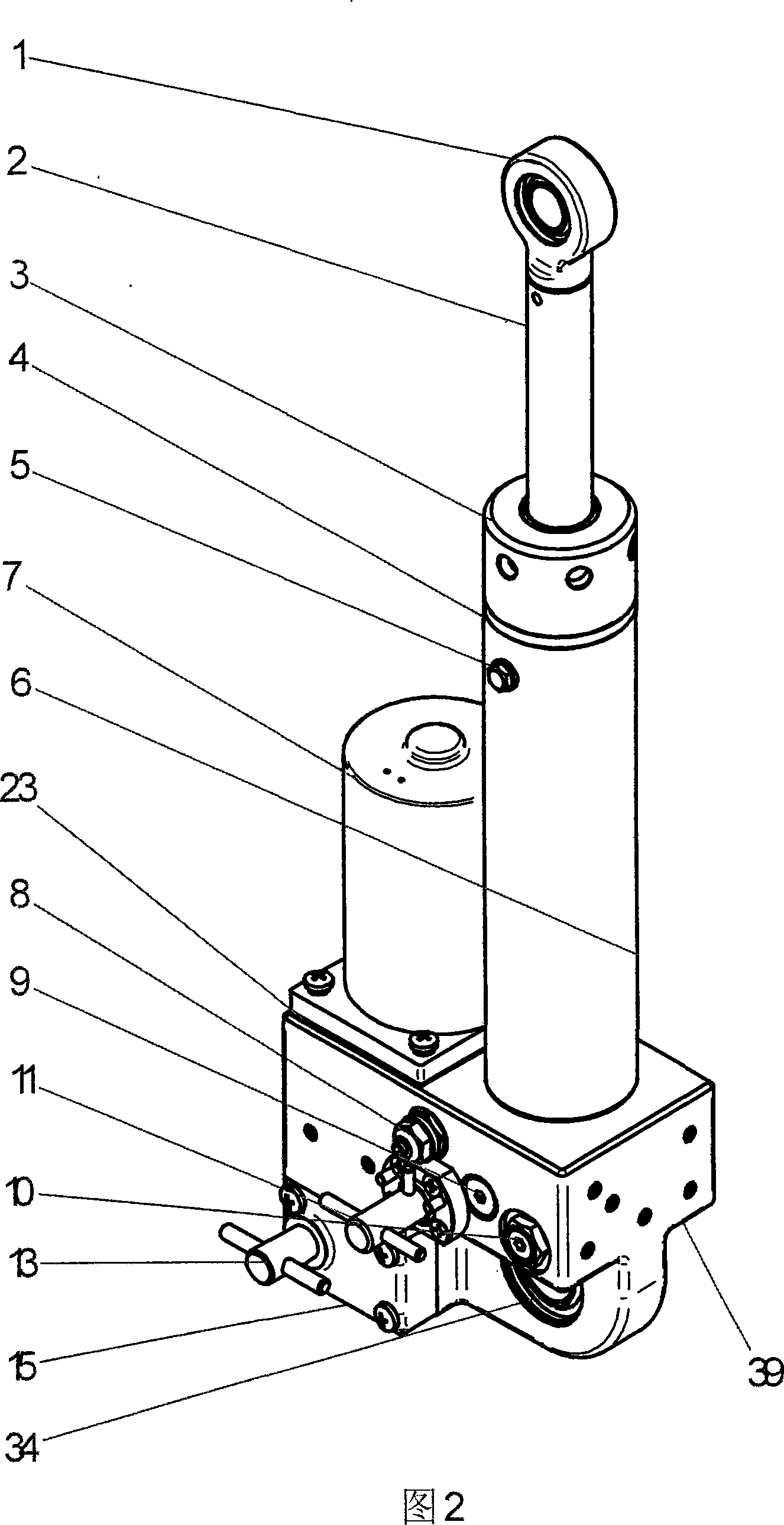

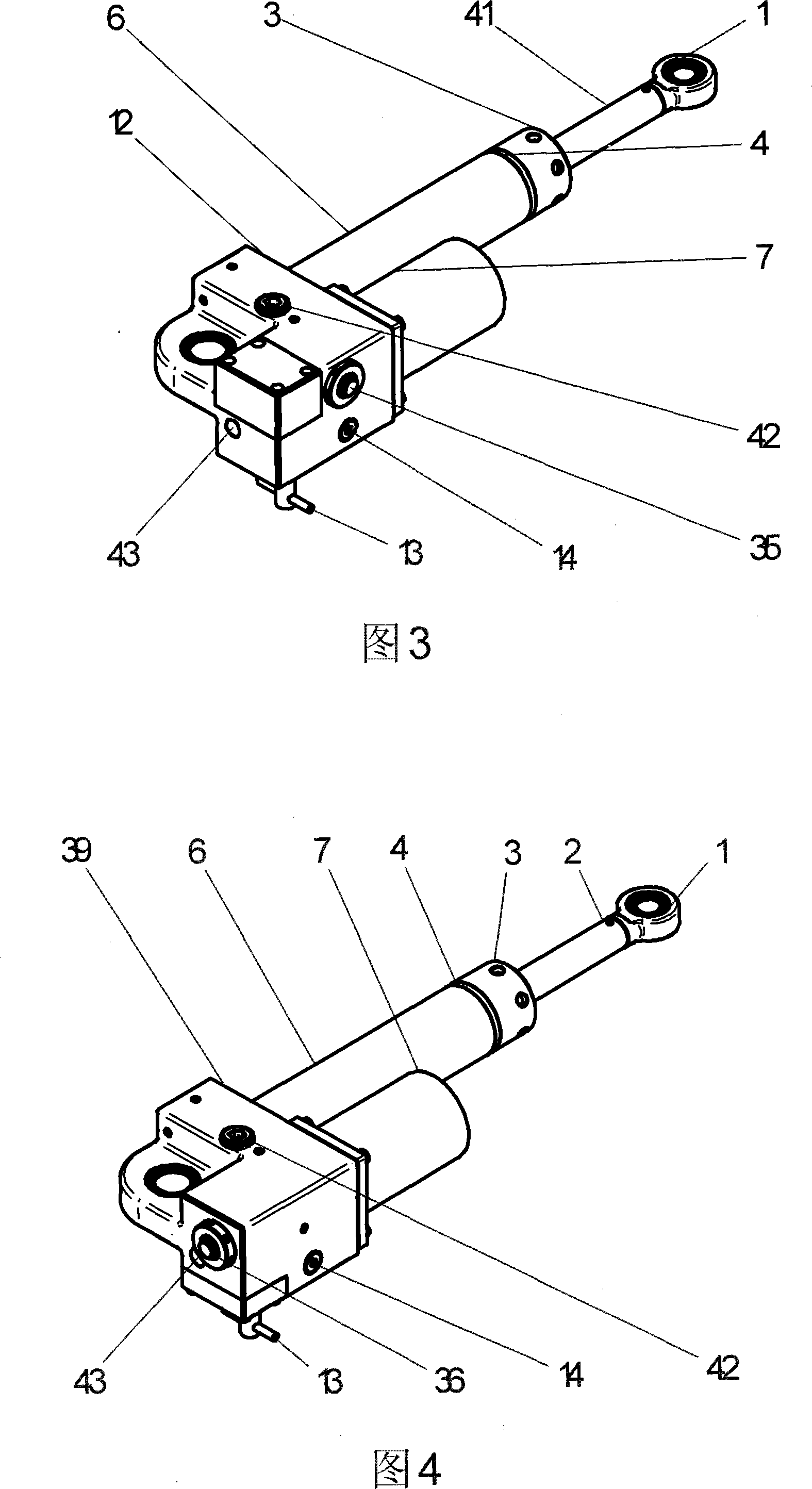

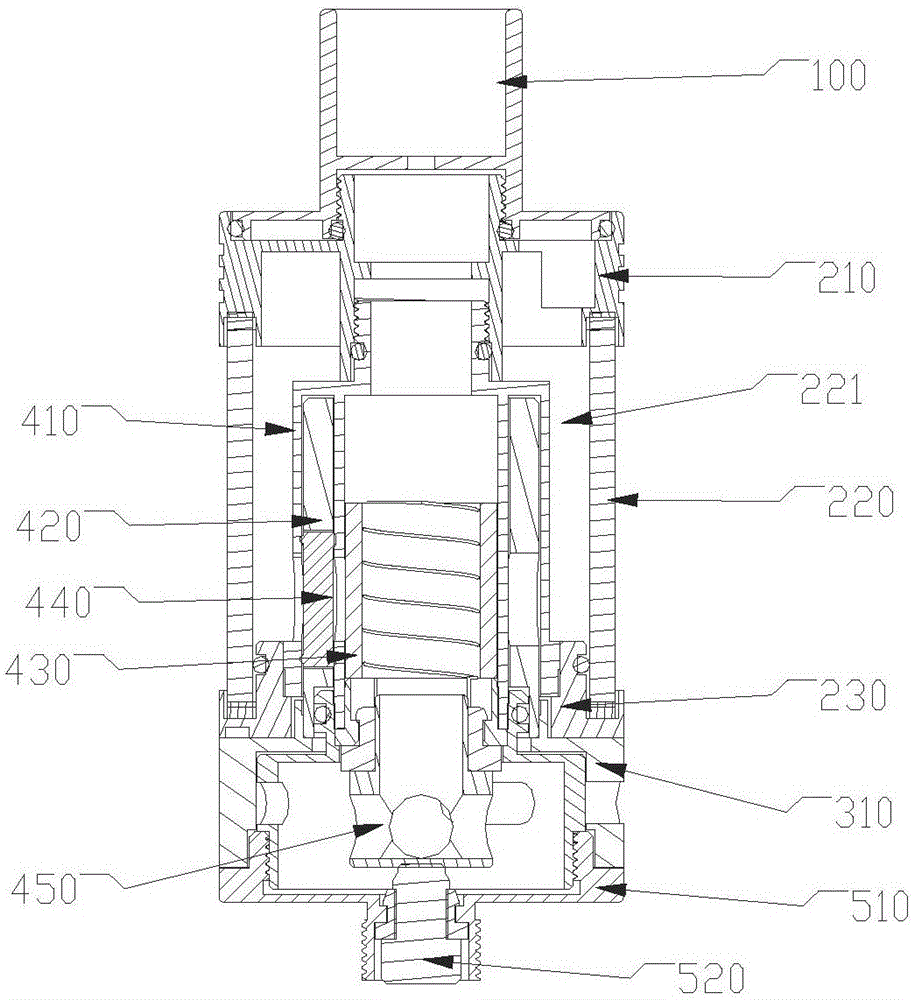

Entirety type electric and manual hydraulic lifter for overturning driving cab

InactiveCN101100200ASolve the oil spill problemCompact structureServomotor componentsLoading-carrying vehicle superstructuresElectric machineFuel tank

The electrically driven and hand driven hydraulic lifting machine for turning integral cab belongs to the field of automotive technology. The electrically driven and hand driven hydraulic lifting machine includes electric pump, hand pump and its operating mechanism, change valve and its operating mechanism, non-return valve for hand pump, one-way throttle valve, hydraulically controlled non-return valve, servo mechanism, unlocking oil cylinder, sealing member and control oil path mounted integrally inside one housing; lifting oil cylinder, piston and relevant parts integrated and mounted on the housing; and motor for the electric pump on the housing. The electrically driven and hand driven hydraulic lifting machine has reliable operation, wide application range, great lifting force and other advantages.

Owner:王树革

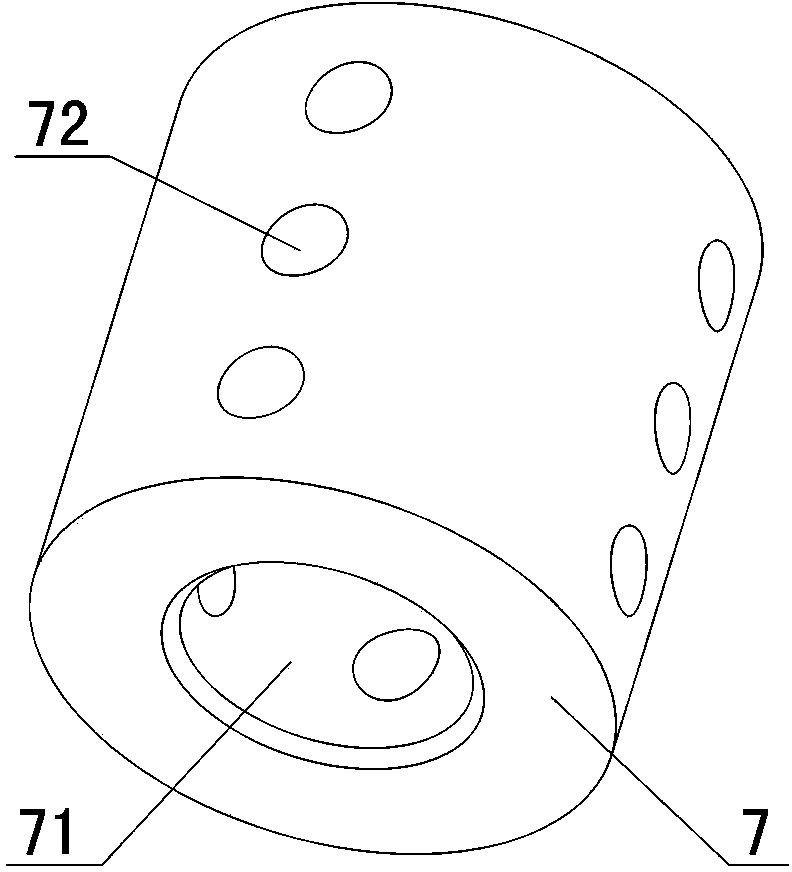

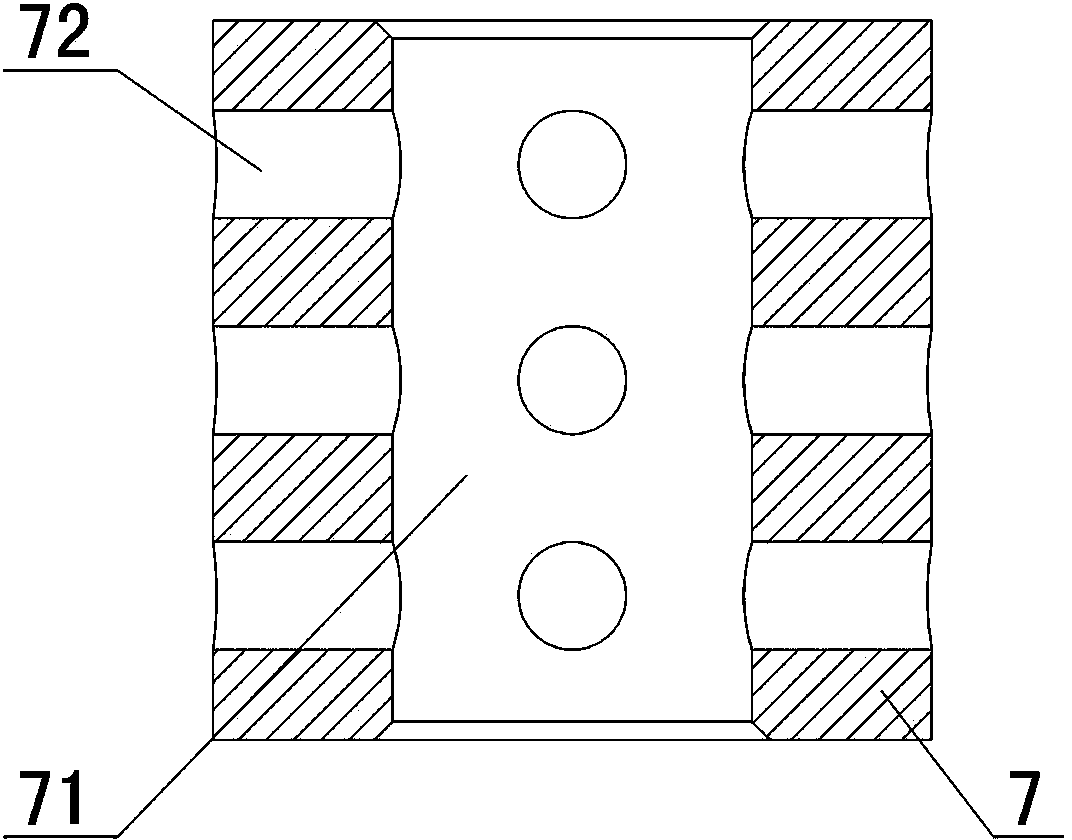

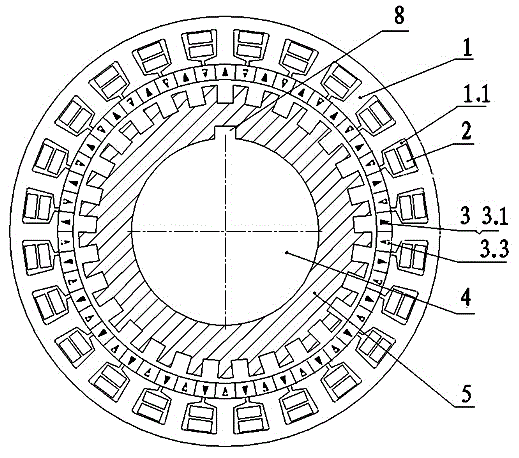

Low-speed reluctance motor and manufacturing method thereof

InactiveCN104917310AIncreased torque densityReduce friction lossMagnetic circuit rotating partsMagnetic circuit stationary partsFriction lossTorque density

The invention relates to a low-speed reluctance motor and a manufacturing method thereof. The low-speed reluctance motor comprises a motor base, stator lamination iron cores, stator exciting windings, an exciting permanent magnet, a rotating shaft and lamination salient pole rotors, wherein the number of pole-pairs of the stator exciting windings and the number of pole-pairs of the lamination salient pole rotors are not equal; the lamination salient pole rotors operate at a fixed speed, and the speed is smaller than the rotation speed of a magnetic field generated by the stator exciting windings. The manufacturing method comprises the manufacturing steps: fixing the exciting permanent magnet, embedding the stator exciting windings in grooves of the stator lamination iron cores, and performing insulating treatment and drying. The low-speed reluctance motor has the advantages that the torque density is improved; a gear box is saved, non-contact transmission is realized, the friction loss is reduced, and the efficiency and the system reliability are improved; the maintenance cost is reduced; the problem of oil leakage is solved; the rotor is firm, durable and resistant to high temperature; the size is reduced, and the utilization rate of installation space is improved; and the manufacturing according to the steps cannot cause demagnetization caused by the fact that the exciting permanent magnet is influenced by the baking temperature.

Owner:中国船舶重工集团公司第七一二研究所

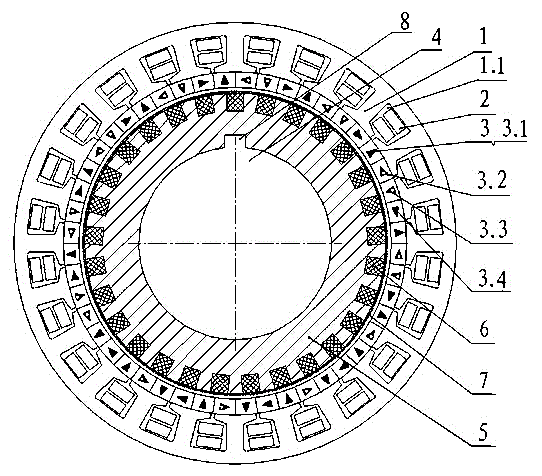

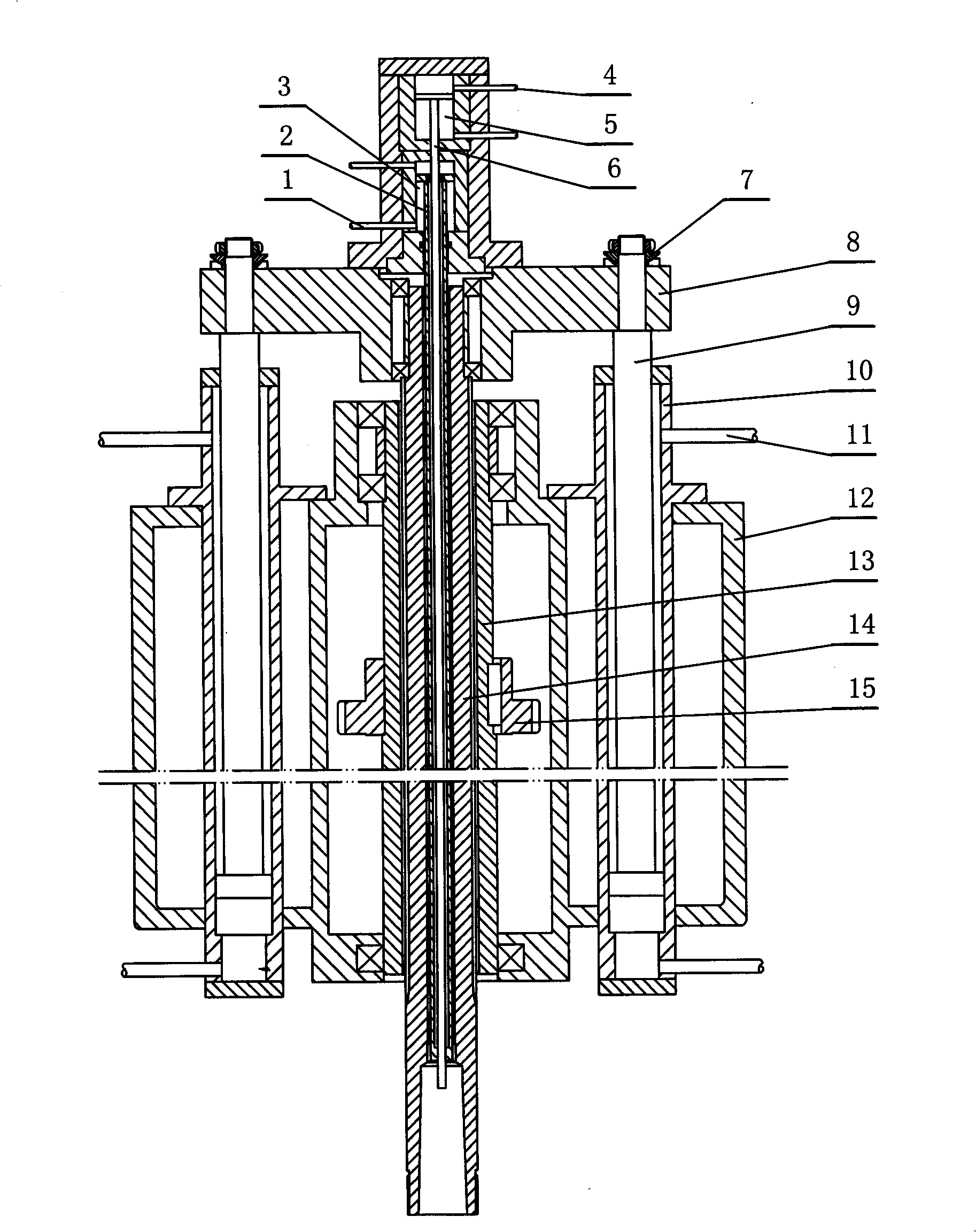

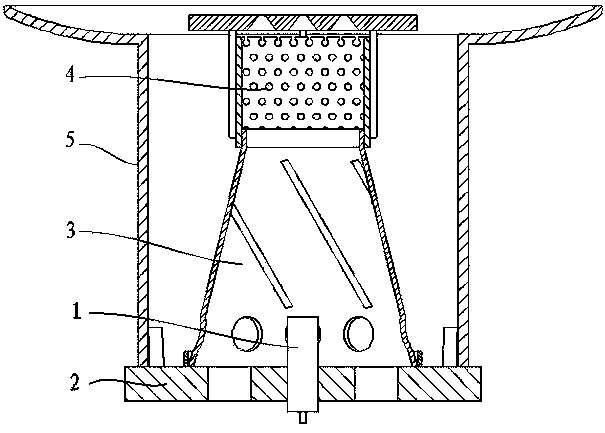

Dynamic high-pressure calibration device of flat type pressure sensor

ActiveCN103712740AGuaranteed accuracySolve the oil spill problemFluid pressure measurementForce/torque/work measurement apparatus calibration/testingPressure senseHigh pressure

The invention discloses a dynamic high-pressure calibration device of a flat type pressure sensor. The dynamic high-pressure calibration device of the flat type pressure sensor comprises a drop hammer hydraulic type high-pressure generating device and a sealed loading device of the flat type pressure sensor, wherein the drop hammer hydraulic type high-pressure generating device comprises a motor assembly, a support assembly, a steel wire rope, a magnet assembly, a heavy hammer, a pressure generator assembly and a standard pressure sensor. The sealed loading device of the flat type pressure sensor comprises a counter-force support, a calibration base, hydraulic oil, a sealing pad, the calibrated flat type pressure sensor, a pressing block, a jack and an oil pump. The hydraulic oil in a cavity of the pressure generator assembly is communicated with the hydraulic oil in a cavity of the calibration base through a connecting pipe, and pressure generated by the pressure generator assembly is transferred to the pressure sensing face of the calibrated flat type pressure sensor through the hydraulic oil delivery connecting pipe. The dynamic high-pressure calibration device of the flat type pressure sensor can achieve dynamic high-pressure calibration of the flat type pressure sensor by adopting the sealed loading device based on a drop hammer hydraulic calibration method.

Owner:THE THIRD ENG CORPS RES INST OF THE HEADQUARTERS OF GENERAL STAFF PLA

Variable propeller gearbox of wind power generator

ActiveCN1587682ACompact structureReduce overall weightToothed gearingsWind motor combinationsWind drivenPropeller

The invention relates to a kind of oar-exchanging bear box of wind-driven generator. The box body includes flange, gear circle, and the back box body. Between the flange and the back box body there are the first-grade and the second-grade inner gear cluster, and the third-grade inner gear circle, input shaft, planet frames and solar wheels at all levels, output gear shaft axis, the input shaft is connected to the first-grade solar wheel, the planet frame at all levels are connected to the next grade solar wheel, the third-grade planet frame is connected with the output gear shaft, the output gear shaft is fixed on the back box body by the bearing. Each-grade planet frame has planet wheel, between the input shaft and flange, between output gear shaft and back box body, there is oil-sealing. Advantages of the invention: take the first and second inner gear circle cluster as a component and make the structure compact; take the inner gear circle cluster and the inner gear circles at all levels, as a part of the box, reduce the weight, and it is easy to process, convenient to dismantle and fix. The planet wheel usnig needle bearing, can increase the bearng capacity, and reduce installing room.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

Silicon-based pressure sensor and manufacturing method thereof

ActiveCN105181187ASimple processImprove production yieldForce measurementDifferential pressureDevice form

The invention relates to a silicon-based pressure sensor and a manufacturing method thereof. The sensor comprises a differential pressure sensitive device, a static pressure compensation unit and a packaging structure, wherein the differential pressure sensitive device employs a differential capacitor structure, the differential pressure sensitive device is characterized in by comprising an upper glass fixing pole board, a movable silicon sensitive chip pole board, a lower glass fixing pole board, a glass bottom board and a pressure guide tube from up to down through packaging; the static pressure compensation unit employs a silicon piezoresistive chip in an absolute packaging mode to measure static pressure magnitude and is characterized by employing a point type suspension mode to be fixed above the differential pressure sensitive device, signal drifting amount is small, space is saved, and the static pressure compensation unit and the differential pressure sensitive device form a compound stacked structure welded in the packaging structure in a suspension mode; the packaging structure comprises a sensor foundation, a pressure leading guide tube and a wire leading seat and is characterized by employing a suspension type structure, the compound differential and static pressure structure is packaged in the sensor foundation in a suspension mode, the wire leading seat is arranged at one end of the foundation, the pressure leading guide tube is arranged at the other end of the foundation, each part is welded on the sensor foundation through the improved welding technology.

Owner:SHENYANG ACAD OF INSTR SCI

Manufacturing method of oil absorbing fiber felt

ActiveCN103437067AImprove performanceSimple processNon-woven fabricsCross-linkManufacturing technology

The invention discloses a manufacturing method of oil absorbing fiber felt, belonging to the technical field of manufacturing of fiber felts. By simultaneously adopting a semi-interpenetrating polymer network technique and an electrostatic spinning technique, the manufacturing method comprises the following steps: firstly, synthesizing monomers, which are unlikely to form cross-linked structures, to linear non-crosslinking methacrylate polymers by suspension polymerization; dissolving the polymers in a solvent suitable for electrostatic spinning to prepare liquor, and adding monomers, which are likely to form cross-linked structures and contain an initiator, into the liquor; preparing polymer liquor containing the semi-interpenetrating network structure by liquor polymerization; after insulating and defoaming, spraying the liquor to a receiving roller by an electrostatic spinning method; and along with volatilization of the solvent, after fibers are cured, fixing the semi-interpenetrating network structure inside the fibers so as to form the fiber felt with an intrinsic oil absorbing function. Compared with existing polypropylene fiber felt, the fiber felt disclosed by the invention has the advantages of higher adsorption rate, stronger oil keeping capacity and the like, and satisfies the industrial practical demands.

Owner:TIANJIN POLYTECHNIC UNIV

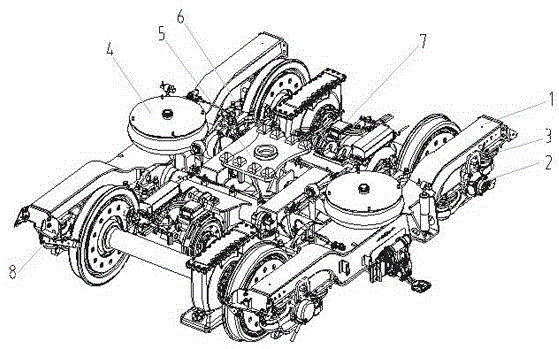

Bogie for A-type broad-gauge metro vehicle

The invention discloses a bogie for an A-type broad-gauge metro vehicle. The bogie comprises a frame, a wheelset and axle box device, a primary suspension device, a secondary suspension device, a central traction device, a foundation brake device, a driving device and a rim lubrication device. The bogie is characterized in that the frame has a large lateral span, the primary suspension adopts a rubber spring, the secondary suspension adopts an air spring, a secondary vertical damper and a horizontal damper to reduce vibration and impact, so that a passenger sits more conformably, two traction rods are adopted between a vehicle body and the bogie for transferring traction and braking force, and the foundation brake device adopts a wheel mounted type disc brake unit. The bogie meets requirements for a Brazil 1A metro project contract, and the bogie for the A-type broad-gauge metro vehicle, which meets requirements for a dual-mode signal system, is researched for the first time; the gauge is 1600 mm and the axle load is 17.5 tons; the bogie has the advantages of high operation quality and convenience for maintenance and can be widely applied to the foreign market.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

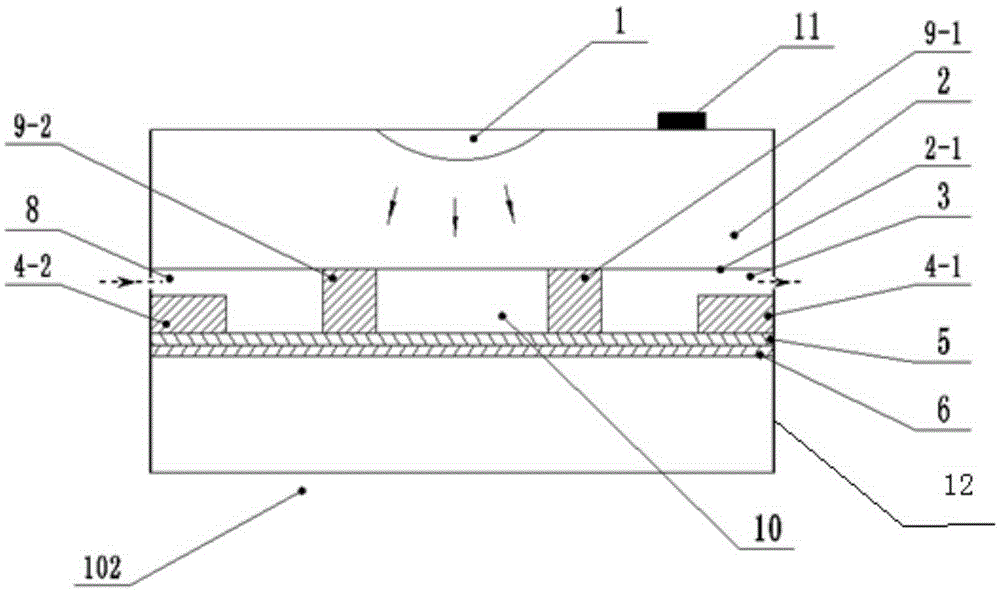

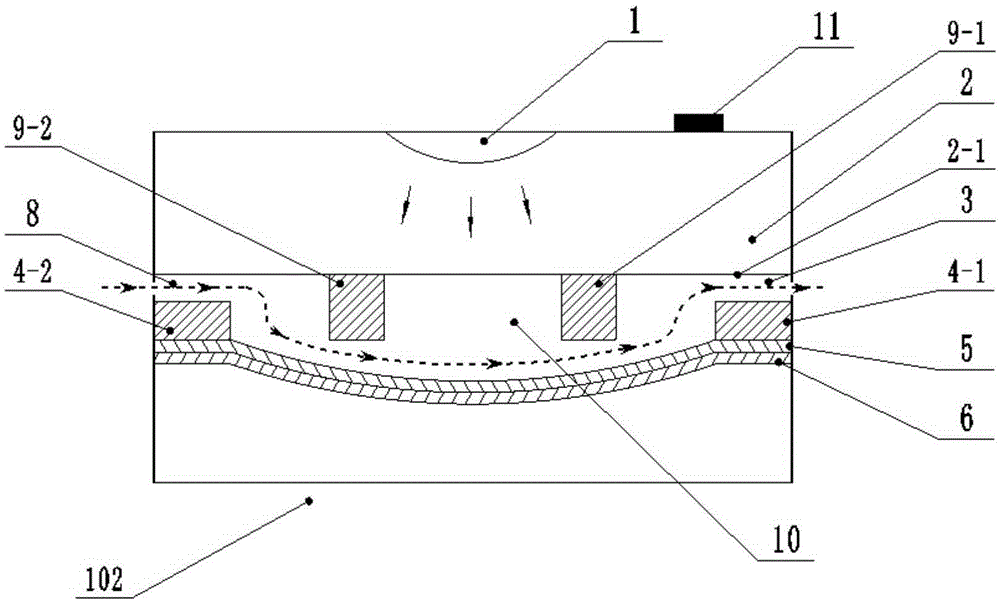

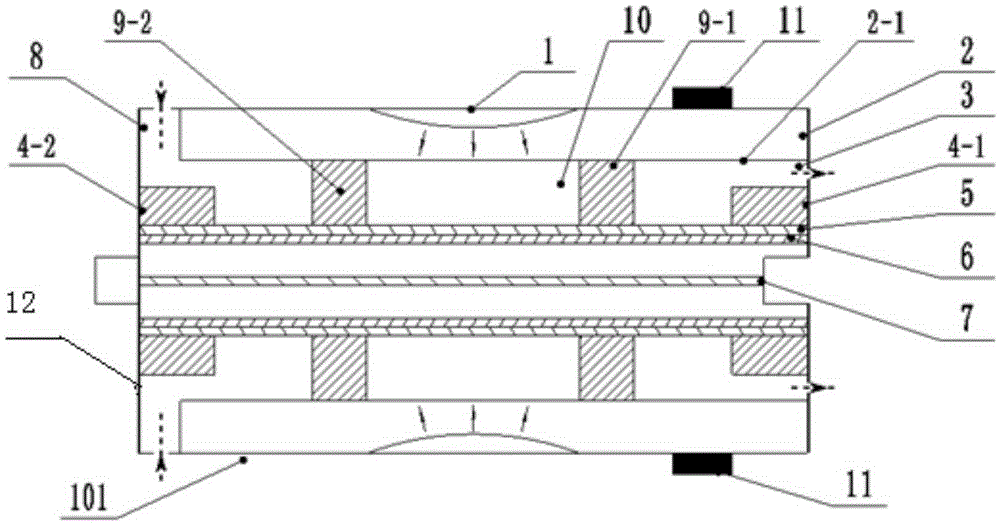

Electronic cigarette oil leakage preventing device adopting light-induced reversible deformation layer and oil leakage preventing method

ActiveCN105411010ASolve the oil spill problemSolve the problem of oil spillTobacco devicesEngineeringElectronic cigarette

The invention provides an electronic cigarette oil leakage preventing device adopting a light-induced reversible deformation layer. The electronic cigarette oil leakage preventing device comprises a housing (12), a light source accommodation cavity (2) provided with a light source (1) in the inside and provided with a transparent light outlet wall (2-1), a light-induced reversible deformation layer (5) provided with a lighted side surface and a back-lighted side surface, and an elastic layer (6) tightly attached to the back-lighted side surface of the light-induced reversible deformation layer (5), wherein the lighted side surface faces the light source (1), an airflow outlet channel is defined between the lighted side surface of the light-induced reversible deformation layer (5) and the light outlet wall (2-1) and the housing (12), and an air inlet hole (8) and an air outlet hole (3) of the airflow channel are respectively formed in the housing (12), one end of every one of the two holes is fixedly connected with the light outlet wall (2-1) or the housing (12), the other end of every one of the two holes is attached to the lighted side of the light-induced reversible deformation layer (5), and therefore blocking of the airflow channel is formed.

Owner:CHINA TOBACCO YUNNAN IND

Pumping unit with wide swing angle

The invention discloses a pumping unit with a wide swing angle, which comprises a motor, a bracket, a connecting rod, a speed change mechanism, a lifting rope, a fixed pulley, a wellhead oil pumping device, a rocker arm, a rocker arm pillar and two crankshaft wheels, wherein one end of the rocker arm is movably connected on the rocker arm pillar, the other end of the rocker arm is connected with the lifting rope, the lifting rope is connected with the wellhead oil pumping device by the fixed pulley which is arranged on the bracket, the two crankshaft wheels are connected with the speed change mechanism, one end of the connecting rod is movably connected with the rocker arm, and the other end of the connecting rod is movably connected with the crankshaft wheels. According to the pumping unit disclosed by the invention, the speed change mechanism is matched with the crankshaft wheels to pump oil, so that a pumping unit can be started and the working of the pumping unit can be maintained by a motor with relatively small power, and the pumping speed and the stroke of the pumping unit can be conveniently regulated.

Owner:德阳振华机械设备制造有限公司

Tar leakage prevention electronic cigarette atomizer

The invention discloses a tar leakage prevention electronic cigarette atomizer. The tar leakage prevention electronic cigarette atomizer comprises a housing (3), wherein an air inlet (11) and an air outlet (12) are formed in the middles of two ends of the housing (3). The tar leakage prevention electronic cigarette atomizer is characterized in that a breather pipe (7) with a first tar leakage prevention film (2) and a second tar leakage prevention film (9) arranged at the two ends respectively is arranged in the housing (3), a tar storage cavity (4) defined by the outer wall of the breather pipe (7) and the inner wall of the housing (3) is formed in the housing (3), micropores are formed in both the first tar leakage prevention film (2) and the second tar leakage prevention film (9), and the micropores have the apertures allowing gas but not liquid to pass. The tar leakage prevention electronic cigarette atomizer is simple and compact in structure and convenient for technological processing.

Owner:CHINA TOBACCO YUNNAN IND

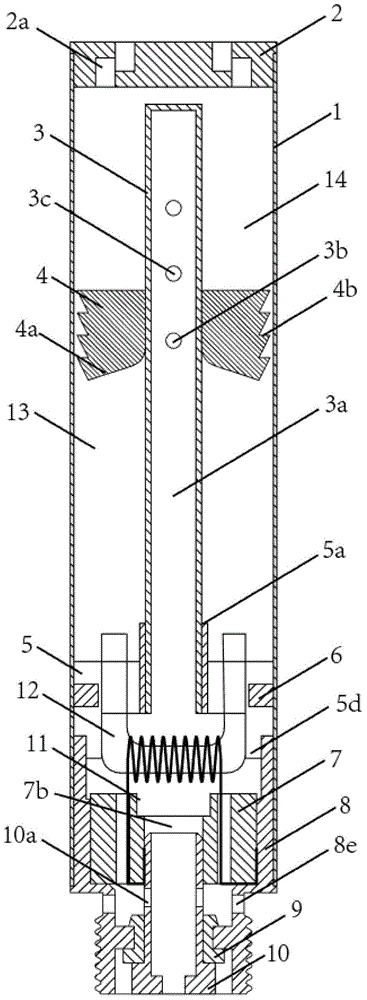

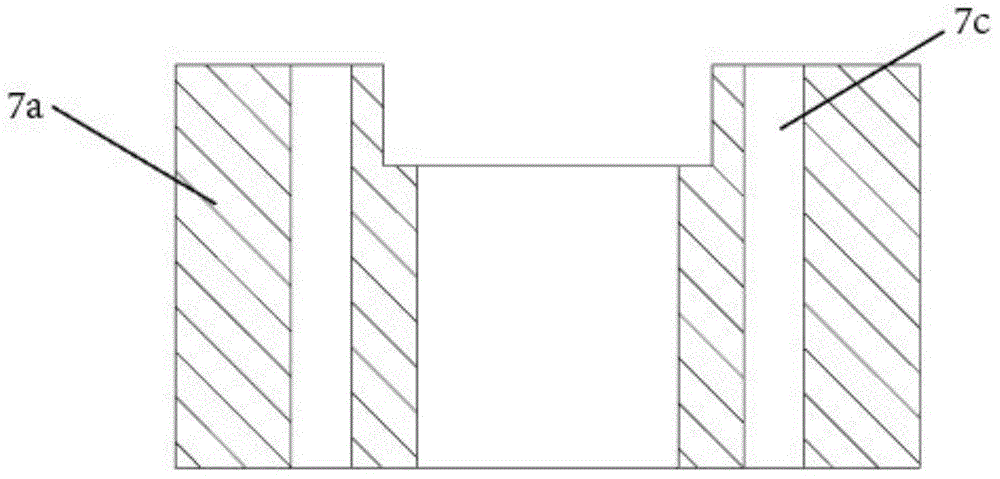

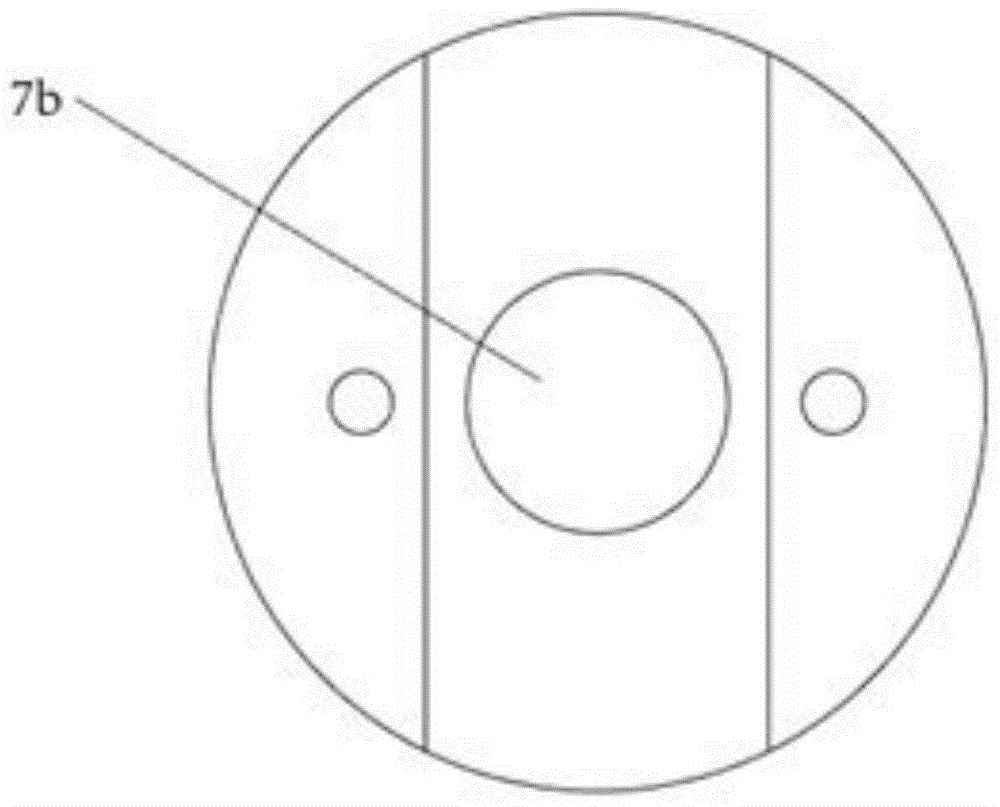

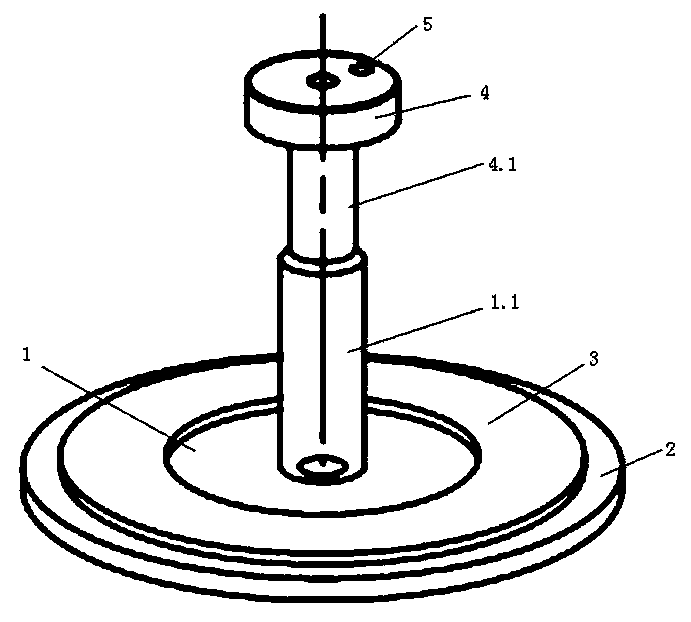

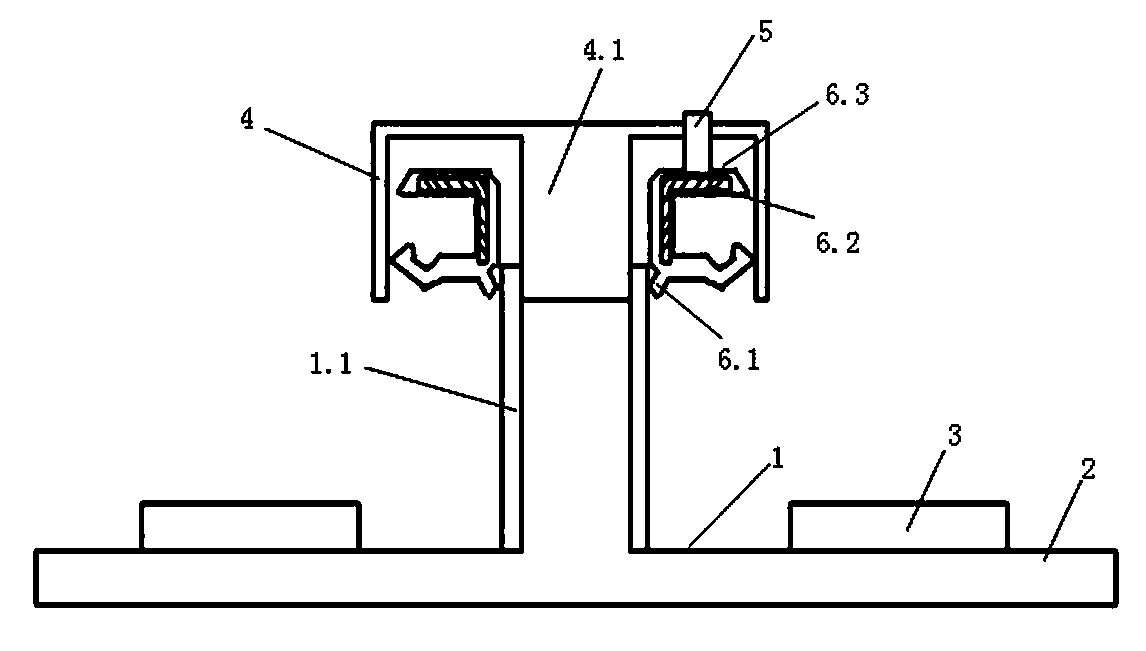

Disposable high-capacity electronic cigarette cartridge capable of preventing tobacco tar leakage

A disposable high-capacity electronic cigarette cartridge capable of preventing tobacco tar leakage comprises a round-tube-shaped casing (1), an axial smoke tube (3), a cigarette holder cover (2), a tobacco tar isolation rubber gasket (4) and an atomizer assembly, wherein the axial smoke tube (3) is arranged in the inner center of the casing, the cigarette holder cover (2) covers the top of the casing, vent holes (2a) are formed in the cigarette holder cover (2), the tobacco tar isolation rubber gasket (4) is arranged at the middle-upper part in the casing and mounted on the smoke tube in a sleeving manner, and the atomizer assembly is arranged at the lower end of the smoke tube; the tobacco tar isolation rubber gasket divides an inner cavity of the casing into an upper annular cavity (14) for accommodating filtration or flavoring materials and a lower tobacco tar storage cup (13) for storing tobacco tar. No tobacco tar storage cotton is used, bacterium breeding can be effectively avoided, air in the annular tobacco tar storage cup can be completely removed, the problem of tobacco tar leakage is effectively solved, the tobacco tar utilization rate is high, the smoke quantity is large, tobacco tar can be prevented from being sucked into the mouth, and the smoking experience is better.

Owner:云南拓宝科技有限公司

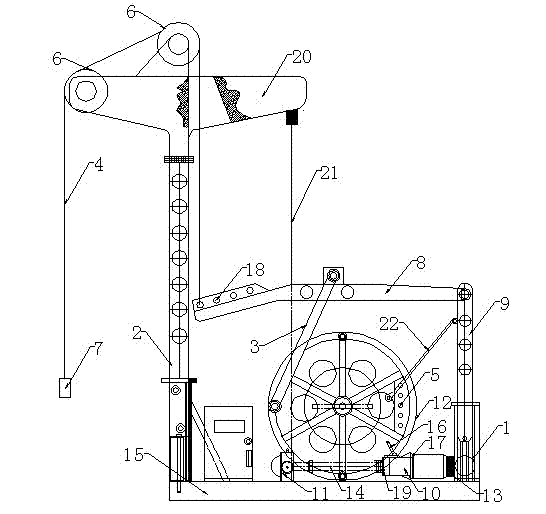

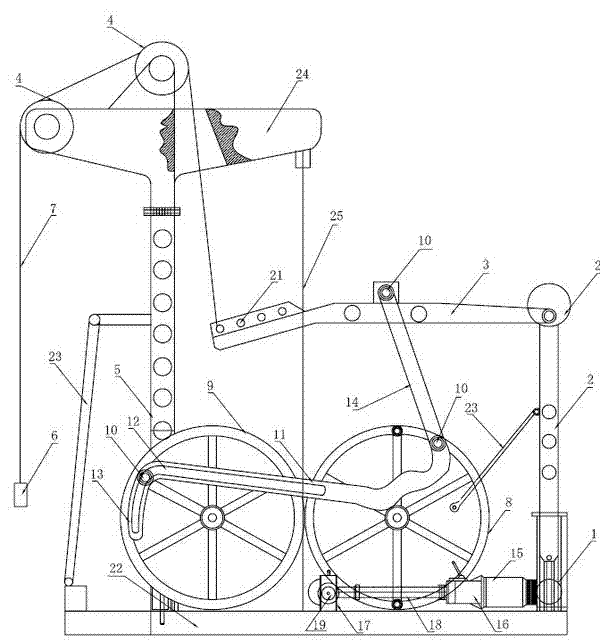

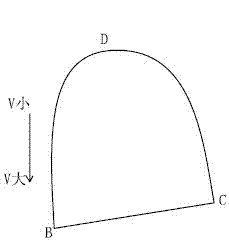

Automatic speed-changing wide-swing-angle oil pumping machine

InactiveCN102808602ASolve the oil spill problemImprove oil pumping efficiencyGearingFluid removalCrankshaftPulley

The invention relates to the technical field of oil extraction machinery, in particular to an automatic speed-changing wide-swing-angle oil pumping machine. The automatic speed-changing wide-swing-angle oil pumping machine comprises an electric motor, a speed changing mechanism, a swing arm support, a swing arm arranged on the swing arm support, a support provided with a fixed pulley and a wellhead oil pumping device, wherein the speed changing mechanism is connected with a driving crankshaft wheel, the driving crankshaft wheel is meshed with a driven crankshaft wheel, the driving crankshaft wheel is connected with a connecting piece through a bearing, one end of the connecting piece is connected with the driven crankshaft wheel, the other end of the connecting piece is connected with the swing arm through a connecting rod, a sliding chute is arranged on the connecting piece of which one end is connected with the driven crankshaft wheel, and a bearing on the driven crankshaft wheel is sleeved in the sliding chute. The automatic speed-changing wide-swing-angle oil pumping machine disclosed by the invention has the advantages that when the two crankshaft wheels are in rotation, since the position of the bearing of a driven pulley is changed, the position of the connecting piece can be also correspondingly changed, a motion trail of the connecting rod is affected by the motion of the connecting piece, the speed of the wellhead oil pumping device in the up-stroke is higher than that in the down-stroke, the oil leakage problem existing in an oil pumping process is avoided, and the oil pumping efficiency is increased.

Owner:德阳振华机械设备制造有限公司

Mineral engineering machinery, disassembly-free oil cavity cleanable bearing block and cleaning method

ActiveCN103867582AExtended service lifeFlexible rotationBearing cleaningRotary machine partsWorking environmentOil storage

The invention discloses a disassembly-free oil cavity cleanable bearing block, which comprises a bearing block body and a bearing cap arranged on the bearing block body, wherein an oil storage cavity is formed in the bearing block body and the bearing cap; a threaded hole communicated with the lateral surface of the bearing block body is formed below the oil storage cavity; a rotary joint of an adjustable oil outlet device is arranged at the threaded hole, so that a function of cleaning an oil cavity of the bearing block without disassembly is realized. The bearing block with the structure has the advantages that the bearing block is easy to use and machine, low in cost and long in service, the service life of a bearing is prolonged, the working environment of the bearing is improved, and the like. In addition, the invention also discloses an oil cavity cleaning method based on the disassembly-free oil cavity cleanable bearing block, which is easy to operate and high in efficiency. Moreover, the invention discloses mineral engineering machinery comprising the disassembly-free oil cavity cleanable bearing block. The mineral engineering machinery has the advantages of simplicity in maintenance and long service life, and the major overhauling cycle of the mineral engineering machinery can be prolonged.

Owner:江苏京冶海上风电轴承制造有限公司

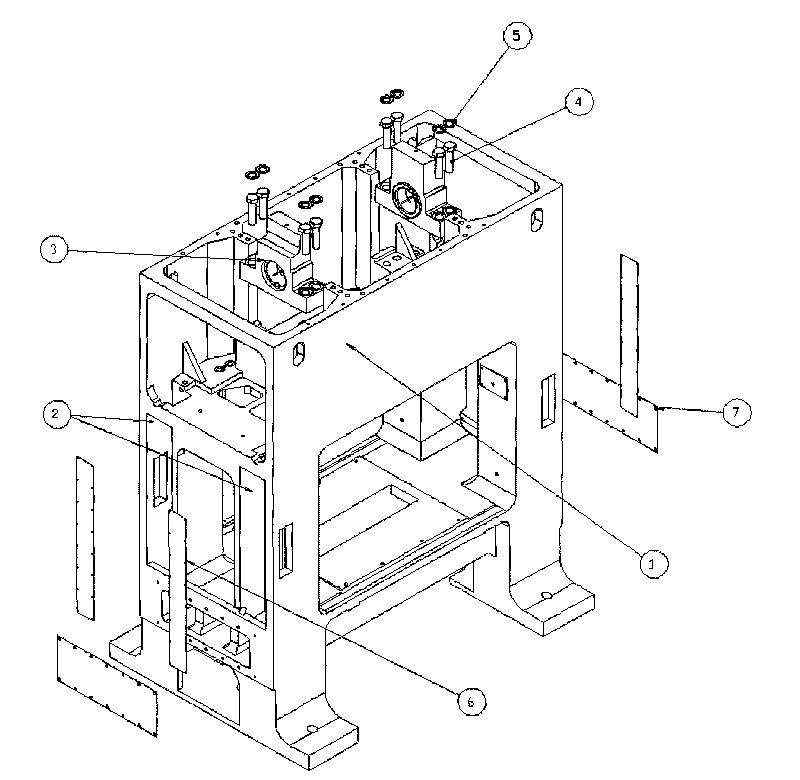

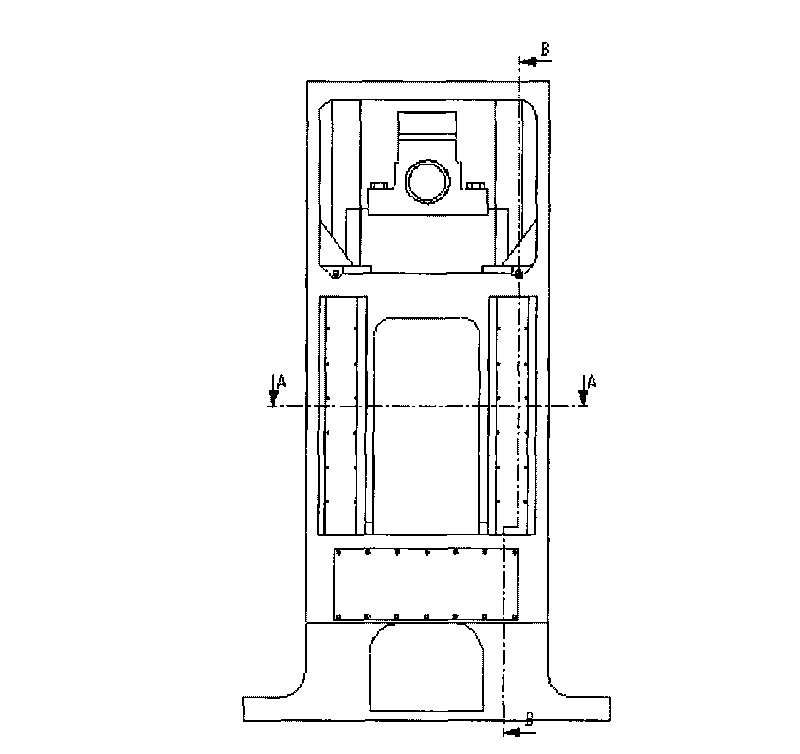

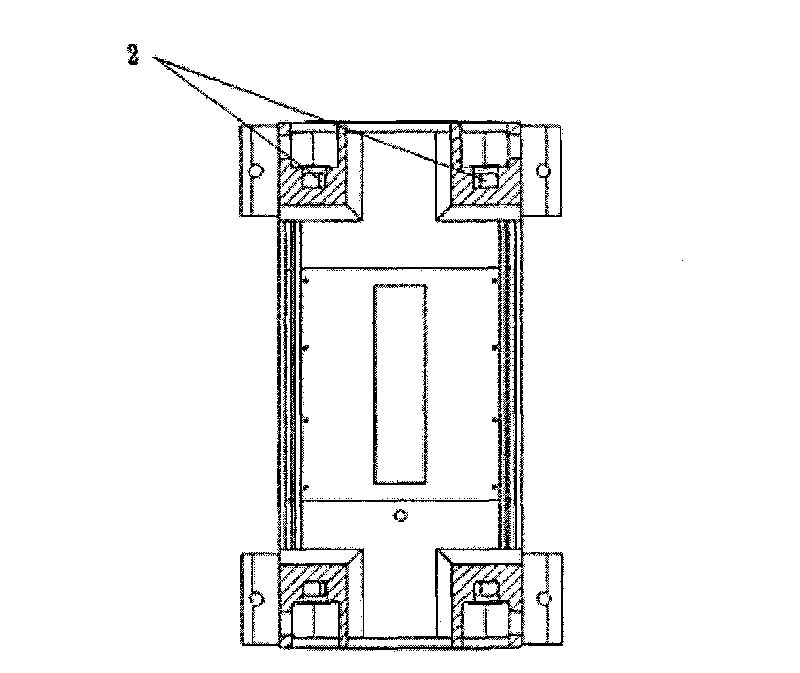

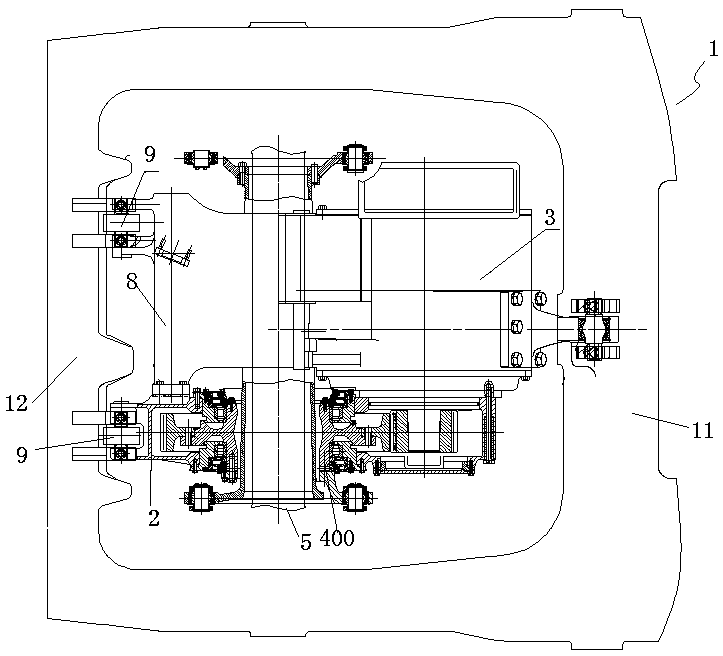

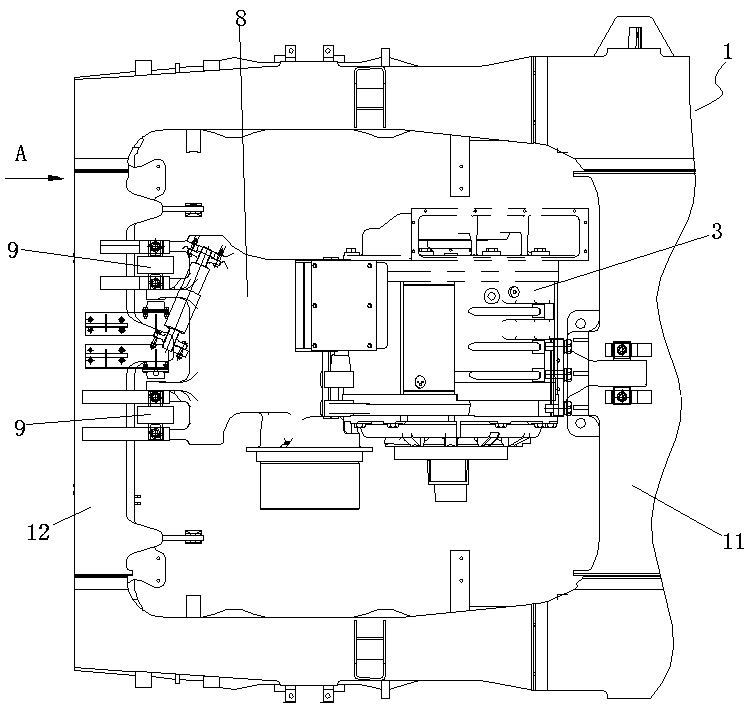

Closed type portal high-speed punch press stand

ActiveCN101733965AEliminate fit gapsHigh precisionPressesEngine lubricationPunch pressHigh intensity

The invention relates to a closed type portal high-speed punch press stand which comprises a table body (1) used as a main working part on the upper part, a lubricating oil channel (2), an oil tank (8), a crankshaft tilting fillet (3), a bolt (4) and a hard thickening flat washer (5), wherein the bottom of the crankshaft tilting fillet (3) is a plane and is positioned on a corresponding plane in the table body (1) and fixed through the bolt (4) and the hard thickening flat washer (5); the lubricating oil channel (2) is distributed on the inner wall on the periphery of the punch press stand, and the upper part of the lubricating oil channel (2) is communicated with a top box (9), while the lower part is communicated with the oil tank (8); both sides at the bottom of the top box (9) are provided with a hole channel (10) communicated with the top box (9) and the lubricating oil channel (2); the bolt (4) is a grade-12.9 high-strength bolt; and the hard thickening flat washer (5) is flat washer chamfered grade A with a hardness grade of HV300. The invention can solve the problems of large mounting difficulty of the crankshaft tilting fillet, high processing expense and device lubricating oil return in the prior art.

Owner:宁波澳玛特高精冲压机床股份有限公司

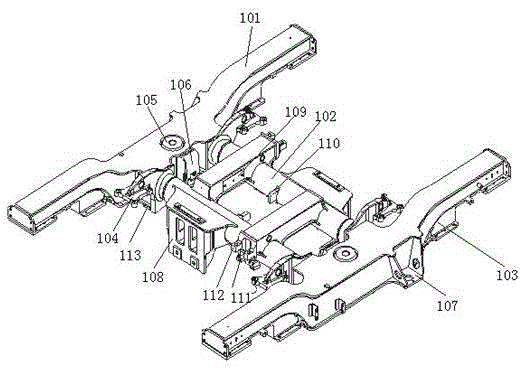

Bogie

ActiveCN107697090AReduce lateral forceReduce failure rateElectric motor propulsion transmissionAxle-boxesBogieInstability

The invention discloses a bogie. The bogie comprises a framework, a gearbox, a traction motor, wheel pairs, a wheel axle, a six-connecting-rod hollow shaft and a suspension cross beam; the suspensioncross beam comprises a beam body, a through groove and a bearing seat, wherein the through groove is transversely formed in the beam body; and the bearing seat is transversely arranged in the groove opening of one end of the through groove in an overhanging manner and fixedly connected with the beam body; one end, with the through groove, of the beam body is fixedly connected with the tractor motor in a longitudinal manner; a sealed cavity formed after connecting one end, with the through groove, of the beam body with the tractor motor sleeves the external surface of the hollow shaft; the other end of the tractor motor is suspended on a middle cross beam of the framework; one end, without the through groove, of the beam body is hooked with a framework end beam through a lifting rod; and adriven gear of the gearbox is sleeved with the bearing seat through a bearing. The bogie has the advantages that a problem of cross instability of heavy-duty freight electric locomotive in the high speed running process is solved by using a driving device elastic suspension mode; and problems of complicated gearbox structure and heavy load on the gearbox are solved because the gearbox adopts a non-load structure.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

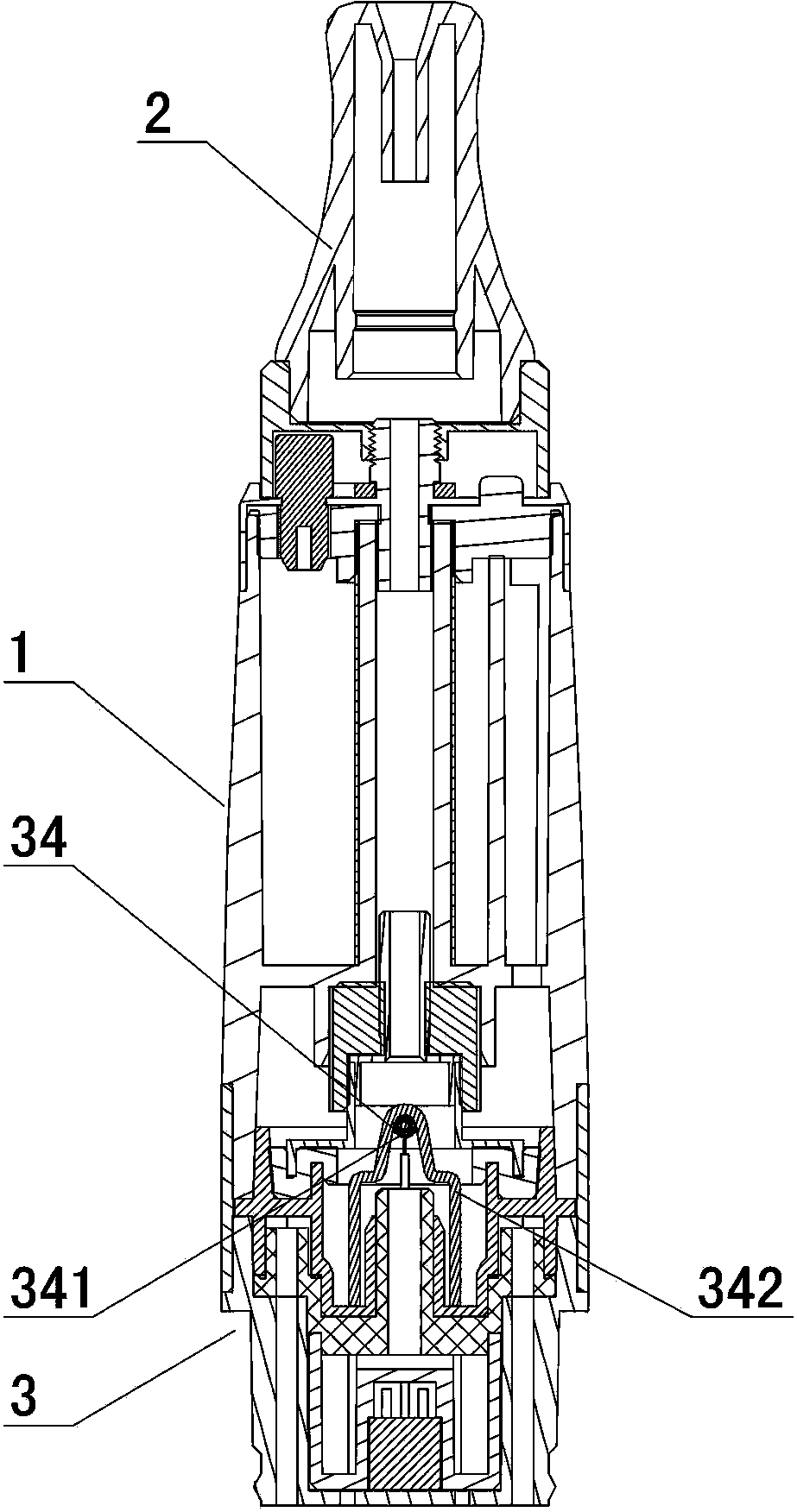

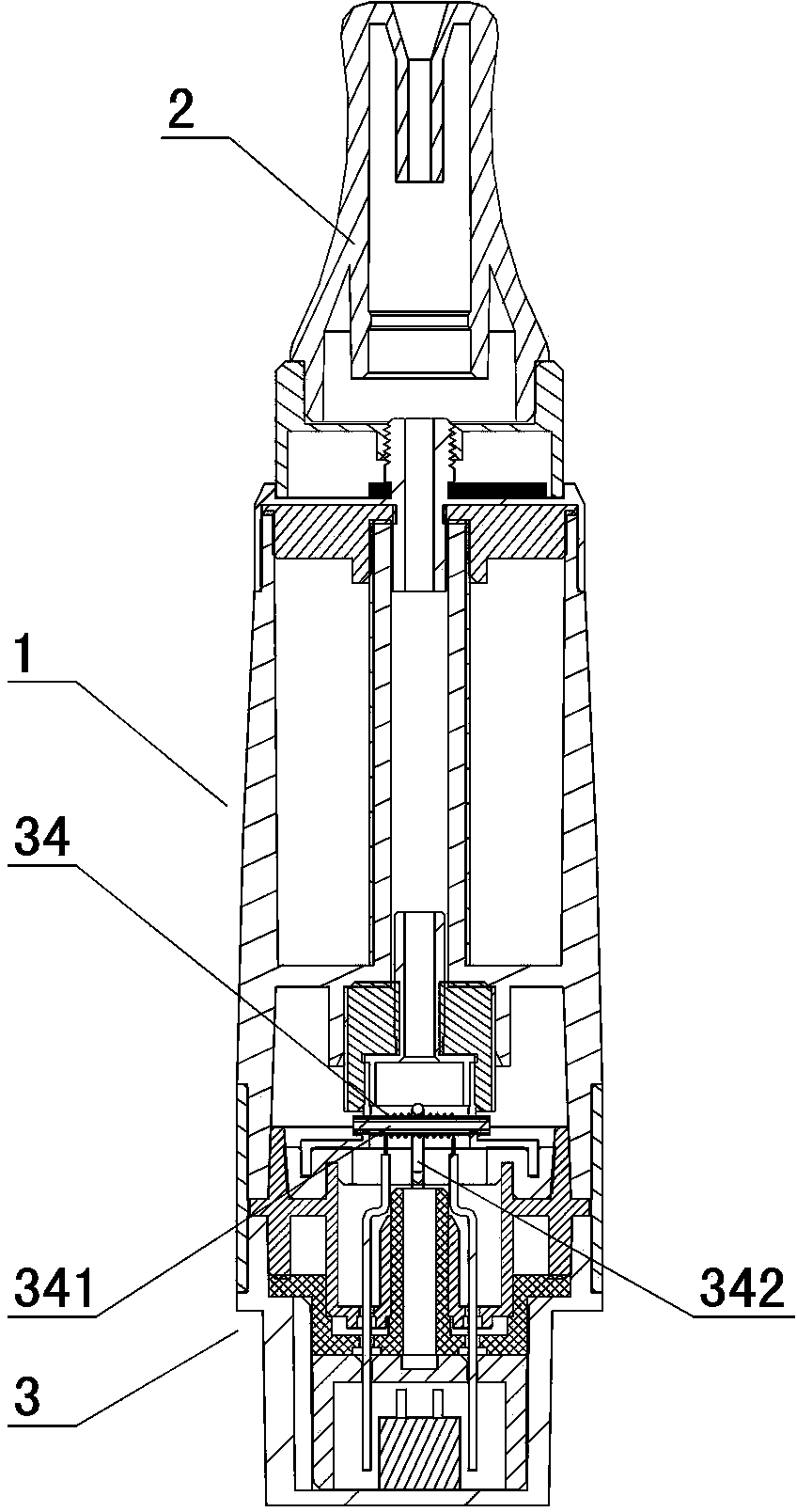

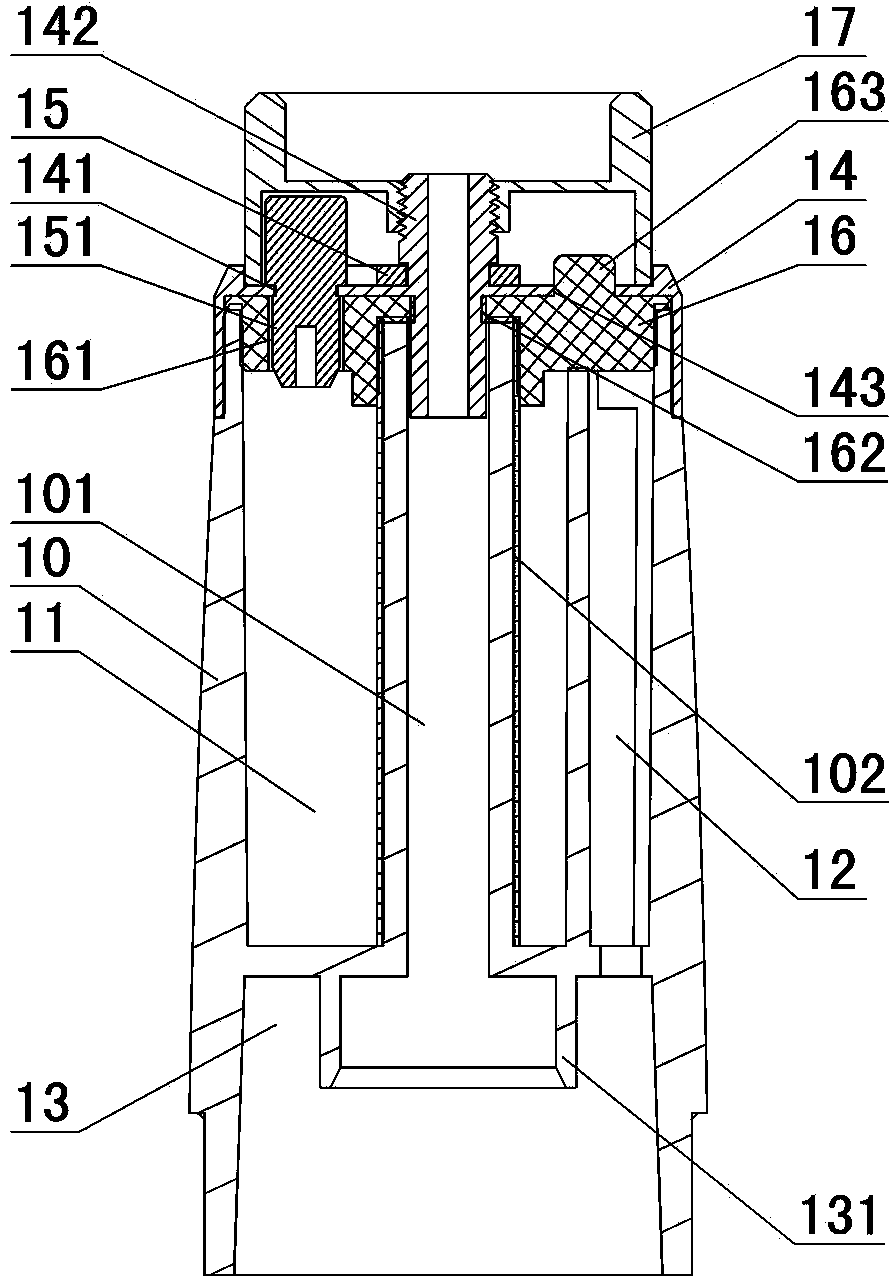

Electronic atomizer

ActiveCN106418714ATo achieve linkage conductionRealize linkage closeTobacco devicesPetroleum engineeringElectric heating

The invention relates to an electronic atomizer which comprises a sucking nozzle, an upper cover, a housing, a lower base, an atomizing tube, an atomizing core, an electric heating seat, a fixing ring, a sealing plug and an adjusting ring. A first installing hole is formed in the middle of the lower base, a first air inlet hole and a second air inlet hole are formed in the electric heating seat and the adjusting ring respectively, the atomizing tube comprises an inner atomizing sleeve and an outer atomizing tube, and a second oil guiding hole and a second oil guiding hole are formed in the side wall of the inner atomizing sleeve and the side wall of the outer atomizing tube respectively. The fixing ring is arranged between the inner atomizing sleeve and the outer atomizing tube and is fixedly connected with the adjusting ring, and the side wall is provided with a third oil guiding hole and a second installing hole corresponding to the second oil guiding hole. The sealing plug matched with the second oil guiding hole in shape is fixed in the second installing hole. The outer wall of the electric heating seat is rotatably sleeved with the adjusting ring. The linkage breakover or closing of an air way and an oil way of the electronic atomizer can be achieved by turning the adjusting ring, and the oil leakage problem of the electronic atomizer can be avoided.

Owner:SHENZHEN HANGSEN STAR TECH +2

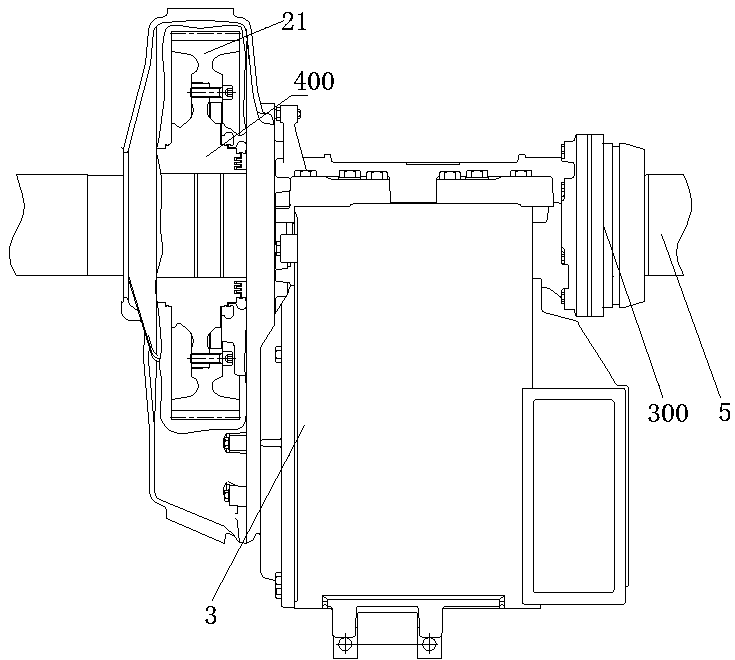

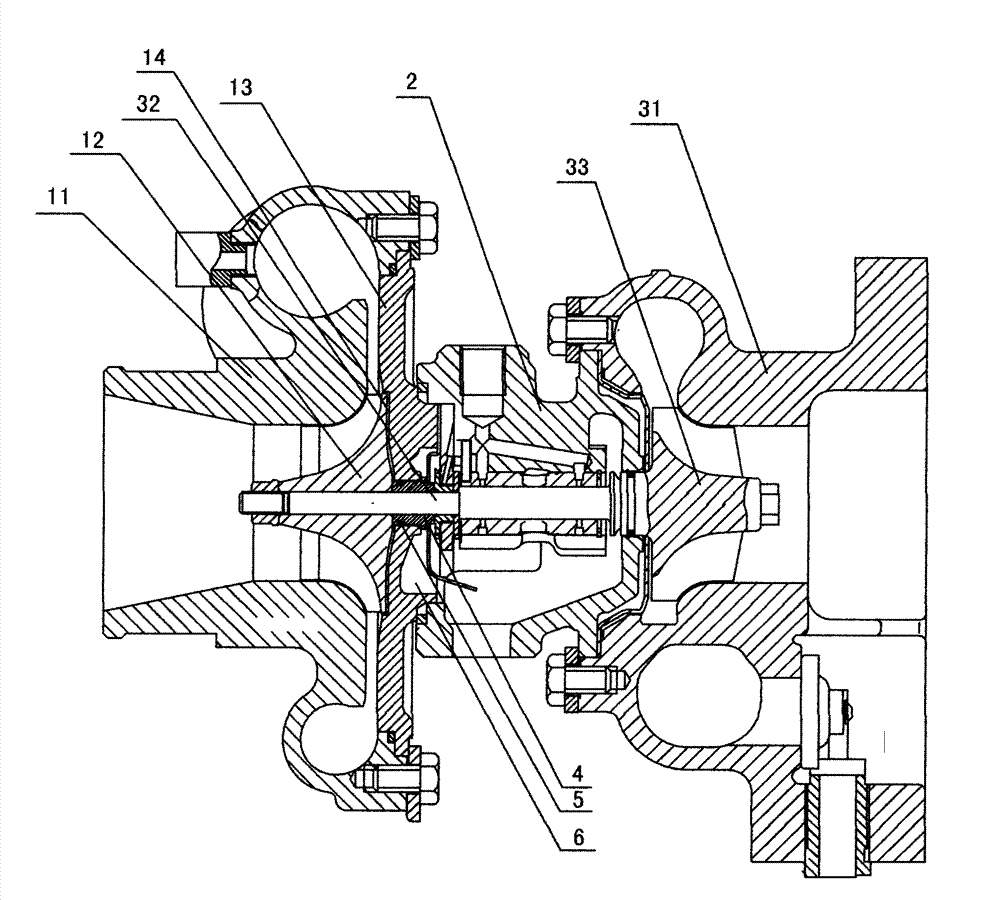

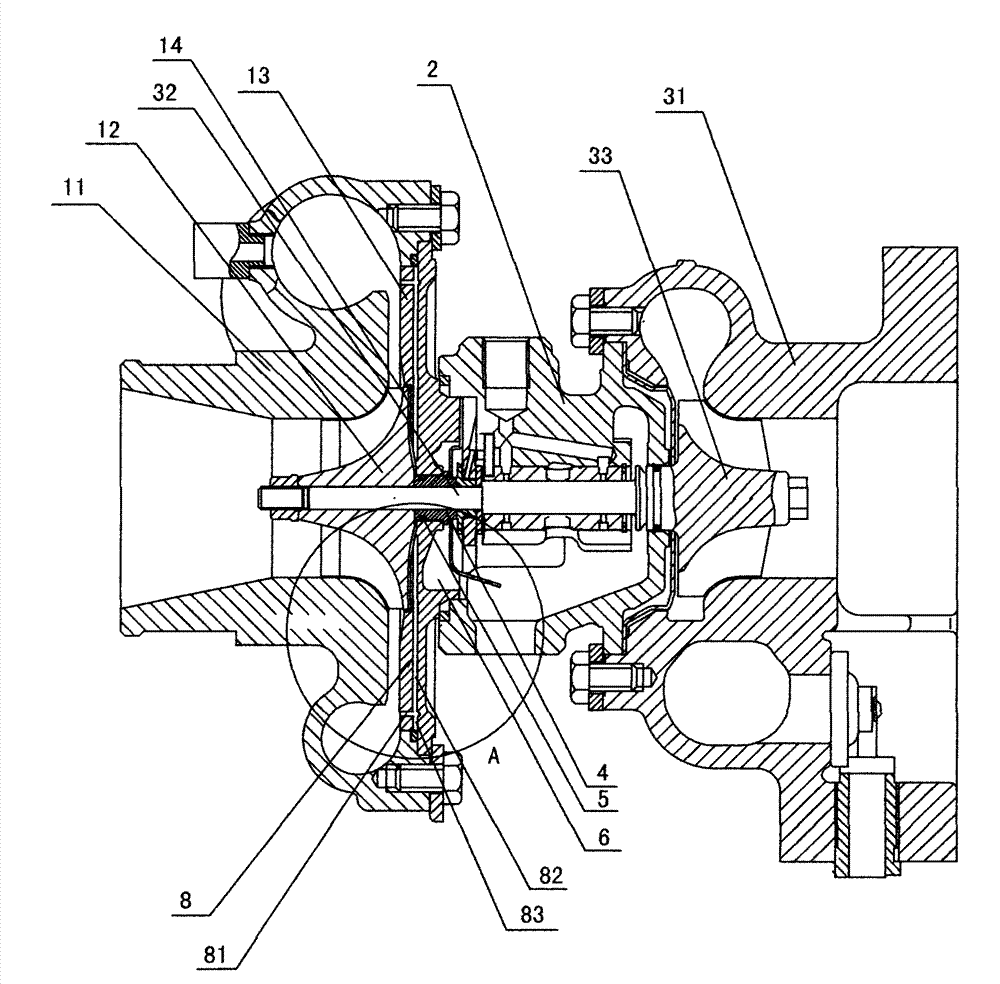

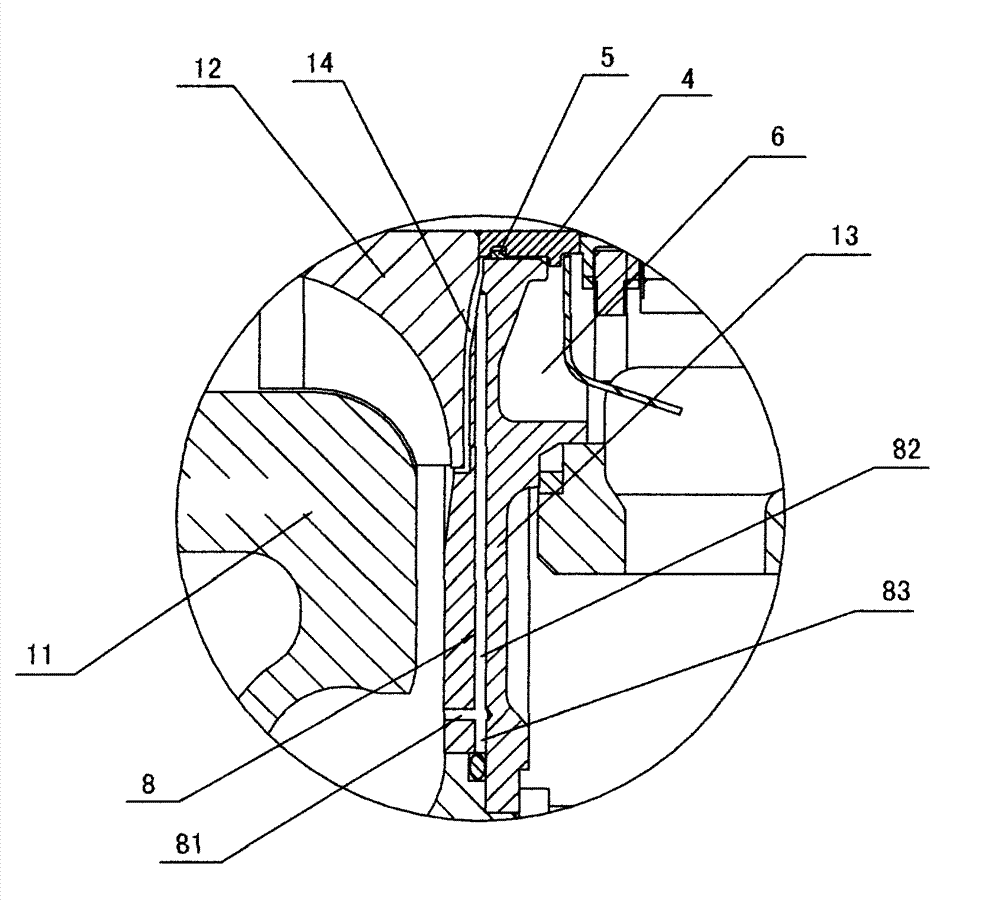

Turbocharger

ActiveCN103174506AReduce negative pressureSolve the oil spill problemInternal combustion piston enginesEngine componentsImpellerAxial symmetry

The invention discloses a turbocharger which comprises a compressor casing, an intermediate body and a turbine casing. A turbine rotating shaft is installed inside the intermediate body. A compressor impeller is fixed at one end of the turbine rotating shaft. A shaft sleeve is sleeved on the turbine rotating shaft. One end of the shaft sleeve contacts the impeller back of the compressor impeller. A compressor back plate is sleeved outside the shaft sleeve. An impeller back gap exists between the impeller back of the compressor impeller and the compressor back plate. Two air through holes are formed in the compressor back plate in an axial symmetry mode. A first end of each air through hole faces the compressor casing. A second end of each air through hole faces the impeller back of the compressor impeller, and is communicated with the impeller back gap. The turbocharger has the advantages that when the turbocharger is in normal work, the pressure of air at the position of the first end of each air through hole is higher than the pressure of air nearby the center of the impeller back of the compressor impeller. Therefore, air can flow to the position of the impeller back of the compressor impeller through the air through holes. The negative pressure at the position of the impeller back of the compressor impeller is reduced, and therefore lubricating oil in a lubricating oil chamber is effectively prevented from being sucked out.

Owner:NINGBO WEIFU TIANLI TURBOCHARGING TECH

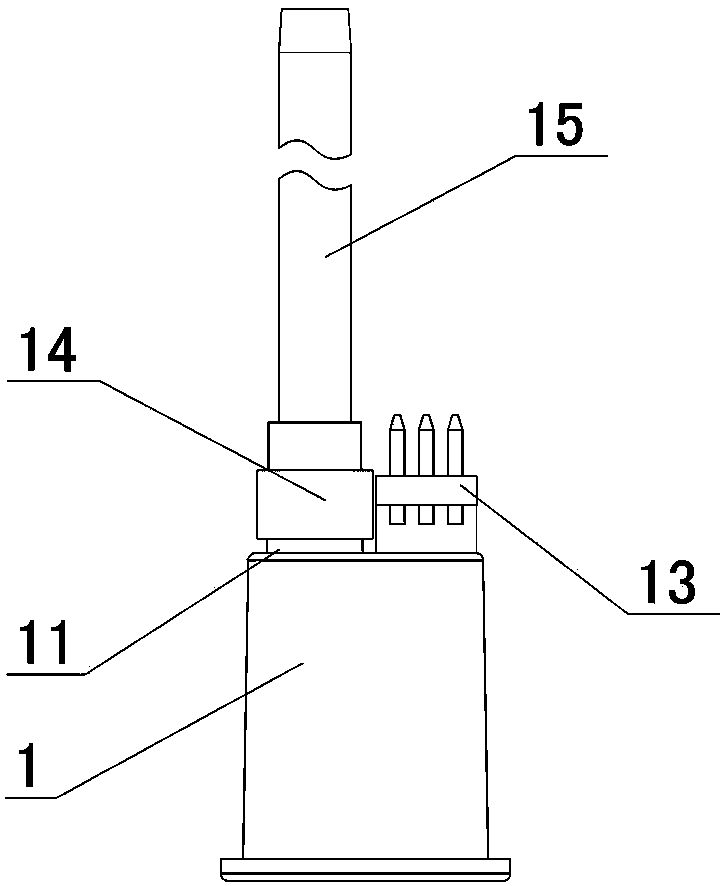

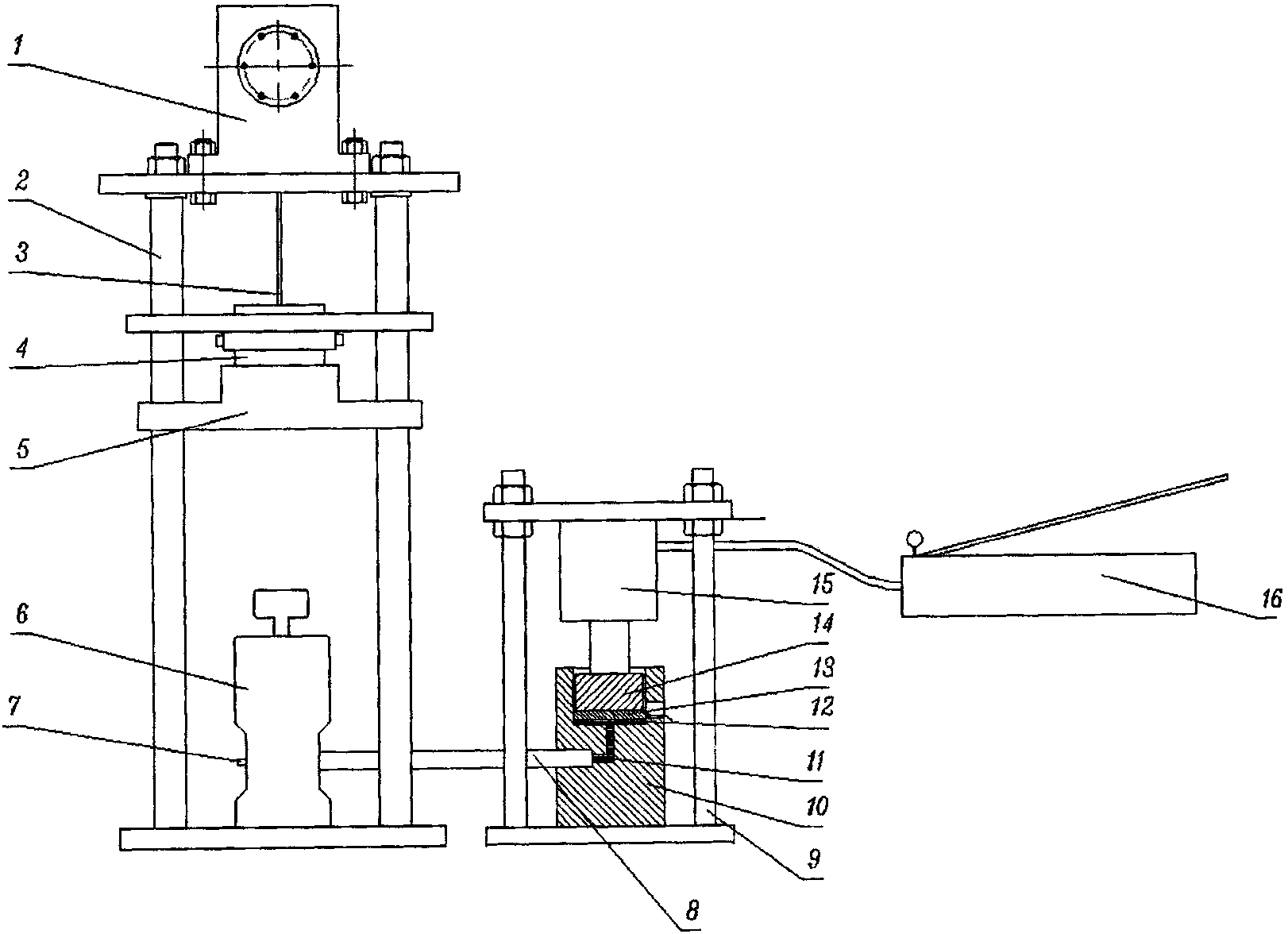

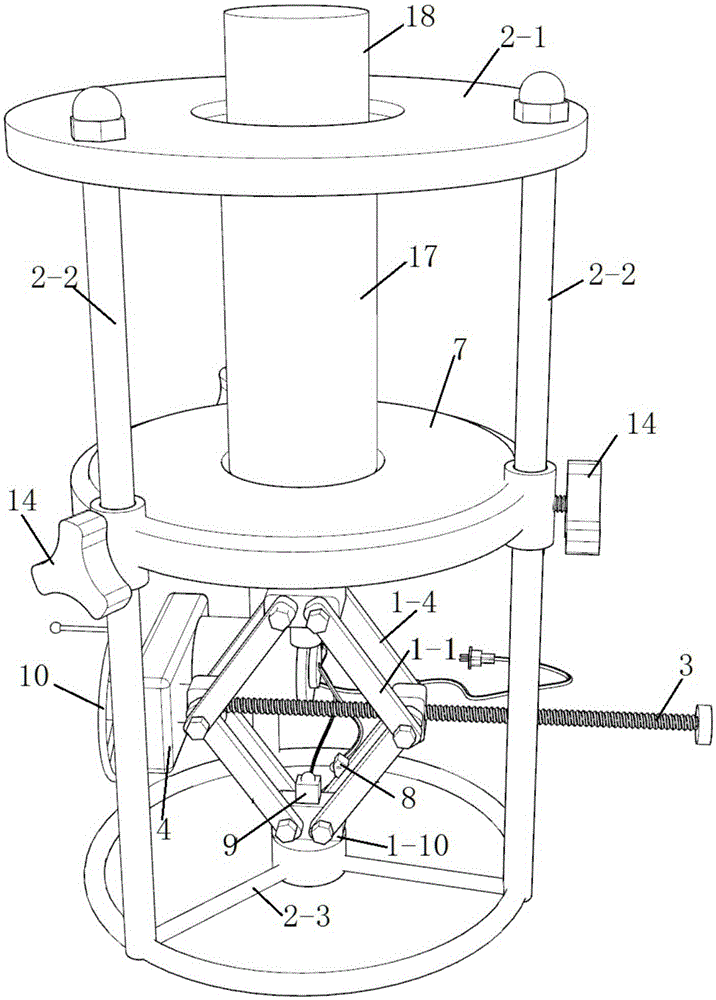

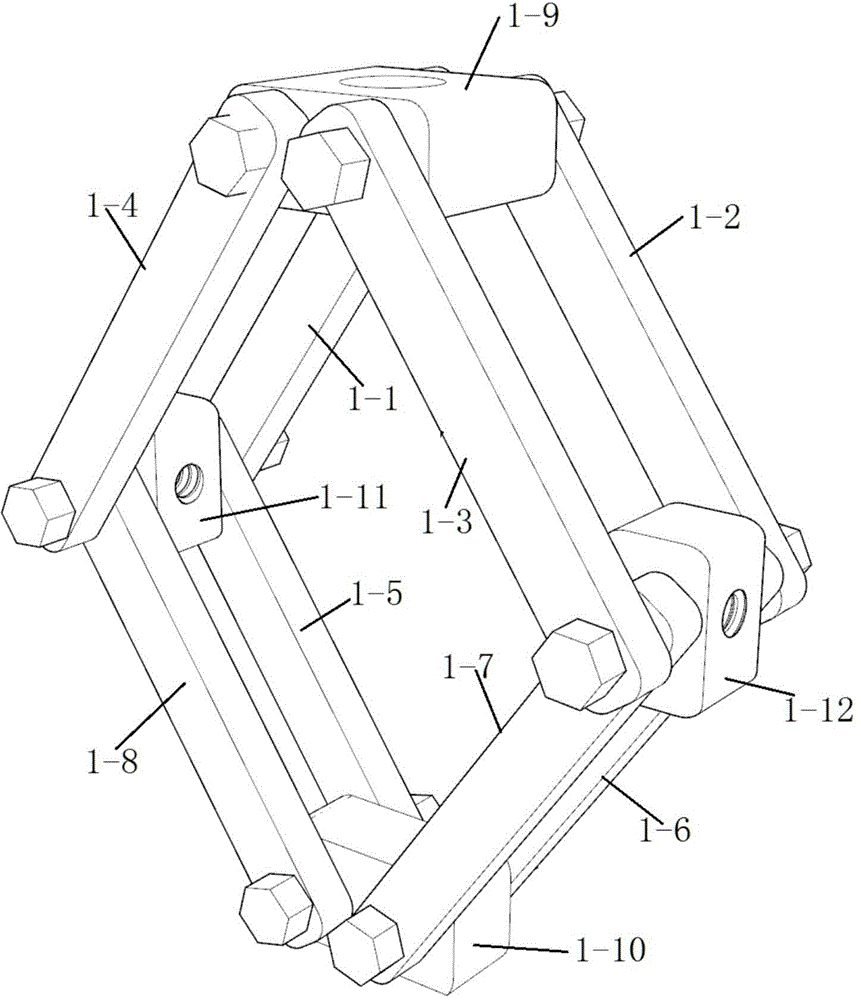

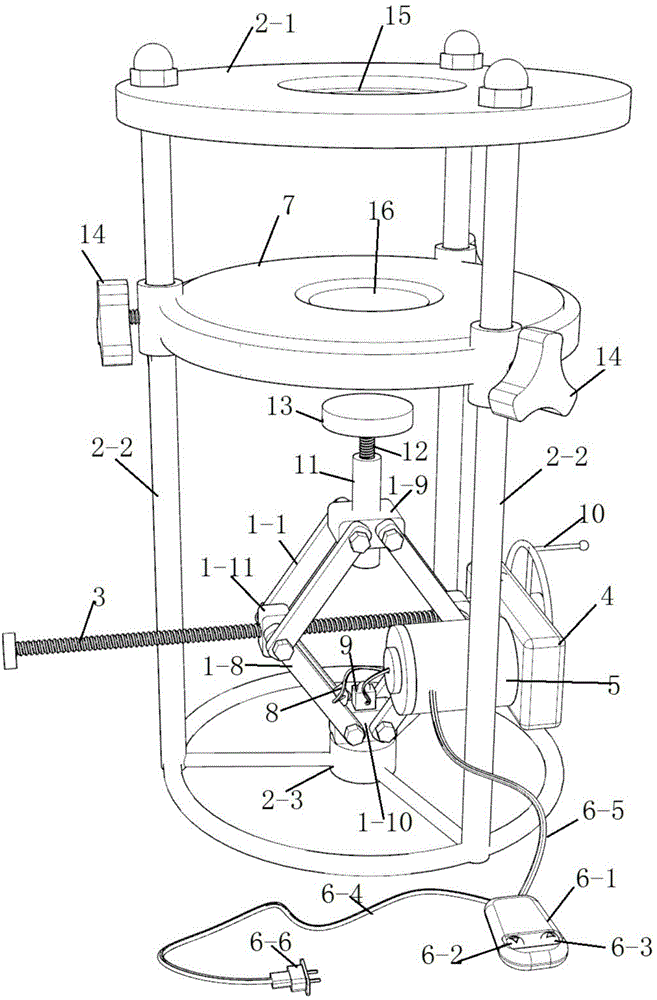

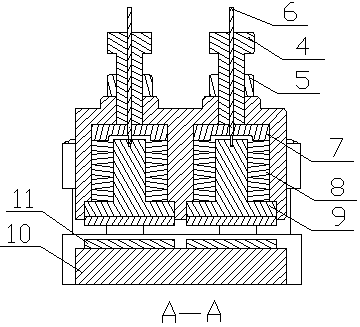

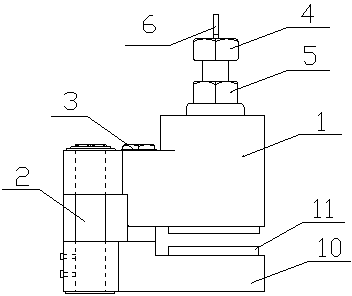

Power-driven and manual integrated specimen demolder

InactiveCN104677705AImprove demoulding efficiencyReduce physical exertionPreparing sample for investigationThreaded pipeElectric machinery

The invention discloses a power-driven and manual integrated specimen demolder. The power-driven and manual integrated specimen demolder comprises a hinge lifting mechanism 1, a support frame 2, a driving screw rod 3, a reduction gearbox 4, a motor 5, a control handle box 6, a lifting supporting plate 7, an upper limiting switch 8, a lower limiting switch 9, a rotary hand wheel 10, an inner thread pipe 11, a lifting screw rod 12, a sample pushing disc 13, a fixed rotary knob 14, an upper demolding hole 15 and a lower demolding hole 16. According to the invention, the integration of power driving and manual operation is adopted, not only can the demolding efficiency be improved and the physical output be relieved, but also manual demolding can be carried out when a power supply is not supplied; two limiting switches are arranged, not only can prevent the driving screw rod from being damaged, but also can prevent the motor from being overloaded; the hinge lifting mechanism can prevent the oil leakage of a hydraulic lifting jack demolder, is high in pushing stroke, and is short in time consumption in pushing by an effective height; ascending and descending operation is coherent, and the operation efficiency is high; the power-driven and manual integrated specimen demolder is simple in structure, low in manufacturing cost, convenient to manufacture and maintain, and convenient to operate.

Owner:武夷学院

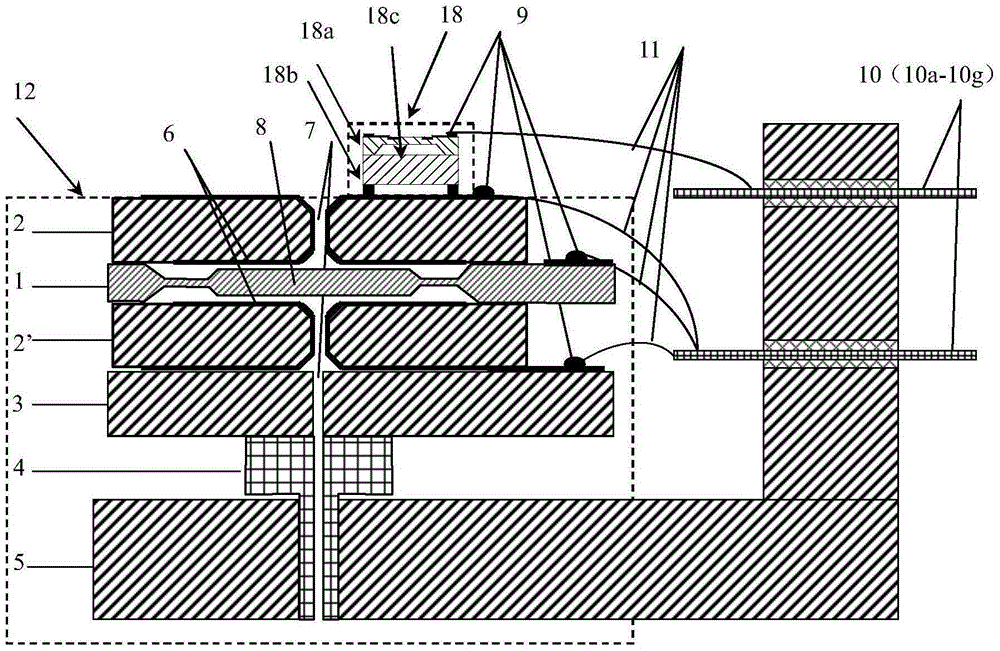

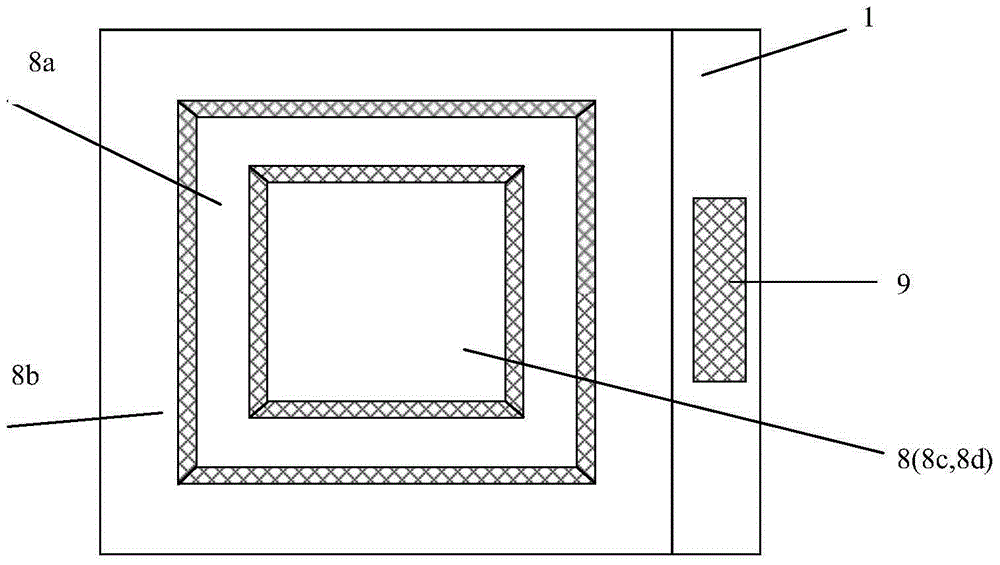

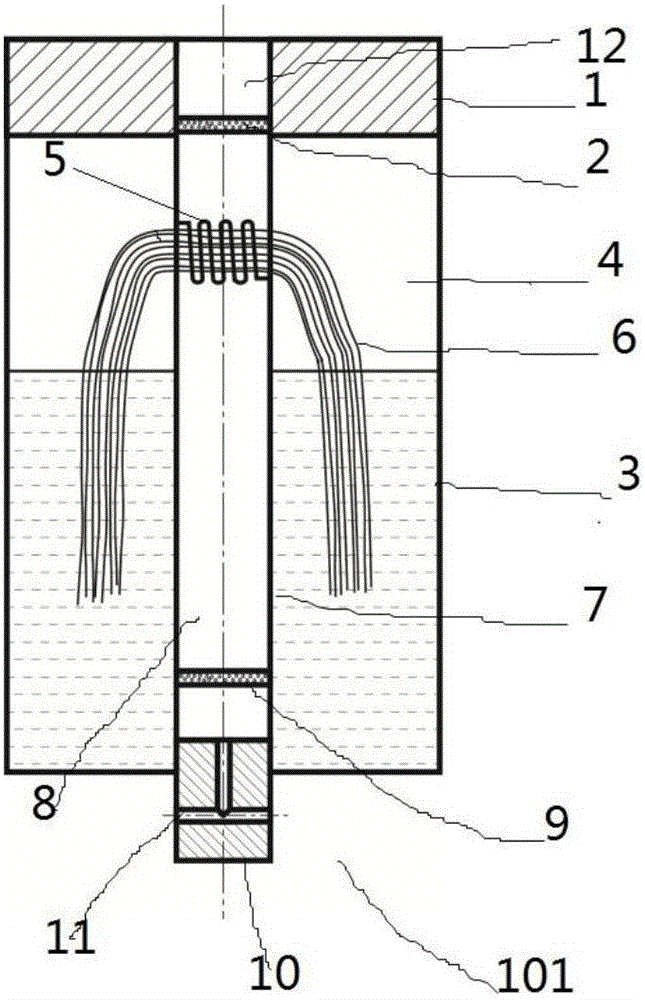

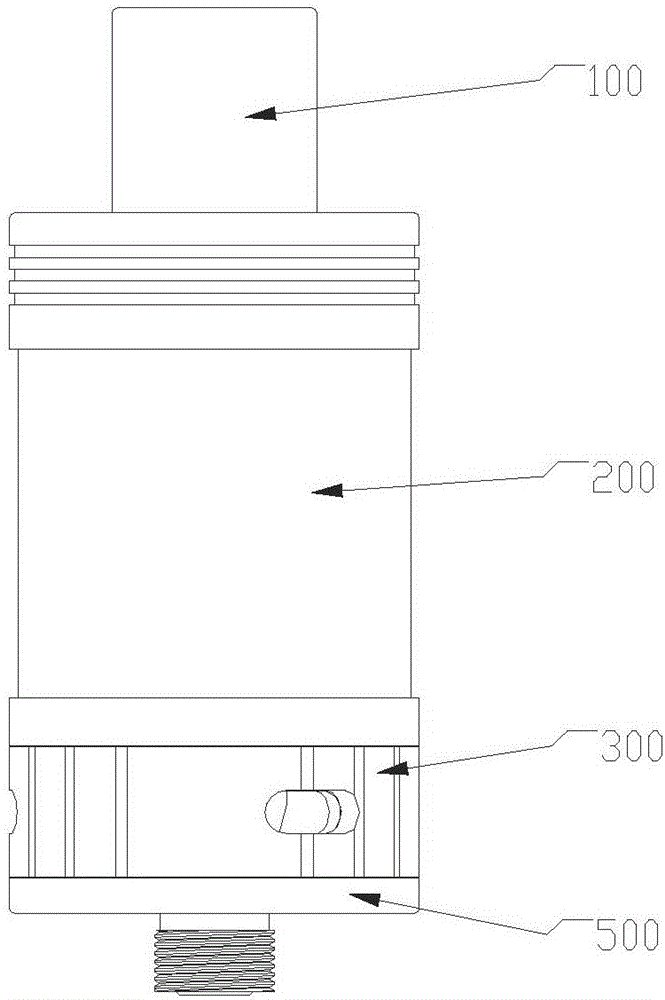

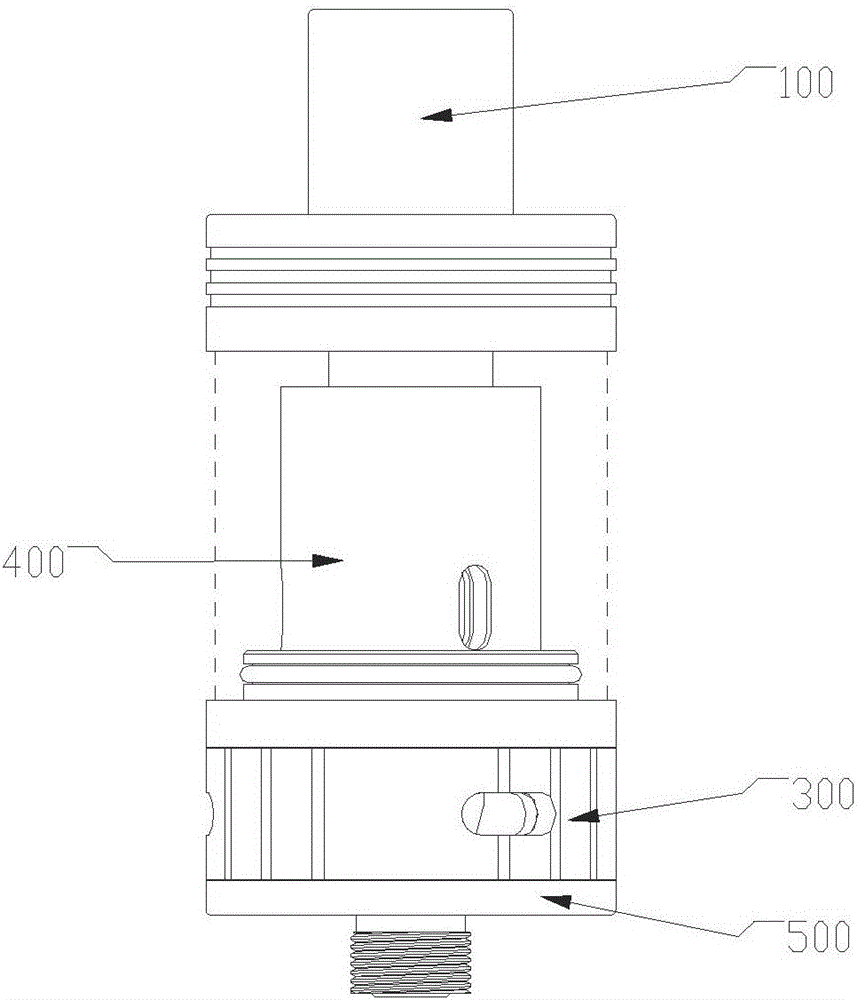

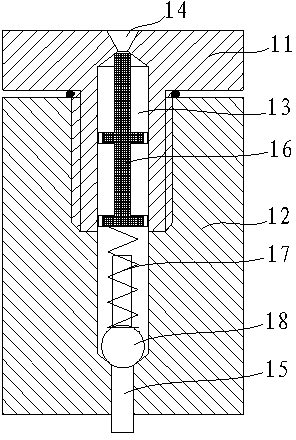

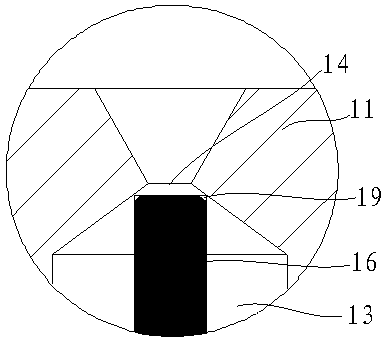

Double cutting feed rotating seal main shaft of honing machine

InactiveCN101347921ASolve the oil spill problemSimple structureHoning machinesEngineeringMachine tool

The invention relates to a main shaft for machine tool, in particular to the double-feeding rotary sealing main shaft of a honing machine; the main shaft comprises a main shaft which can be fixed in a main shaft box in a rotary mode, and a main shaft sleeve sleeved on the main shaft by moveable connection. The main shaft of the invention is characterized in that the main shaft is a hollow shaft; the upper end of the main shaft can be fixed on a supporting frame in a rotary mode, and the lower end of the main shaft can be fixed on the main shaft box in a rotary mode; a rough honing feed cylinder and a finish honing feed cylinder are fixedly arranged on the supporting frame arranged at the upper end of the main shaft and are concentric with the main shaft; a finish honing push rod in the finish honing feed cylinder is sheathed in a hollow rough honing push rod for rough honing feed cylinder, and the finish honing push rod and the hollow rough honing push rod are arranged in the hollow main shaft; a reciprocating cylinder which drives the main shaft to make reciprocating beeline motion is fixed on the main shaft box, and the upper end of a piston rod in the reciprocating cylinder is fixedly connected to the supporting frame. As the structure and the motion form of the main shaft are changed, the problem of oil leakage of a sealing clamp for honing machine is fundamentally solved. Thus, the structure of the sealing clamp and that of the main shaft become simpler and more reasonable.

Owner:NINGXIA YINCHUAN DAHE CNC MACHINE

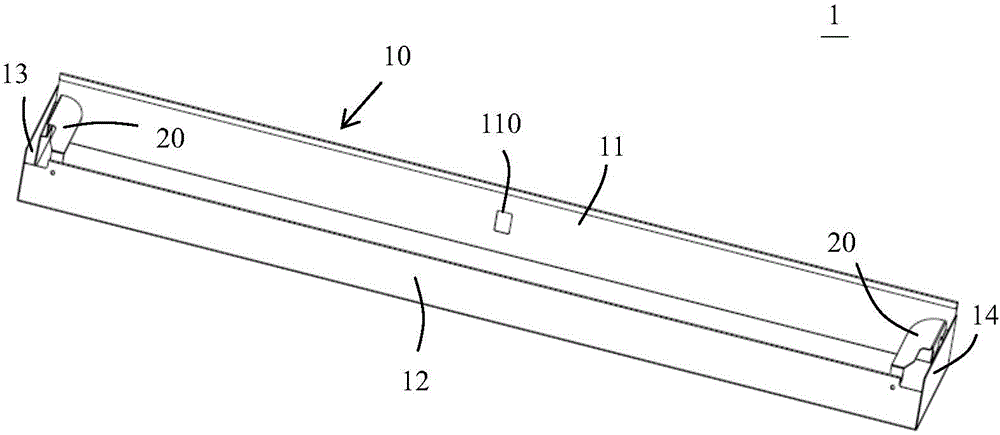

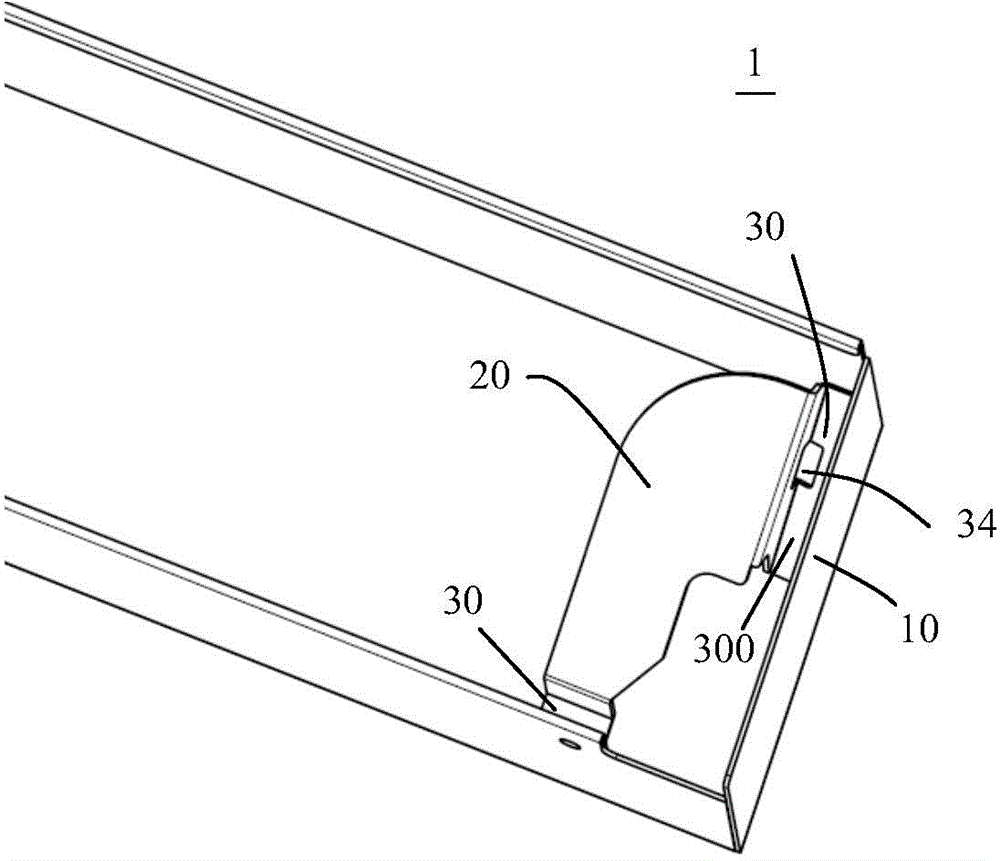

Flatness detection device and detection method

Owner:柳州上汽汽车变速器有限公司

Extractor hood and oil cup thereof

ActiveCN104421993ASolve the oil spill problemImprove satisfactionDomestic stoves or rangesLighting and heating apparatusWaste oilPetroleum engineering

The invention provides an extractor hood and an oil cup thereof, wherein the top of the oil cup is provided with an opening, the oil cup comprises a side wall enclosing the opening and a first fixing member positioned in the side wall and used for fixing the oil cup on the extractor hood. The oil cup further comprises an oil leakage preventing part, wherein the oil leakage preventing part is connected between the side wall and the first fixing member, and provided with a concave space which is adjacent to the side wall and lower than the top end of the side wall. According to the oil cup, the oil leakage preventing part is arranged between the side wall and the first fixing member, therefore, waste oil dropping in the first fixing member can not directly overflow from the top end of the side wall and can flow in the concave space of the oil leakage preventing part, and finally is guided inside the oil cup, so that the problem of oil leakage of an existing oil cup is solved.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

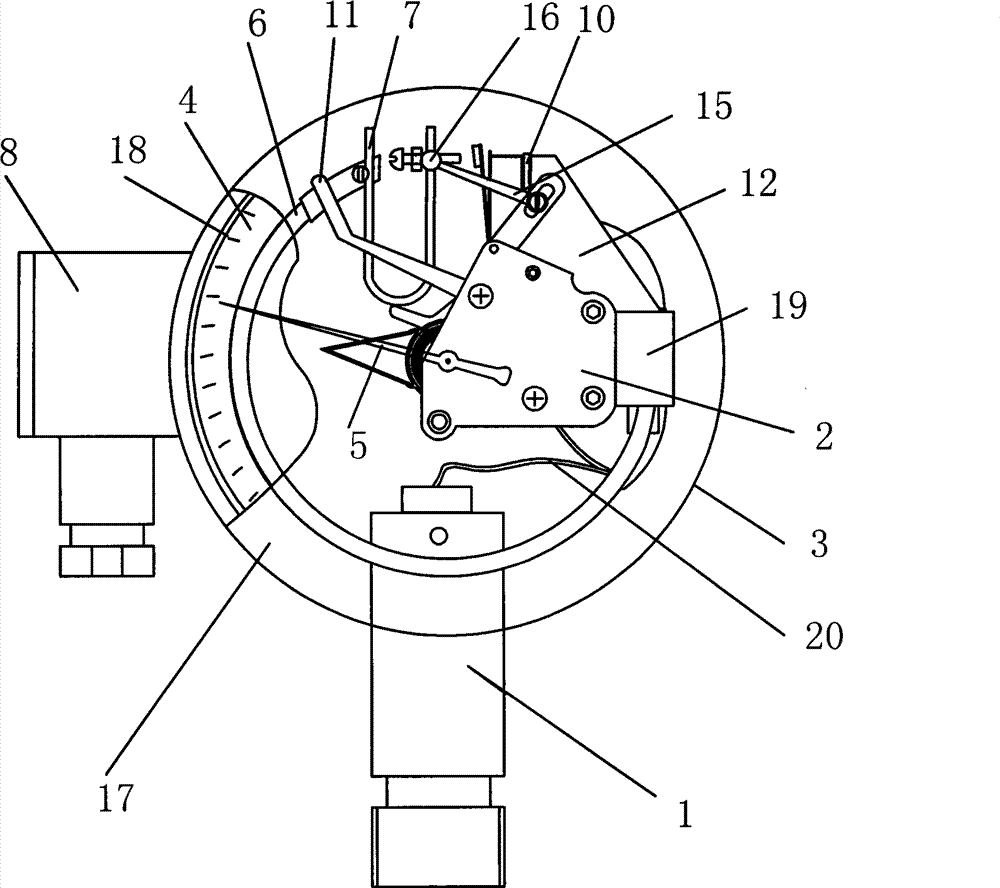

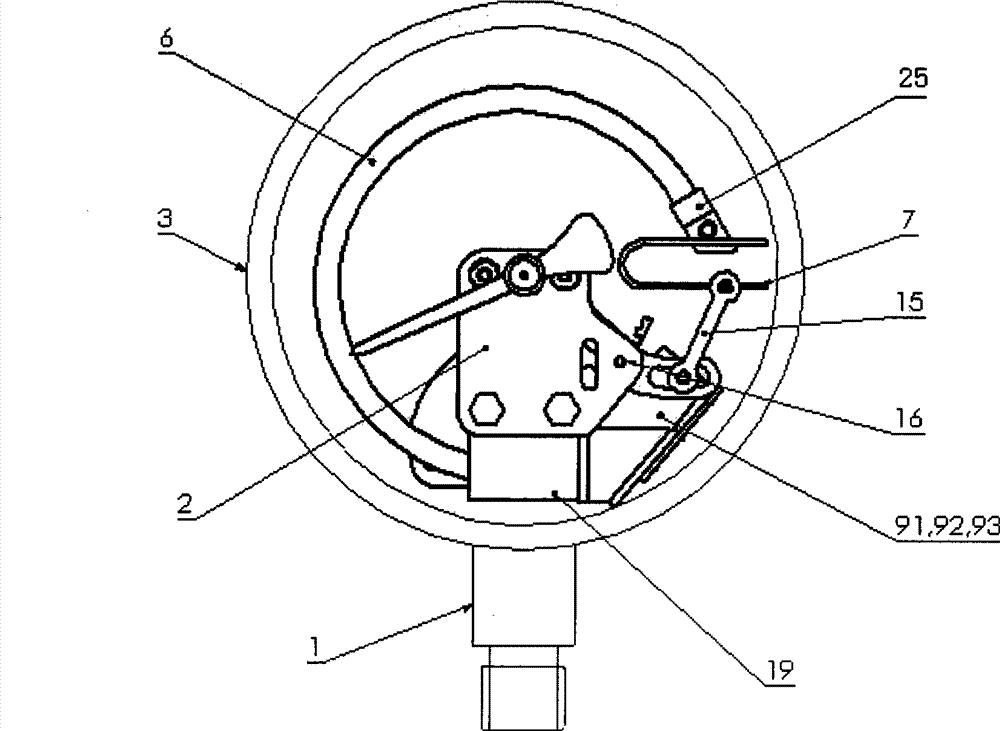

Vibration resistant pointer type SF6 gas density controller

ActiveCN101387891BPrecise positioningImprove the limit effectSwitchgear arrangementsRatio controlElectrical devicesEngineering

Owner:SHANGHAI ZHUODIAN ELECTRIC +1

Mechanical yaw brake

InactiveCN103697088ASimple structureSolve the oil spill problemAxially engaging brakesBraking elementsBrakeClassical mechanics

The invention discloses a mechanical yaw brake comprising an upper clamp box and a lower clamp box. The upper clamp box and the lower clamp box are fixedly connected together through bolts. The mechanical yaw brake further comprises moving pins penetrating the upper and lower clamp boxes. At least one fitting set of compressing pin, ejector block and disc spring is mounted inside the upper clamp box. Two ends of each disc spring are abutted to the corresponding compressing pin and the ejector block respectively. A locking nut and an adjusting bolt are arranged above each compressing pin. The upper end of each ejector block is provided with a central fitting hole, each compressing pin is provided with a central fitting hole, and each locking nut is also provided with a central fitting hole, wherein a marker rod is disposed in the fitting holes, one end of the marker rod is fixedly connected with the ejector block, the other end of the marker rod is exposed out of the locking nut, and the part, close to the locking nut, of the marker rod is provided with a visual mark line. The mechanical yaw brake is simple in structure, hydraulic oil is not required, and the oil leakage problem is substantially solved; checking pre-tightening force through indication of the marker rods is required only, maintenance is convenient, and the service life of the mechanical yaw brake is long.

Owner:CHANGSHA EASTAR MACHINERY

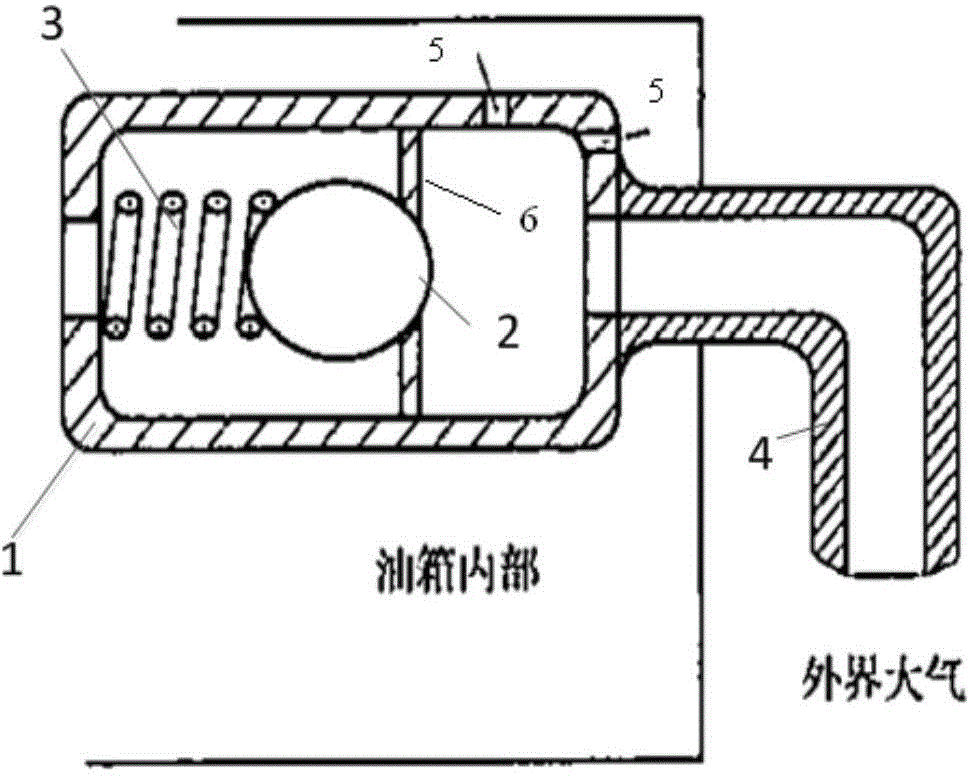

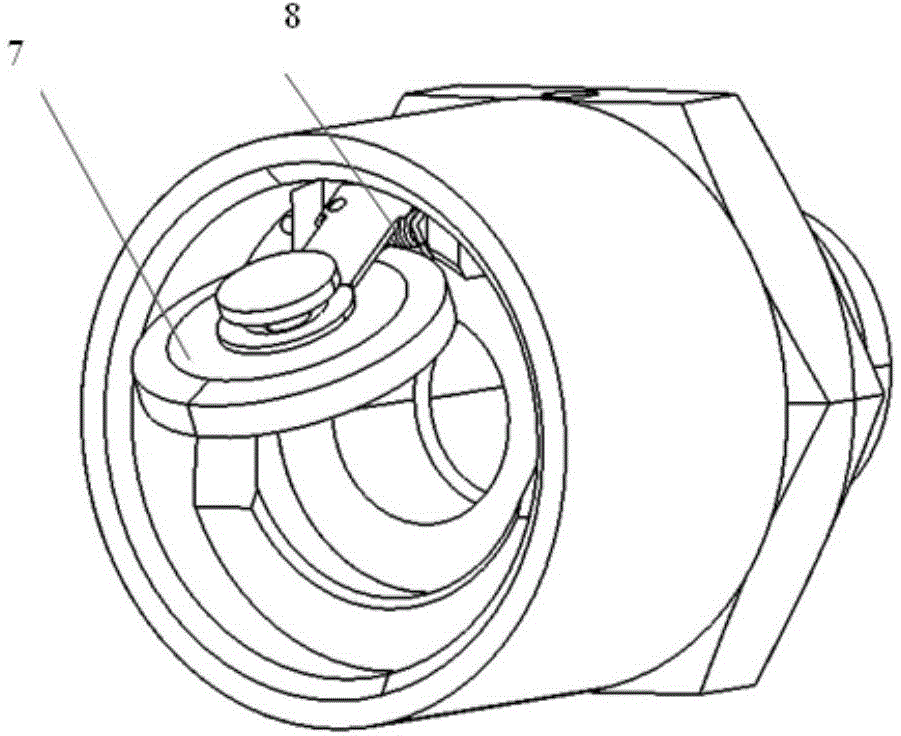

Two-way ventilation device for universal airplane wing fuel tank ventilation system

The invention belongs to the technical field of universal airplane wing fuel tank ventilation and relates to a two-way ventilation device for a universal airplane wing fuel tank ventilation system. The two-way ventilation device is of a pure mechanical structure and is mainly composed of a shell, a valve assembly, a spring and the like. The airplane climbing exhausting function and the function that a valve is opened to supplement air when negative pressure exists in a fuel tank in the descending process can be achieved. When an airplane rolls and flies at a large angle, the valve assembly is closed, and therefore the problem that a large amount of fuel of the fuel tank leaks through a ventilation pipe is solved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Novel domestic alcohol oil burner

The invention discloses a novel domestic alcohol oil burner which comprises a base, a straight spray nozzle, a big-end-down fire collection cover, a fire distribution cap and a sound insulation barrel, wherein an air inlet is formed in the base, the straight spray nozzle is installed in the center of the base, the top and the side face of the fire distribution cap are provided with fire distribution holes respectively, and the sound insulation barrel is installed on the base and surrounds around the fire collection cover and the fire distribution cap. The upper end of the sound insulation barrel is provided with a fire tray extending out of the barrel. According to the novel domestic alcohol oil burner, the straight spray nozzle is utilized for sufficiently spraying out alcohol oil in an atomization mode, the spraying force of the nozzle is greatly reduced, fire power is prevented from being too excessive, balance distribution of fire power is achieved through the fire collection effect of the fire collection cover and the fire distribution effect of the fire distribution cap, the fire spraying mode is more scientific and reasonable on the condition that the heat value is not lowered, the requirement for domestic miniaturization can be met, the sound insulation barrel can effectively prevent noise produced when the novel domestic alcohol oil burner is used from diffusing and can also play a certain fire collection role, and multiple problems in the prior art are effectively solved.

Owner:张建忠

Rotary oil cylinder capable of preventing travel regulation rod from falling

ActiveCN104389847AInhibit sheddingSolve the oil spill problemFluid-pressure actuatorsEngineeringMechanical engineering

The invention provides a rotary oil cylinder capable of preventing a travel regulation rod from falling, and aims to solve a problem that the travel regulation rod falls. The rotary oil cylinder has key points that the diameter of a polish rod is greater than the diameter of a screw on each travel regulation rod, and a seam allowance structure is formed by the polish rod and an aperture. Since the seam allowance structure is arranged, even if threads on the travel regulation rod fail, the travel regulation rod does not fall from an oil cylinder spacing end cover. The rotary oil cylinder has the active effects that insecurity caused by that the travel regulation rod falls is avoided, and meanwhile, an oil leakage problem generated since the travel regulation rod falls can be avoided.

Owner:SHENYANG NORTHEAST ELECTRIC POWER CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com