Bogie

A bogie and frame technology, applied in the field of bogies, can solve the problems of increasing the complexity of the gearbox structure, the uncertain change of the gearbox air pressure distribution, and the increased risk of gearbox oil leakage, so as to ensure lateral stability and ensure Safe operation, solve the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

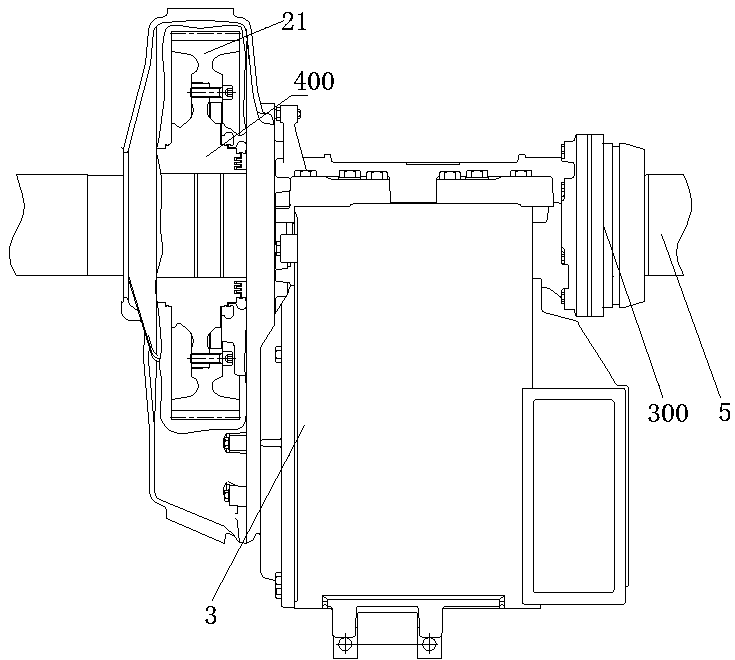

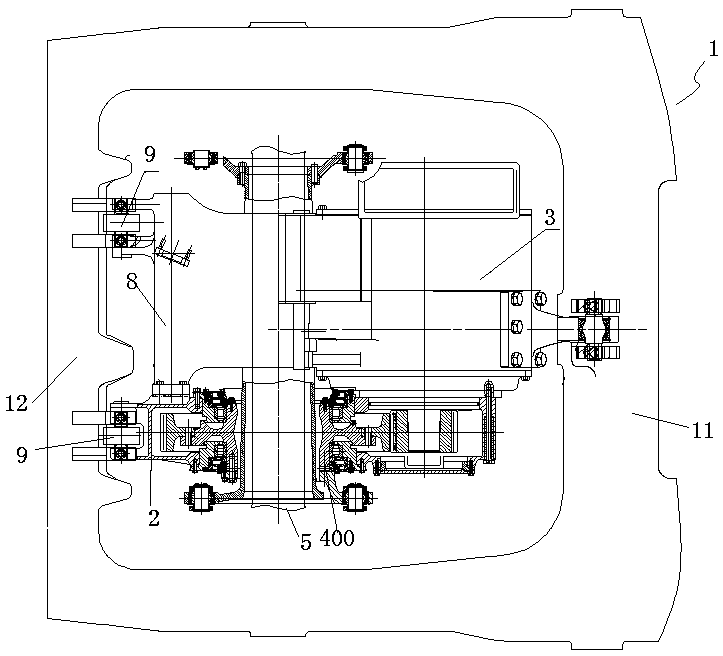

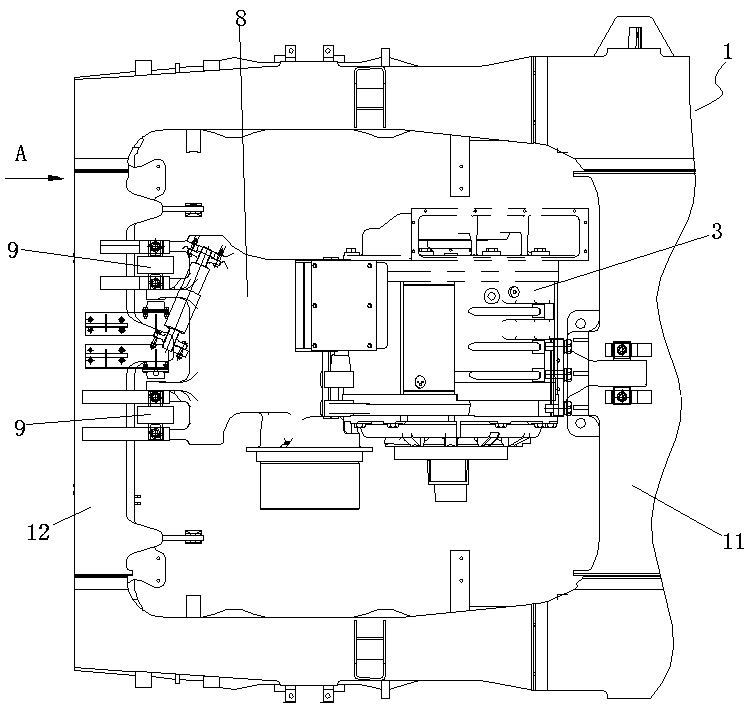

[0034] Such as Figure 3-6 As shown, a bogie includes a frame 1, a gearbox 2, a traction motor 3, a wheel set 4 and an axle 5 arranged at the bottom of the frame 1, a six-link hollow shaft, and a suspension beam 8. The hollow shaft 6 of the six-link hollow shaft is sleeved on the axle 5 .

[0035] The suspension crossbeam 8 includes a beam body 81 , a through groove 82 arranged transversely on the beam body 81 , and a bearing seat 83 cantilevered laterally at the notch at one end of the through groove 82 and fixedly connected with the beam body 81 . The bearing seat 83 is integrally formed with the beam body 81 .

[0036] Along the longitudinal direction, one end of the beam body 81 with the through groove 82 is fixedly connected with the traction motor 3, and the closed cavity formed after the connection is sleeved on the outer surface of the hollow shaft 6; the other end of the traction motor 3 is suspended from the frame 1 through the motor suspension seat on the middle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com