Flatness detection device and detection method

A technology for flatness detection and flatness, which is applied to measuring devices, instruments, etc., to achieve fast and accurate detection, simple structure, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will further explain and describe the flatness detection device and detection method involved in the present invention with reference to the drawings and specific implementations of the specification, but the explanation and description do not constitute an improper limitation of the technical solution of the present invention.

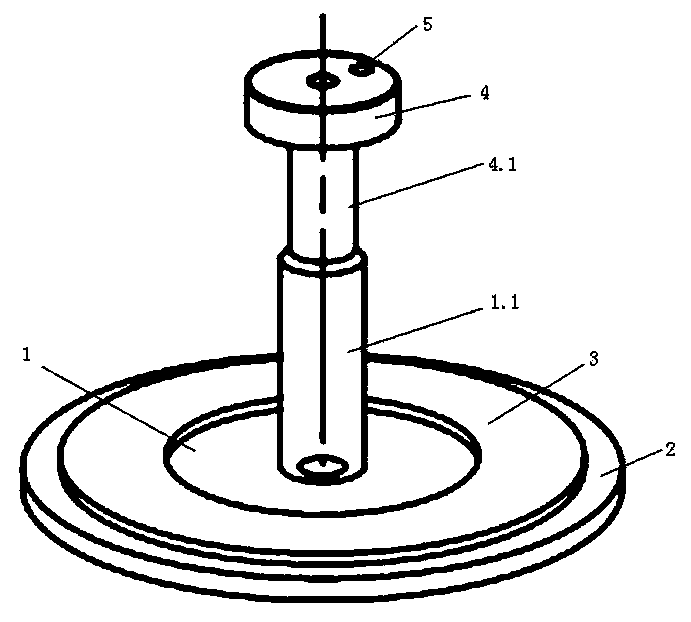

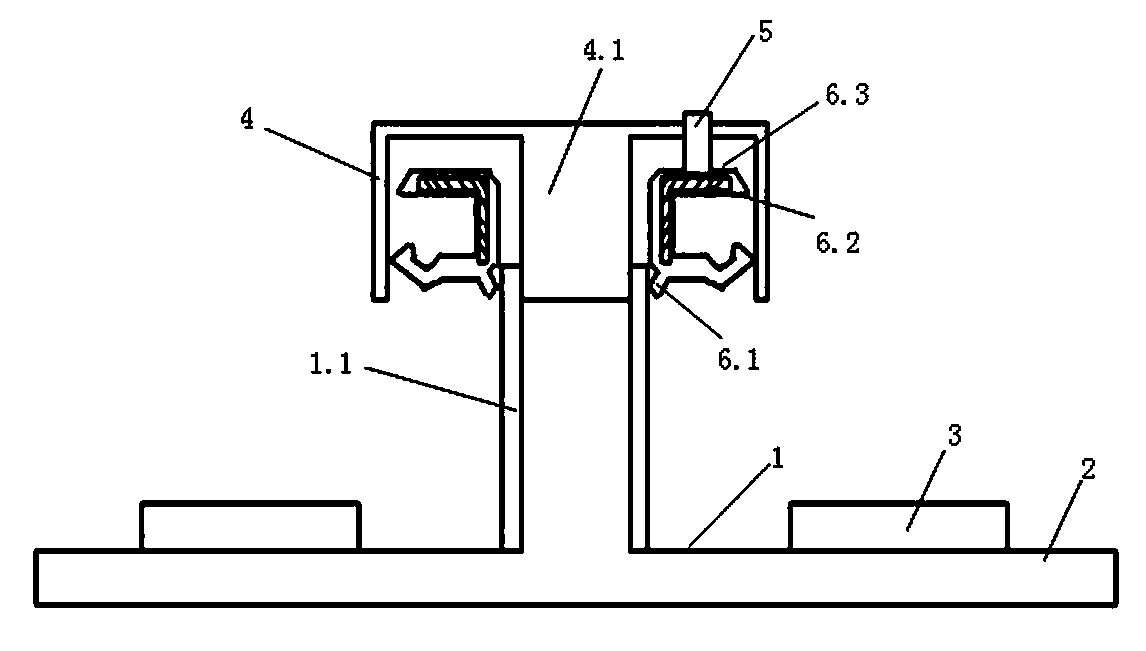

[0018] Such as figure 1 As shown, the present invention provides a flatness detection device, including a detection platform 1, a dial and a rotating body 4, the rotating body 4 is provided with a probe 5, the dial includes a large dial 2 and a small dial 2, the detection platform 1 and a large dial 2 is an integrally formed disc, and the small dial 3 is arranged above the large dial 2 and is the same as the center of the large dial 2.

[0019] A sleeve 1.1 for fixing the oil seal to be tested is provided at the center of the testing platform 1.

[0020] The rotating body 4 has a rotating shaft 4.1, and the rotating shaft 4.1 is movably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com