Entirety type electric and manual hydraulic lifter for overturning driving cab

A cab, integral technology, applied in the field of electric and manual hydraulic lifts for integral cab overturning, can solve the problems of poor assembly process, unsafe, oil leakage, etc., to achieve clean structure, reliable leakage prevention and processing. good craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

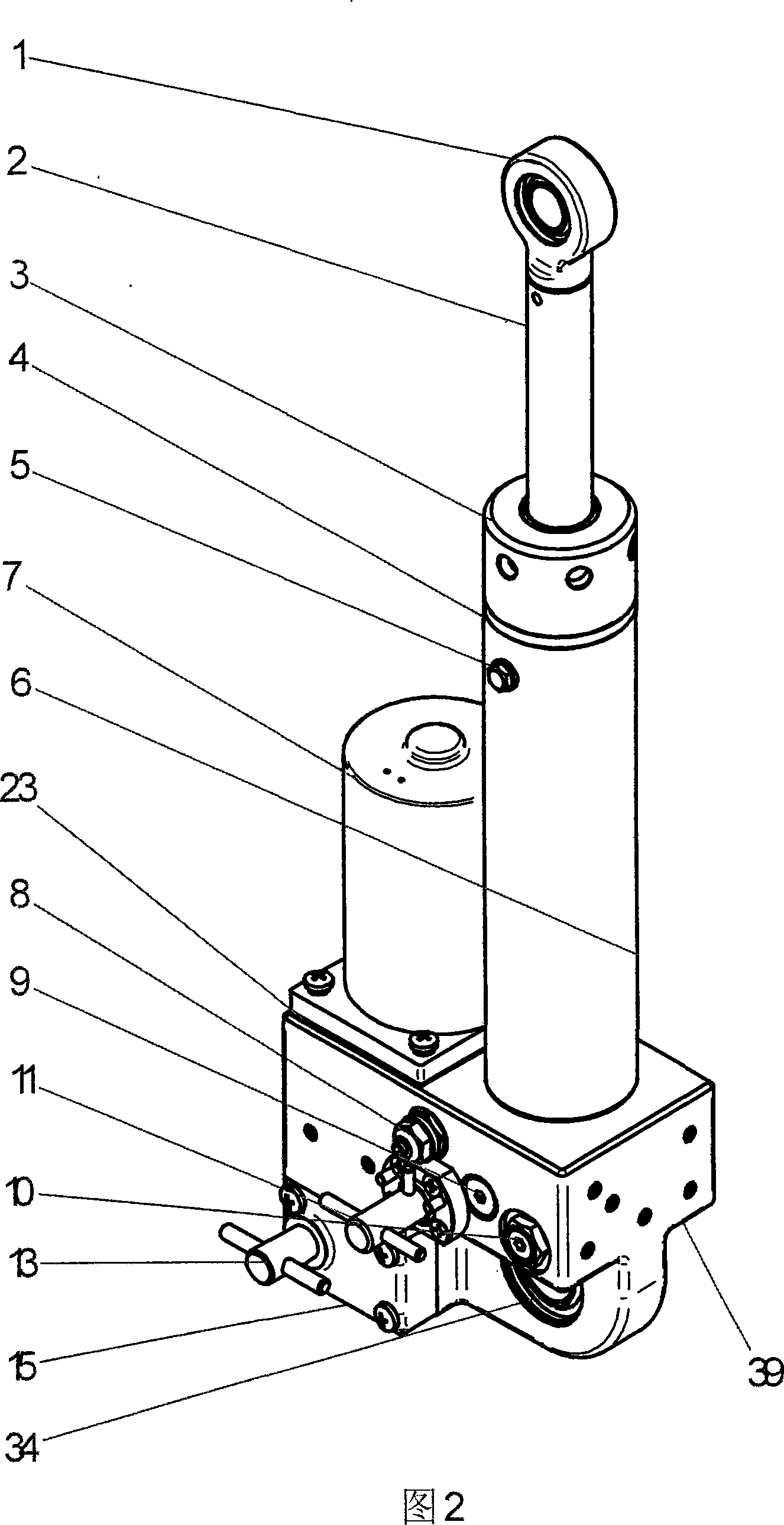

[0085] The follow-up oil cylinder 35 is arranged on the left end face of the main body, and the lift cylinder 40 does not contain a follow-up device. The mechanism 15 in the way of rotating the swing cam of the manual pump is arranged on the rear end surface on the left side of the lifting body;

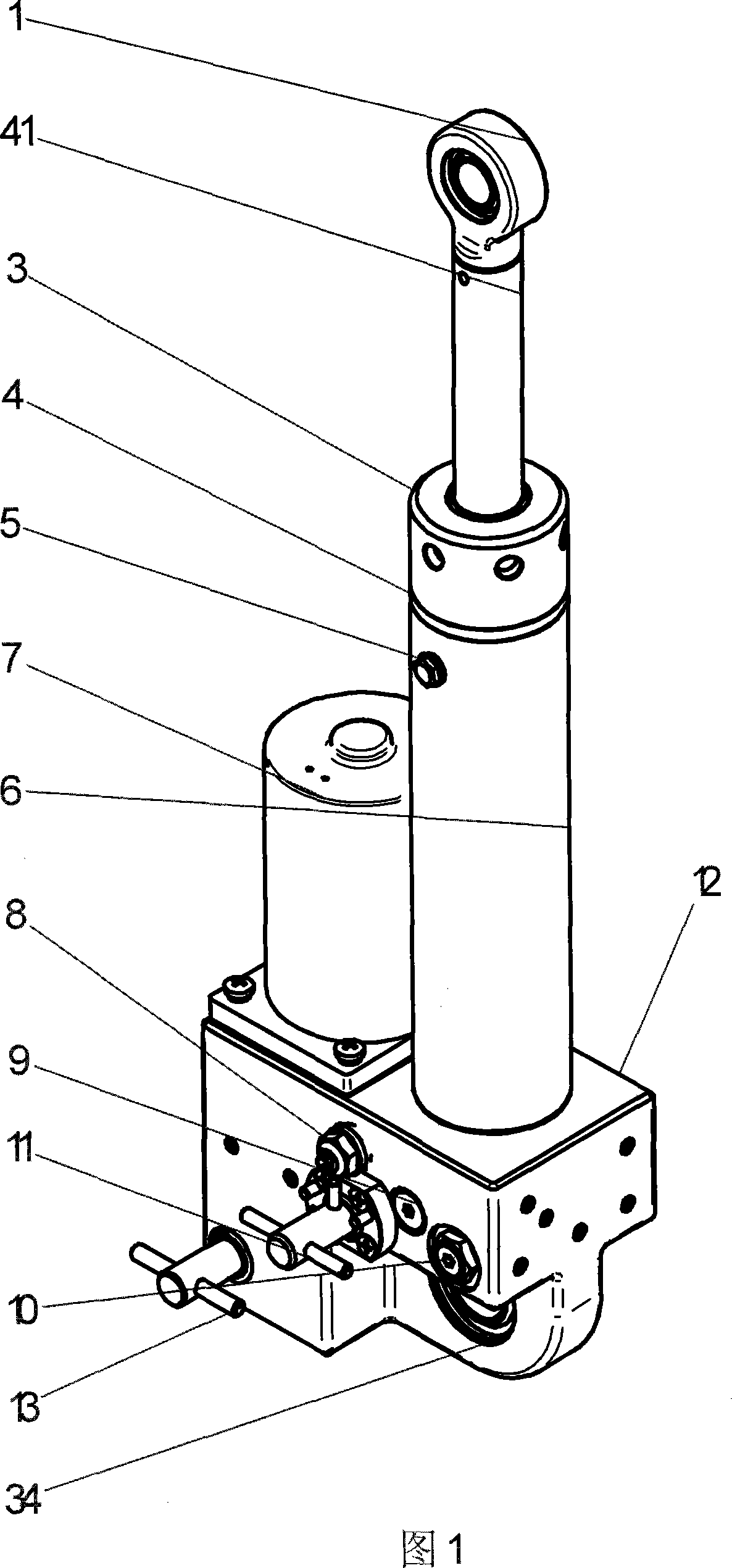

[0086] The present invention is composed of a lifting body 12 , an integral hydraulic pump 24 , a manual pump 13 , a servo cylinder 35 and a lifting cylinder 40 .

[0087] On the left side of the lift body, a motor 7, a dust-proof and shock-absorbing pad 23, an electric pump anti-leakage device 21, and an integral hydraulic pump 24 are installed in sequence from top to bottom, and a manual pump 13 and a follower Lifting oil cylinder 40 is installed on oil cylinder 35, right upper end face;

[0088] On the front of the lifting body, a manual pump 13 and an operating mechanism, a relief valve 8, a reversing valve 11 and an operating mechanism, a one-way throttle valve 9 and a hydrauli...

Embodiment 2

[0111] In order to realize the automatic opening of the cab clamp lock, the present invention adopts an automatic unlocking device, that is, the follow-up oil cylinder installed on the left end surface of the body in embodiment 1 is replaced with an unlocking oil cylinder, and the lifting oil cylinder in embodiment 1 is replaced with a follow-up oil cylinder replace;

[0112] Replace the two-position four-way rotary reversing valve with a two-position four-way differential reversing valve,

[0113] Arrange the unlocking cylinder on the left end face of the main body, and the lifting cylinder 40 contains an oil-guiding groove type follow-up device (type B lifting cylinder described in the technical solution), and a differential oil passage is formed by a reversing valve 11. The upper and lower chambers of the follow-up lifting cylinder 20 provide high-pressure oil to complete the lifting, and the mechanism 15 in the form of a manual pump rotating swing cam is arranged on the re...

Embodiment 3

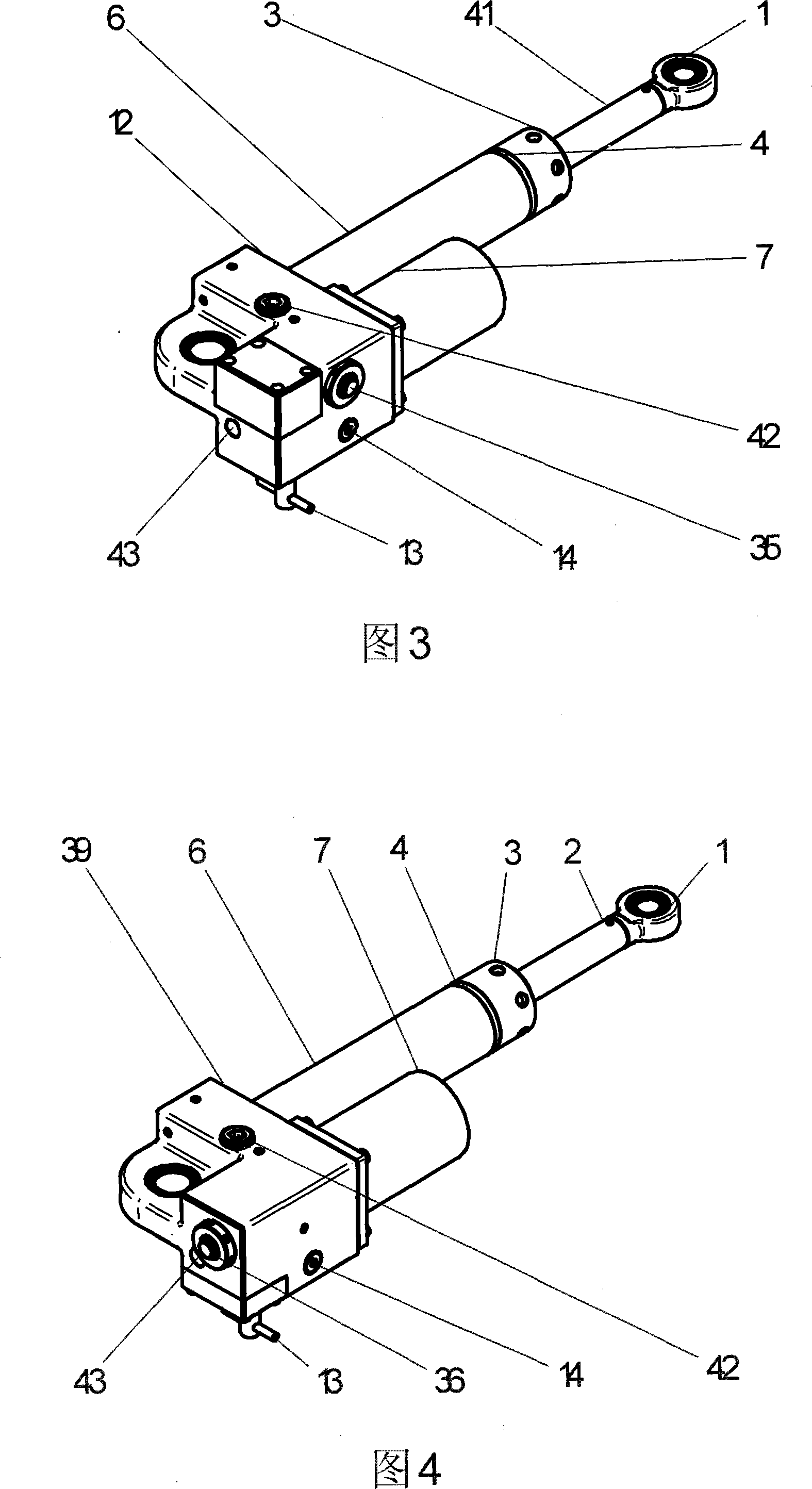

[0120] Considering the need for a large follow-up stroke of the cab, the vertical follow-up oil cylinder 36 is arranged on the lower left end surface of the body 39, and the lift cylinder 40 does not contain a follow-up device (type A lift cylinder described in the technical solution). The mechanism 15 of the manual pump rotating swing cam is arranged on the front face of the left side of the body;

[0121] The layout of all other parts is identical with embodiment 1;

[0122] What present embodiment adopts is body 39, and body has 37 holes altogether and sees figure mark (seeing as shown in Figure 19):

[0123] The difference between body 39 and body 12 is:

[0124] The 011 channel of the body 12 is horizontal, and the 011 channel of the body 39 is vertical;

[0125] Hole 012 and hole 013 of body 12 are on the left rear side of the body, and holes 012 and 013 of body 39 are on the left front side of the body; The outer groove of the cam structure of the manual pump is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com