Patents

Literature

86results about "Shaft cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

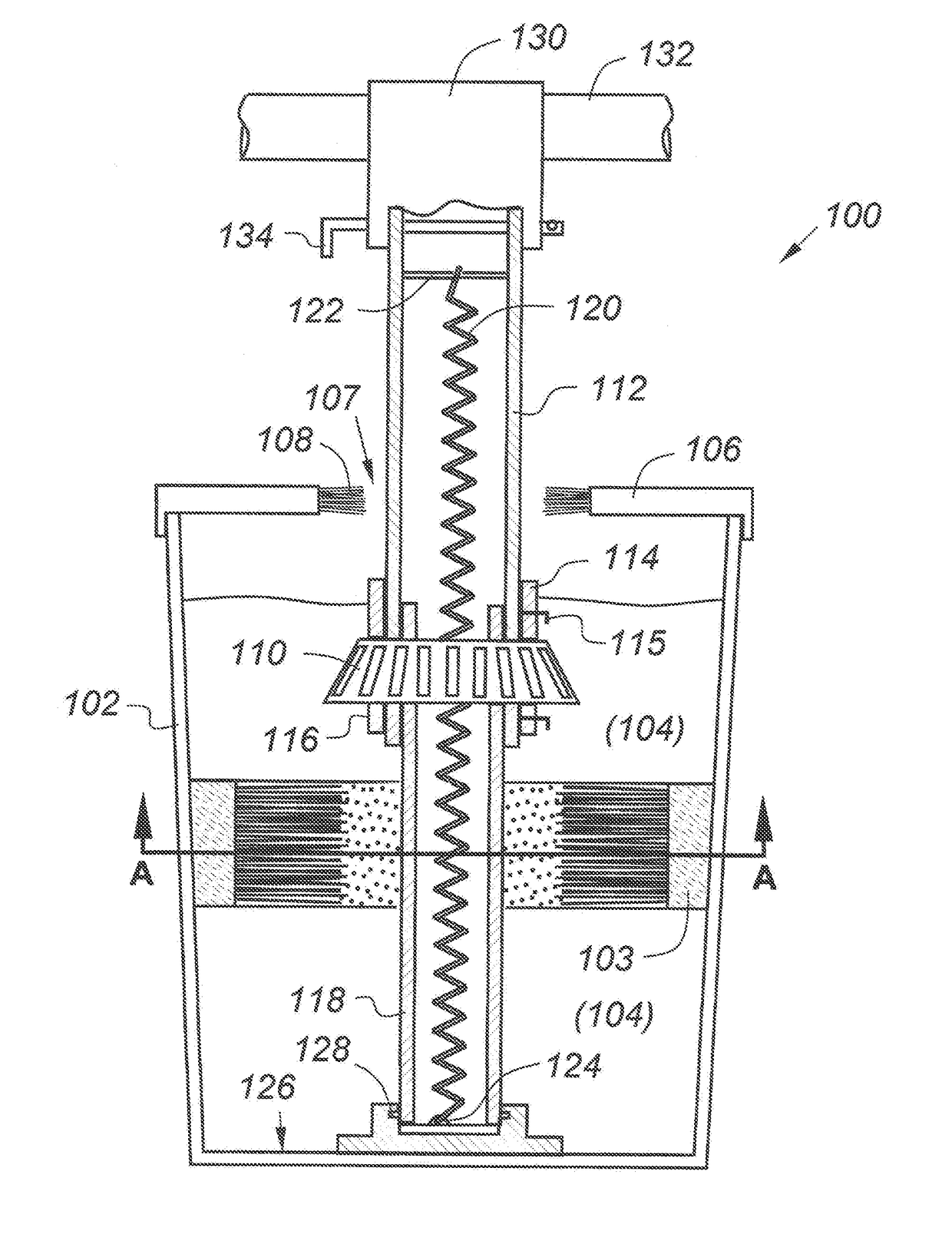

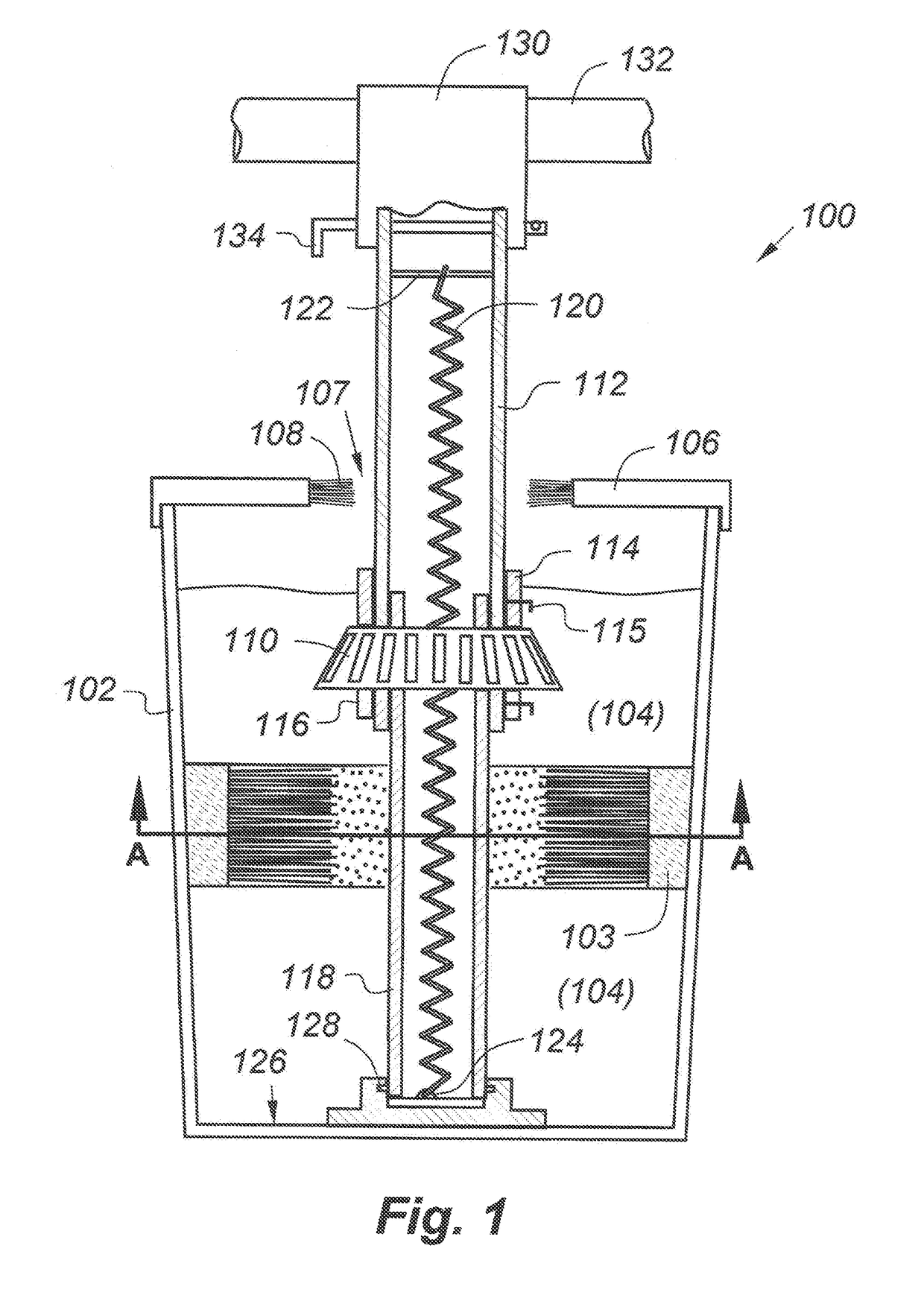

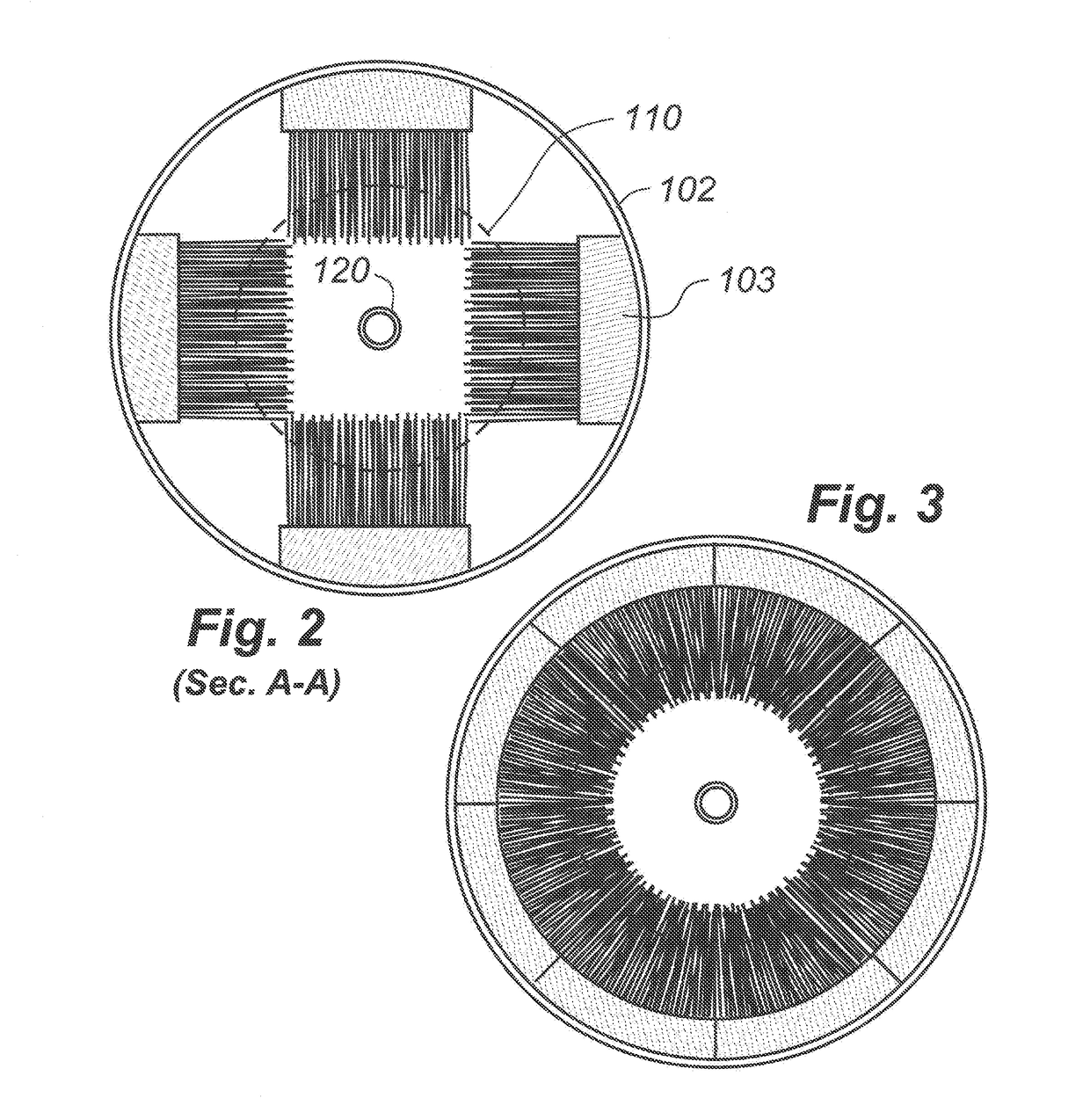

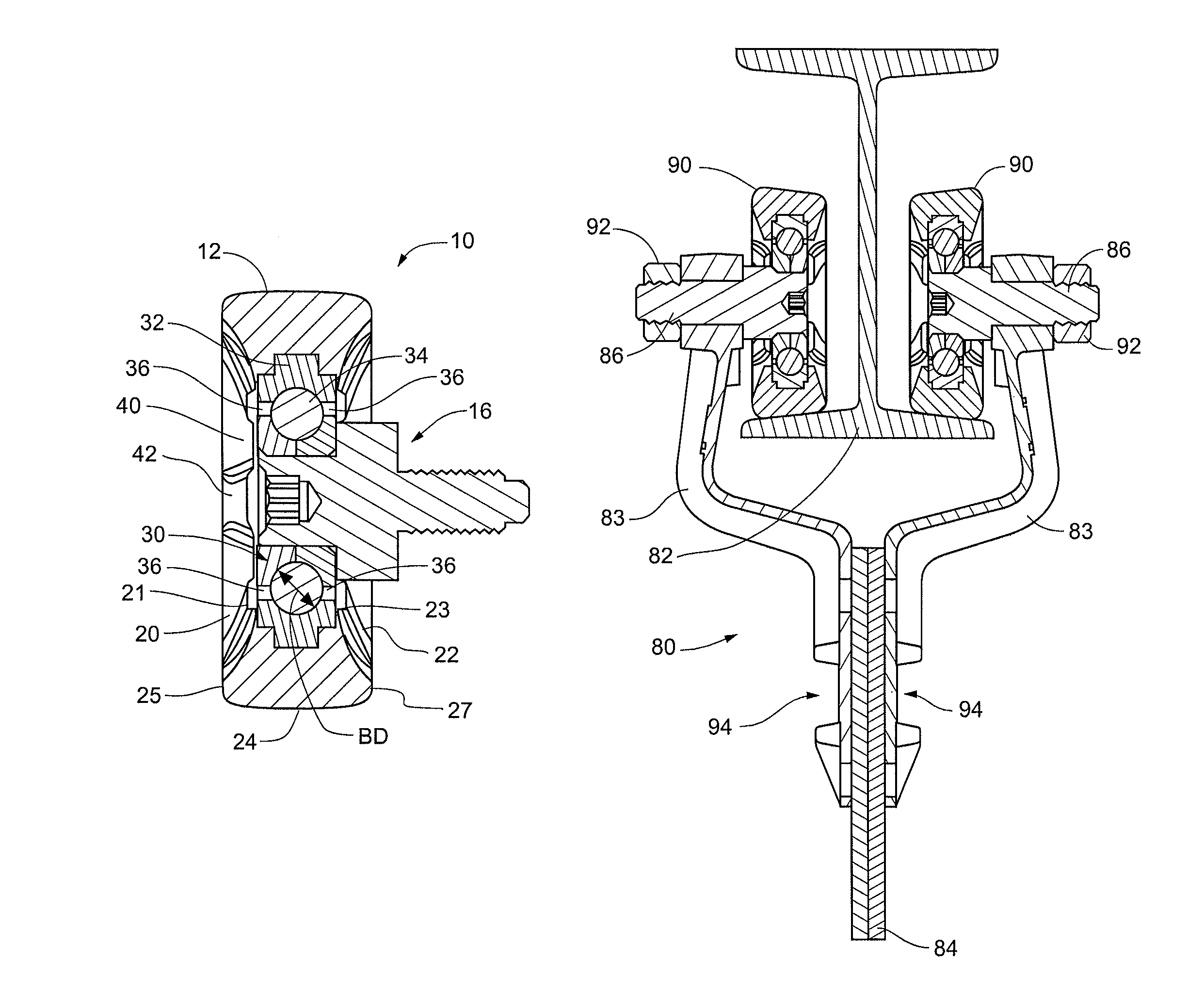

Manually operated bearing cleaning apparatus

A simple but effective manually operated bearing cleaning apparatus comprises a container adapted to receive a solvent. One or more brushes mounted on the inner sidewall of the container have bristles oriented generally toward a centerline of the container, while leaving a central opening enabling a bearing to pass therethrough. A telescoping sleeve including a lower sleeve with a lower end, and an upper sleeve with an upper end is configured to receive a bearing to be cleaned between upper and lower retainers on the upper sleeve. A coupling is provided between the lower end of the lower sleeve and the inner bottom surface of the container, whereby a user moves the upper sleeve in an up-and-down motion, forcing the bearing through the central opening of the bristles, thereby cleaning the bearing in the solvent.

Owner:LANCASTER CHRISTOPHER NEIL

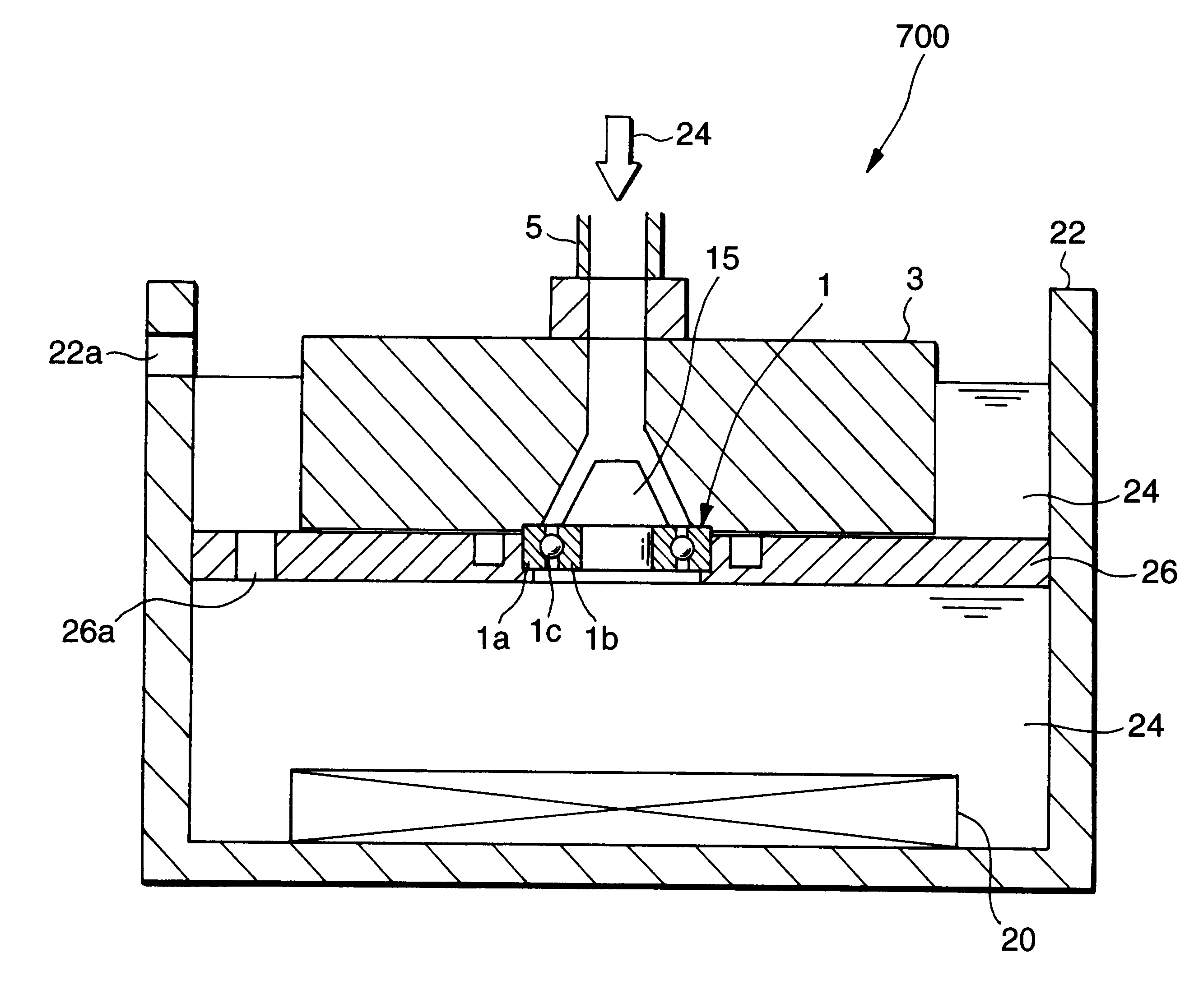

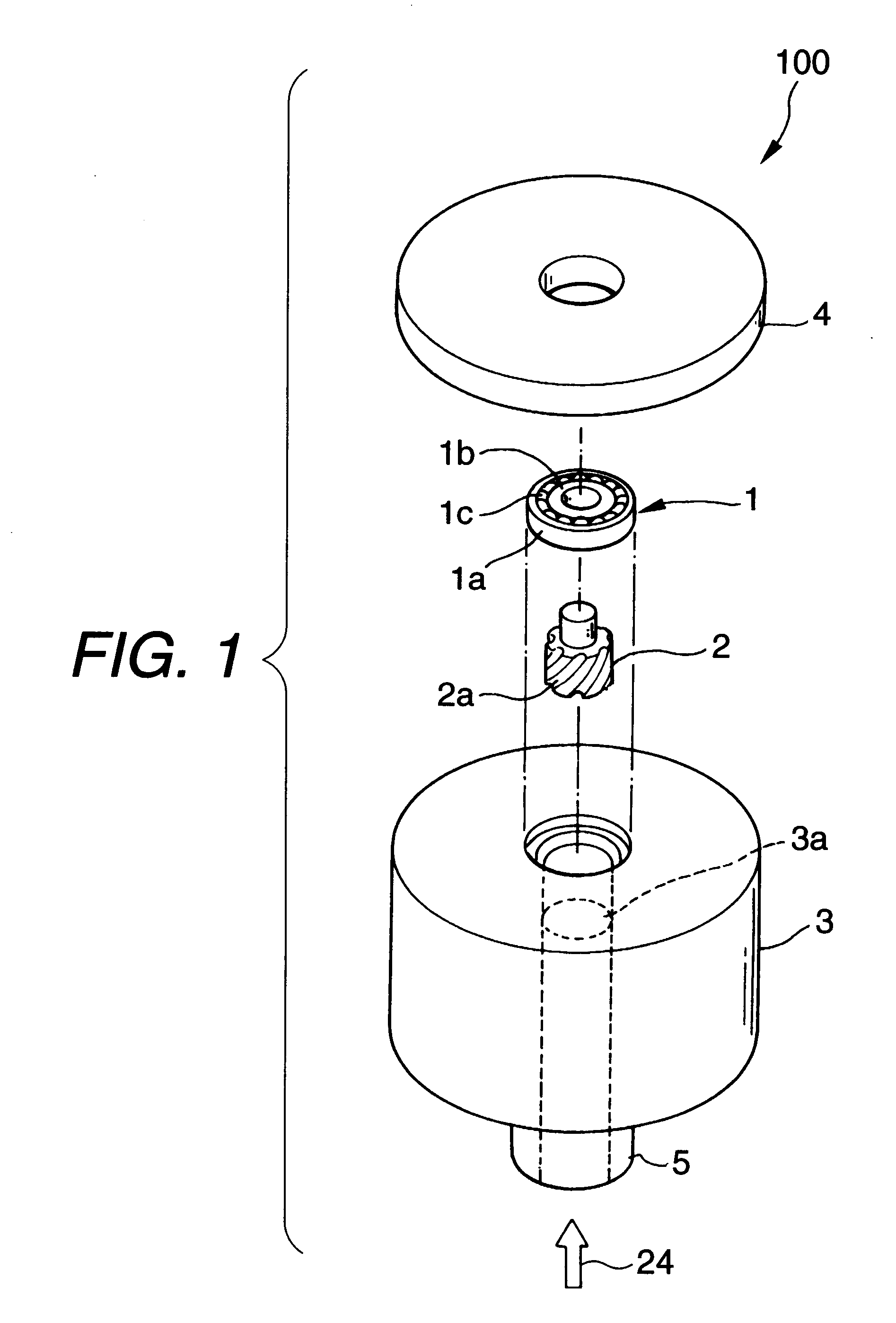

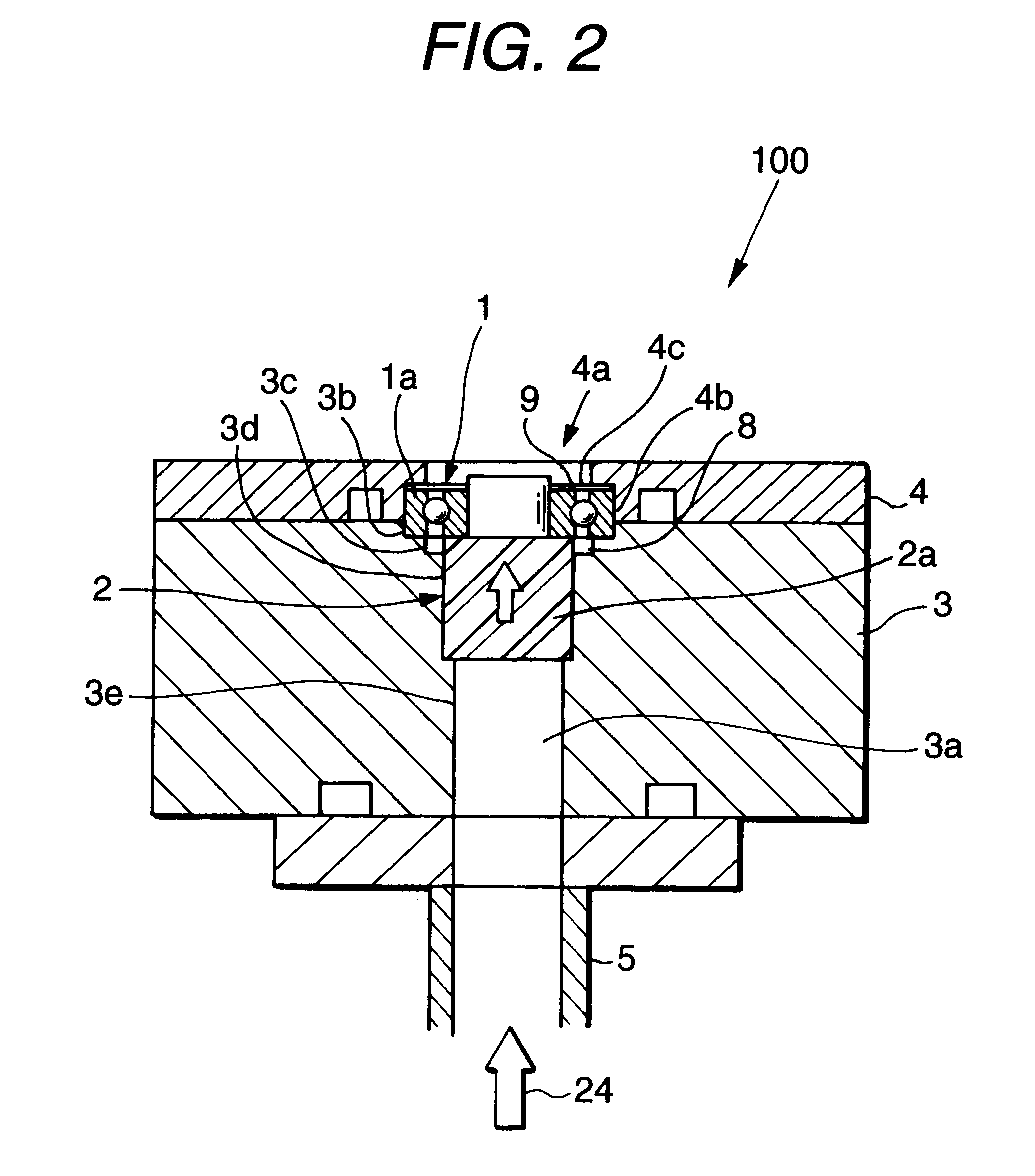

Ball/roller bearing cleaning apparatus

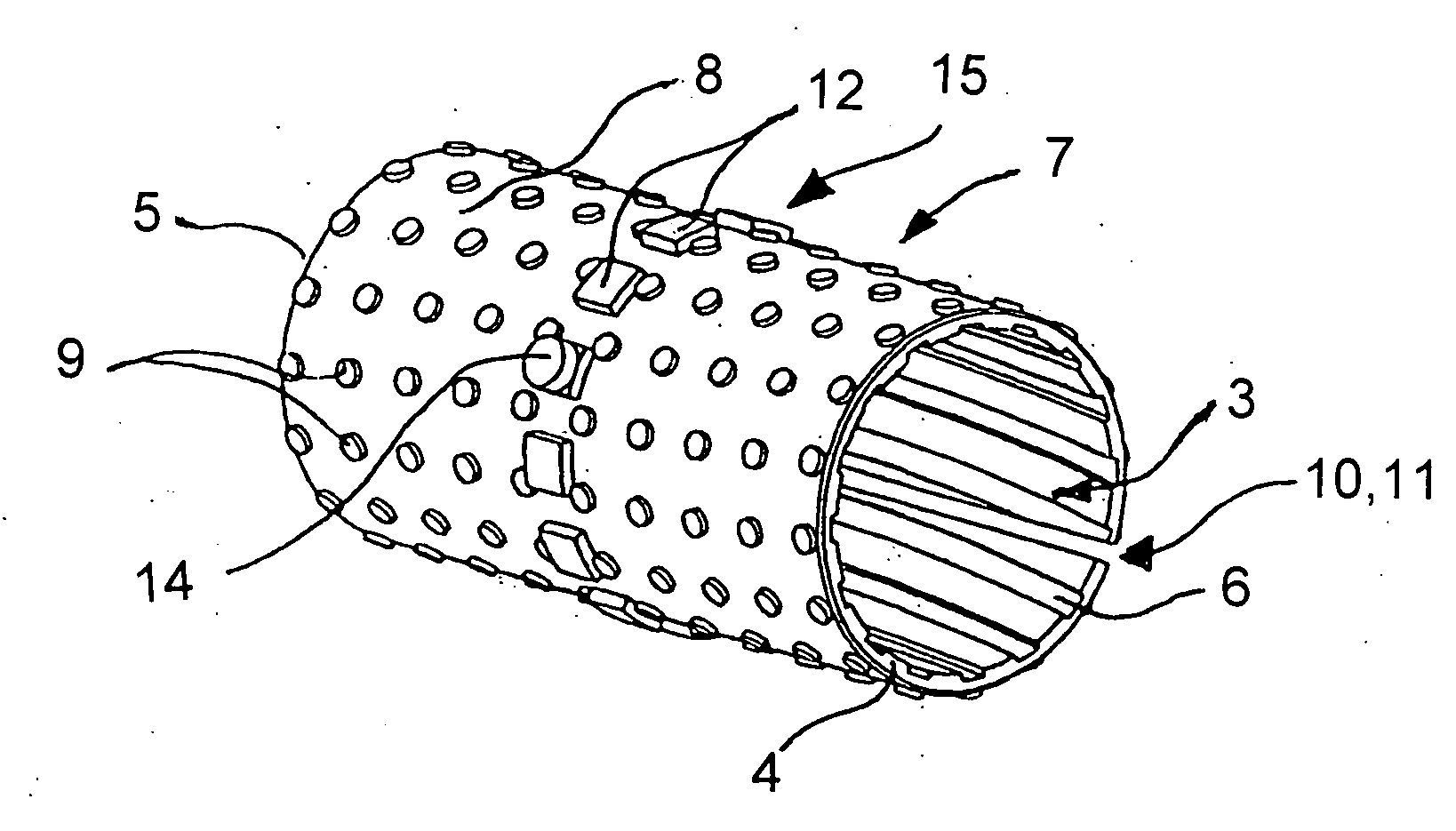

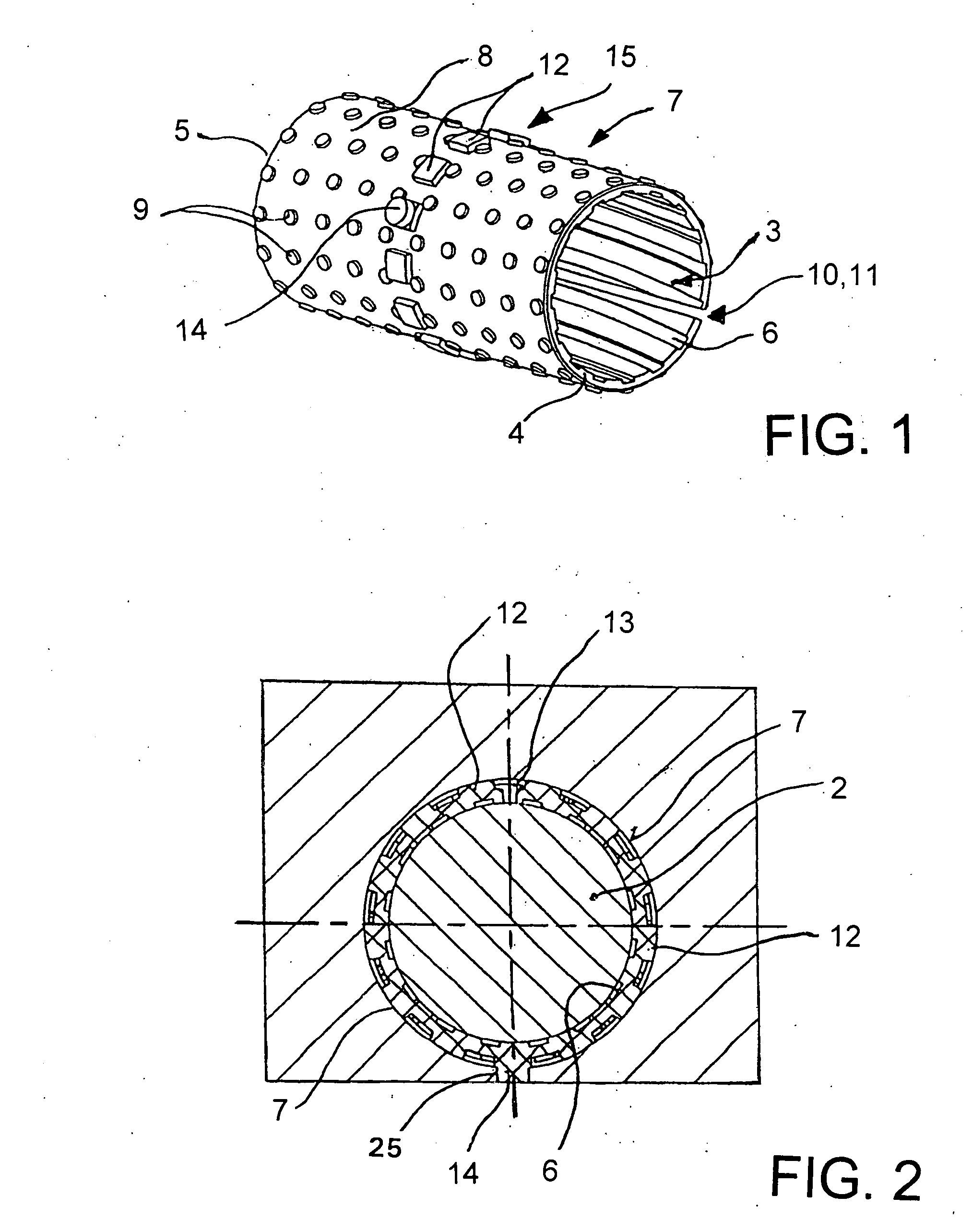

The present ball / roller bearing cleaning method is a method which, using cleaning liquid 24, cleans a bearing to be cleaned 1 composed of an inner ring 1b, an outer ring 1a, a rolling bodies 1c and a retainer. In the cleaning method, the cleaning liquid 24 is made to flow through the bearing to be cleaned 1 from the axial direction of the present bearing 1 into spaces in which the raceway surfaces of the inner and outer rings 1b and 1a of the bearing to be cleaned 1 surround the rolling bodies 1c and retainer. For example, a cylindrical-shaped rotary die 2 having spiral grooves 2a is interposed into a cleaning liquid supply passage, and the cleaning liquid 4 is supplied to thereby rotate the cylindrical-shaped rotary die 2, whereby the cleaning liquid having high pressure can be supplied to the bearing to be cleaned 1 from the cylindrical-shaped rotary die 2.

Owner:NSK LTD

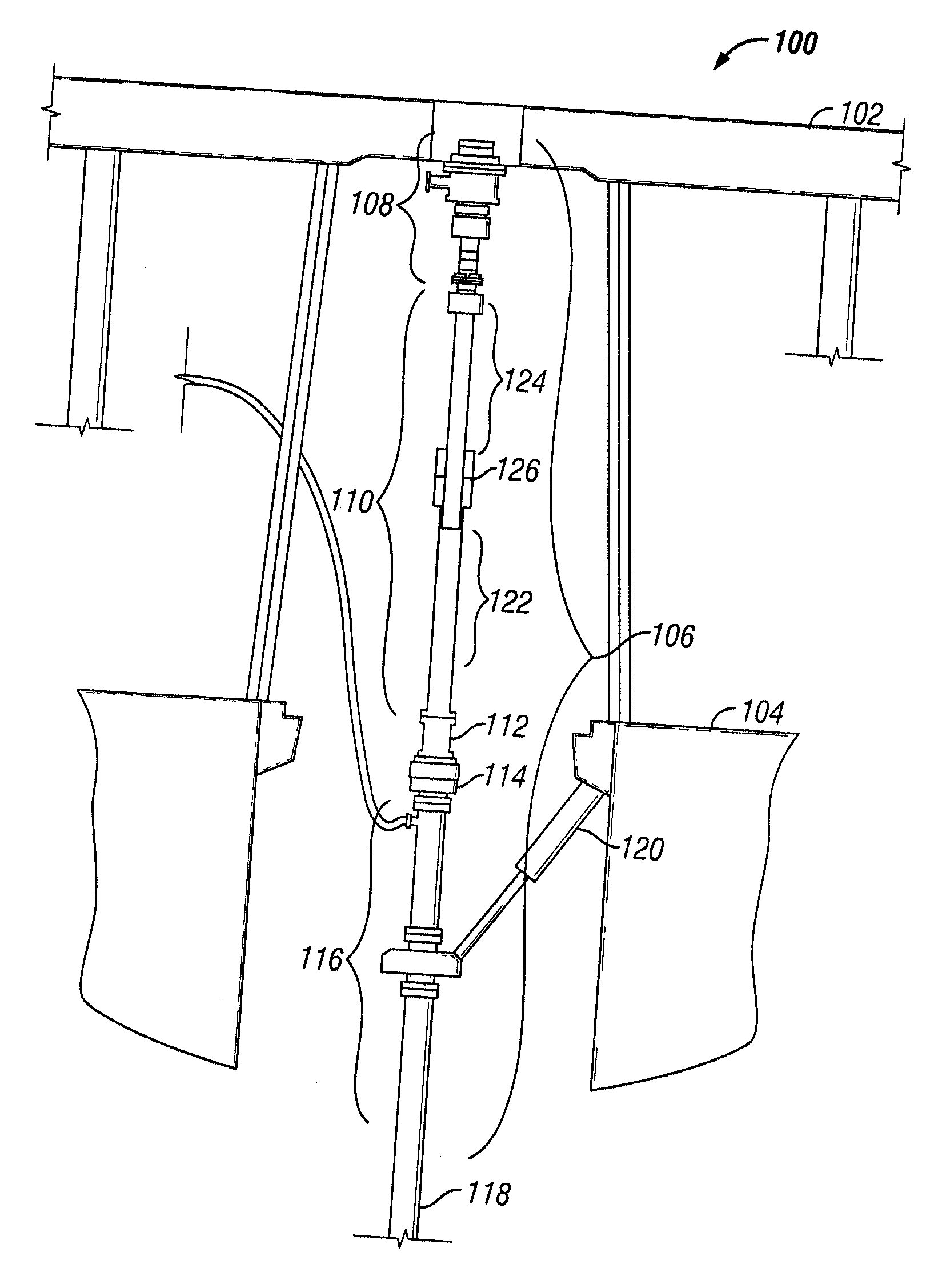

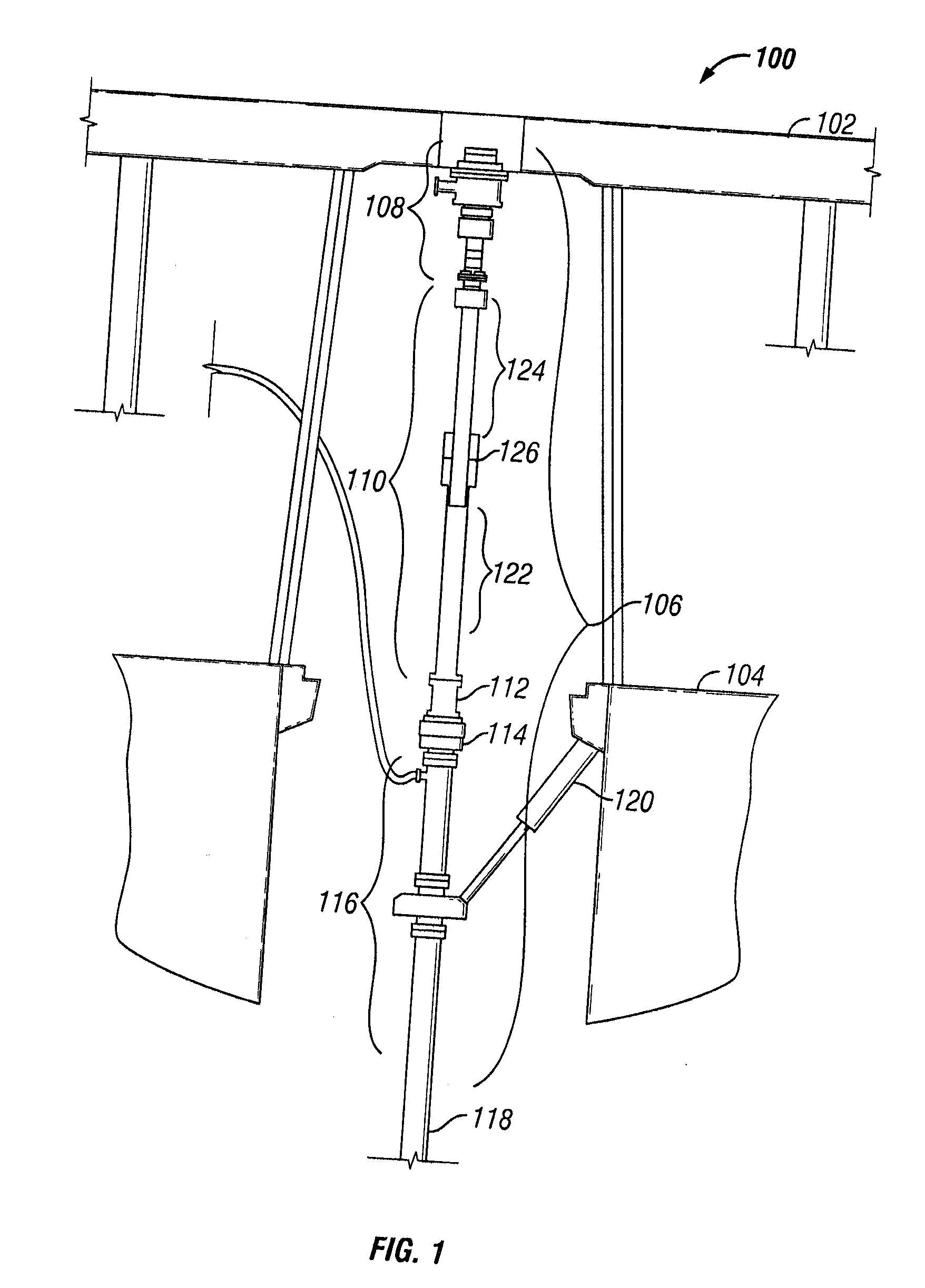

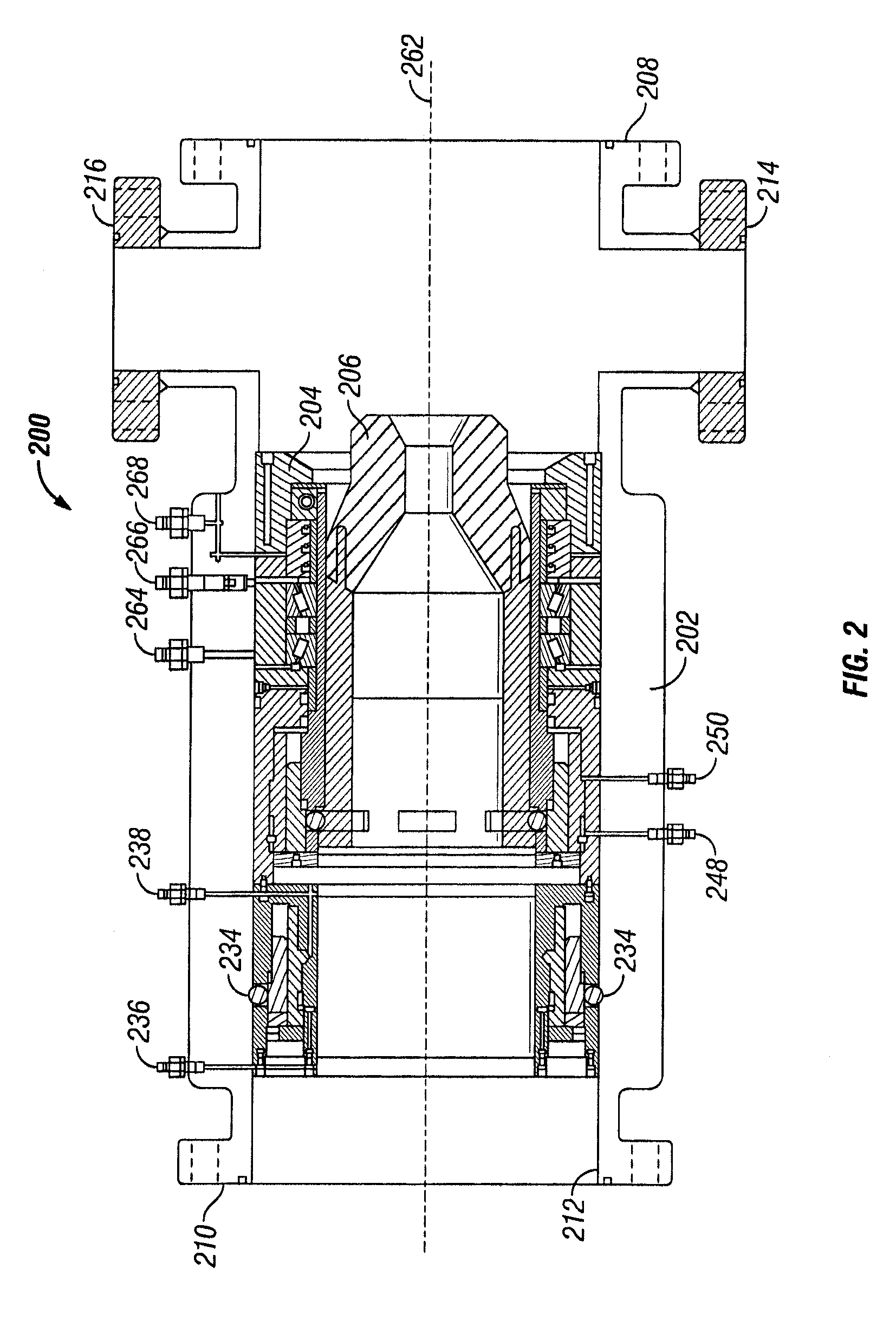

Flushing procedure for rotating control device

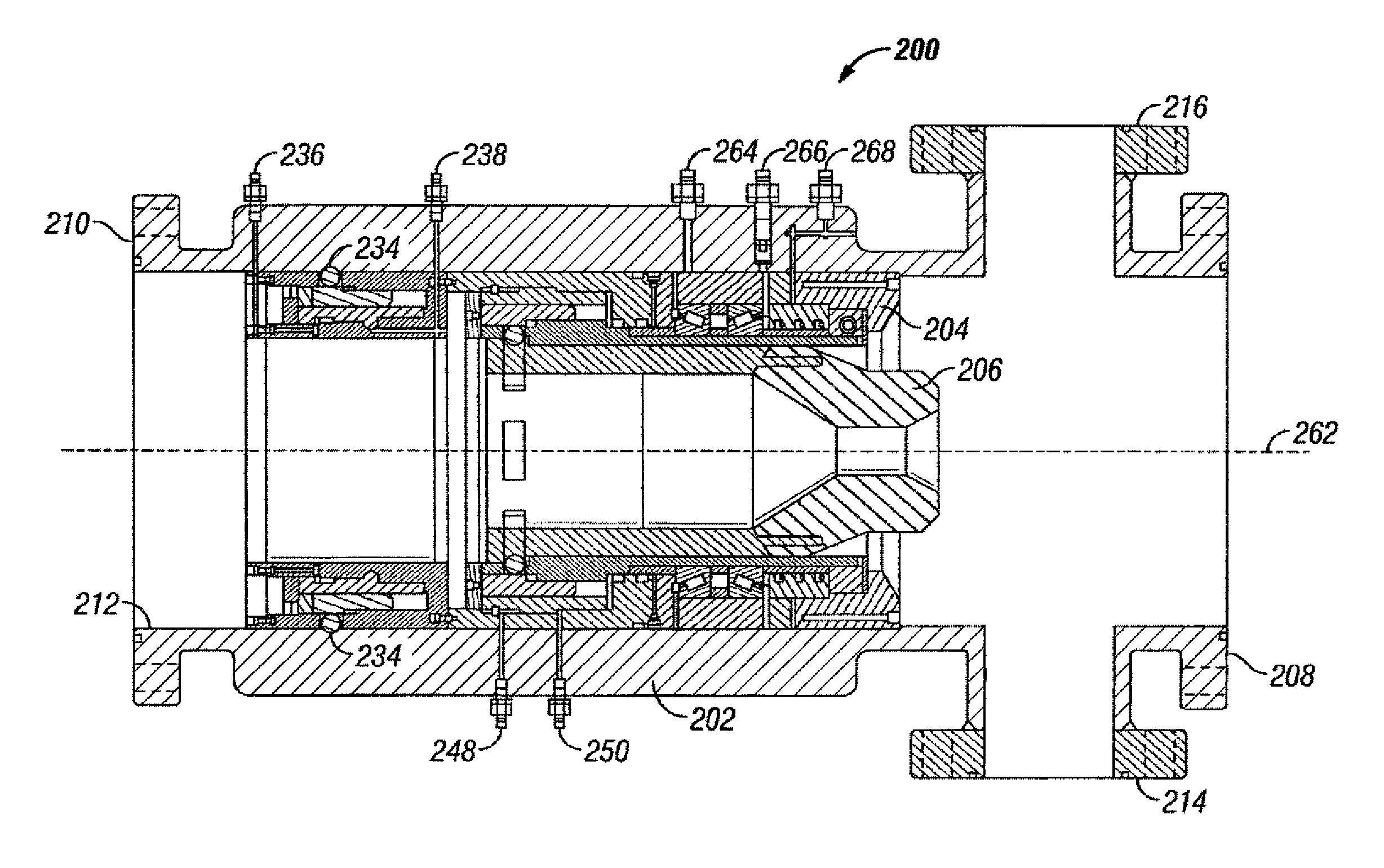

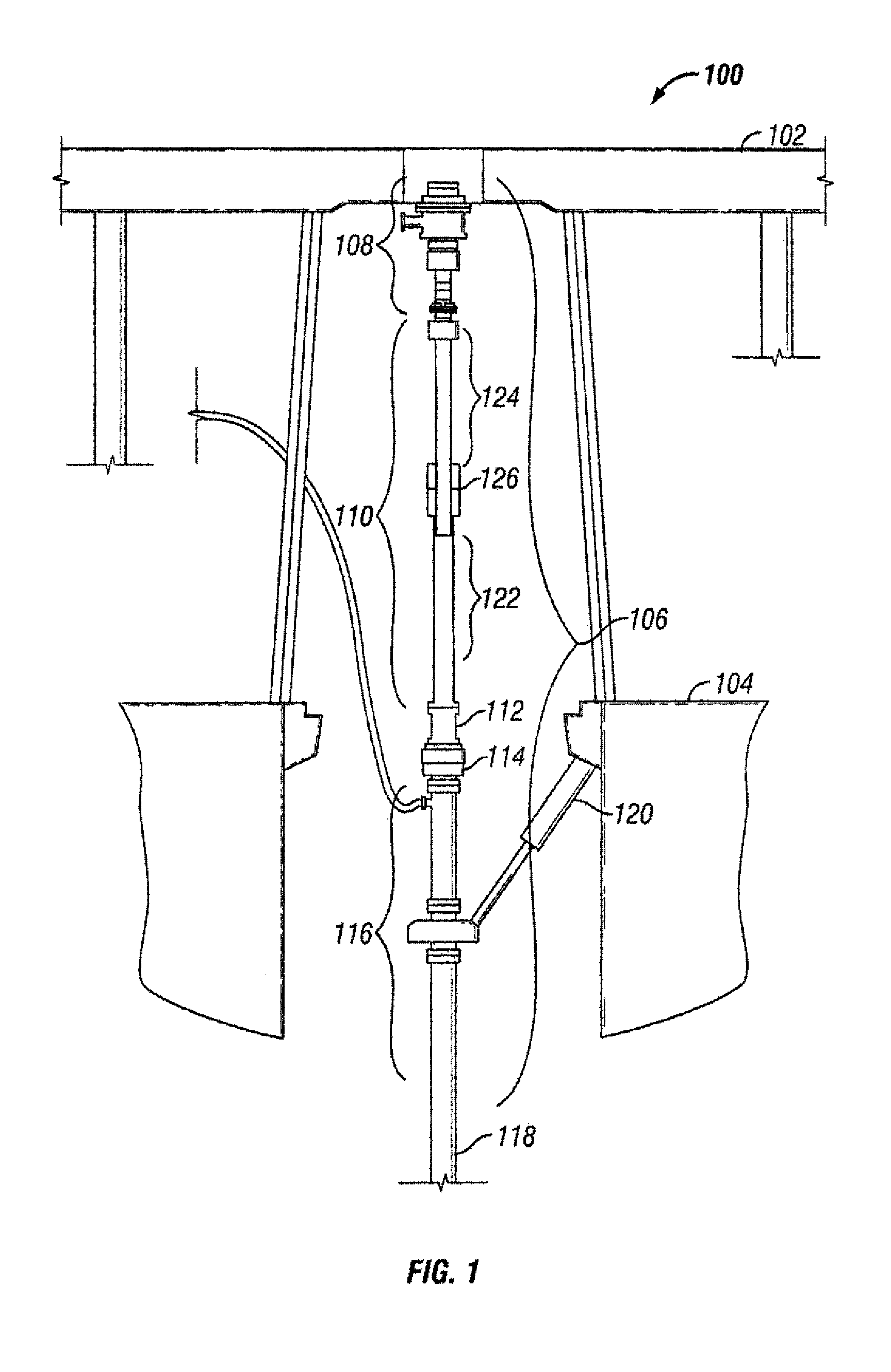

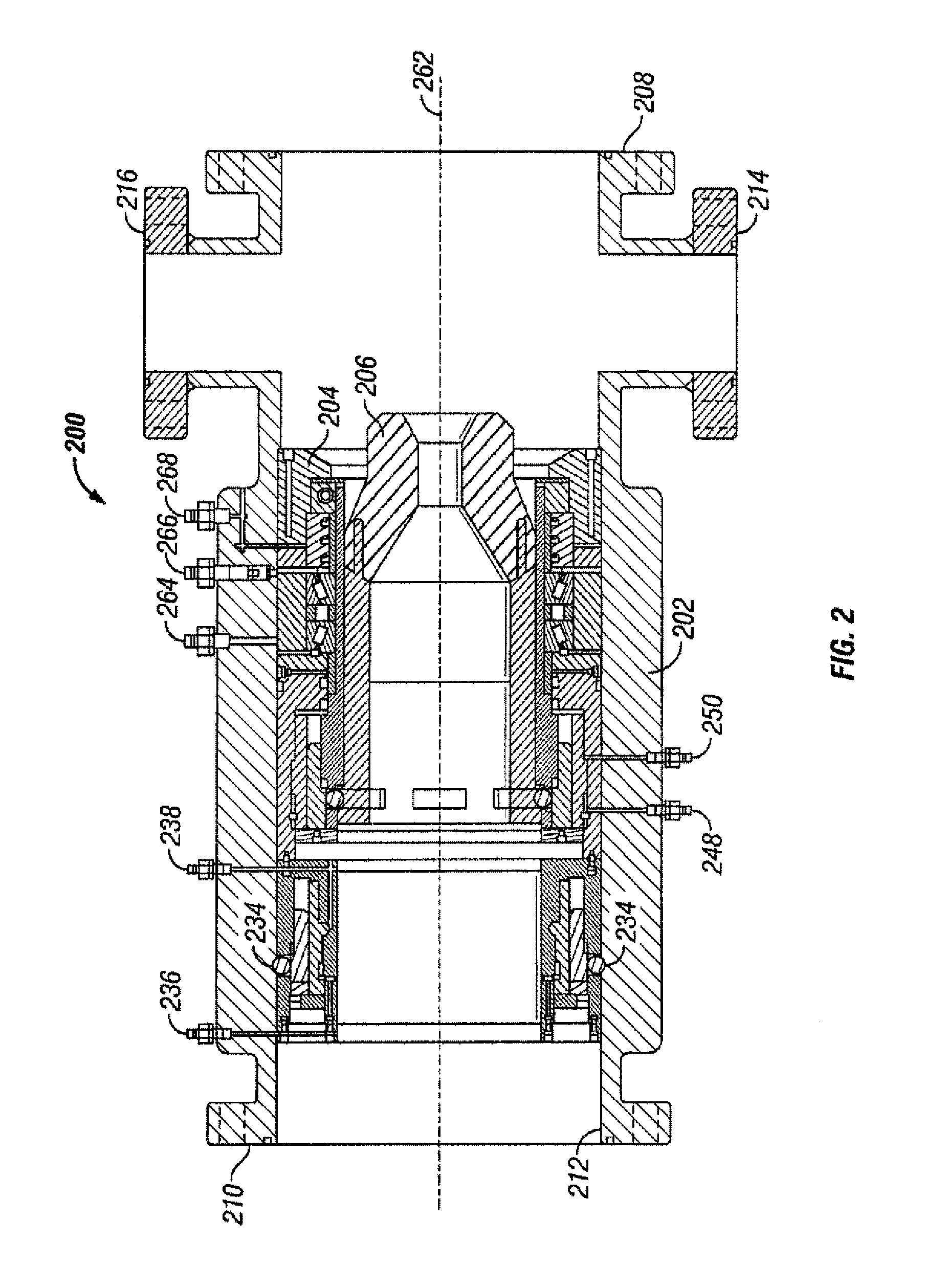

A method of flushing a wellbore fluid from a downhole tool containing a bearing package includes pumping hydraulic oil through at least one of a hydraulic inlet line and at least one of a pneumatic inlet line connected to the main housing and into an annulus formed between the bearing package and a main housing of the downhole tool, wherein the hydraulic oil replaces the wellbore fluid in the annulus, removing the wellbore fluid from the annulus through at least one hydraulic outlet line and at least one pneumatic outlet line connected to the main housing, pumping air through the at least one pneumatic inlet line connected to the main housing and removing the hydraulic oil from the at least one pneumatic inlet line connected to the main housing, and removing the hydraulic oil through at least one pneumatic outlet line connected to the main housing.

Owner:SMITH INT INC

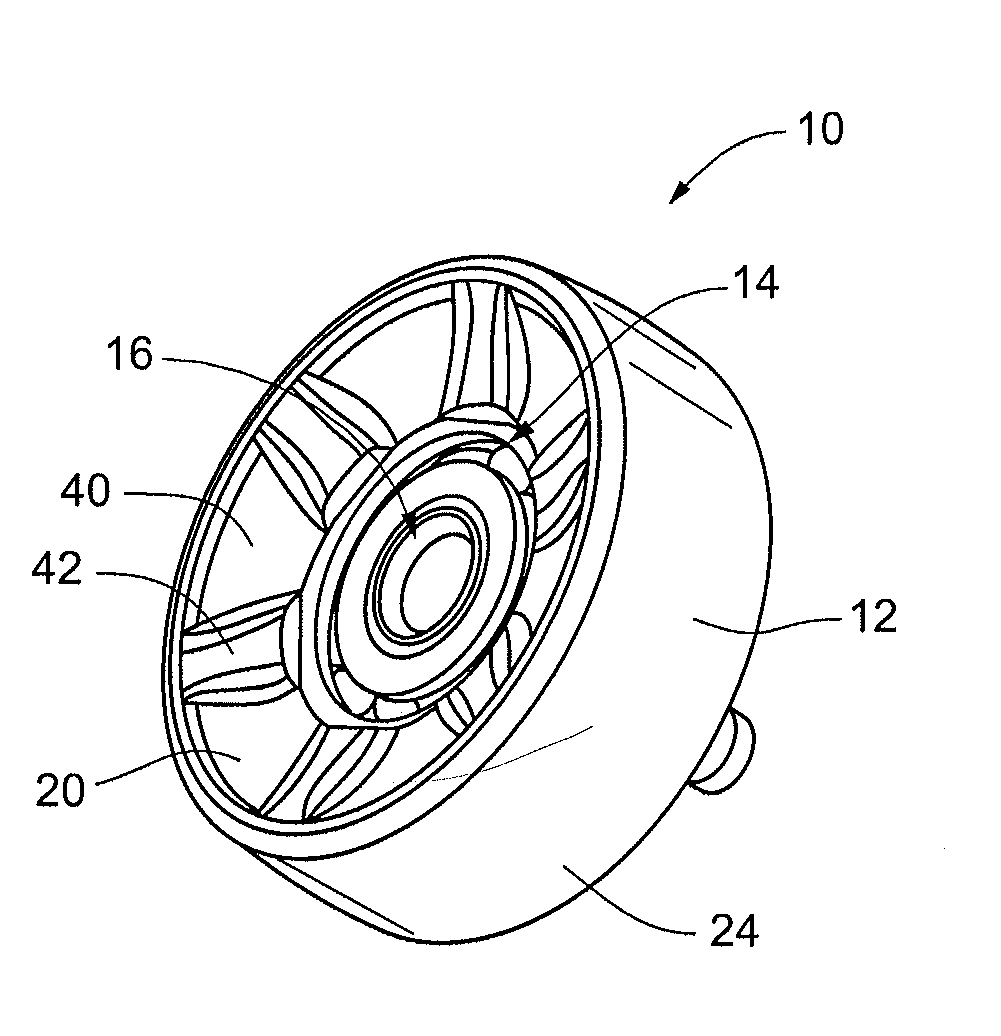

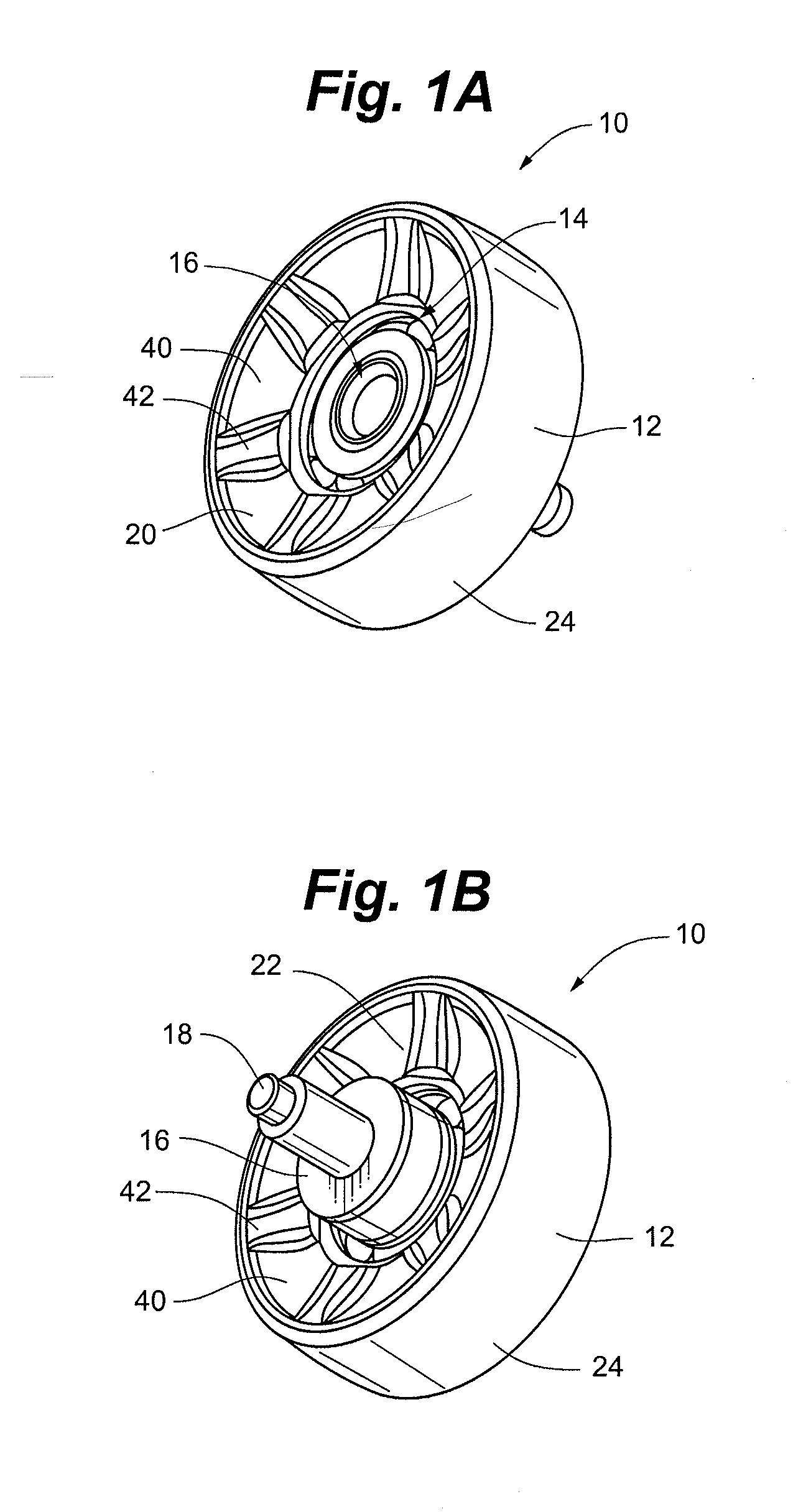

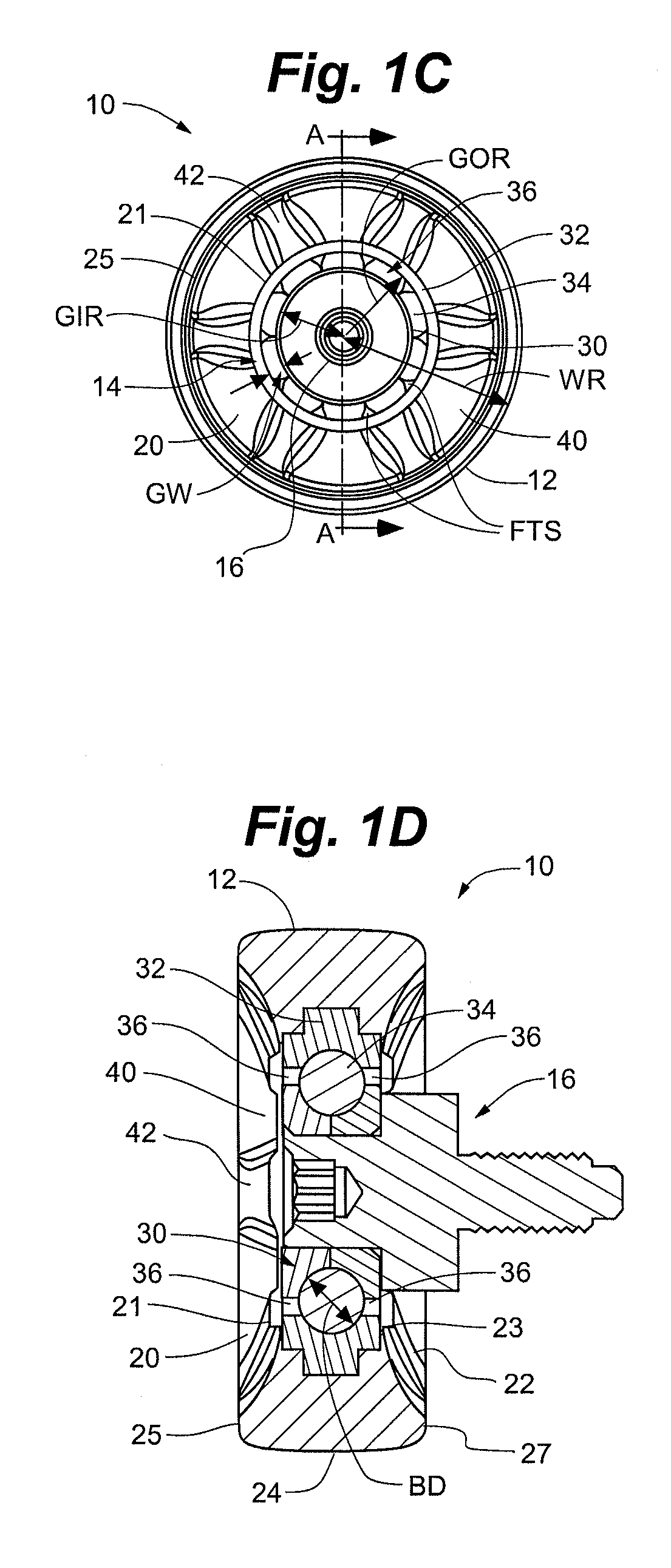

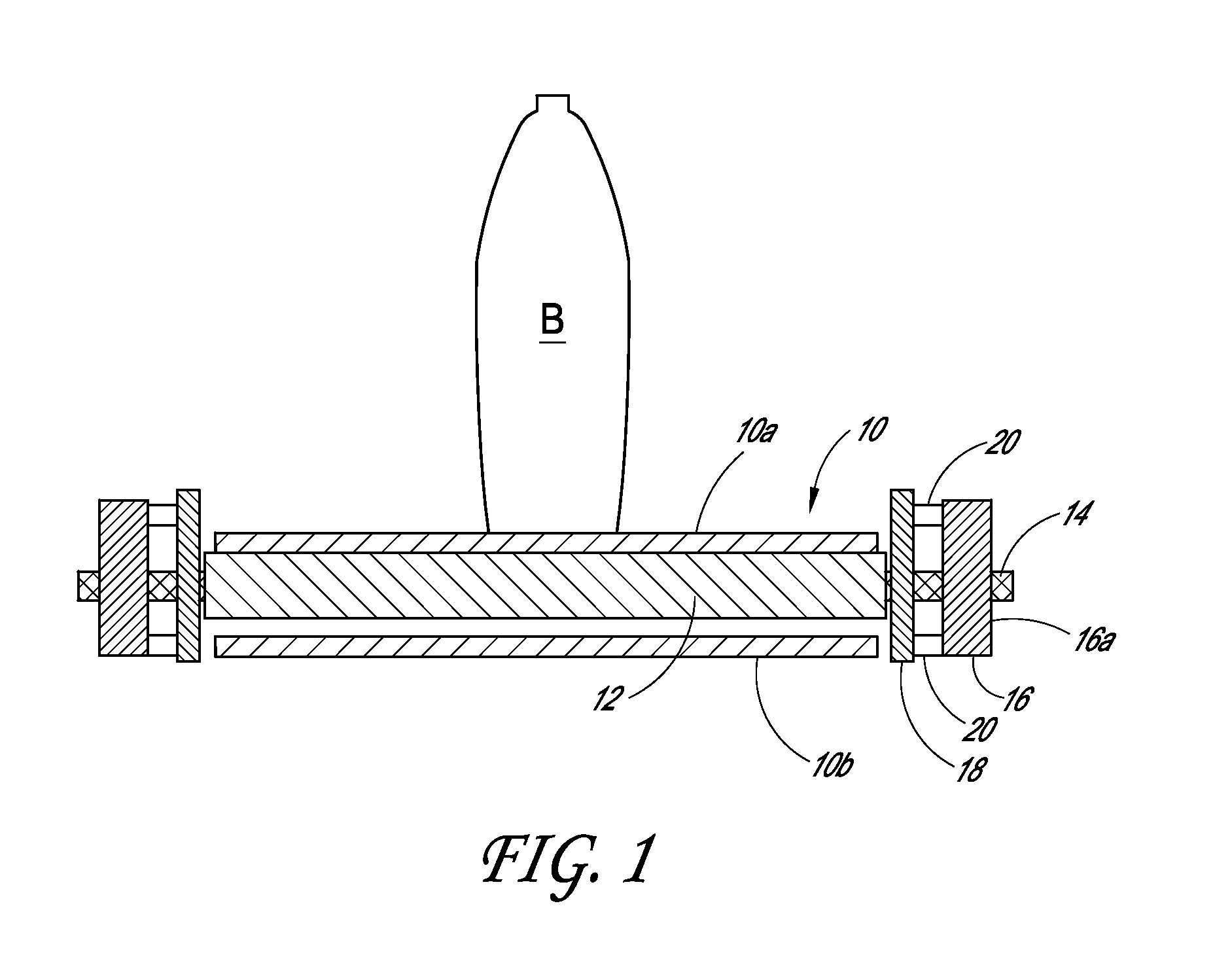

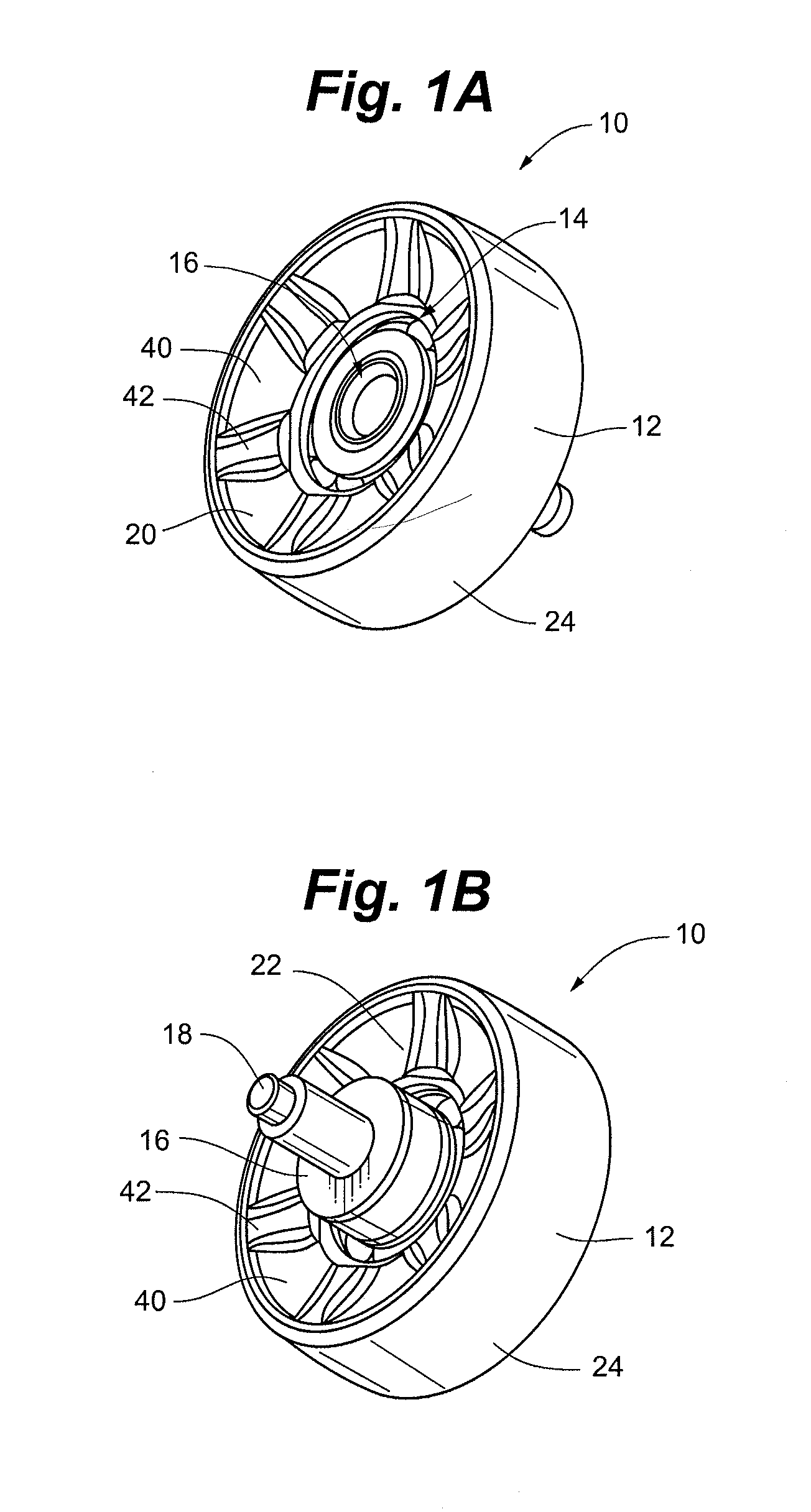

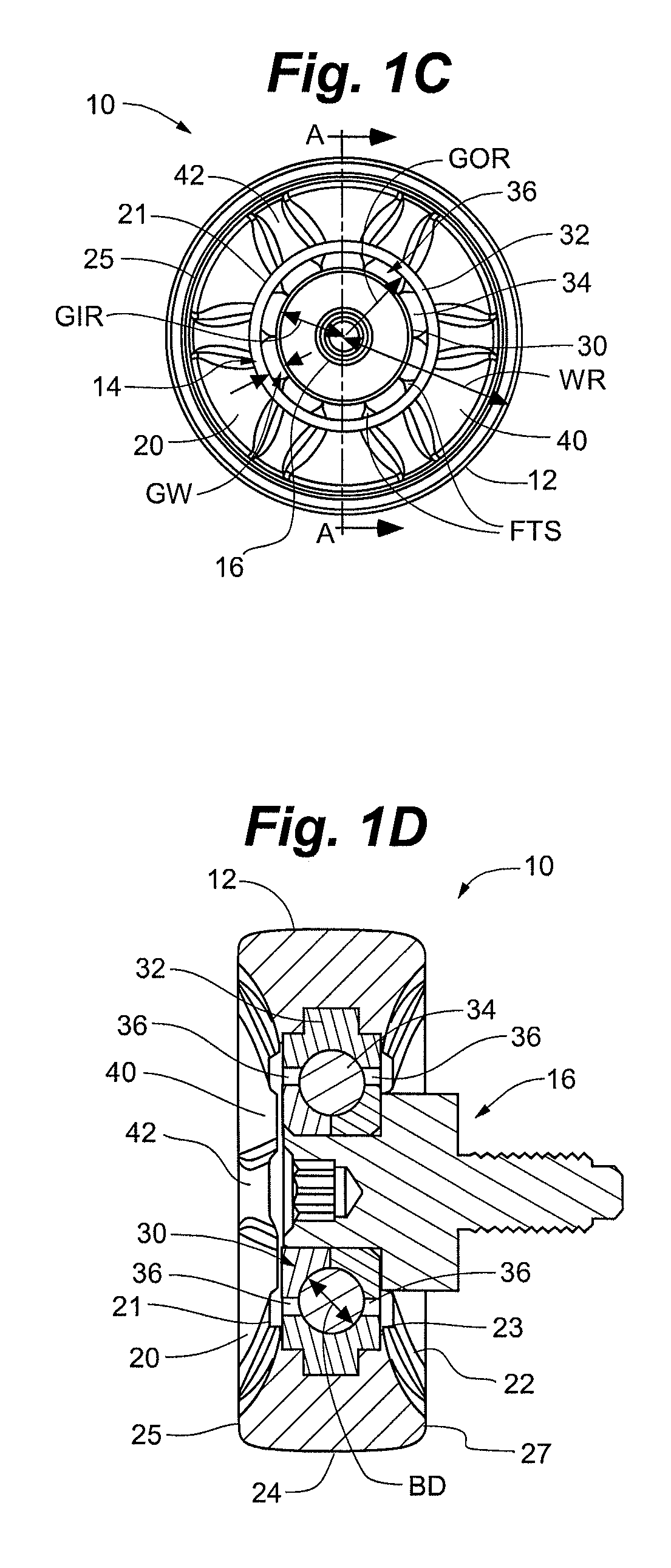

Trolley Wheel Technology

The invention provides a trolley wheel assembly for a conveyor system, e.g., an overhead conveyor system. In certain embodiments, the wheel assembly includes at least one wheel face having a contour (optionally a funneling configuration and / or one or more surface features) configured to facilitate flow of a fluid toward an open bearing assembly of the wheel assembly. In some embodiments, the wheel assembly includes an inner race, outer race, and bearings having a particular hardness arrangement, optionally together with a polymer wheel having certain filler features. Methods for cleaning such a trolley wheel assembly are also provided.

Owner:OCONOMOWOC MFG

Flushing procedure for rotating control device

Owner:SMITH INT INC

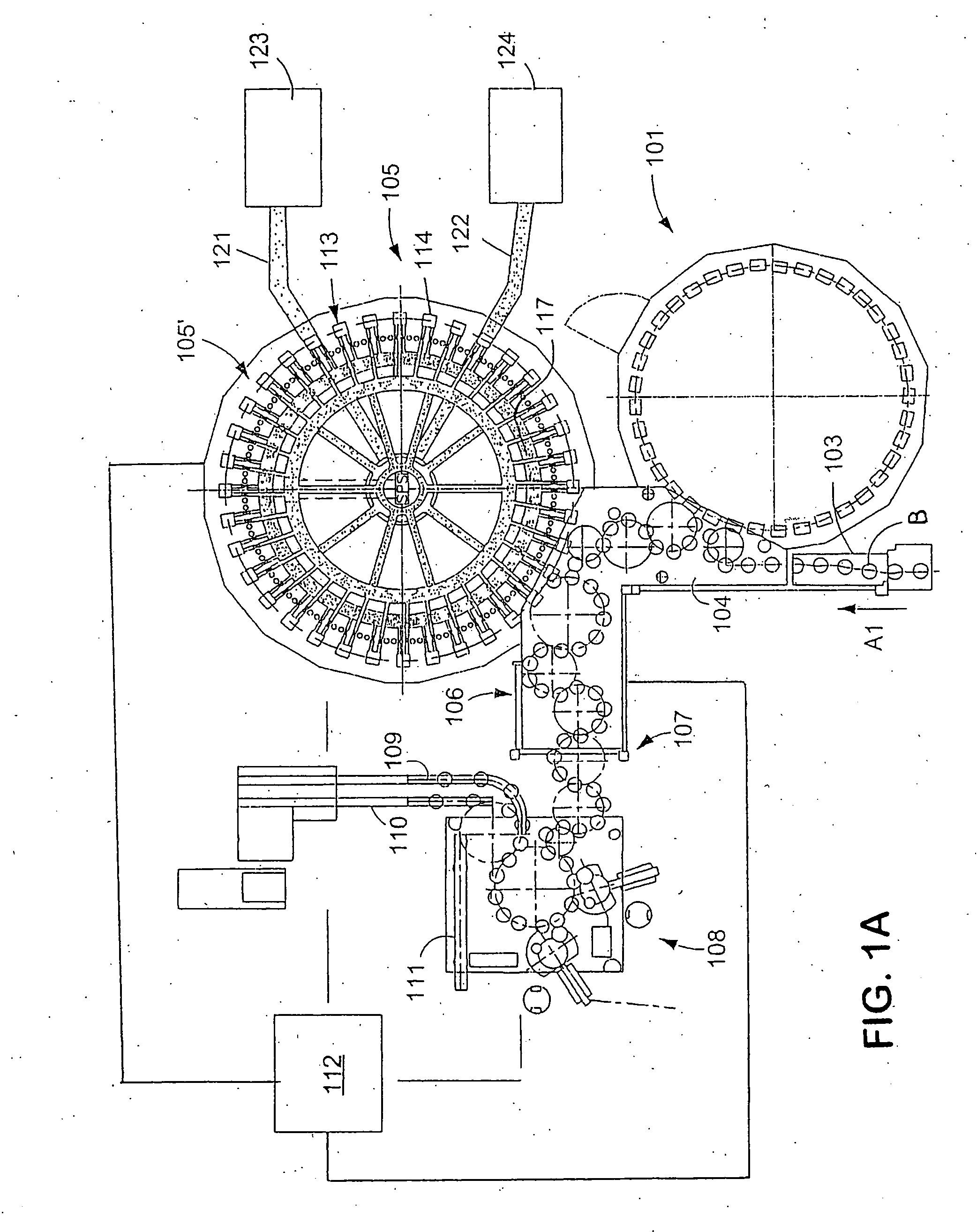

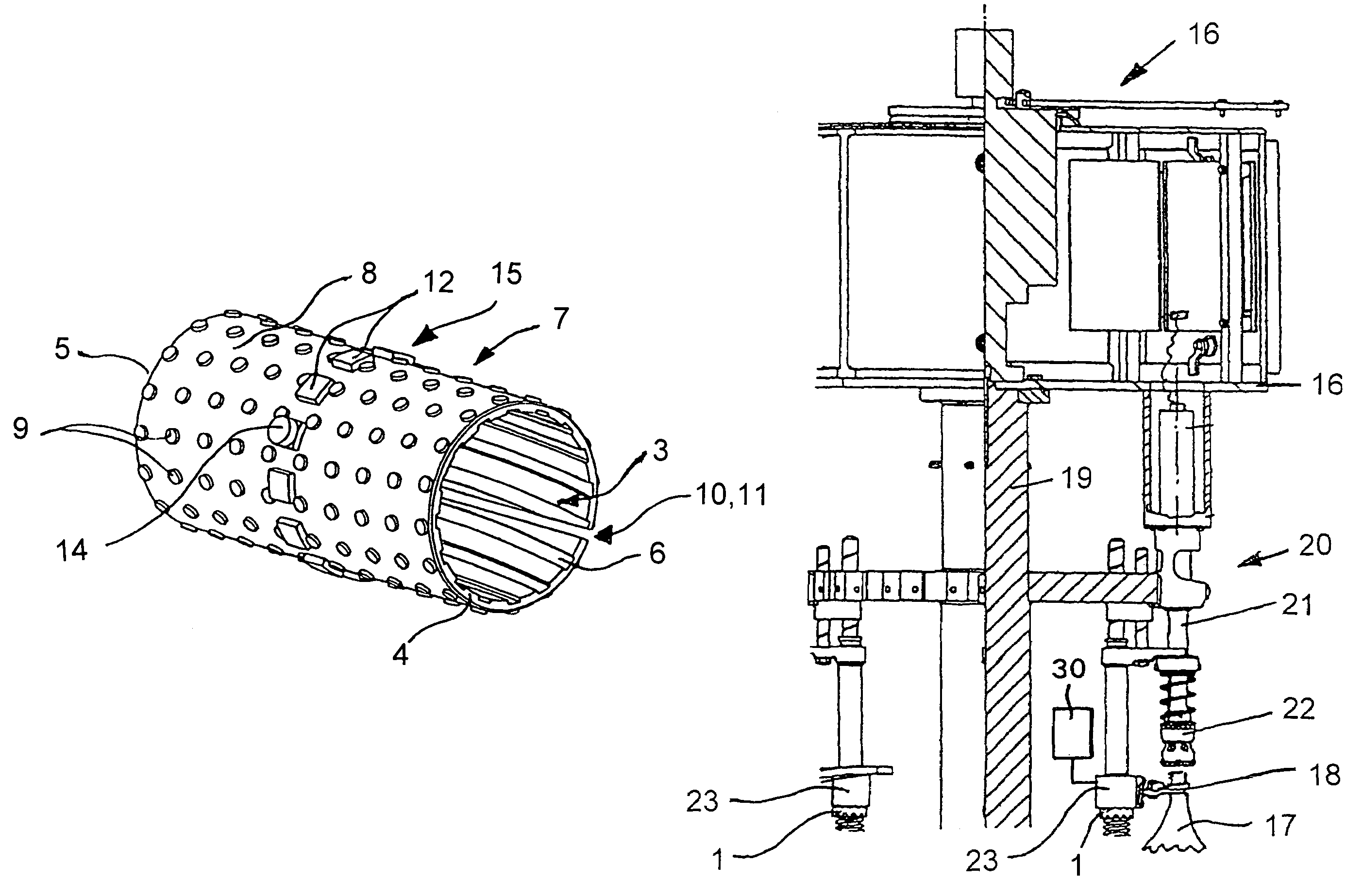

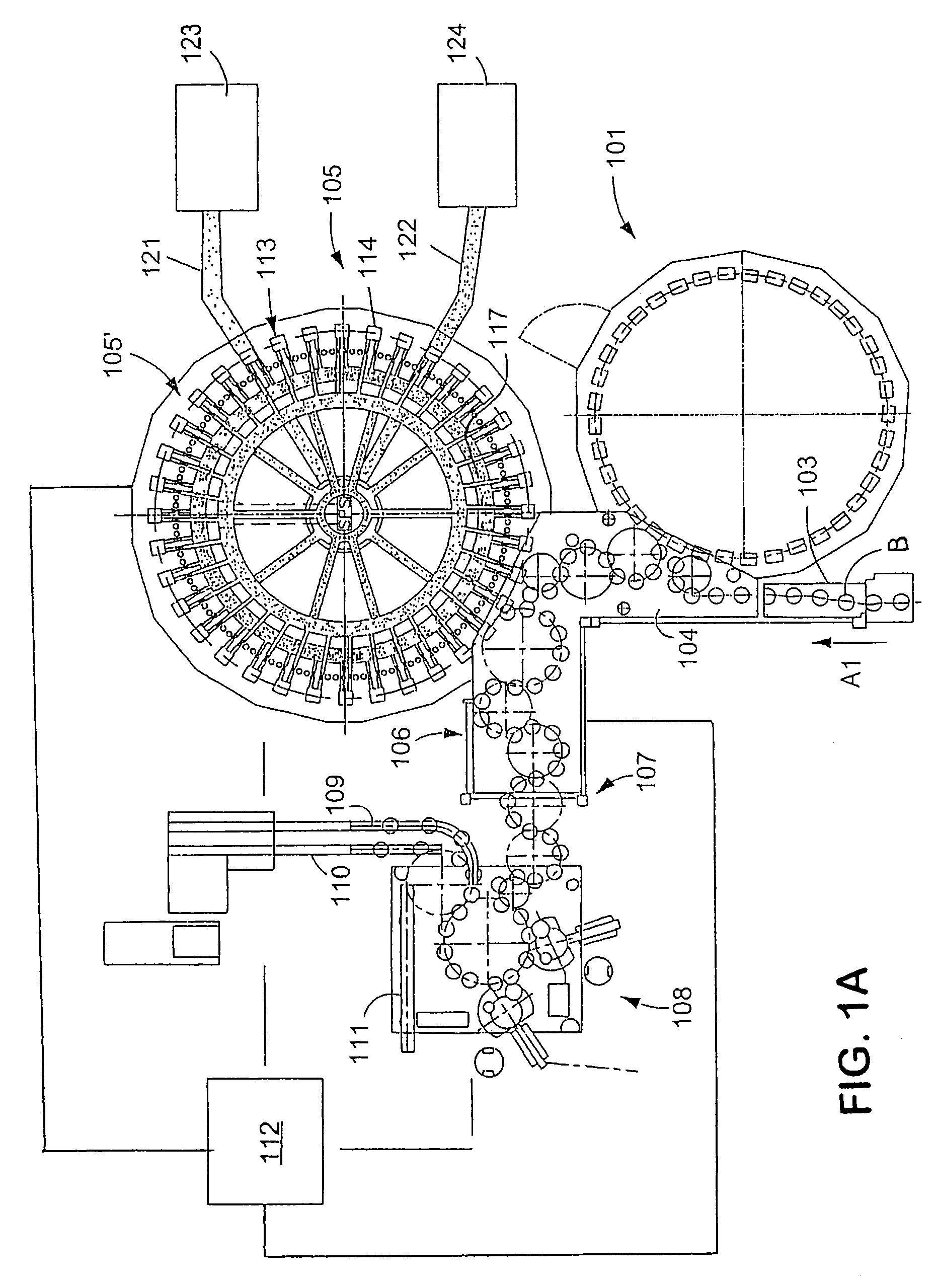

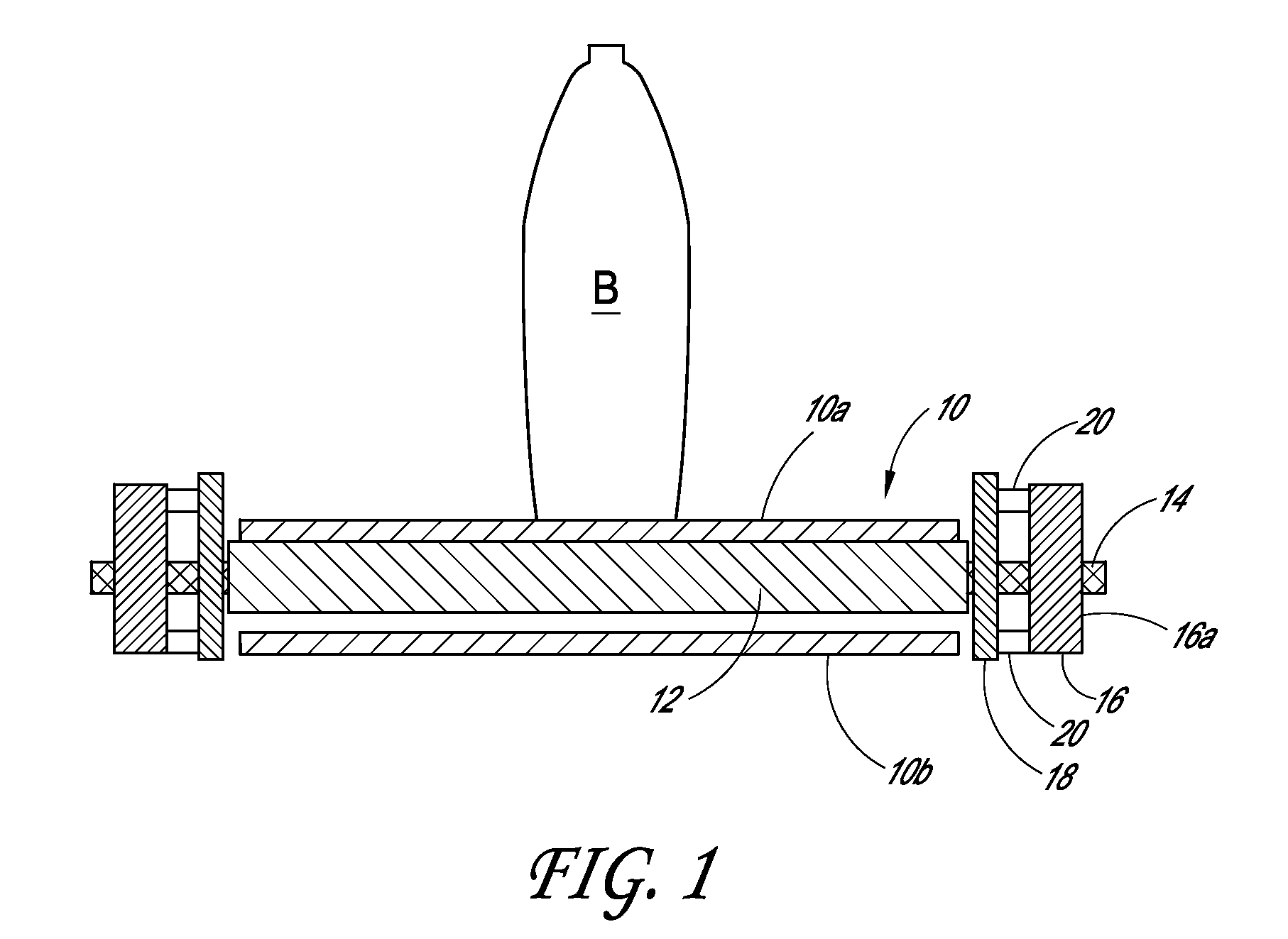

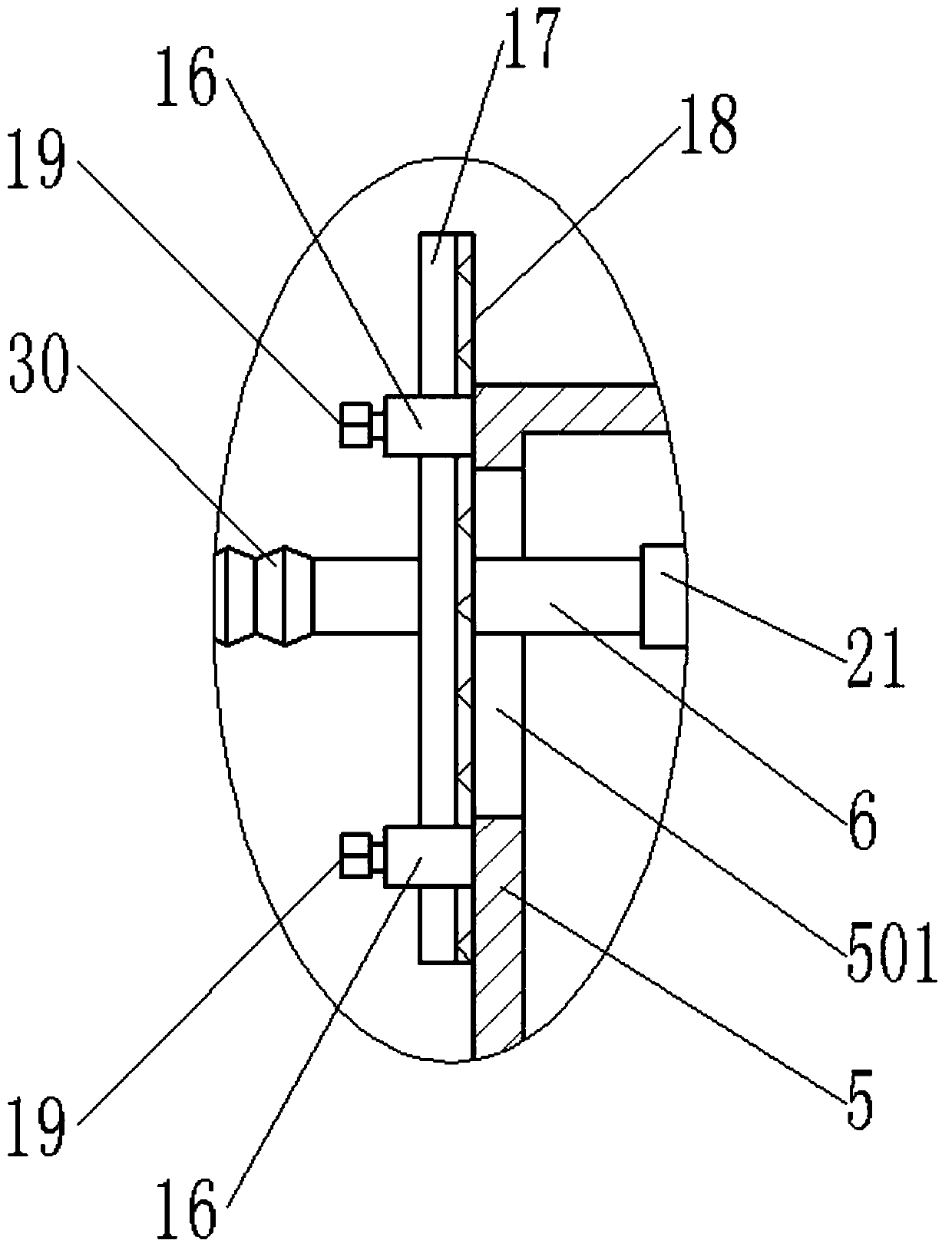

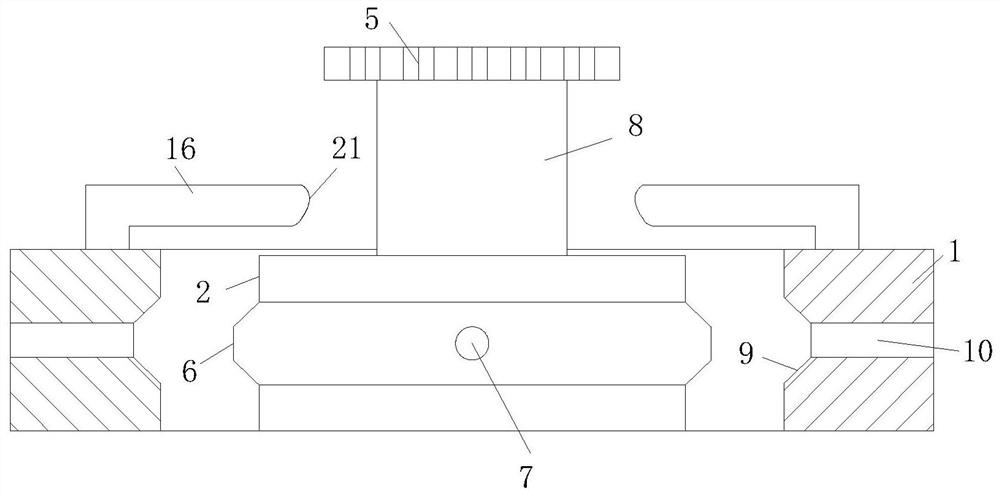

Beverage bottling plant having a beverage bottle closing machine with a bearing system to guide a reciprocating shaft in the beverage bottle closing machine

InactiveUS20070000207A1Constant and repeatable cleaningConstant gainCapsThreaded caps applicationTrademarkEngineering

A beverage bottling plant having a beverage bottle closing machine with a bearing system to guide a reciprocating shaft in the beverage bottle closing machine. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

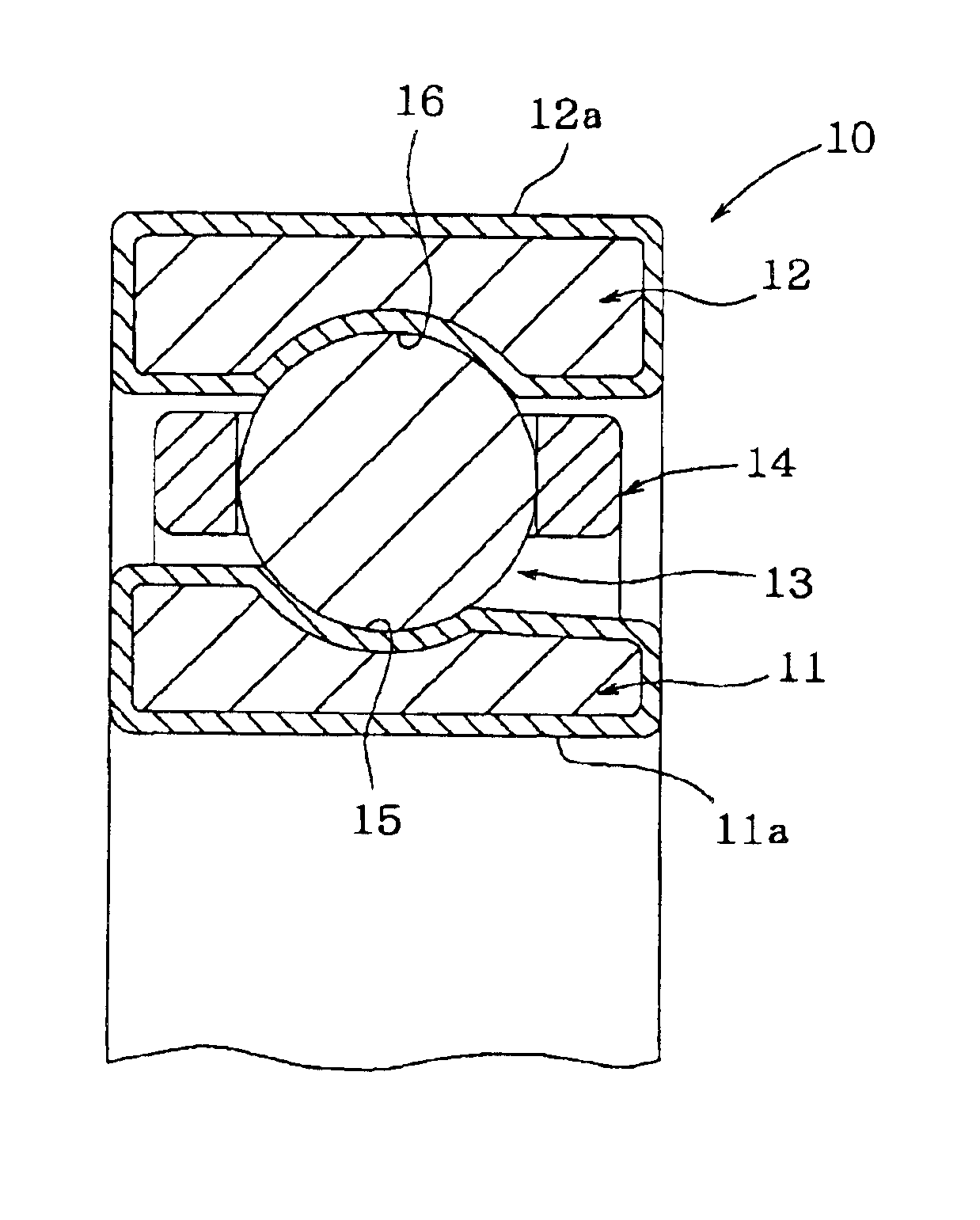

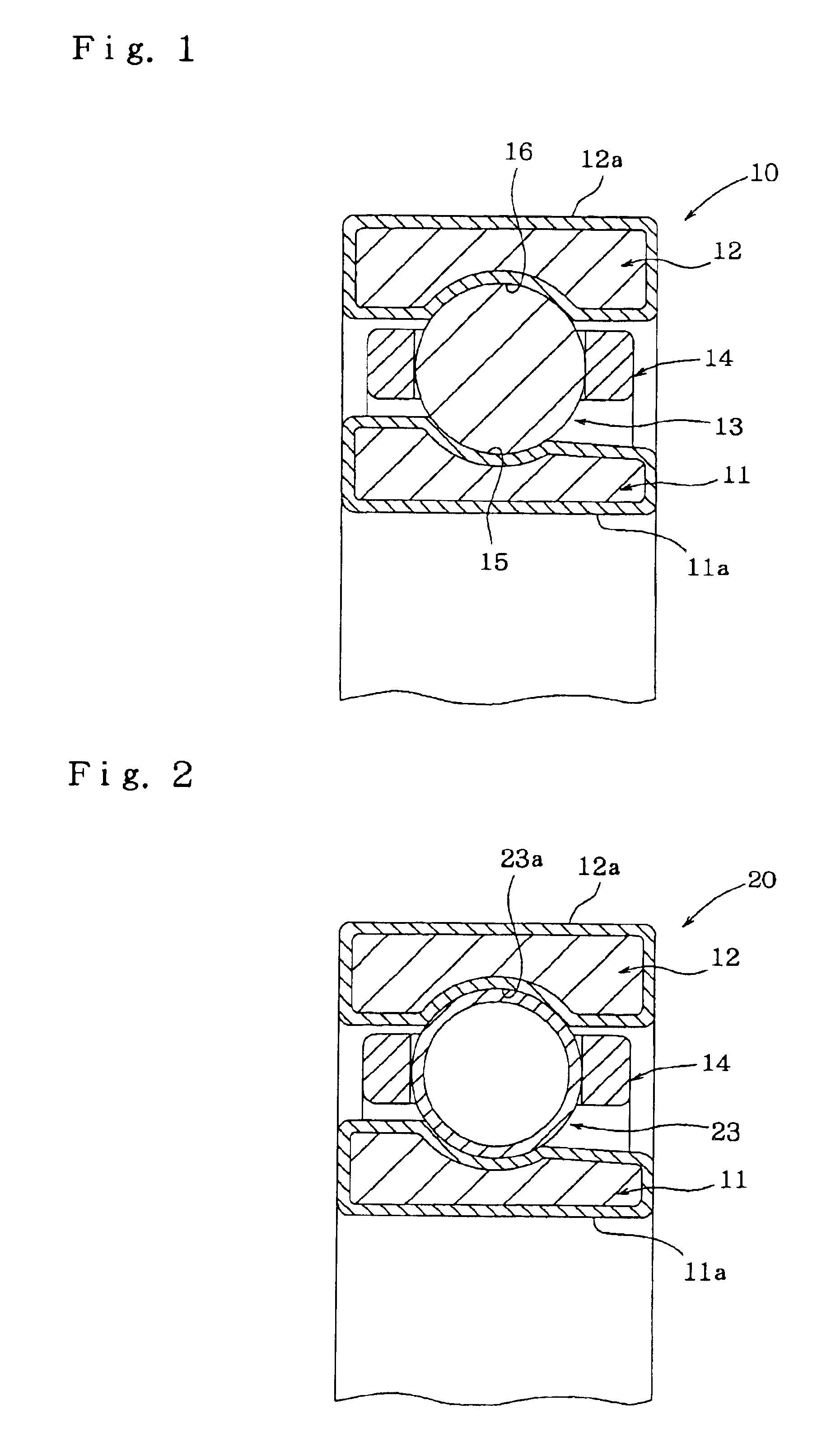

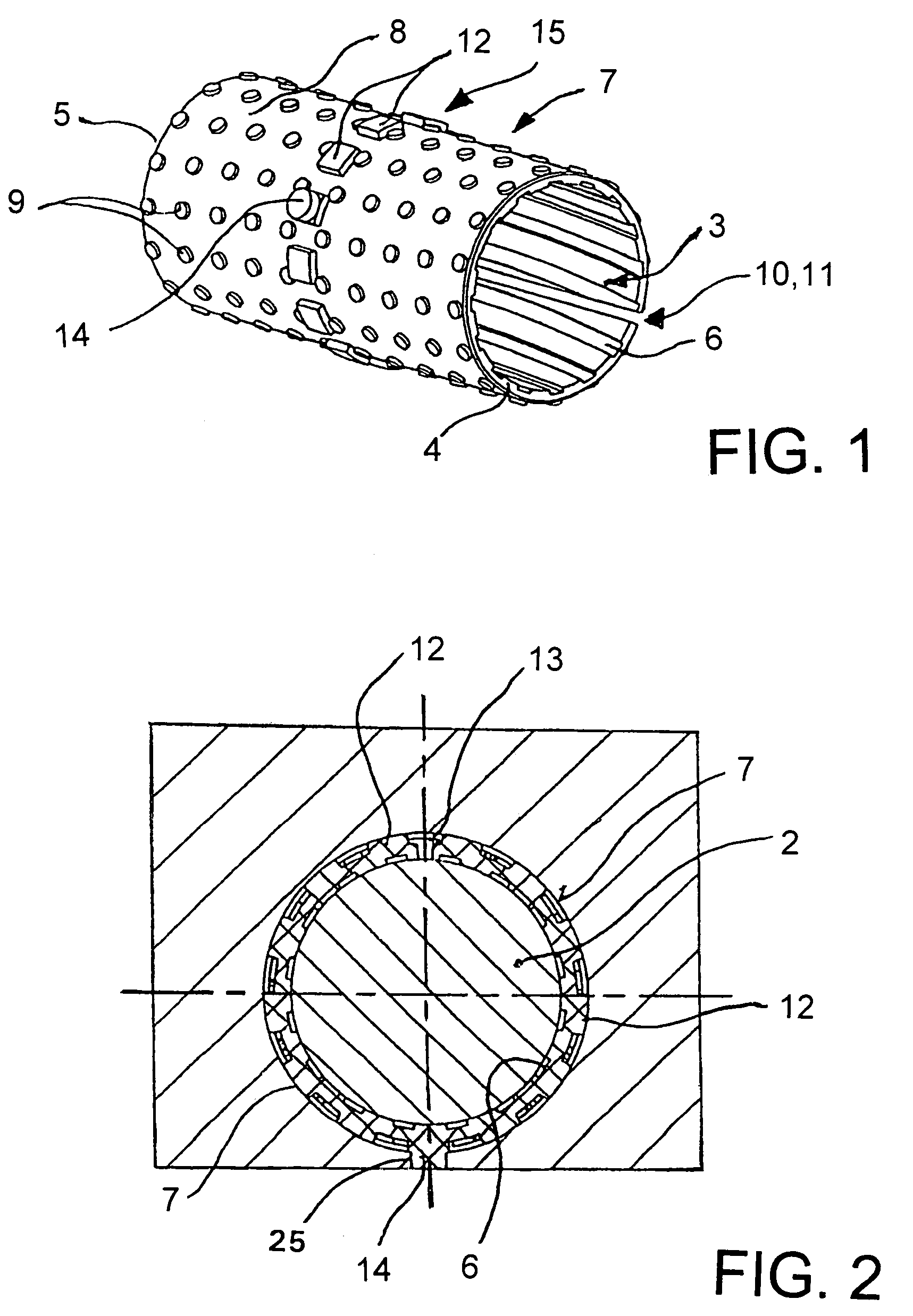

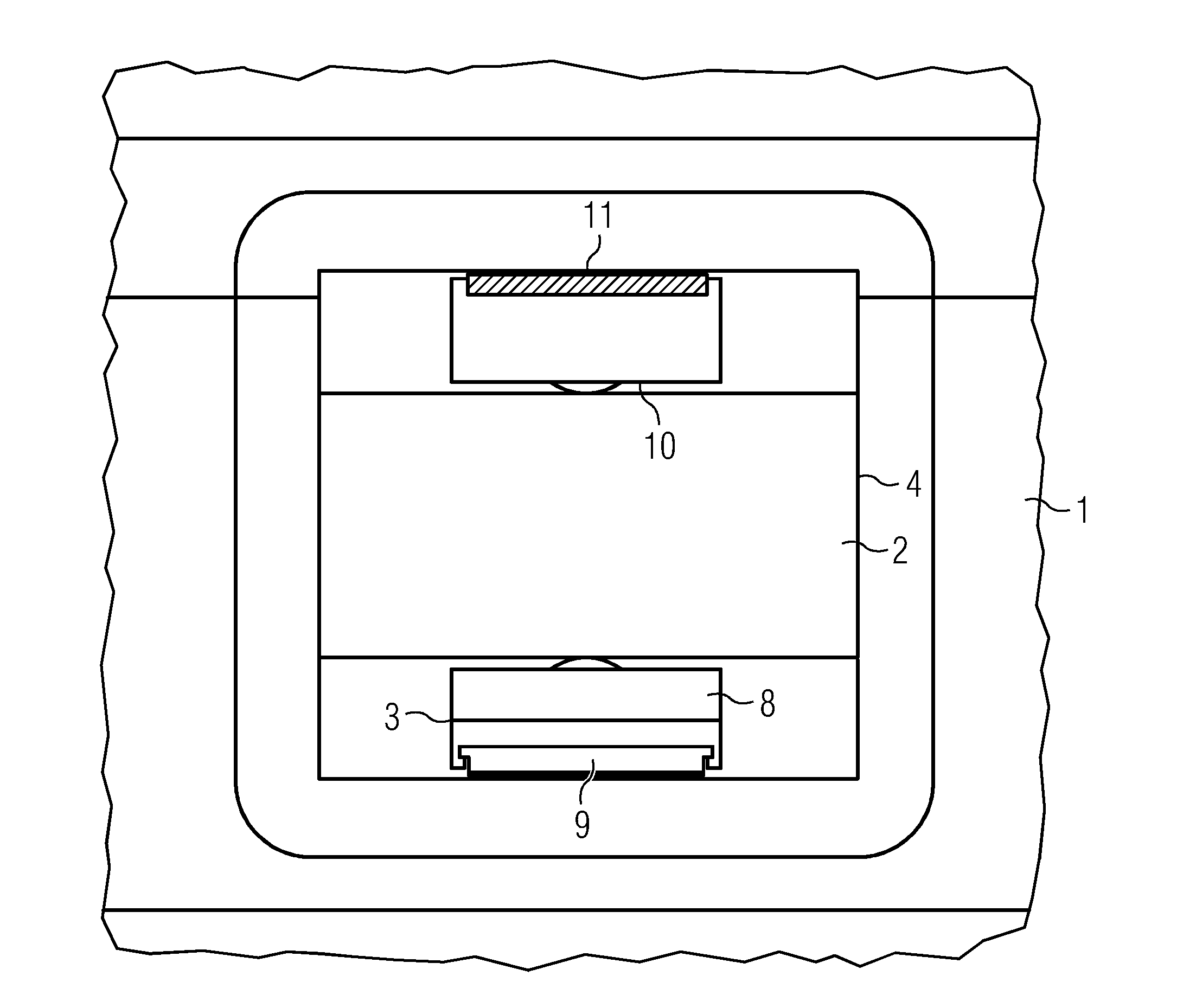

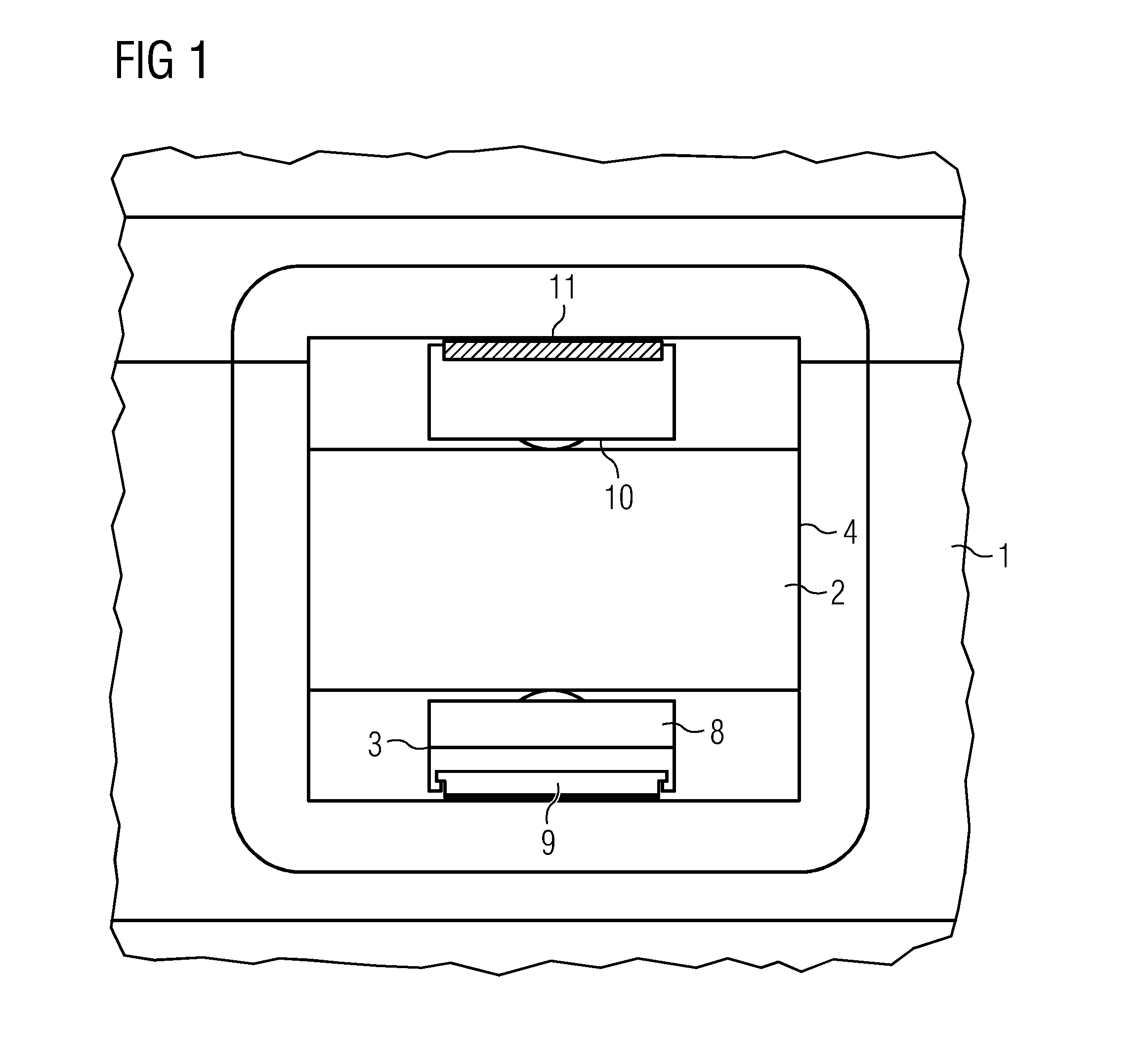

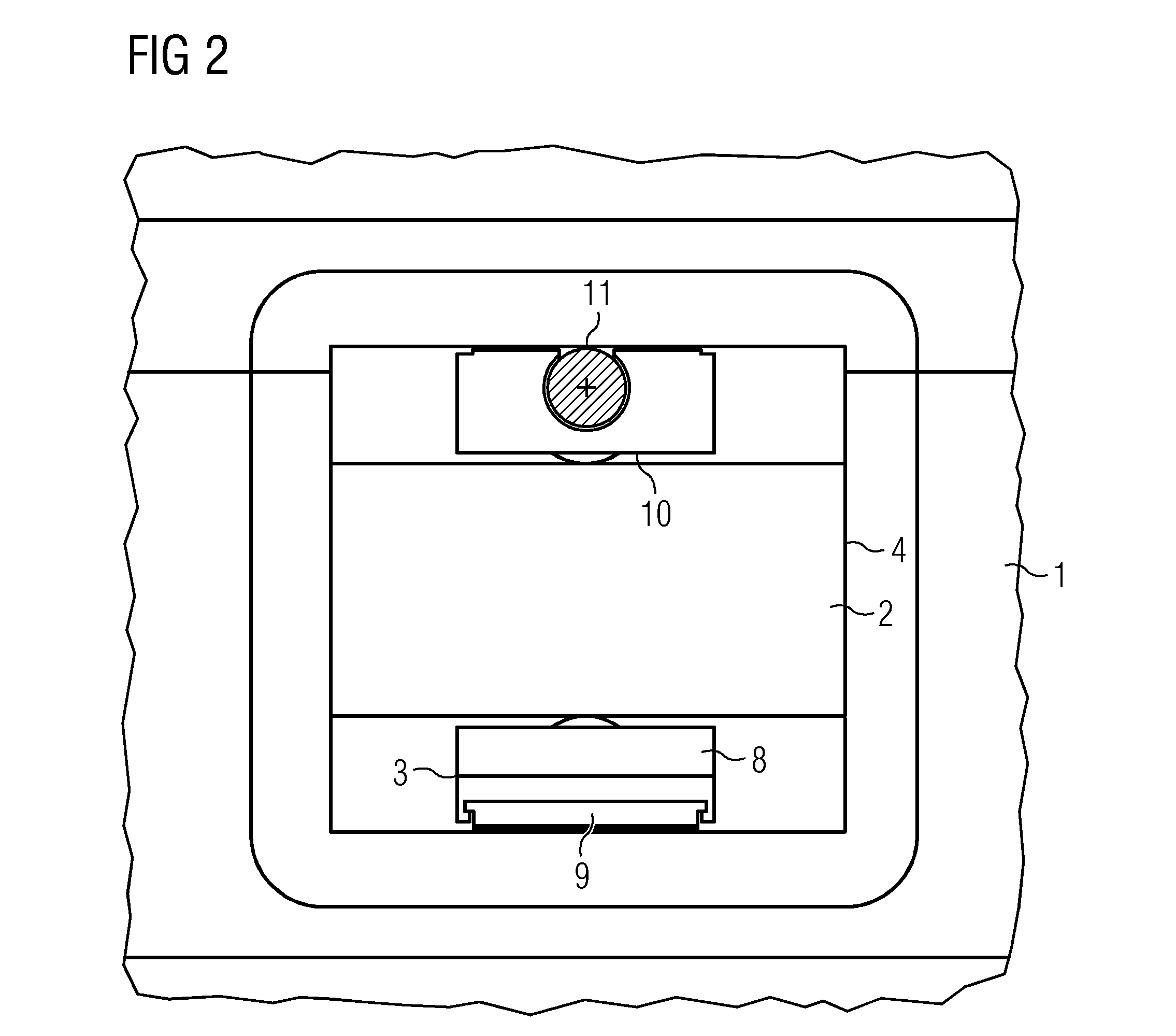

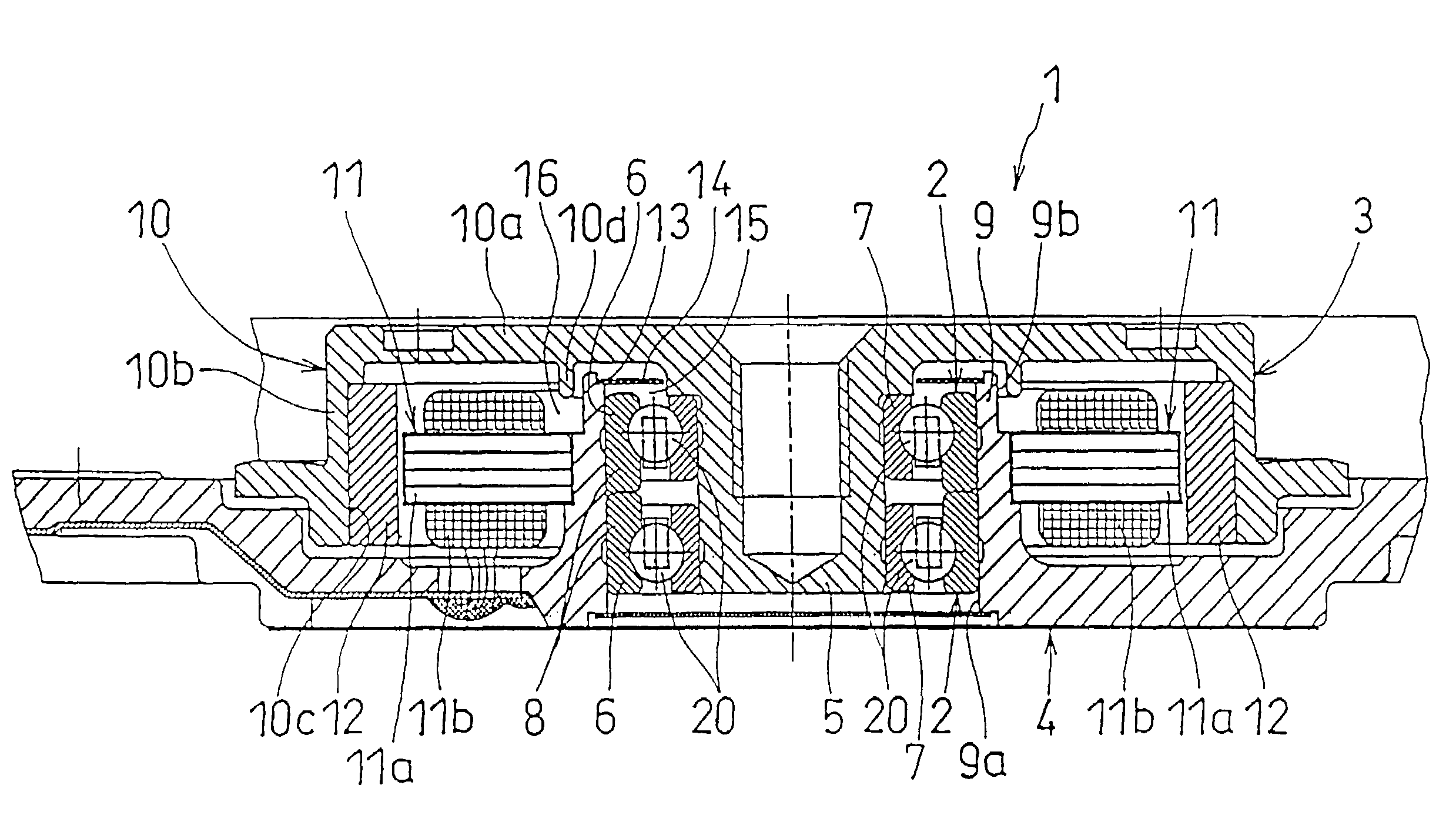

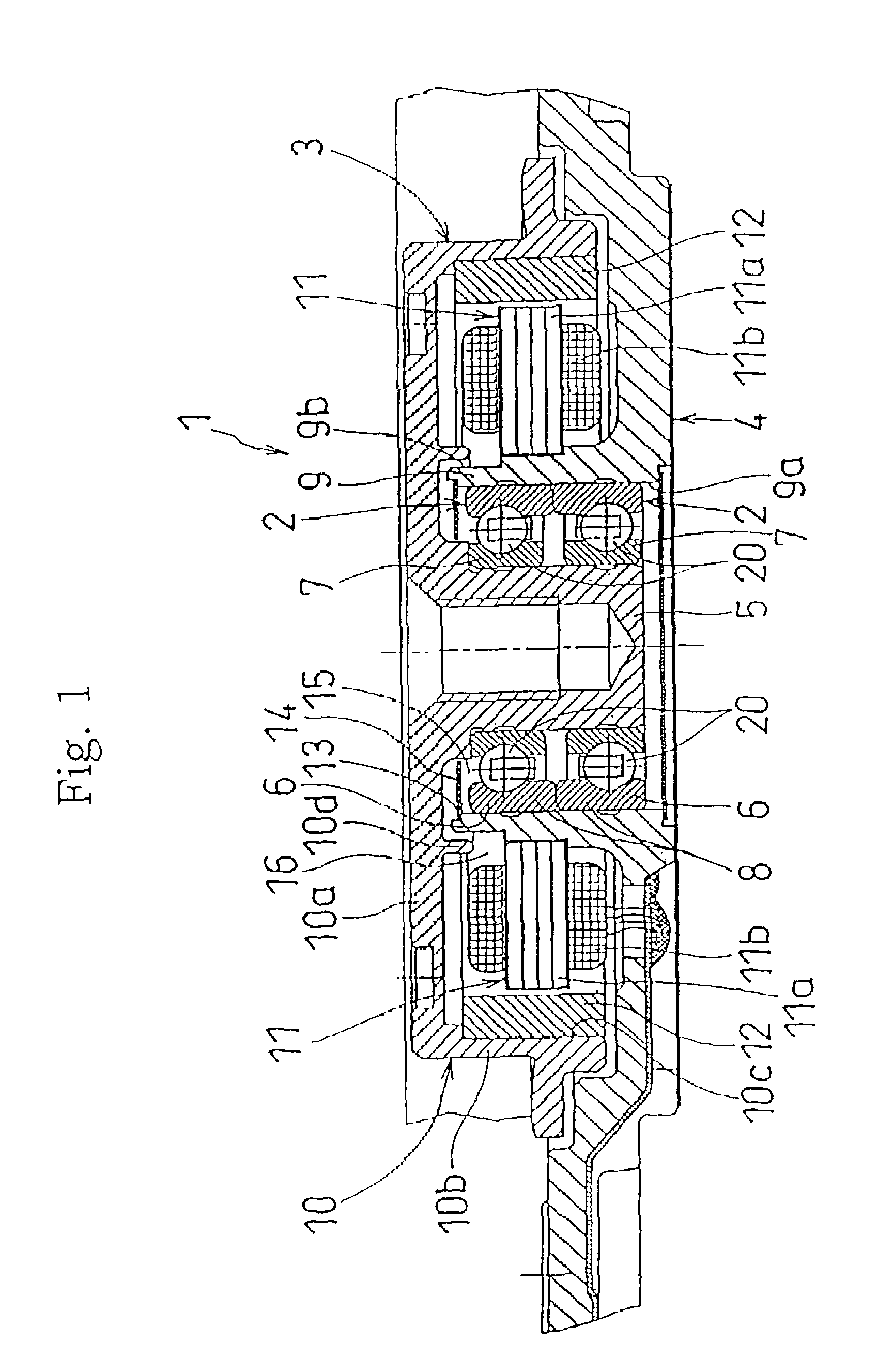

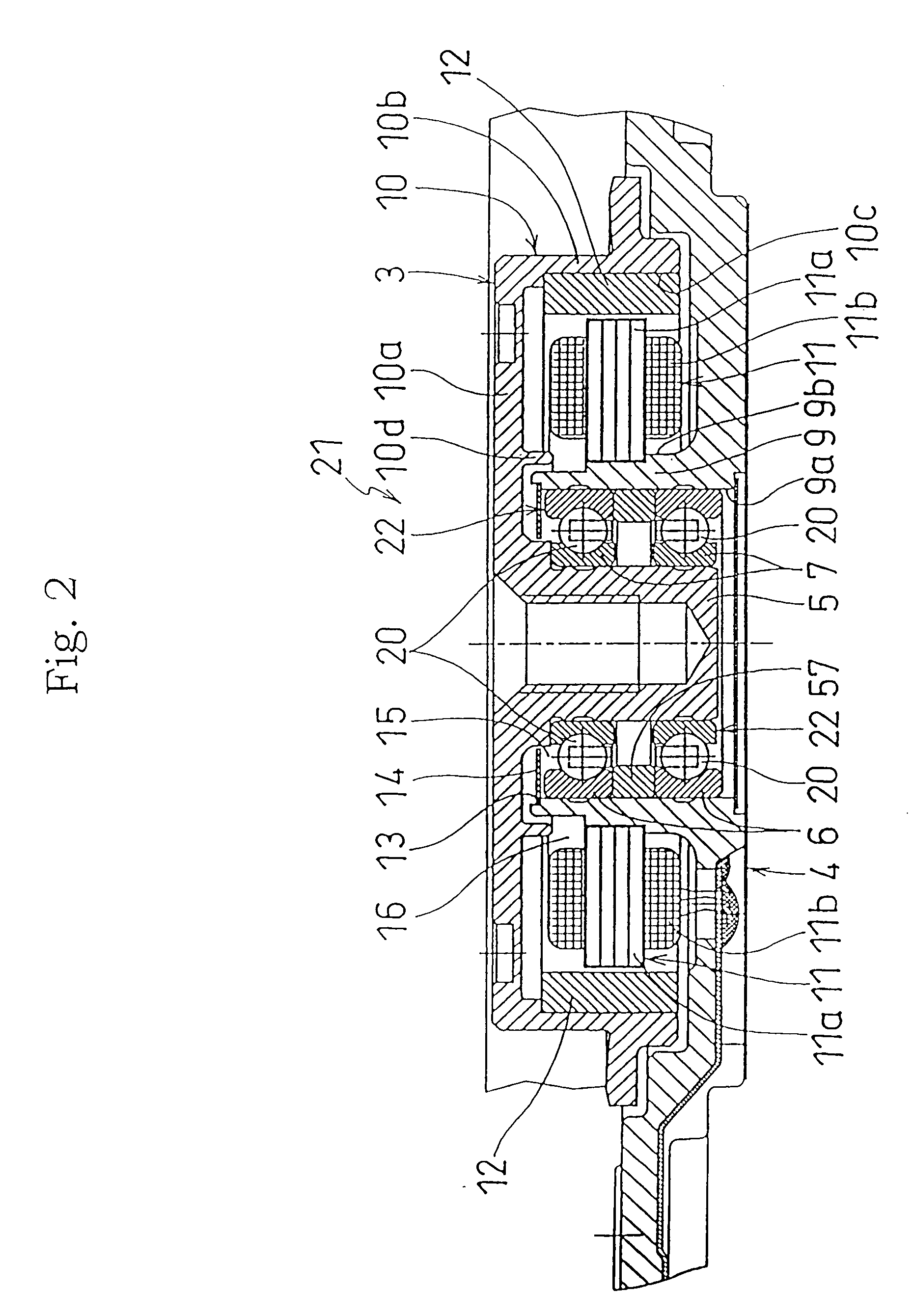

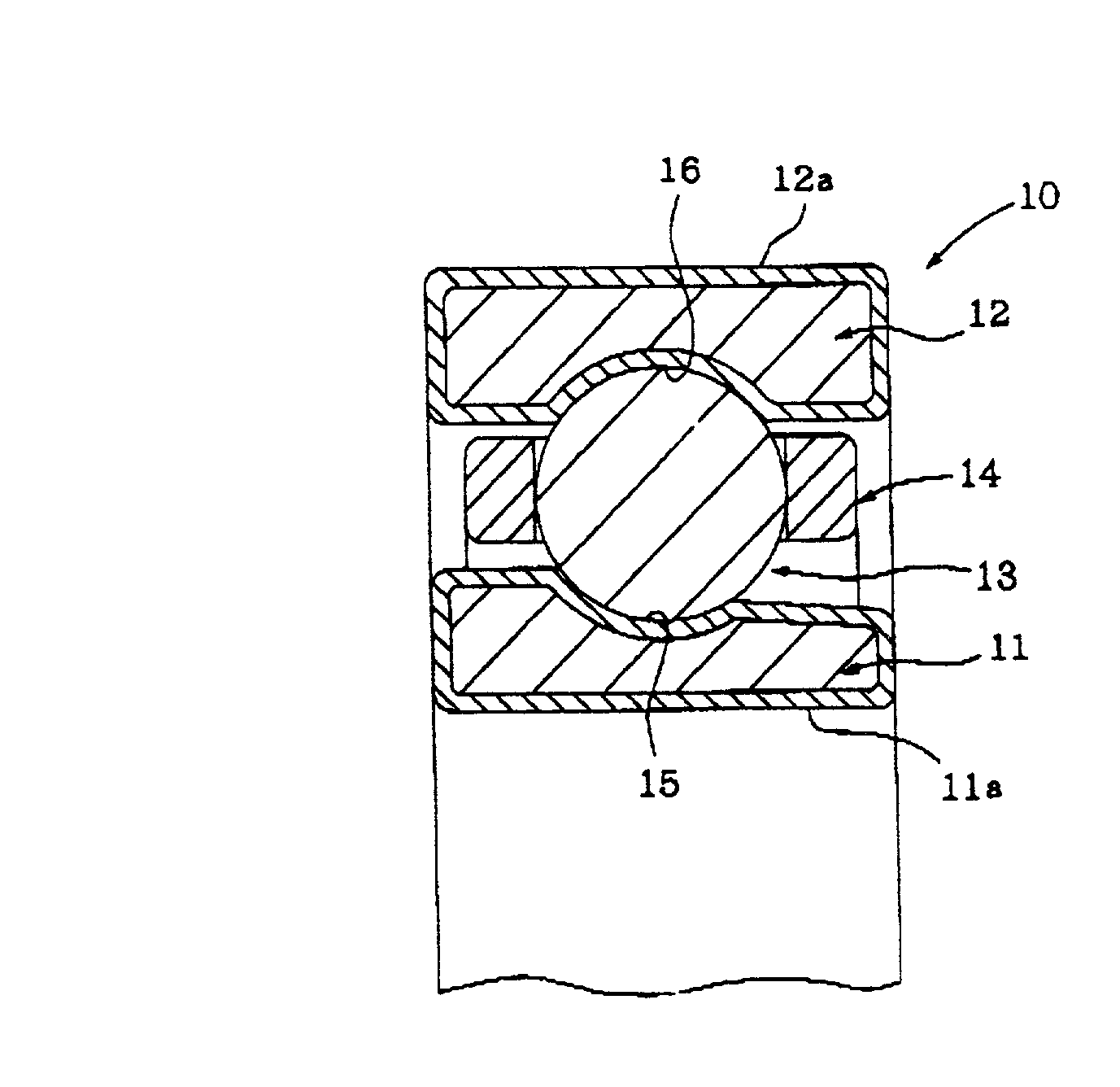

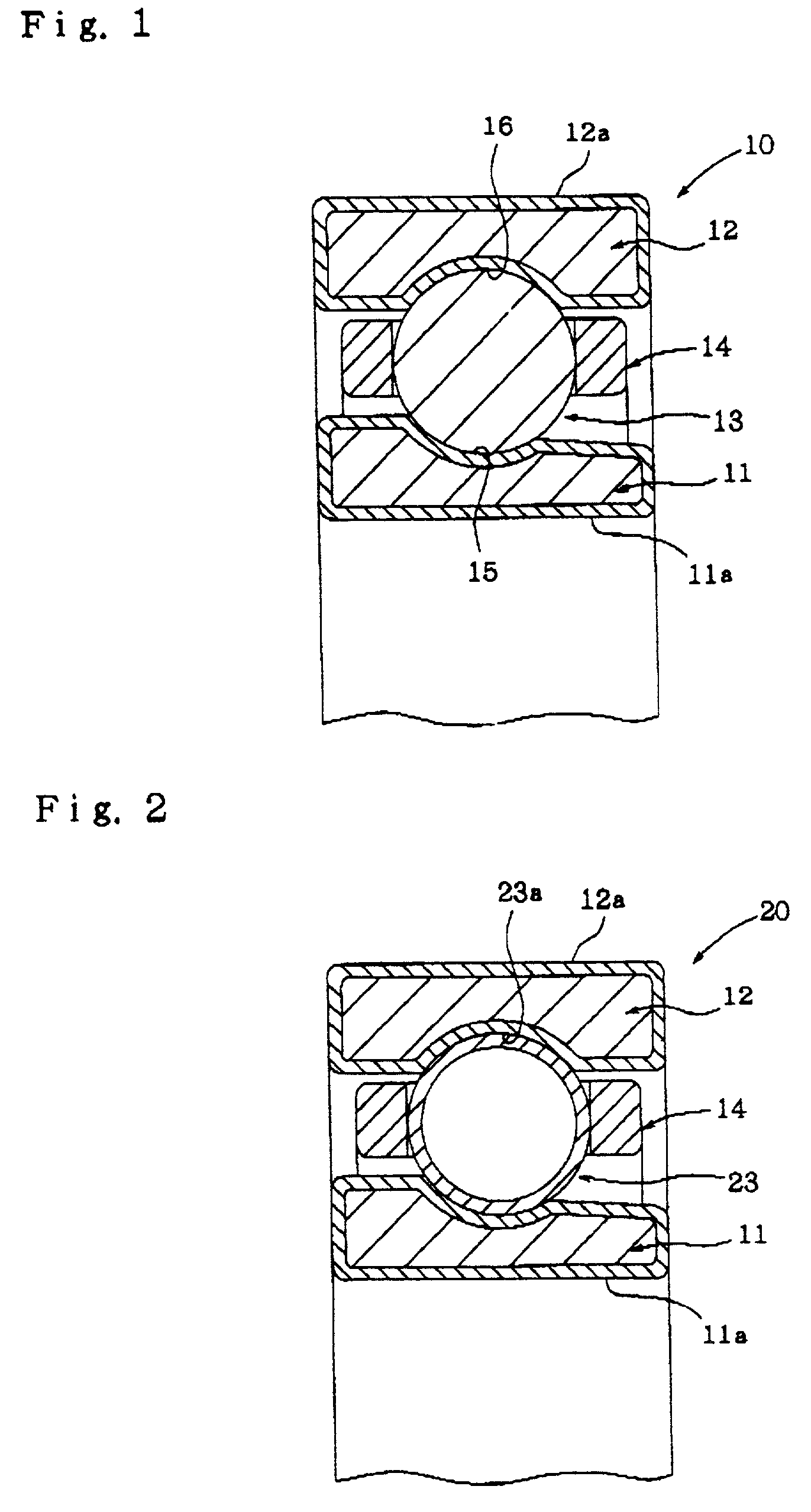

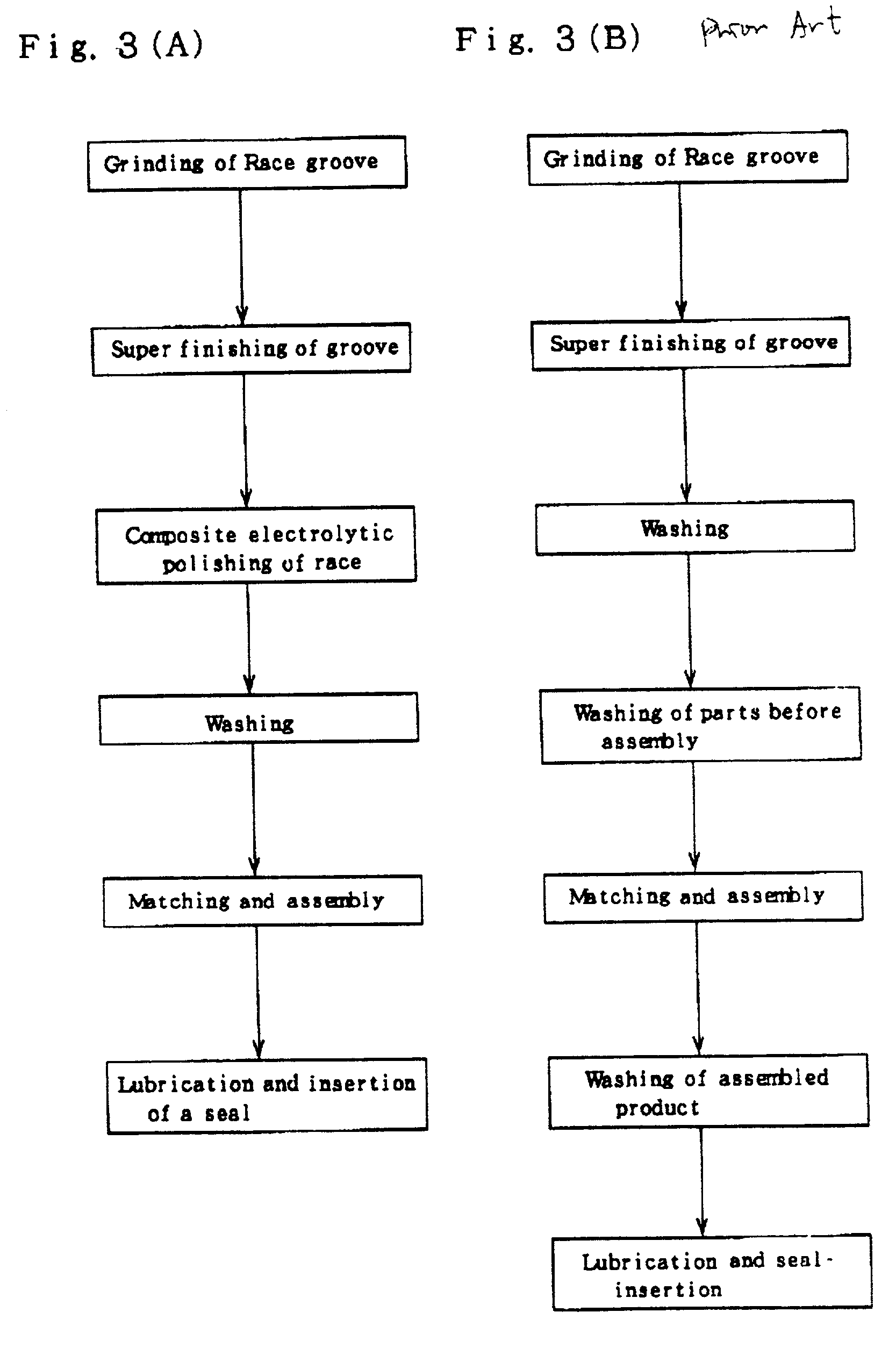

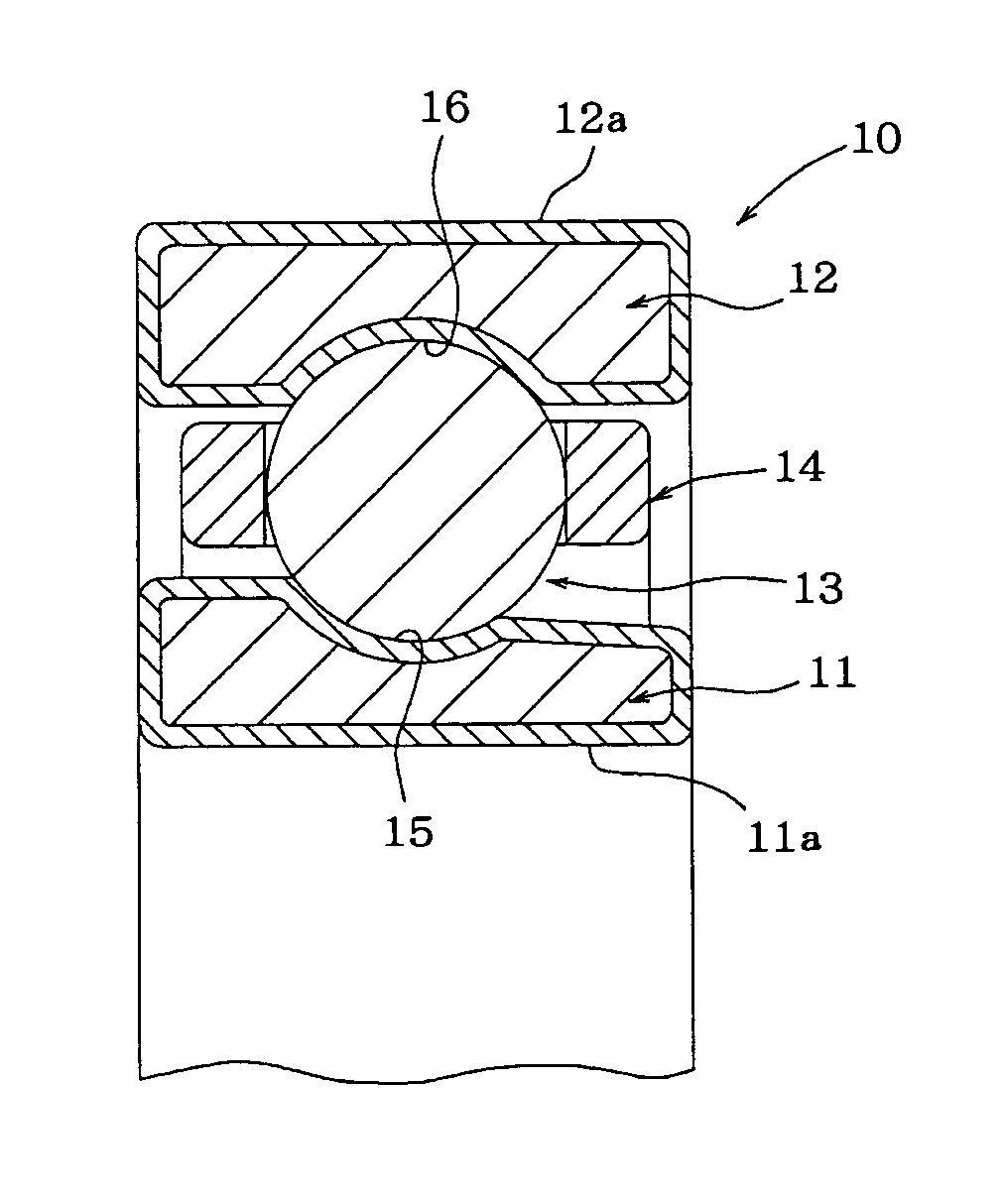

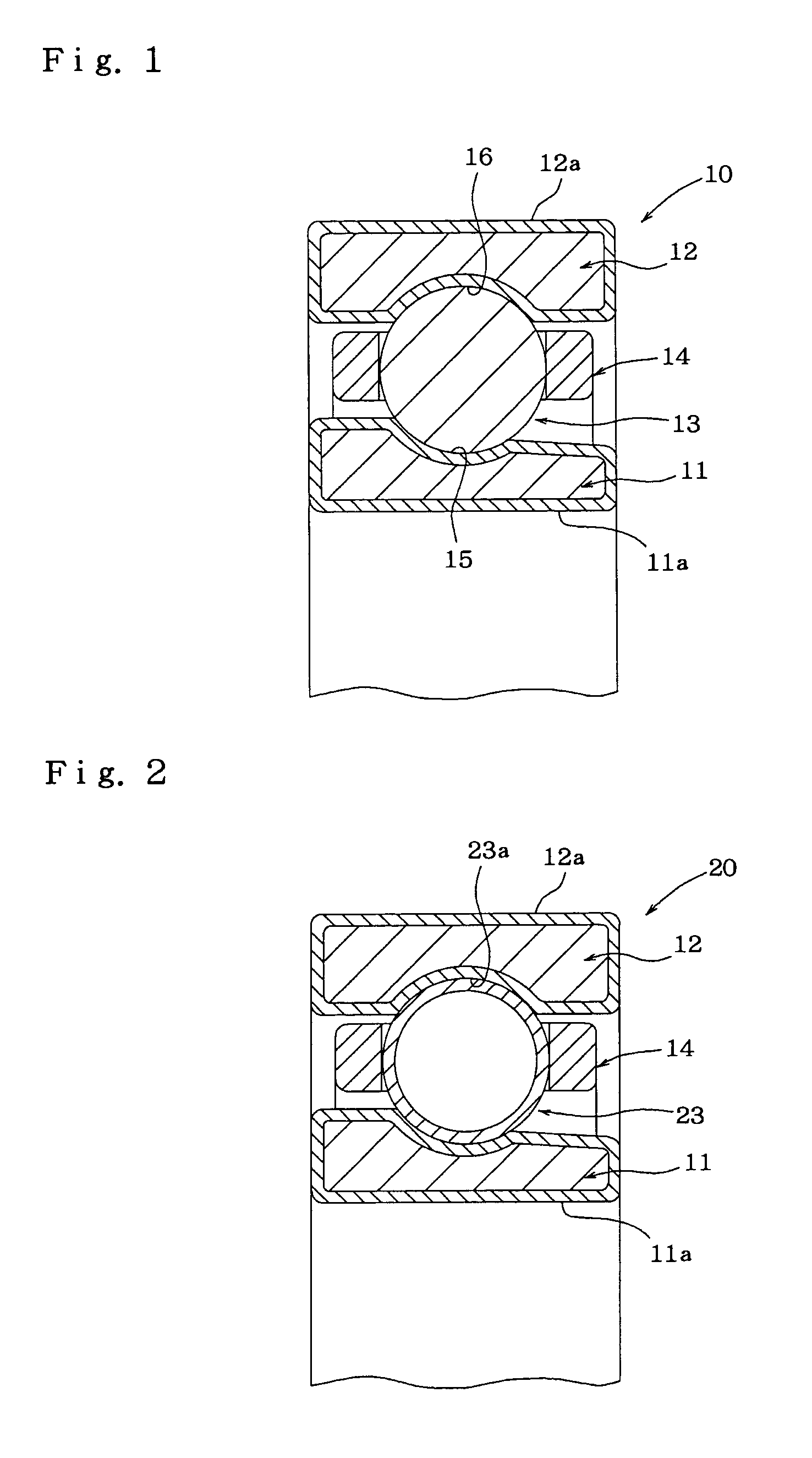

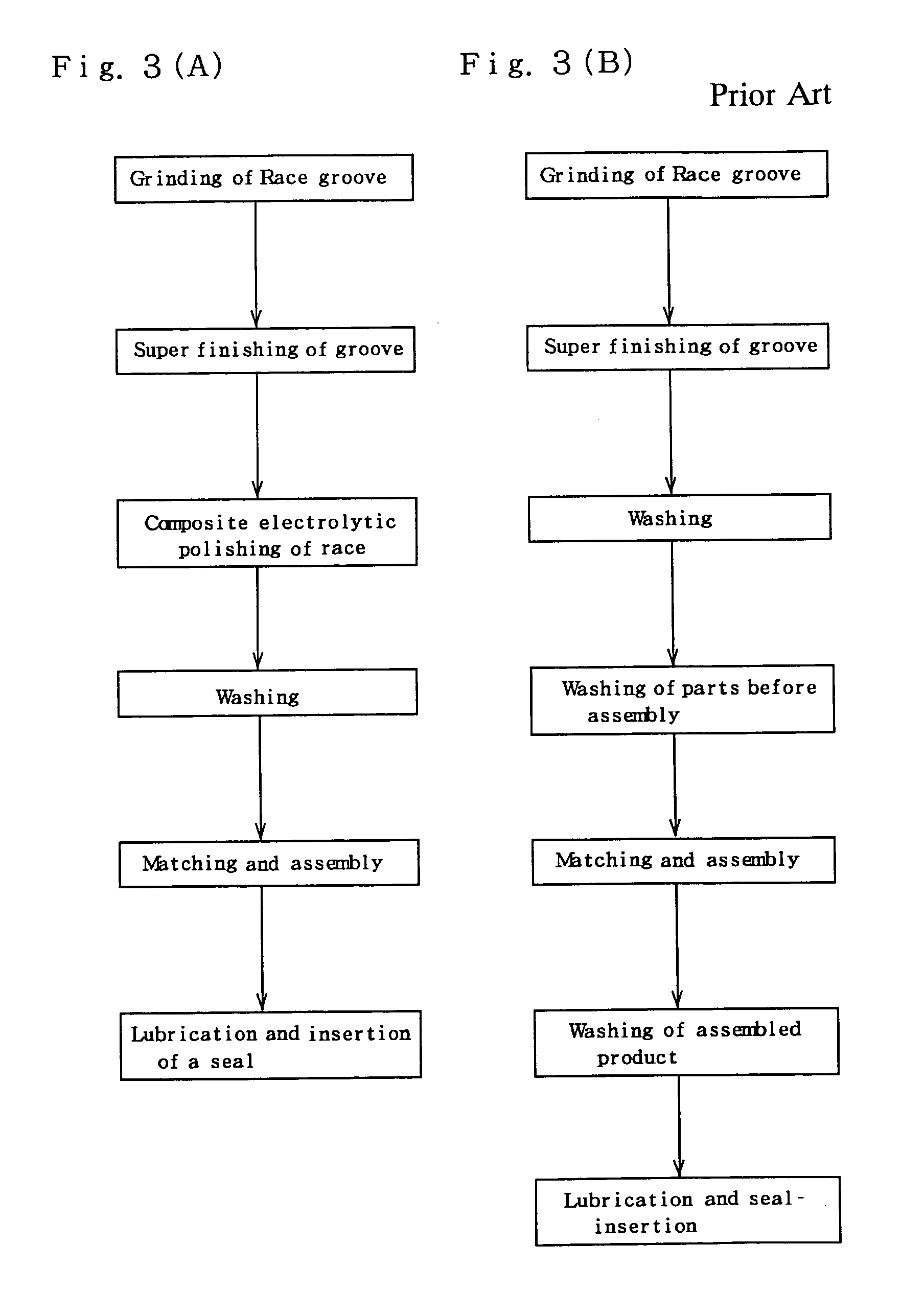

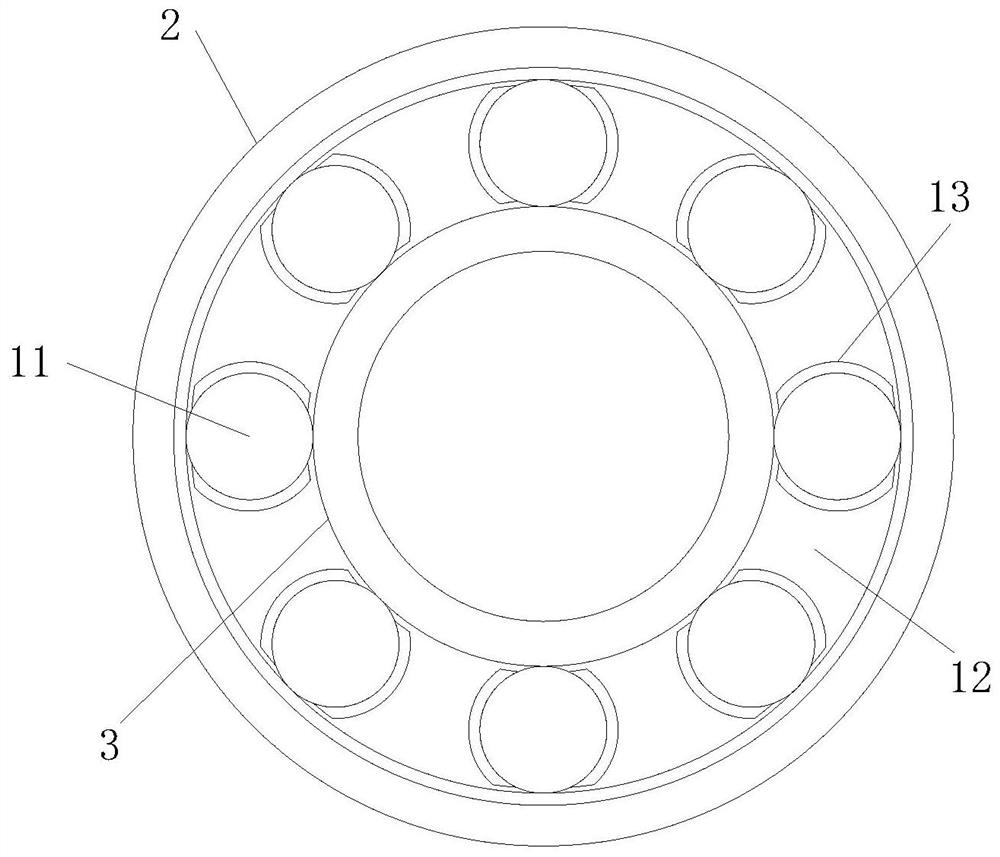

Rolling-bearing and bearing unit

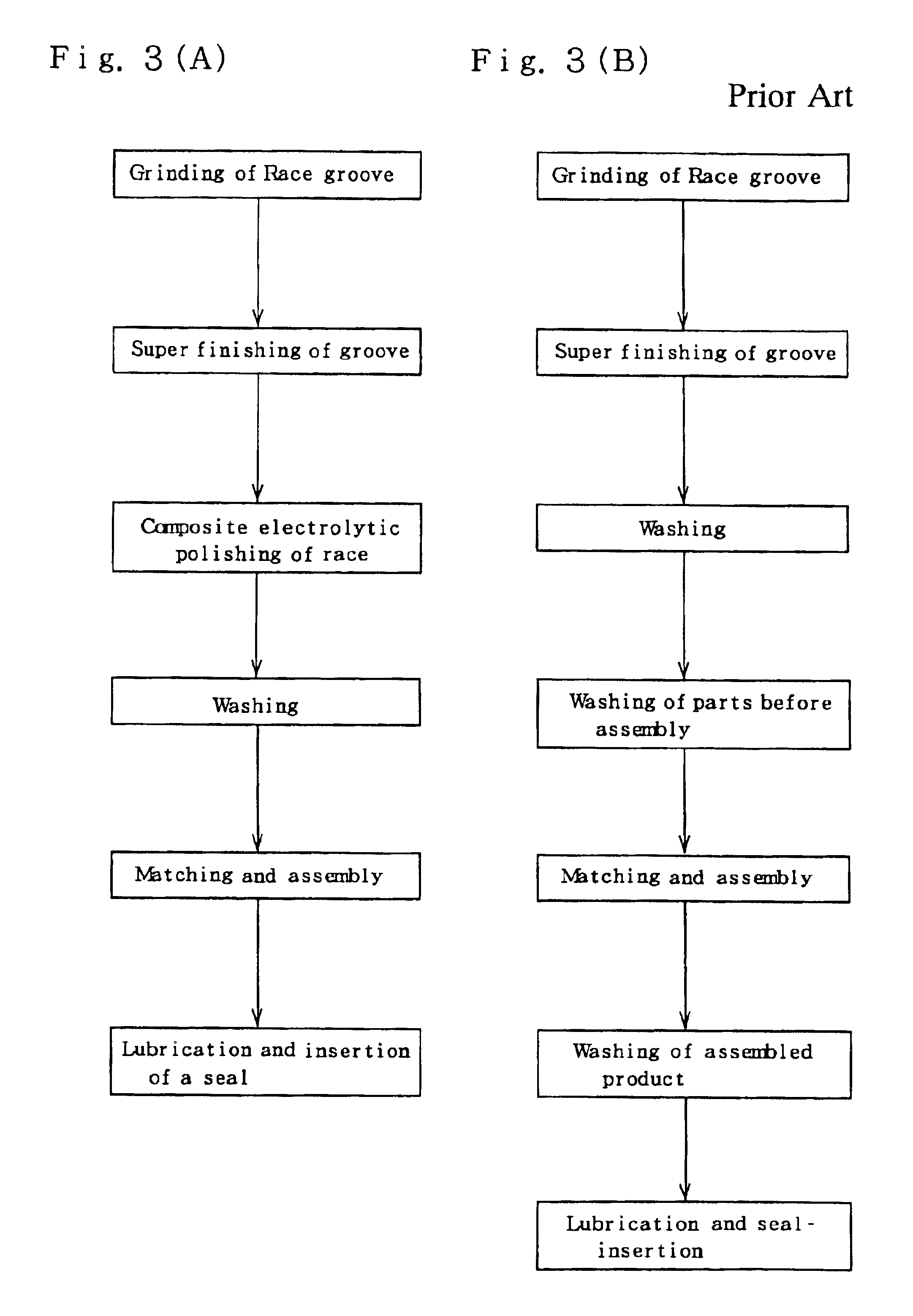

InactiveUS6896416B2Reduce pollutionBearing cleaningAbrading processSurface layerRolling-element bearing

A rolling bearing 10 comprises races 11, 12 having a raceway 15, 16 and rolling elements 13 having a rolling contact surface, wherein at least the raceway 15, 16 of the races 11, 12 has a machined surface, and a surface layer 11a, 12a is formed on the machined surface by electrochemically or chemically dissolving the machined surface, whereby contamination is substantially reduced.

Owner:NSK LTD

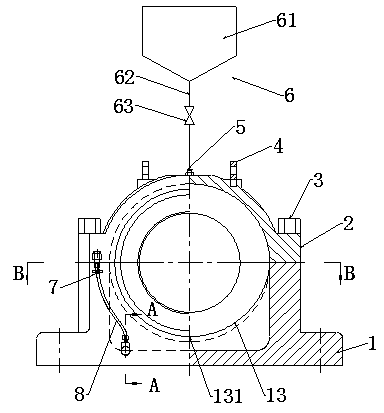

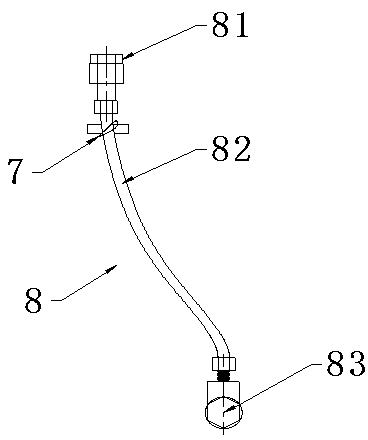

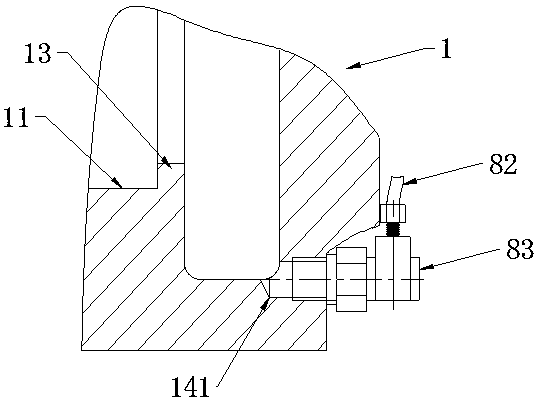

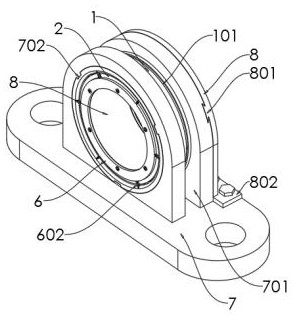

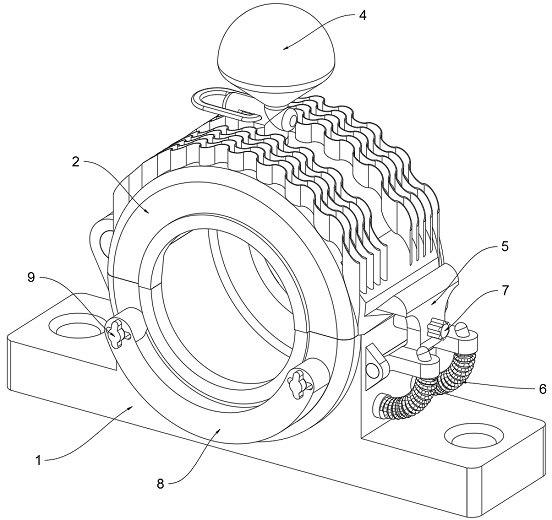

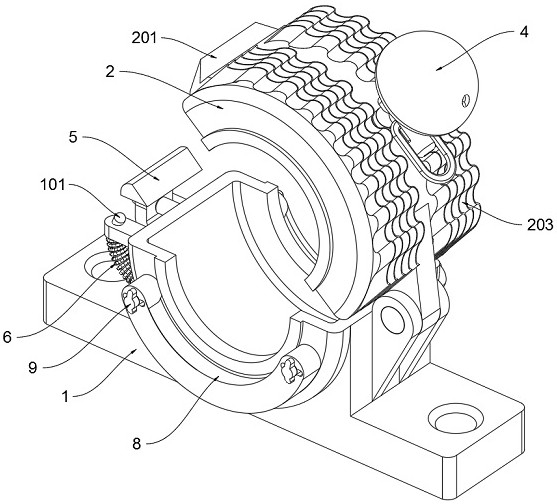

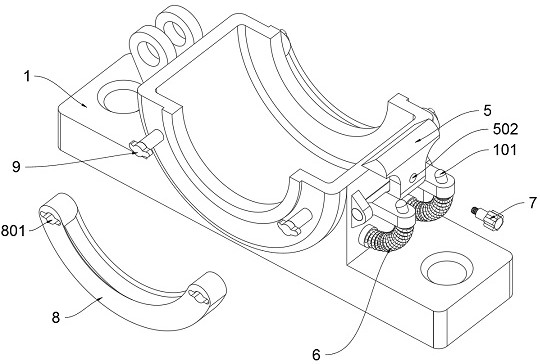

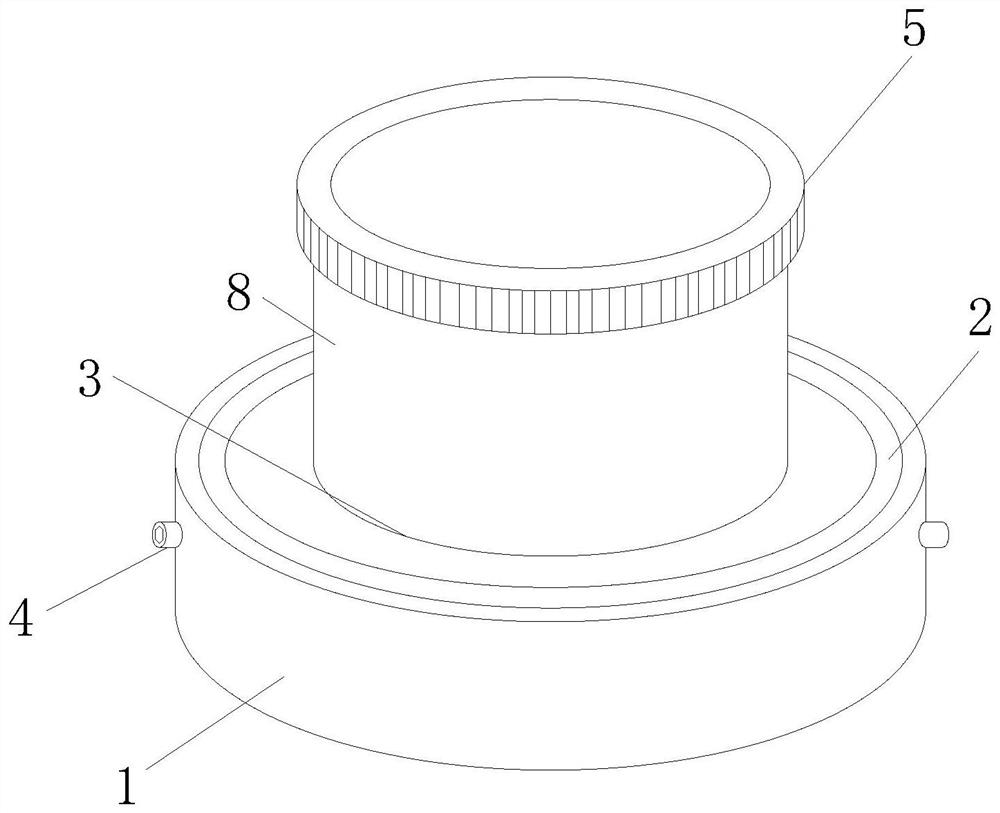

Mineral engineering machinery, disassembly-free oil cavity cleanable bearing block and cleaning method

ActiveCN103867582AExtended service lifeFlexible rotationBearing cleaningRotary machine partsWorking environmentOil storage

The invention discloses a disassembly-free oil cavity cleanable bearing block, which comprises a bearing block body and a bearing cap arranged on the bearing block body, wherein an oil storage cavity is formed in the bearing block body and the bearing cap; a threaded hole communicated with the lateral surface of the bearing block body is formed below the oil storage cavity; a rotary joint of an adjustable oil outlet device is arranged at the threaded hole, so that a function of cleaning an oil cavity of the bearing block without disassembly is realized. The bearing block with the structure has the advantages that the bearing block is easy to use and machine, low in cost and long in service, the service life of a bearing is prolonged, the working environment of the bearing is improved, and the like. In addition, the invention also discloses an oil cavity cleaning method based on the disassembly-free oil cavity cleanable bearing block, which is easy to operate and high in efficiency. Moreover, the invention discloses mineral engineering machinery comprising the disassembly-free oil cavity cleanable bearing block. The mineral engineering machinery has the advantages of simplicity in maintenance and long service life, and the major overhauling cycle of the mineral engineering machinery can be prolonged.

Owner:江苏京冶海上风电轴承制造有限公司

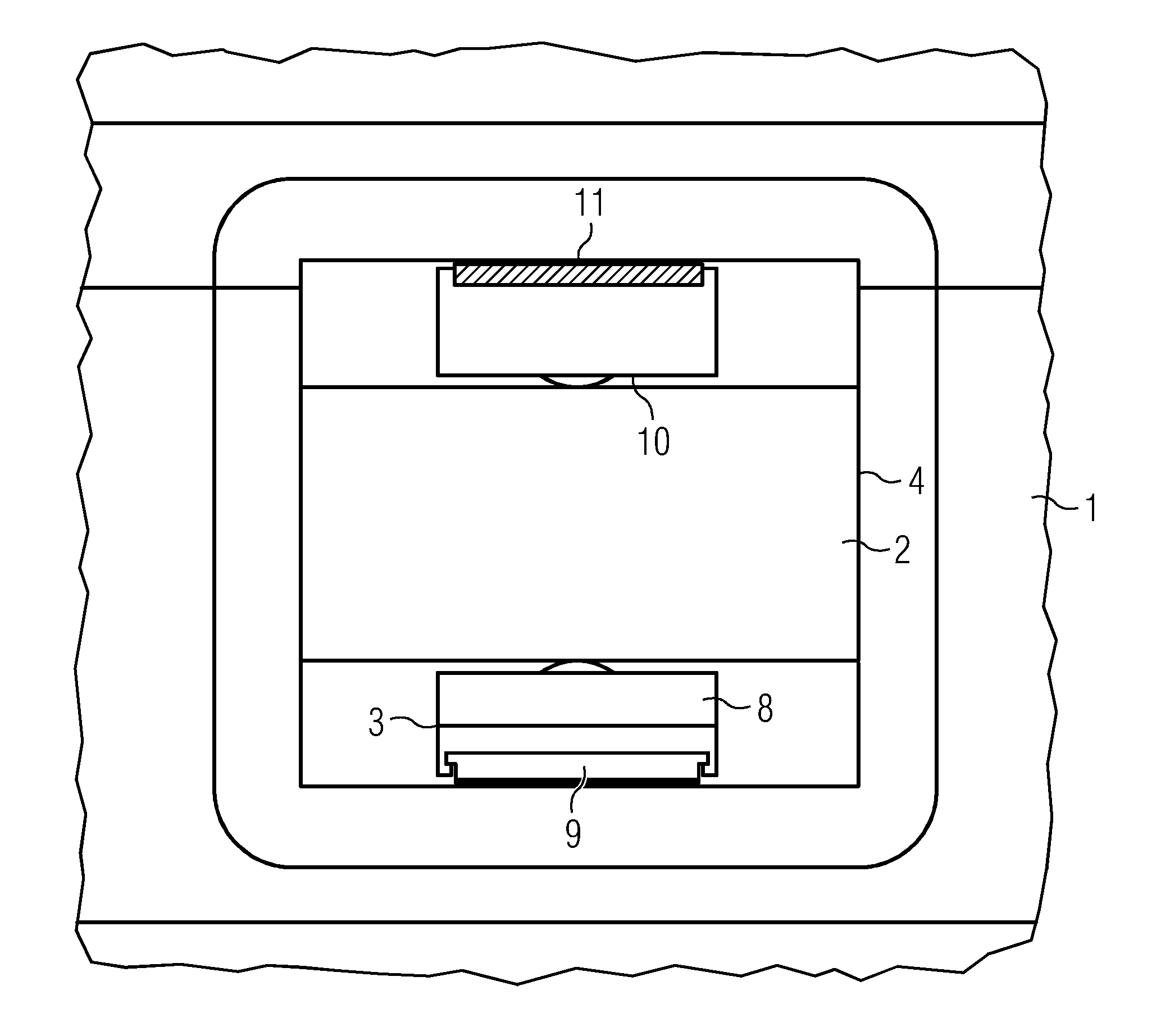

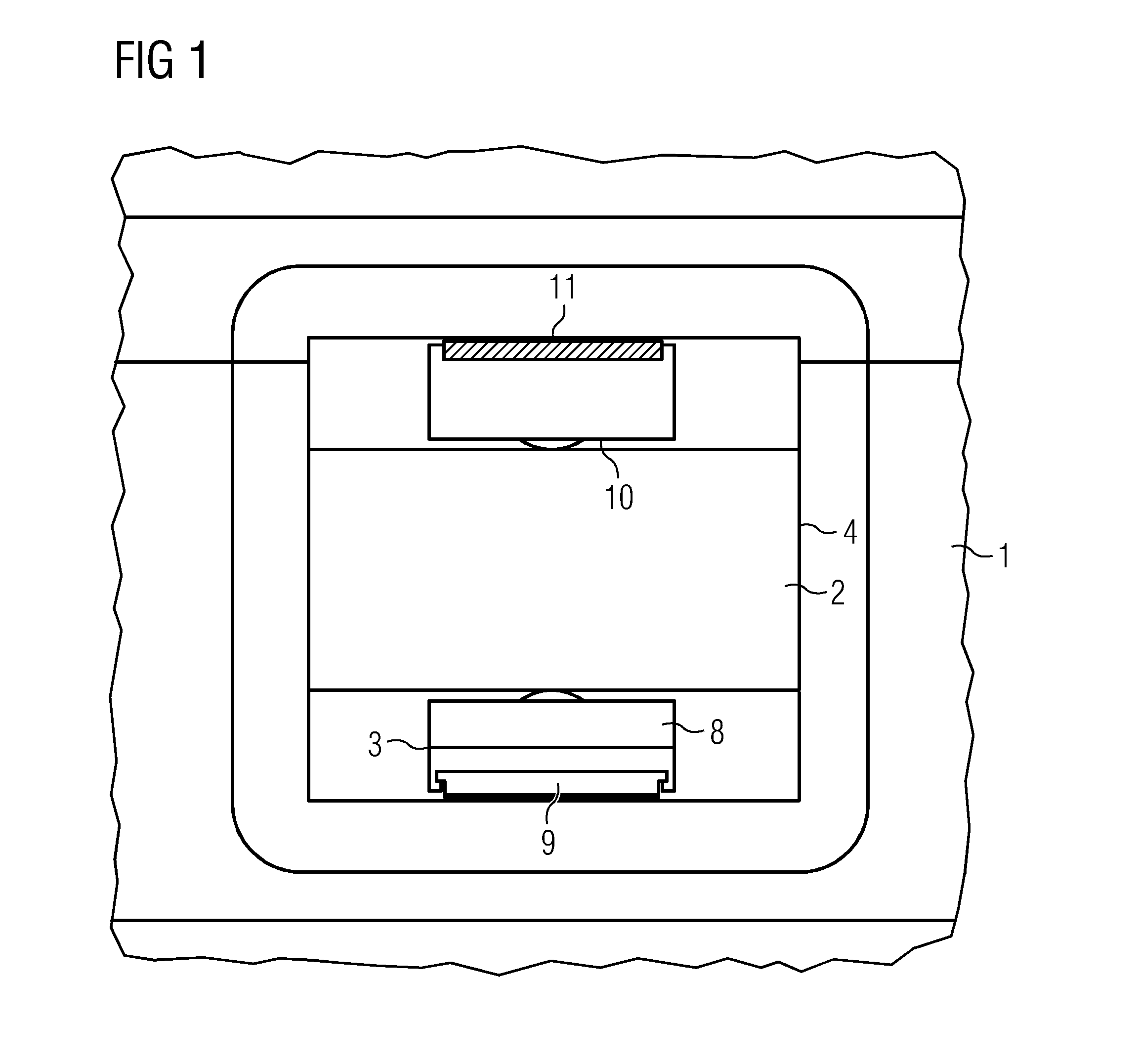

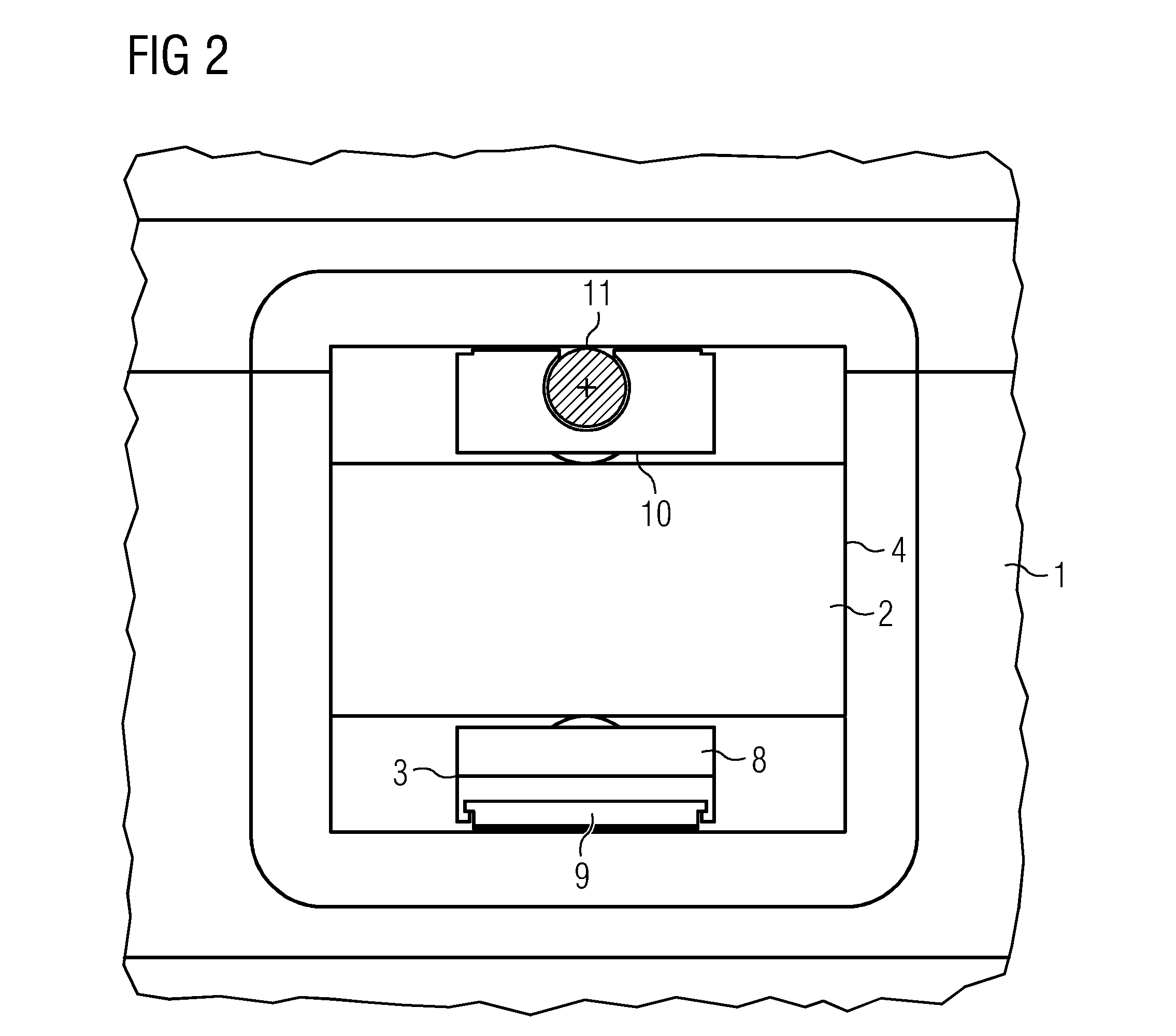

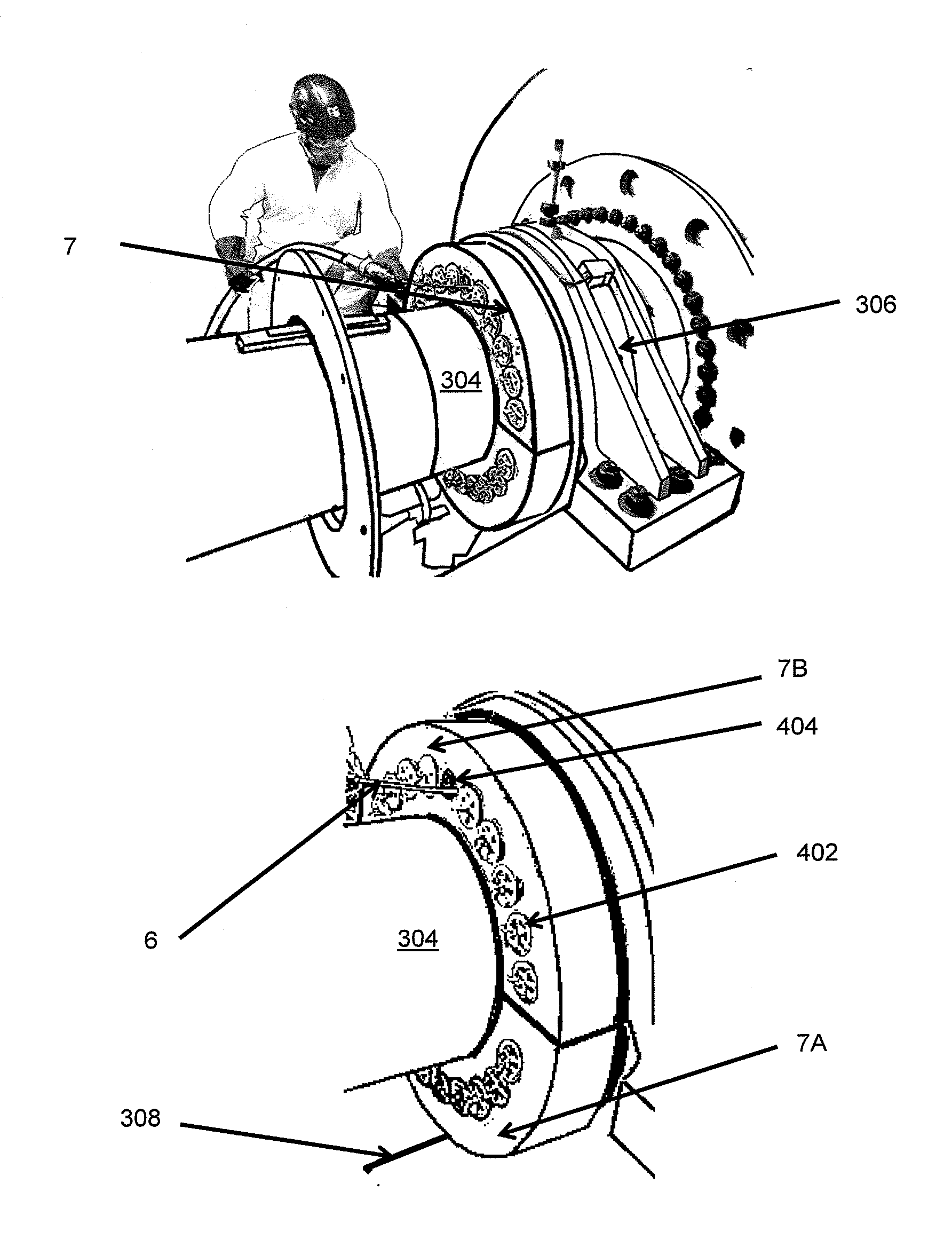

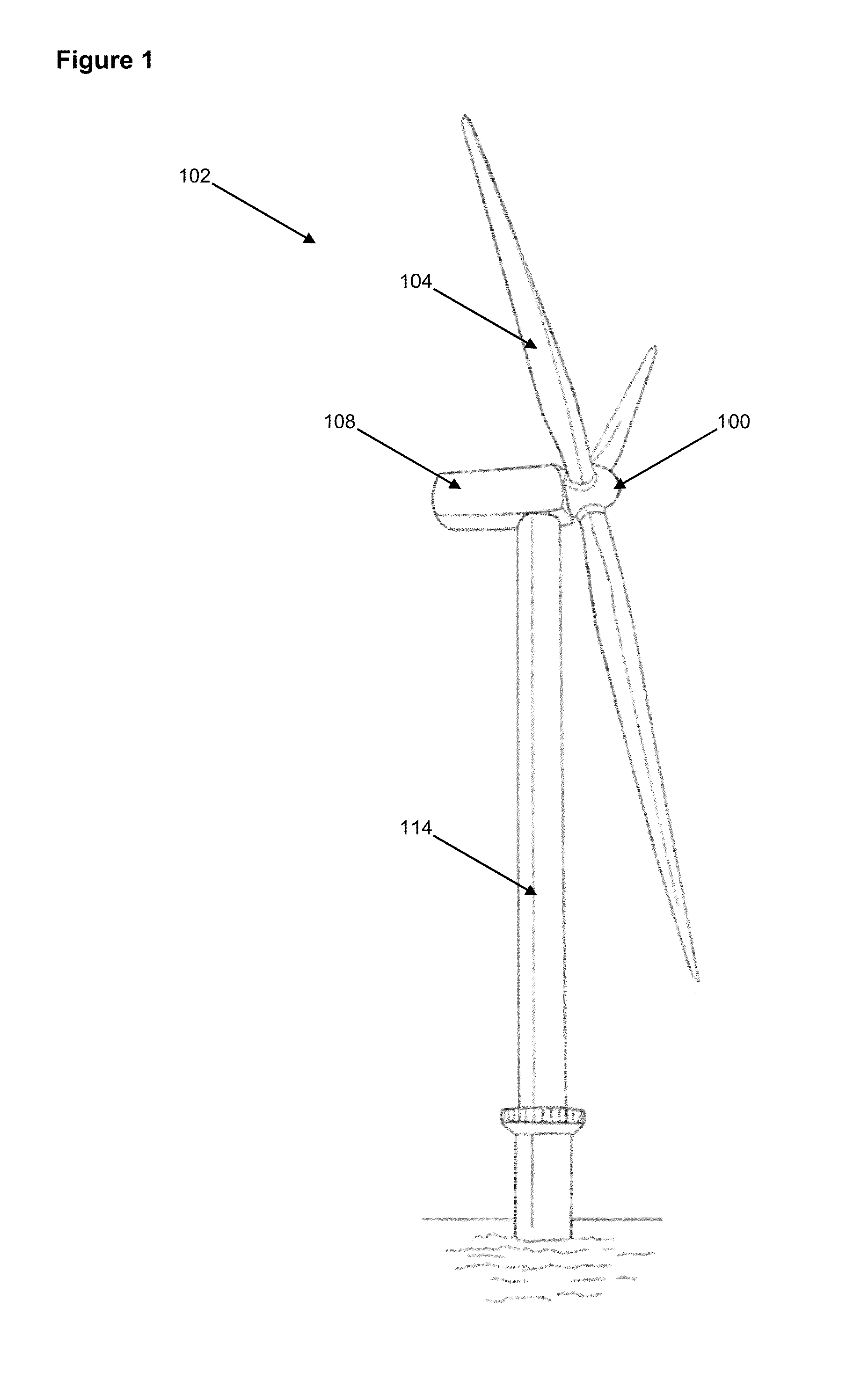

Sliding bearing and method to perform service at a sliding bearing

ActiveUS8936397B2Weak lubricationEasy to wearBearing repair/replacementBearing cleaningTurbinePlain bearing

A sliding bearing of a wind turbine and a method to perform a service at a sliding bearing are proposed. The sliding bearing has a first bearing shell and a second bearing shell and a plurality of bearing pads arranged between the first bearing shell and the second bearing shell. The bearing pads are connected to the second bearing shell and the first bearing shell has a sliding surface that is prepared and arranged so that the bearing pads can slide along the sliding surface when the bearing shells are moved in respect to each other. A machining element is arranged between the first bearing shell and the second bearing shell to treat the sliding surface of the first bearing shell.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Beverage bottling plant having a beverage bottle closing machine with a bearing system to guide a reciprocating shaft in the beverage bottle closing machine

InactiveUS7415816B2Constant and repeatable cleaningConstant gainCapsThreaded caps applicationEngineeringBottle

A container filling plant having a container closing machine with a bearing system to guide a reciprocating shaft in the container closing machine. The bearing system is designed to be cleaned to minimize the presence of contaminants in the bearing system and in the product in the containers to be closed.

Owner:KHS GMBH

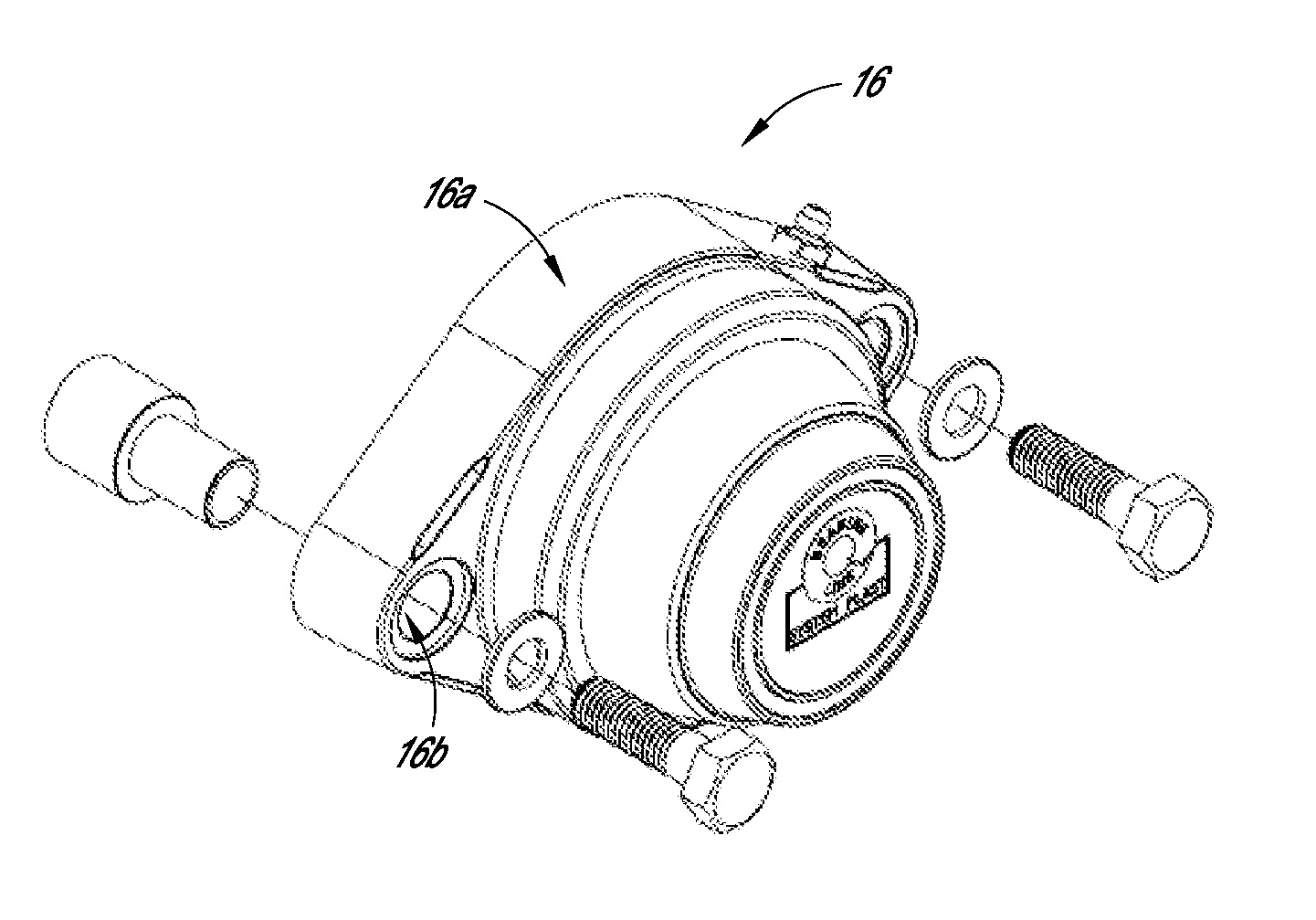

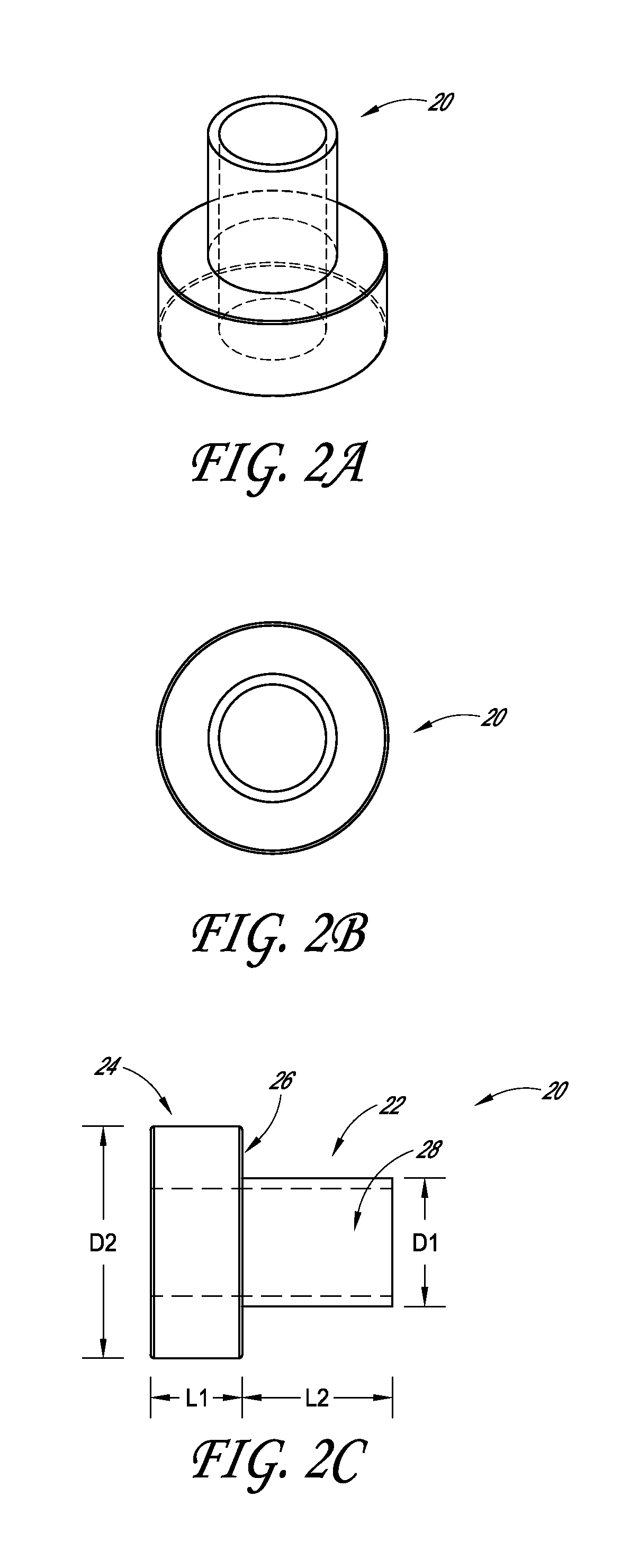

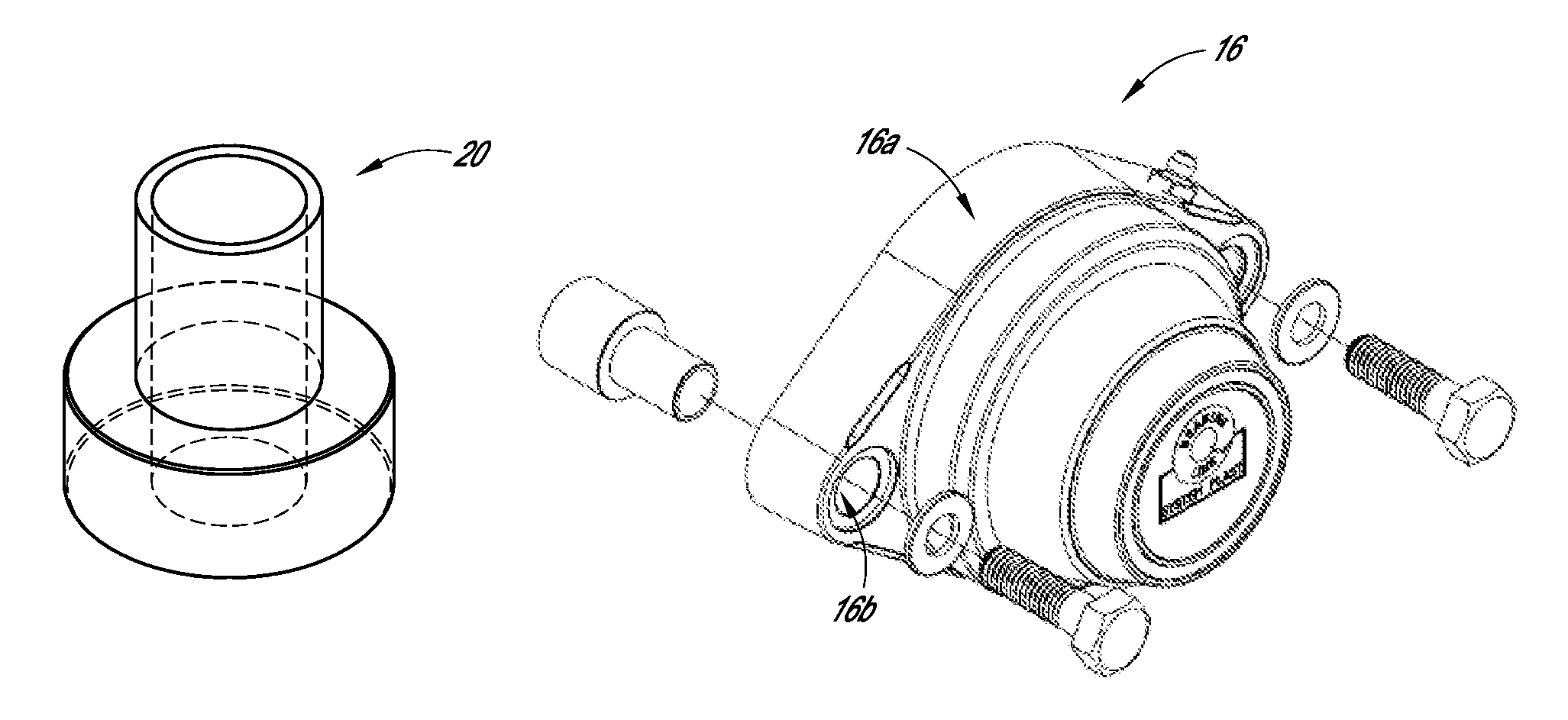

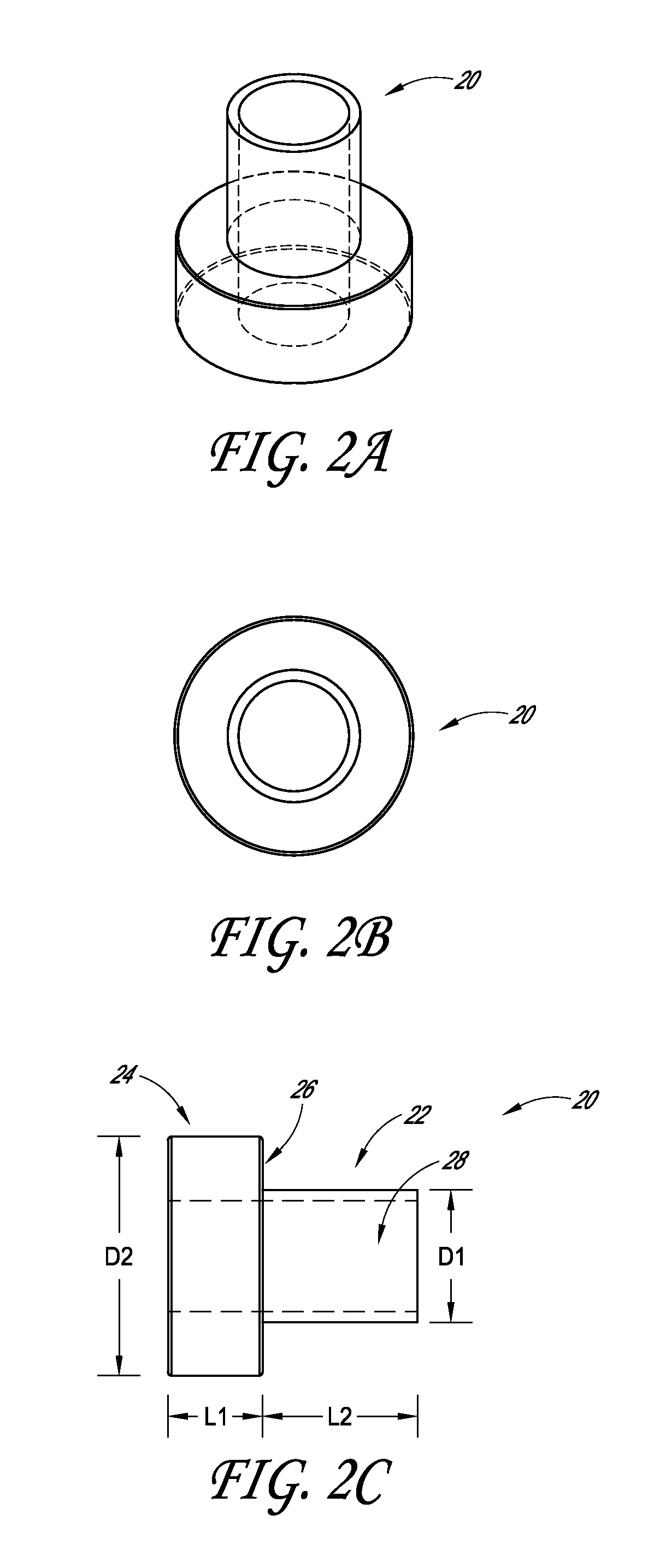

Bearing stand-off devices

InactiveUS20150026983A1Increase amount of accessibleMore exposureWashersBearing cleaningConveyor beltEngineering

Various embodiments of stand-off devices and methods are disclosed. The stand-off device can space a bearing assembly apart from a support, such as a frame of a conveyor belt, thereby providing access between the bearing assembly and the frame, such as for cleaning fluid. Certain embodiments of the stand-off device include a first end and a second end, with the first end being receivable in a securing hole of the bearing assembly and the second end configured to protrude from the bearing assembly.

Owner:SOLUS INDAL INNOVATIONS

Bearing stand-off devices

InactiveUS9555976B2Increase amount of accessibleMore exposureWashersBearing cleaningEngineeringMechanical engineering

Various embodiments of stand-off devices and methods are disclosed. The stand-off device can space a bearing assembly apart from a support, such as a frame of a conveyor belt, thereby providing access between the bearing assembly and the frame, such as for cleaning fluid. Certain embodiments of the stand-off device include a first end and a second end, with the first end being receivable in a securing hole of the bearing assembly and the second end configured to protrude from the bearing assembly.

Owner:SOLUS INDAL INNOVATIONS

Sliding bearing and method to perform service at a sliding bearing

ActiveUS20140086515A1Bearing also increasesWeak lubricationBearing repair/replacementBearing cleaningEngineeringTurbine

A sliding bearing of a wind turbine and a method to perform a service at a sliding bearing are proposed. The sliding bearing has a first bearing shell and a second bearing shell and a plurality of bearing pads arranged between the first bearing shell and the second bearing shell. The bearing pads are connected to the second bearing shell and the first bearing shell has a sliding surface that is prepared and arranged so that the bearing pads can slide along the sliding surface when the bearing shells are moved in respect to each other. A machining element is arranged between the first bearing shell and the second bearing shell to treat the sliding surface of the first bearing shell.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

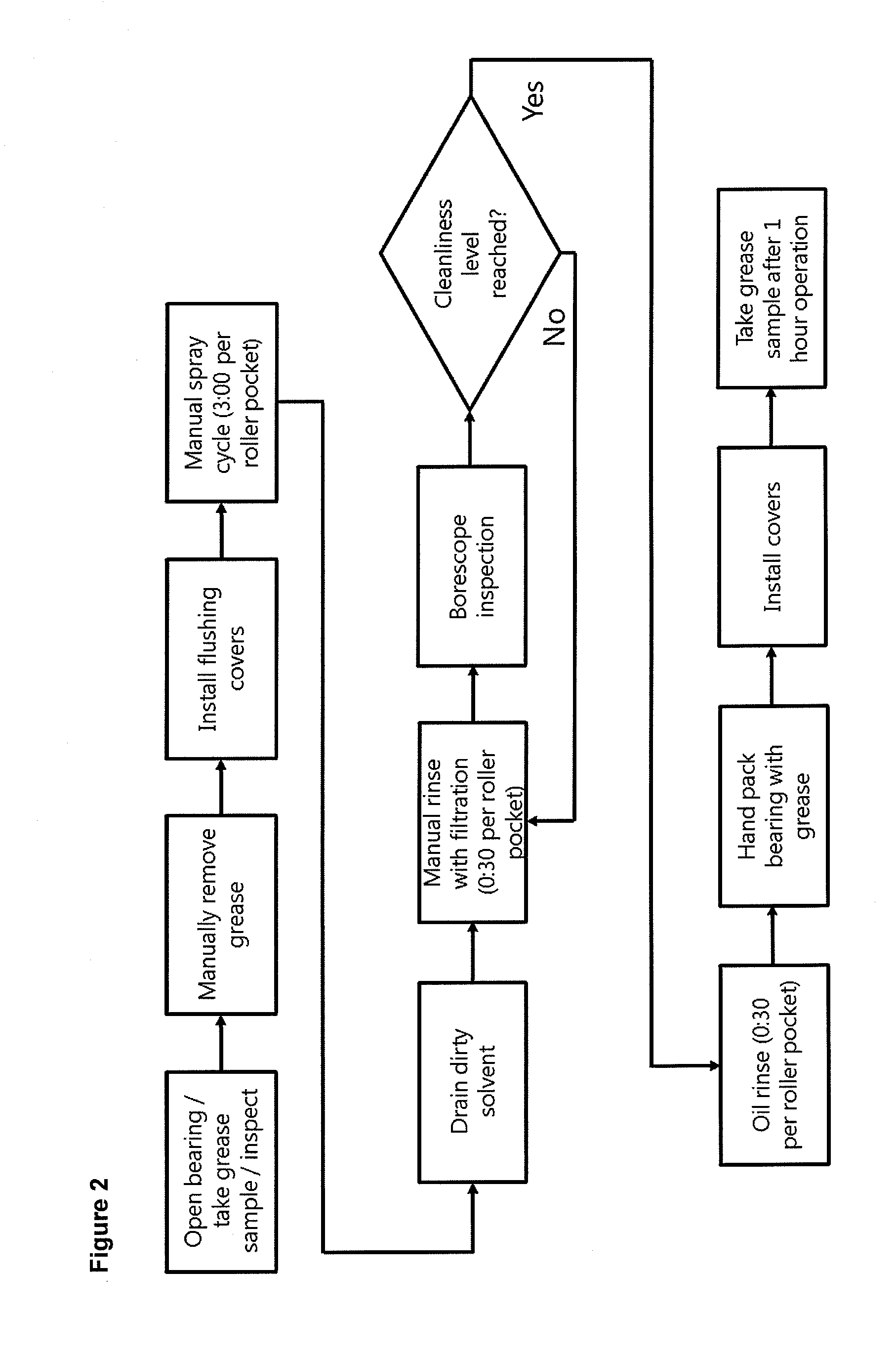

Bearing Grease

ActiveUS20150377294A1Effective lubricationEasy to useLighting and heating apparatusBearing cleaningSpray nozzleEngineering

A method is disclosed for replacing grease in a main bearing of a wind turbine, the main bearing located in a housing and the housing having least one cover plate. the bearing cover plate is removed from the housing, grease is manually removed from the main bearing, and a flushing cover is installed on the housing in place of the bearing cover plate. The flushing cover has at least two parts, the parts fitting around the main shaft, and each part having a seal so that when its attached to the bearing housing, the flushing cover forms a seal with the main shaft. The flushing cover has holes allowing access to the main bearing, and a solvent or oil is sprayed via one of the holes onto the main bearing to remove grease, the remaining holes being sealed by a removable plug. Solvent or oil is pumped out of the housing via a port at the bottom of the housing or flushing cover. The process is repeated for each hole, and the flushing cover removed, the main bearing packed with grease, and the bearing cover plate re-affixed. The spraying step involves pumping solvent or oil from a reservoir to the spray nozzle, and the step of pumping solvent or oil out of the bearing housing involves pumping solvent or oil to the reservoir via a return hose. This means that the solvent or oil is recycled during the replacing of the grease. An apparatus for flushing grease from a main bearing of a wind turbine is also described.

Owner:INSIGHT ANALYTICS SOLUTIONS HLDG LTD

Spindle motor and method of manufacturing the same

InactiveUS7246440B2Reduce manufacturing costLess expensiveRoller bearingsBearing cleaningBall bearingElectric motor

Owner:MINEBEA CO LTD

Trolley wheel technology

The invention provides a trolley wheel assembly for a conveyor system, e.g., an overhead conveyor system. In certain embodiments, the wheel assembly includes at least one wheel face having a contour (optionally a funneling configuration and / or one or more surface features) configured to facilitate flow of a fluid toward an open bearing assembly of the wheel assembly. In some embodiments, the wheel assembly includes an inner race, outer race, and bearings having a particular hardness arrangement, optionally together with a polymer wheel having certain filler features. Methods for cleaning such a trolley wheel assembly are also provided.

Owner:OCONOMOWOC MFG

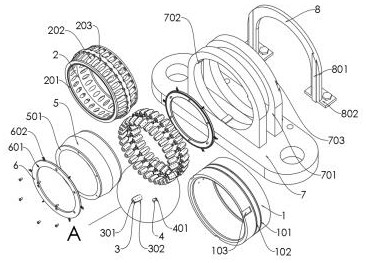

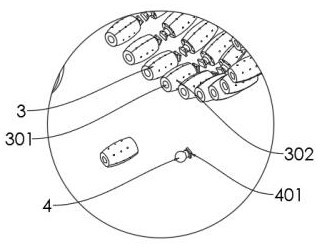

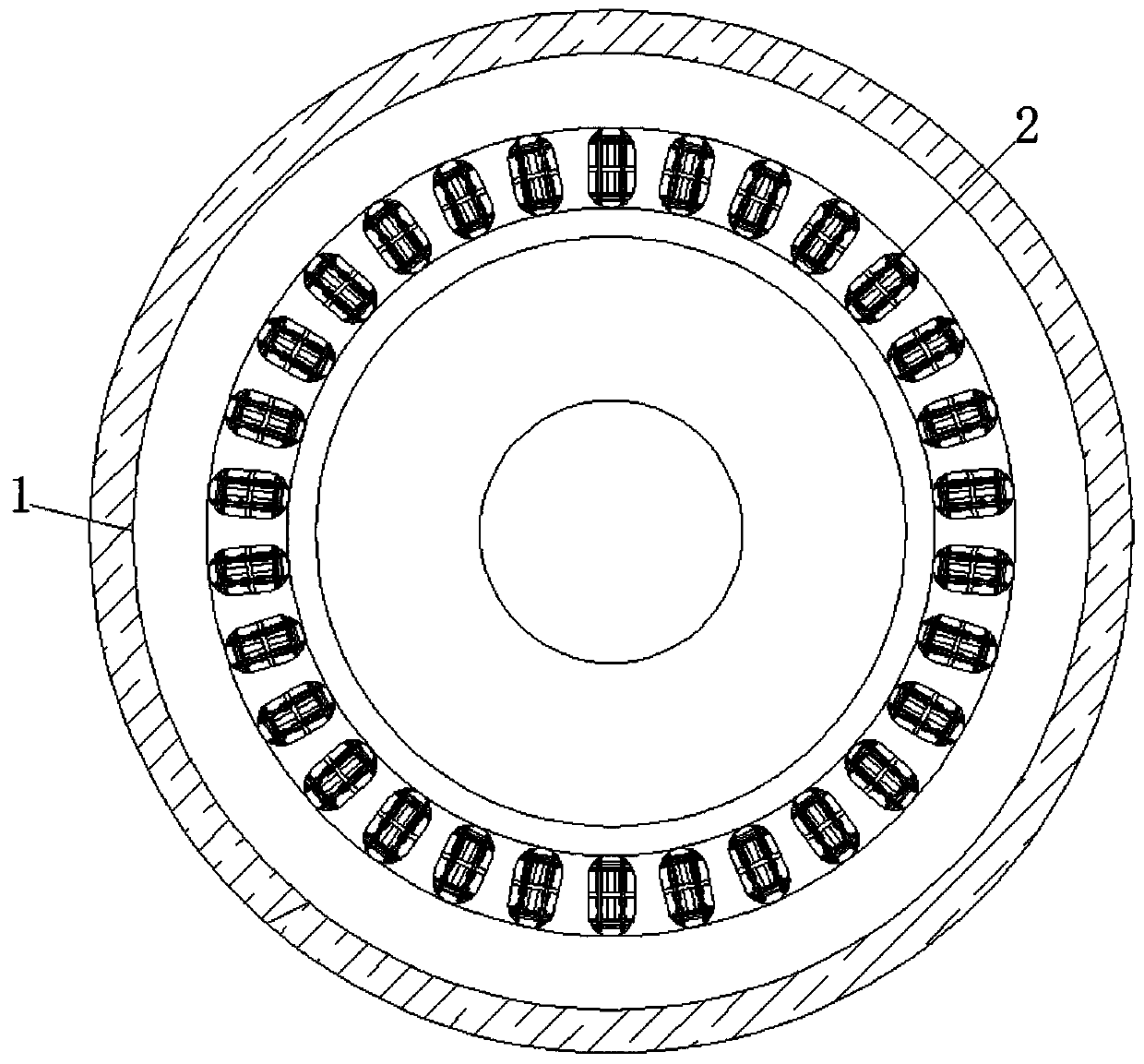

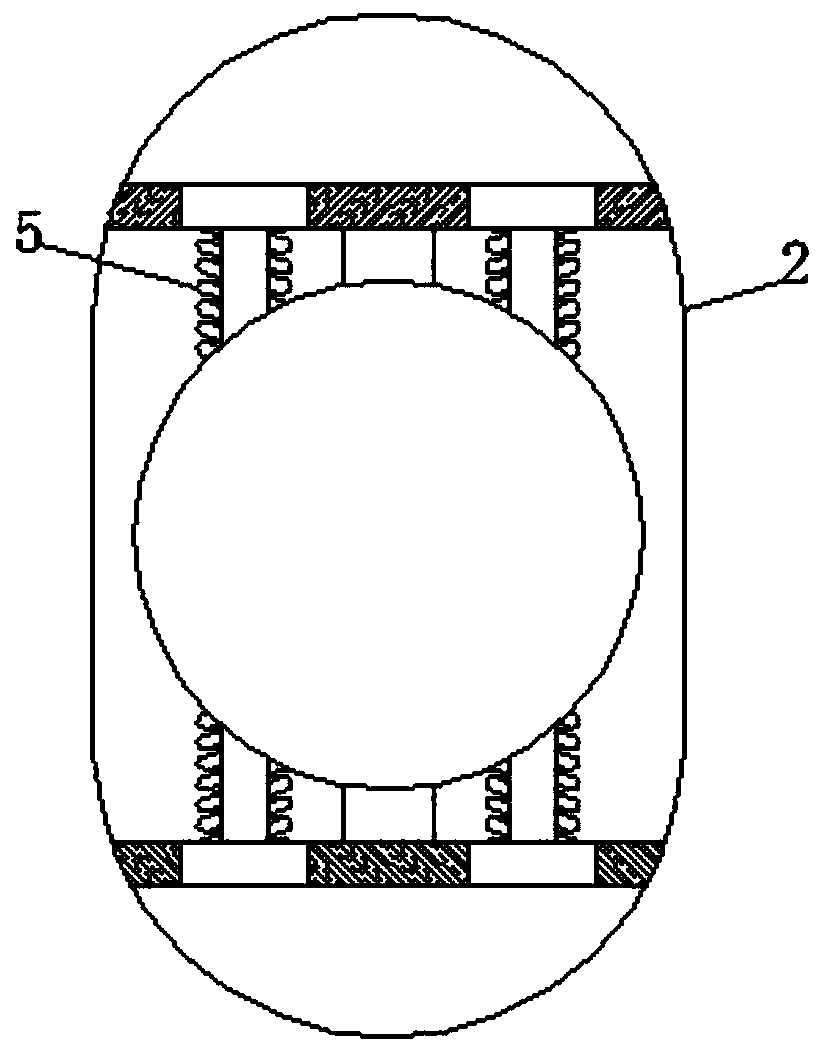

Self-aligning roller bearing used based on stirring equipment

ActiveCN114576266AImprove cooling effectExtended service lifeRolling contact bearingsBearing cleaningParticulatesThermodynamics

The invention provides a self-aligning roller bearing based on stirring equipment, and relates to the field of bearings. The bearing outer ring is installed in the bearing seat, the fixing frame is inserted into the right side wall of the bearing seat, the retainer and the bearing inner ring are sleeved with the bearing outer ring, the retainer is arranged between the bearing outer ring and the bearing inner ring, the heat dissipation roller is rotationally connected into the retainer, and the ball head is connected into one side wall of the heat dissipation roller. The lantern rings are mounted on the left side wall and the right side wall of the bearing inner ring, the heat dissipation rollers promote lubricating oil to flow in the heat dissipation rollers through the heat dissipation channels and the heat dissipation holes, heat is taken away by flowing through the heat dissipation holes while the heat dissipation rollers are lubricated, better heat dissipation of the bearing is facilitated, the heat dissipation effect of the bearing is improved, and the service life of the bearing is prolonged; the problems that the solid roller is in a friction state for a long time, internal heat cannot be dissipated in time, deformation and chip falling are prone to occurring, dust and other particulate matter cannot be effectively cleaned, and consequently the roller and the bearing inner and outer rings are rapidly abraded are solved.

Owner:山东华工轴承有限公司

Rolling-bearing and bearing unit

A rolling bearing 10 comprises races 11, 12 having a raceway 15, 16 and rolling elements 13 having a rolling contact surface, wherein at least the raceway 15, 16 of the races 11, 12 has a machined surface, and a surface layer 11a, 12a is formed on the machined surface by electrochemically or chemically dissolving the machined surface, whereby contamination is substantially reduced.

Owner:NSK LTD

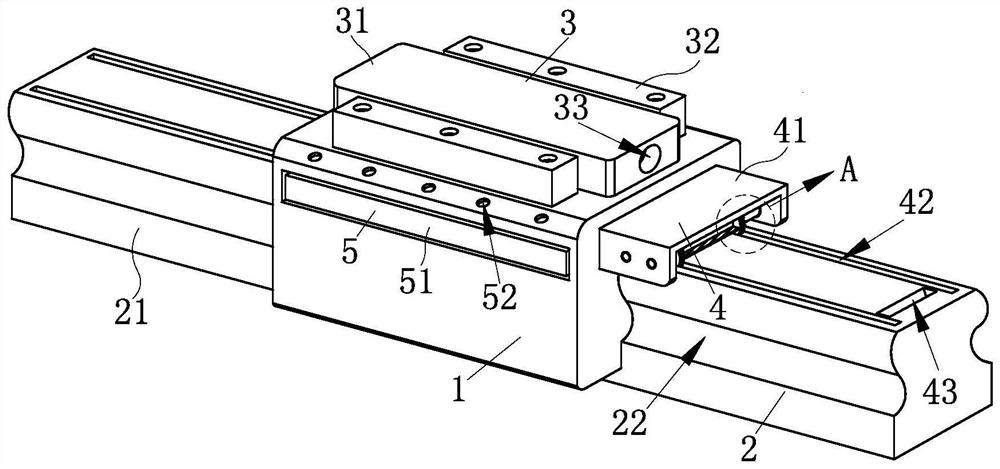

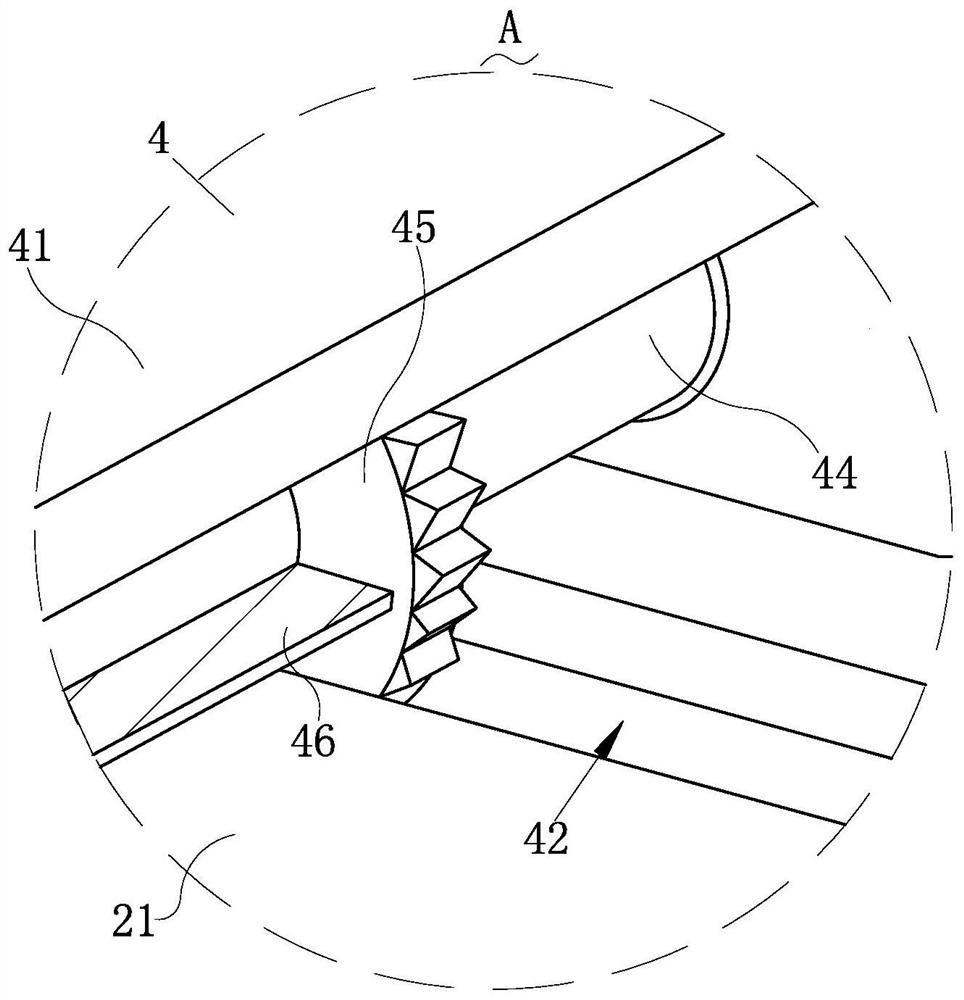

Guide rail

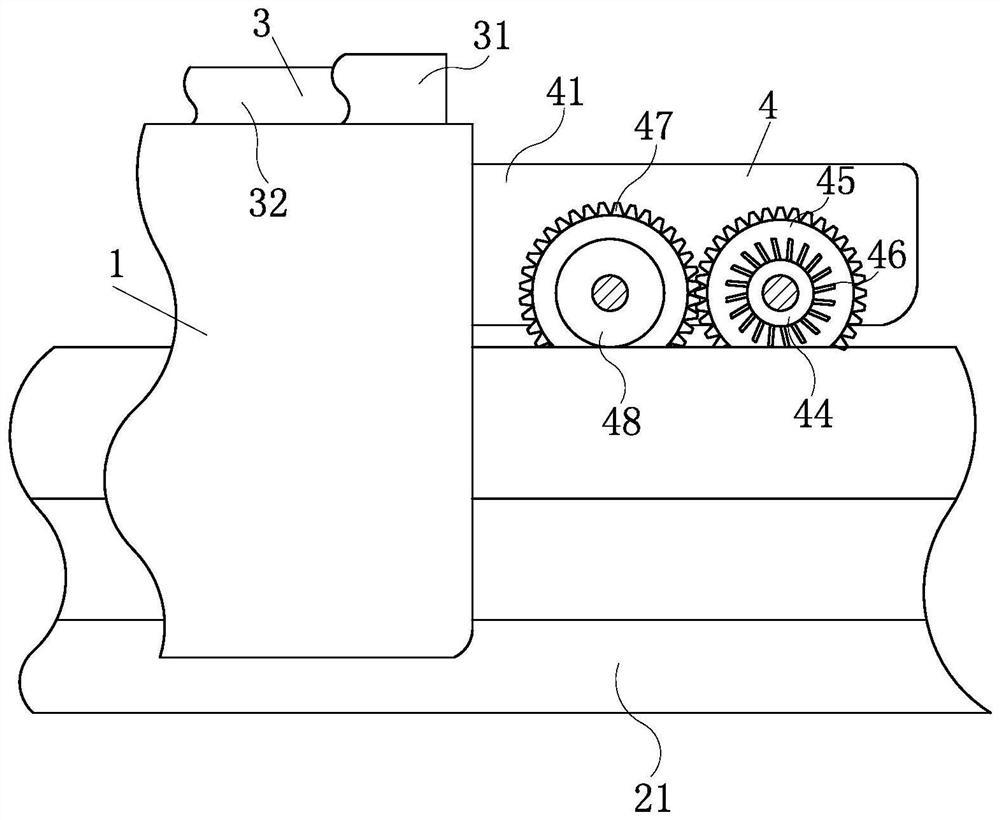

ActiveCN111795071AImplement rolling connectionsEnsure normal walkingLinear bearingsBearing assemblyForeign matterGear wheel

Owner:黄山中创精密制造有限公司

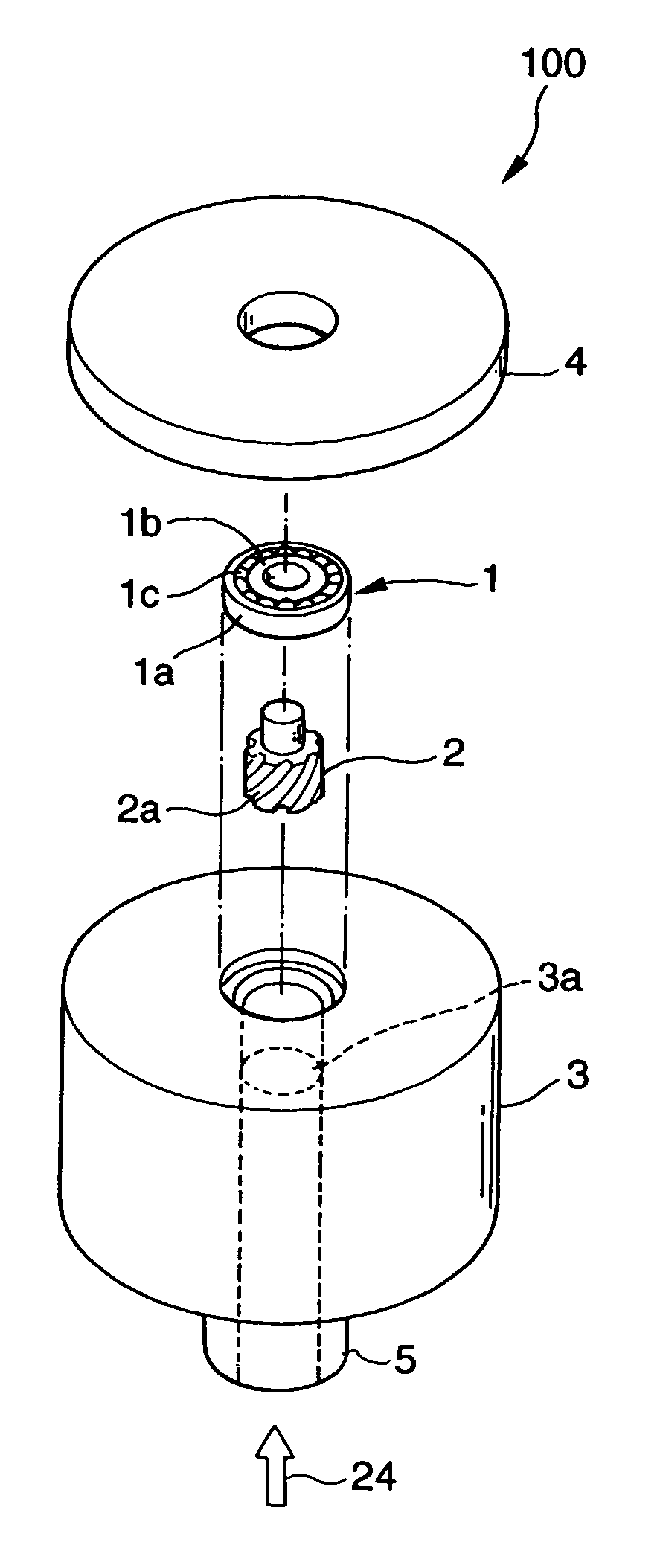

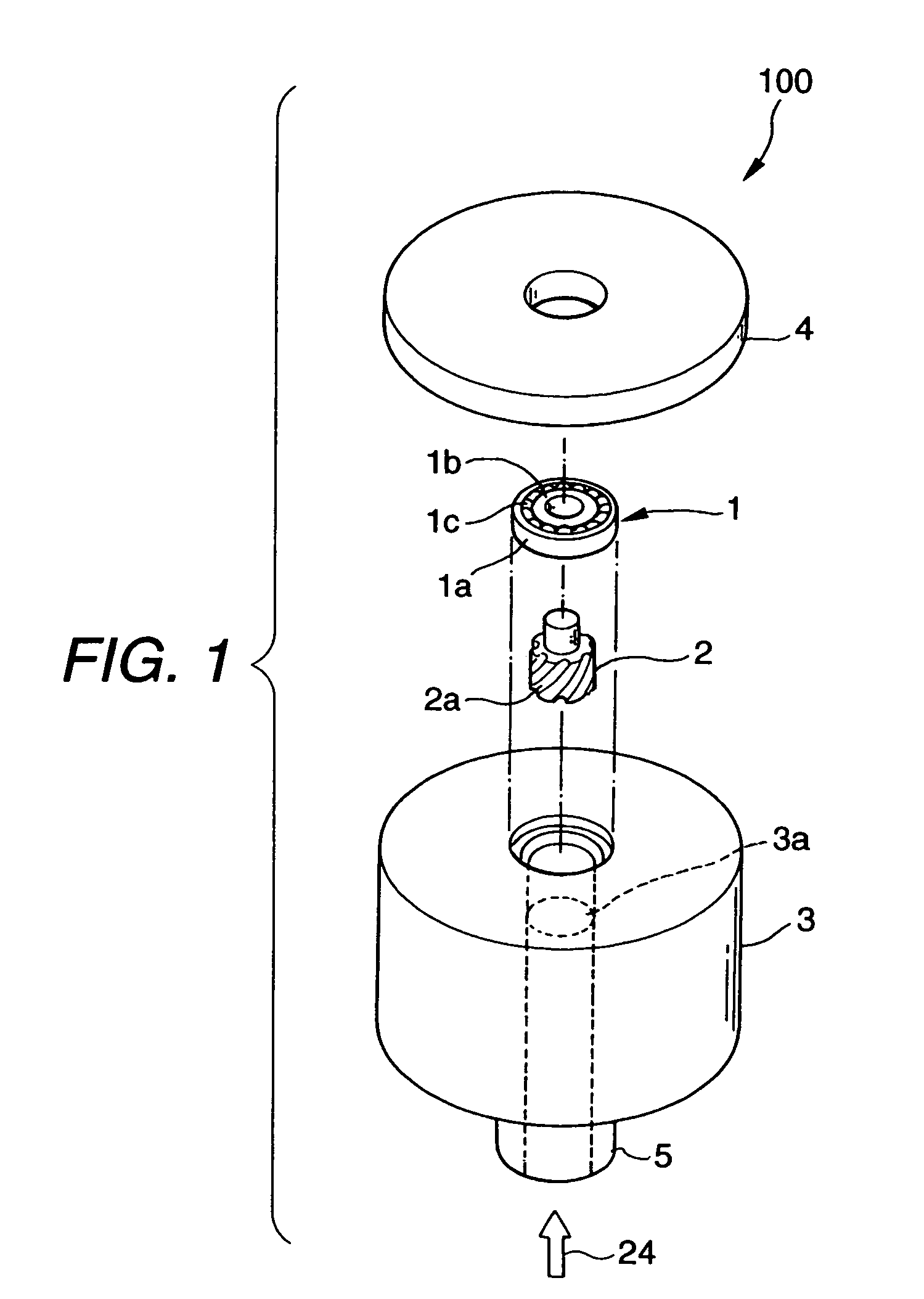

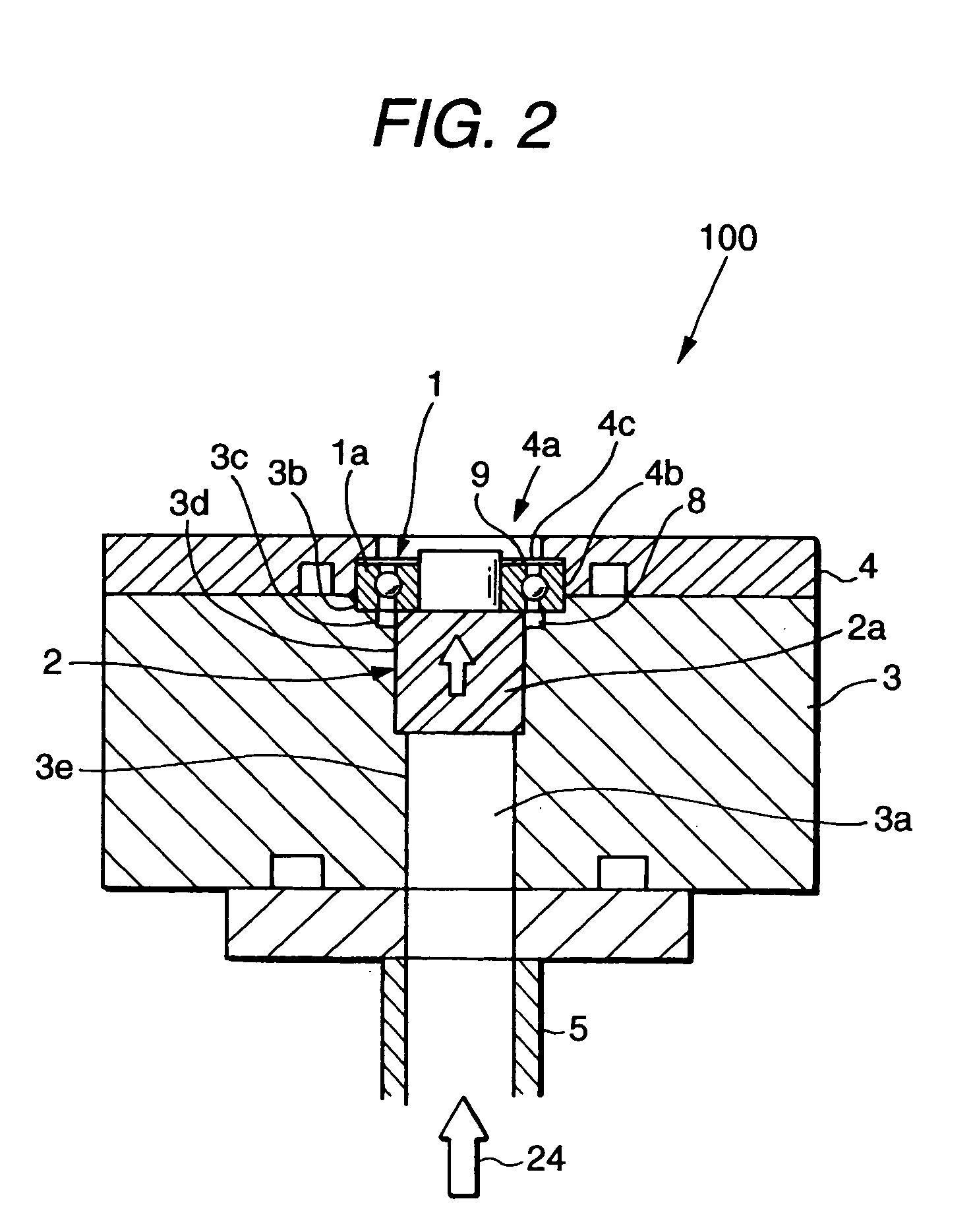

Ball/roller bearing cleaning method and apparatus thereof

The present ball / roller bearing cleaning method is a method which, using cleaning liquid 24, cleans a bearing to be cleaned 1 composed of an inner ring 1b, an outer ring 1a, a rolling bodies 1c and a retainer. In the cleaning method, the cleaning liquid 24 is made to flow through the bearing to be cleaned 1 from the axial direction of the present bearing 1 into spaces in which the raceway surfaces of the inner and outer rings 1b and 1a of the bearing to be cleaned 1 surround the rolling bodies 1c and retainer. For example, a cylindrical-shaped rotary die 2 having spiral grooves 2a is interposed into a cleaning liquid supply passage, and the cleaning liquid 4 is supplied to thereby rotate the cylindrical-shaped rotary die 2, whereby the cleaning liquid having high pressure can be supplied to the bearing to be cleaned 1 from the cylindrical-shaped rotary die 2.

Owner:NSK LTD

Bearing cage polishing cleaning method

InactiveCN106015335AImprove surface qualityReduce manufacturing costBearing cleaningRotary machine partsPimpleEngineering

The invention discloses a method for finishing and cleaning a bearing cage, which relates to a method for cleaning and finishing a cage. The invention solves the problem that different degrees of thorn-like bumps appear on the surface of the outer diameter or inner diameter of the existing bearing cage after silver plating, the silver plating quality of the bearing cage cannot meet the technical requirements of the product, and the problem of increasing the manufacturing cost of the bearing exists. Step 1. Use oblique triangular brown corundum with a particle size of 90-100 as the finishing material; Step 2. Select the corresponding specifications of the finishing material according to the pocket size of the bearing cage; Step 3. Use the existing finishing machine. The weight of the finishing material is 175kg, and the amount of finishing liquid is 800-1000ml of anti-rust liquid; step 4, determine the number of bearing cages in the finishing machine according to the outer diameter specification of the bearing cage, and use the finishing machine to fix the bearing cage Carry out polishing and cleaning, and the polishing time is 2.5 to 3.5 hours. The invention is used for cleaning the surface of the bearing cage.

Owner:AVIC HARBIN BEARING

Rolling-bearing and bearing unit

A rolling bearing 10 comprises races 11, 12 having a raceway 15, 16 and rolling elements 13 having a rolling contact surface, wherein at least the raceway 15, 16 of the races 11, 12 has a machined surface, and a surface layer 11a, 12a is formed on the machined surface by electrochemically or chemically dissolving the machined surface, whereby contamination is substantially reduced.

Owner:NSK LTD

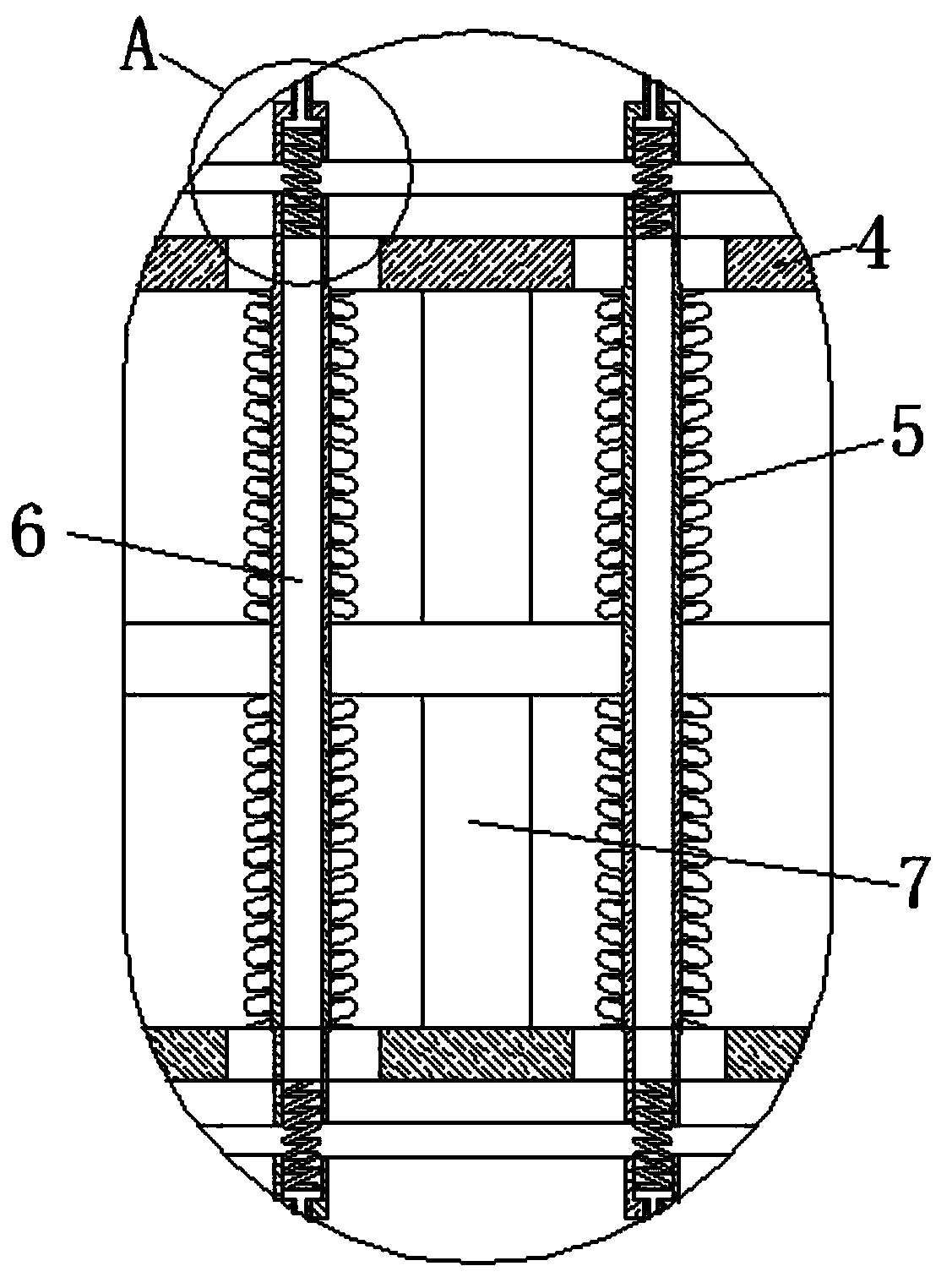

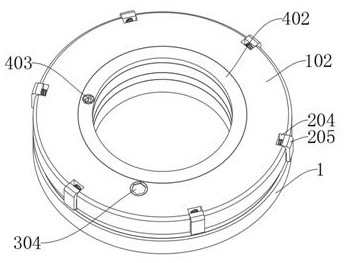

Novel-structure bearing seat for four-row tapered roller bearings for rolling mill

ActiveCN113464569AGuaranteed stabilityStability impactBearing assemblyBearing cleaningEngineeringStructural engineering

The invention provides a novel-structure bearing seat for four-row tapered roller bearings for a rolling mill, and relates to the technical field of bearing seats. The novel-structure bearing seat comprises a bearing bottom seat, an oil injection component and oil storage tanks. The left end and the right end of the top of the bearing bottom seat are connected with the left end and the right end of the bottom of a bearing top seat correspondingly, and the right end of the bearing top seat is connected with a clamping hook. The oil injection assembly is installed on the top side of the bearing top seat. The clamping hook is respectively connected with an arc-shaped spring and a manual bolt. The two oil storage tanks are in a circular arc shape, and the oil storage tanks are connected with the bearing bottom seat through rotary knobs. When the bearing top seat is rotationally buckled to the top of the bearing bottom seat, thrust is applied to the clamping hook through the arc-shaped spring, the clamping hook is driven to rotate leftwards, the bottom side of the clamping hook makes contact with the top side of a barb, the right end of the bearing top seat is fixed through the clamping hook, the stability of a bearing in the bearing top seat is guaranteed, and a bearing is easier and more convenient to disassemble, assemble and fix.

Owner:盐城支点机械制造有限公司

Ball bearing capable of using friction force to eliminate point corrosion phenomenon

ActiveCN110778603AElimination of pittingReduce gapBearing cleaningBall bearingsBall bearingThreaded pipe

The invention relates to the technical field of bearings, and discloses a ball bearing capable of using friction force to eliminate a point corrosion phenomenon. The ball bearing capable of using thefriction force to eliminate the point corrosion phenomenon comprises a base, wherein a rolling ball groove is movably connected in the base, an induction spring is movably connected in the rolling ball groove, a support plate is fixedly connected with one end, far away from the rolling ball groove, of the induction spring, an oil pipe is movably connected with one end, far away from the inductionspring, of the support plate, through an adjusting spring, and a hollow channel is fixedly connected between two symmetrical parts, located on the lower portion of the support plate, of the oil pipe.Lubricating oil enters the hollow channel under the action of extrusion force, and is sucked into scrapers through a threaded pipe, and when the threaded pipe is stretched and continuously moves closeto the surfaces of rolling balls, the lubricating oil flows out of an oil outlet along with the threaded pipe, each scraper is correspondingly arranged on the surface of each rolling ball, lubricating work occurs in the rolling ball groove, and due to high rolling friction heat in the rolling ball groove, moisture can be evaporated, and impurities can be left in the rolling ball groove, and therefore the effect that the lubricating work cannot cause the point corrosion phenomenon is realized.

Owner:海宁科巍轴承科技有限公司

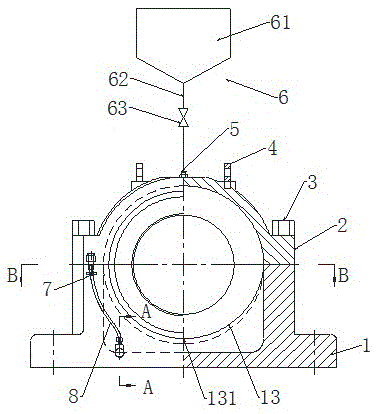

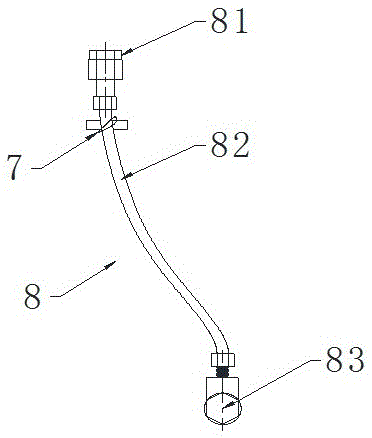

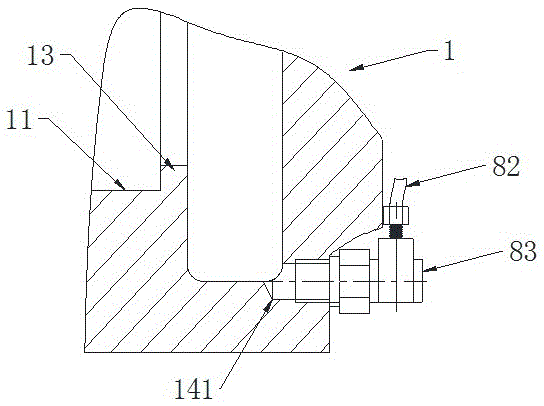

Engineering machine, dismounting-free bearing block with oil cavity capable of being cleaned and cleaning method for oil cavity

InactiveCN105570314AExtended service lifeFlexible rotationBearing cleaningRotary machine partsWorking environmentScrew thread

The invention discloses a bearing block. The bearing block comprises a bearing block body and a bearing cover. An oil storage cavity is formed in the bearing block body and the bearing cover. A hole for communicating the oil storage cavity with the side face of the bearing block body is formed below the oil storage cavity. A rotation connecter of an adjustable oil outlet device is arranged at the hole. The adjustable oil outlet device comprises the rotation connector, a buckling type hose assembly and a plug. A connector, not provided with a thread, at one end of the buckling type hose assembly is connected to the rotation connector, and the plug is arranged on a connector, with a thread, at the other end of the buckling type hose assembly. The function that the oil cavity of the bearing block can be cleaned without dismounting is achieved, and therefore the service life of a bearing is prolonged, the work environment of the bearing is improved, and other beneficial effects are also achieved. In addition, the invention discloses a cleaning method for the oil cavity of the bearing block. The invention further discloses an engineering machine comprising the bearing block. The invention further discloses a mineral engineering machine comprising the bearing block.

Owner:CHANGSHA XIANZHENG YIXIANG MASCH TECH CO LTD

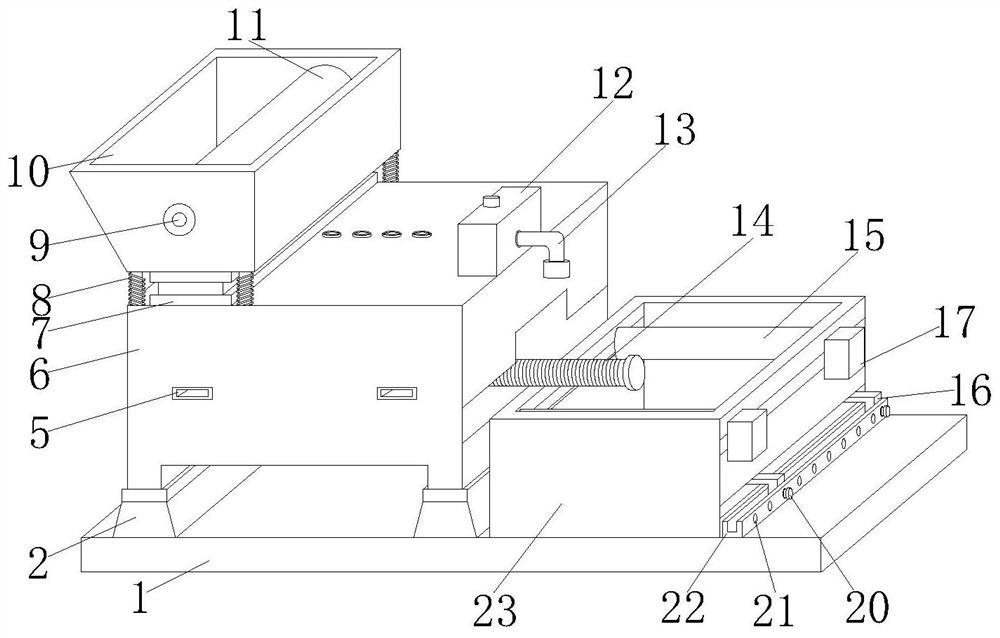

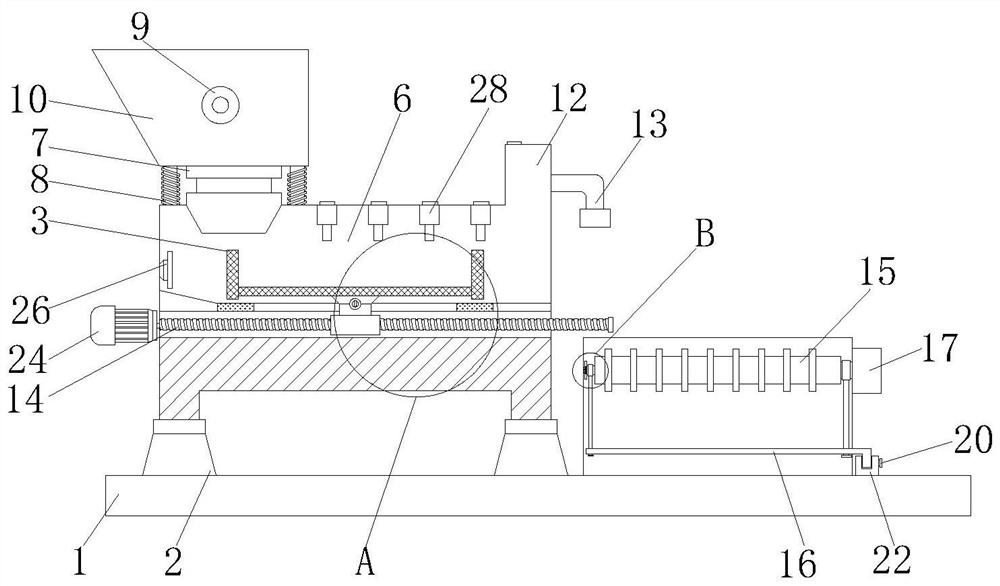

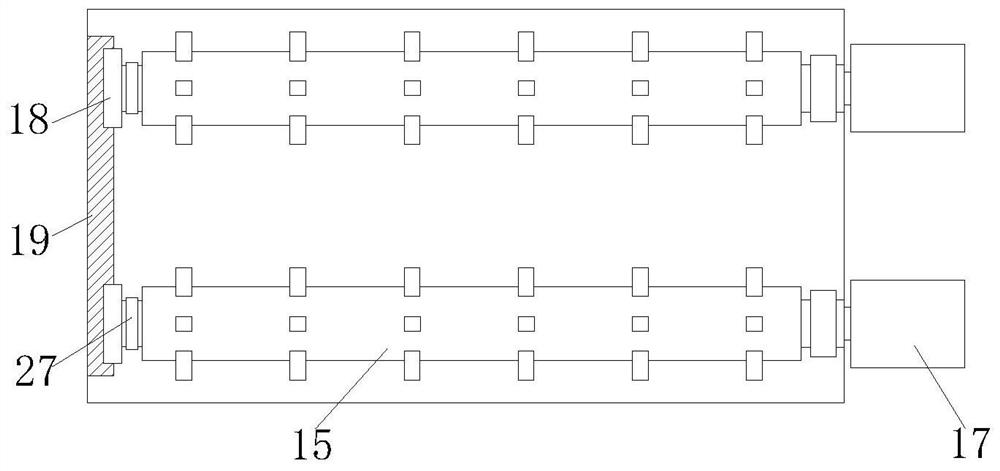

Bearing roller production detection assembly line

InactiveCN112775070APolishing machinesRevolution surface grinding machinesElectric machineryHigh pressure water

The invention discloses a bearing roller production detection assembly line. The assembly line comprises a base, a box body, a feeding box and a polishing detection box, wherein supporting frames are symmetrically and fixedly connected to the top of the left end of the base, the box body is connected to the tops of the two supporting frames, a connecting through pipe is fixedly connected to the top of the box body, the feeding box is installed at the top of the connecting through pipe, a connecting shaft is arranged in the feeding box, the two ends of the connecting shaft are fixedly connected to the front wall and the rear wall of the feeding box correspondingly, and the connecting shaft is movably sleeved with a guide roller. The assembly line is reasonable in design and convenient to operate, through structural design of a cleaning filter screen, an adjusting shaft, a water outlet pipe opening, a transverse lead screw, a second motor, a sliding seat, a drying fan and a high-pressure water gun, a passing detection bearing sample can be subjected to high-pressure washing, impurity particles attached to the surface of a bearing are cleaned away, a cleaning area is increased, and cleaning is more thorough.

Owner:陈新琴

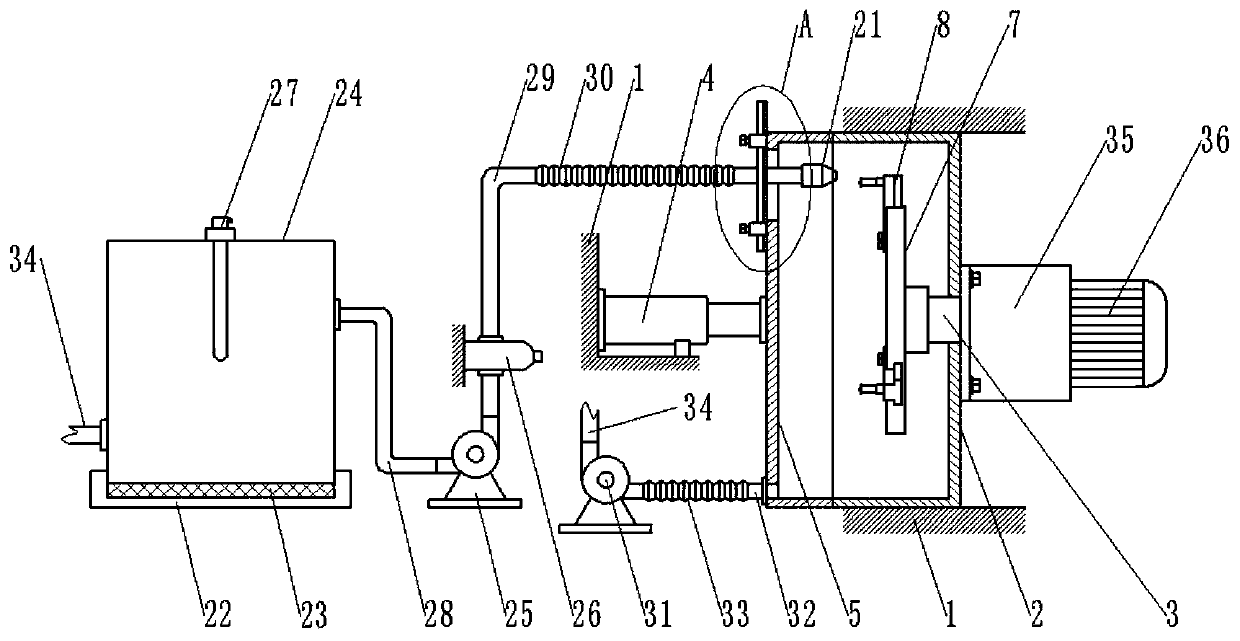

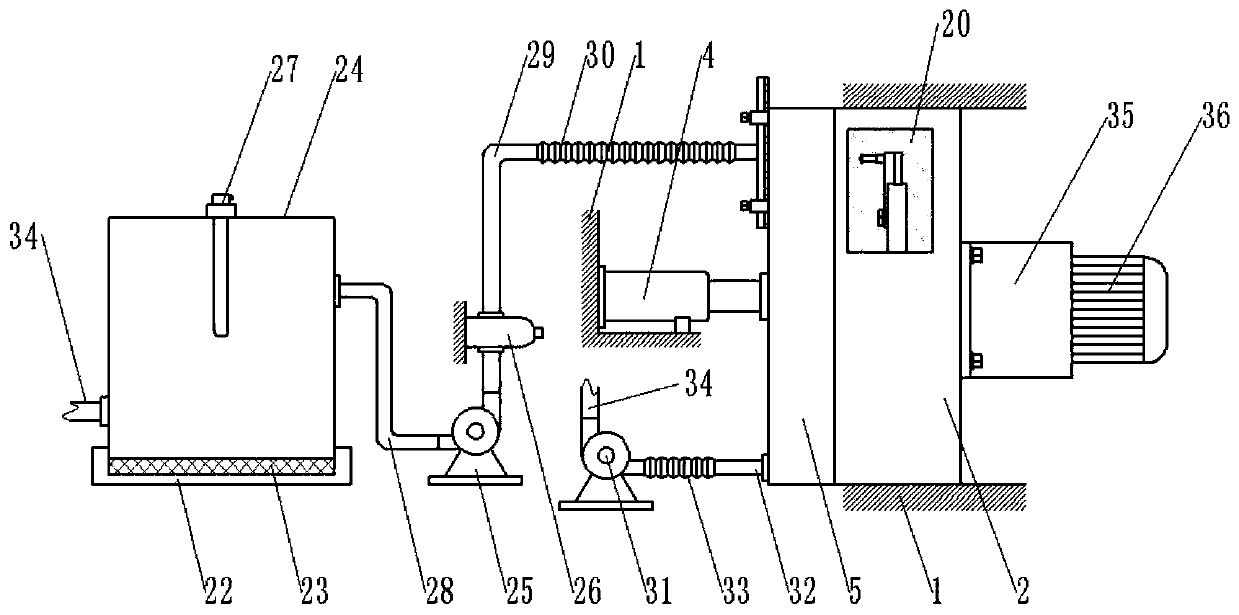

Heating device for large bearing of mining machinery

ActiveCN111330893AEasy to rinseImprove the heating effectBearing cleaningStorage heatersThermodynamicsOil supply

The invention discloses a heating device for a large bearing of mining machinery. The heating device comprises a machine frame and further comprises a first box body, an electric cylinder, a second box body, an oil spraying pipe, an oil supply system and an oil return system; an opening is formed in the left side of the first box body, a driving device is installed on the outer wall of the right side of the first box body, a bearing placement assembly is arranged in the first box body, and the bearing placement assembly is connected with the output end of the driving device through a rotatingshaft; the electric cylinder is arranged on the machine frame and is horizontally arranged, the middle of the outer wall of the left side of the second box body is fixedly connected with the top end of an output rod of the electric cylinder, an opening is formed in the right side of the second box body, the right end of the oil spraying pipe is located in the second box body, the left end of the oil spraying pipe is located on the left side of the left side wall of the second box body, the oil supply system is connected with the left end of the oil spraying pipe, and the oil return system is used for recycling oil sprayed to the bearing by the oil spraying pipe and conveying the oil back to the oil supply system. The heating device can conveniently and effectively wash and heat the large bearing.

Owner:新昌县昌泰轴承有限公司

Industrial antiskid bearing

ActiveCN112013030ARotation will not freezeEffective rotationRolling contact bearingsBearing cleaningGear wheelClassical mechanics

The invention relates to the field of part bearings. The invention particularly relates to an industrial antiskid bearing. The industrial antiskid bearing comprises a bearing pedestal, an outer sleevering is arranged on the outer surface of the inner side of the bearing pedestal, an inner sleeve ring is arranged on the inner side of the outer sleeve ring, an anti-skid bolt is arranged on the outer surface of one side of the bearing pedestal, a fixed gear disc is arranged on the outer surface of the upper end of the inner sleeve ring, a protruding ring is arranged on the surface of the outer side of the outer sleeve ring, an anti-skid screw hole is formed in the outer surface of the inner side of the protruding ring, an extension pipe is arranged between the inner sleeve ring and the fixedgear disc, and rolling balls are arranged between the outer sleeve ring and the inner sleeve ring. The industrial antiskid bearing is provided with the anti-skid bolt, the fixed gear disc and a rolling ball retainer, sliding between the outer sleeve ring and the bearing seat can be well prevented, the whole bearing can be in butt joint with an industrial gear, collision and friction between the rolling balls can be effectively prevented, and the industrial antiskid bearing can bring better use prospects.

Owner:杭州康丰机械设备有限公司

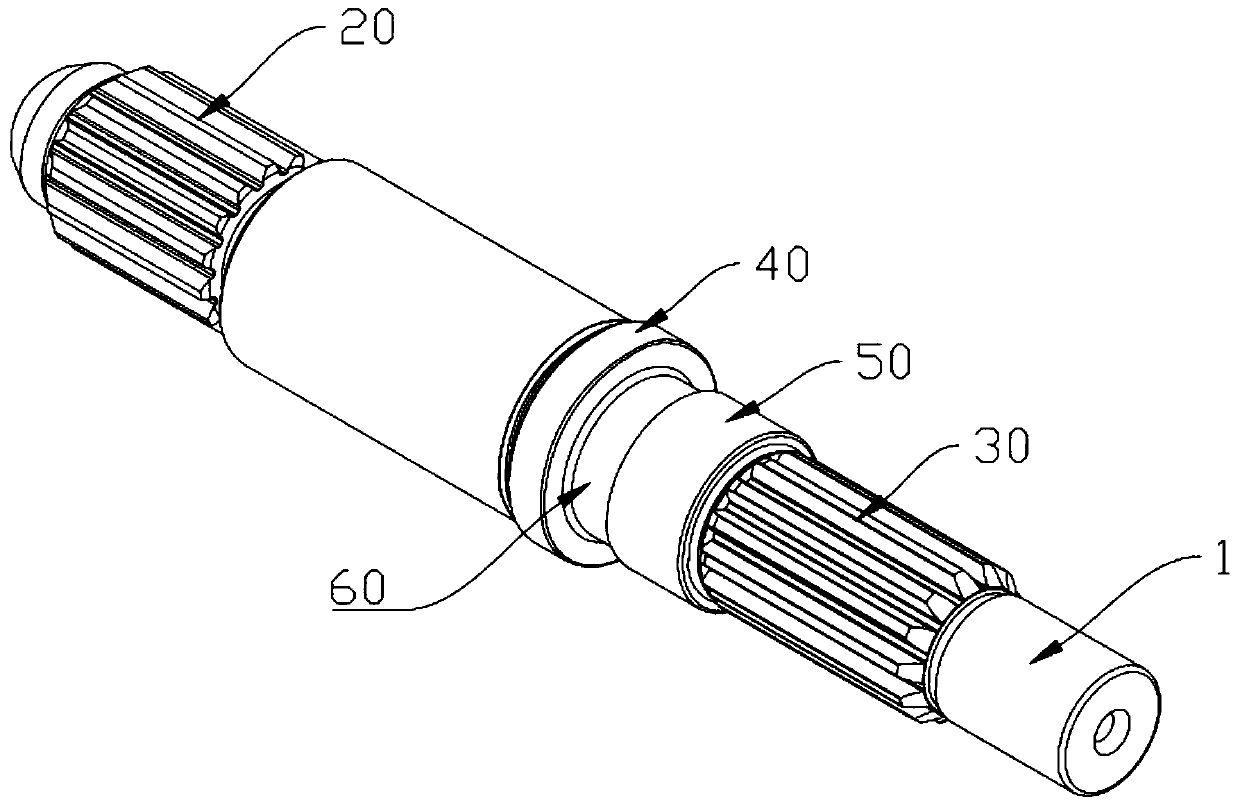

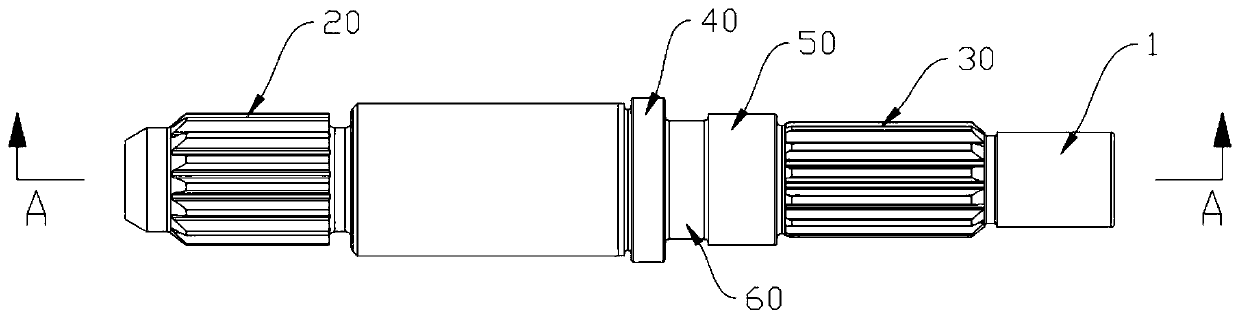

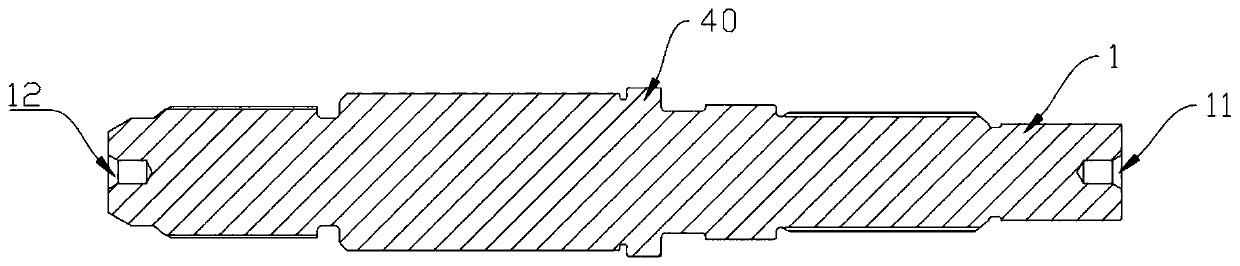

Spline transmission shaft and machining technology thereof

PendingCN110778594AEasy to assembleOptimize assembly processBearing cleaningCouplings for rigid shaftsImpellerDrive shaft

The invention discloses a spline transmission shaft and a machining technology thereof. The spline transmission shaft comprises a cylindrical main shaft, wherein threaded holes are formed in the central axis directions of the two ends of the main shaft; a first spline and a second spline are formed in the surfaces of the two ends of the main shaft; an annular limiting ring and a limiting table arearranged between the first spline and the second spline; the limiting table is close to the first spline; the limiting ring is close to the second spline; and one end, close to the second spline, ofthe limiting ring is provided with an annular limiting groove. According to the spline transmission shaft, the threaded holes are formed in the two ends of the main shaft, the spline transmission shaft is fixed through the matching of screws and the threaded holes, the installation is simple, the disassembly is convenient, the assembly process of the transmission shaft is greatly facilitated, thelimiting ring and the limiting table perform the function of limiting, the assembly is simple; and in addition, the splines are arranged at the two ends of the main shaft, and the splines are matchedwith a driving device and an impeller, so that the transmission is stable and the safety is high.

Owner:扬州英诺精密机械科技有限公司

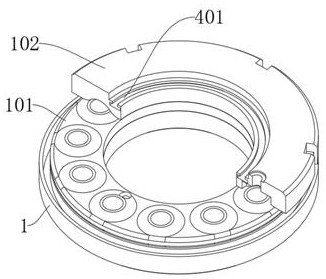

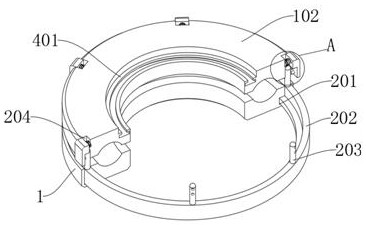

Improved thrust ball bearing suitable for heavy-load low-speed working condition

ActiveCN113653731AQuick installationAffect normal workBearing cleaningBall bearingsBall bearingEngineering

The invention provides an improved thrust ball bearing suitable for a heavy-load and low-speed working condition, relates to the technical field of bearings, and aims to solve the problems that when an existing thrust ball bearing is used, impurities on bearing balls need to be removed through disassembly, and time and labor are wasted. The improved thrust ball bearing comprises a main body, a connecting piece, a cleaning piece and a smearing piece, and an arc-shaped groove is formed in the top of the main body; the connecting piece is mounted at the top of the main body; a sliding groove in the connecting piece is formed in the top of the main body, and a top groove in the connecting piece is formed in the edge position of a top plate; the cleaning piece is mounted in the main body and the top plate, and an inner groove in the cleaning piece is formed in the top of the main body and the bottom of the top plate; and the smearing piece is installed on the top of the top plate, and a flow guide groove in the smearing piece is formed in the top of an inner plate. The arc-shaped structures at the outer ends of scrapers are attached to balls installed in the inner plates, impurities generated when the scrapers clean the balls are discharged through gaps between the inner plates, and the steps of bearing disassembly and re-cleaning are reduced.

Owner:聊城鲁寰轴承有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com