Mechanical yaw brake

A yaw brake, mechanical technology, applied in the direction of the brake type, axial brake, brake components, etc., can solve the problems of piston wear, engine room oil pollution, oil cylinder oil leakage, etc., to solve the oil leakage problem and improve the service life Long, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

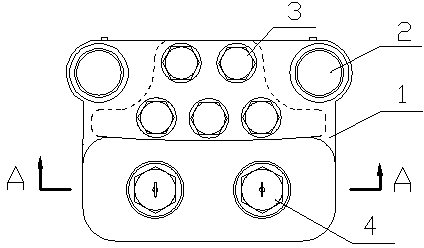

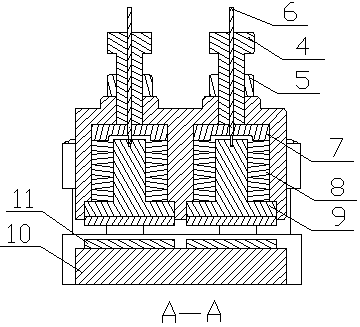

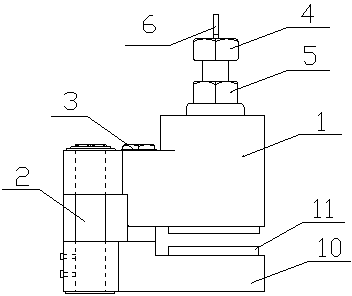

[0014] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a mechanical yaw brake includes an upper tong box 1 and a lower tong box 10, and the upper and lower tong boxes are fixedly connected together by five M24×160 bolts 3; The movable pin 2 of the lower clamp box and the lower clamp box; two sets of matching pressing pins 7, top clamping blocks 9 and disc springs 8 are installed in the upper clamp box, and the two ends of the disc spring 8 are respectively pressed against Push the pressing pin 7 and the pressing block 9; above the pressing pin 7, be provided with a lock nut 4 and an adjusting bolt 5 for adjusting the pressing force of the pressing pin 7; The upper end of the jacking block 9, the center of the pressing pin 7 and the locking nut 4 are provided with a matching hole, and a marking rod 6 is installed in the matching hole, and one end of the marking rod 6 is connected to the top tight The block 9 is fixedly connected, and the other end is expose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com