Novel-structure bearing seat for four-row tapered roller bearings for rolling mill

A tapered roller bearing and rolling mill technology, applied in the direction of bearing, bearing cooling, bearing assembly, etc., can solve the problems such as difficulty in releasing the heat of the bearing in time, shortening the service life of the internal lubricating oil, affecting the lubrication effect of the bearing, etc., so as to avoid excessive bearing temperature. High, avoid waste, improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

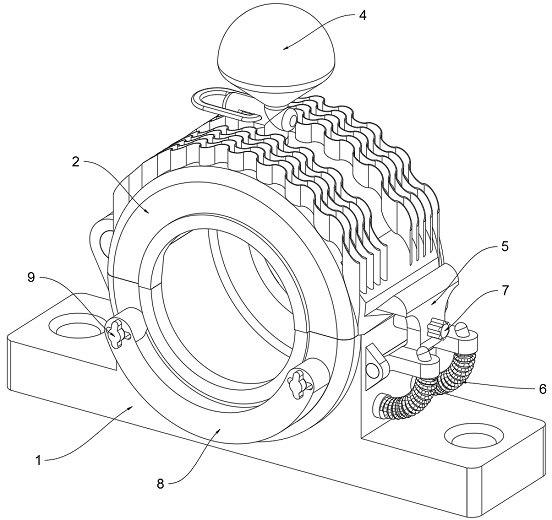

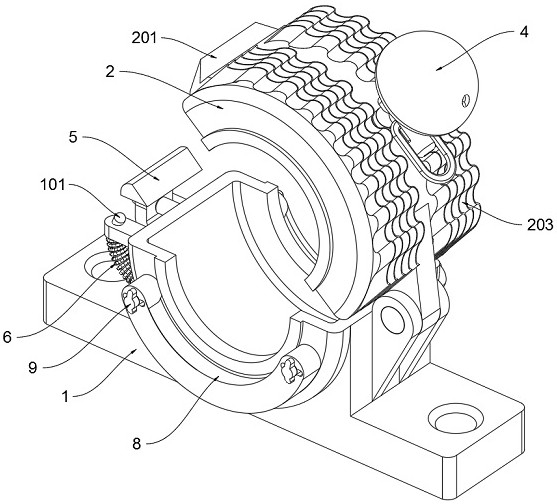

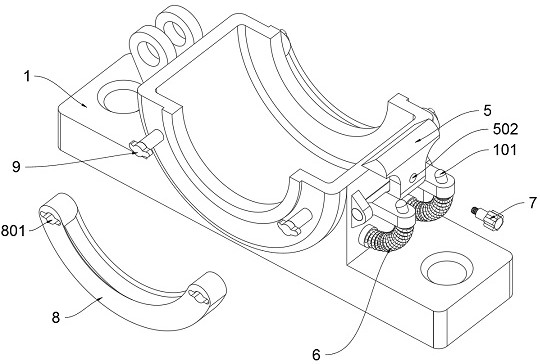

[0044] as attached figure 1 to the attached Figure 9 shown:

[0045] The invention provides a bearing seat for a four-row tapered roller bearing for a rolling mill with a new structure, comprising a bearing base 1, an oil injection assembly 4 and an oil storage tank 8;

[0046]The left and right ends of the top of the bearing base 1 are respectively connected to the left and right ends of the bottom of the bearing top base 2, and the right end of the bearing top base 2 is connected to the hook 5; the top side of the bearing top base 2 is equidistantly provided with cooling fins 203, and the cooling fins 203 are in the form of waves The cooling fins 203 increase the heat dissipation area on the top side of the bearing top seat 2, thereby improving the heat dissipation effect of the internal bearing and avoiding excessive bearing temperature, which affects the service life of the lubricating oil; the left end of the bearing top seat 2 is rotationally connected with the left en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com