Industrial antiskid bearing

An anti-skid and bearing technology, which is applied in the field of component bearings, can solve problems such as unprotected parts, reduce friction coefficient, outer ring sliding, etc., achieve long service life, reduce wear, and improve running accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

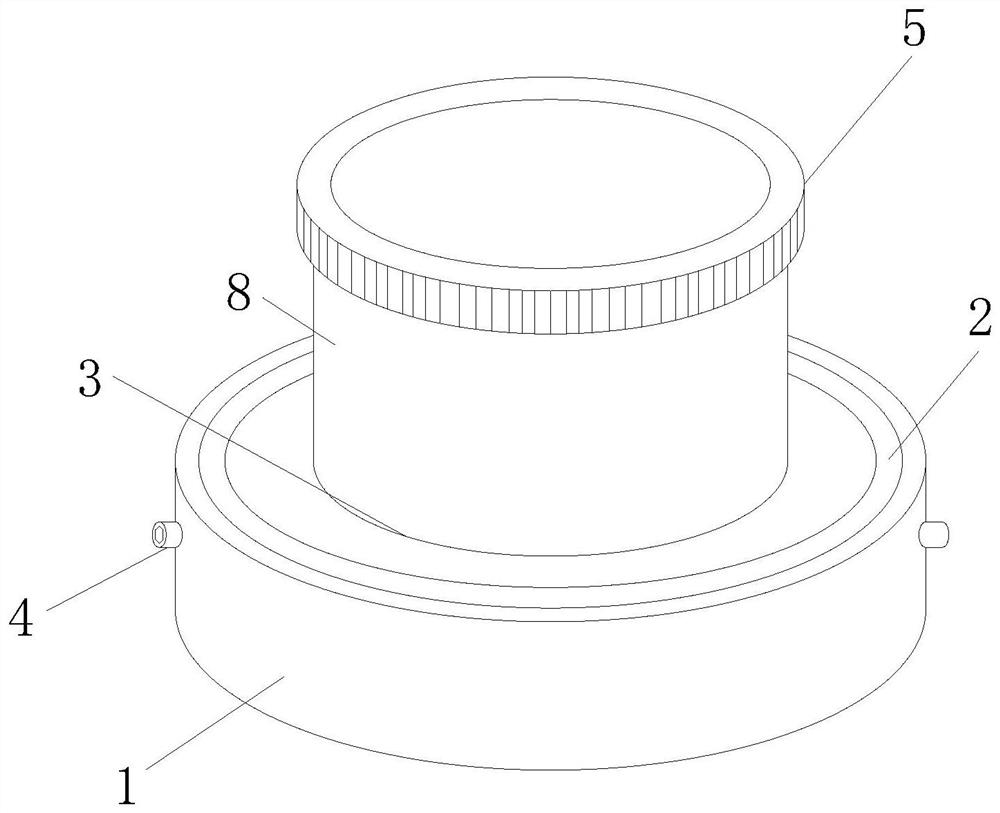

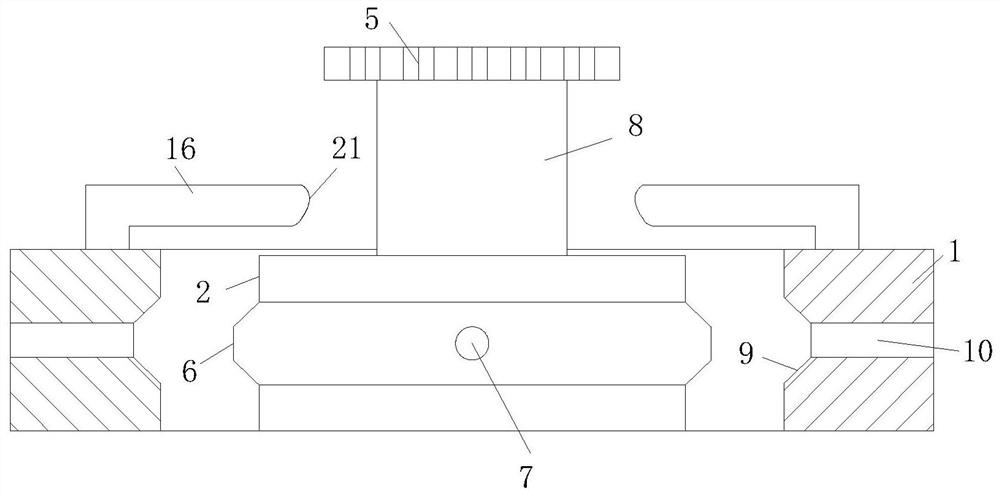

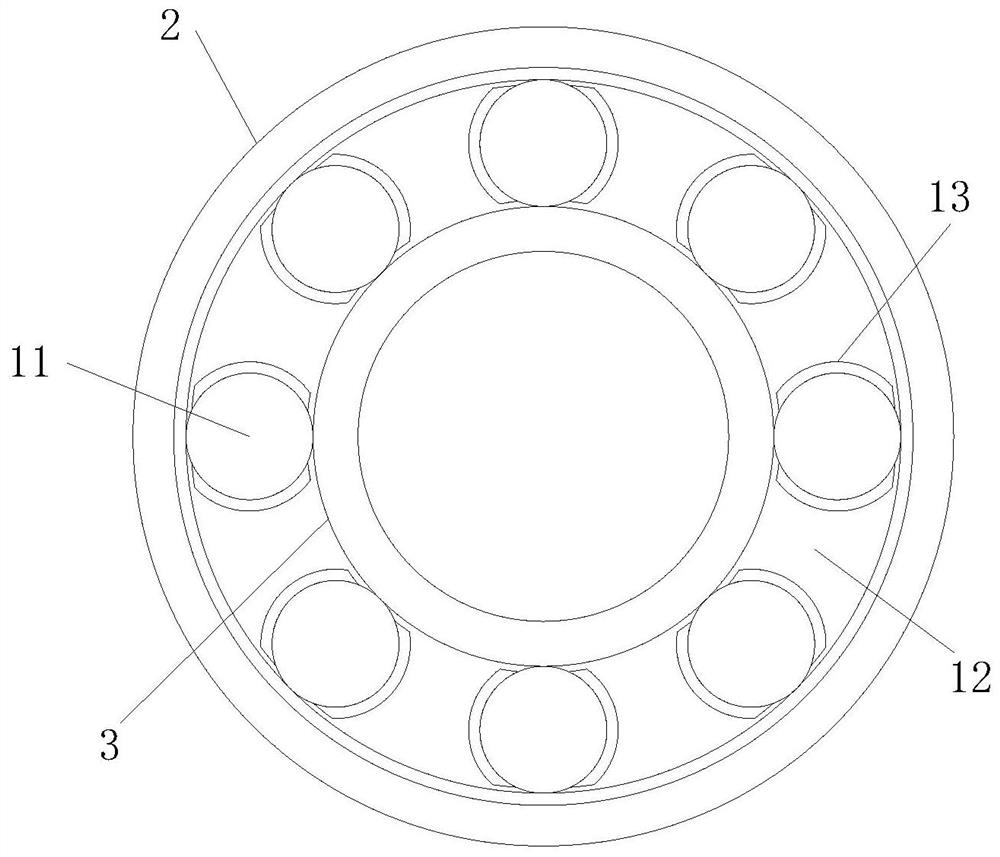

[0029] As an embodiment of the present invention, a mounting bolt 15 is arranged between the extension pipe 8 and the fixed gear plate 5, and the fixed gear plate 5 is fixedly connected with the extension pipe 8 through the mounting bolt 15, and the extension pipe 8 and the A slot is provided between the inner rings 3, the fixed gear disc 5 is fixedly connected to the inner ring 3 through the extension tube 8, and the fixed gear disc 5 is movably connected to the outer ring 2 through the inner ring 3; The bolt 15 enables the fixed gear disc 5 to follow the extension tube 8 and the inner ferrule 3 to rotate, and a slot is provided between the extension tube 8 and the inner ferrule 3, and the fixed gear disc 5 is fixedly connected to the inner ferrule 3 through the extension tube 8 , the fixed gear plate 5 is movably connected with the outer ring 2 through the inner ring 3, so that the fixed gear plate 5 has the rotation characteristics of a bearing, and the rotation is smoother....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com