Mineral engineering machinery, disassembly-free oil cavity cleanable bearing block and cleaning method

A bearing seat and cleaning oil technology, applied in cleaning methods and appliances, cleaning methods using liquids, bearings, etc., can solve the problems of abrasive wear, oil film damage, difficulty, etc., to prevent dust from entering and preventing oil leakage problems, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

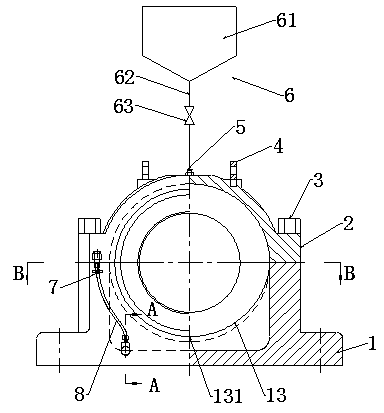

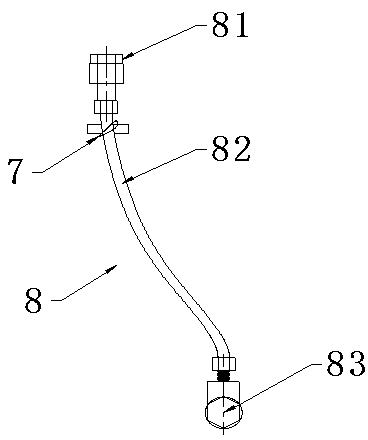

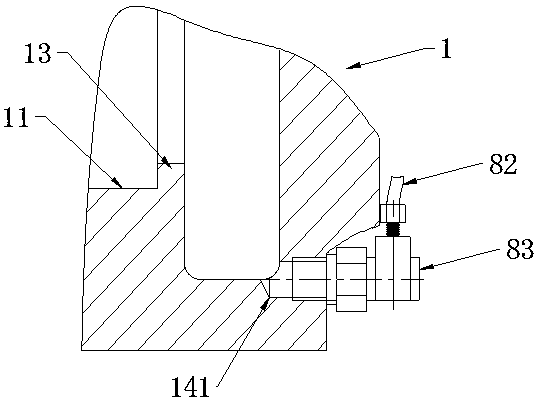

[0049] The purpose of the present invention is to provide a bearing housing that can clean the oil chamber without disassembly. The bearing housing has a simple structure, and the oil chamber of the bearing housing can be cleaned without disassembling the bearing housing, bearings and related parts. And the method for cleaning the oil cavity of the bearing seat is relatively simple. The second object of the present invention is to provide a method for cleaning the oil chamber of the bearing seat based on the above-mentioned disassembly-free and washable oil chamber. The third object of the present invention is to provide a mining engineering machine using the above-mentioned bearing housing with no-disassembly and washable oil cavity.

[0050] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com