Improved thrust ball bearing suitable for heavy-load low-speed working condition

A thrust ball bearing, heavy-duty low-speed technology, applied in the field of bearings, can solve the problems of affecting the progress of mechanical work, reducing work efficiency, time-consuming and labor-intensive, etc., and achieve the effect of reducing cleaning steps, improving work efficiency and simplifying steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

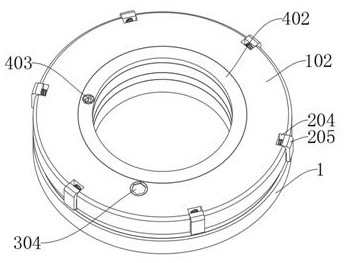

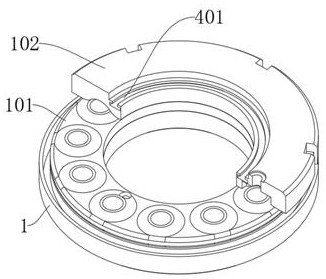

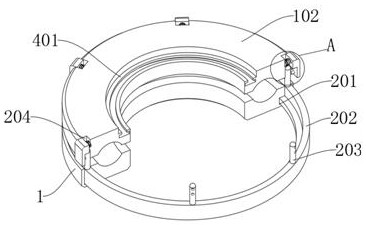

[0033] as attached figure 1 to attach Figure 7 Shown:

[0034] The present invention provides an improved thrust ball bearing suitable for heavy-duty low-speed working conditions, comprising: a main body 1, an arc-shaped groove is provided on the top of the main body 1, and a connecting piece 2 is installed on the top of the main body 1; the connecting piece 2, The chute 201 in the connecting piece 2 is arranged on the top of the main body 1, and the top groove 204 in the connecting piece 2 is set at the edge position of the top plate 102; the cleaning piece 3, the cleaning piece 3 is installed inside the main body 1 and the top plate 102, and The inner groove 301 in the cleaning part 3 is located at the top of the main body 1 and the bottom of the top plate 102; top.

[0035] Wherein, the main body 1 includes: an inner plate 101, the inside of the inner plate 101 is installed with evenly arranged balls, and the inner plate 101 is installed on the top of the main body 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com