Tar leakage prevention electronic cigarette atomizer

An electronic cigarette atomizer and anti-oil leakage technology, which is applied in the field of electronic cigarettes, can solve the problems of complex structure and difficult control of the amount of smoke oil added to the heating device, and achieve the effect of convenient processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

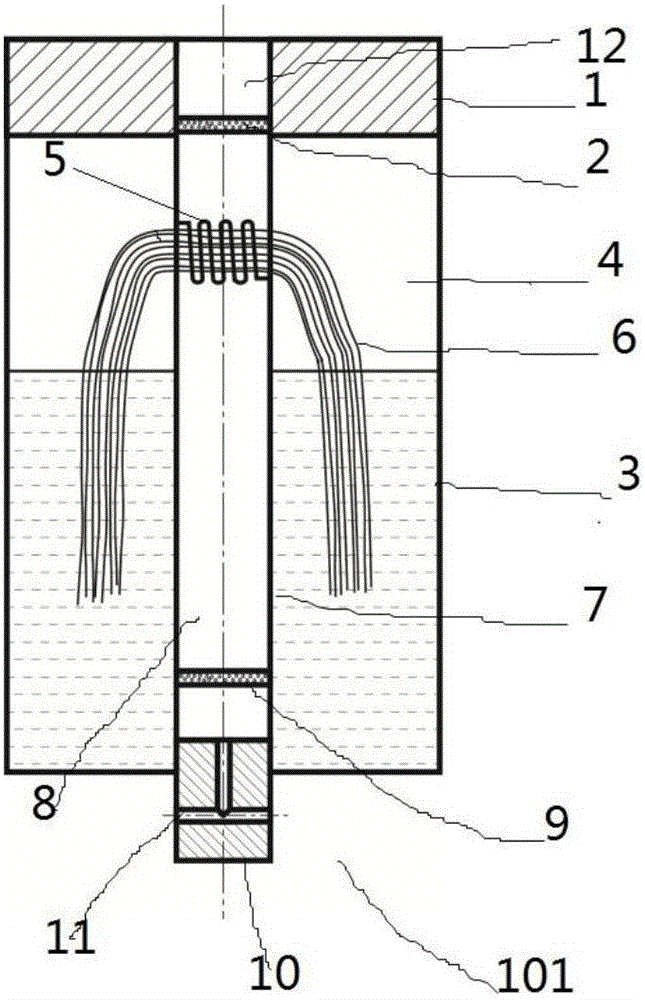

[0024] An oil-leakage-proof electronic cigarette atomizer, which includes a housing 3 with an air inlet 11 and an air outlet 12 in the middle of both ends, and the housing 3 includes a first oil-leakage film 2 and a The vent pipe 7 of the second anti-leakage film 9, and the oil storage chamber 4 surrounded by the outer wall of the vent pipe 7 and the inner wall of the housing 3, the first anti-leakage film 2 and the second anti-leakage film There are micropores on the anti-leakage film 9, and the aperture of these micropores allows gas to pass through but does not allow liquid to pass through.

[0025] In a preferred embodiment of the present invention, the ventilation pipe 7 also has a heating body 5 inside.

[0026] In this embodiment, the heating body 5 is wrapped by the oil guiding member 6 .

[0027] In this embodiment, the first oil leakage prevention film 2 and the second oil leakage prevention film 9 are each independently separated from the end of the housing 3 by a ...

Embodiment 2

[0034] An oil-leakage-proof electronic cigarette atomizer, which includes a housing 3 with an air inlet 11 and an air outlet 12 in the middle of both ends, and the housing 3 includes a first oil-leakage film 2 and a The vent pipe 7 of the second anti-leakage film 9, and the oil storage chamber 4 surrounded by the outer wall of the vent pipe 7 and the inner wall of the housing 3, the first anti-leakage film 2 and the second anti-leakage film There are micropores on the anti-leakage film 9, and the aperture of these micropores allows gas to pass through but does not allow liquid to pass through.

[0035] In a preferred embodiment of the present invention, the ventilation pipe 7 also has a heating body 5 inside.

[0036] In this embodiment, the heating body 5 is covered by the oil guide 6 .

[0037] In this embodiment, the first oil leakage prevention film 2 and the second oil leakage prevention film 9 are respectively attached to the end of the housing 7 independently.

[0038...

Embodiment 3

[0044] An oil-leakage-proof electronic cigarette atomizer, which includes a housing 3 with an air inlet 11 and an air outlet 12 in the middle of both ends, and the housing 3 includes a first oil-leakage film 2 and a The vent pipe 7 of the second anti-leakage film 9, and the oil storage chamber 4 surrounded by the outer wall of the vent pipe 7 and the inner wall of the housing 3, the first anti-leakage film 2 and the second anti-leakage film There are micropores on the anti-leakage film 9, and the aperture of these micropores allows gas to pass through but does not allow liquid to pass through.

[0045] In this embodiment, the heating body 5 is penetrated by the oil guiding member 6 .

[0046] In this embodiment, the first oil leakage prevention film 2 and the second oil leakage prevention film 9 are each independently separated from the end of the housing 7 by a certain distance.

[0047] In this embodiment, the housing 3 has an electrical connector 10 and a mouthpiece 1 outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com